Patents

Literature

400results about How to "Rapid mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

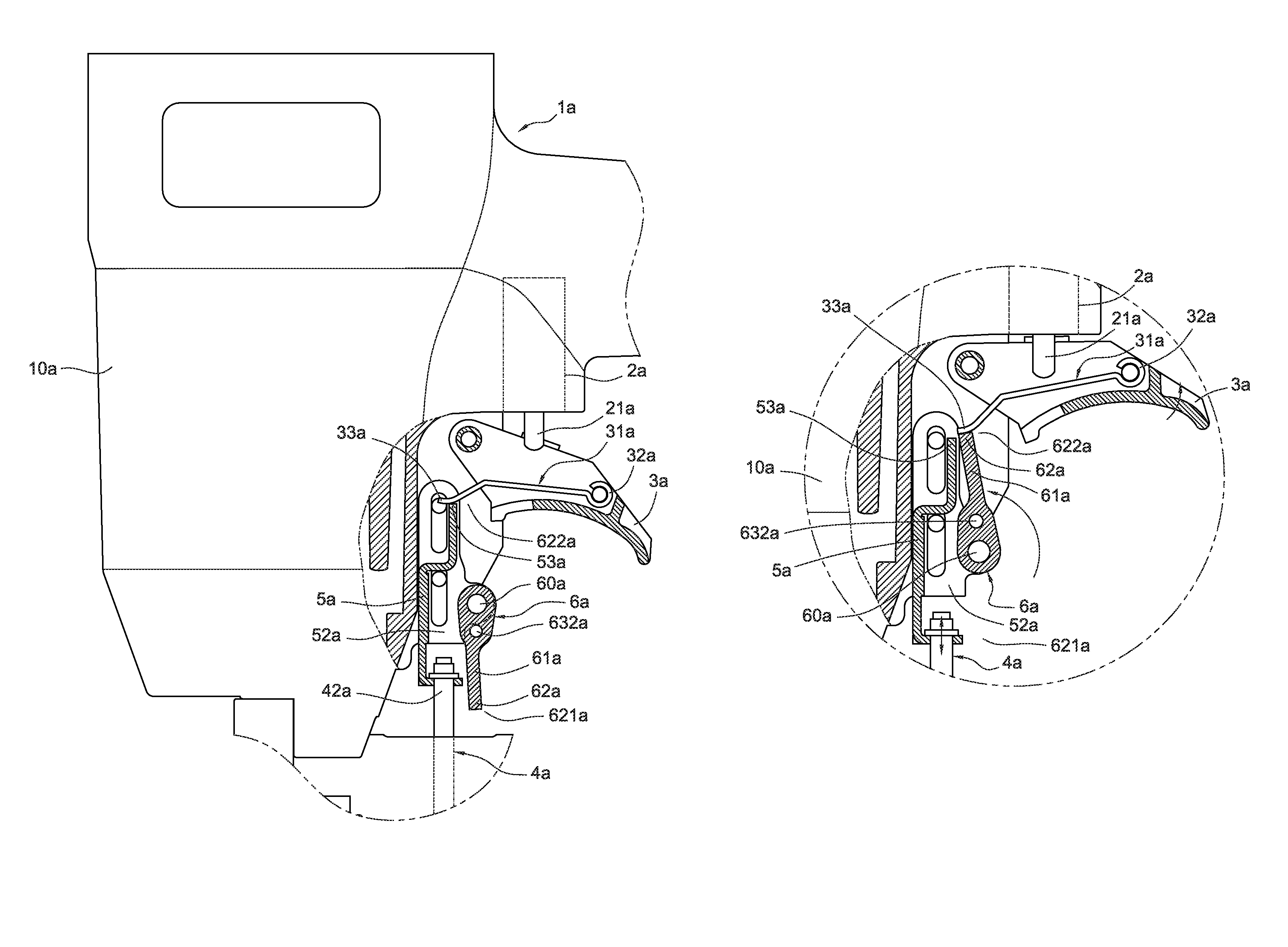

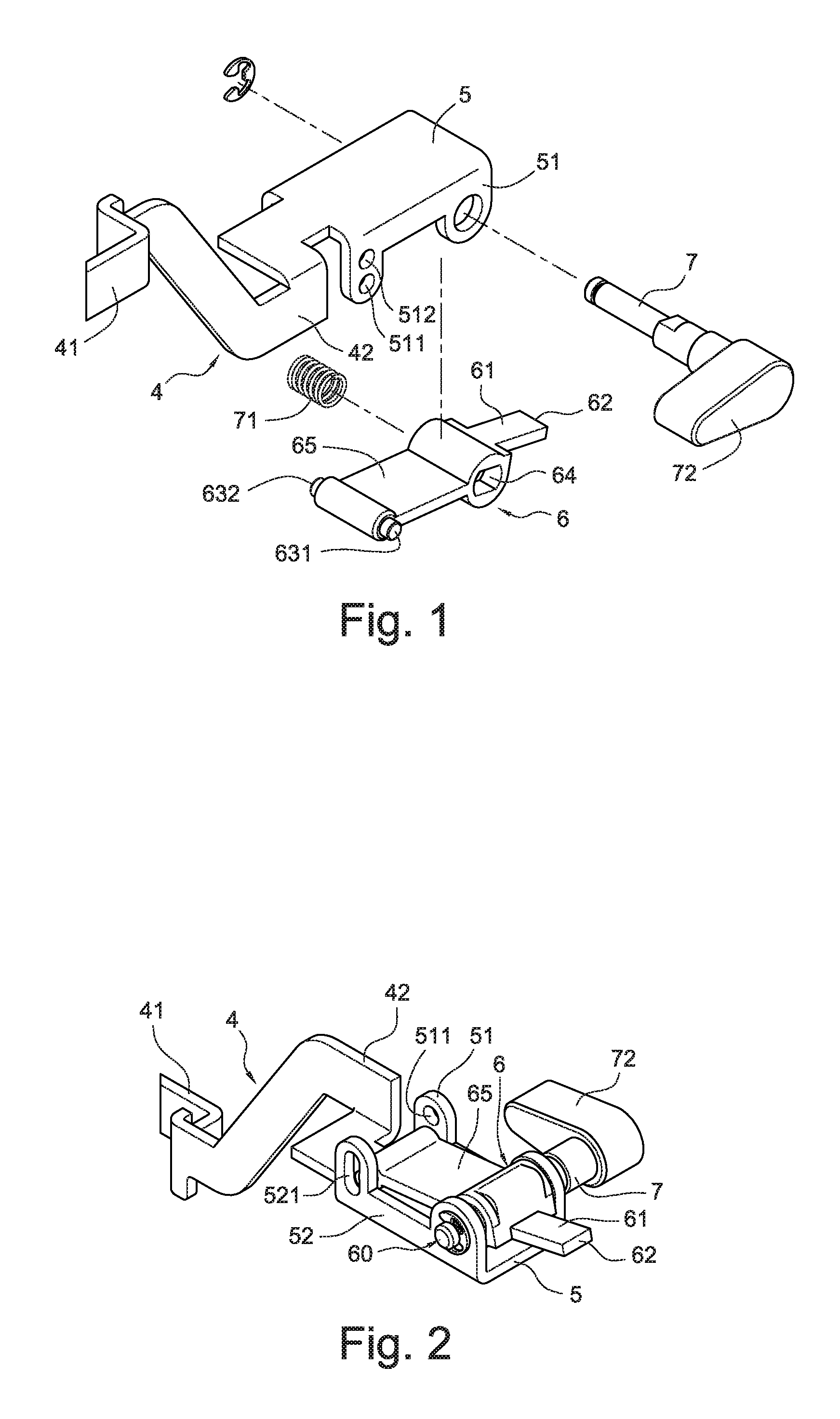

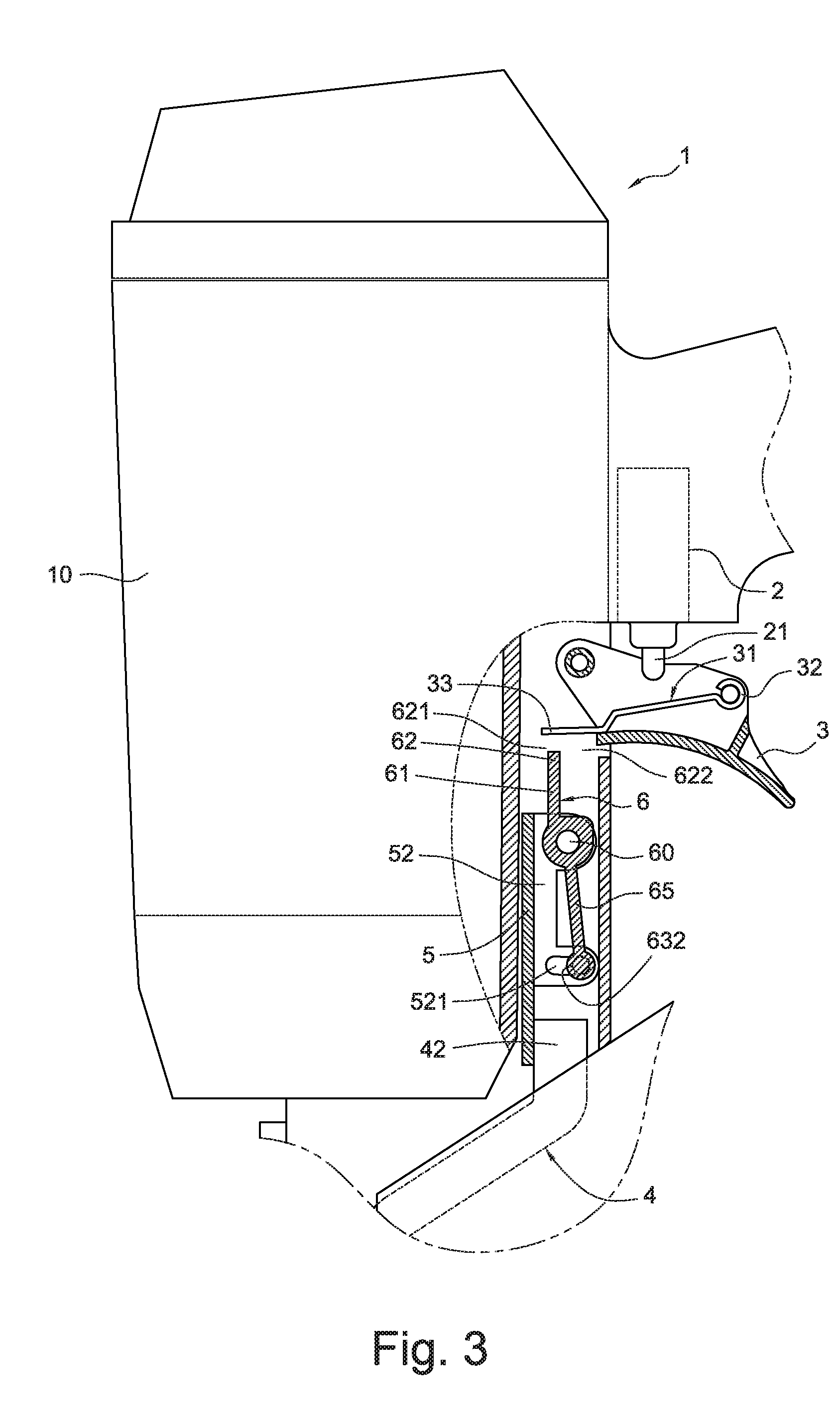

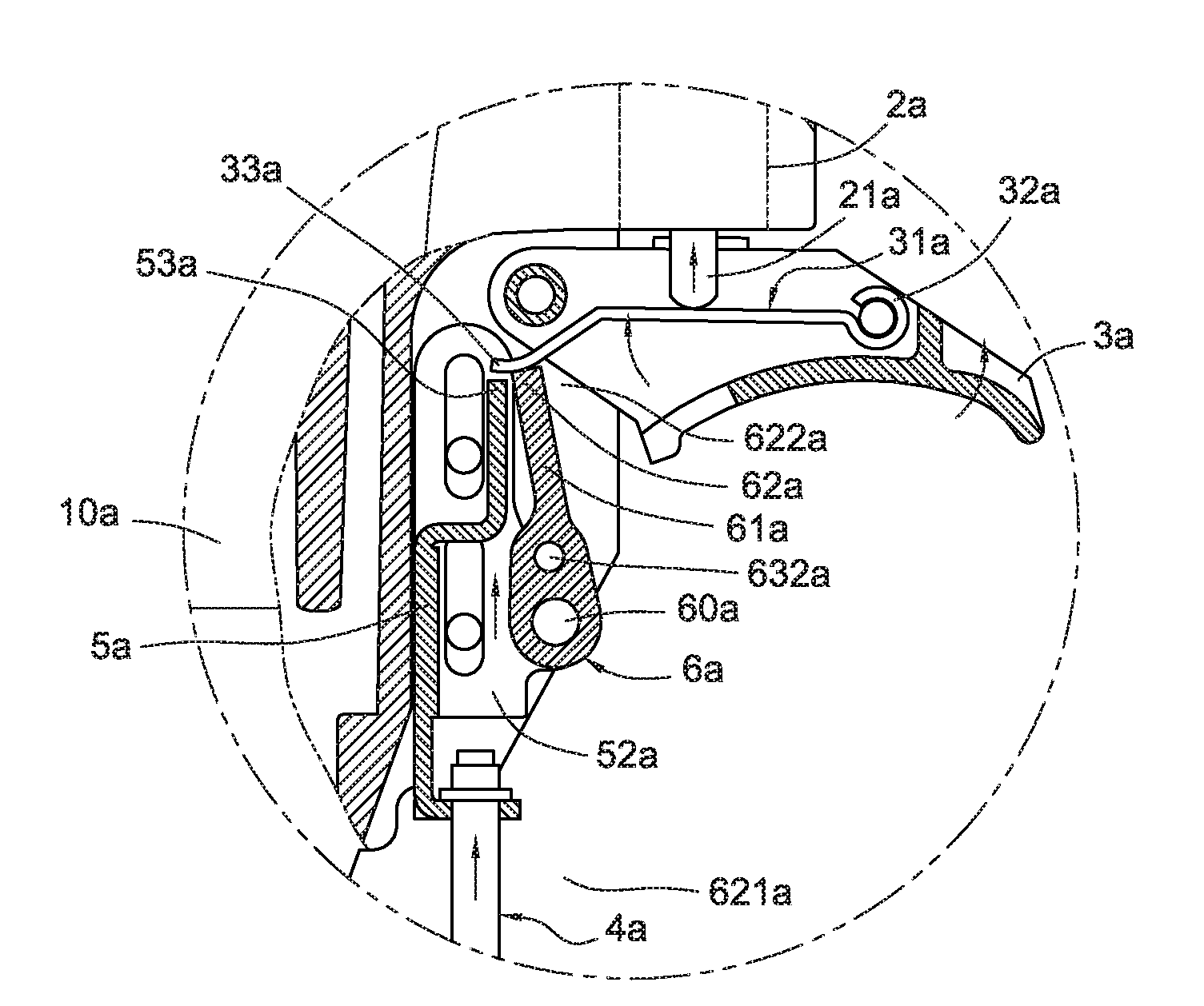

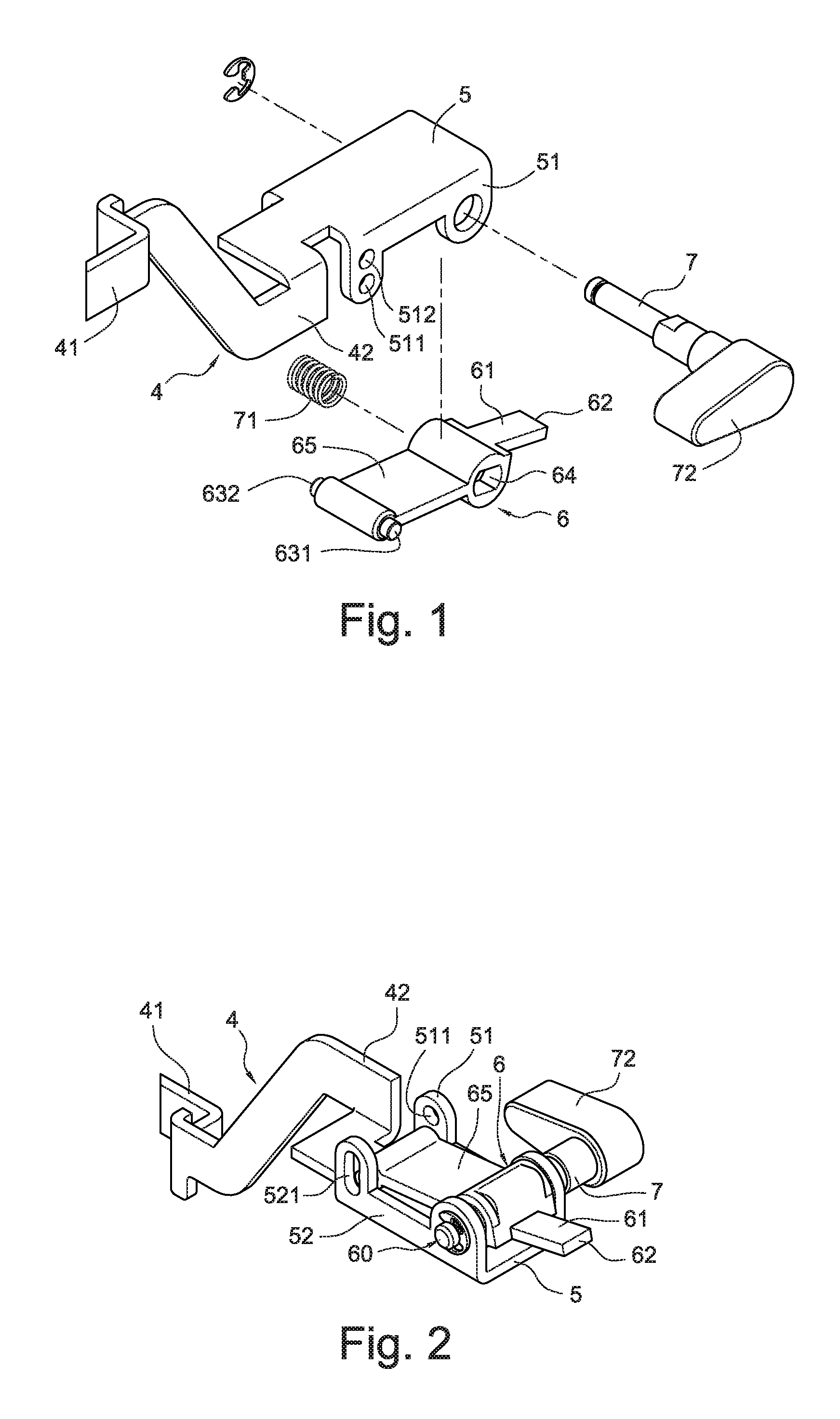

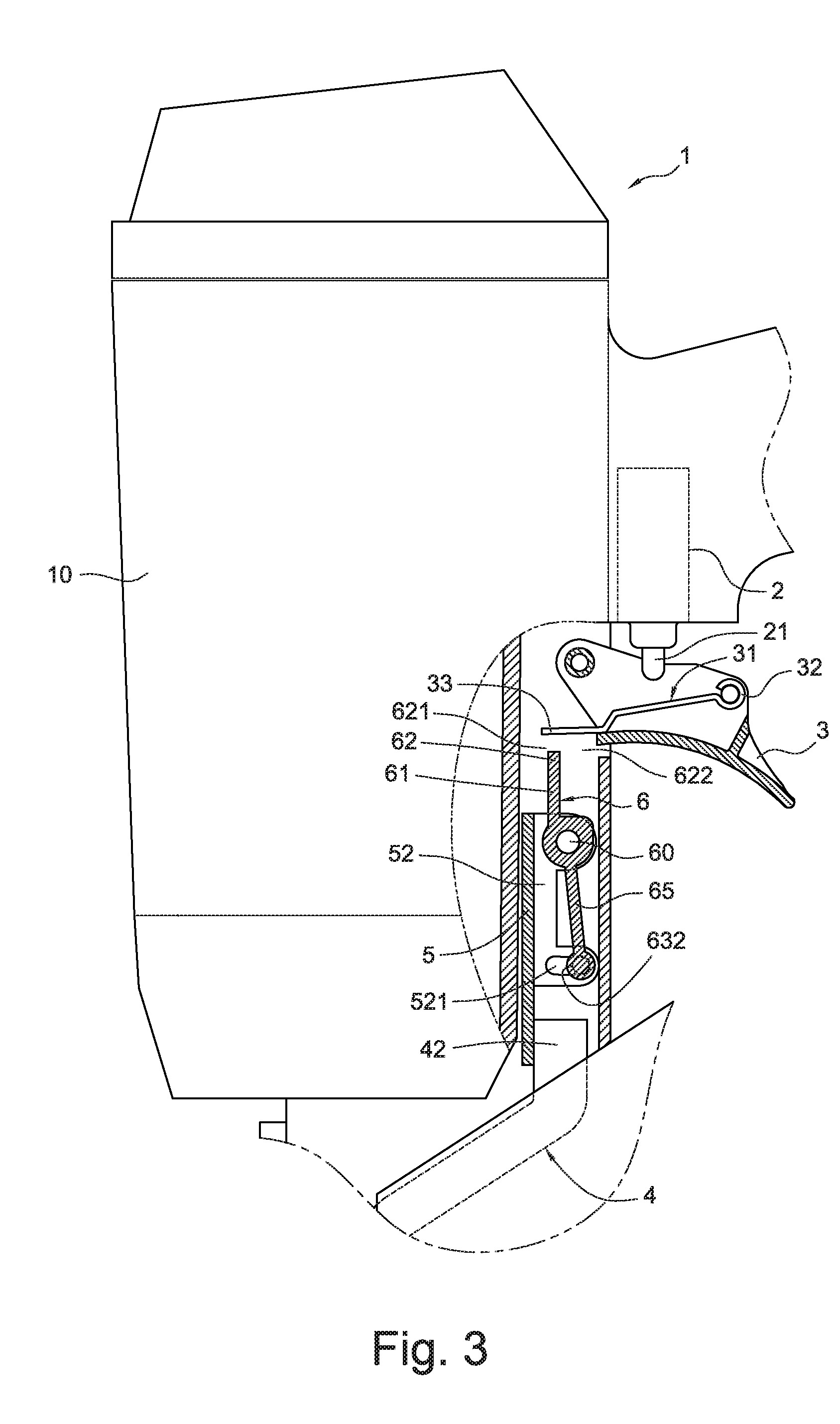

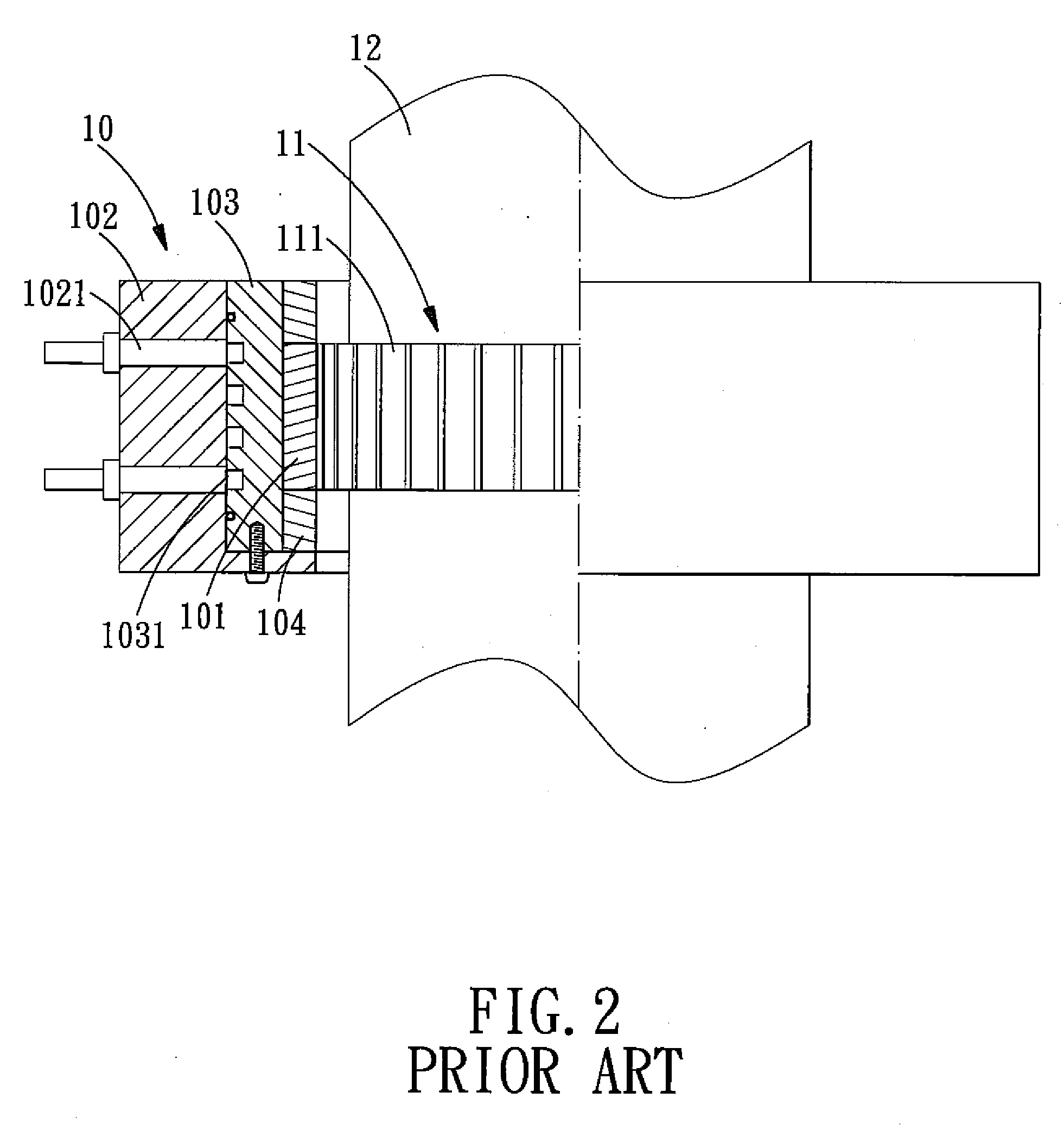

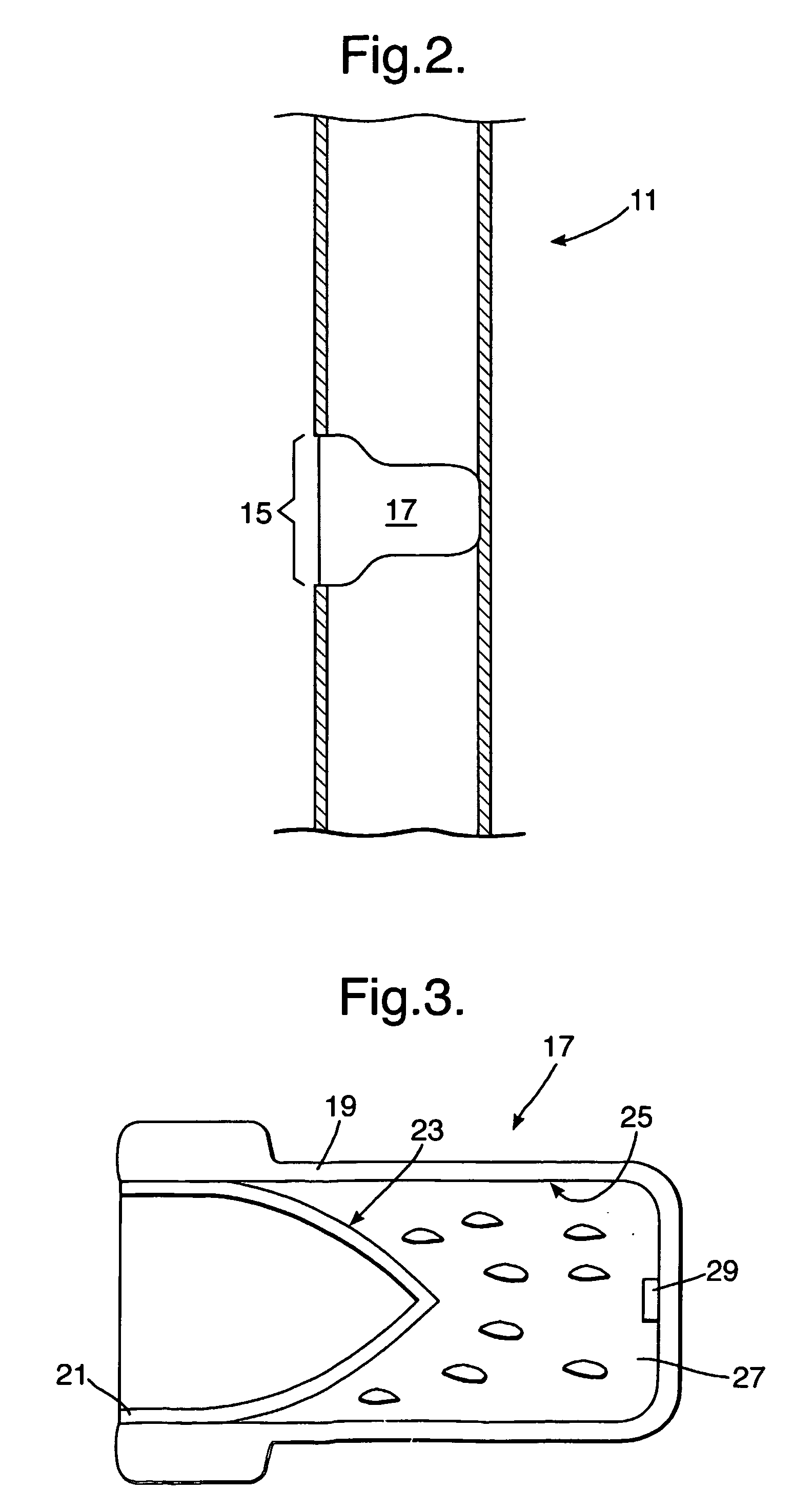

Nail gun switch mechanism

InactiveUS7810688B2Simple structureRapid mass productionStapling toolsNailing toolsEngineeringNail gun

A nail gun switch mechanism includes a gun body and a trigger. A safety slidable bar has a bottom part which extends outside of a hitting mouth at a bottom of the gun body. The trigger has a trigger lever being pivotably disposed therein. A top part of the safety slidable bar extends near to an end of the trigger and a swing arm is pivotably disposed on the top part of the safety slidable bar. The swing arm includes an arm part extending from a pivotal center of the swing arm and a push part extending from