Patents

Literature

77results about How to "Increase vibrational energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

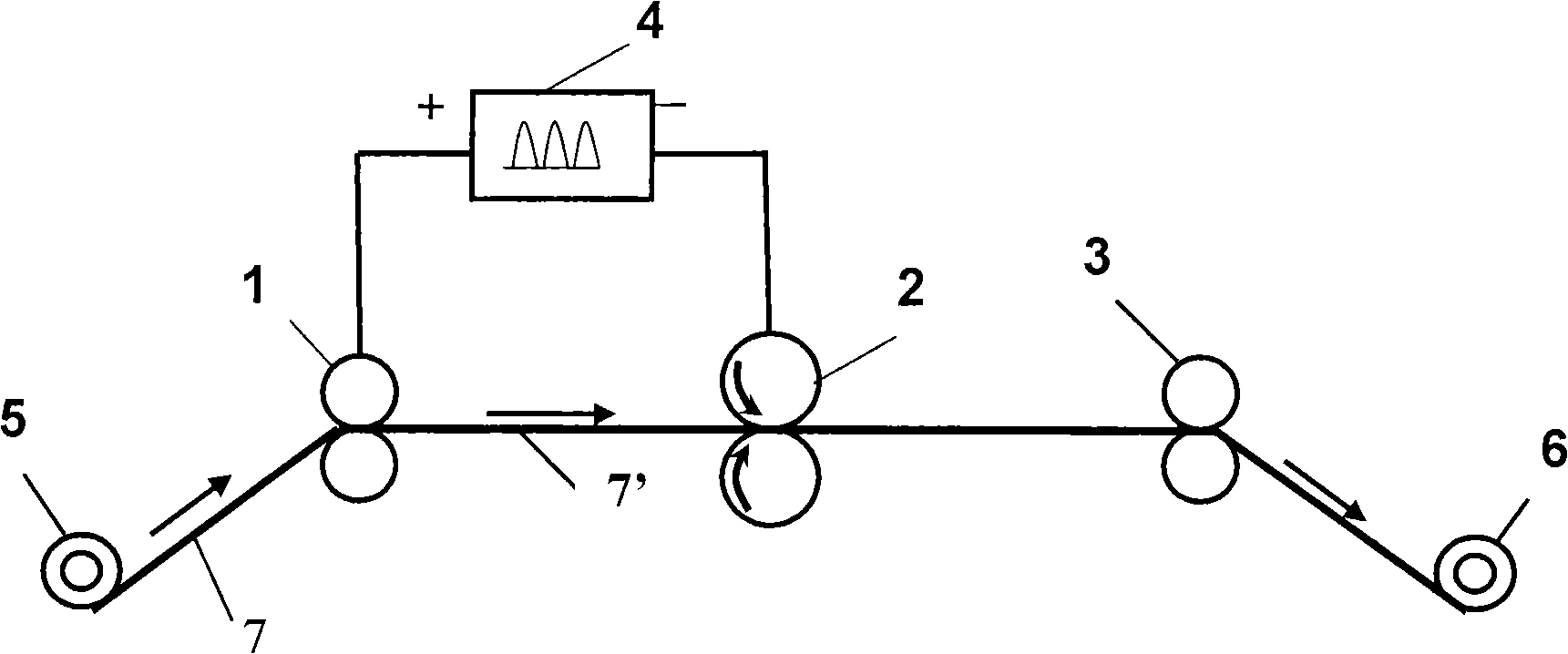

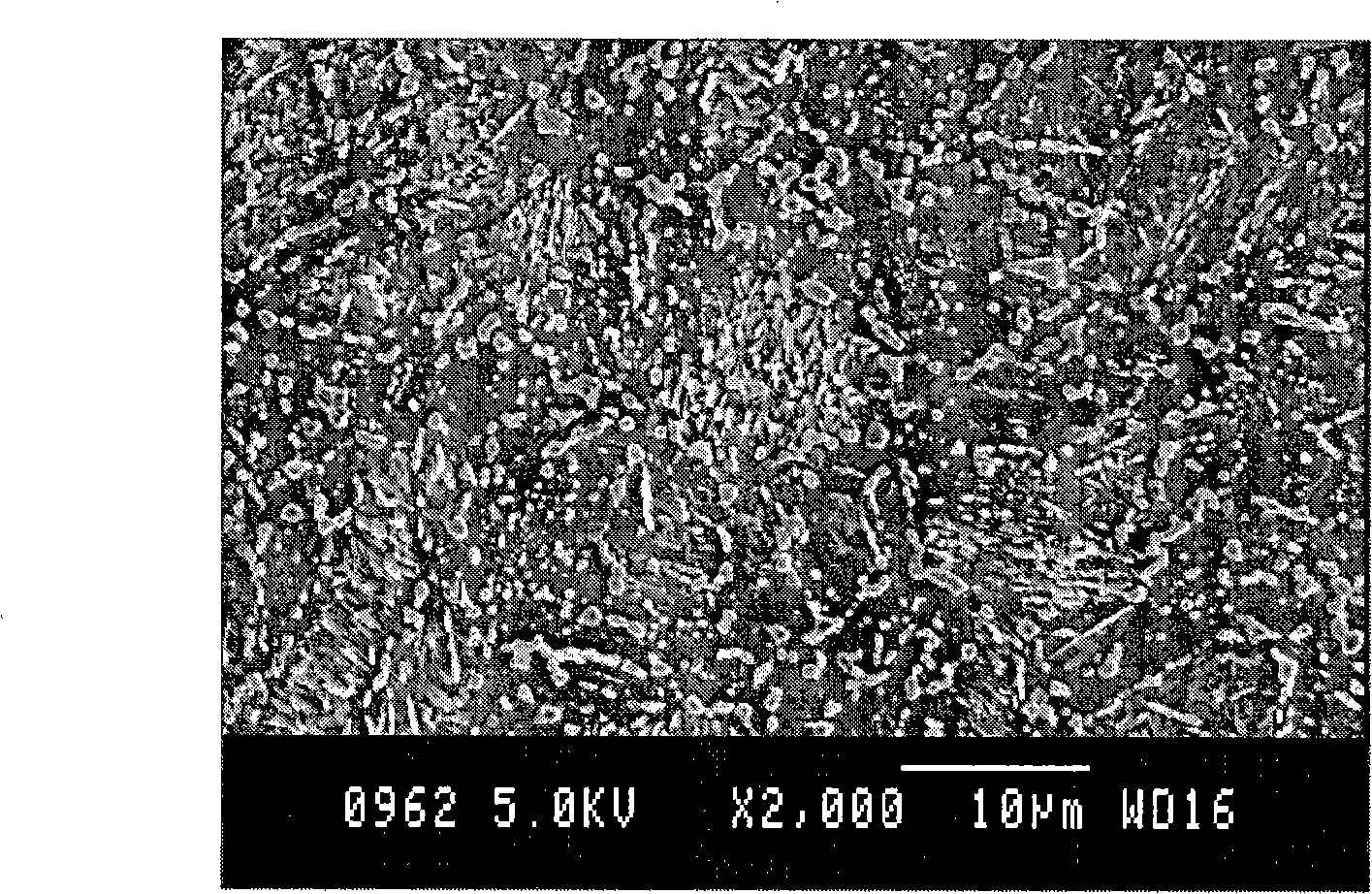

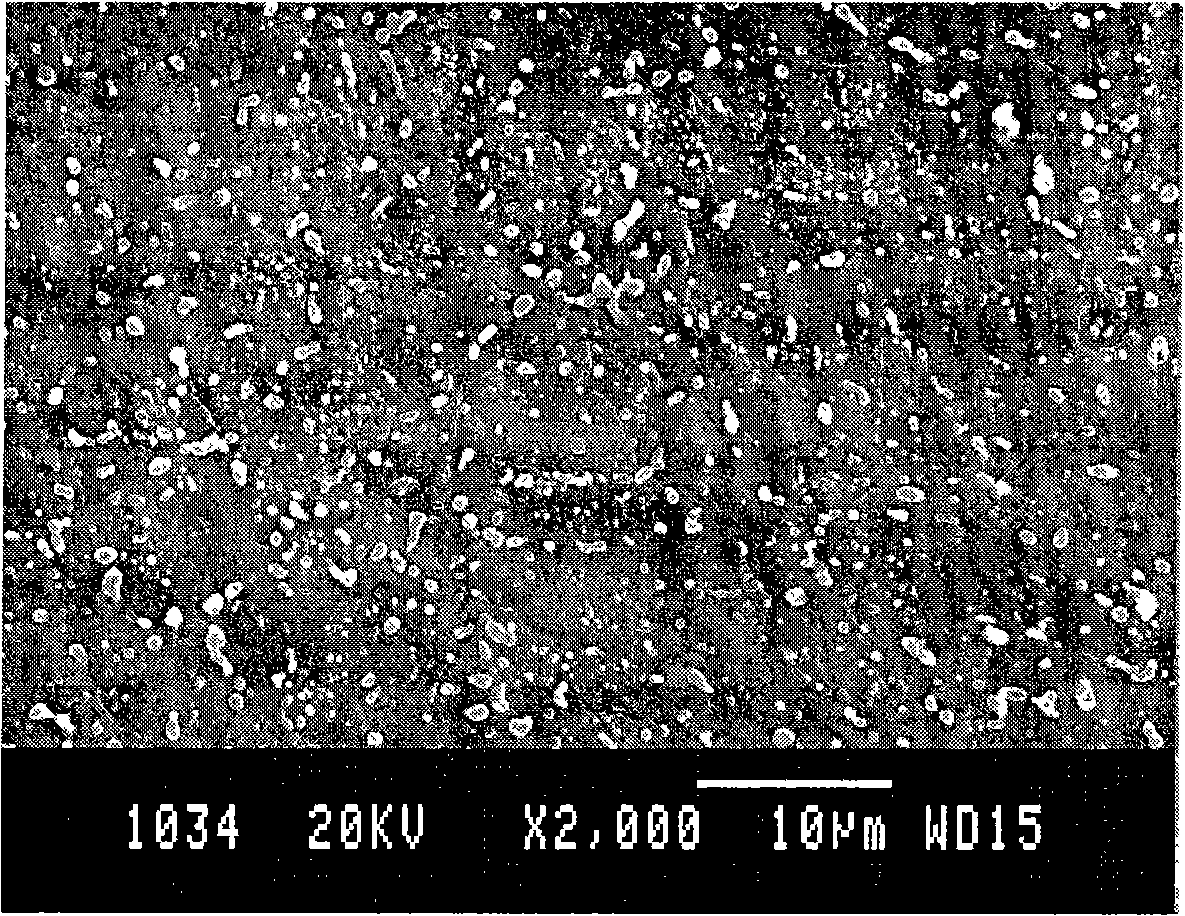

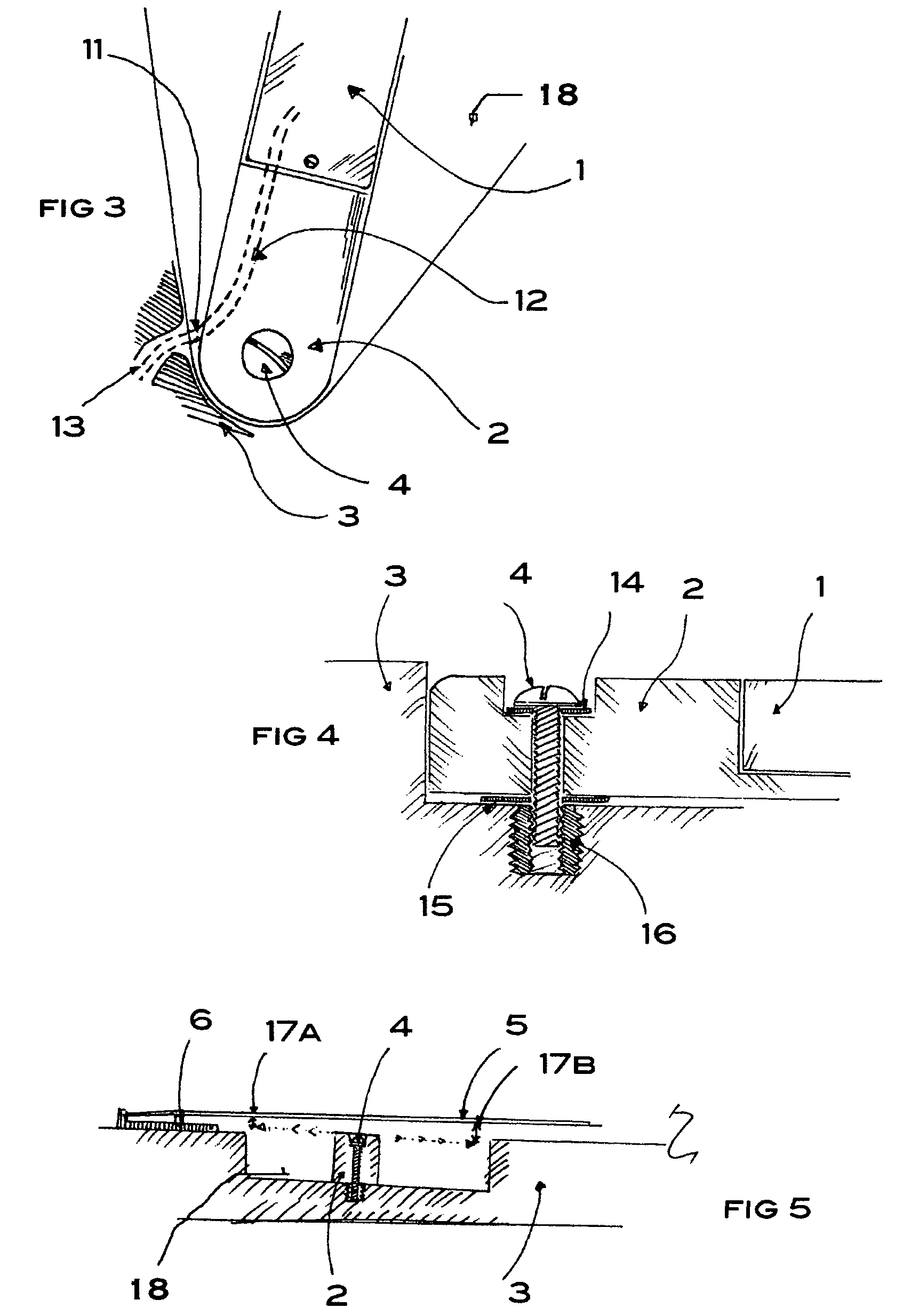

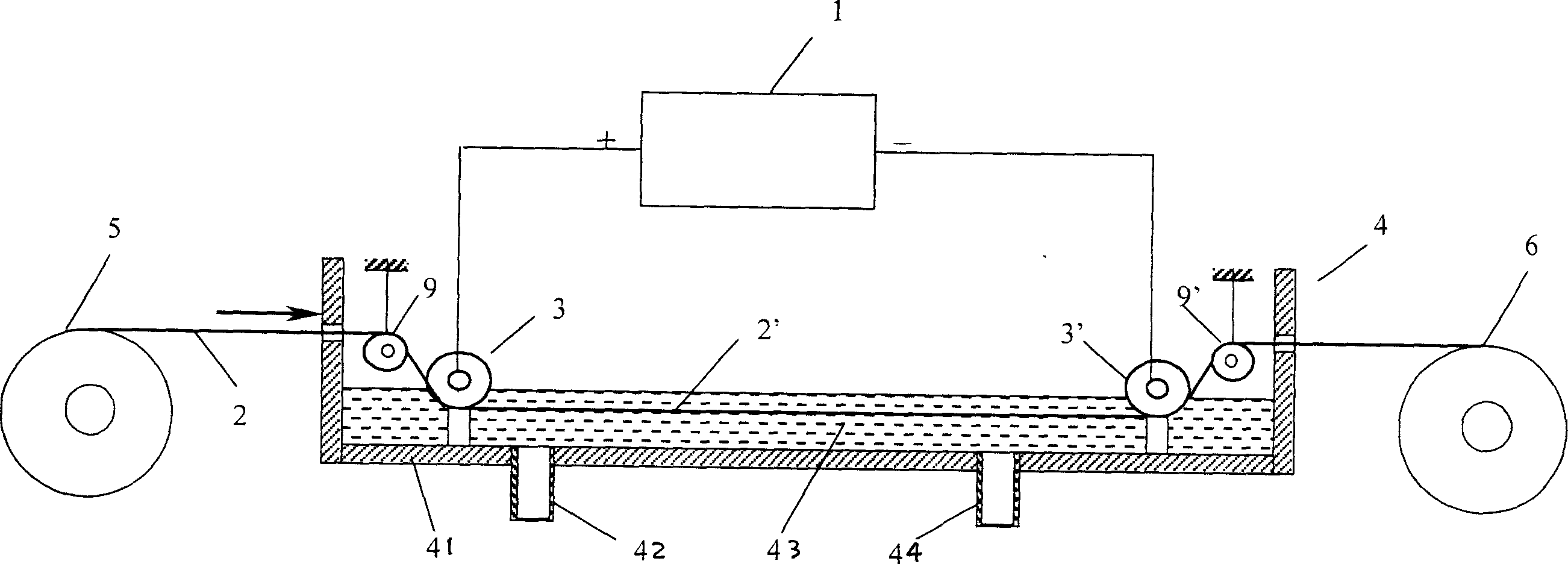

High-strength high-toughness AZ91 magnesium alloy strip eletrotoughening process method and system

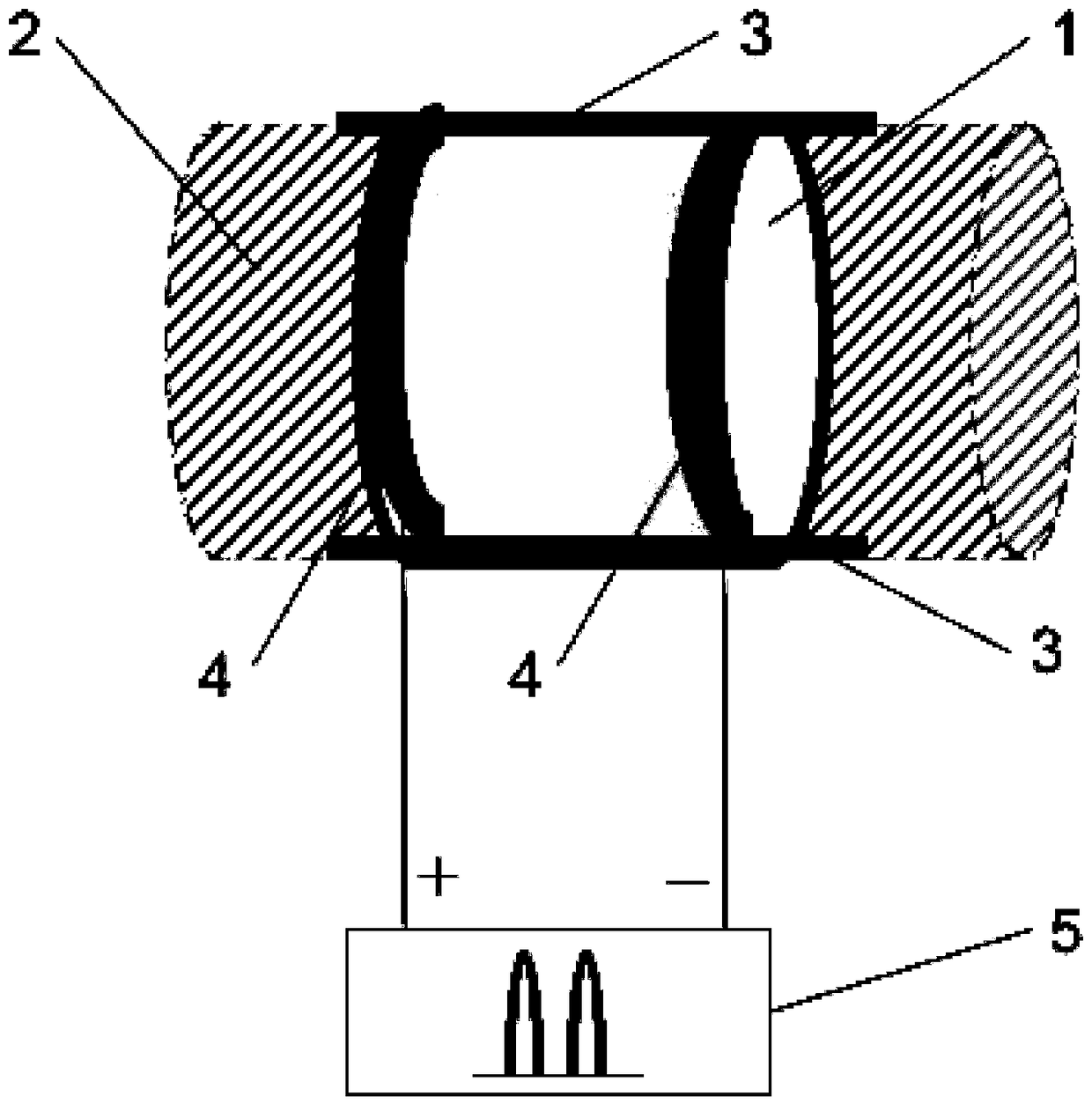

InactiveCN101298653AOxidation does not occurToughening treatment is widely applicableHigh energyRoom temperature

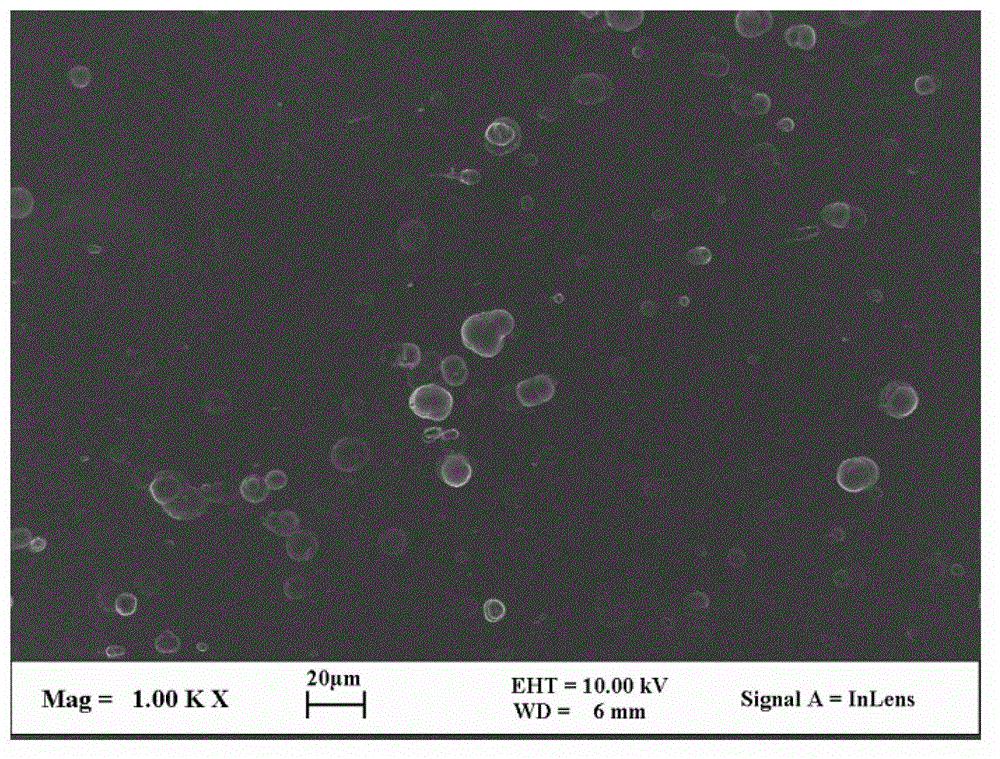

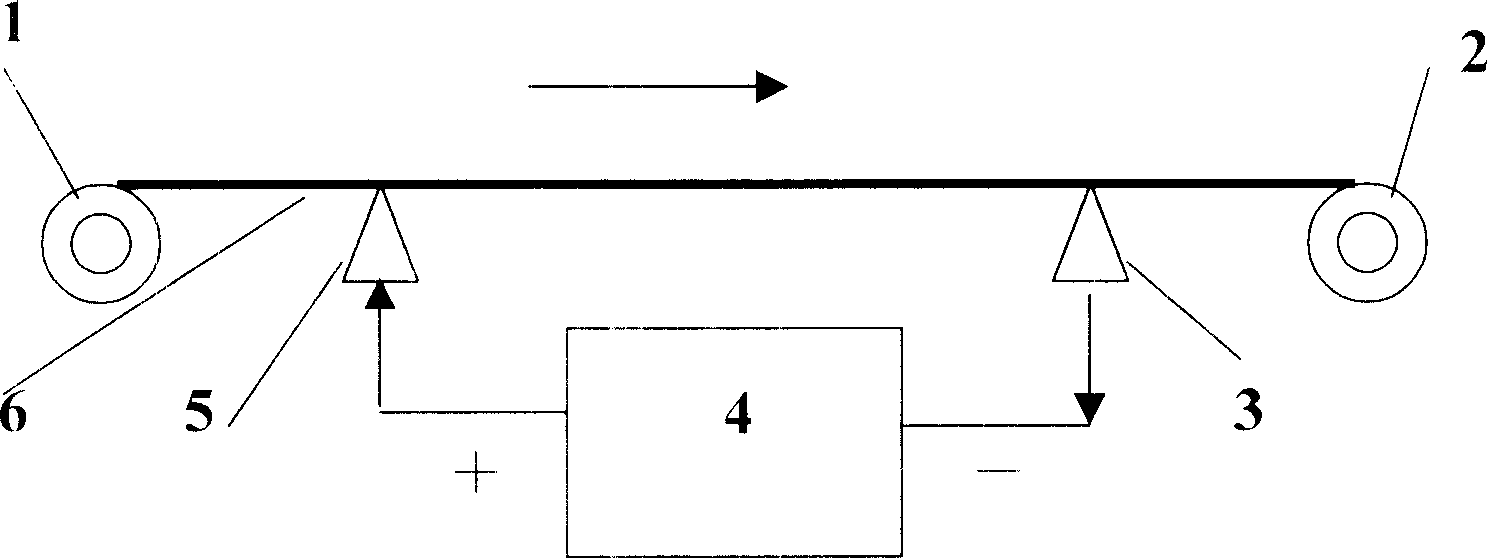

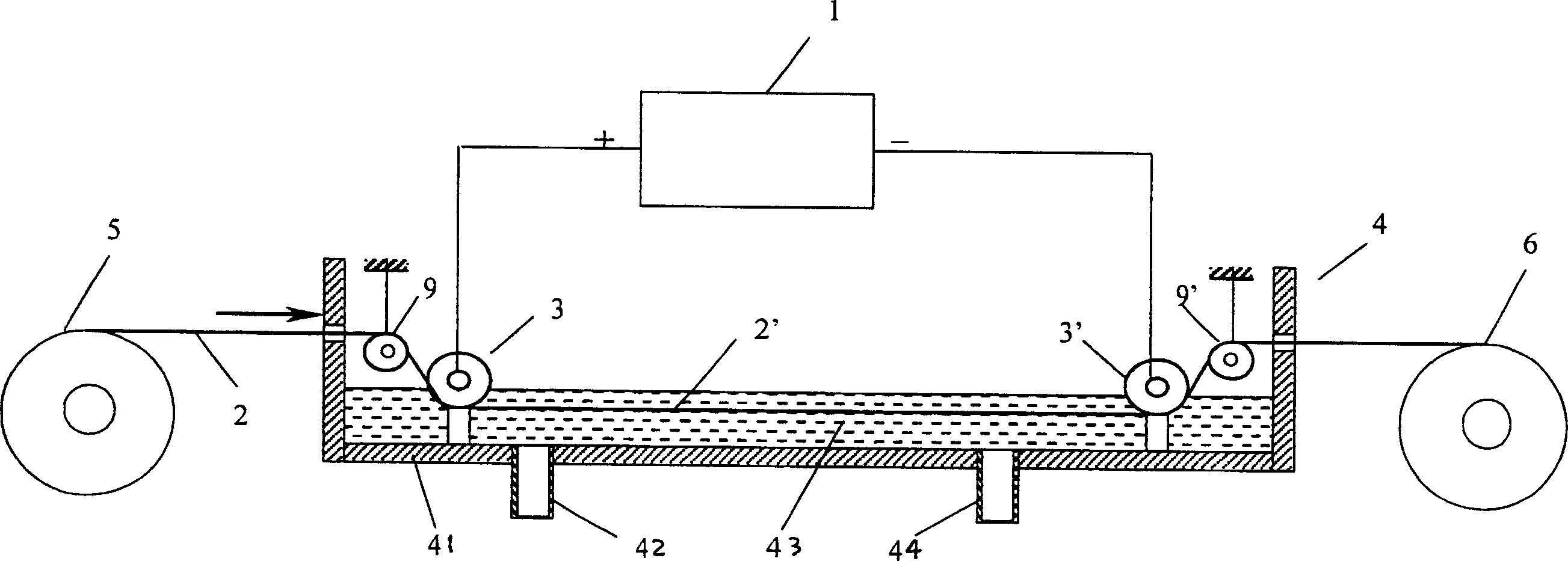

The invention discloses an electro-strengthening and toughening processing method of a belt material of AZ91 magnesium alloy and a system thereof. The electro-strengthening and toughening processing method comprises following steps: when the belt material of magnesium alloy is transmitted at a certain speed which is driven by a roller on an electro plastic rolling machine, high-energy impulse current that is output by an impulse power source through an electrode is input into an electriferous region section of the moving belt material of magnesium alloy, and the Joule heating effect and the non-heating effect are generated in the electriferous region section, thus causing the phase transition of internal microscopic constitution from bulky lath-shaped Beta-Mg17Al12 that are gathering and agglomerating in an initial state to Beta-Mg17Al12 particles that are evenly distributed and approximately sphere-shaped, or causing the solid solution effect that leads Beta-Mg17Al12 to be dissolved in a substrate; the processed belt material can be naturally air cooled at room temperature. The electro-strengthening and toughening processing method of the belt material of AZ91 magnesium alloy has short processing time and high production efficiency, and simultaneously avoids the high-temperature oxidation of the magnesium alloy. After the electro-strengthening and toughening processing, the microscopic constitution of the belt material of magnesium alloy can be remarkably improved, the unit extension of the microscopic constitution is increased from 11.8 percent in the initial aging state to over 20 percent, and the tensile strength of the microscopic constitution is not dramatically lowered.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

