Piston-type particle-damping energy-dissipation vibration-reduction sleeper

A particle damping, piston-type technology, applied in the field of rail transit, can solve problems such as high cost and aggravated vehicle body vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

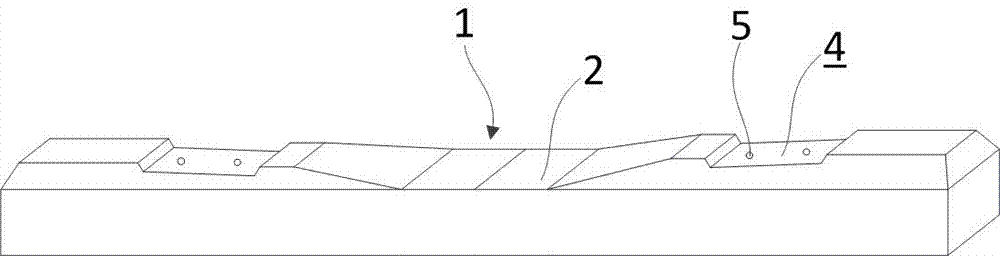

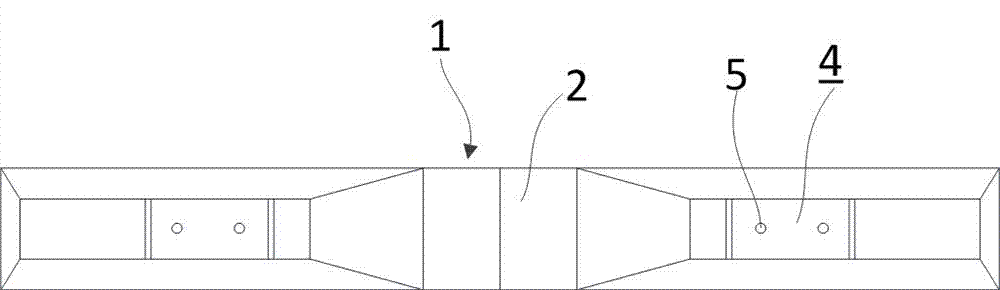

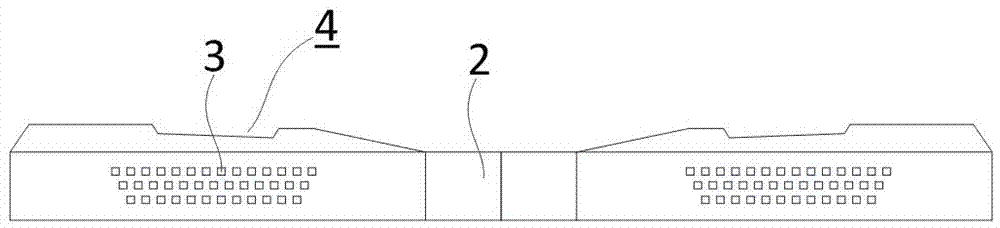

[0029] Example 1: Such as figure 1 , 2 As shown, this embodiment specifically relates to a piston-type particle damping energy dissipation and vibration reduction sleeper 1. The piston-type particle damping energy dissipation and vibration reduction sleeper 1 includes a sleeper body 2 and a piston-type particle damping element 3 embedded in the sleeper body 2 ; The upper surface of the sleeper body 2 is provided with a rail groove 4; the rail groove 4 is used to install a rail.

[0030] Such as figure 1 , 3 As shown, the piston-type particle damping energy dissipation and vibration reduction sleeper 1 of this embodiment is a long sleeper type, wherein the upper surface of the sleeper main body 2 is provided with two supporting rail grooves 4; the two supporting rail grooves 4 are respectively located in the sleeper main body 2 ends; in this embodiment, the length, width, and height of the sleeper body 2 are 2600mm, 330mm, and 250mm respectively; the sleeper body 2 is made of concr...

Embodiment 2

[0045] Example 2: Such as Picture 10 , 11 As shown, the main difference between this embodiment and Embodiment 1 is that the piston-type particle damping energy dissipation and vibration damping sleeper 1 of this embodiment is a short sleeper type sleeper; the upper surface of the sleeper body 2 of this embodiment only has one supporting rail. Slot 4; in this embodiment, the length, width, and height of the sleeper body 2 are 1200mm, 330mm, and 250mm respectively; when in use, a group of two piston-type particle damping energy dissipation and vibration damping sleepers 1 constitute a complete sleeper; The two piston-type particle damping energy dissipation and vibration damping sleepers 1 in the same group are respectively installed on both sides of the rail to support the two steel rails respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com