the arm part toward outside. The push part is configured to be switched to a first or a second swing position and thus driven by the safety slidable bar to touch the trigger lever so as to operate the nail gun in a sequential or a contact actuation mode.

Owner:ROBERT BOSCH TOOL +1

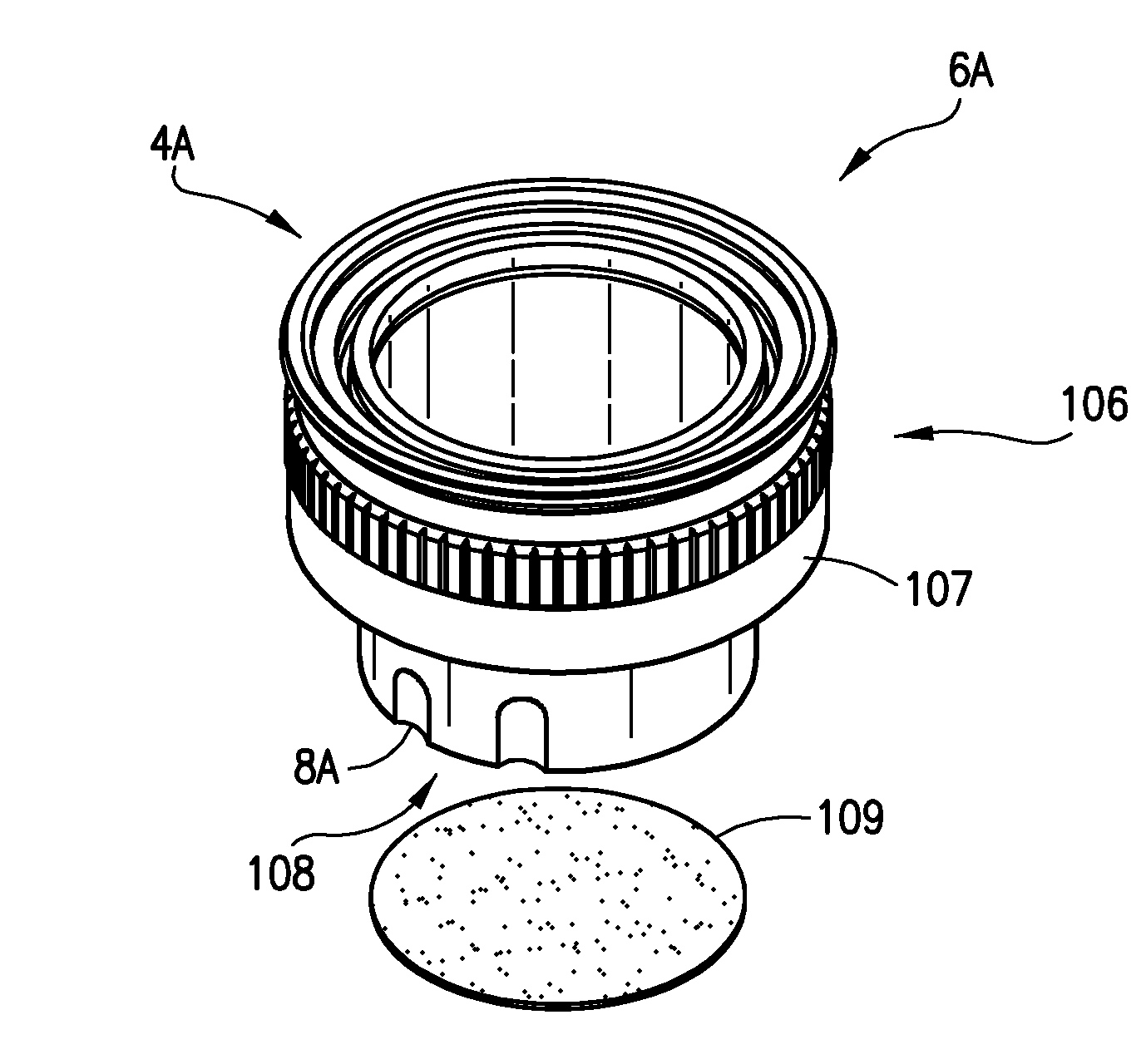

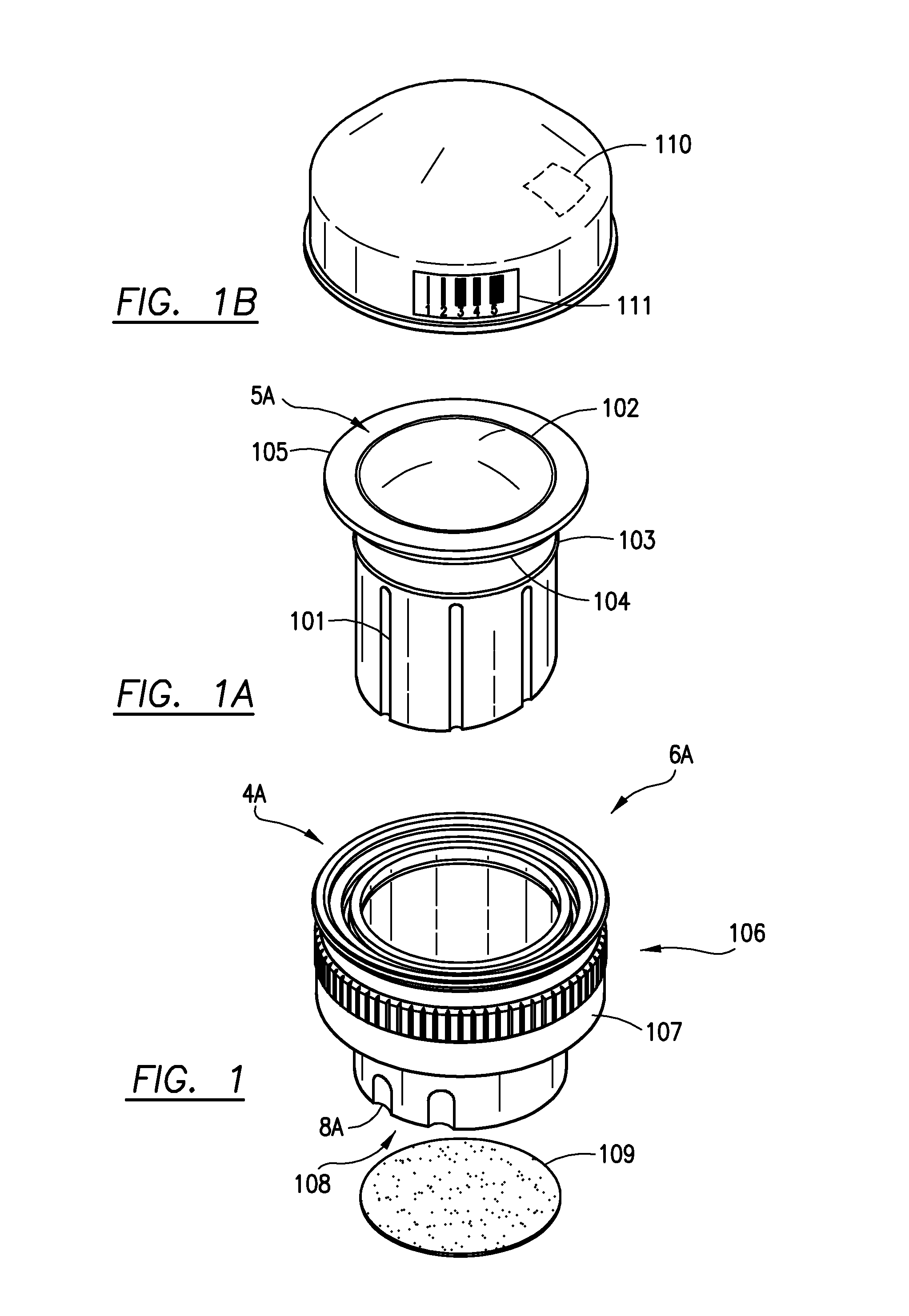

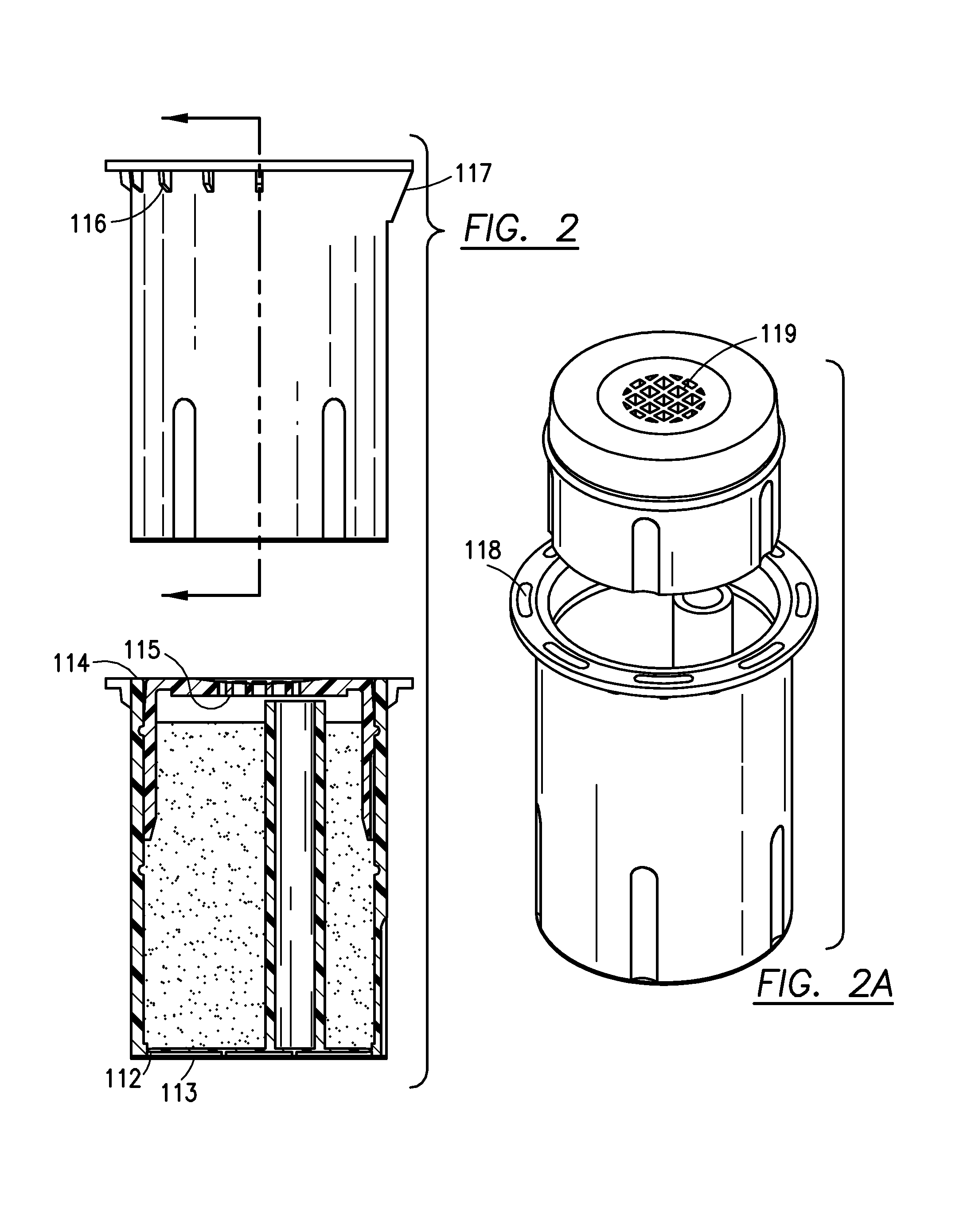

Container cap

A cap dispensing chamber to hold powder and / or liquids in a contained unit with a line of weakening, including but not limited to for bottles, pouches, cartons, cans, drums, IV bags, syringes, and any other type of container that can hold a product. The body and the plunger fits snugly with one another allowing ingredients to be stored and activated by an individual when on a as needed basis. A dust cover for allowing RFID, Nano and barcodes that can be applied during or post manufacturing or any location on or in the invention A body can be molded with a screw cap, snap lid, click-in, or by itself that can ultimately fit on any type or style container.