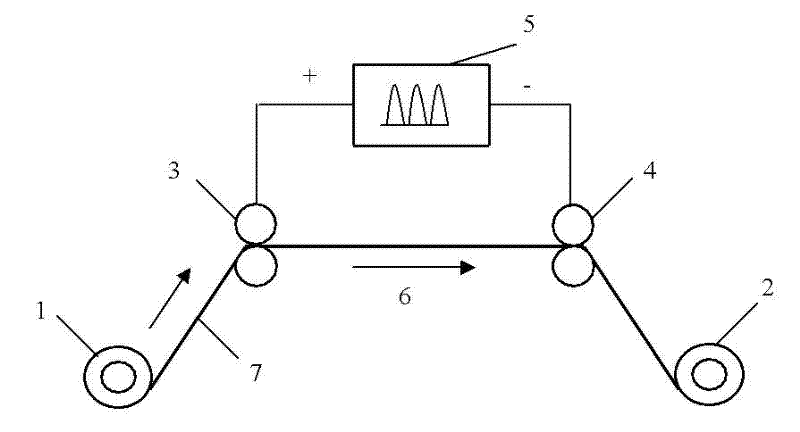

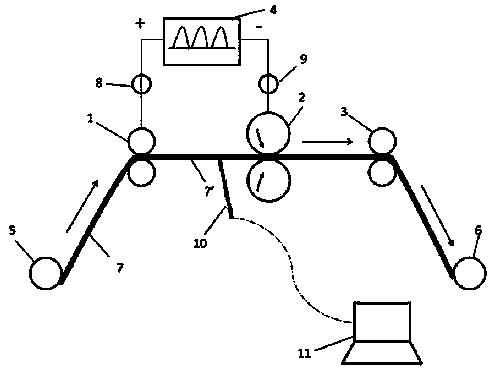

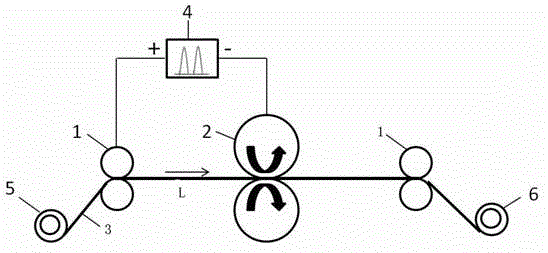

Method for promoting growth of GOSS textures of silicon steel strips by using pulse current

InactiveCN102212671AReduce the degree of oxidationShort initial recrystallization timeFurnace typesHeat treatment furnacesAir atmosphereElectricity

The invention discloses a method for promoting growth of GOSS textures of silicon steel strips by using pulse current. The method comprises the following steps of: conveying the silicon steel strips at the speed of 2 to 10 meters per minute under the drive of a conveying device; and guiding the pulse current of a pulse power supply to a moving silicon steel strip electrifying zone through a pair of electric contact devices, and performing electric stimulation treatment on the silicon steel strip electrifying zone in air atmosphere to promote the generation of a large amount of GOSS textures in the primary re-crystallization process, wherein the silicon steel strips are in a high magnetic induction cold-rolled state, the thickness of the silicon steel strips is 0.1 to 0.5 millimeter, the width of the silicon steel strips is 10 to 150 millimeters and the silicon content of the silicon steel strips is 0.5 to 6.5 percent. Compared with the traditional thermal treatment furnace annealing treatment process, the method has the advantages of low energy consumption, high production efficiency and low production cost, and the GOSS textures in the primary re-crystallization process have manycomponents. By electron back-scattered diffraction (EBSD) detection, the GOSS texture content of the silicon steel strips treated by adopting electric stimulation of the pulse current reaches 15 to 25 percent.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

