Method for endowing Ni-enriched TiNi shape memory alloy with two-way shape memory characteristic

A technology of memory alloy and memory, which is applied in the field of endowing Ni-rich TiNi shape memory alloy with two-way memory characteristics, which can solve problems such as difficulty in realizing memory performance, and achieve strong cycle deformation stability, reduced energy consumption, and short response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

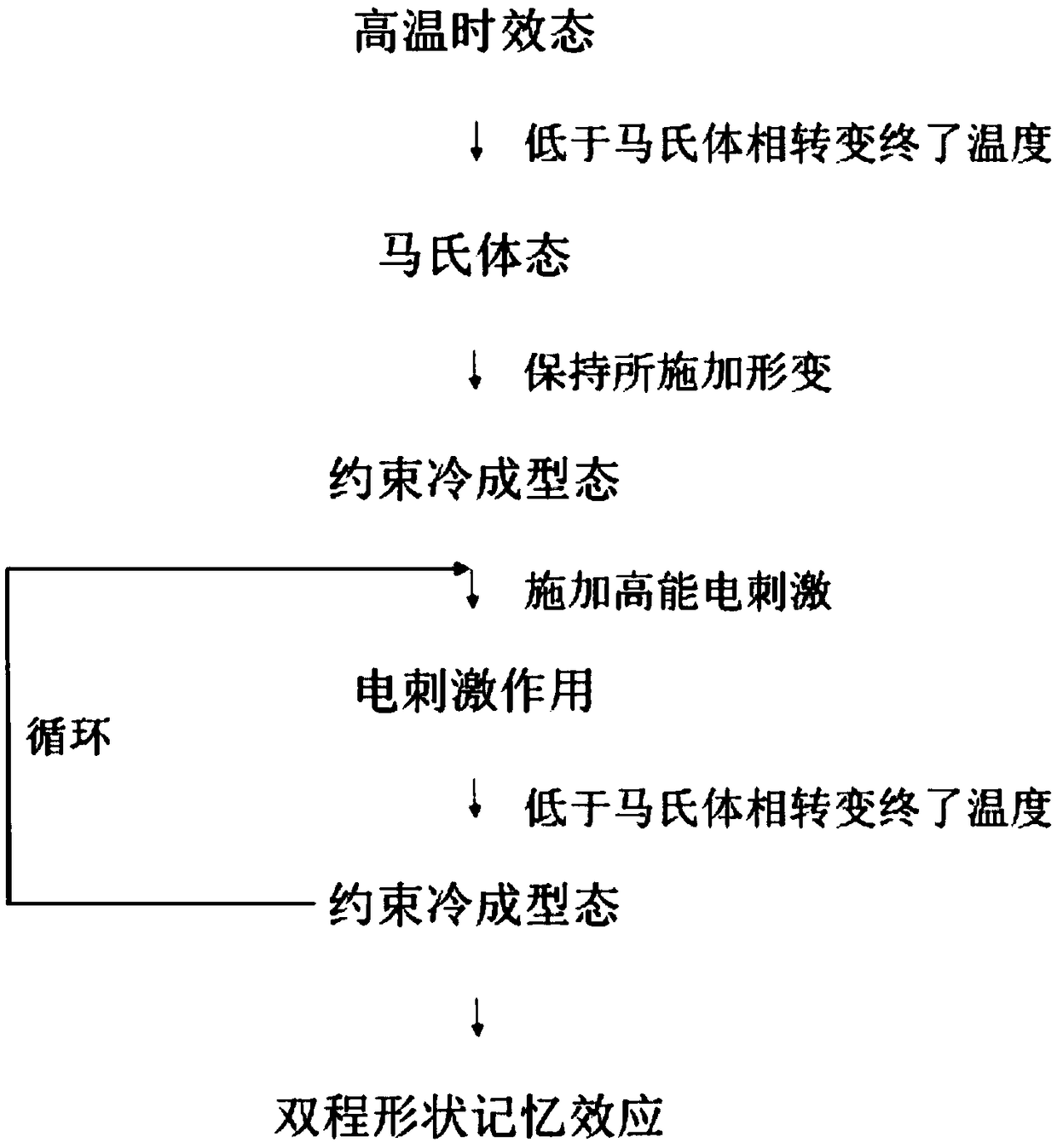

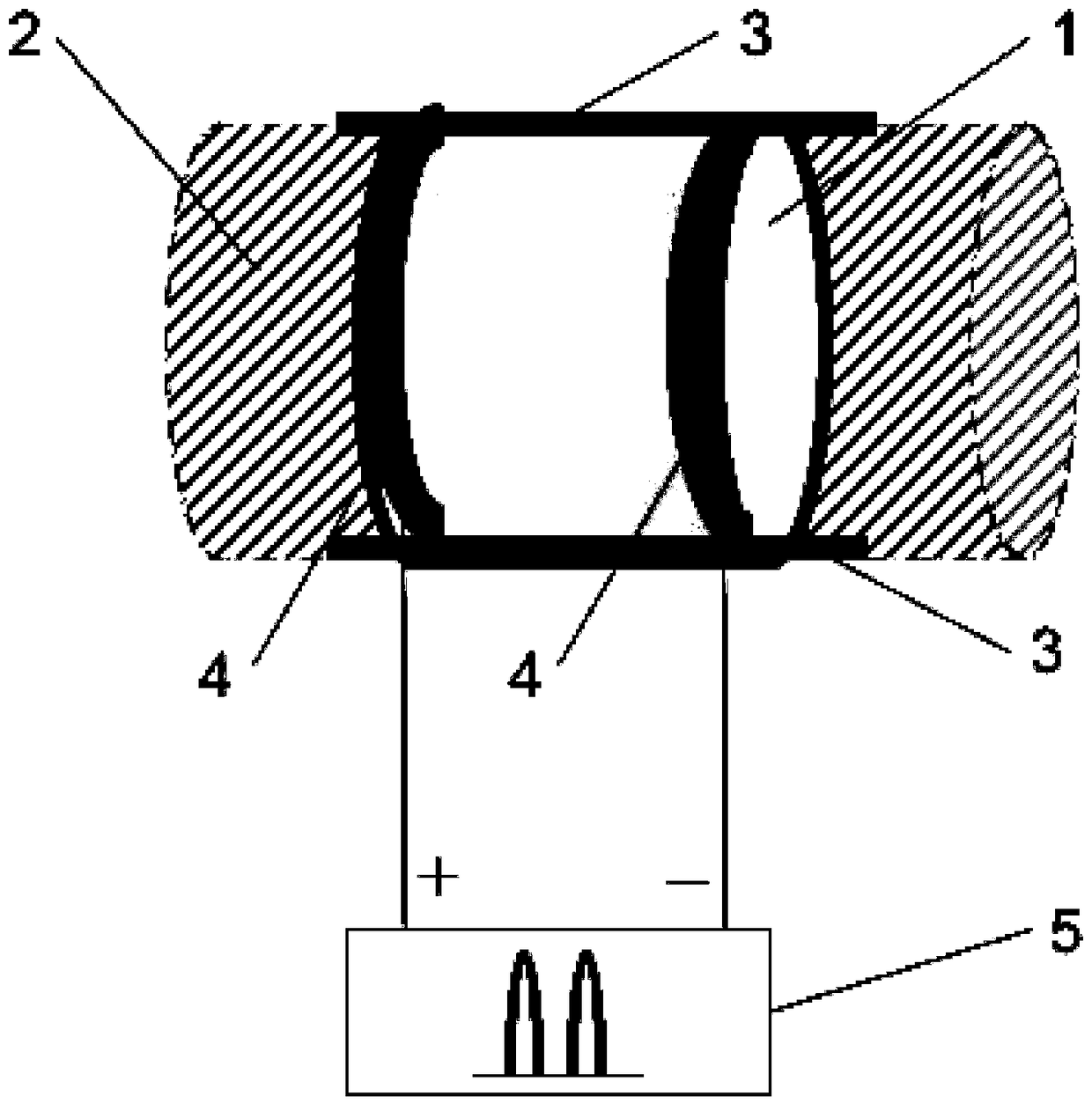

[0025] see Figure 1~2 As shown, the method for imparting the two-way memory property of this Ni-rich state TiNi shape memory alloy is characterized in that: the two-way memory property refers to the "thermal expansion and contraction" type two-way shape memory property, and the steps of the endowment method yes:

[0026] (1) The chemical composition and atomic percentage in the Ni-rich state TiNi shape memory alloy are: Ni50.8~60.0%, and the balance is Ti, and the mass percent of impurities C and O in the Ni-rich state TiNi shape memory alloy should be Less than 0.3%;

[0027] (2) The Ni-rich state TiNi shape memory alloy adopts a pipe 1 as the training object, the wall thickness of the pipe 1 is 0.3-50mm, the outer diameter is 5-350mm, and the length is 10-300mm;

[0028] (3) Aging treatment of the TiNi shape memory allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com