Owner:GACERS LLC

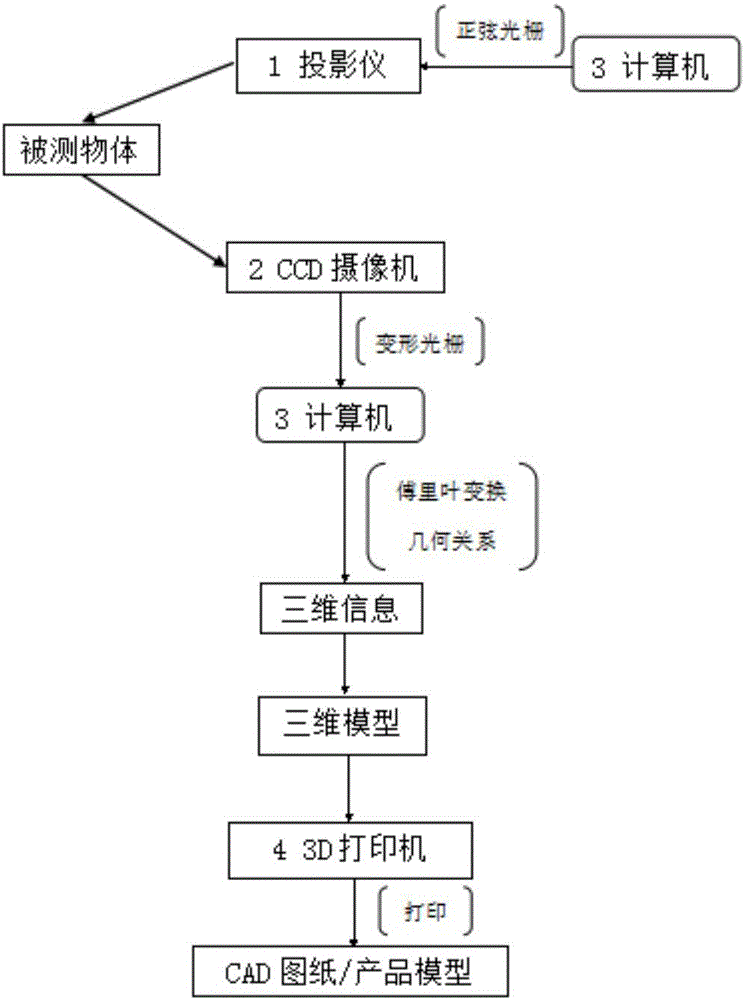

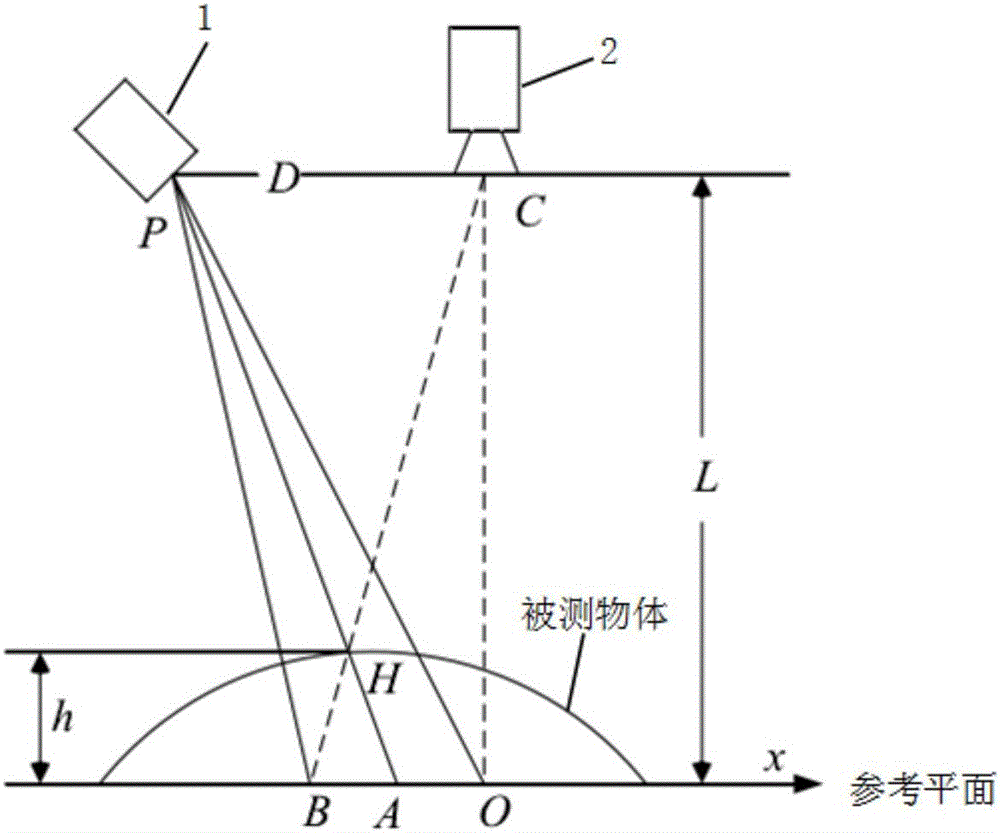

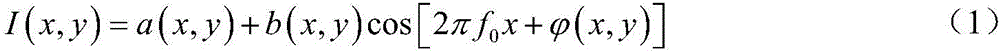

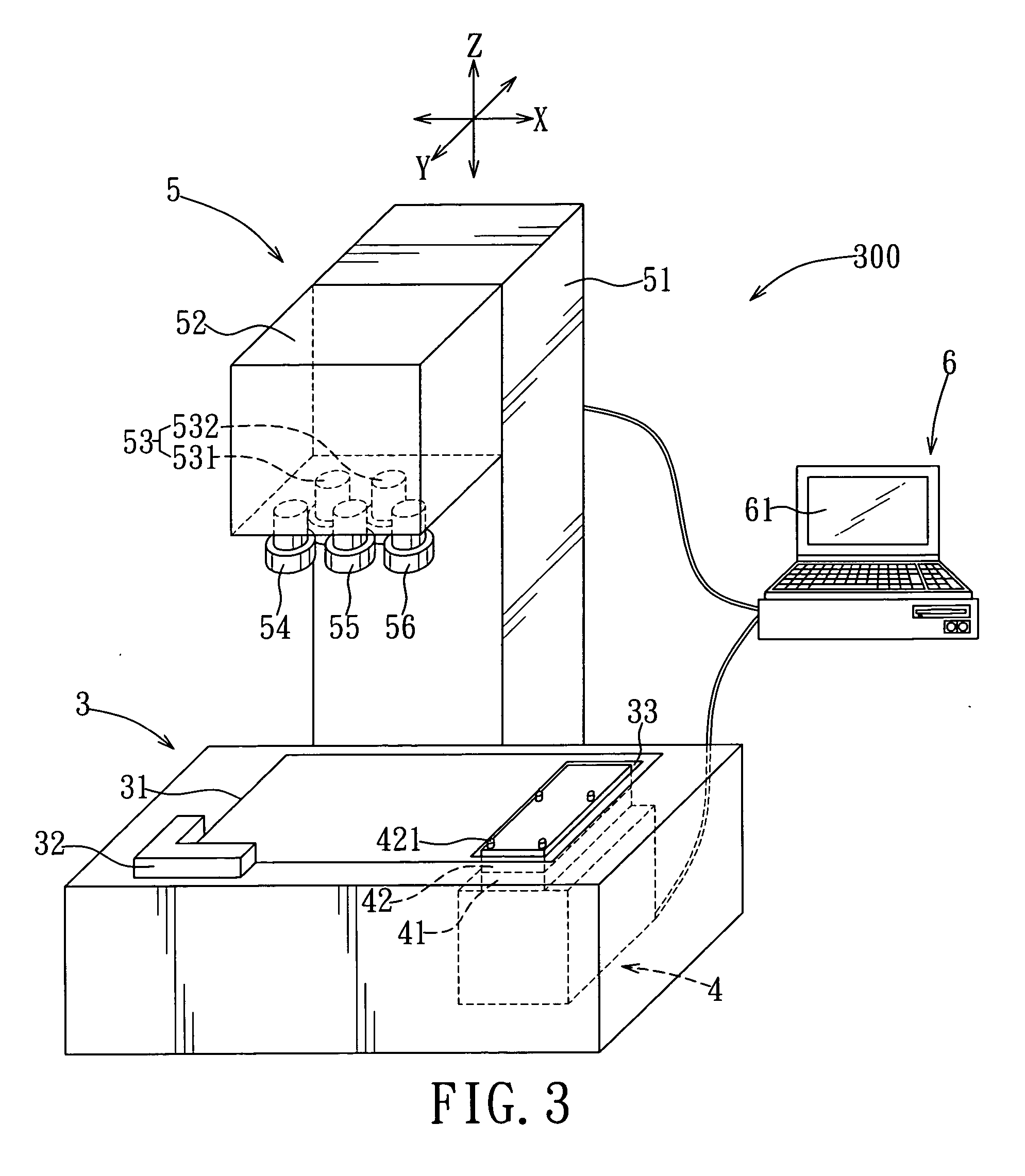

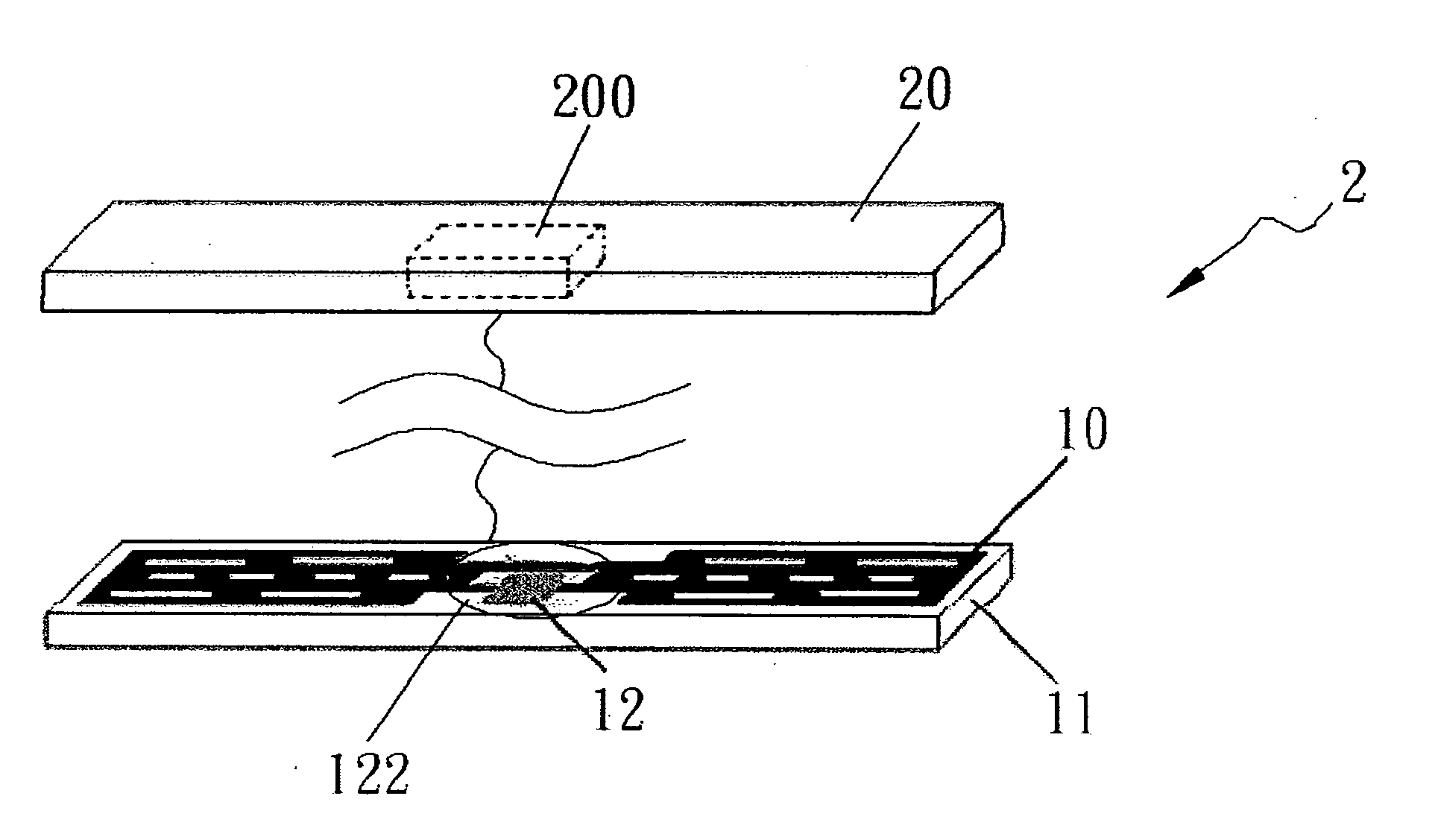

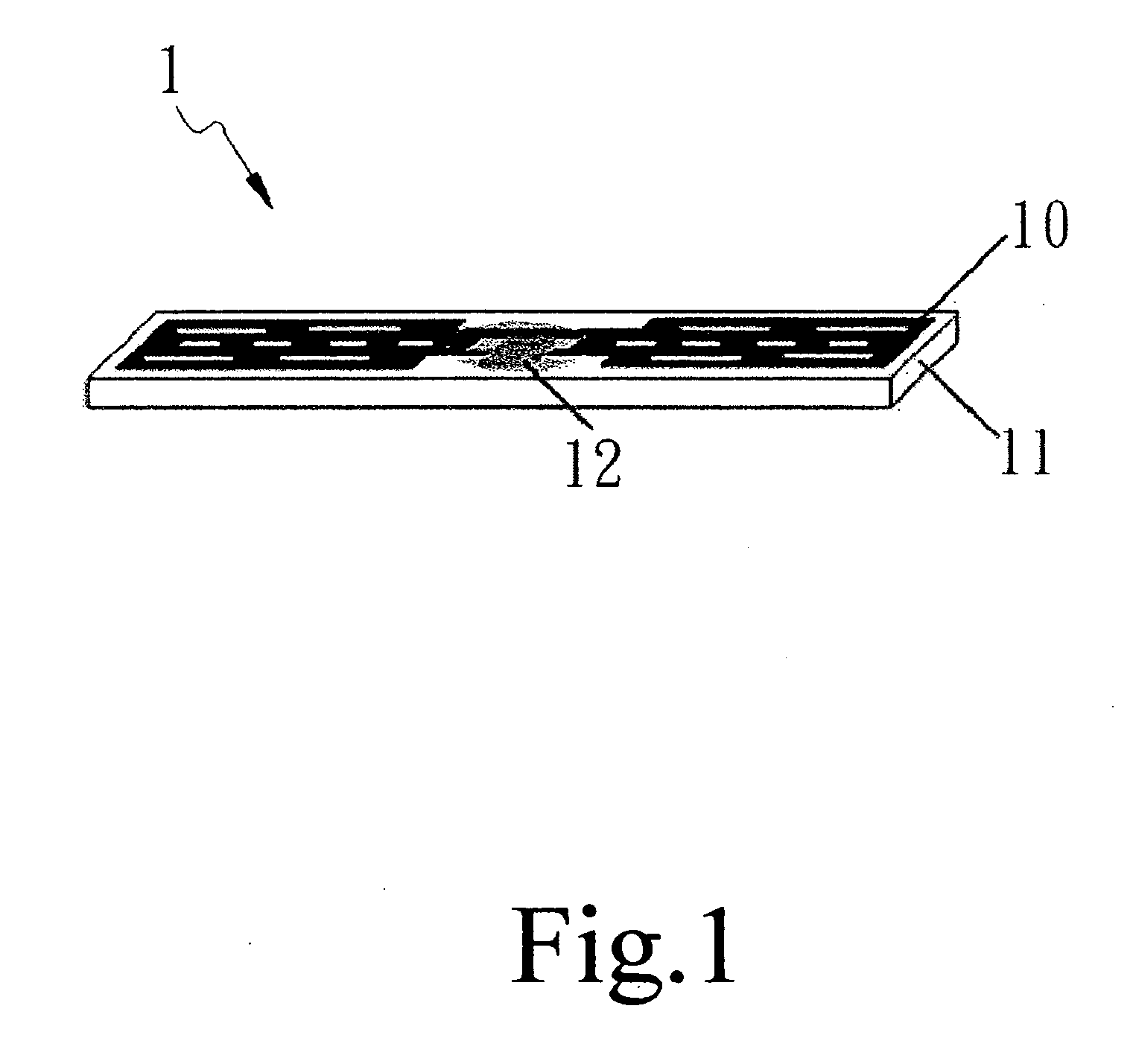

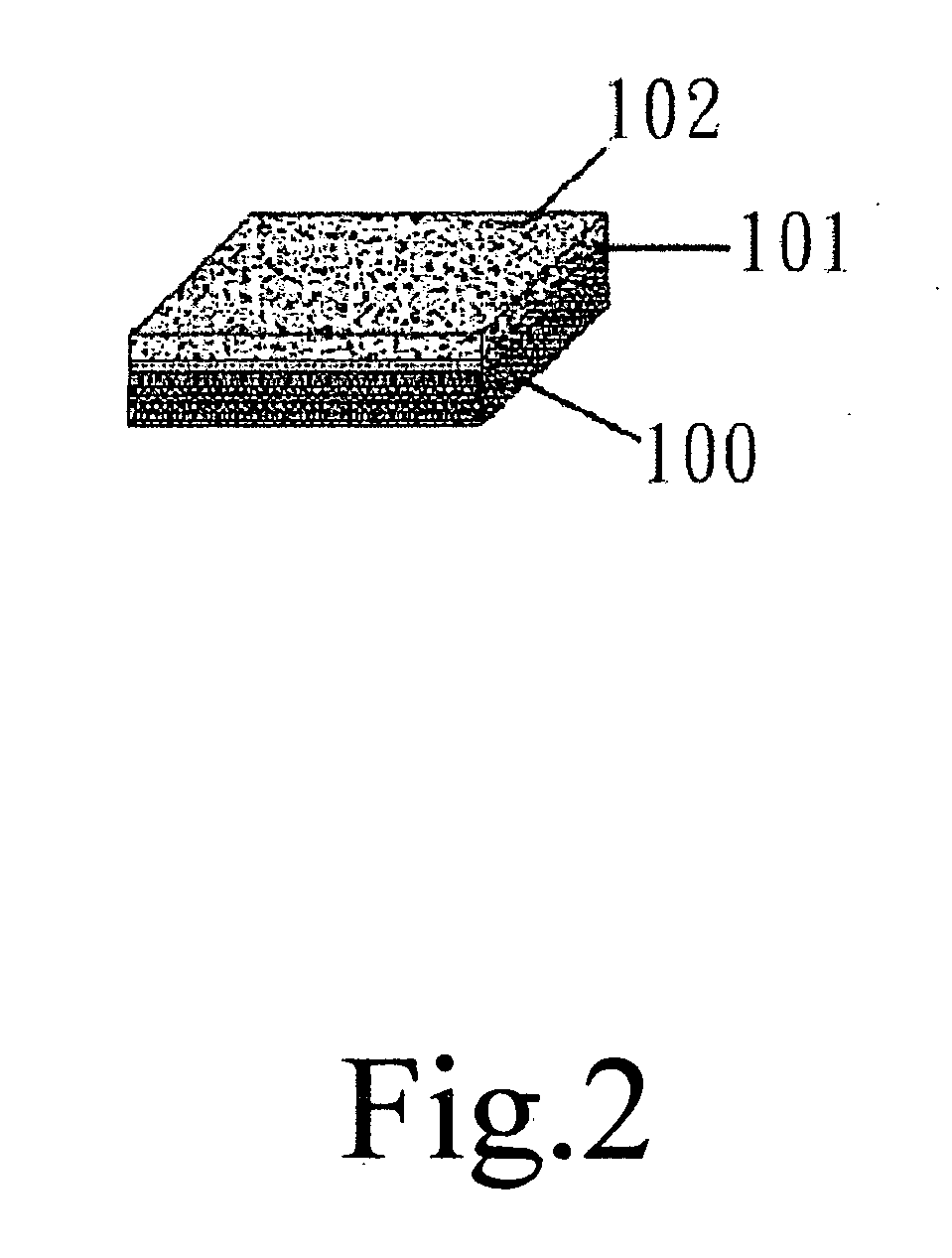

Structured light based three-dimensional reconstruction system and structured light based three-dimensional reconstruction method

InactiveCN106289109AAccurate 3D reconstructionRapid mass productionUsing optical meansSinusoidal gratingReconstruction method

The invention discloses a structured light based three-dimensional reconstruction system and a structured light based three-dimensional reconstruction method. The method includes: projecting a sinusoidal grating image towards a detected object through a projector, acquiring a deformed grating image through a camera, and performing data processing through a computer to obtain morphology of the detected object and generate a three-dimensional model. The structured light based three-dimensional reconstruction system and the structured light based three-dimensional reconstruction method have advantages of high precision, low cost, easiness in implementation and the like, functions of detected object scanning and model recovery are achieved, precision three-dimensional reconstruction can be realized, and quick batch production is realized as well.

Owner:CHANGAN UNIV

Nail Gun Switch Mechanism

InactiveUS20090159633A1Simple structureRapid mass productionStapling toolsNailing toolsEngineeringNail gun

A nail gun switch mechanism includes a gun body and a trigger. The gun body has a trigger valve being disposed therein and a safety slidable bar being slidably disposed on. The safety slidable bar has a bottom part which extends outside of a hitting mouth at a bottom of the gun body. The trigger has a trigger lever being pivotably disposed therein, which is configured for driving the trigger valve to open. A top part of the safety slidable bar extends near to an end of the trigger and a swing arm is pivotably disposed on the top part of the safety slidable bar. The swing arm includes an arm part extending from a pivotal center of the swing arm and a push part extending from the arm part toward outside. The push part is configured to be switched to a first swing position and thus driven by the safety slidable bar to touch the trigger lever so as to operate the nail gun in a sequential actuation mode. The push part is configured to be switched to the second swing position and thus driven by the safety slidable bar to touch the trigger lever so as to operate the nail gun in a contact actuation mode.