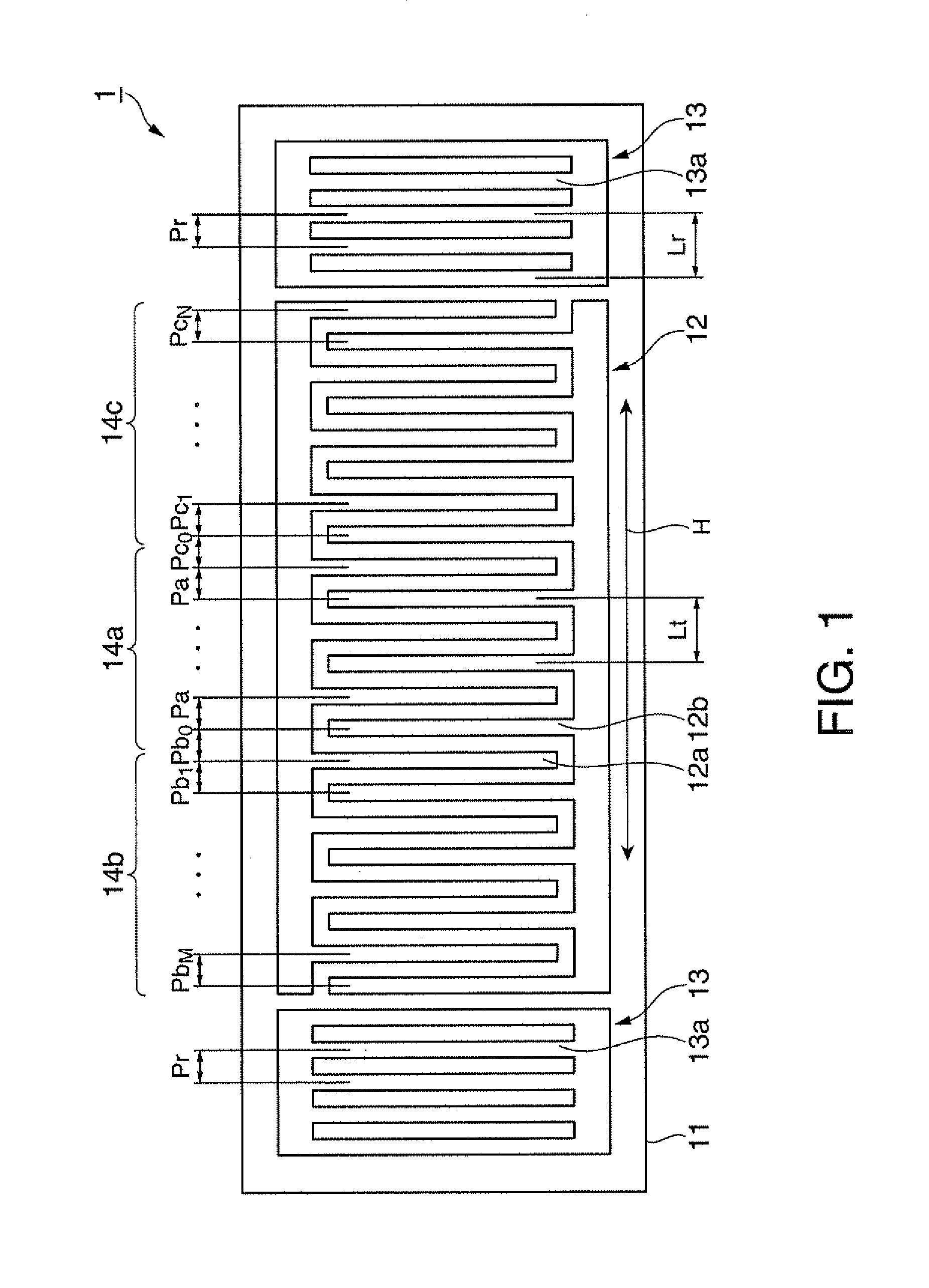

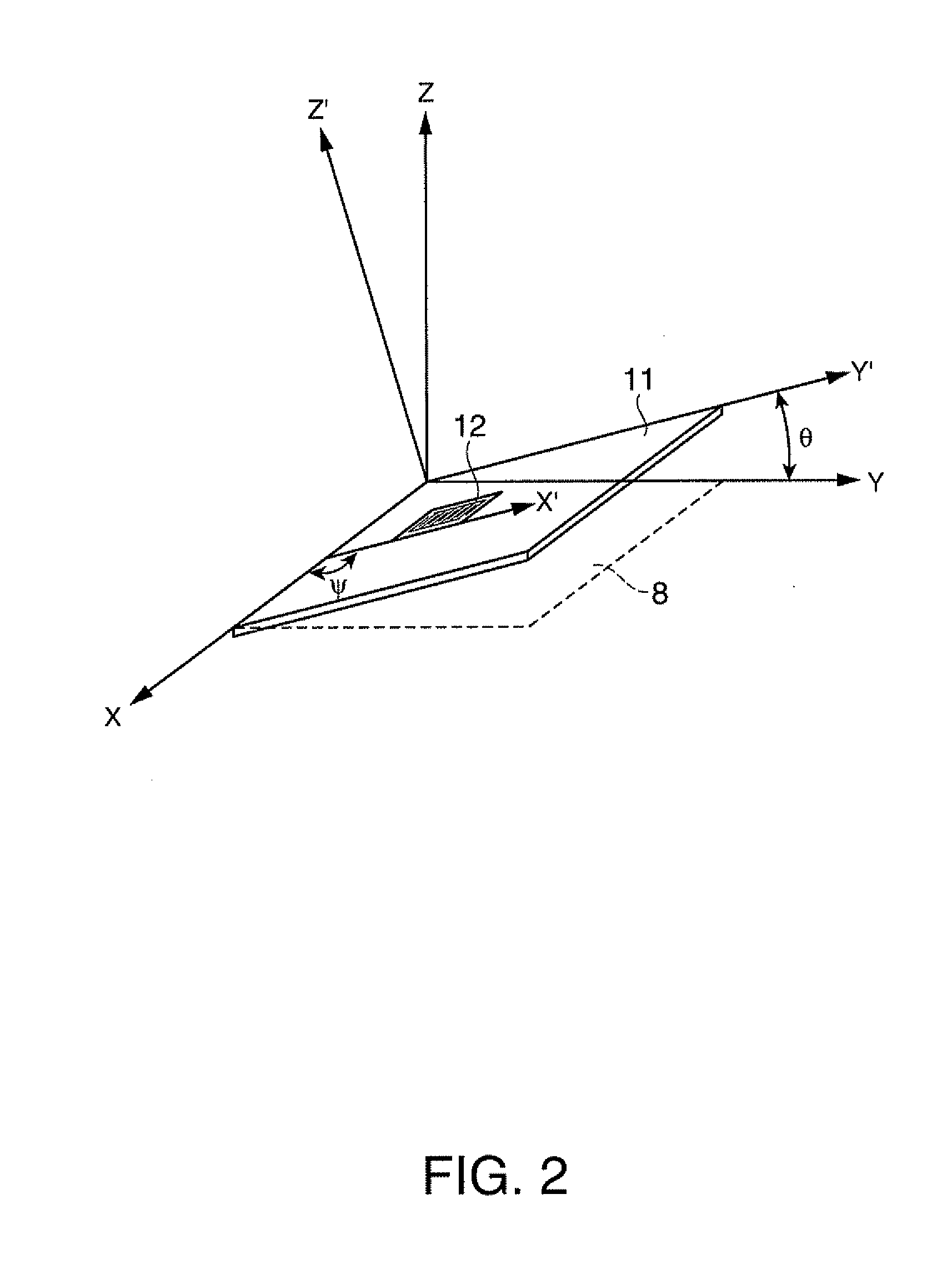

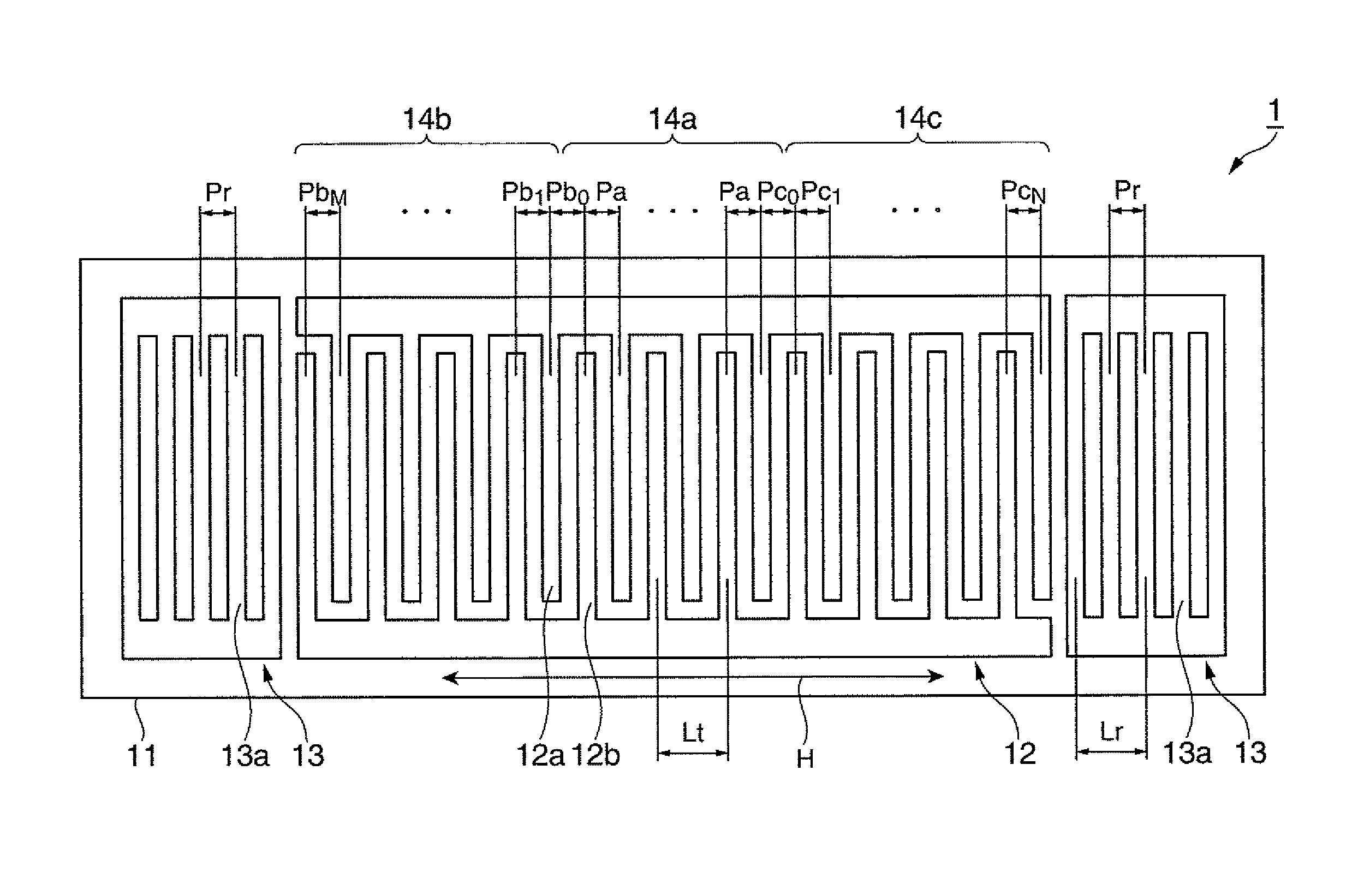

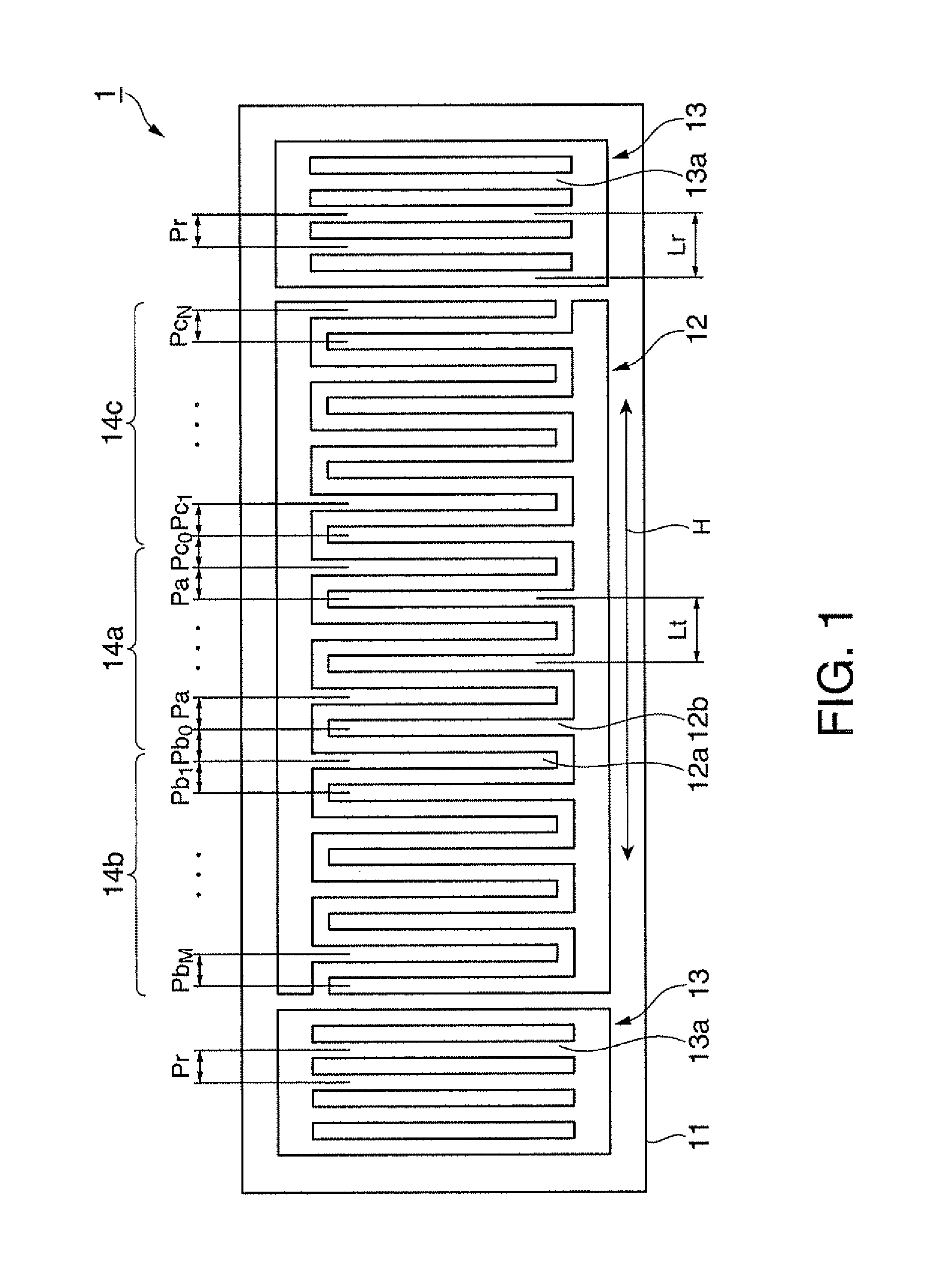

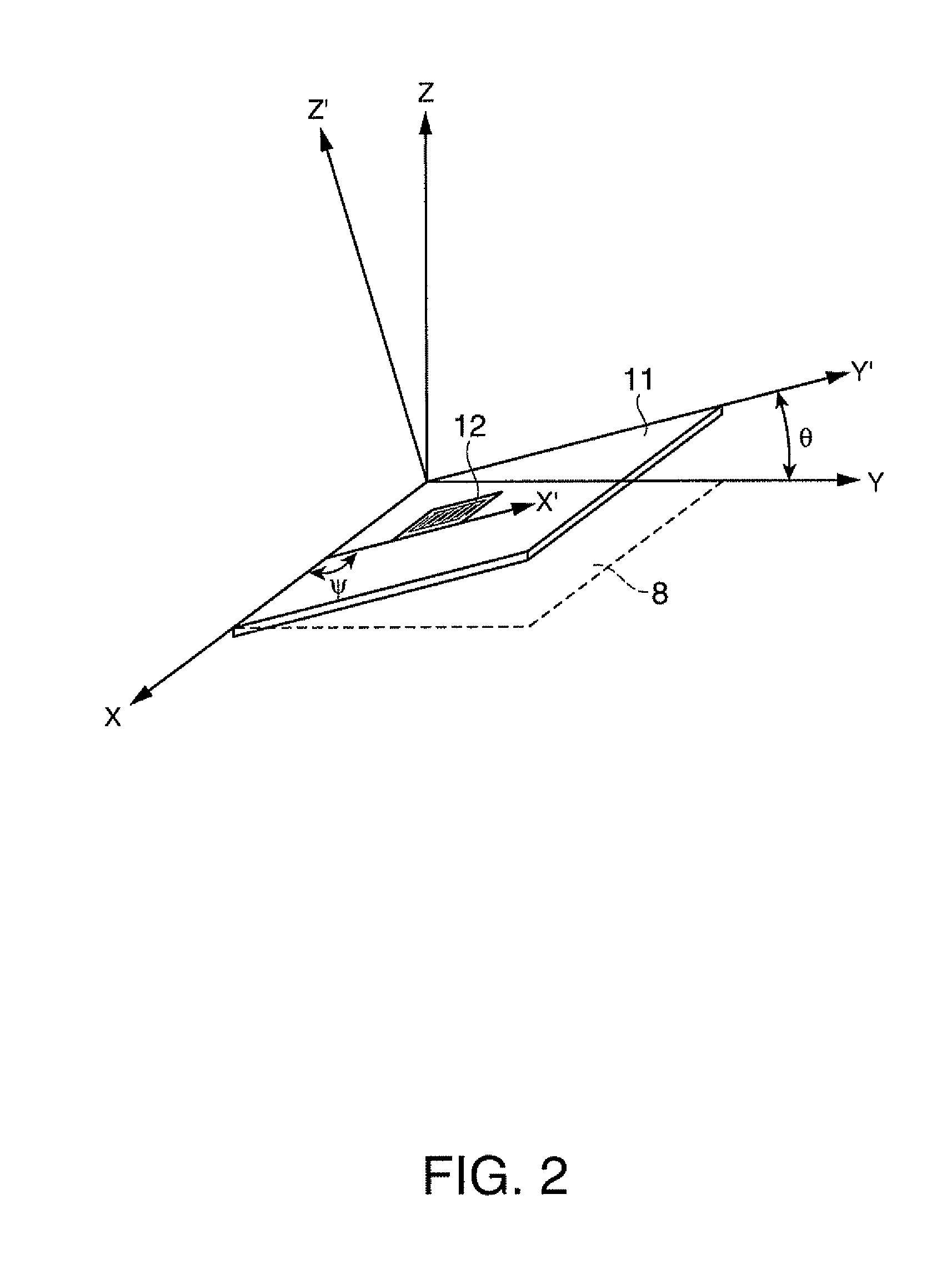

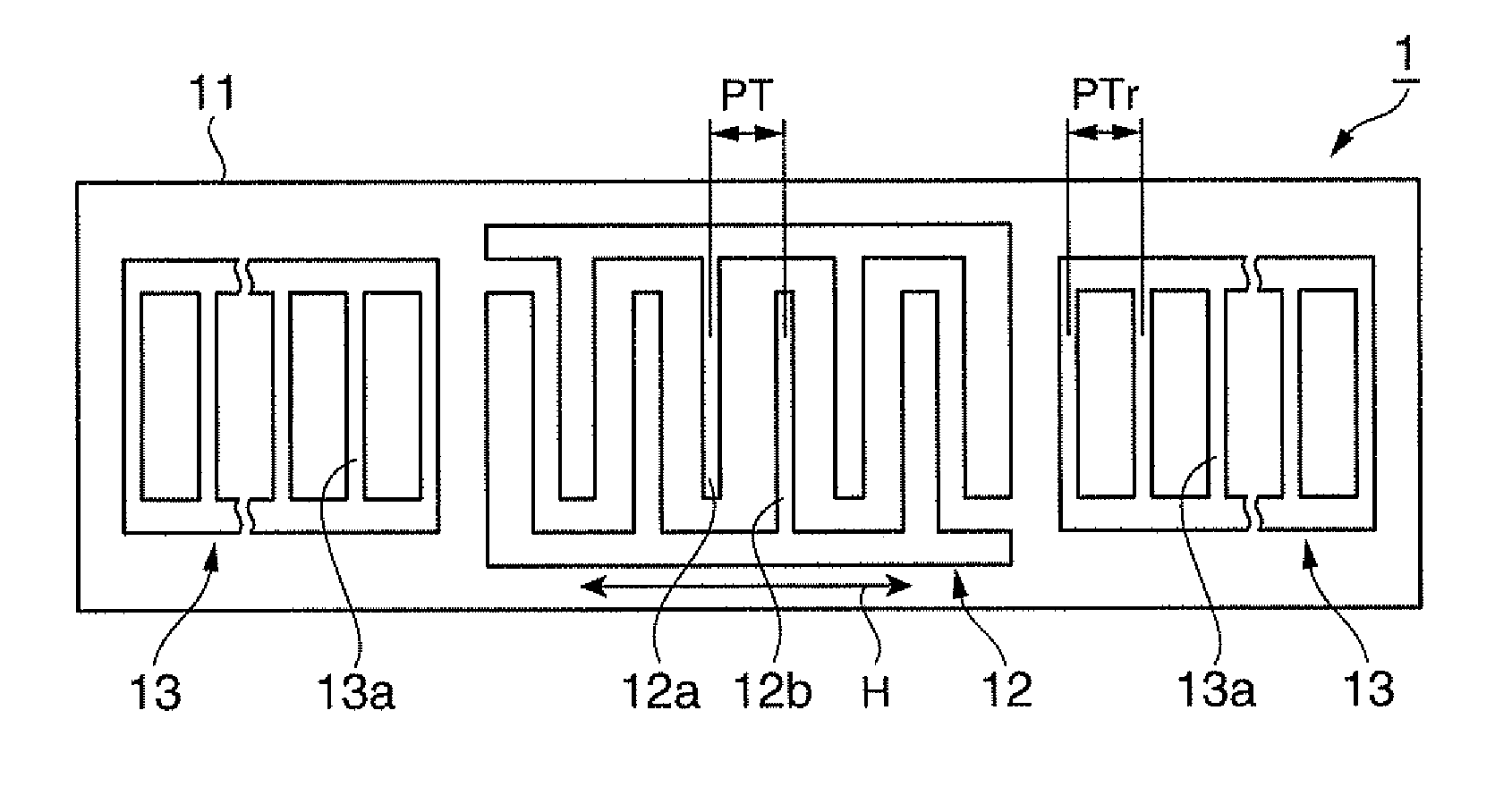

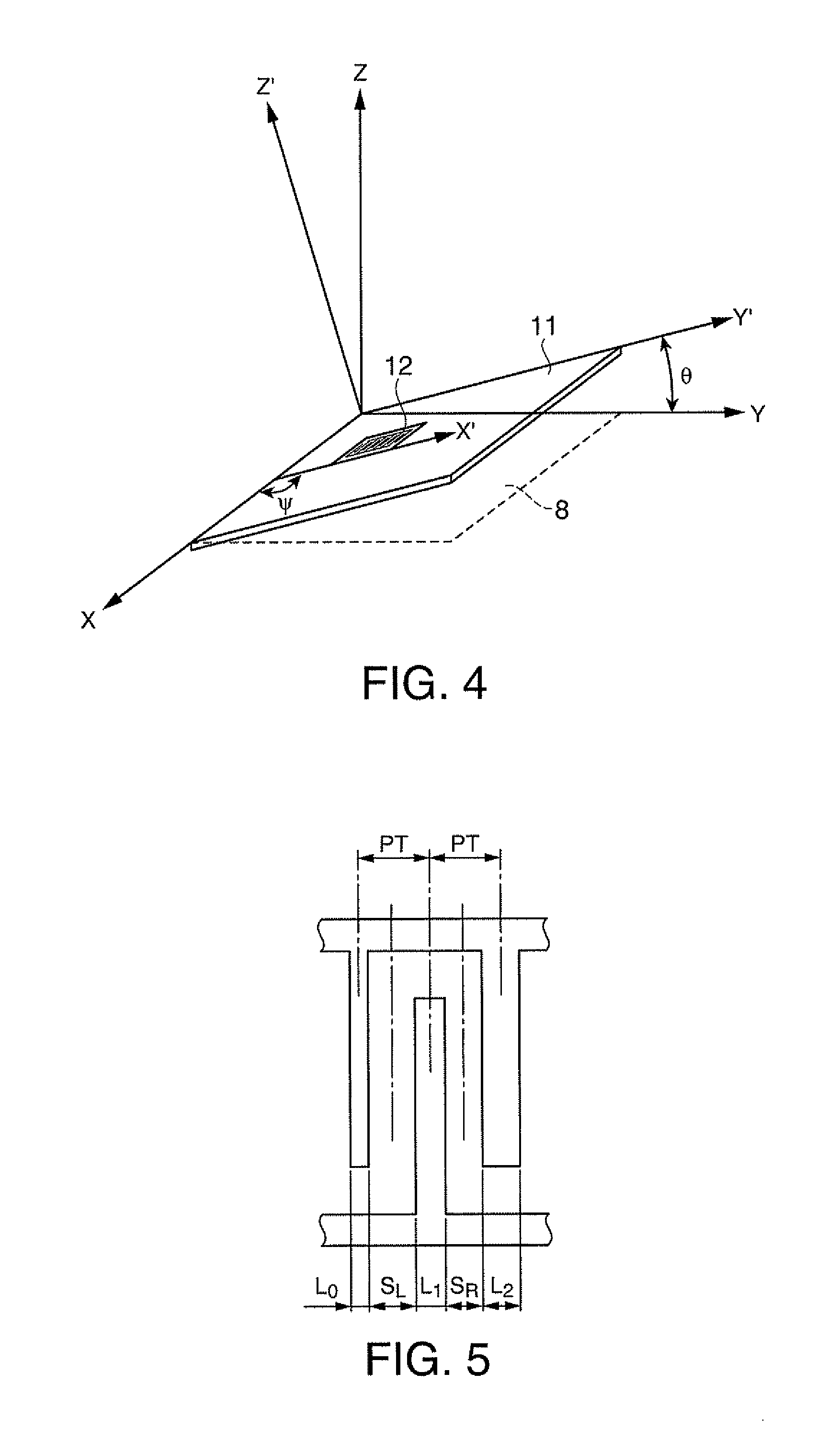

Surface acoustic wave resonator, surface acoustic wave oscillator, and surface acoustic wave module unit

ActiveUS20110199160A1Improve Q valueSmall sizePiezoelectric/electrostriction/magnetostriction machinesImpedence networksAcoustic waveSurface acoustic wave oscillators

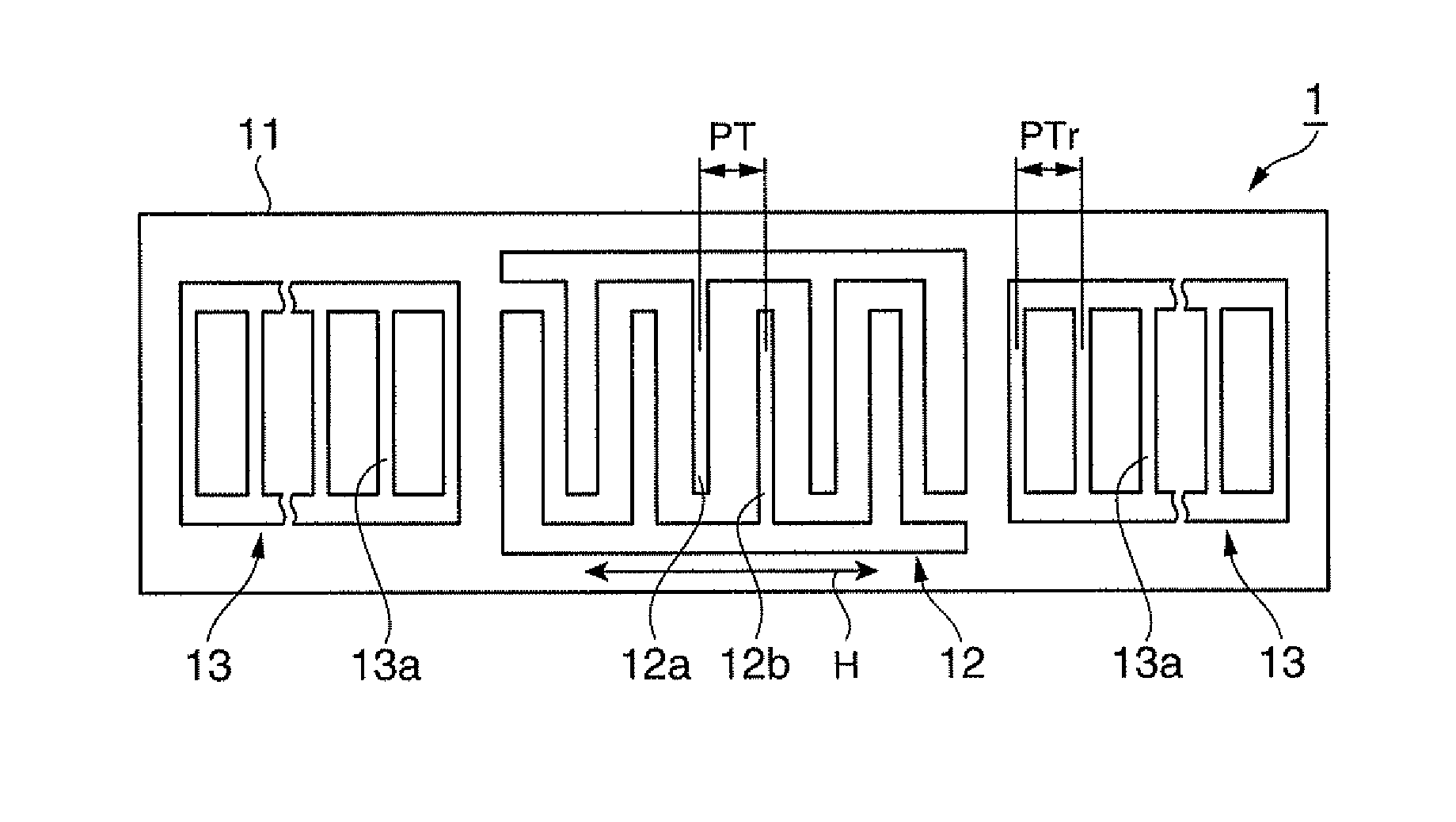

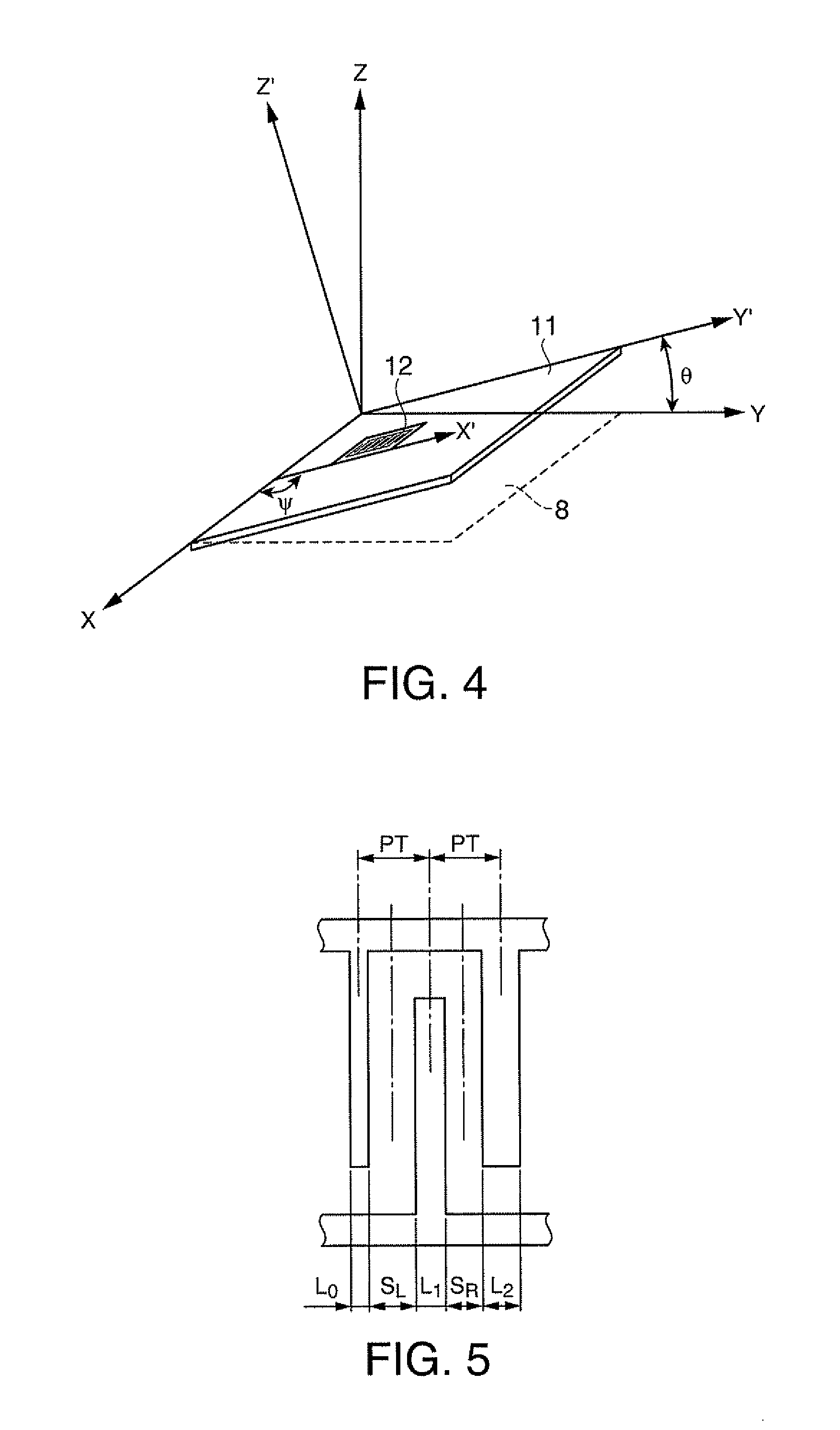

It is possible to reduce the size of a surface acoustic wave (SAW) resonator by enhancing a Q value. In a SAW resonator in which an IDT having electrode fingers for exciting SAW is disposed on a crystal substrate, the IDT includes a first region disposed at the center of the IDT and a second region and a third region disposed on both sides of the first region. A frequency is fixed in the first region and a portion in which a frequency gradually decreases as it approaches an edge of the IDT is disposed in the second region and the third region. When the frequency of the first region is Fa, the frequency at an edge of the second region is FbM, and the frequency at an edge of the third region is FcN, the variations in frequency are in the ranges of 0.9815<FbM / Fa<0.9953 and 0.9815<FcN / Fa<0.9953, respectively.

Owner:PANASONIC CORP +1

Method for promoting phase change strengthening and toughening of two-phase titanium alloy strip by using pulse current and strip

The invention discloses a method for promoting phase change strengthening and toughening of a two-phase titanium alloy strip by using pulse current. The method comprises the following steps: tensioning a TC4 titanium alloy strip through a decoiling device, a winding device, a roller and a support roller of a rolling mill, so that the strip is in tightly elastic contact with the roller; driving the strip to transmit at the speed of 150-800mm / min through friction force by virtue of the roller; inputting the pulse current into a power-up area section of the strip through the roller, the support roller and the like, wherein the pulse current generates a joule heating effect and a non-thermal effect in the power-up area section of the strip within 12-18 seconds, so that the internal microstructure of the strip turns into a two-phase long-axis structure or a two-phase dual-state structure from an original quasi-single phase thick equiaxed structure; and then cooling by natural air at room temperature. Through adjustment of parameters of the pulse current, the TC4 strip with the two-phase long-axis structure and the two-phase dual-state structure can be quickly obtained, thus the ductility is increased; the treatment temperature is far lower than 960 DEG C of a traditional thermal treatment process; the processing process of the titanium alloy strip can be finished without a short period of time at relatively low temperature without an oxidation phenomenon; and therefore, the method is energy-saving, environmentally friendly, safe and efficient.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

