Shock absorption type press machine workbench

A press and worktable technology, applied in the field of presses, can solve the problems of long processing cycle, self-weight, large vibration amplitude of worktable, etc., and achieve the effect of strong deformation recovery ability, increase recovery ability, and reduce the weight of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

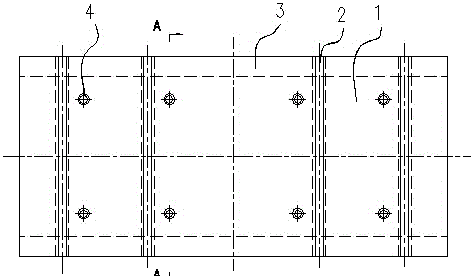

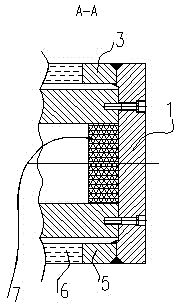

[0009] The present invention as figure 1 , 2 As shown: it is fixedly connected to the fuselage 5, and its platen 1 is provided with connecting holes, and the lower edge of the two long sides of the platen 1 is fixedly provided with a reinforcing bar 3 connected with the platen 1, and the platen 1 There are at least one pair of T-shaped grooves 2 arranged symmetrically with respect to the central axis for installing the mold on the surface of the plate; the water tanks 6 are fixedly connected under the two reinforcing bars 3, and the shock-absorbing rubber plate 7 is fixedly connected under the platen 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com