Owner:ROBERT BOSCH TOOL +1

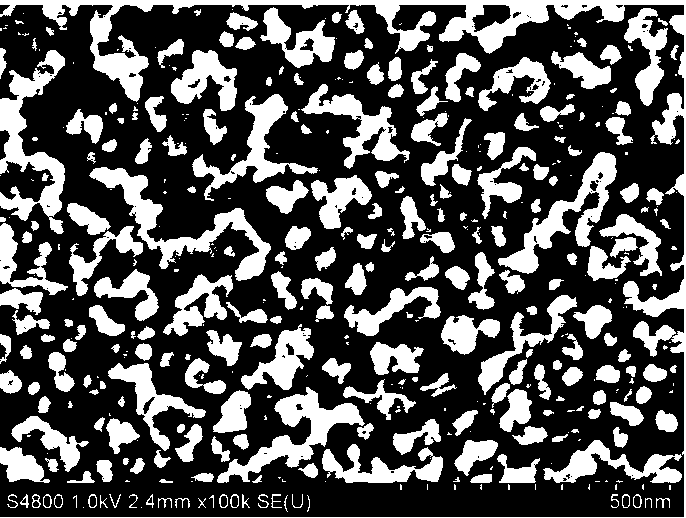

Preparation method and application of carbon-based metal organic frame (MOF) compound derivative material

The invention discloses preparation method and application of a carbon-based metal organic frame (MOF) compound derivative material, and belongs to the technical field of preparation of a functional nanometer material. The preparation method comprises the steps of placing a carbon fiber / polyacrylonitrile (PAN) thin film in an MOF precursor solution, achieving self-assembly of different morphologies of an MOF on different substrates at a room temperature, mixing the obtained product and an appropriate amount of melamine, and then performing thermal reduction on in-situ catalytic growth carbon nanotube (CNT) in an inert atmosphere to obtain the carbon-based MOF derivative material. The function nanometer material prepared by the method has the physical characteristics of high conductivity, rapid ion transmission passage, good flexibility, favorable self-support structure and the like and shows long service lifetime, high-capacity electric storage performance and excellent electrochemicalstability during energy storage and conversion; and the preparation process of the whole material is simple, no toxic product during reaction is generated, and the material is green and environmental-friendly and is suitable for industrial production on a large scale.

Owner:NANJING UNIV OF TECH

Silk nanofiber manufacturing method

InactiveCN104532365APromote swellingAvoid influenceAnimal materialSilk filament obtainingInorganic saltsFiber

The invention relates to a silk nanofiber manufacturing method, and belongs to the technical field of nano material manufacturing. The manufacturing method includes the steps that silk obtained after degumming treatment is transferred to a solution composed of an inorganic salt or weak acid or weak alkali small molecule compound, deionized water and alcohols, after binding force between nano fibrils in the silk is weakened through soaking, the silk solution is transferred to a high-voltage cell crushing machine or an emulsification machine or a pulp refiner or a crushing machine of a high-speed stirring device, and the soaked silk is mechanically crushed to obtain silk nanofibers. A silk nanofiber solution obtained through the method is similar to the shape of hydrogel, the silk nanofibers are obtained through centrifuging or filtering separation, manufacturing time is short, equipment is simple, operation influence factors are few, and control is convenient. The adopted small molecule compound avoids influences of strong acid or strong alkali on the silk nano fibrils, and the crushing machine can be used for quickly manufacturing the silk nanofibers on a large scale.

Owner:WUHAN TEXTILE UNIV

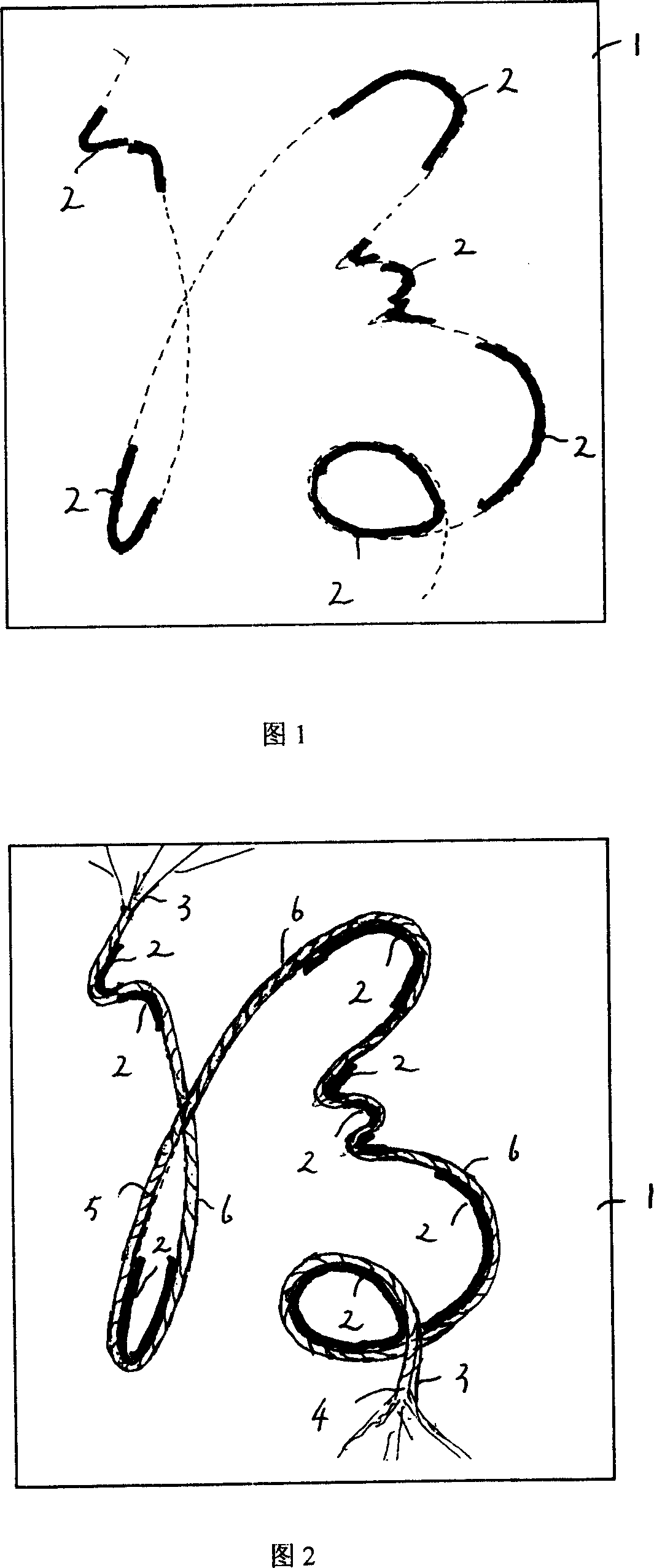

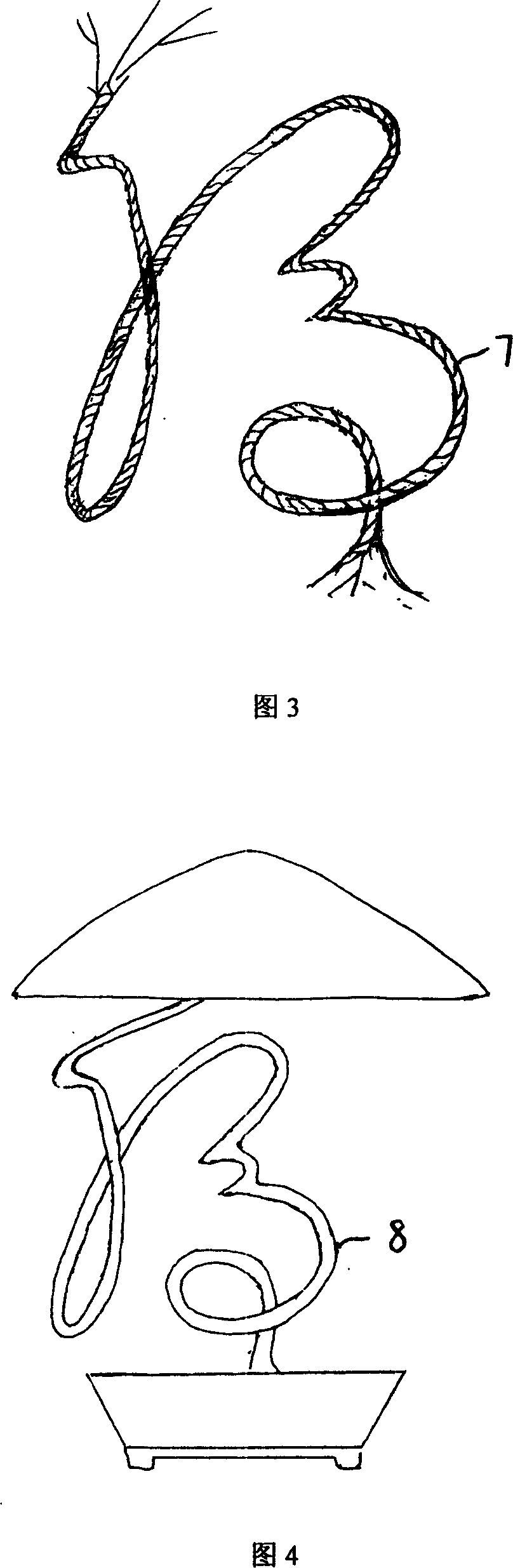

Mold shaping method for cursive script potted landscape

InactiveCN1986248AShort styling timeFont standardOrnamental structuresSpecial ornamental structuresMetallurgyGreenhouse

The technological process of mold shaping for cursive script potted landscape includes the following steps: determining the cursive script text, making mold through copying the cursive script onto iron plate and welding iron sheets to the iron plate, arranging nursery stock with iron wire in parallel and tying the both together with plastic belt, shaping the nursery stock through bending, soil-less cultivating in a greenhouse, planting in land, grafting, and trimming and transplanting into pot. The said process can form cursive script potted landscape in 2-3 years and may batch produce.

Owner:江苏春辉生态农林股份有限公司

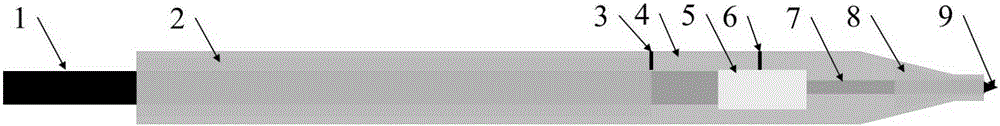

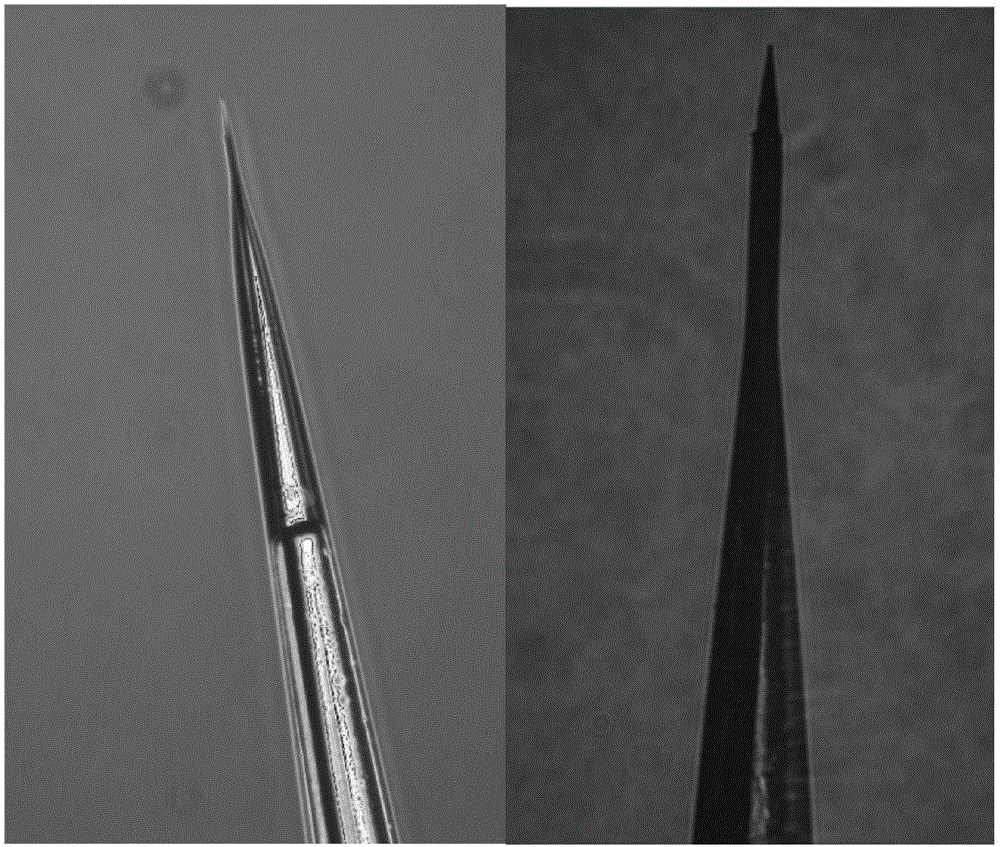

Preparation method of carbon fiber ultramicroelectrode

ActiveCN105203607AReduce the difficulty of operationControllable shape and scaleMaterial electrochemical variablesBatch productionCopper wire

The invention discloses a preparation method of a carbon fiber ultramicroelectrode. The method comprises steps as follows: a carbon fiber and a copper wire are bonded through a conductive silver adhesive and axially sent into a glass capillary tube, the steel wire is sealed and fixed through paraffin, the glass capillary tube through which the carbon fiber penetrates is pulled into a carbon fiber strip electrode by a puller, after the paraffin in the glass tube is molten through heating and seals the tip, the paraffin left outside the tip of the capillary tube is cleaned and removed through acetone, and the carbon fiber ultramicroelectrode is obtained through electrochemical etching in a NaOH solution. The carbon fiber ultramicroelectrode can be prepared effectively with the method, the yield of the carbon fiber ultramicroelectrode is increased, batch production of ultramicroelectrodes is rapid and convenient, and the preparation cost of the ultramicroelectrode is reduced.