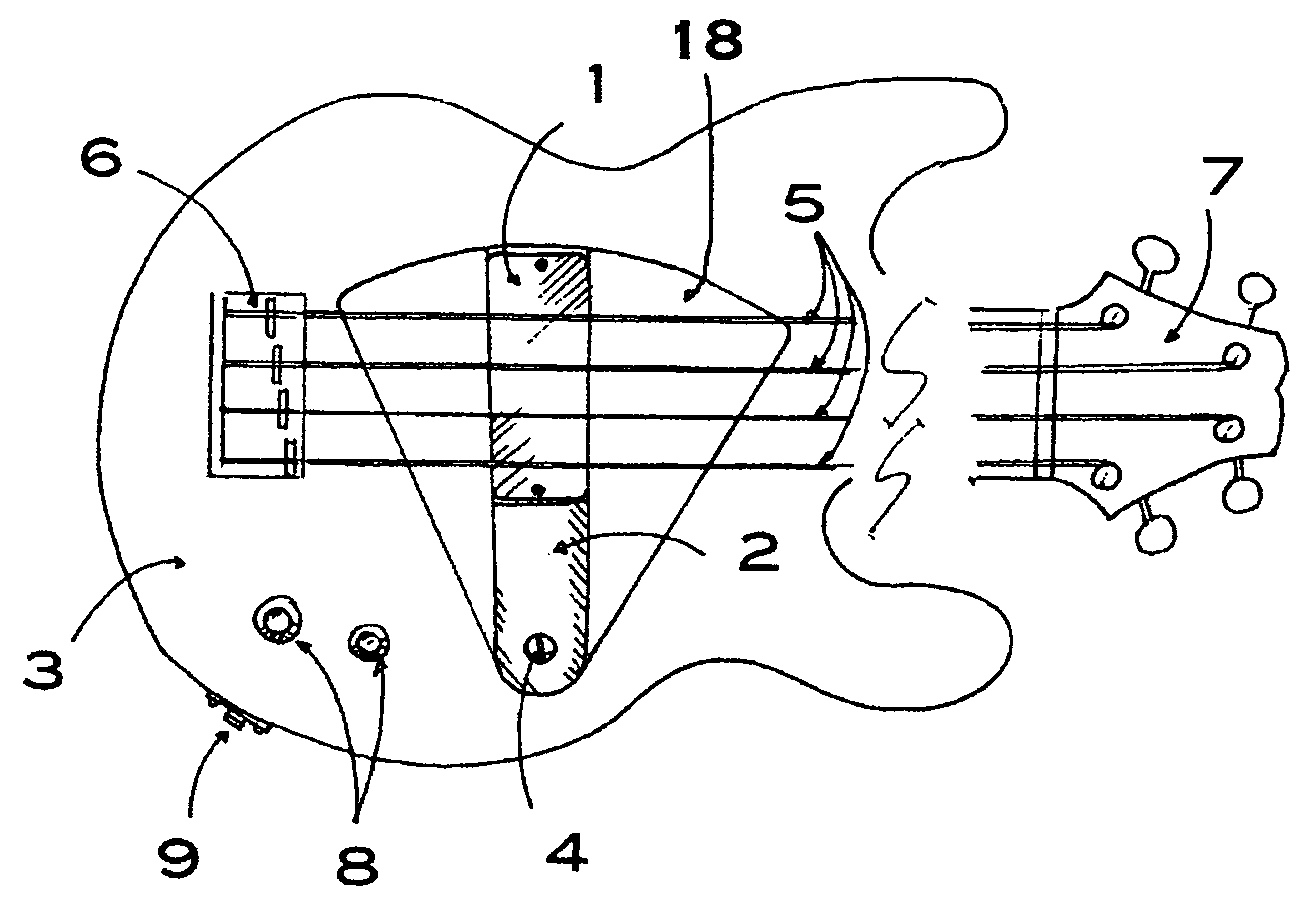

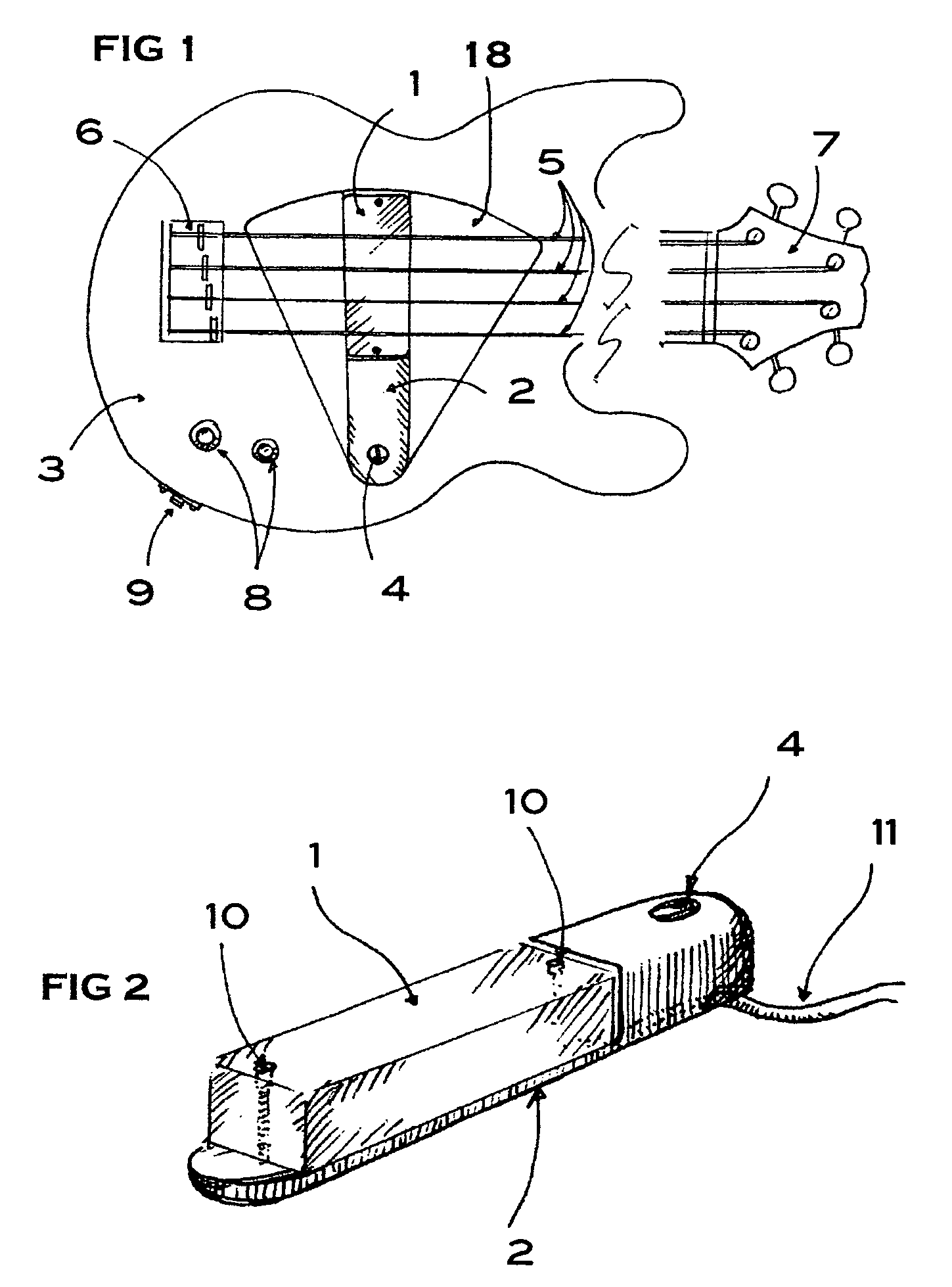

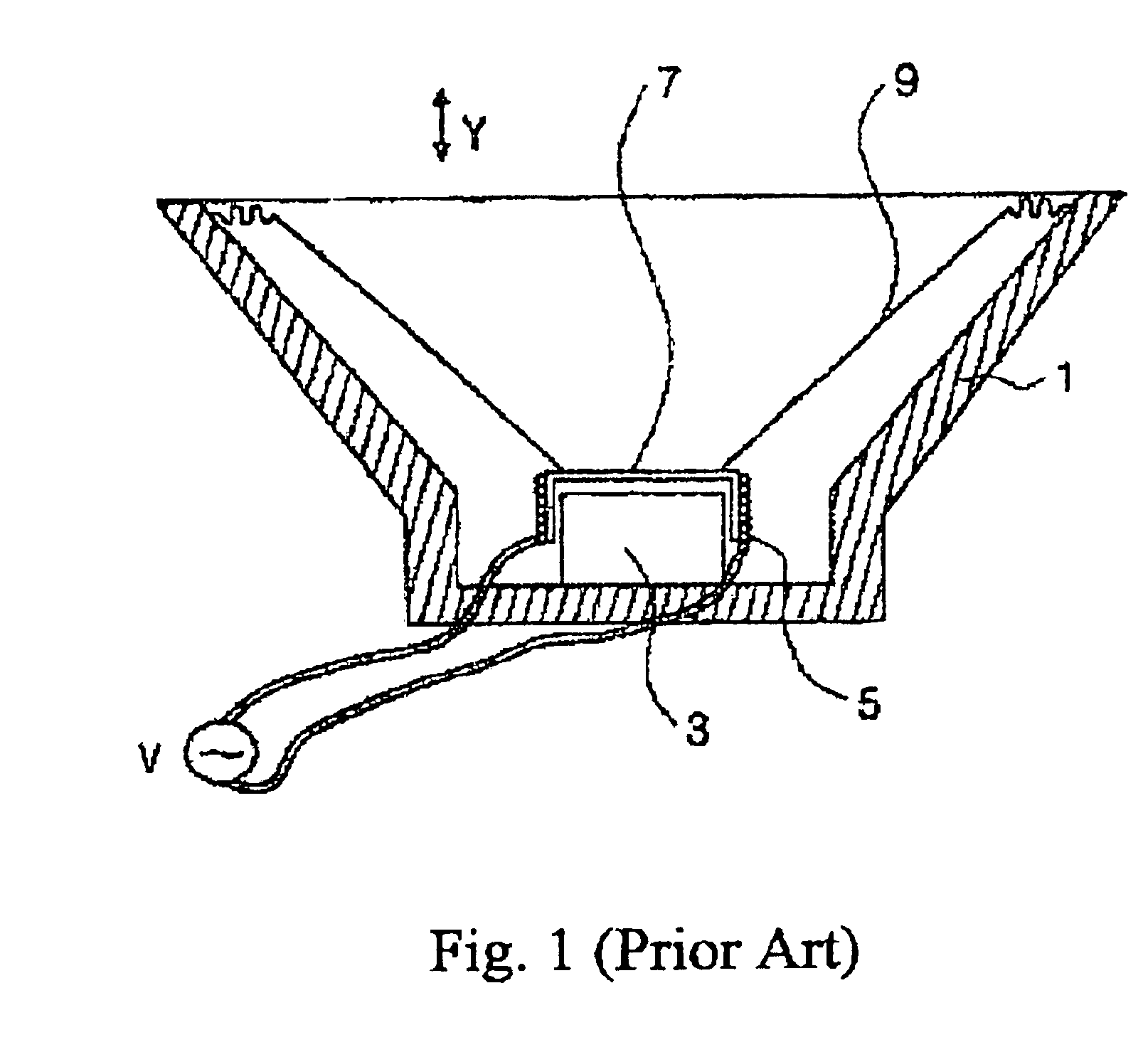

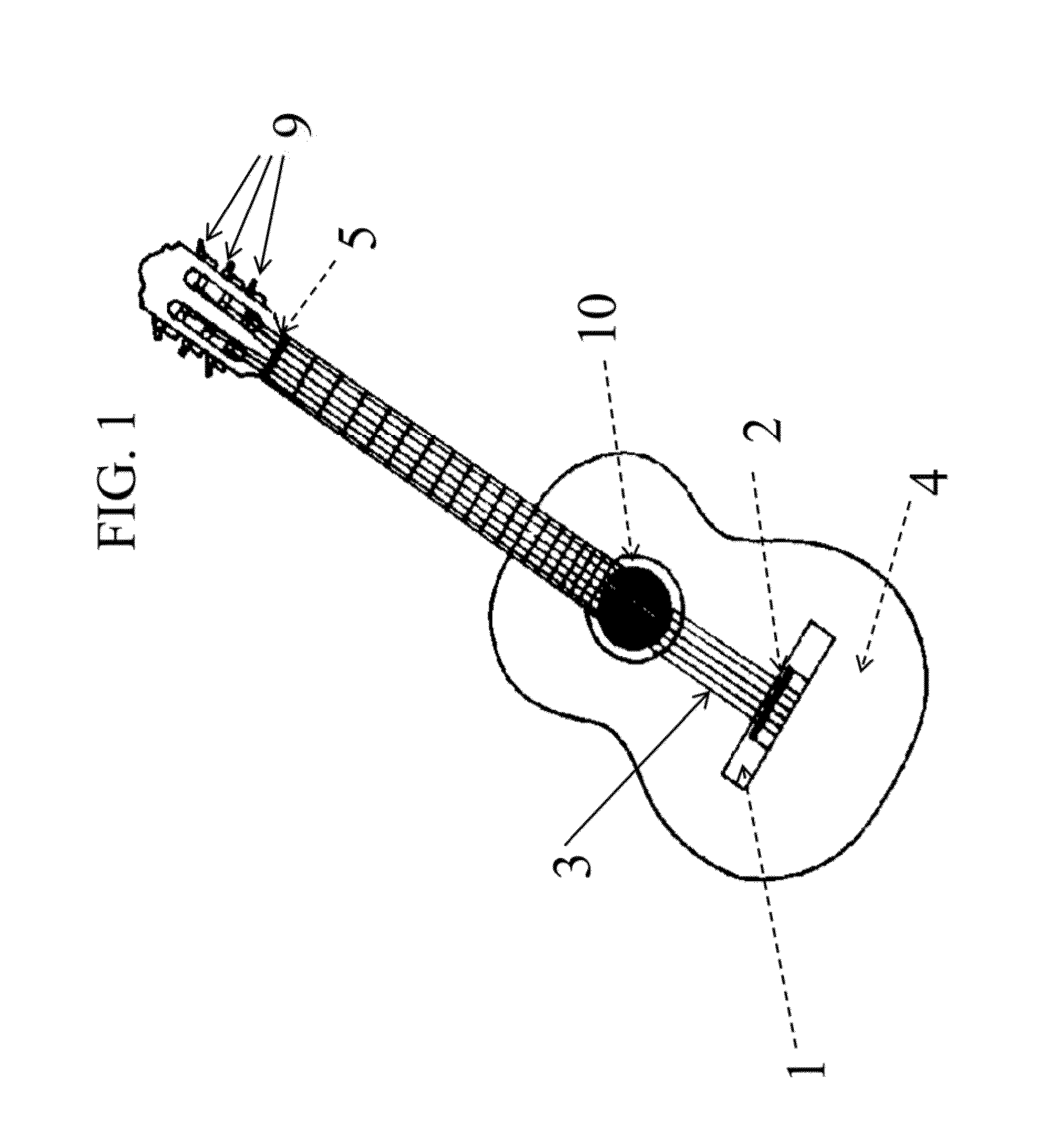

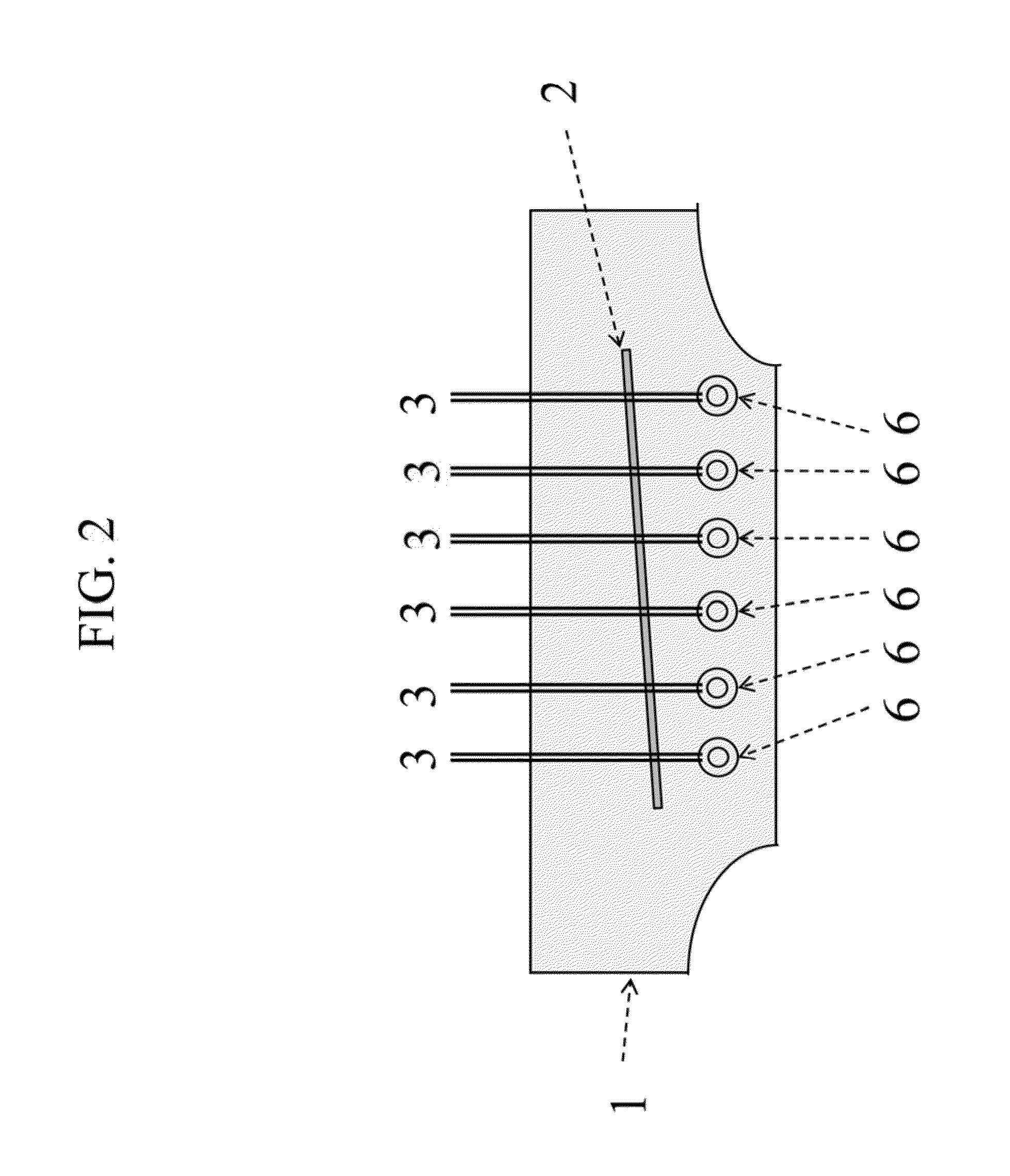

Movable stringed instrument pickup system

InactiveUS7060888B2Counteracting diminution in volumeReduce vibrational energyElectrophonic musical instrumentsElectric guitarEngineering

A pivoting electromagnetic pickup device is provided. The invention generally is comprised of an elongated support structure, an electromagnetic pickup, a pivoting means, and an angular position locking means. The extremity of the elongated support structure is pivotally attached to the front face of an electric guitar or electric base body, between the front face and the strings, restricting its movement to a curvilinear path substantially normal to the axis of rotation and substantially parallel to the plane of the strings. The pickup is mounted to the elongated support structure, between the elongated support structure and the strings. Attaching the elongated support structure to the guitar body in a pivotal relationship is the pivoting means. The angular position locking means can be engaged to continuously vary the resistance to angular motion, from no resistance to maximum resistance, where the elongated support structure is substantially locked to a chosen angular position.

Owner:SPALT MICHAEL SEBASTIAN

Second-phase electrical stimulation nodulizing method for Ni-enriched TiNi shape memory alloy

The invention provides a second-phase electrical stimulation nodulizing method for Ni-enriched TiNi shape memory alloy. The method comprises steps as follows: driving the TiNi memory alloy belt or plate to move at a certain speed by a roller through electric plasticity roller; inputting high-energy pulse current output by a pulse power supply to an electrifying part of the moving TiNi alloy through an electrode; and carrying out joule heating effect and electron wind non-thermal effect on the electrifying part, so as to transform the internal microscopic structure from the initial sheet sor polygonal second phase to uniformly distributed spherical second phase while being subjected to solution treatment. The processed TiNi alloy belt or the plate can be cooled by air at room temperature. According to the method, the implementation time is short, the production efficiency is high, and the TiNi alloy is prevented from oxidizing at high temperature.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method of implementing on line softening annealing of medium, high carbon steel wire using high energy electric pulse

InactiveCN1904088ASmooth rotationPromotes the recrystallization processFurnace typesHeat treatment furnacesHigh carbonHigh energy

The present invention relates to an on-line continuous softening annealing method of medium-high carbon steel wire by utilizing high-energy electric pulse. Said method includes the following steps: utilizing decoiling equipment and winding-up equipment to drive steel wine and make it be moved towards the winding-up equipment at a certain speed; setting a high-energy pulse power supply, said high-energy pulse power supply can continuously output high-energy electric pulse and utilizing a pair of electrodes to apply the high-energy electric pulse to the moving steel wire so as to make the steel wire undergo the process of continuously softening annealing treatment.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

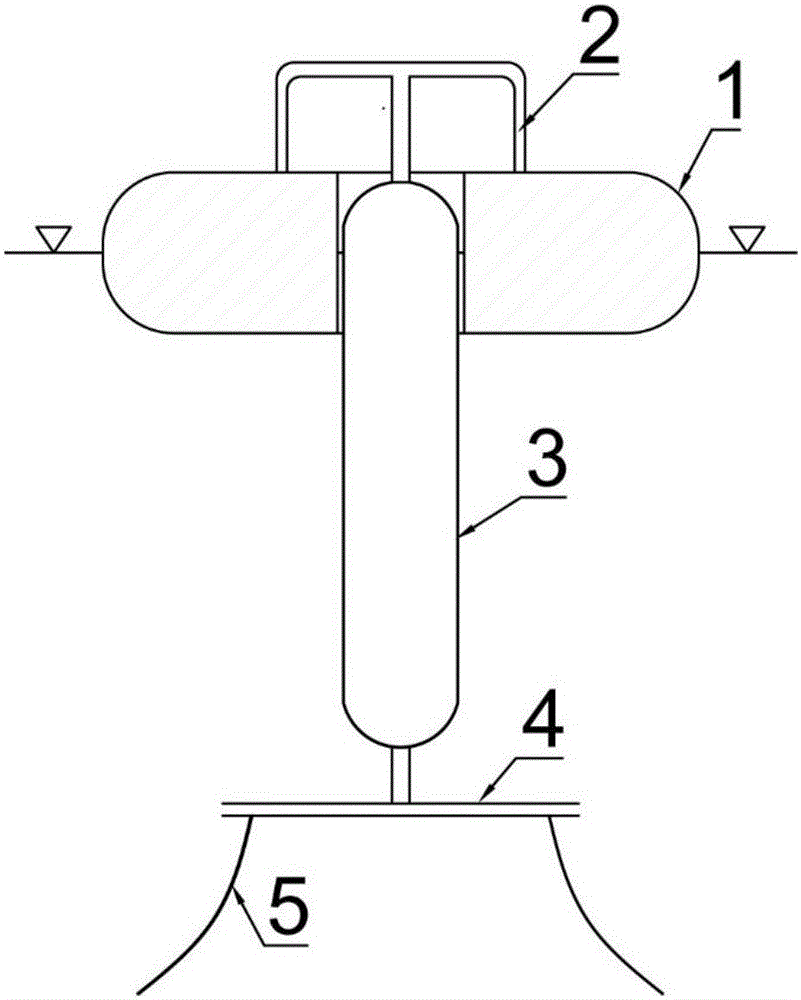

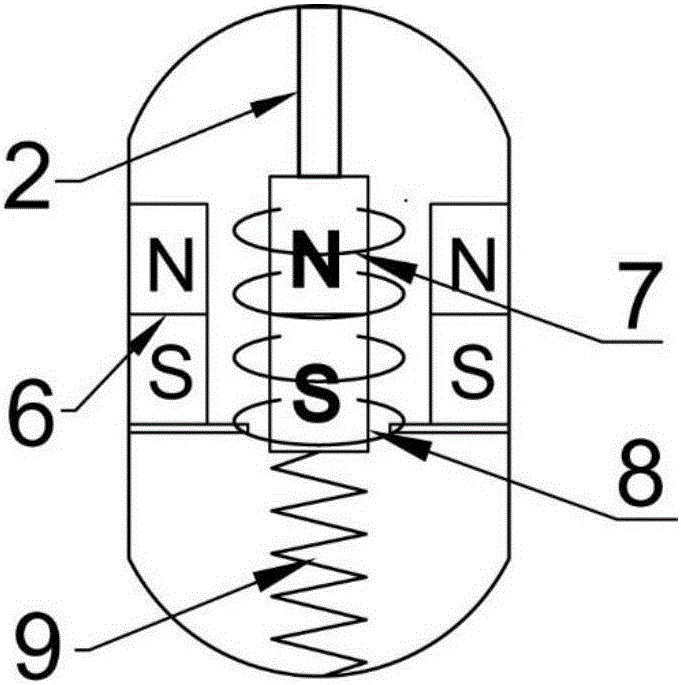

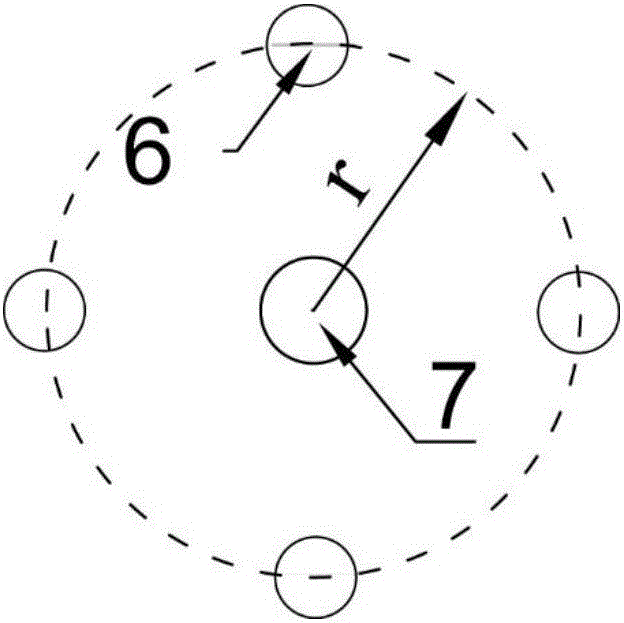

Non-linear direct-drive float type wave power generation device

ActiveCN105697223AImprove capture efficiencyReduce the amplitude of up and down vibrationHydro energy generationMachines/enginesMagnetic tension forceWave power generation

The invention provides a non-linear direct-drive float type wave power generation device. When the non-linear direct-drive float type wave power generation device is placed in sea, sea wave drives a float to perform up-down movement and further drives a first magnet to perform up-down movement, an induction coil is enabled to cut magnetic field line generated by the first magnet, and therefore the function of generating power by utilizing wave energy is realized; meanwhile, a magnetic force generated by second magnets positioned at the periphery of the first magnet and that generated by the first magnet interact with an elastic force generated by a spring in an energy output system, so that the system has negative stiffness, the vibration energy is increased, the potential energy well of the energy output system shows a double-well characteristic, and the energy capture efficiency, especially the energy capture efficiency at a low frequency is improved.

Owner:SHANGHAI JIAO TONG UNIV

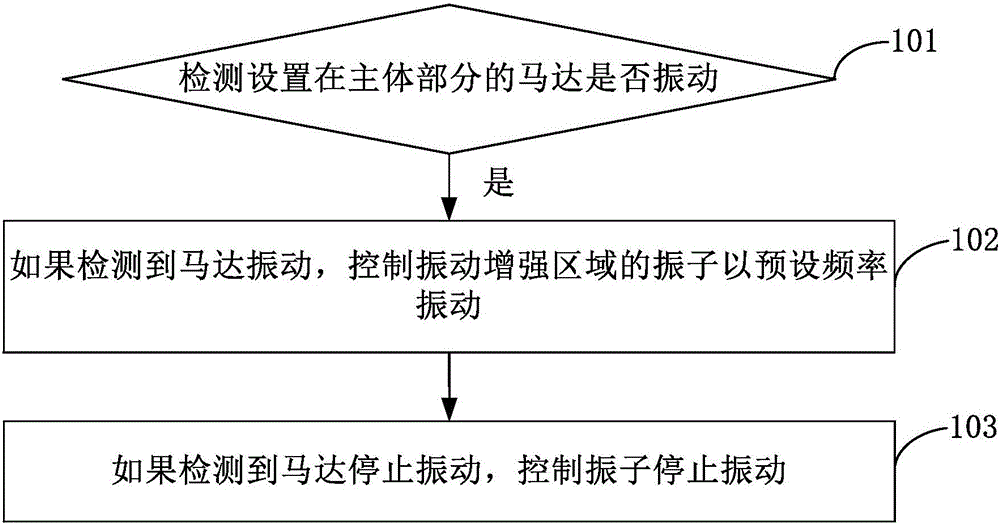

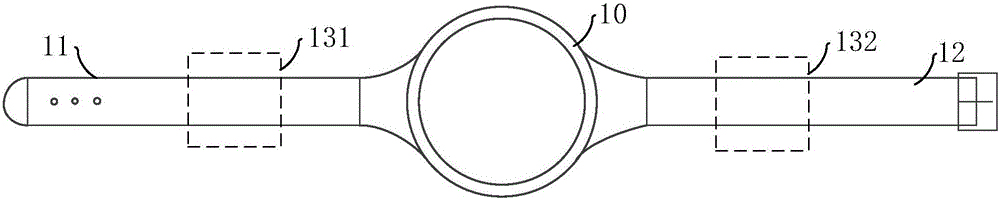

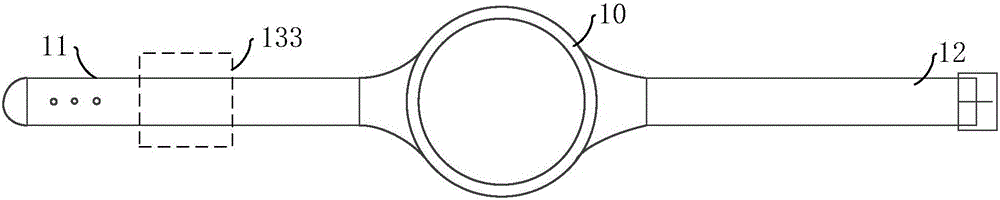

Method and apparatus for controlling vibration of electronic equipment and electronic equipment

ActiveCN105739685AIncrease vibrational energyEnhanced Haptic FeedbackInput/output for user-computer interactionMechanical oscillations controlEngineeringElectron device

The invention provides a method and apparatus for controlling vibration of electronic equipment, and the electronic equipment. The electronic equipment comprises a main body part and a wristband part; and the wristband part is provided with a vibration reinforcing region. The method comprises the steps of detecting whether a motor arranged in the main body part vibrates; if detecting that the motor vibrates, controlling a vibrator in the vibration reinforcing region to vibrate under a preset frequency; and if detecting that the motor stops vibrating, controlling the vibrator to stop vibrating. According to the technical scheme adopted by the invention, the wristband part can assist the main body part in vibrating so as to improve integral vibration energy of the electronic equipment and reinforce touch feedback to a user.

Owner:BEIJING SHUNYUAN KAIHUA TECH LTD

Surface acoustic wave resonator, surface acoustic wave oscillator, and surface acoustic wave module unit

ActiveUS8358177B2Improve vibrationIncrease vibrational energyPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface acoustic wave oscillatorsAcoustic wave

It is possible to reduce the size of a surface acoustic wave (SAW) resonator by enhancing a Q value. In a SAW resonator in which an IDT having electrode fingers for exciting SAW is disposed on a crystal substrate, the IDT includes a first region disposed at the center of the IDT and a second region and a third region disposed on both sides of the first region. A frequency is fixed in the first region and a portion in which a frequency gradually decreases as it approaches an edge of the IDT is disposed in the second region and the third region. When the frequency of the first region is Fa, the frequency at an edge of the second region is FbM, and the frequency at an edge of the third region is FcN, the variations in frequency are in the ranges of 0.9815<FbM / Fa<0.9953 and 0.9815<FcN / Fa<0.9953, respectively.

Owner:PANASONIC CORP +1

Preparation method of superfine hetian jade powder and application thereof

InactiveCN108295089AUniform particle sizeHigh porosityCosmetic preparationsHydroxy compound active ingredientsMaterials preparationMedicine

The invention relates to the field of material preparation, in particular to a preparation method and application of superfine hetian jade powder. The invention provides the preparation method of thesuperfine hetian jade powder; jade is made into jade powder by applying a superfine pulverizing technology, mercury and arsenic which are harmful to human bodies are removed at high temperature, and thus, the jade powder is applied to cosmetics and pharmaceutical preparations. The invention also provides the application of the superfine hetian jade powder in the pharmaceutical preparations; purplejade cream prepared by adding Chinese herbal medicines such as lithospermum root has the effects of eliminating illness, dehumidifying, expelling pus and decay, regenerating tissue, treating scaldingdue to hot water or fire, detoxifying, sterilizing, removing decay and moistening skin.

Owner:陈桂芳

High energy continuous electric pulse on line annealing method of copper wire and its device

InactiveCN1618993AReduce energy consumptionReduce the degree of oxidationFurnace typesHeat treatment furnacesElectricityProduction line

A method for in-line annealing copper wire by high-energy continuous electric pulses includes delivering the copper wire toward the winder, applying the high-energy electric pulses to the moving copper wire by a high-energy electric pulse source and a pair of contacts, and forced cooling. Its advantages are low energy consumption and high productivity.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

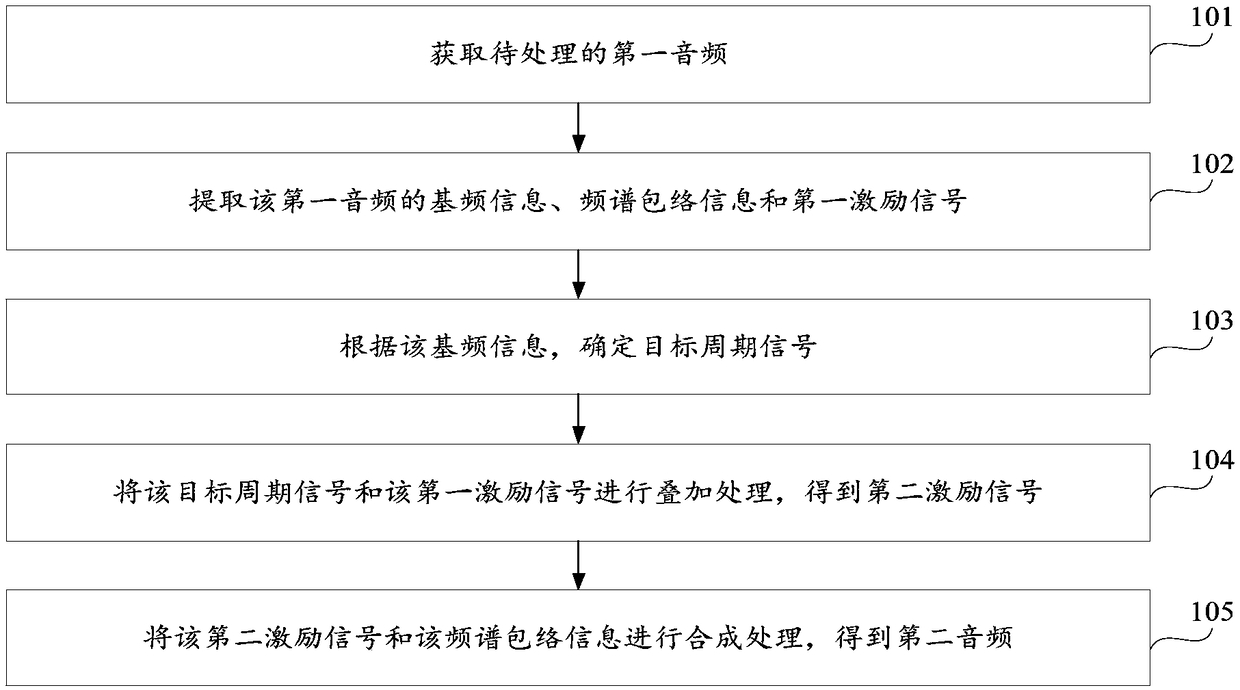

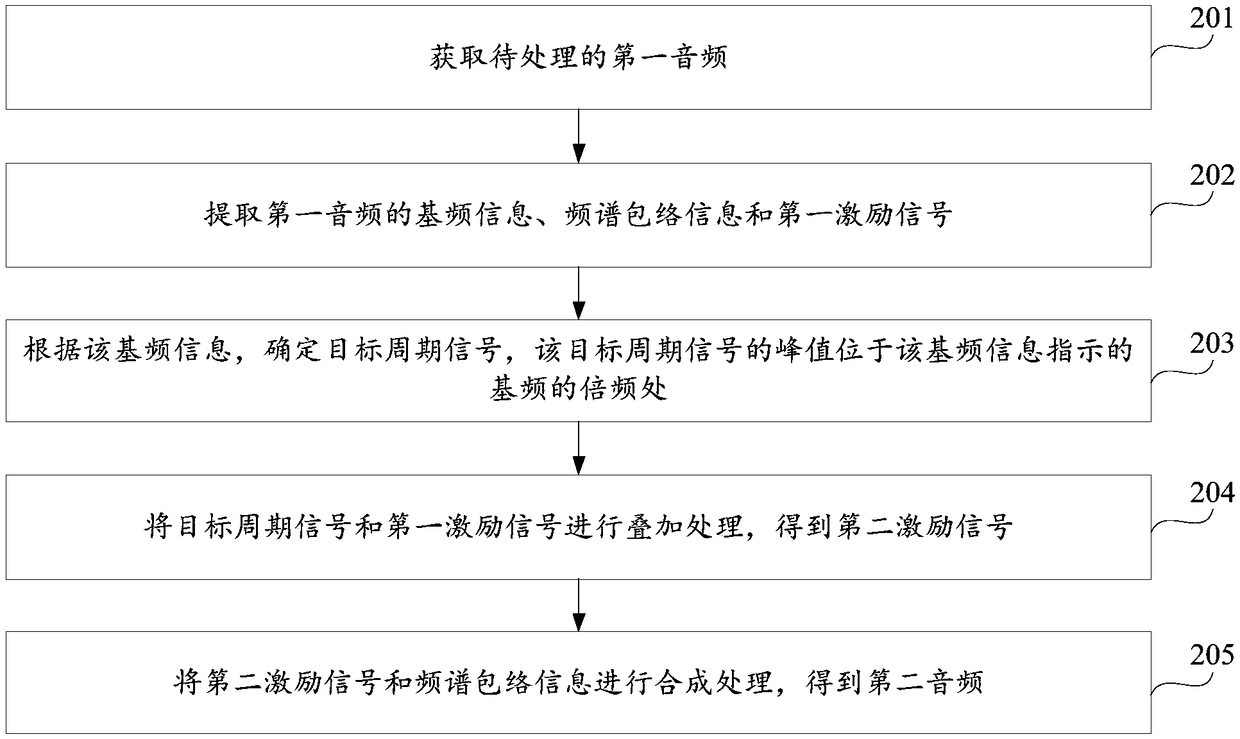

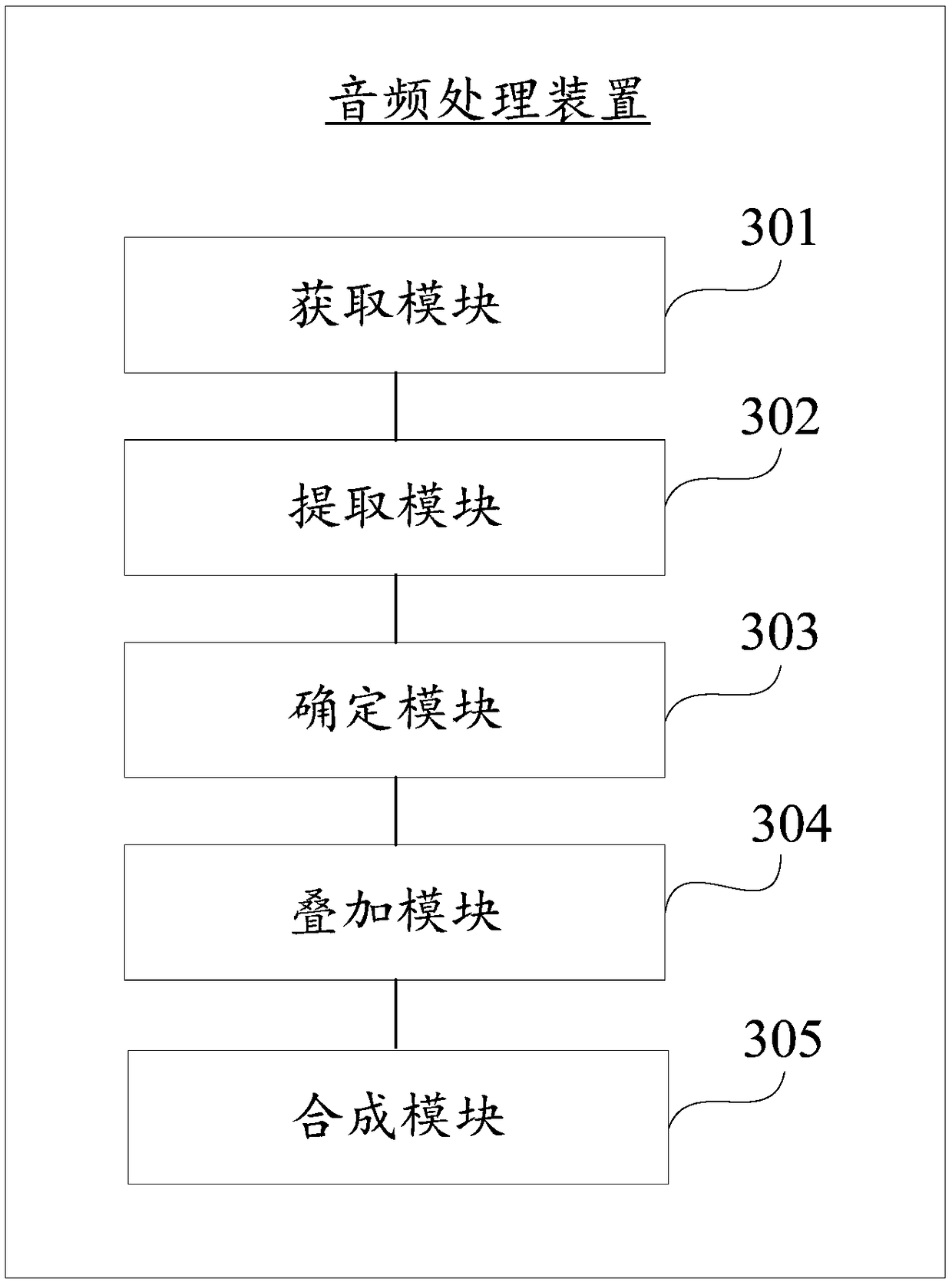

Audio processing method and device, and storage medium

ActiveCN109065068AClarity has little effectIncrease vibrational energySpeech analysisFrequency spectrumFundamental frequency

