A high-aluminum bronze coating for volumetric damage repair and its preparation method

A high-aluminum bronze, damage repair technology, applied in coating, metal material coating process, fusion spraying and other directions, can solve the problems of large thermal stress, large coating thickness, high oxidation degree of high-aluminum bronze coating, and achieve Avoid the effects of oxidation and phase transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

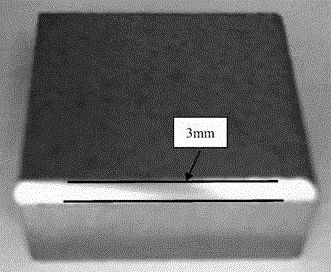

[0024] For the high-aluminum bronze coating used for volumetric damage repair in this embodiment, see Figure 7 , and its thickness is 3mm.

[0025] The preparation method of the high-alumina bronze coating for volume damage repair in this embodiment is as follows:

[0026] ① Use gas-atomized high-alumina bronze powder with a particle size of 15 μm to 45 μm as the spraying powder, and first place it in an oven at 120°C for 3 hours; set aside.

[0027] The chemical composition of the gas-atomized high-alumina bronze powder used in this example is as follows: Al: 13.30wt%, Fe: 4.93wt%, Mn: 1.62wt%, Zn: 0.33wt%, Ni: 0.31wt%, Co: 5.49wt%, Cu balance.

[0028] ② Degreasing, derusting, and sandblasting roughening pretreatment on the surface of the copper alloy substrate, and cleaning the surface of the substrate with acetone.

[0029] The copper alloy base material used in this embodiment is H62 brass, and the size is 20mm×20mm×10mm.

[0030] The sandblasting roughening process ...

Embodiment 2~ Embodiment 4)

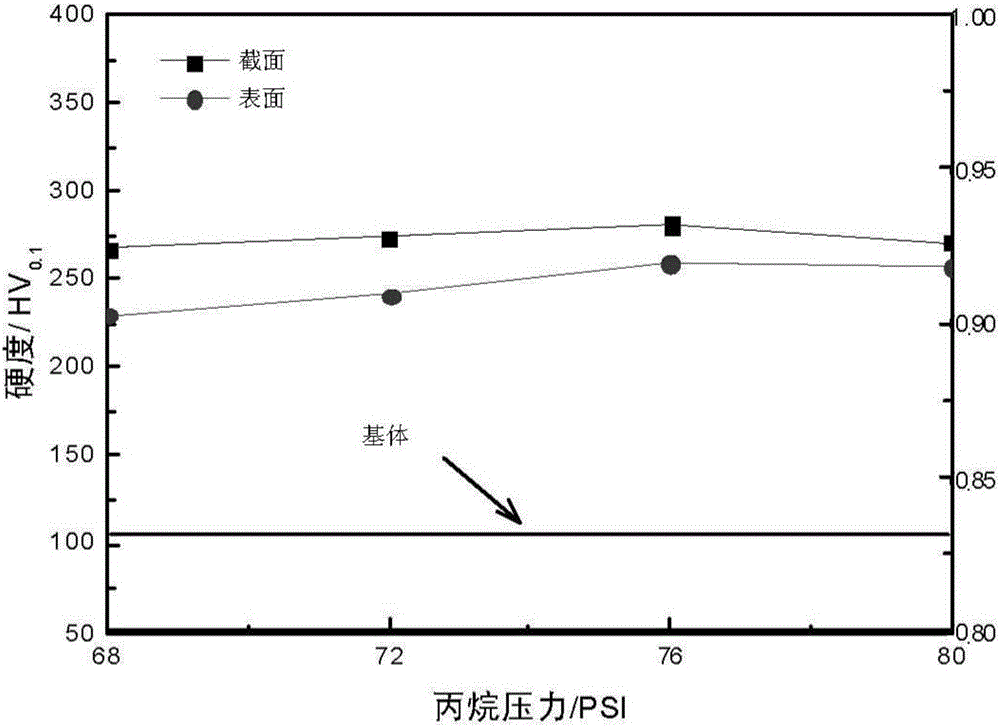

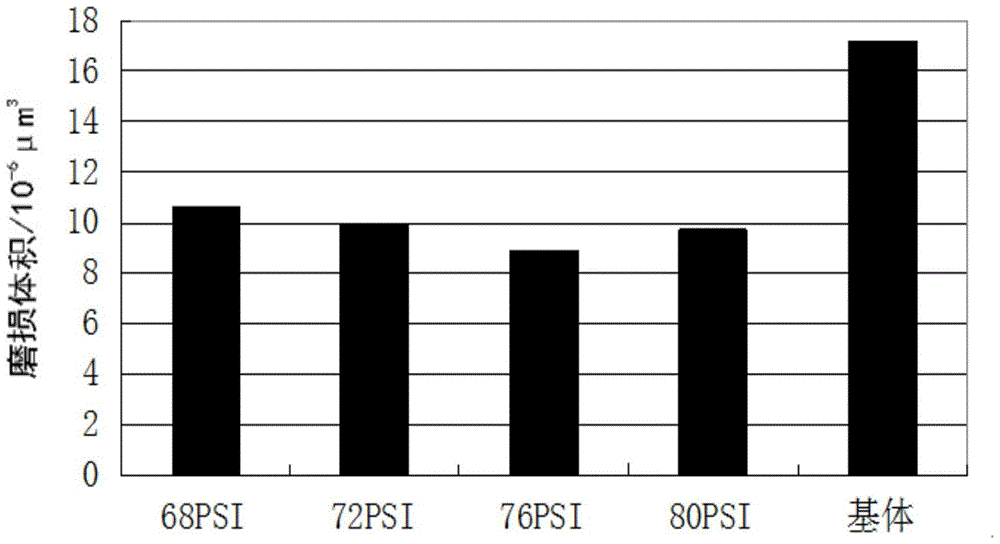

[0035] Each embodiment is basically the same as Embodiment 1, except that the propane pressure, flame temperature and spray particle temperature are different, see Table 1 for details.

[0036] Table 1

[0037] Example 1 Example 2 Example 3 Example 4 propane pressure 68PSI 72PSI 76PSI 80PSI Flame temperature 630℃ 700℃ 780℃ 850℃ Spray particle temperature 350℃ 390℃ 430℃ 480℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com