Owner:SOUTHEAST UNIV

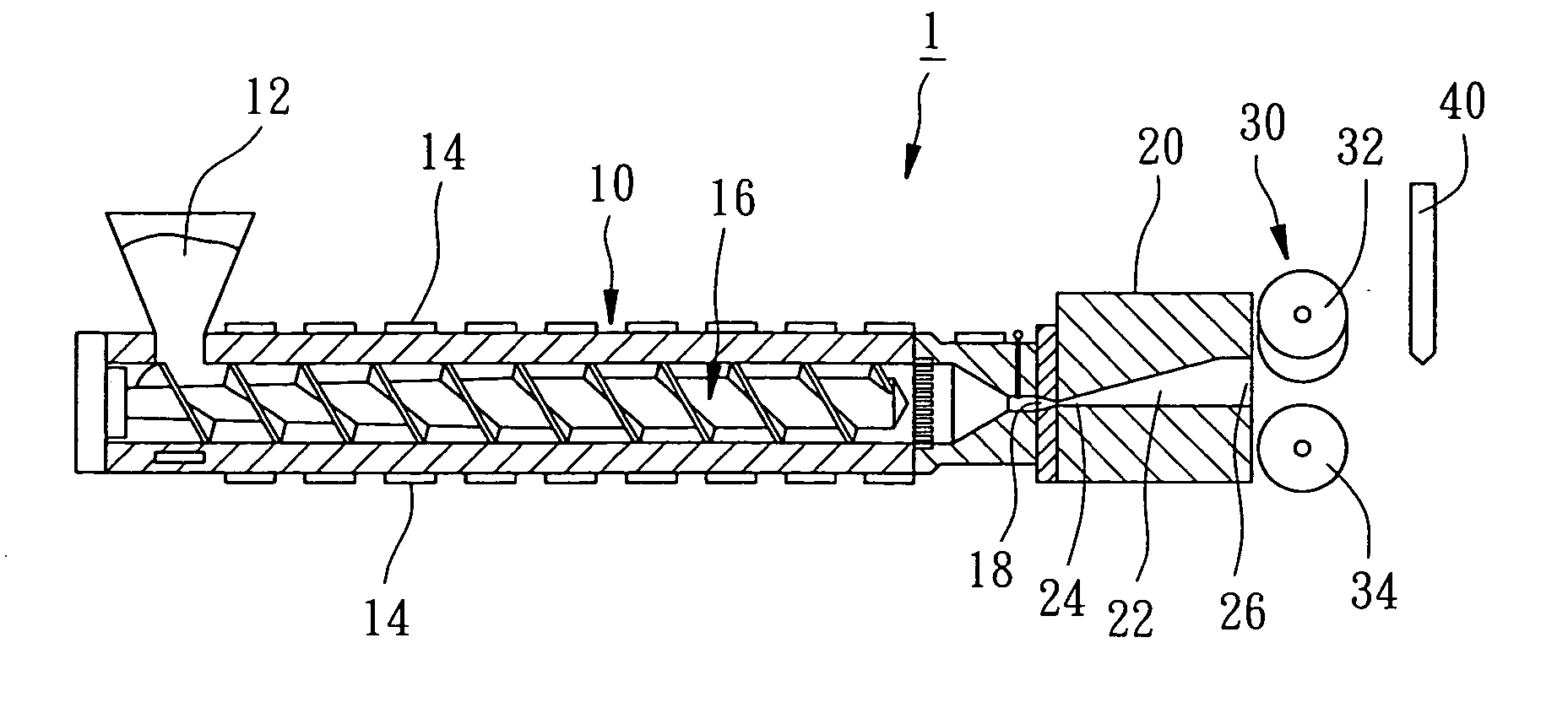

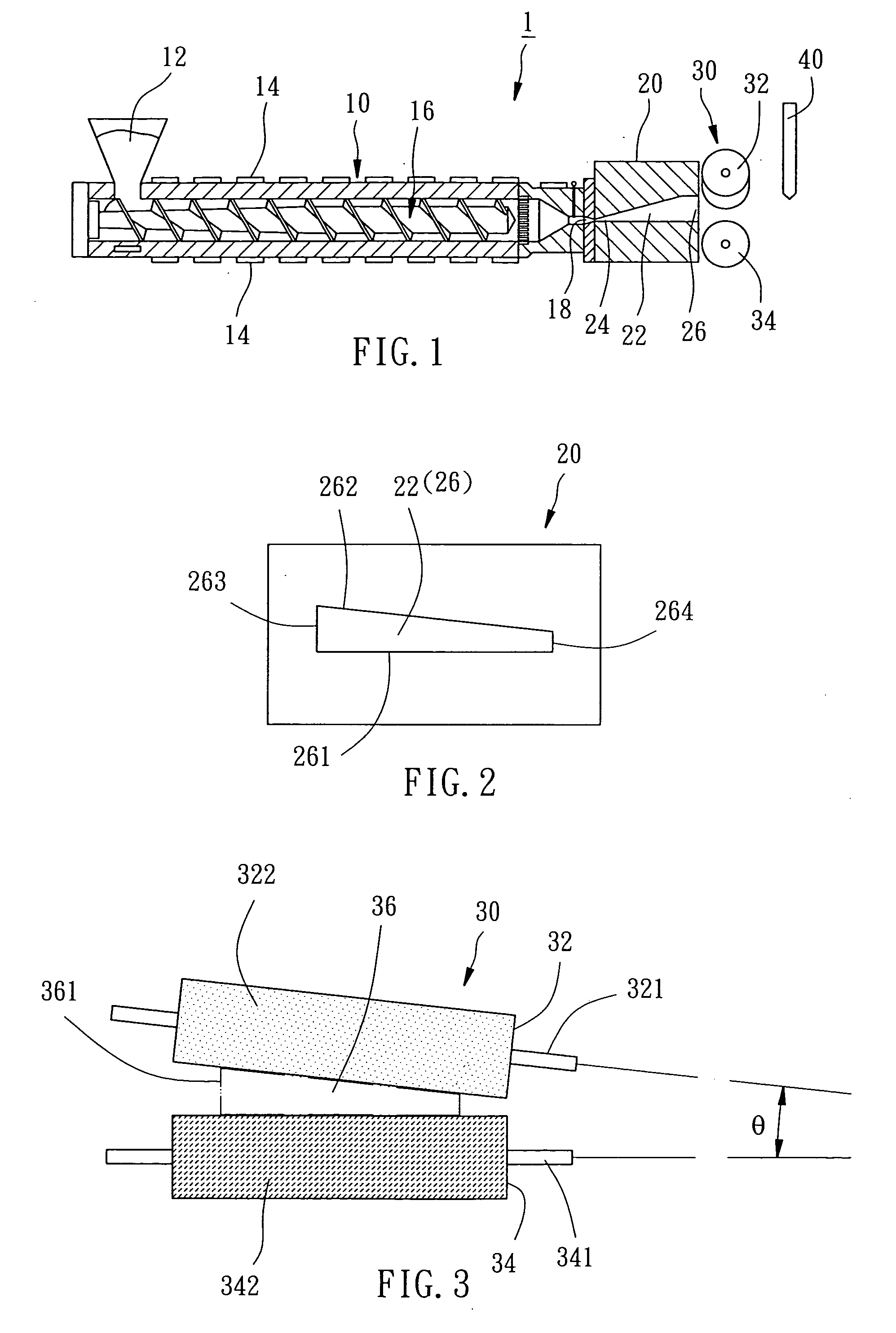

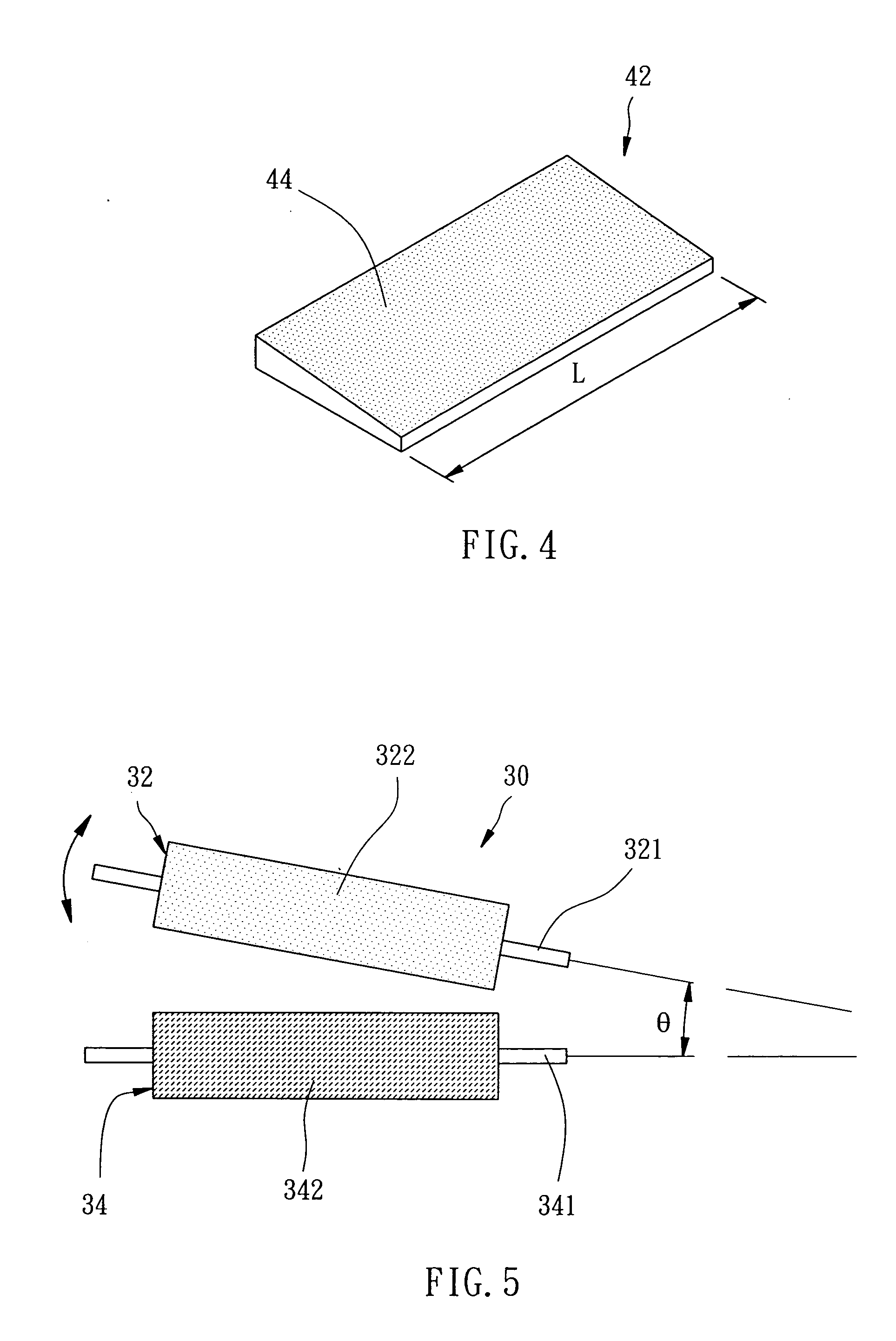

Apparatus of making wedged plates

An apparatus for making wedged plate has an extruder to provide melted plastic material. A die head has a channel with an inlet and an outlet. The inlet of the die head is connected to an outlet of the extruder. The outlet of the die head has a thick side and a narrow side. A rolling device has two rollers and a space between the rollers. The space has a thick portion and a narrow portion at opposite sides. The space of the rolling device is aligned with the outlet of the die head, so that the plastic material flows into the space of the rolling device via the die head and is rolled by the rollers. A cutting device is arranged behind the rolling device to cut the rolled plastic material to get wedged plates.

Owner:FRANCIS CHUNG HWA PAN

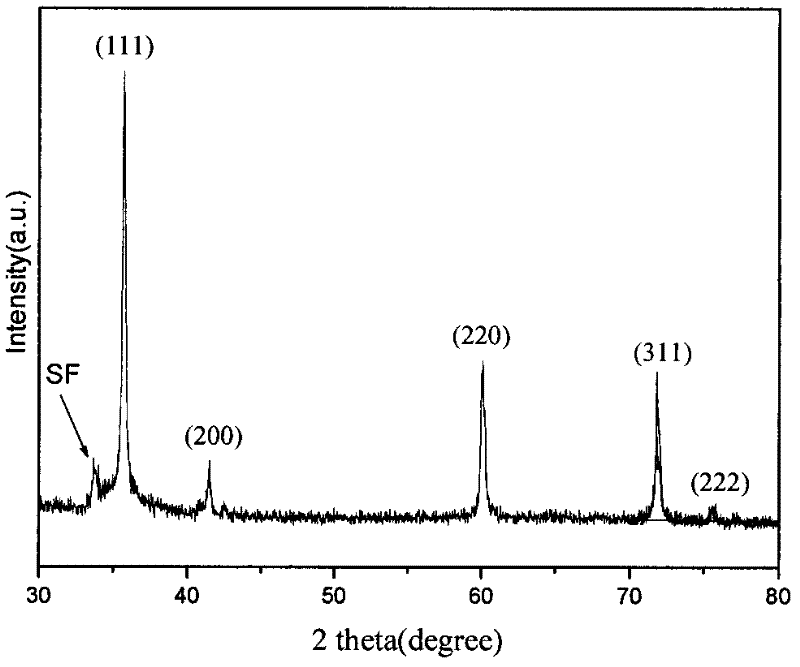

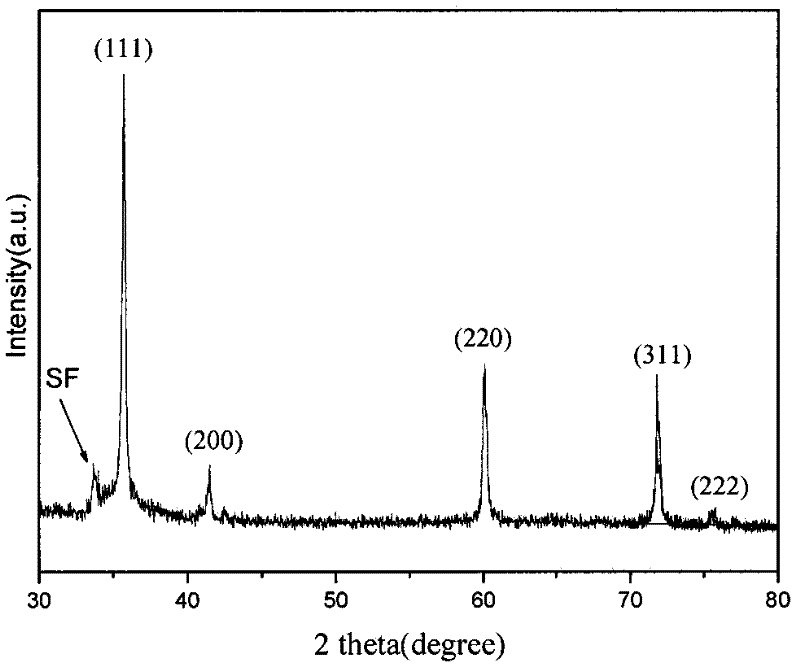

Lithium metal alloy negative electrode material and preparation method and application thereof

ActiveCN110120502AUniform depositionWon't happenCell electrodesSecondary cellsCyclic processPower flow

The invention provides a lithium metal alloy negative electrode material. The negative electrode material comprises lithium alloy serving as a framework and metal lithium filling the framework. The lithium alloy has lithium ion conductivity, and compared with a traditional three-dimensional structure only having electron conductivity, a better three-dimensional ion and electron conductivity network can be formed, so that metal lithium is uniformly deposited, lithium dendrites cannot be generated even if charging and discharging are carried out under the condition of great current density, anda remarkable battery polarization phenomenon is not generated. The lithium alloy material which can be subjected to extraction and insertion of lithium is adopted as the structural framework, after metal lithium is used up in the circulating process, the capacity of the alloy framework can be further released, and the circulating performance of the battery is guaranteed. The used raw materials arewide in source, low in price, simple in process and suitable for rapid large-scale production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

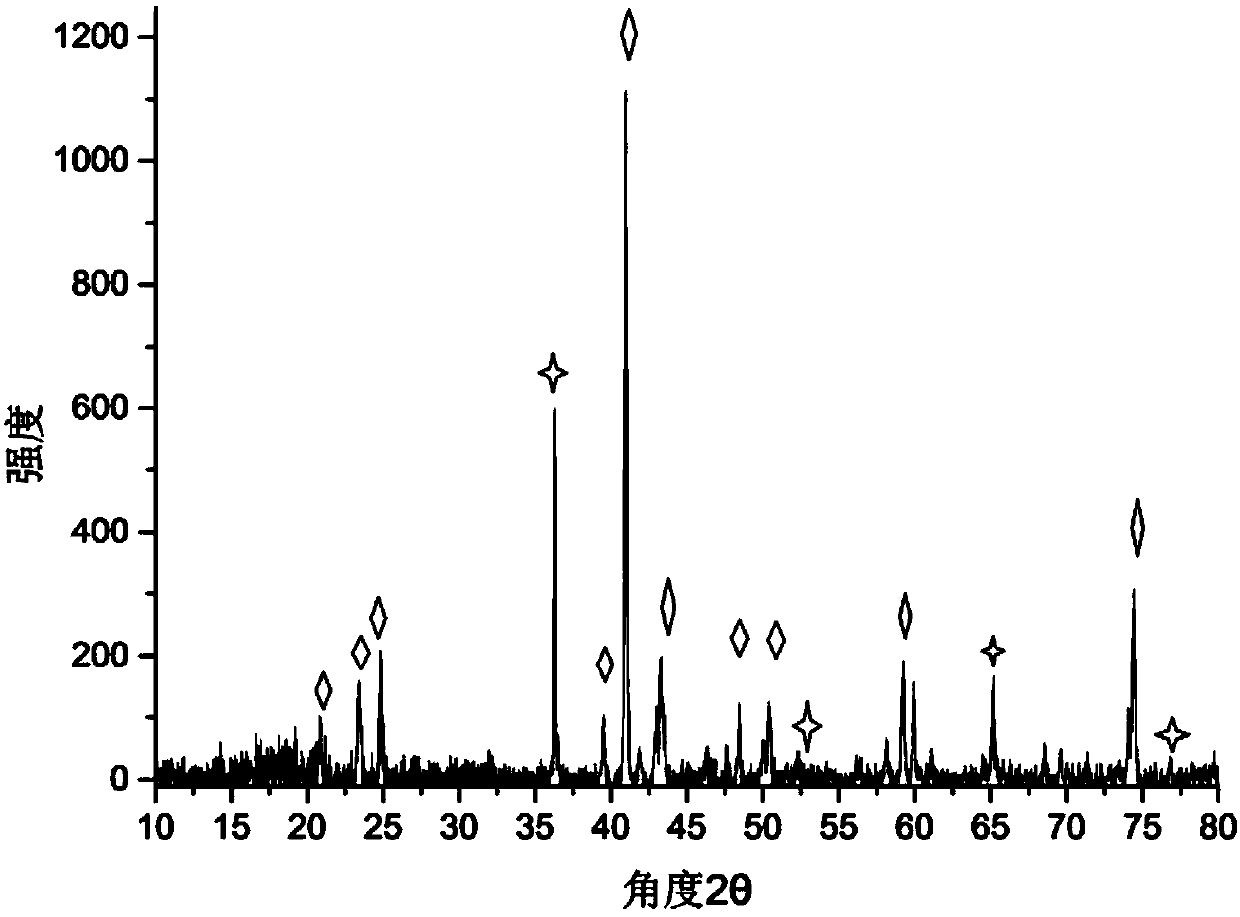

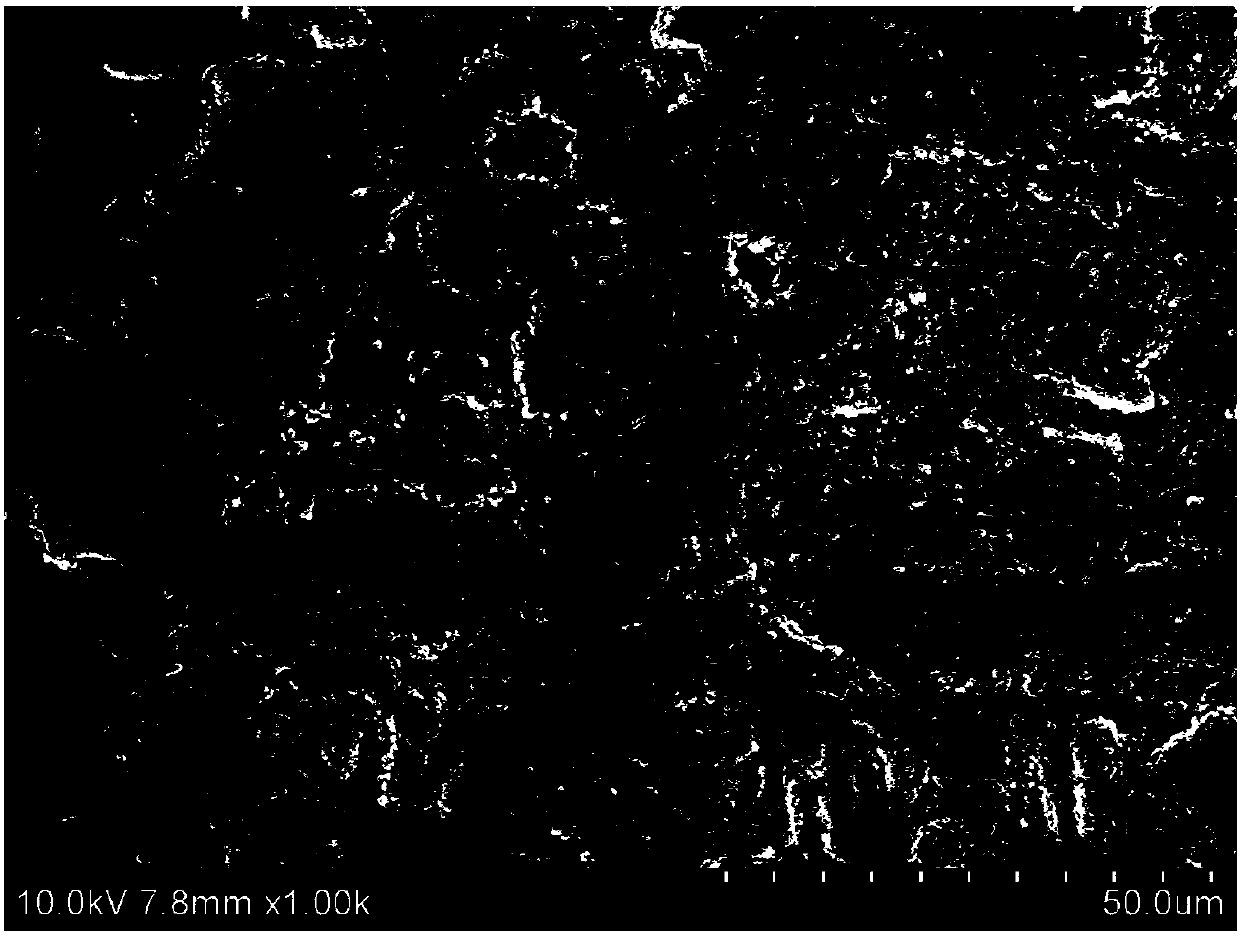

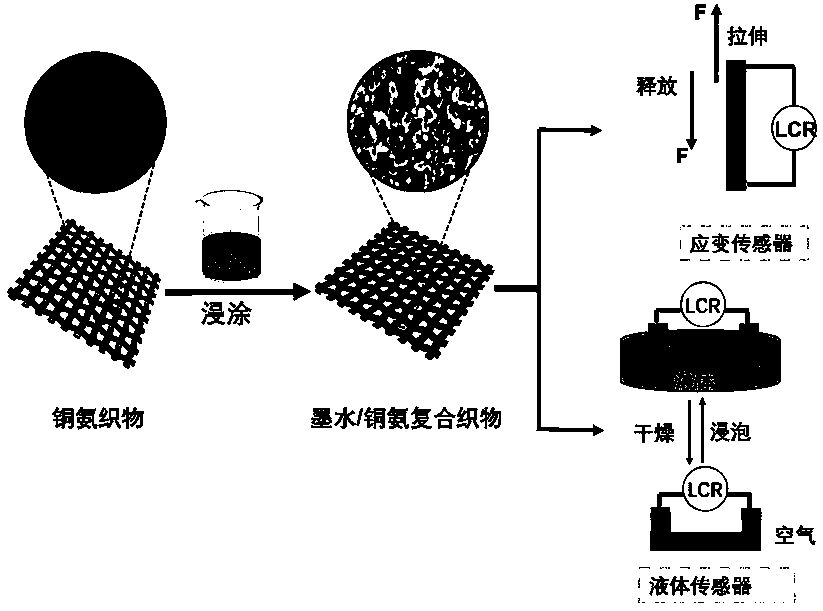

Wearable multifunctional flexible sensor and manufacturing method thereof

ActiveCN109115266AUniversalRapid mass productionForce measurementMaterial resistanceCelluloseEnvironmental resistance

The invention belongs to the electronic material technology field and discloses a multifunctional flexible sensor and a manufacturing method thereof. The multifunctional flexible sensor comprises a flexible substrate layer and an inductive and conductive composite material layer. The flexible substrate layer comprises a cellulose fabric. The inductive and conductive composite material layer is mainly carbon ink. Through a simple and effective dip-coating method, the manufacturing of the multifunctional flexible sensor is realized. The multifunctional flexible sensor has universality and is suitable for most of cellulose fabrics. The sensor has characteristics of rapid and large scale manufacturing, low cost, good product performance, simple operation, environmental protection and the like.The multifunctional flexible sensor combines the functions of a strain sensor and a liquid sensor and has a wide application prospect in the fields of environment monitoring, human body motion and awearable field.