The invention discloses an audio processing method and device, and a storage medium and belongs to the voice technology field. The method comprises steps that a to-be-processed first audio is obtained; the fundamental frequency information, the frequency spectrum envelope information and a first excitation signal of the first audio are extracted; according to the fundamental frequency information,a target period signal is determined, and the peak of the target period signal is at the frequency doubling portion of the fundamental frequency indicated by the fundamental frequency information; the target period signal and the first excitation signal are superposed to obtain a second excitation signal; the second excitation signal and the frequency spectrum envelope information are synthesizedto obtain a second audio. The method is advantaged in that human voice sharpness of the first audio can be improved, noise amplification of the first audio is avoided, and audio quality after processing is improved.

Owner:GUANGZHOU KUGOU TECH

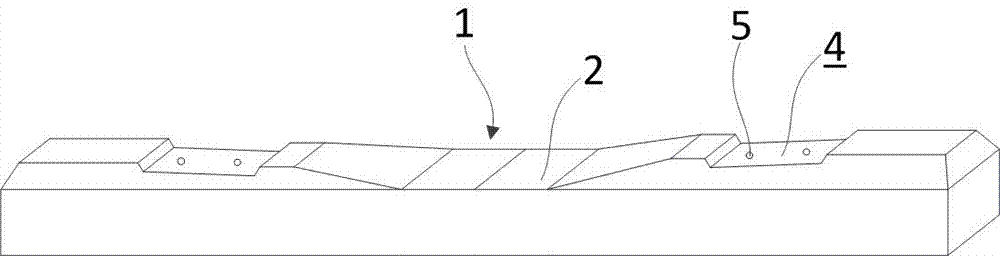

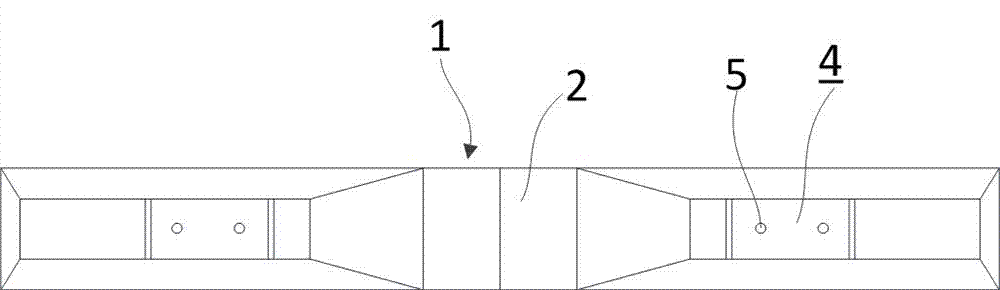

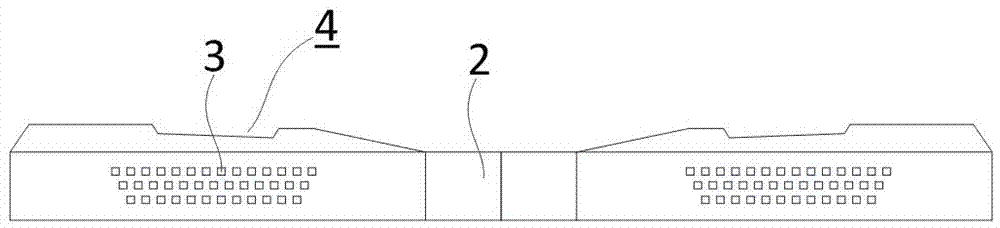

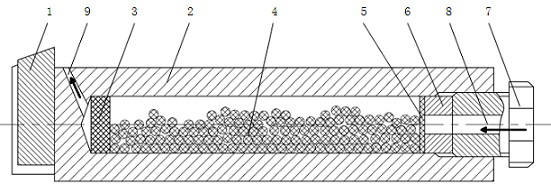

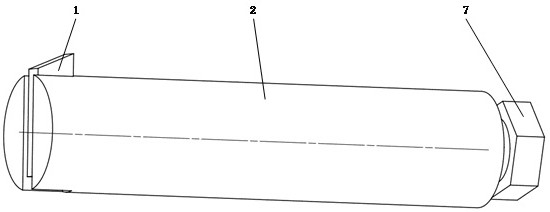

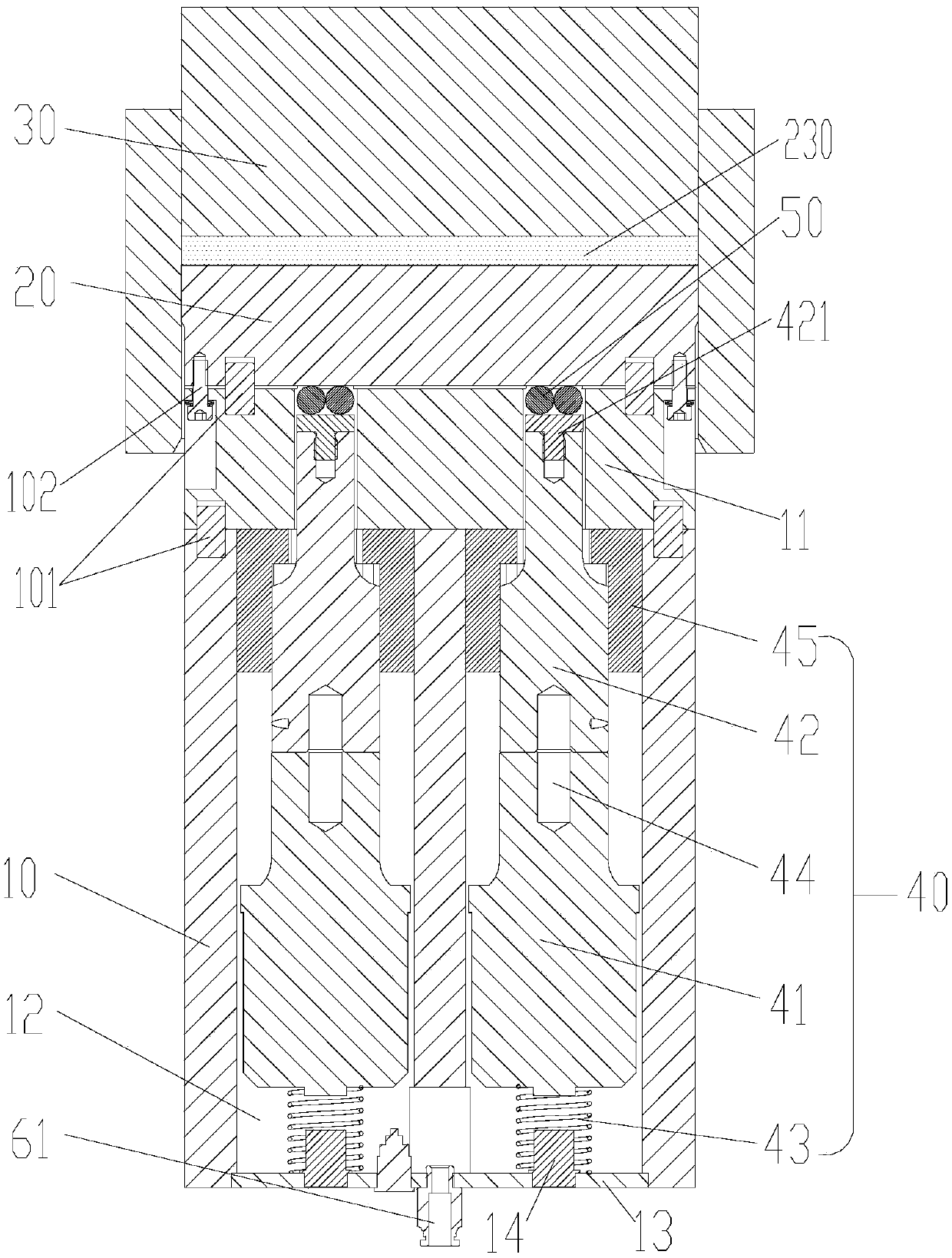

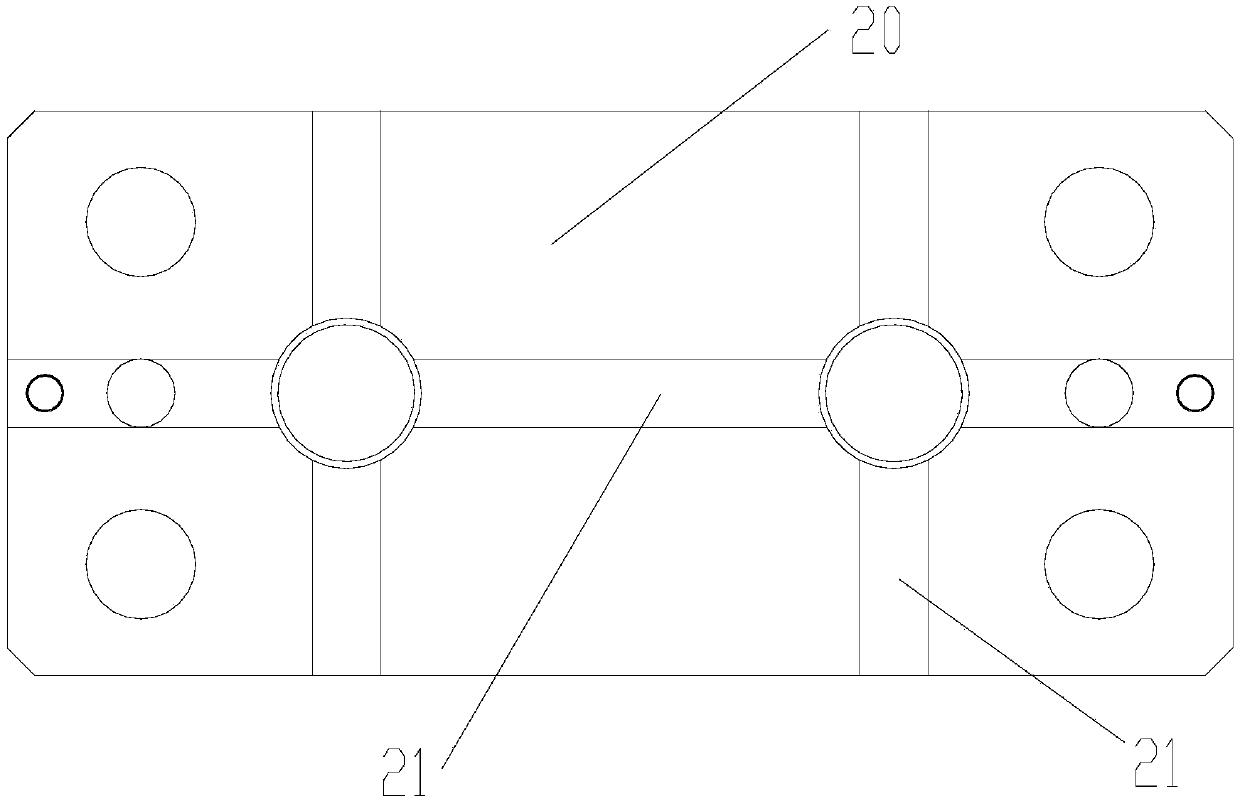

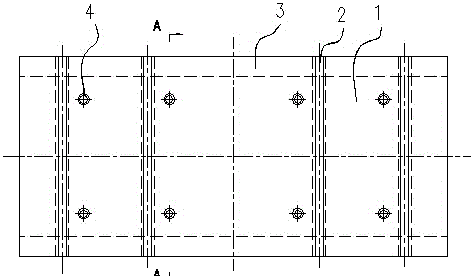

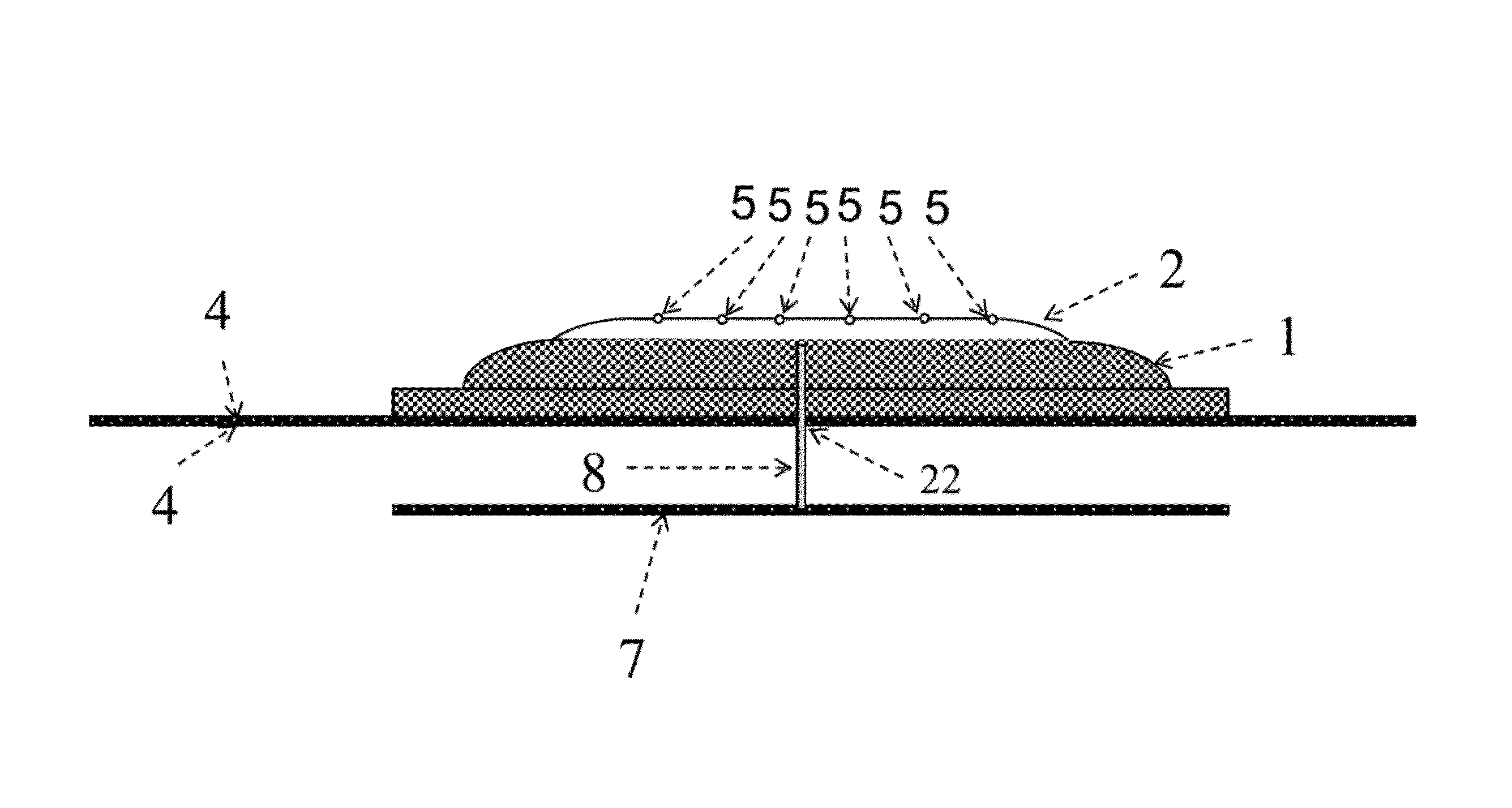

Piston-type particle-damping energy-dissipation vibration-reduction sleeper

PendingCN107503247AIncrease vibrational energyIncrease dampingBallastwayEngineeringVibration isolation

The invention discloses a piston-type particle-damping energy-dissipation vibration-reduction sleeper. The piston-type particle-damping energy-dissipation vibration-reduction sleeper comprises a sleeper body and piston-type particle-damping elements buried into the sleeper body; rail bearing grooves are formed in the upper surface of the sleeper body; the piston-type particle-damping elements comprise shells, and damping particles and metal balls are arranged inside the shells; the metal balls are fixedly connected with the sleeper body through metal wires. The piston-type particle-damping energy-dissipation vibration-reduction sleeper has the advantages that the piston-type particle-damping elements arranged inside the sleeper body can absorb and consume vibration energy of the sleeper body; the mode that the piston-type particle-damping elements are buried into the sleeper body is equivalent to the effect of increasing damping of the piston-type particle-damping energy-dissipation vibration-reduction sleeper; the piston-type particle-damping energy-dissipation vibration-reduction sleeper can dissipate vibration energy generated through the wheel rail effect, and the vibration-reduction vibration-isolation effect is achieved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

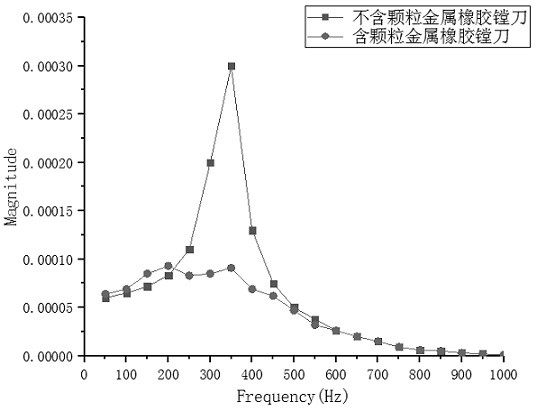

Vibration reduction cooling boring cutter based on metal rubber and manufacturing method thereof

The invention provides a vibration reduction cooling boring cutter based on metal rubber and a manufacturing method thereof. The vibration reduction cooling boring cutter comprises a hollow cutter bar and a cutter head located at one end of the cutter bar, the metal rubber is arranged in an inner cavity of a guide rod, a cooling liquid inlet is formed in the end, deviating from the cutter head, of the cavity, and the other end of the cavity extends towards the cutter head to form a cooling liquid discharging through hole. When the cutter generates impact vibration in the cutting work, the cylindrical metal rubber and particle metal rubber rub the inner wall of the cutter bar to generate friction damping; cooling liquid flows through the metal rubber and flows in a porous structure of the metal rubber, flow channels in gaps are complex and changeable, when high-frequency vibration is generated outside, the vibration amplitude is changed through the internal coupling effect of the cooling liquid and the metal rubber, and resonance is avoided; and meanwhile, the throttling damping effect on flowing of the cooling liquid is achieved, vibration is effectively reduced, the contact area of the cooling liquid and the cutter bar is increased, and heat generated in the working process of the cutter is taken away.

Owner:FUZHOU UNIV

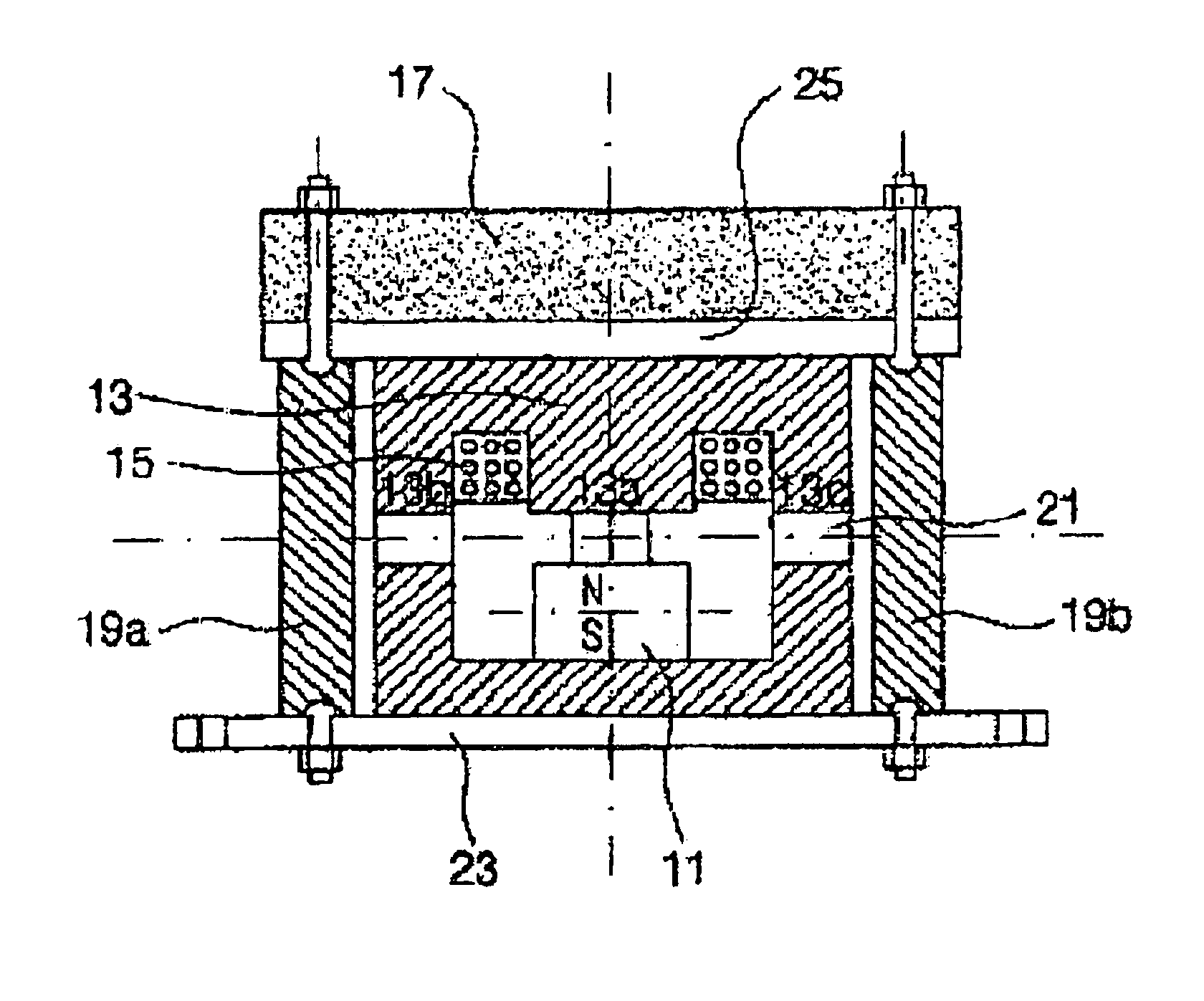

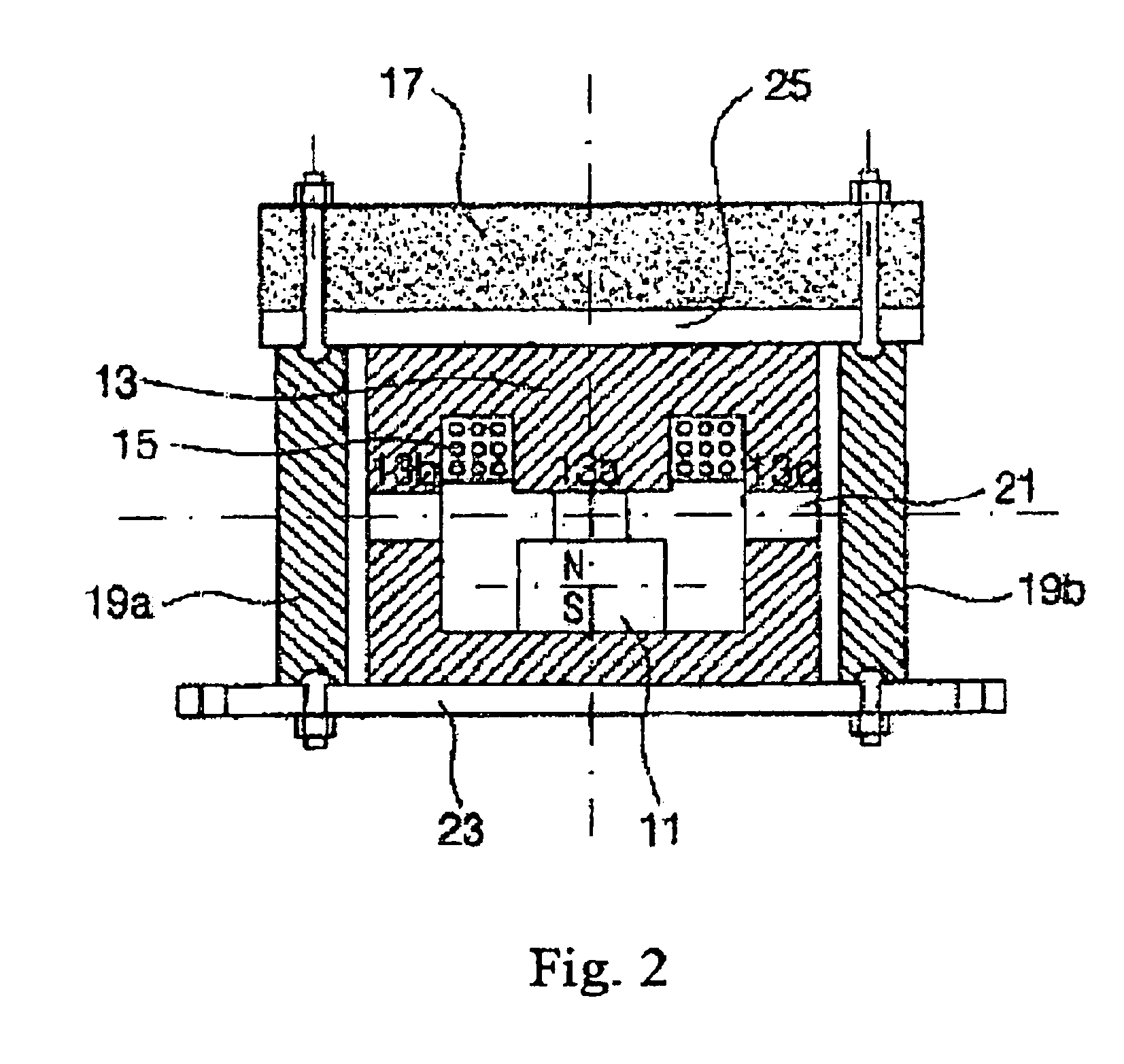

Electro-mechanical transducer

InactiveUS6903474B2Increase in inertial forceIncrease vibrational energyElectrical transducersBone conduction transducer hearing devicesEngineeringTransducer

An apparatus adopting an iron core and an inertial mass is disclosed for exerting high power output by converting a sound signal to vibration so as to stimulate the human hearing organs through the bones. A sound-to-vibration conversion apparatus comprises a housing, a permanent magnet having an N-pole and an S-pole, only one pole of which is fixed to the housing, an electromagnet movably installed into the housing faced either the S-pole or N-pole of the permanent magnet, whichever one is not fixed to the housing, and an inertial mass for amplifying the inertial force of reciprocating movement of the electromagnet, so that the housing with the permanent magnet can be vibrated by the electromagnet, whereby the electromagnet vibrates in a reciprocating fashion towards or away from the permanent magnet in accordance with the incubation between the polarity formed at the electromagnet by acoustic signal applied to the electromagnet and either the N-pole or the S-pole of the permanent magnet.

