Second-phase electrical stimulation nodulizing method for Ni-enriched TiNi shape memory alloy

A memory alloy and electric stab technology is applied in the field of second phase electric stimulation spheroidization of Ni-rich TiNi shape memory alloy, which can solve the problems of reducing the recovery force of the alloy phase transformation and the recoverable strain value, and achieves the avoidance of heating and cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

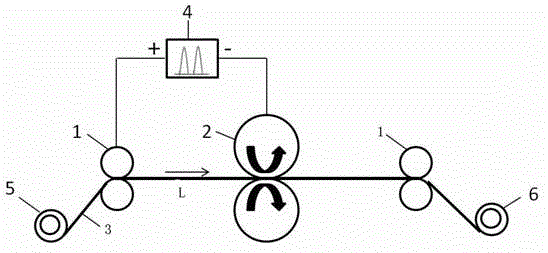

[0018] See attached figure 1 As shown, this kind of Ni-rich state TiNi shape memory alloy second-phase electrical stimulation spheroidization method is characterized in that: the steps of the method are:

[0019] (1) The atomic percentage of the Ni content in the Ni-rich state TiNi shape memory alloy is greater than or equal to 50.8%;

[0020] (2) Pass the strip or plate 3 of TiNi shape memory alloy through the uncoiling device 5, winding device 6, roll 2 and two sets of support rolls 1 of the rolling mill to realize the two-way movement of the strip or plate 3, the strip or plate 3 and the roll 2 And there is elastic contact between the two sets of support rolls 1, there must be close elastic contact between the roll 2 and the TiNi alloy strip or plate 3, the alloy strip or plate 3 does not undergo plastic deformation, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com