Owner:FUDAN UNIV

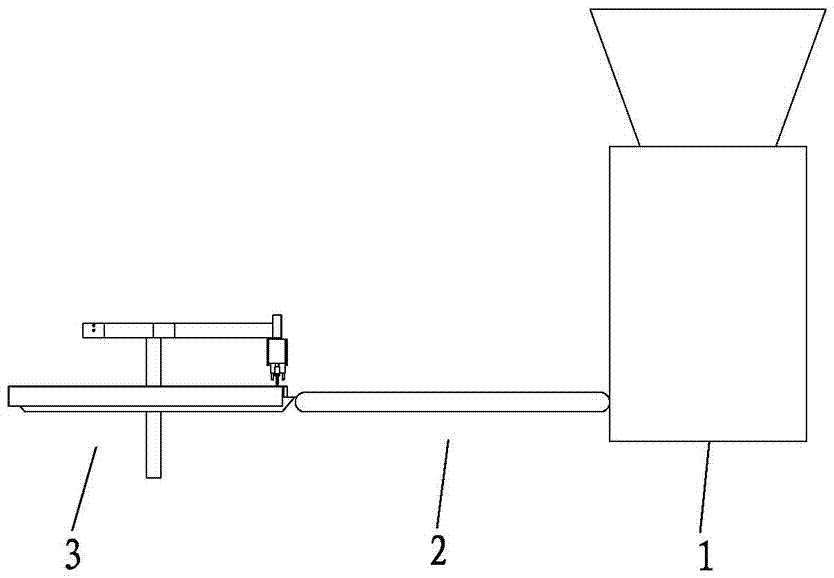

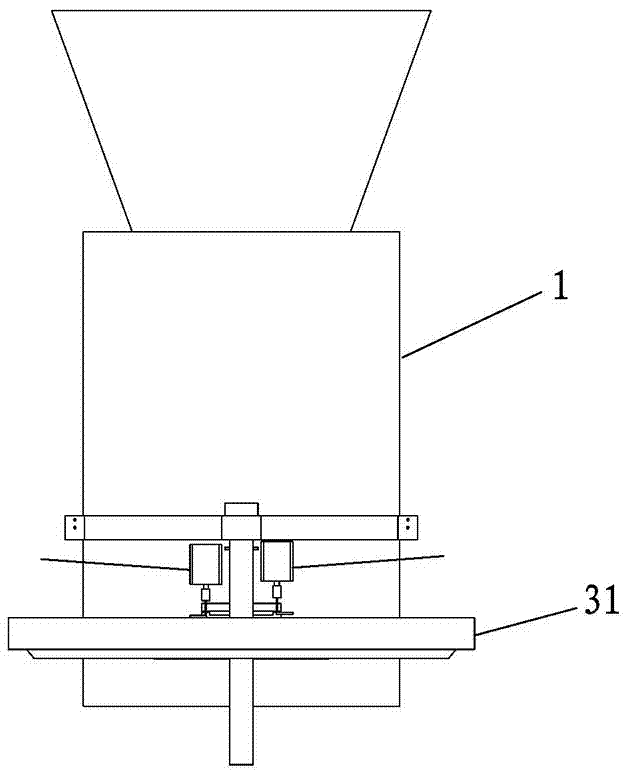

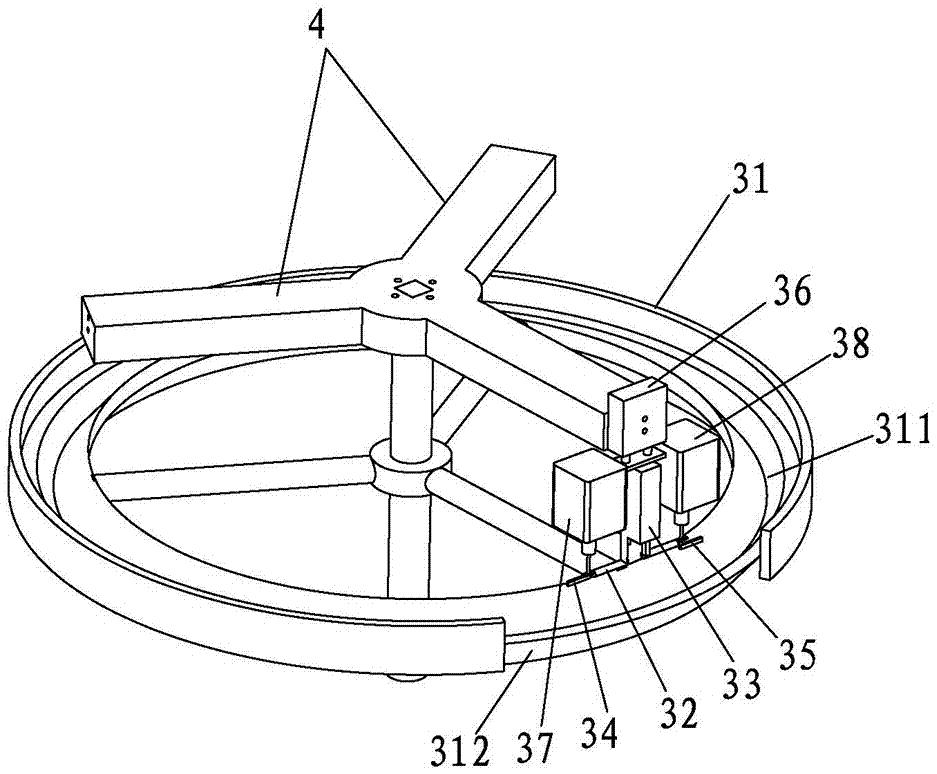

Full automation gold ingot shape Ravioli forming device and all-in-one machine

ActiveCN107047679ASimple structureIngenious and reasonable designDough processingMoulding deviceManufacturing line

The invention discloses a full automation gold ingot shape Ravioli forming device and all-in-one machine. The all-in-one machine comprises a raw material process unit, a transmission unit and a forming unit connected in sequence, the forming unit comprises a turntable and a forming mechanism; sunk grooves of middle sinking are arranged in the turntable; the forming mechanism is arranged above the sunk grooves, the forming mechanism comprises a mandrill, gas claws, a left swing rod and a right swing rod, the mandrill and the gas claws are located between the left swing rod and the right swing rod, the mandrill is connected with an elevating drive unit for driving the lifting of the drive unit, the left swing rod and the right swing rod are in horizontal extension and high-and-low arrangement, and are in connection with a rotating drive unit for leading the two to reverse swing towards the middle. The Ravioli forming device is simple in forming structure, wise and ingenious in design, the full automation molding of gold ingot shape Ravioli is achieved, the all-in-one machine adopts the line production mode, makes the gold ingot shape Ravioli to be produced fast and in batch, increases the production efficiency of ingot shape Ravioli, and significant saves labor and production cost.

Owner:XIAMEN UNIV OF TECH

Preparation method of beta-nano-SiC

ActiveCN102432013AReduce manufacturing costRapid mass productionCarbon compoundsNanotechnologyHydrofluoric acidNitrate

A preparation method of beta-nano-SiC comprises the following steps of: mixing starch or cane sugar with soluble glass according to the mass ratio of 1:1-5, or mixing starch or cane sugar with nitrate according to the mass ratio of 1:0.01-0.5, then mixing with soluble glass with the mass ratio of starch to soluble glass being 1:1-5, standing for 5-30 minutes after uniformly mixing, dying the mixture at the temperature of 60-120 DEG C for 5-20 hours to obtain a dried substance; carrying out a carbothermal reduction reaction for 3-20 hours by heating the dried substance to 1100-1400 DEG C underthe protection of argon gas, and naturally cooling to room temperature after the reaction so as to obtain a primary reaction product; roasting the primary reaction product at the temperature of 600-800 DEG C for 1-5 hours, and removing unreacted carbon; immersing for 12-48 hours by using a mixed acid composed of hydrochloric acid and hydrofluoric acid at the volume ratio of 1:1-5, removing superfluous silica from the product, washing, filtering and drying to finally obtain beta-nano-SiC. The preparation method provided by the invention requires low cost, has a simple technology, and is suitable for large-scale industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

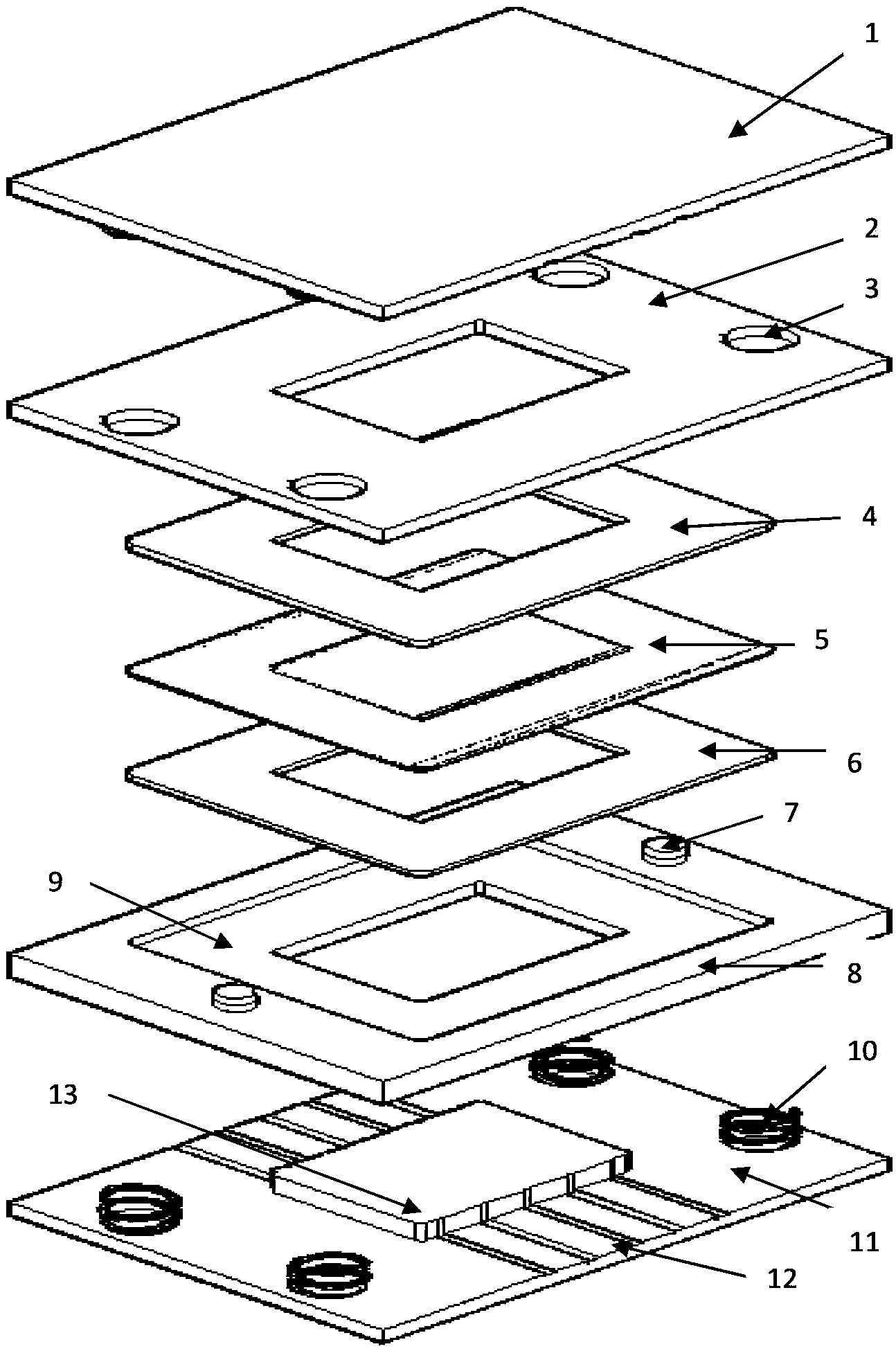

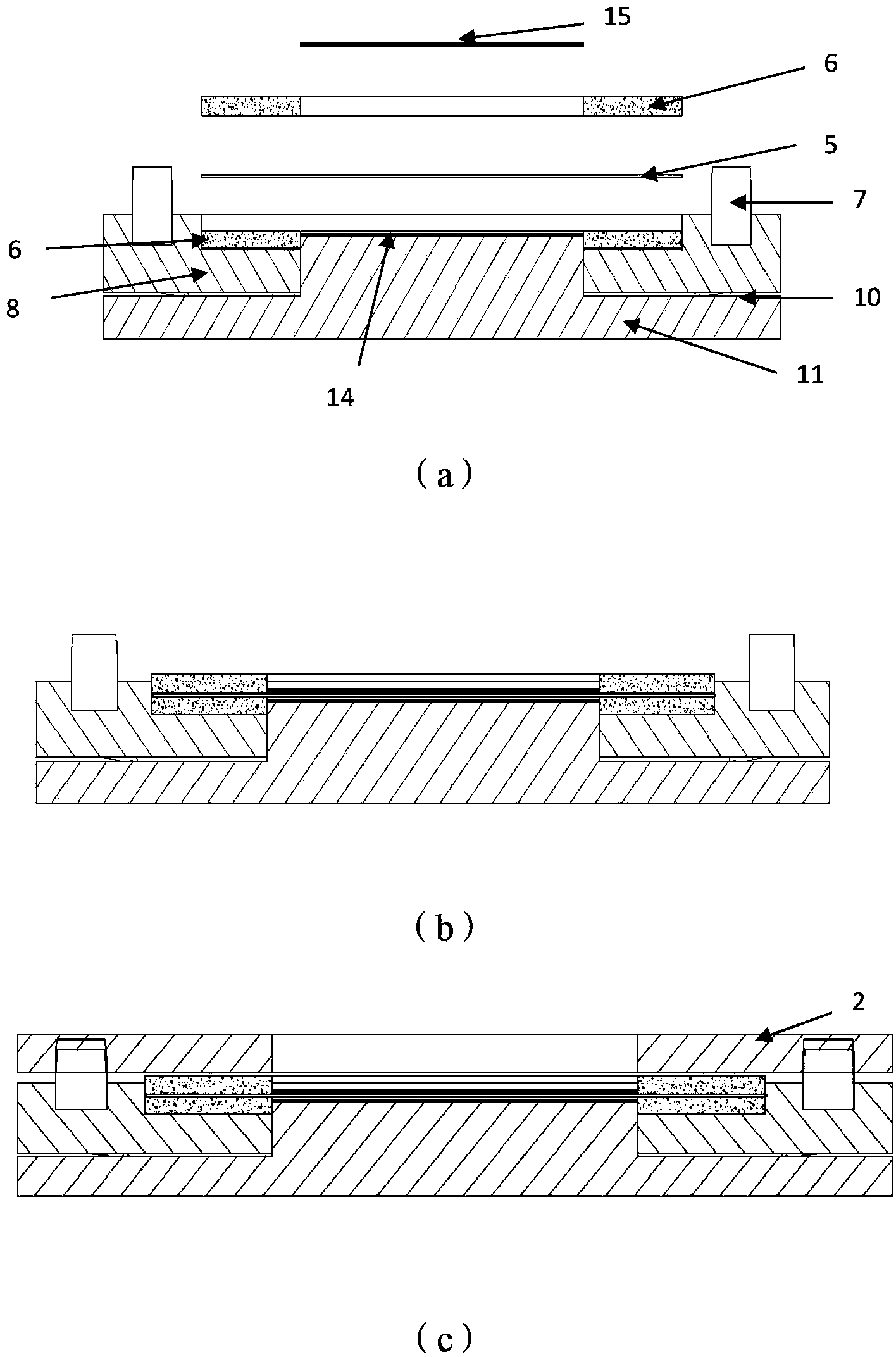

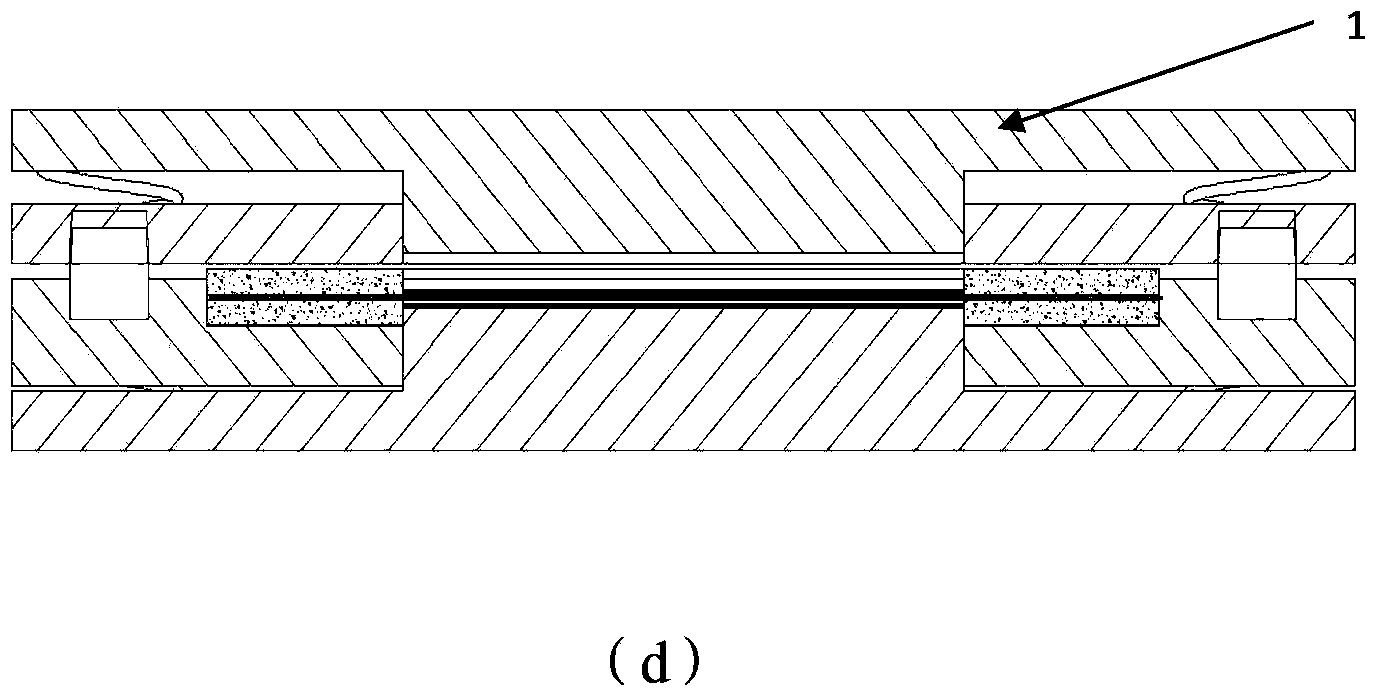

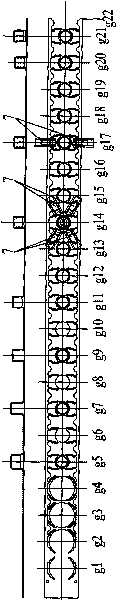

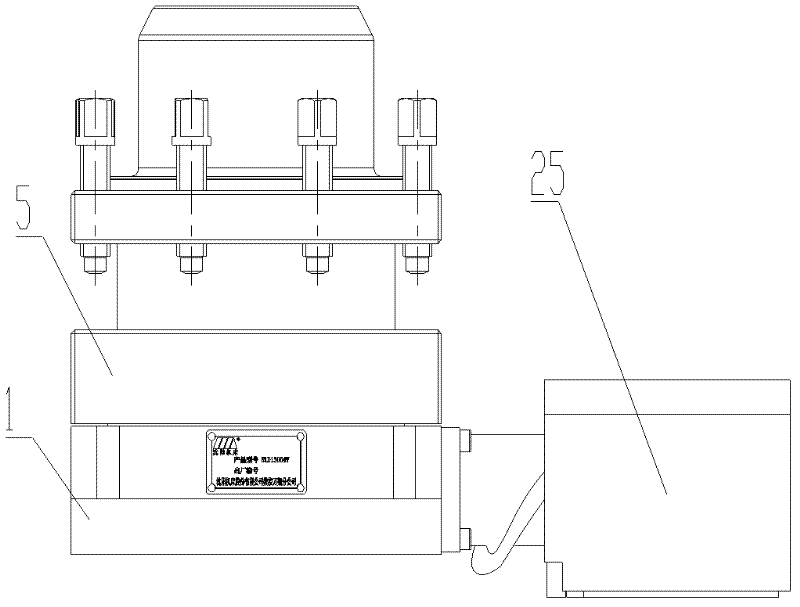

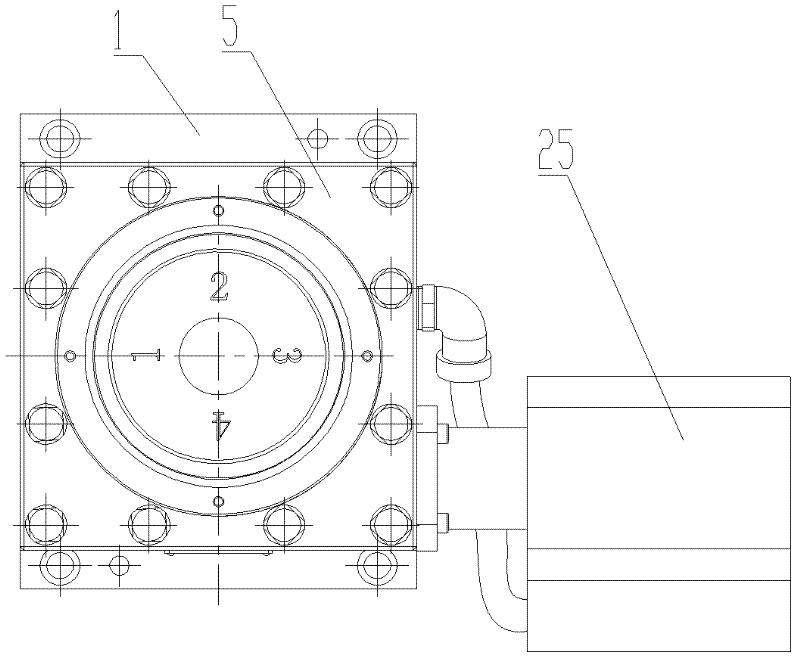

Membrane electrode pressing mould and its operation method

ActiveCN103887519APrecise positioningAvoid damageCell electrodesFuel cellsStress conditionsWater vapor

A membrane electrode pressing mold includes an upper pressing plate, an upper positioning plate, an upper positioning cushion, a lower positioning cushion, a lower positioning plate and a lower pressing plate which are sequentially superimposed. A first electrode and a second electrode, or a first diffusion layer and a second diffusion layer are accurately positioned by positioning holes on the upper and lower positioning cushions, positioning through holes on the upper and lower positioning plates and compressing convex platforms on the upper and lower pressing plates. Compared with the prior art, the membrane electrode pressing mold not only achieve accurate positioning of one electrode and the other electrodes, and a diffusion layer and an electrode, water vapor in a hot pressing process can be discharged smoothly by design of an exhaust flow channels of the upper and lower pressing plates, the problem that a catalyst or carbon powder is splashed throughout under the action of the water vapor can be avoided, and at the same time, the upper and lower positioning cushions make an electrolyte membrane clamped between the upper and lower positioning cushions rapidly-deformed or polluted in the heat and stress conditions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