Owner:TWIN SAVER

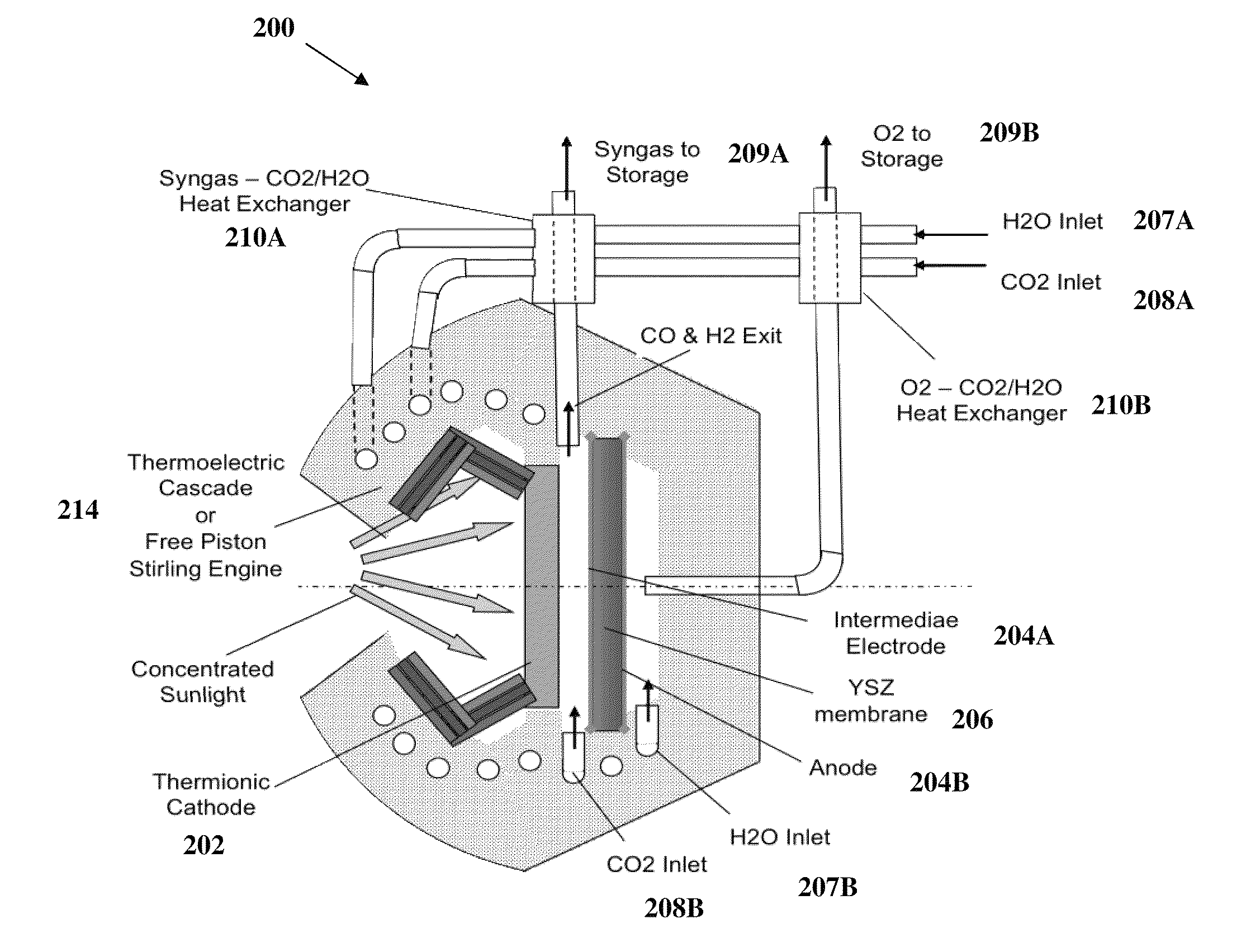

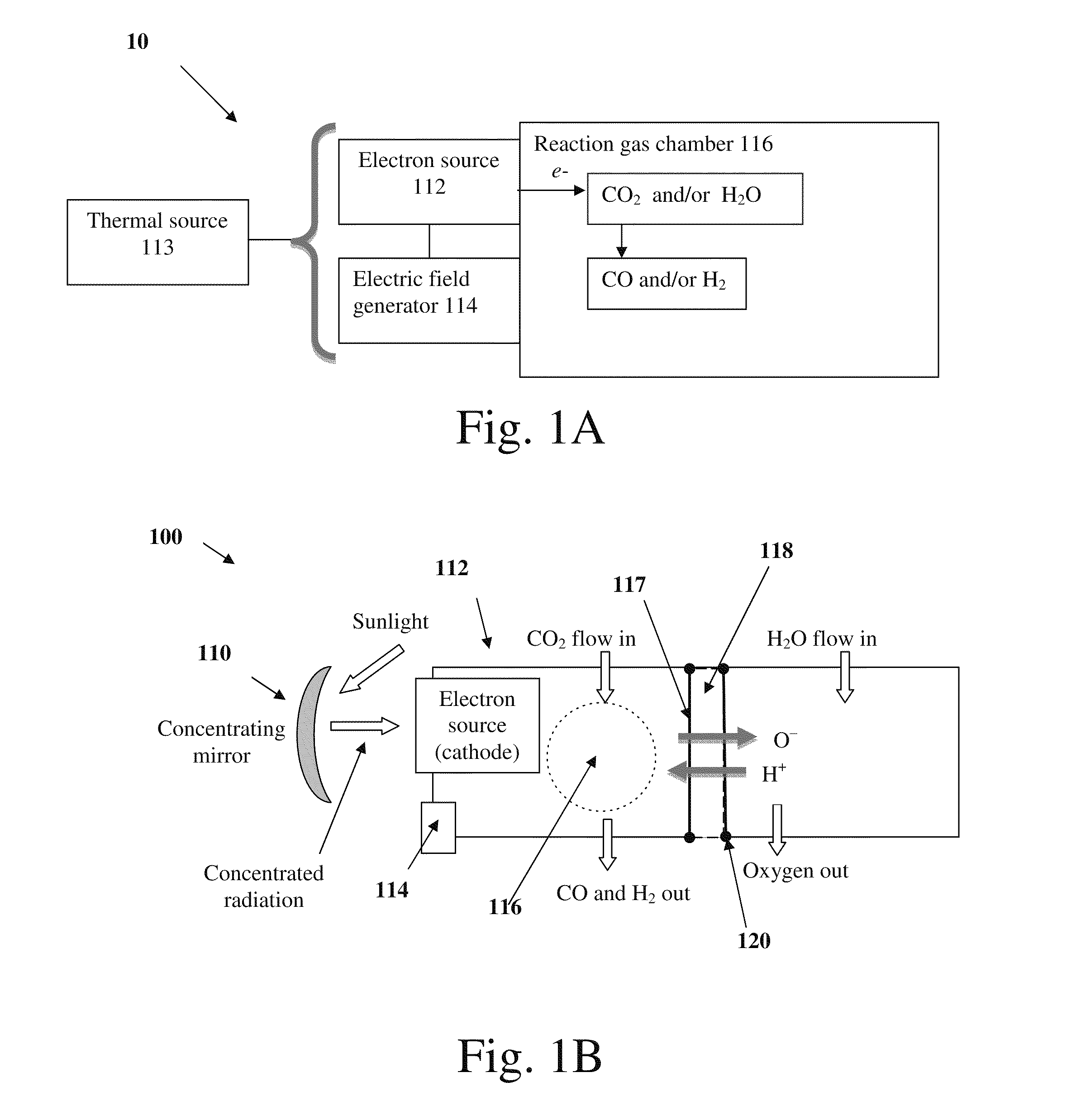

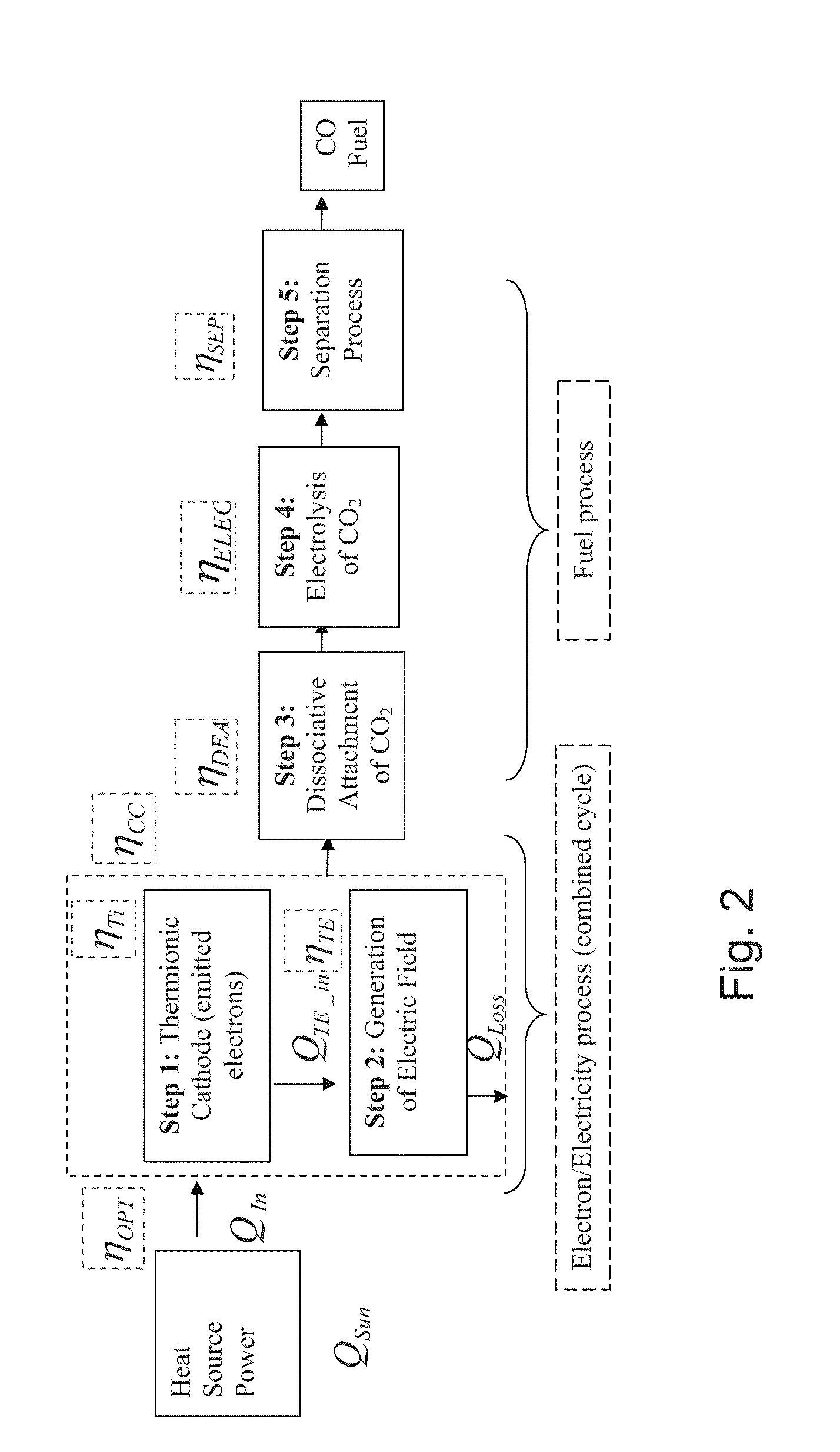

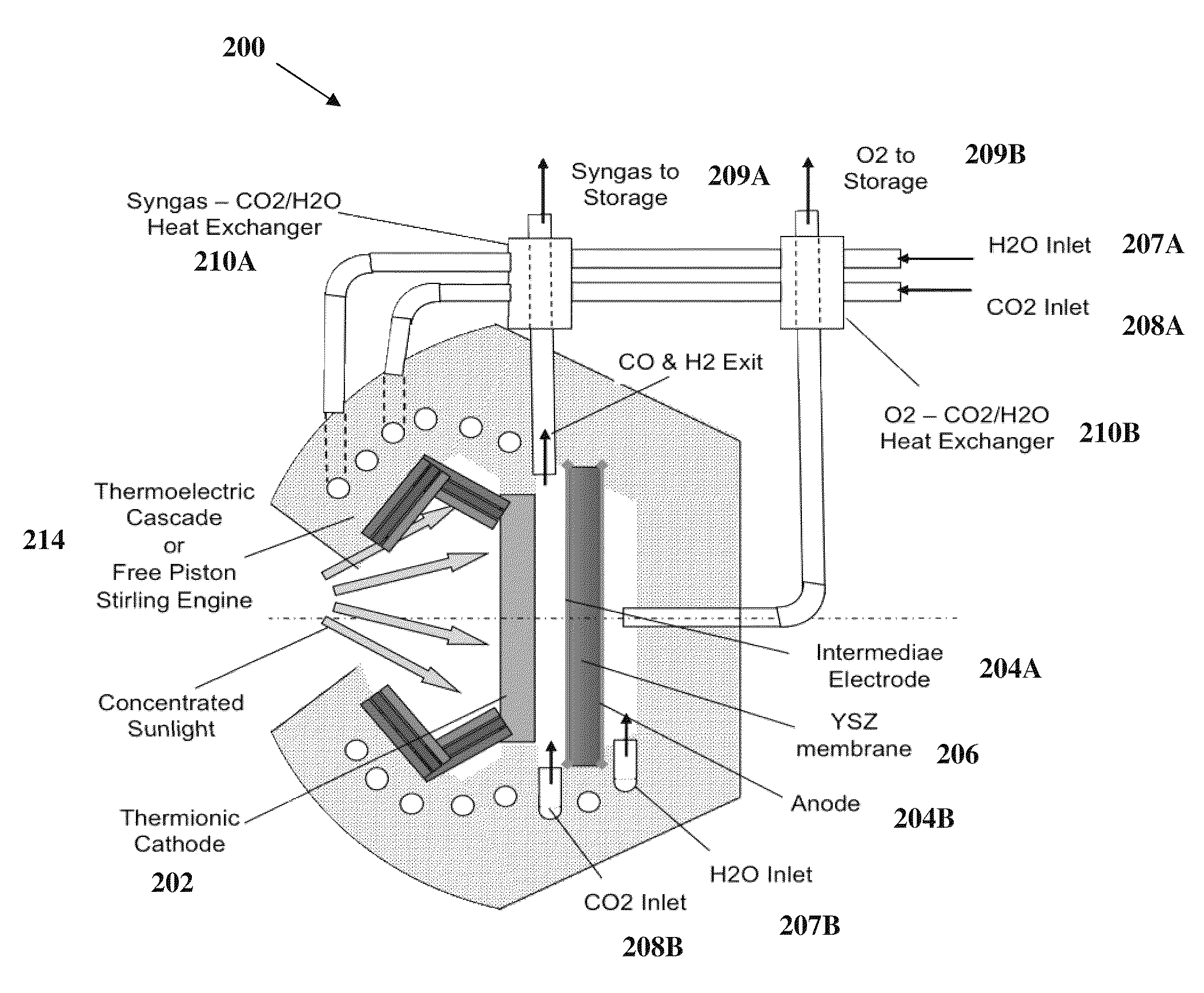

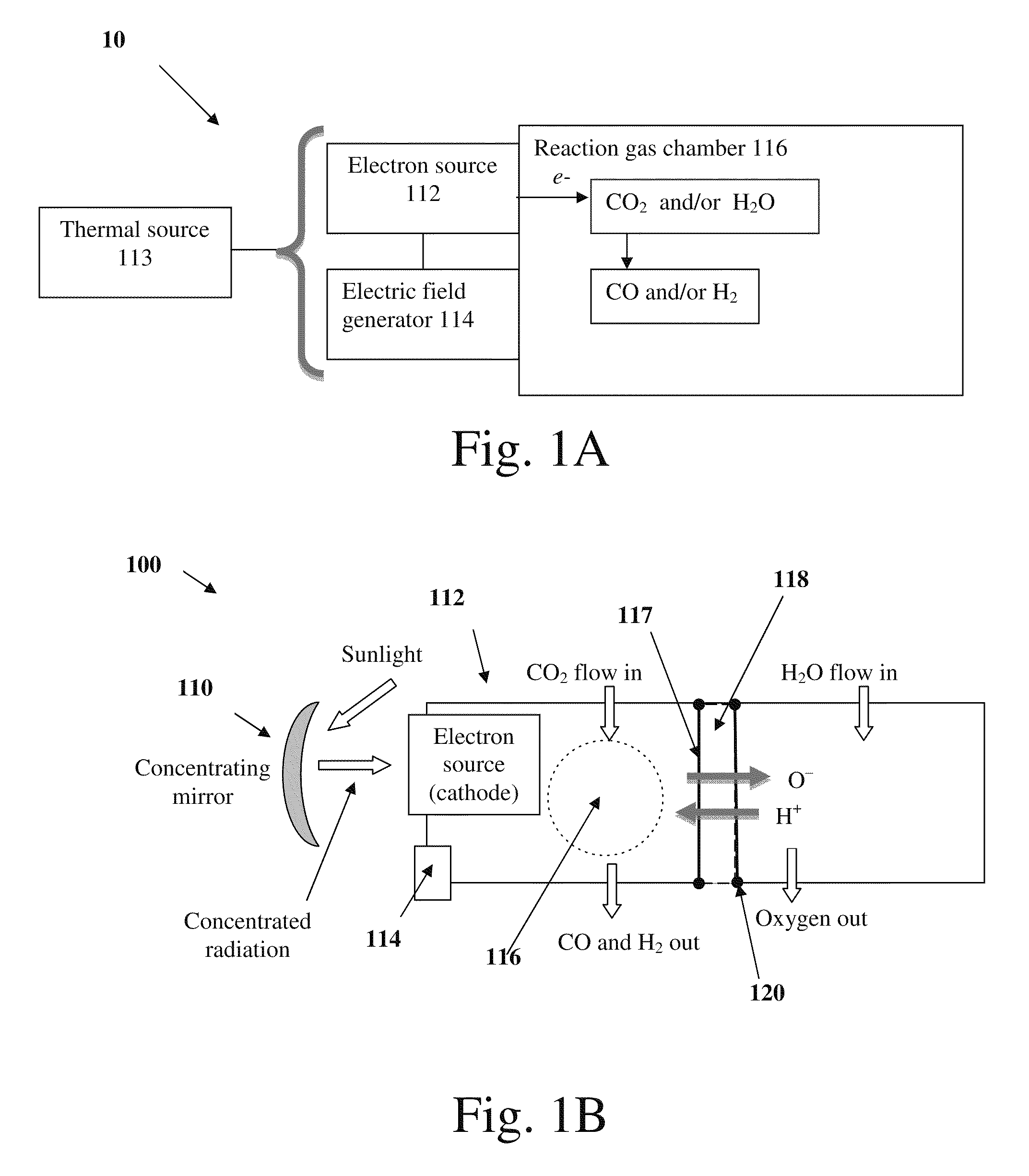

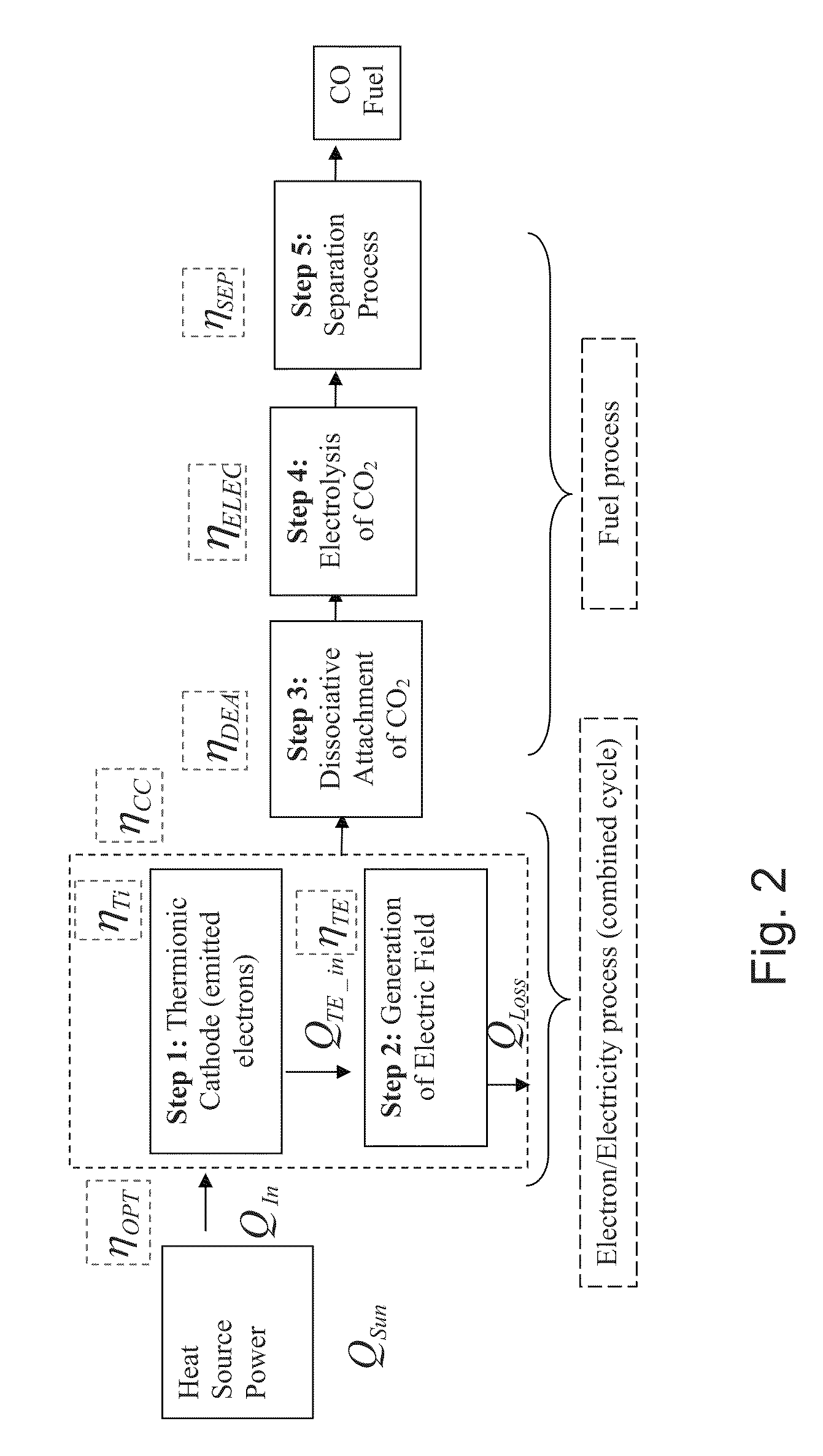

System and method for chemical potential energy production

ActiveUS20110108435A1Reduce the amount requiredIncrease vibrational energyCellsOxygen/ozone/oxide/hydroxideElectron sourceGas chamber

The present invention relates to a system comprising a heat source to provide heat at the desired temperature and energy field (e.g. a solar concentrator); an electron source configured and operable to emit electrons; an electric field generator generating an electric field adapted to supply energy sufficient to dissociate gas molecules; and a reaction gas chamber configured and operable to cause interaction between the electrons with the molecules, such that the electrons dissociate the molecules to product compound and ions via dissociative electrons attachment (DEA) within the chamber.