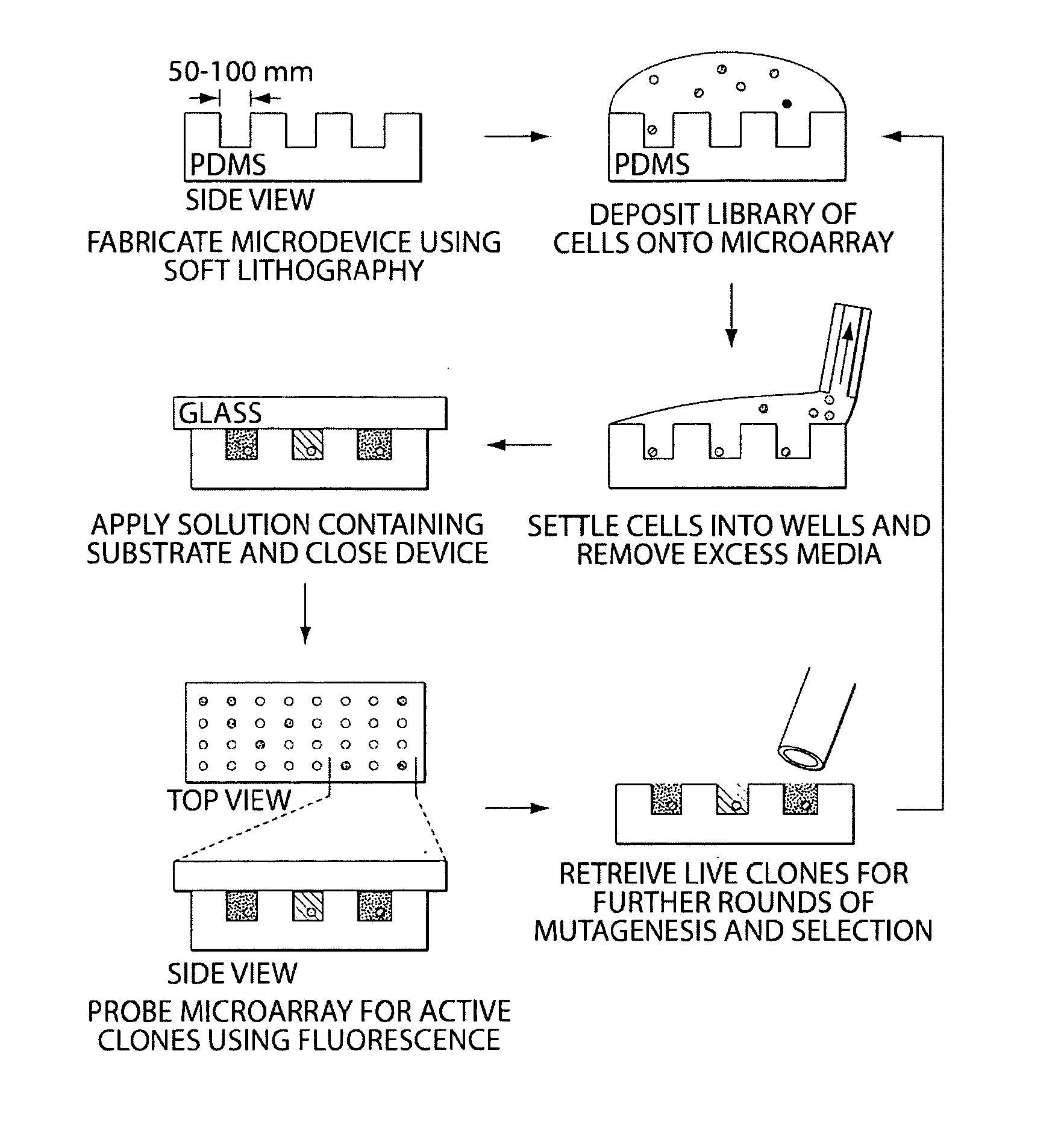

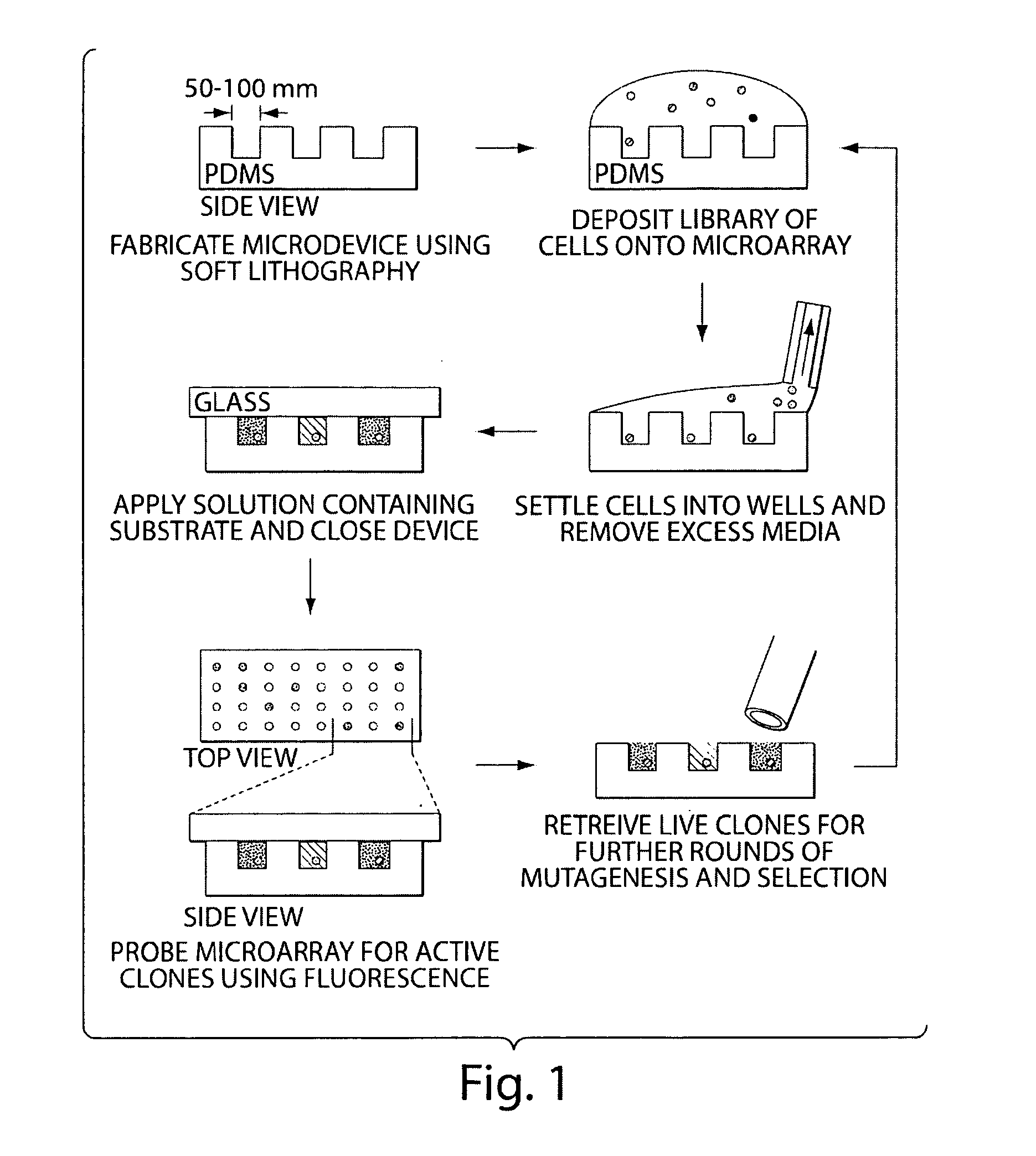

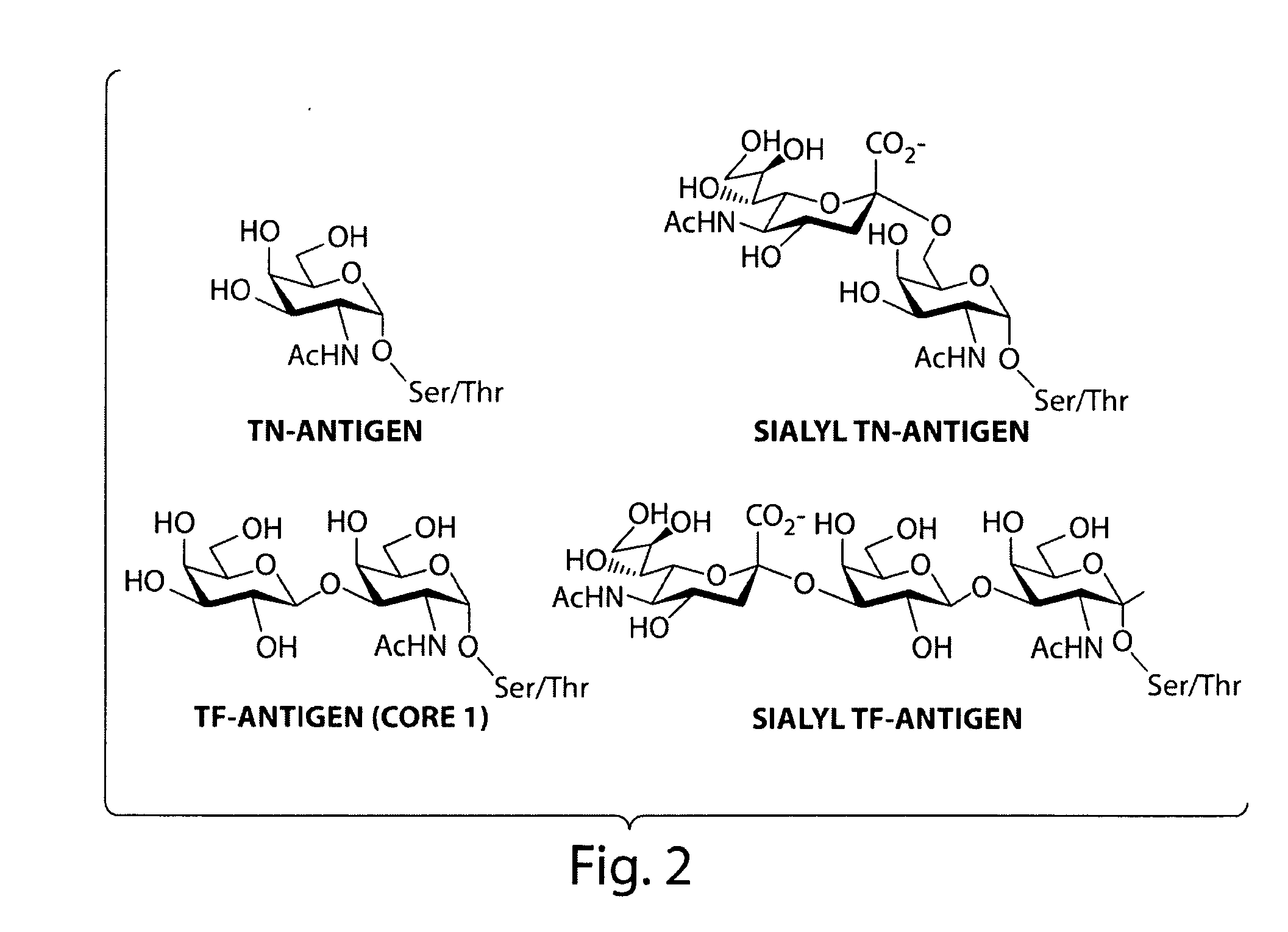

Compositions and Methods for Spatial Separation and Screening of Cells

InactiveUS20110124520A1Rapid mass productionAltered selectivityMicrobiological testing/measurementLibrary screeningMicroreactorSubstrate Specificities

The invention provides a method for isolating particular members from a library of variant cells in individual microreactors, wherein the phenotype of the biomolecule secreted by the cell is evaluated on the basis of multiple parameters, including substrate specificity and kinetic efficiency.

Owner:WHITEHEAD INST FOR BIOMEDICAL RES +1

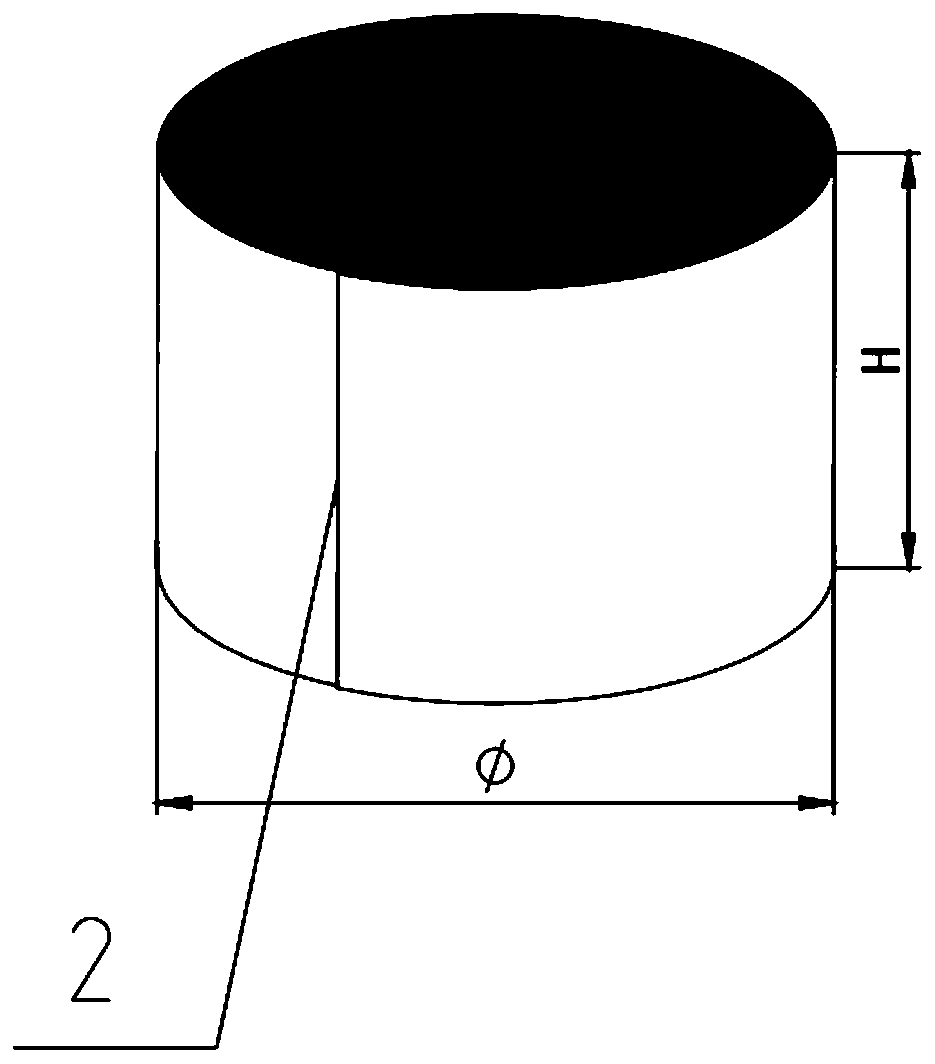

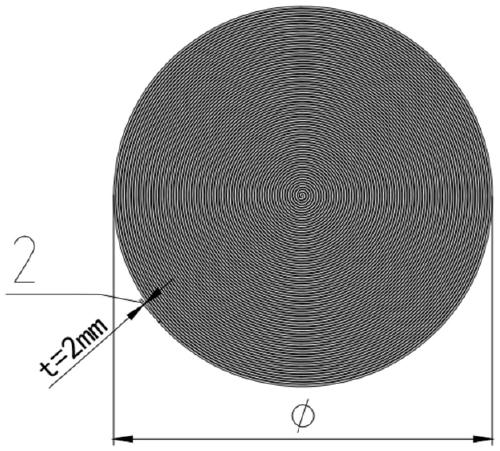

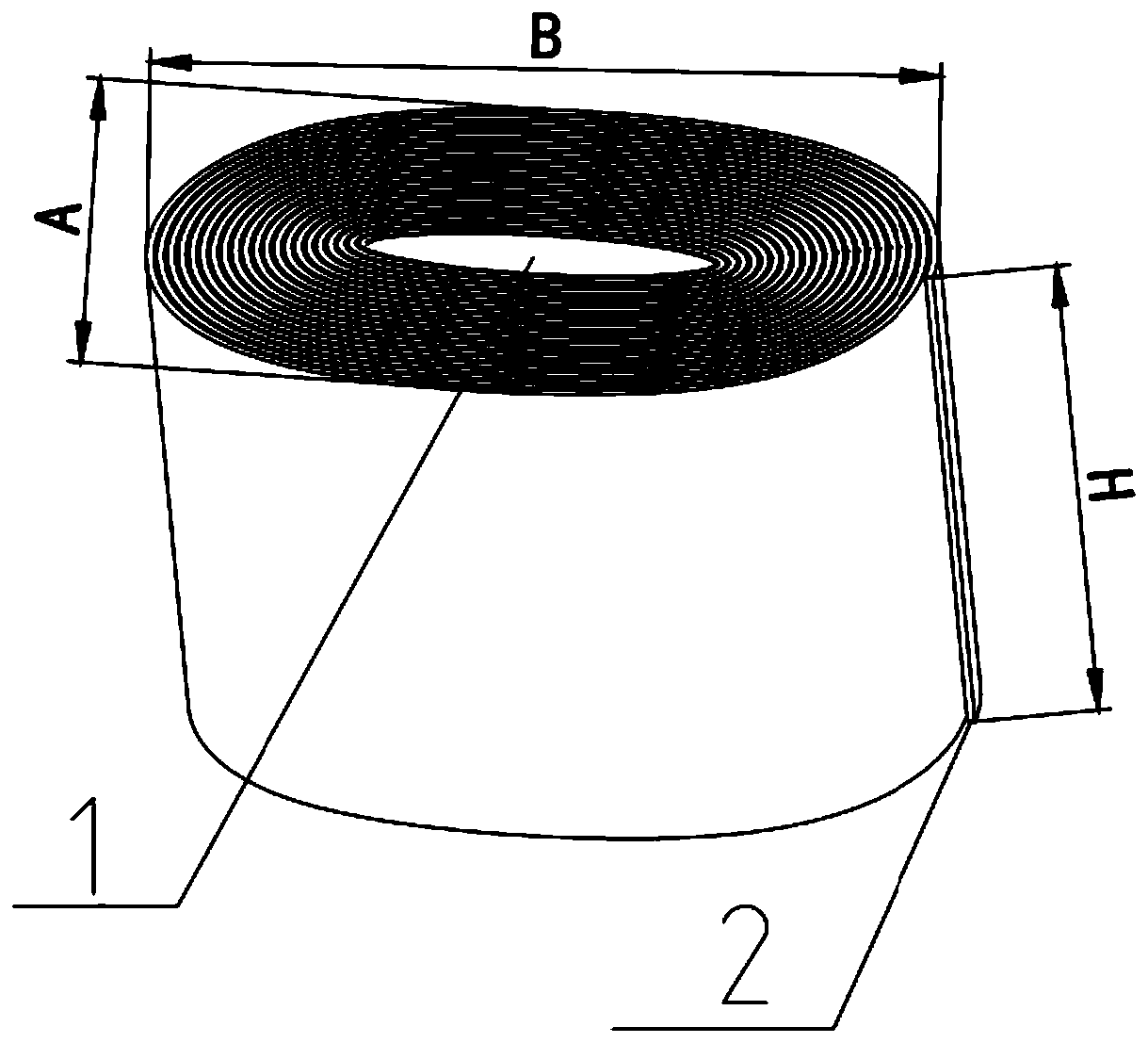

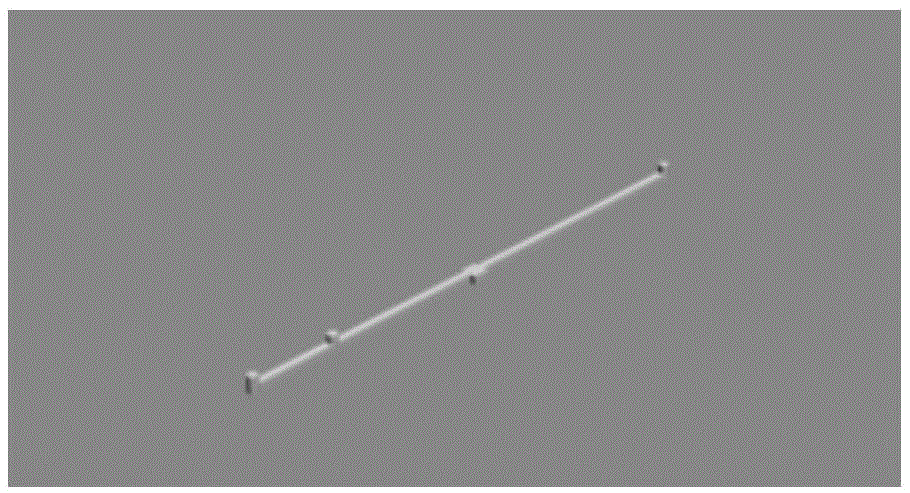

Manufacturing method of artificial dielectric multilayer cylindrical lens

ActiveCN111262042ASimple manufacturing processMade preciselyAntennasMaterials scienceArtificial dielectrics

The invention provides a manufacturing method of an artificial dielectric multilayer cylindrical lens. A granular material with a high dielectric constant epsilon (1.0<epsilon< / =3.0) is adhered to a single-sided adhesive foam substrate with a low dielectric constant (1.0<epsilon<2.0), a width (10 mm<H<10000 mm) and a thickness (0<t<10 mm); and rolling or pressing into an n-layer (1< / =n< / =1000) cylinder and elliptic cylinder with a height of H (10 mm<H<10000 mm) and the diameter of D is then carried out; and the epsilon of each layer is the same, different or gradually reduced (2.0> / =epsilon>1.0). The cylindrical lens manufactured through the method is ultra-light in weight, ultra-wide in frequency, capable of meeting the application requirements of various antennas, simple and feasible inmanufacturing process, high in quality consistency, low in manufacturing cost, particularly suitable for batch production, and particularly suitable for mobile communication 5G, 4G, MIMO and even millimeter wave base station antennas.