Owner:YEDA RES & DEV CO LTD

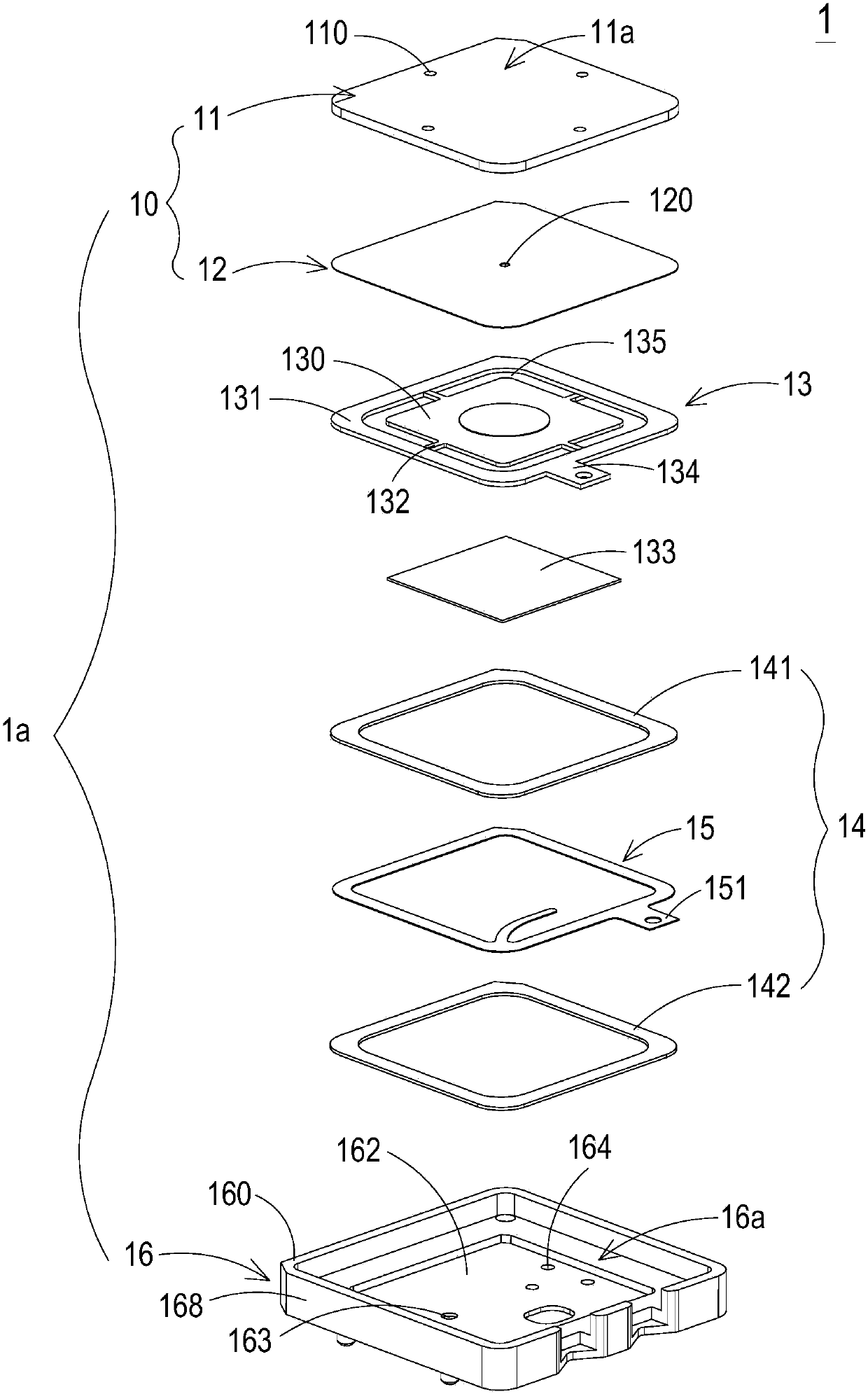

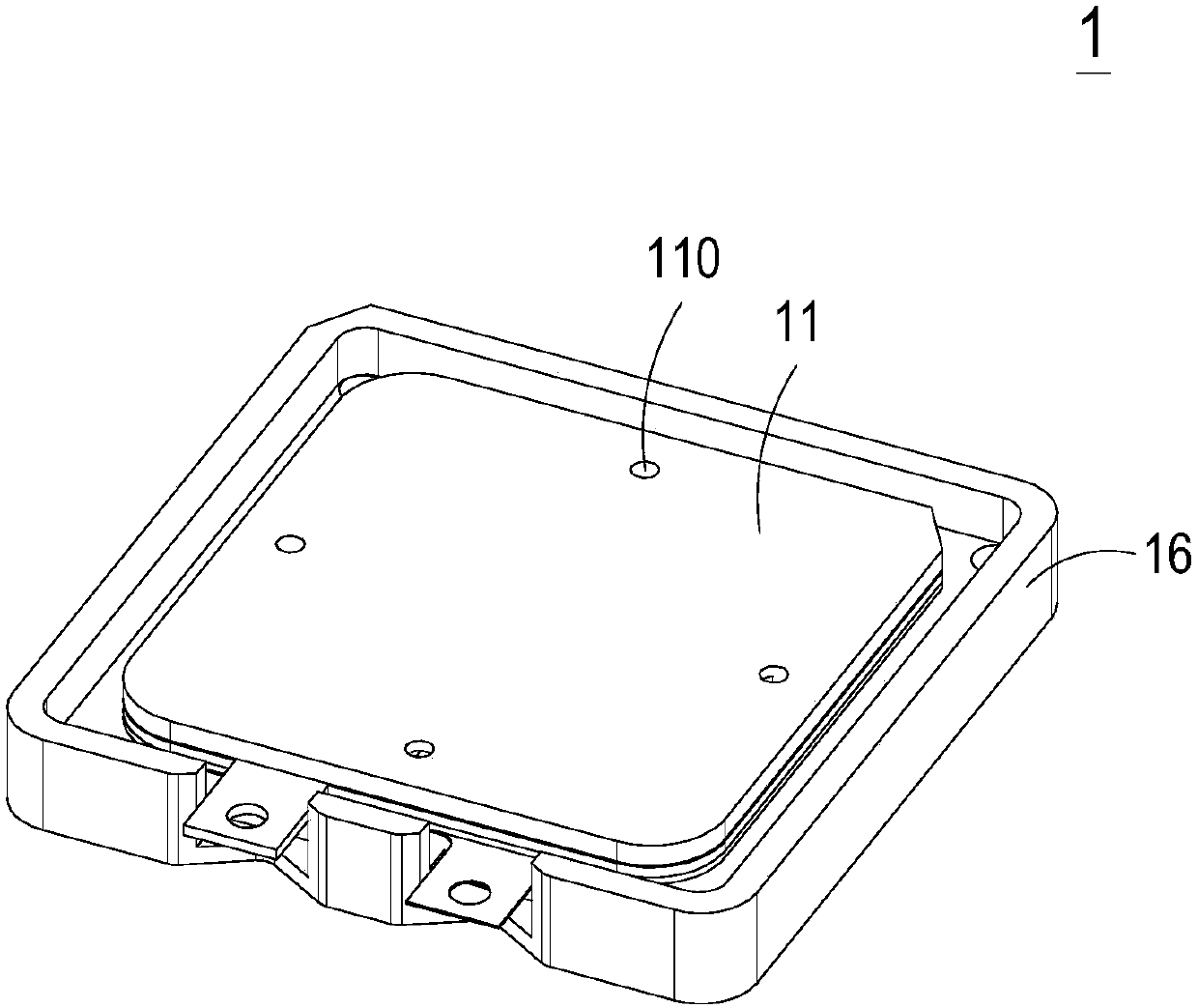

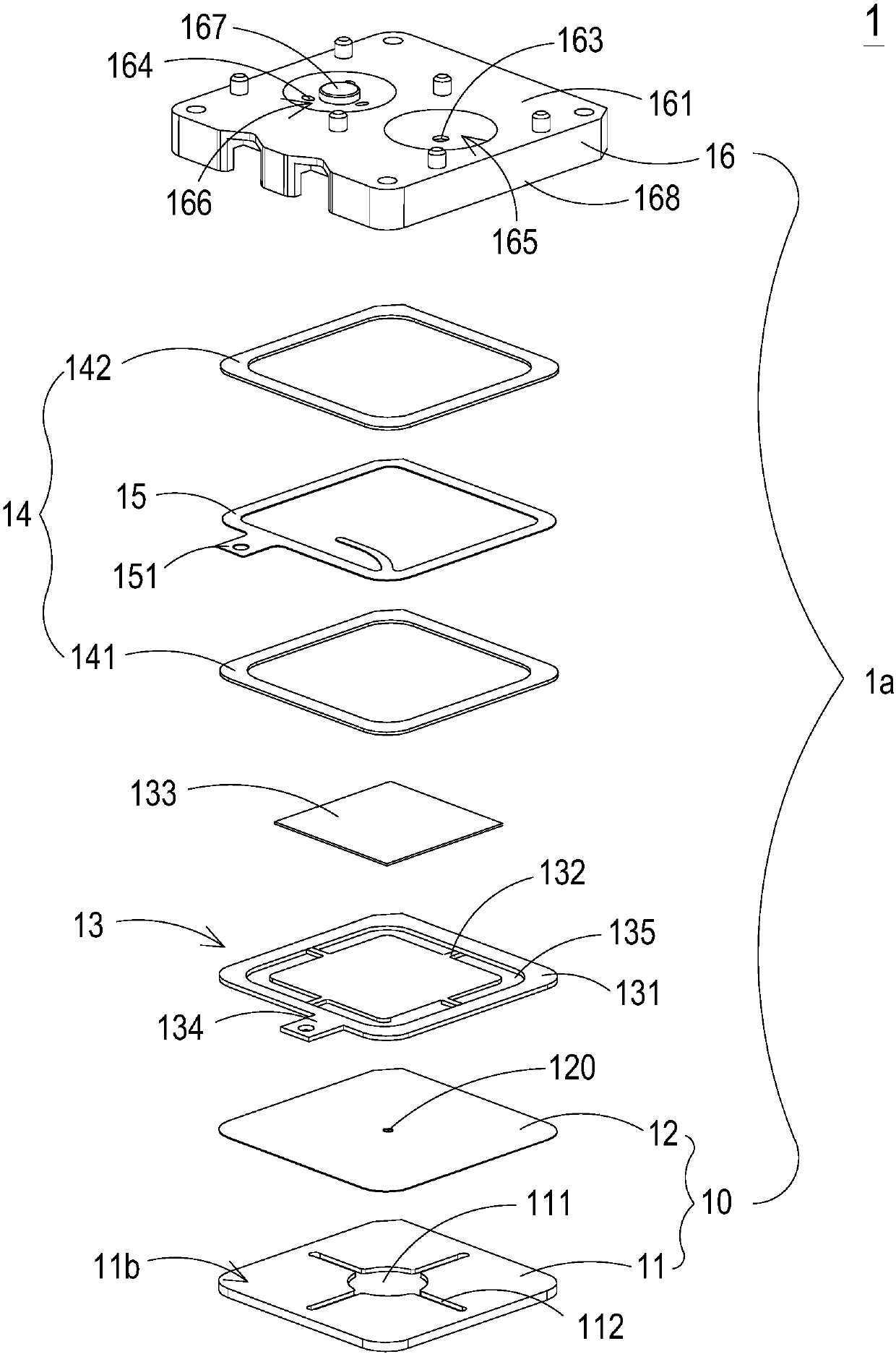

Micro fluid control device

ActiveCN107795465AVolume reduction and thinningReduce assembly errorsFlexible member pumpsPositive-displacement liquid enginesFluid controlPiezoelectric actuators

A micro fluid control device comprises a piezoelectric actuator and a shell. The piezoelectric actuator is provided with a suspension plate, an outer frame, a support and a piezoelectric ceramic plate. The suspension plate is in a square form and is provided with a first surface and a second surface, and the second surface is provided with a convex part. The outer frame is arranged outside the suspension plate in a surrounding mode and is also provided with a first surface and a second surface. The areas except the second surface of the outer frame and the convex part of the second surface ofthe suspension plate are all coplanar. The shell comprises a gas collection plate and a base. The gas collection plate is of a frame structure with a holding space. The base is formed by connecting agas inlet plate and a resonantor and is arranged in the holding space so as to close the piezoelectric actuator. A glue layer is arranged between the second surface of the outer frame of the piezoelectric actuator and the resonantor of the base, so that a needed depth of a compression cavity is maintained between the piezoelectric actuator and the resonantor.

Owner:MICROJET TECH

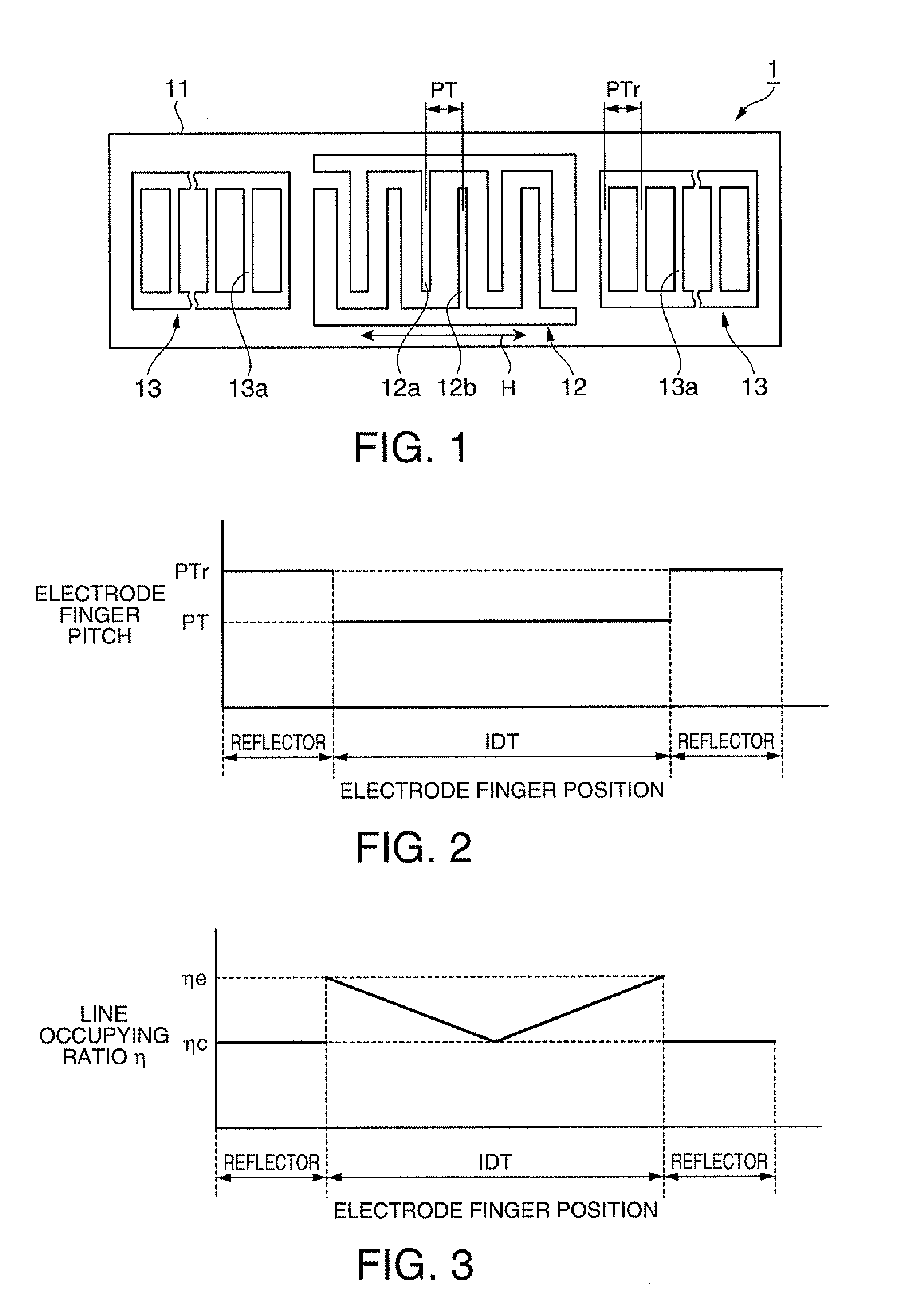

Surface acoustic wave resonator, surface acoustic wave oscillator, and surface acoustic wave module unit

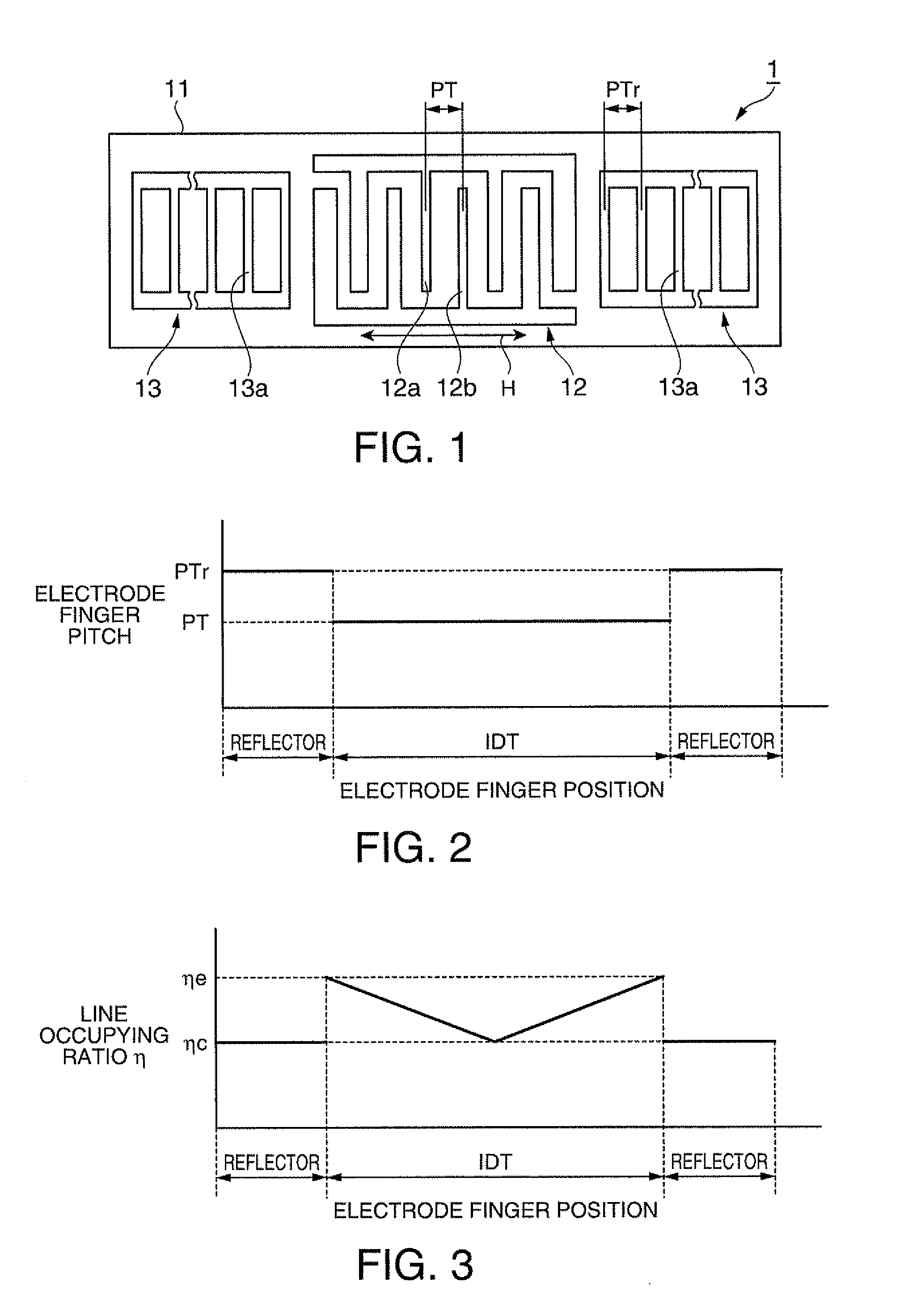

ActiveUS20110204984A1Reduce power consumptionImprove confinementImpedence networksOscillations generatorsSurface acoustic wave oscillatorsSurface acoustic wave resonators

It is possible to reduce the size of a surface acoustic wave resonator by enhancing the Q value. In a surface acoustic wave resonator in which an IDT having electrode fingers for exciting surface acoustic waves is formed on a crystal substrate, a line occupying ratio is defined as a value obtained by dividing the width of one electrode finger by the distance between the center lines of the gaps between one electrode finger and the electrode fingers adjacent to both sides thereof, and the IDT includes a region formed by gradually changing the line occupying ratio from the center to both edges so that the frequency gradually becomes lower from the center to both edges than the frequency at the center of the IDT.

Owner:SEIKO EPSON CORP

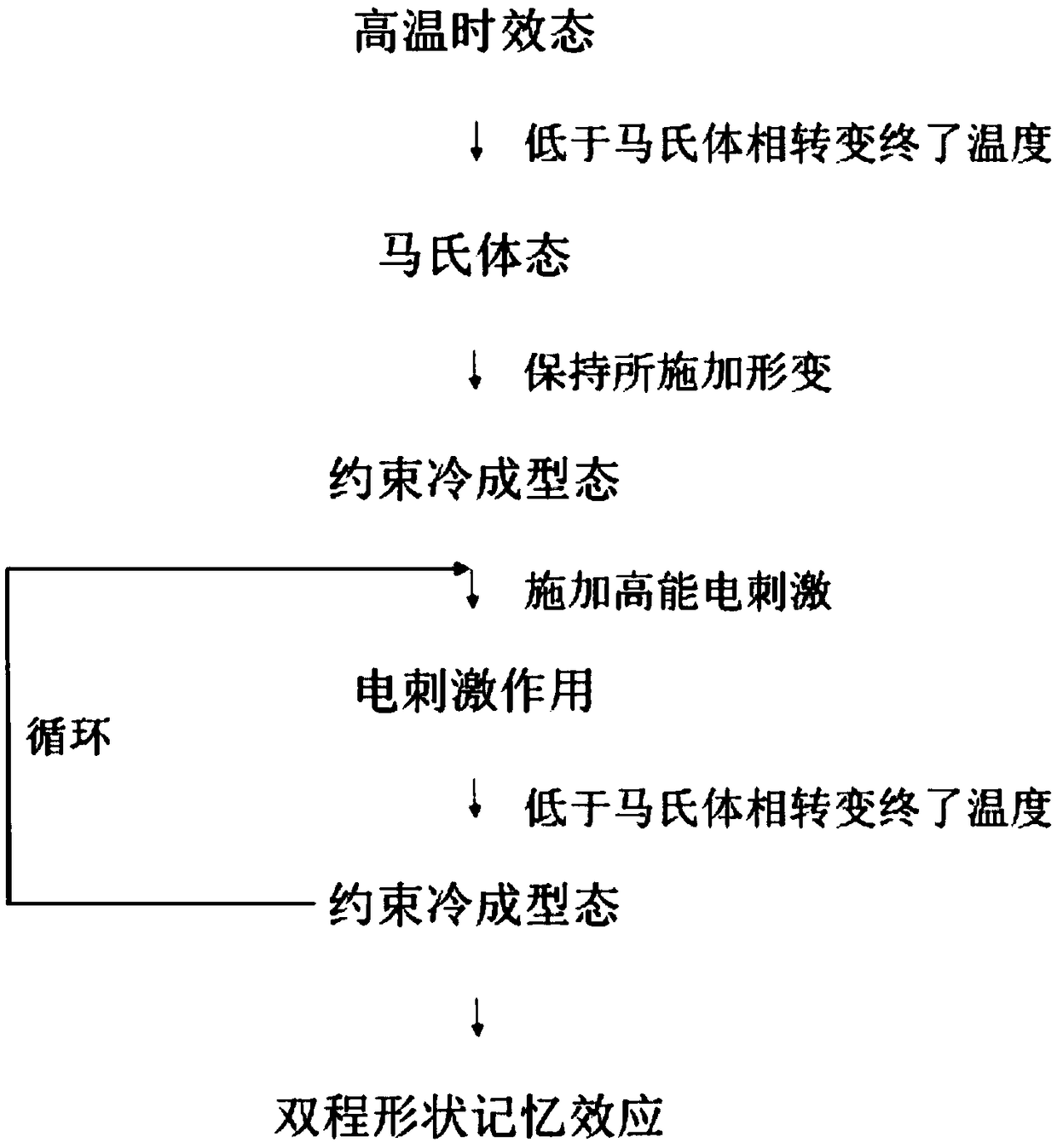

Method for endowing Ni-enriched TiNi shape memory alloy with two-way shape memory characteristic

The invention discloses a method for endowing a Ni-enriched TiNi shape memory alloy with a two-way shape memory characteristic. The method comprises the following steps: applying high-energy electrical stimulation to a constrained cold-formed TiNi shape memory alloy, coupling a Joule heating effect caused in a low temperature range of 150-250 DEG C with the electron wind effect, promoting the internal defects (such as dislocation) of the alloy to be in directional arrangement along a constraint stress direction, enabling a martensite variant to be in orientated growth, then 'memorizing' the cold forming state as a high temperature shape, 'memorizing' a high-temperature aging state as a low temperature shape, matching a mechanical training method to form the electrical stimulation-mechanical training method, and endowing the Ni-enriched TiNi shape memory alloy with the 'thermal expansion and cold contraction' type two-way shape memory characteristic. According to the method, the high-energy electrical stimulation and martensitic phase transition alternative cycle period duration can be greatly shortened, the production efficiency is improved, and the energy consumption is reduced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

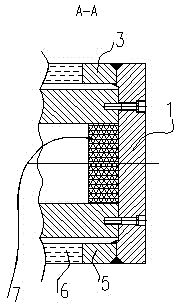

Ultrasonic device for powder compression molding

ActiveCN109551614AIncrease vibrational energyHigh frequencyShaping press ramUltrasoundUltrasonic vibration

The invention relates to an ultrasonic device for powder compression molding. The ultrasonic device for the powder compression molding comprises a die holder, a concave die arranged on the die holderand a convex die arranged opposite to the concave die, the convex die is matched with the concave die, and the convex die and the concave die form a cavity chamber for powder compression together; theultrasonic device for the powder compression molding is characterized in that at least one supersonic vibration generator is arranged in the die holder, vibration output parts of the supersonic vibration generators are arranged facing the concave die, wherein at least one impacting piece is arranged between the concave die and the vibration output parts of the supersonic vibration generators, andthe supersonic vibration generators can drive the impacting pieces to impact the concave die. According to the ultrasonic device for the powder compression molding, the supersonic vibration generators drive the impacting pieces to impact the concave die, and thus the vibration, generated in the working process of the ultrasonic device, to powder materials is high in energy and high in frequency;and thus obtained products after being subjected to the compression molding by the ultrasonic device are high in compactness and have good mechanical properties.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

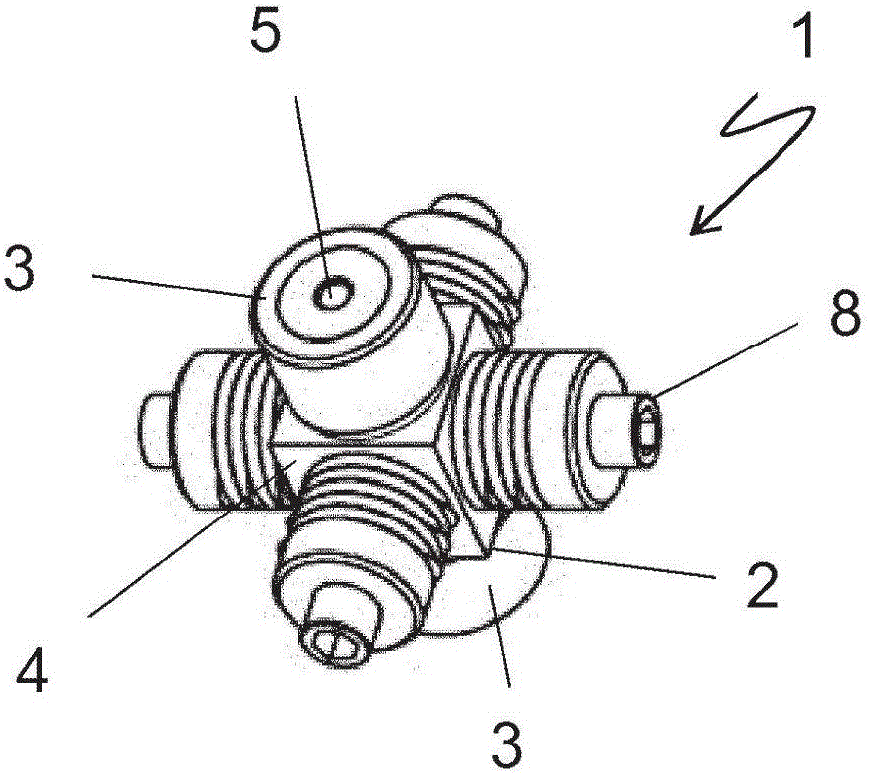

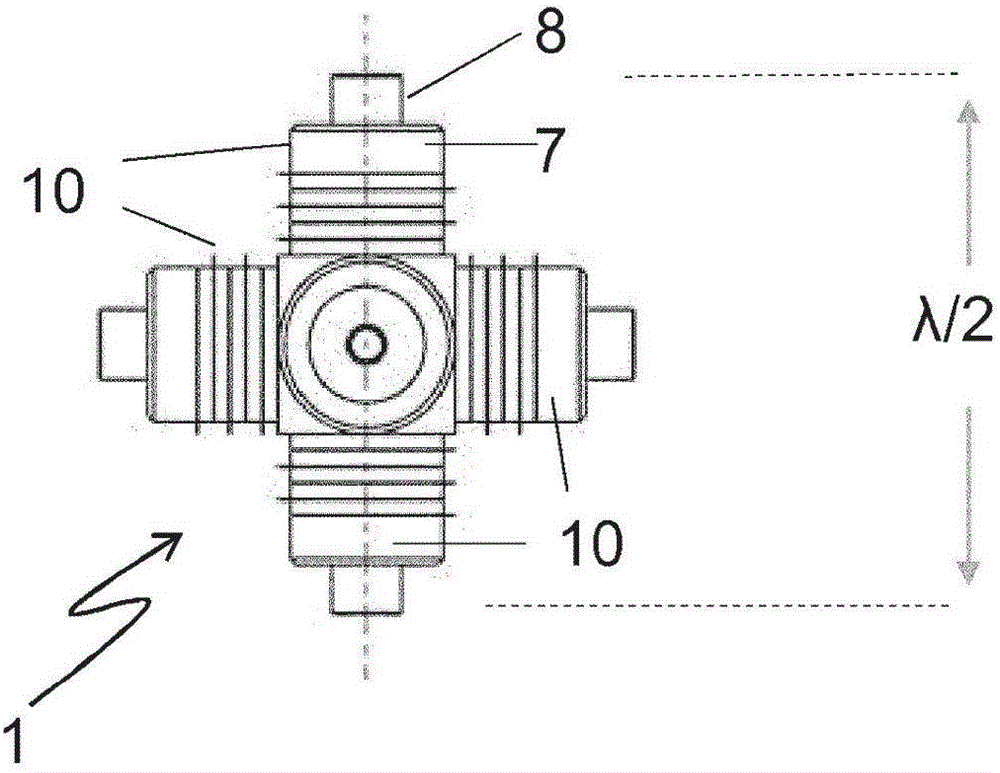

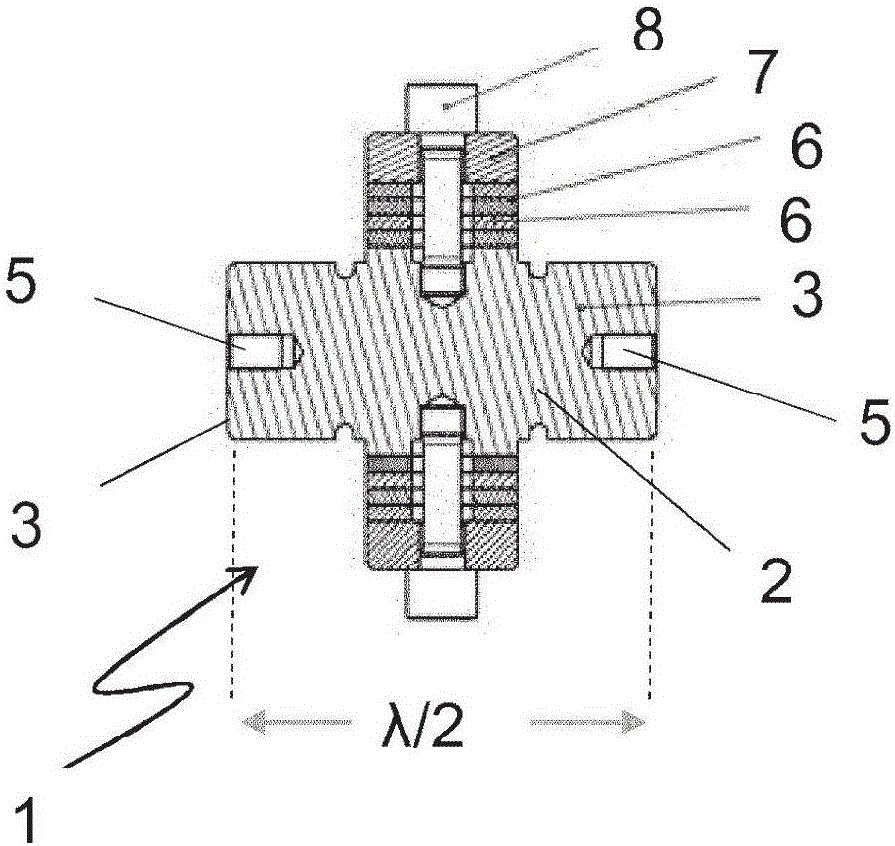

Converter unit

ActiveCN105960291AIncrease vibrational energyMechanical vibrations separationNon-electric welding apparatusEngineeringUltrasonic transmission

The invention relates to a converter unit comprising an ultrasonic transmission element having: a transmission surface for transmitting an ultrasonic vibration to a tool that can be attached to the transmission surface, or to a material that is in contact with same, in a longitudinal direction along a longitudinal axis of the ultrasonic transmission element; and at least one ultrasonic transducer for generating an ultrasonic vibration with a propagation direction that is not oriented along the longitudinal direction, wherein the converter unit has an ultrasonic natural frequency. In order to provide a converter unit comprising an ultrasonic transmission element having: a transmission surface for transmitting an ultrasonic vibration to a tool that can be attached to the transmission surface, or to a material that is in contact with same, in a longitudinal direction along a longitudinal axis of the ultrasonic transmission element; and at least one ultrasonic transducer for generating an ultrasonic vibration with a propagation direction that is not oriented along the longitudinal direction, wherein the converter unit has an ultrasonic natural frequency by means of which a high vibration energy can be generated, according to the invention, the ultrasonic transducer is arranged in the propagation direction in a region of + / -lambda / 4 about the longitudinal axis of the ultrasonic transmission element, where lambda is the wavelength of the vibration belonging to the ultrasonic natural frequency.

Owner:HERRMANN ULTRACHALLTECHNIK GMBH & CO KG

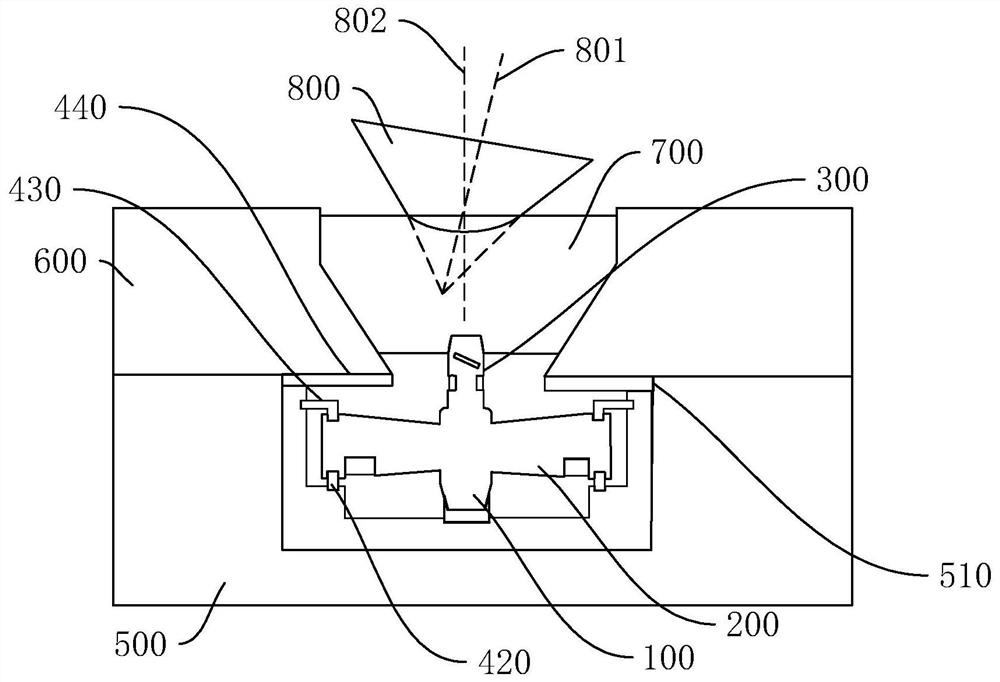

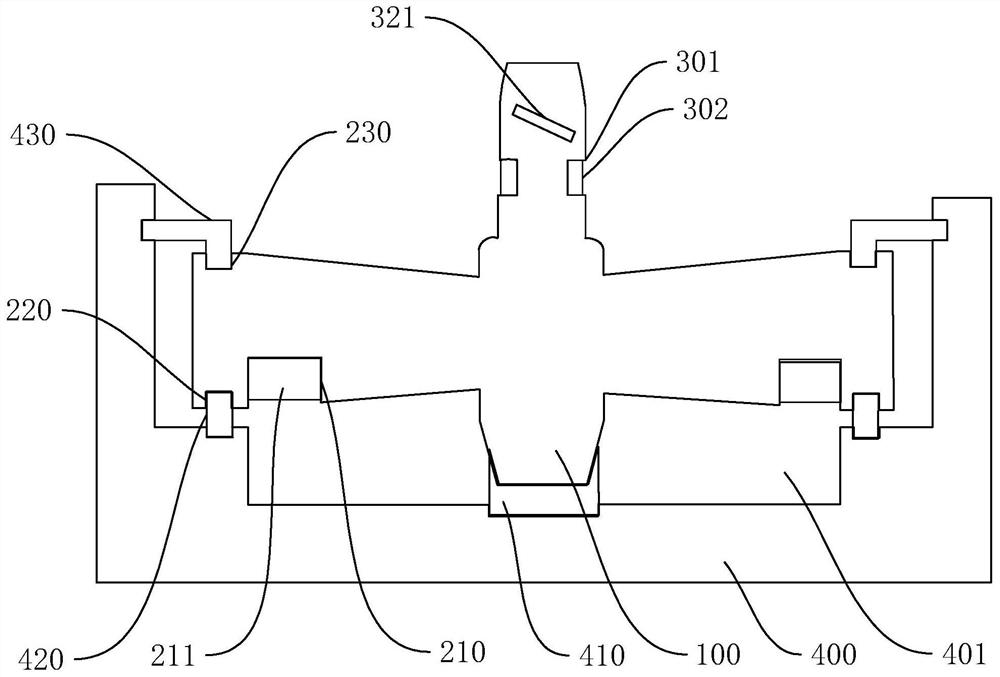

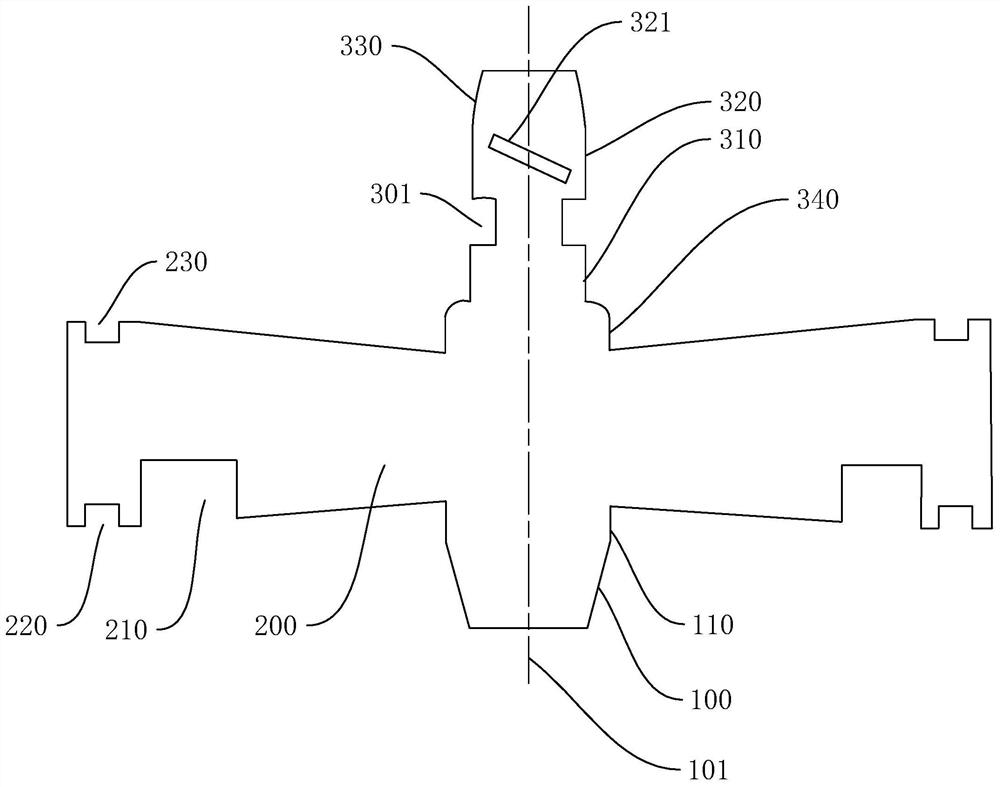

Device for forming bevel gear through ultrasonic-assisted cold-rocking-rolling and machining method

ActiveCN112756708AIncrease vibrational energyMeet processing needsGear teethPiezoelectric actuatorsEngineering

The invention discloses a device for forming a bevel gear through ultrasonic-assisted cold-rocking-rolling. The device comprises a base, a lower die and an ultrasonic horn, wherein the base has an accommodating cavity with an upward opening; the lower die is used for clamping a workpiece; the ultrasonic horn is mounted in the accommodating cavity and comprises a positioning section, a first vibration mounting section and a vibration conversion output section which are sequentially and coaxially arranged along a vertical axis; the positioning section is connected with the base and is positioned in the circumferential direction; a first piezoelectric actuator is mounted on the first vibration mounting section; a second piezoelectric actuator is mounted on the vibration conversion output section; ultrasonic vibration generated by the first piezoelectric actuator and ultrasonic vibration generated by the second piezoelectric actuator are superposed; and the vibration conversion output section makes contact with the workpiece and is used for transferring the ultrasonic vibration to the workpiece. The accommodating cavity is used for accommodating the ultrasonic horn, and ultrasonic vibration with larger vibration energy is generated after the ultrasonic vibration generated by the first piezoelectric actuator and the second piezoelectric actuator on the ultrasonic horn is utilized and superposed, so that the machining requirement is met.

Owner:CENT SOUTH UNIV

System and method for chemical potential energy production

ActiveUS8268138B2Increase vibrational energyCellsOxygen/ozone/oxide/hydroxideElectron sourceGas chamber

The present invention relates to a system comprising a heat source to provide heat at the desired temperature and energy field (e.g. a solar concentrator); an electron source configured and operable to emit electrons; an electric field generator generating an electric field adapted to supply energy sufficient to dissociate gas molecules; and a reaction gas chamber configured and operable to cause interaction between the electrons with the molecules, such that the electrons dissociate the molecules to product compound and ions via dissociative electrons attachment (DEA) within the chamber.

Owner:YEDA RES & DEV CO LTD

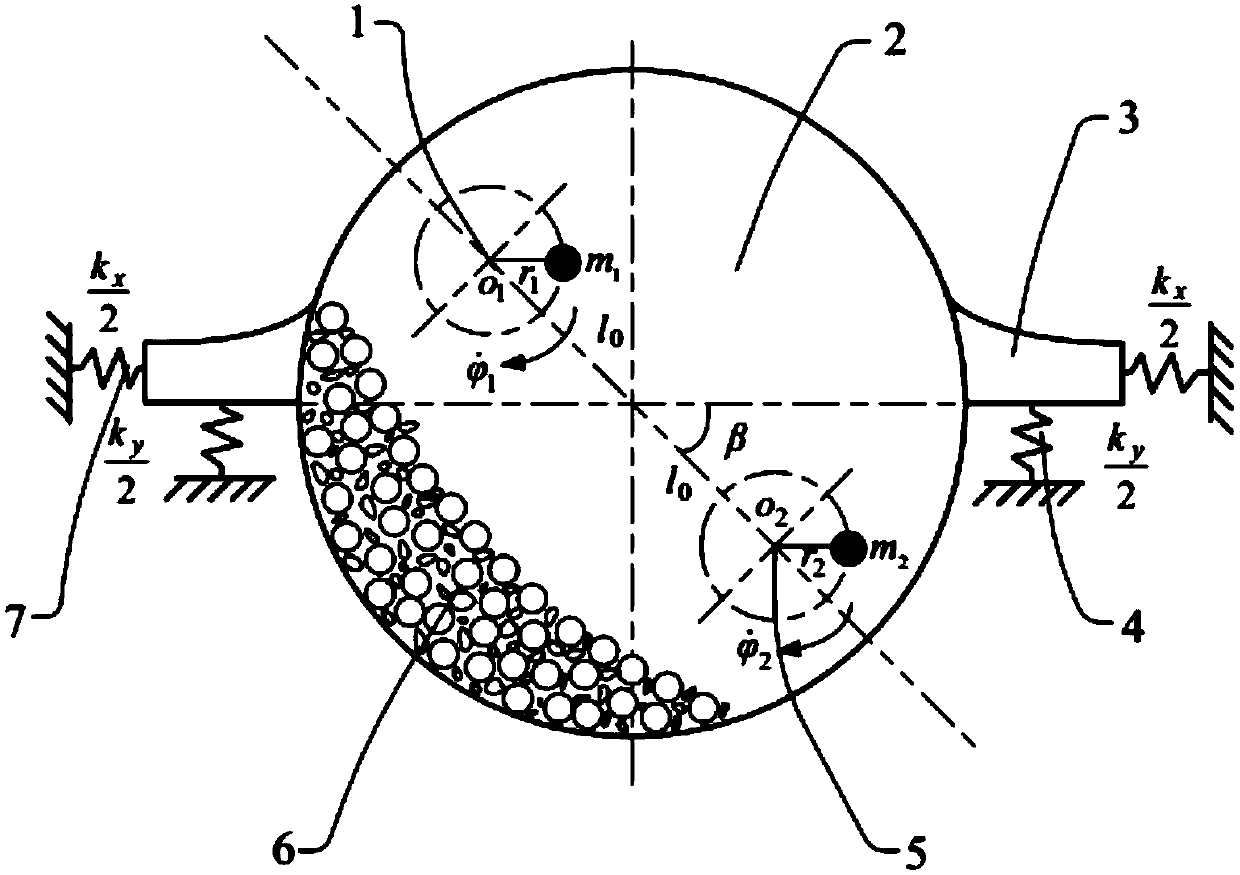

Double-motor self-synchronous driving vibration ball mill

InactiveCN109647589AIncrease vibrational energyImprove ball milling effectGrain treatmentsPhase differenceVibration exciter

The invention belongs to a grinding device, and provides a double-motor self-synchronous driving vibration ball mill. The system adopts a structure that the center of a cylinder body is eccentric witha power main shaft, the cylinder body is used as an excitation body, the mass moments of two vibration exciters are different, and m1r1 is larger than m2r2; the two vibration exciters are symmetrically installed relative to the center of a roller, the connecting line of rotating centers of the two vibration exciters is in a beta angle with the horizontal direction (beta is equal to 0-90 degrees),and the vibration exciter with the large mass moment is arranged on the left upper part; and meanwhile, the installation of the vibration exciters meets a certain position conditions, when the systemis operated stably, two motors achieve synchronization and operate stably, the steering is the same, and the phase difference is stable to be close to Pi. At the moment, the motion mode of the rolleris in the coexistence of swing and circular motion, due to the fact that the phase difference is close to Pi, so that swing occupies the main part. Ball milling medium in the roller is continuously thrown away under the action of the combined movement of swinging and the circular motion, the ball milling medium roll from a high position to a lower position, a high-strength rolling impact effect is generated, and ball milling of the materials is realized.

Owner:NORTHEASTERN UNIV

Shock absorption type press machine workbench

InactiveCN105619878AImprove deformation recovery performanceImprove stabilityPressesEngineeringMachine press

Provided is a shock absorption type press machine workbench. The workbench is fixedly connected to a machine body. Reinforcing strips connected with a workbench plate into a whole are fixedly arranged on the lower edges of two long sides of the workbench plate, water tanks are fixedly connected to the lower portions of the two reinforcing strips correspondingly, and the lower portion of the workbench plate is fixedly connected with a shock absorption rubber plate. Vibration energy of the workbench plate is absorbed by the shock absorption rubber plate. The weight is added through the water tanks on the lower portions of the edges of the workbench plate, tensile force borne by the two sides of the workbench plate is increased by the high weight of water, the deformation restoration capacity of the workbench plate is improved, and meanwhile the stability of the workbench plate is improved through shock absorption performance of the water.

Owner:YANGZHOU FORGING MACHINE TOOL

Sympathetic parallel plate resonator for acoustic instruments

ActiveUS9196230B1Easy to manufactureRapid mass productionStringed musical instrumentsParallel plateEngineering

Owner:ELLIOT JERRY C

High energy continuous electric pulse on line annealing method of copper wire and its device

InactiveCN1300347CReduce energy consumptionReduce the degree of oxidationFurnace typesHeat treatment furnacesElectricityProduction line

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Surface acoustic wave resonator, surface acoustic wave oscillator, and surface acoustic wave module unit

ActiveUS8299680B2Improve confinementSmall sizeImpedence networksPiezoelectric/electrostriction/magnetostriction machinesSurface acoustic wave oscillatorsAcoustic wave

It is possible to reduce the size of a surface acoustic wave resonator by enhancing the Q value. In a surface acoustic wave resonator in which an IDT having electrode fingers for exciting surface acoustic waves is formed on a crystal substrate, a line occupying ratio is defined as a value obtained by dividing the width of one electrode finger by the distance between the center lines of the gaps between one electrode finger and the electrode fingers adjacent to both sides thereof, and the IDT includes a region formed by gradually changing the line occupying ratio from the center to both edges so that the frequency gradually becomes lower from the center to both edges than the frequency at the center of the IDT.

Owner:SEIKO EPSON CORP

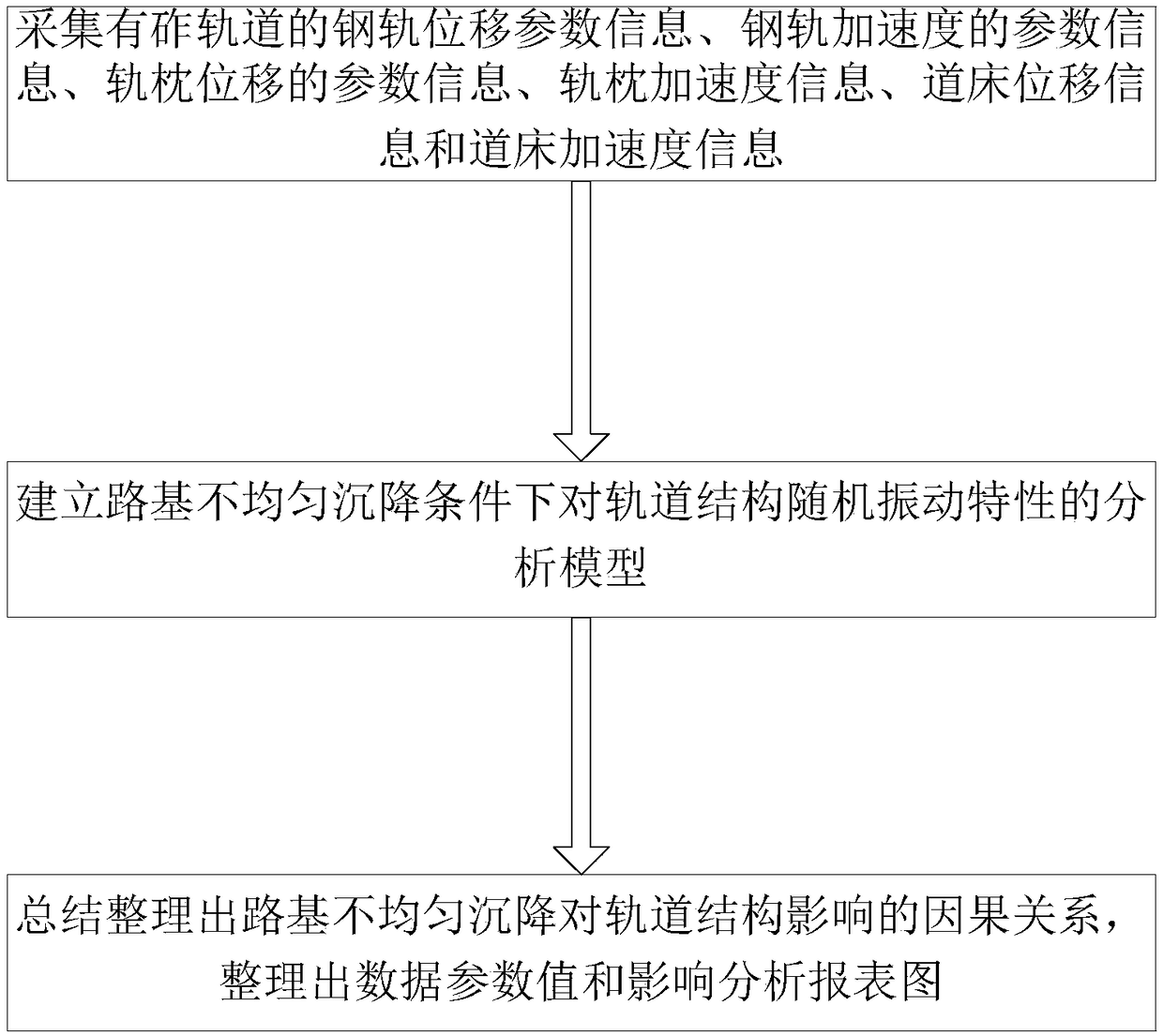

Analysis method for effects of uneven settlement of subgrade on random vibration characteristics of track structure

InactiveCN108228932AIncrease vibrational energyGeometric CADDesign optimisation/simulationEngineeringRandom vibration

The invention discloses an analysis method for effects of uneven settlement of a subgrade on random vibration characteristics of a track structure. The method comprises the following steps of S1, collecting rail displacement parameter information, rail acceleration parameter information, sleeper displacement parameter information, sleeper acceleration information, track bed displacement information and track bed acceleration information of a ballast track; S2, an analysis model of the random vibration characteristics of the track structure under the condition of uneven settlement of the subgrade is established, and the characteristics of the track structure are analyzed and evaluated by calculating uneven settlement reduction coefficients of the subgrade; S3, the causal relationship of theeffects of the uneven settlement of the subgrade on the track structure is summarized, and data parameter values and impact analysis reports are sorted out.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com