Owner:XIAN HAITIAN ANTENNA TECH CO LTD

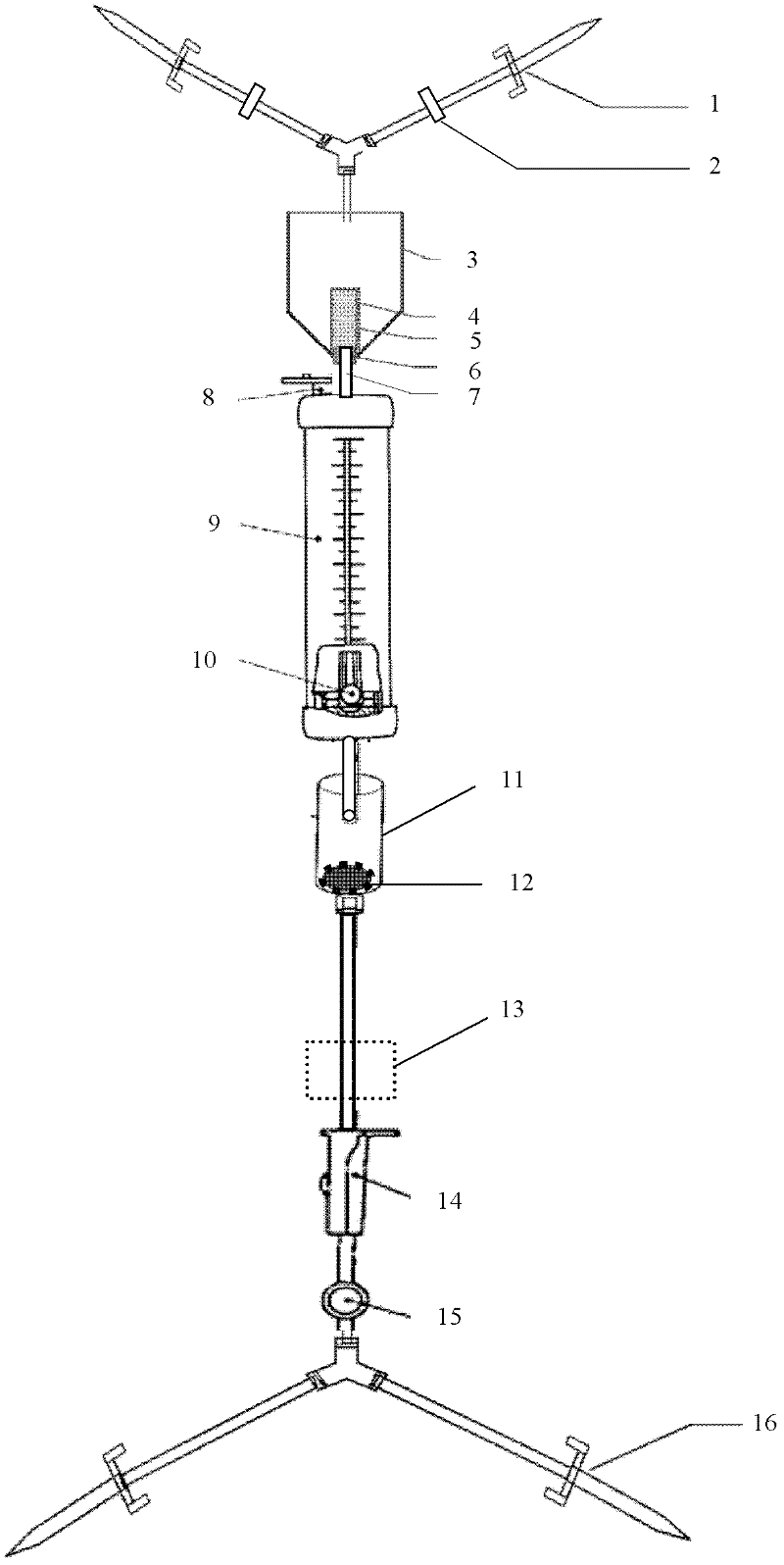

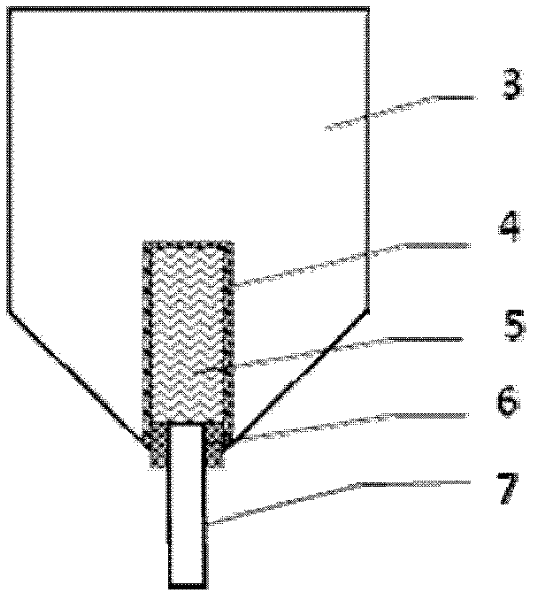

Infusion set for producing lignum aquilariae resinatum and production method of lignum aquilariae resinatum

InactiveCN102577856AReduce tree mortalityEasy for mass productionFiltering accessoriesPressure infusionDiameter at breast heightUrology

Disclosed are an infusion set for producing lignum aquilariae resinatum and a production method of lignum aquilariae resinatum. The infusion set comprises a liquid storage container and an infusion tube. The infusion tube is connected to the lower end of the liquid storage container. The liquid storage container is used for containing inducing liquid for lignum aquilariae resinatum, and the inducing liquid for lignum aquilariae resinatum is delivered into a trunk. In the method, the infusion set is used to produce lignum aquilariae resinatum. The inducing liquid for lignum aquilariae resinatum is delivered into the trunk through the infusion tube so as to produce lignum aquilariae resinatum. The infusion set is applicable to trees of Aquilaria sinensis with different ages and diameters at breast height to produce the lignum aquilariae resinatum, the shortages of rot, death and the like caused by easily caused large-area bark and trunk injuries due to fast infusion speed and failure of precise quantitation and control are overcome, and the tree death rate is lowered greatly. The infusion set is reusable, easy in batch production, and convenient in large-scale popularization.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI +1

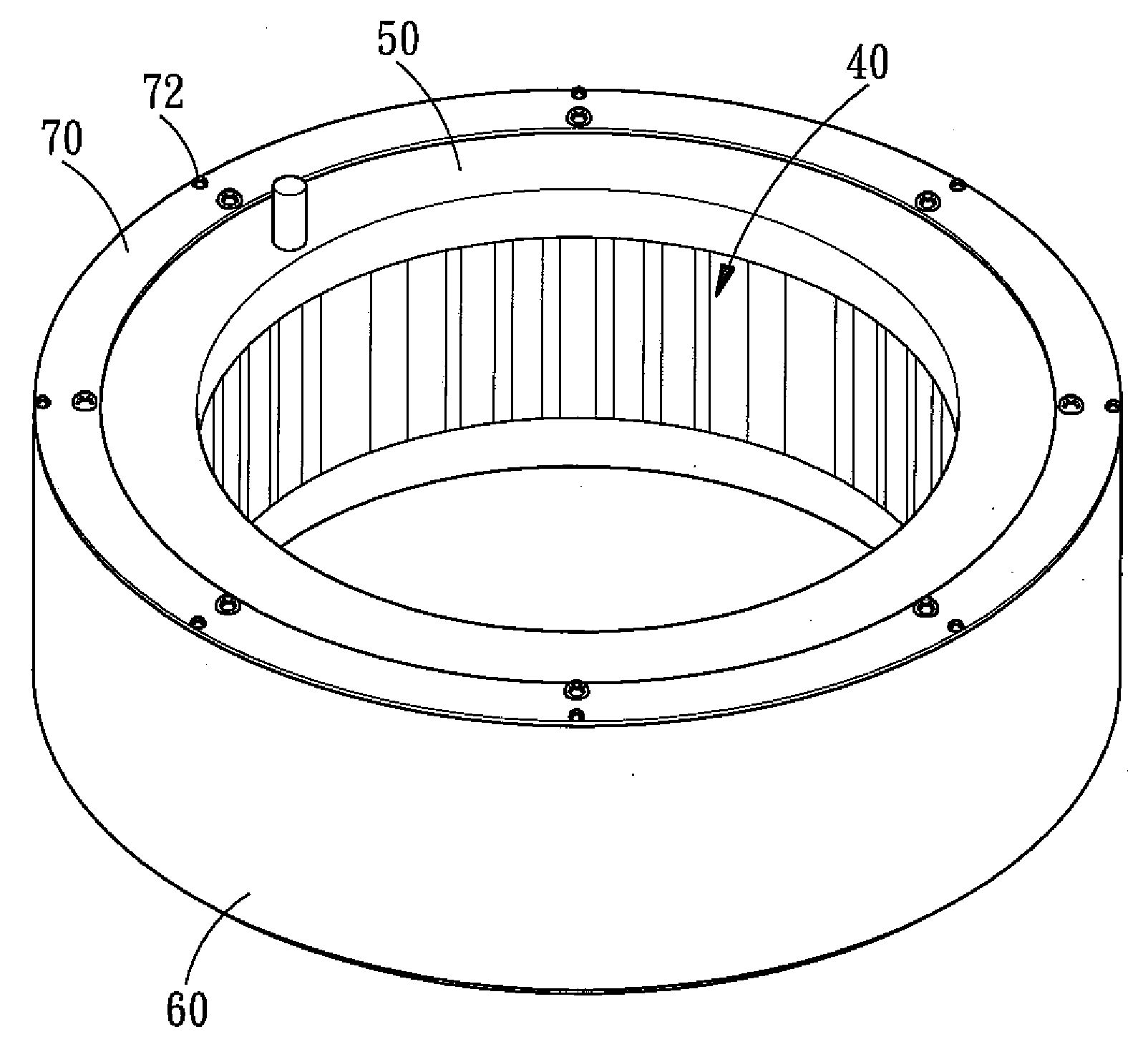

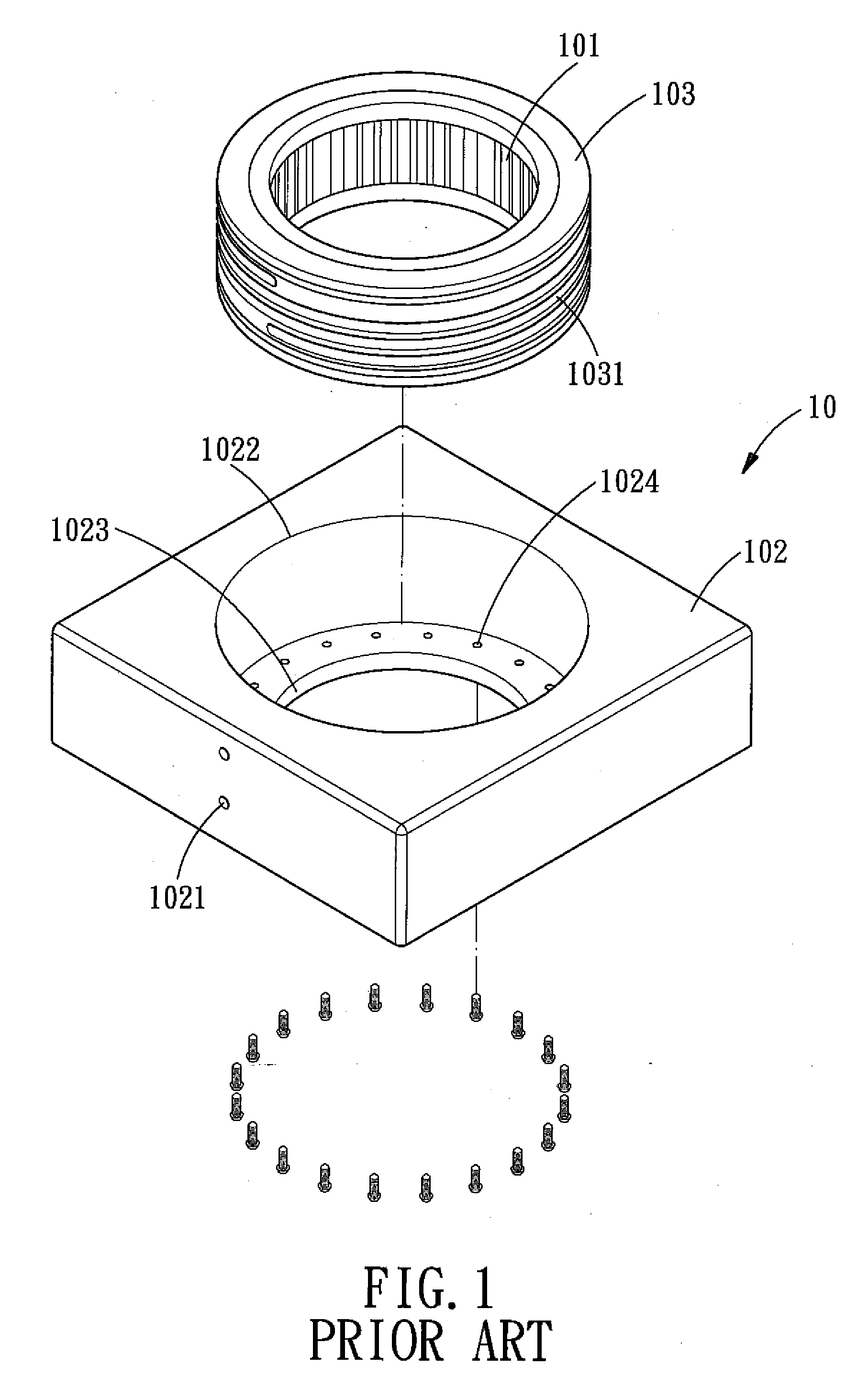

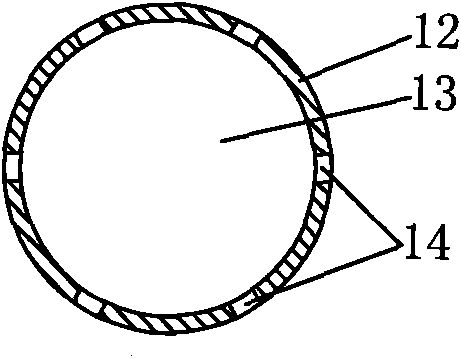

Water Cooled Stator for a Direct Drive Torque Motor

InactiveUS20090079279A1Low costConsumes less materialMagnetic circuit stationary partsCooling/ventillation arrangementTorque motorSilicon

A water cooled stator for a direct drive torque motor comprises a stator base, silicon steel sheets, coils, sealing glue and a water cooled sealing tube. A helical water groove is defined in the outer surface of the stator base. The silicon steel sheets and coils are fixed in the stator base by the sealing glue after solidification. Then, the water cooled sealing tube is directly mounted outside the stator to seal the helical water groove by liquid. By such arrangement, the water cooled sealing tube is used to accomplish simple and independent water cooled sealing, the volume of the products can be effectively reduced, and the water cooled sealing tube can be applied to various tool machines.

Owner:HIWIN MIKROSYST

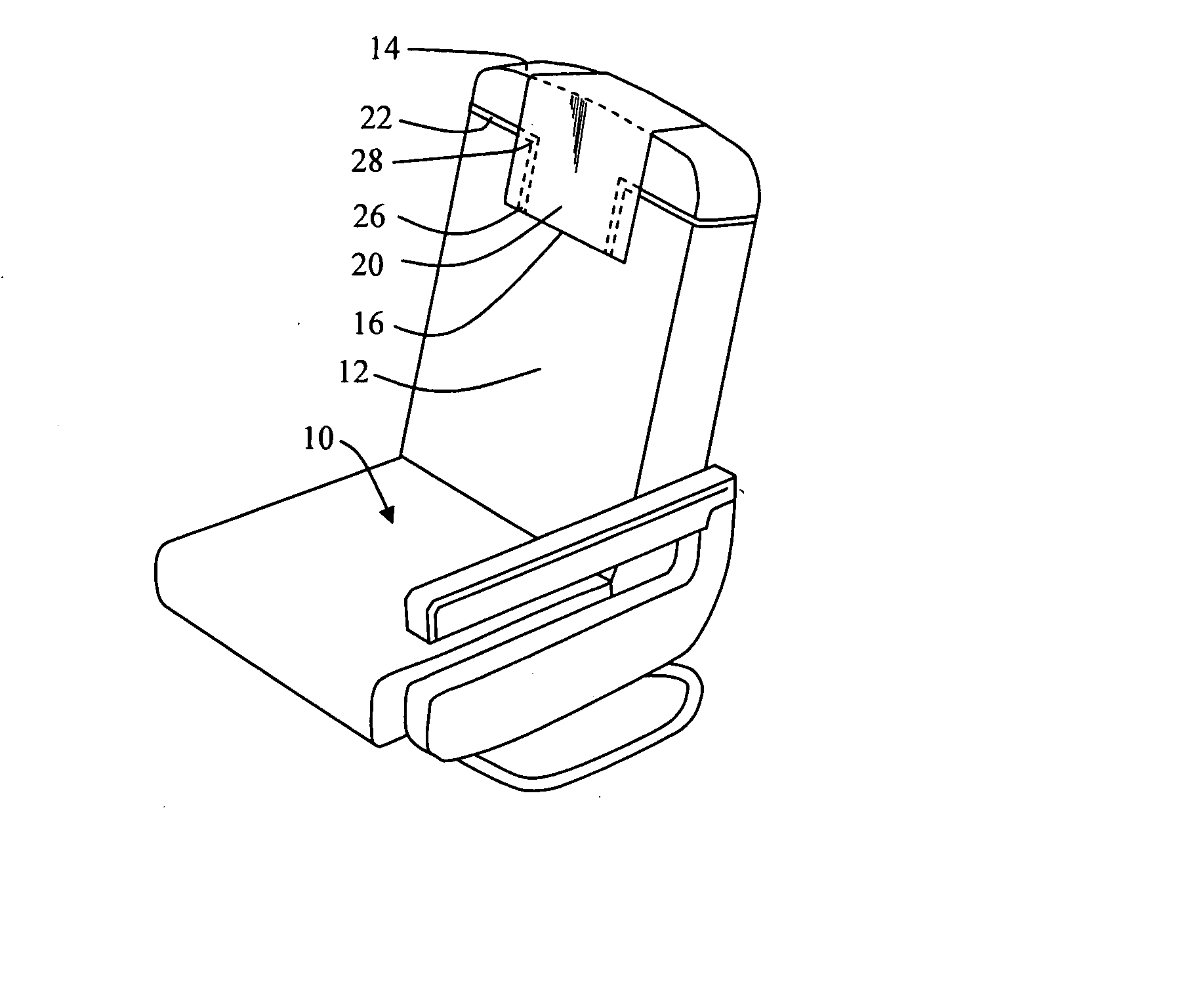

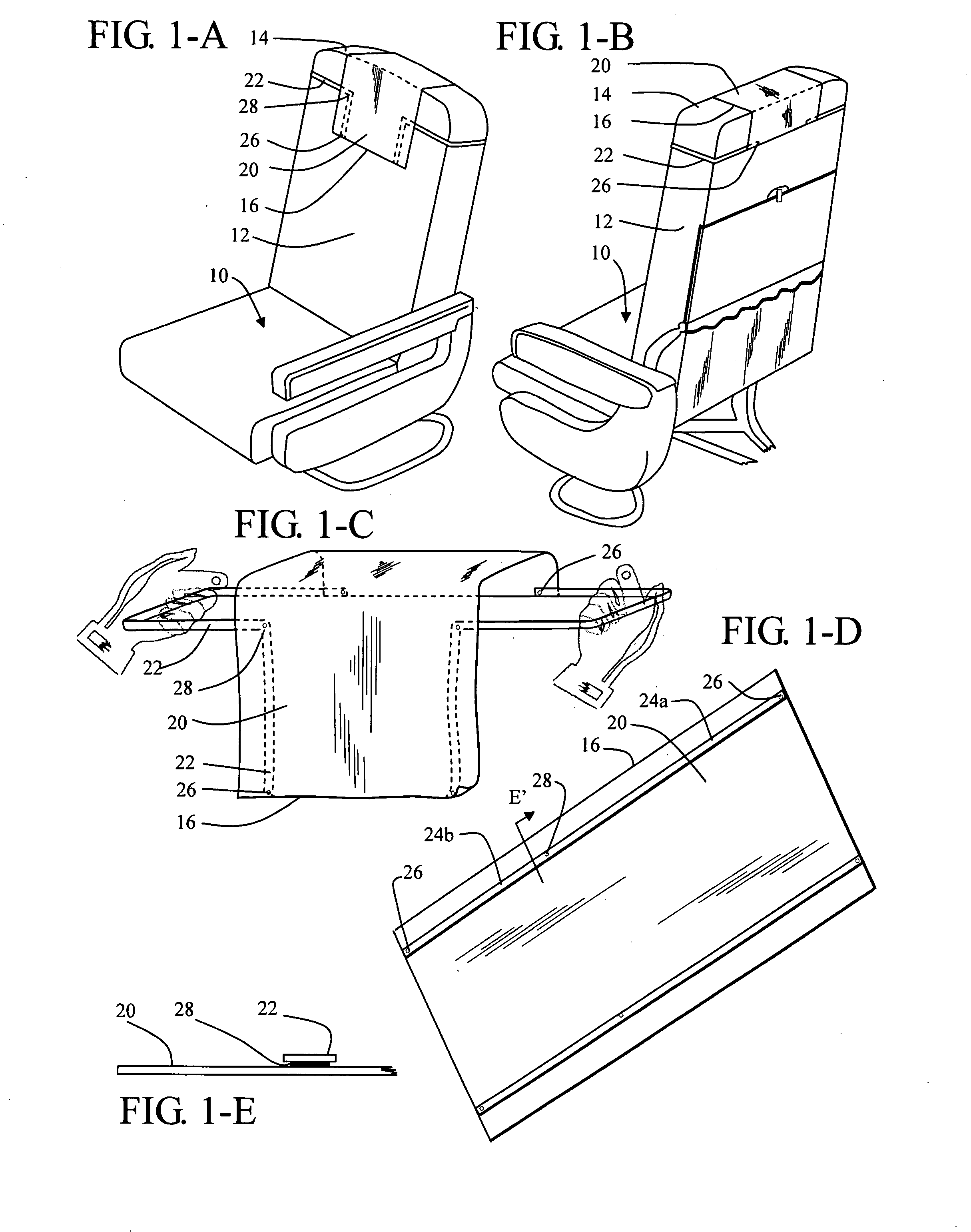

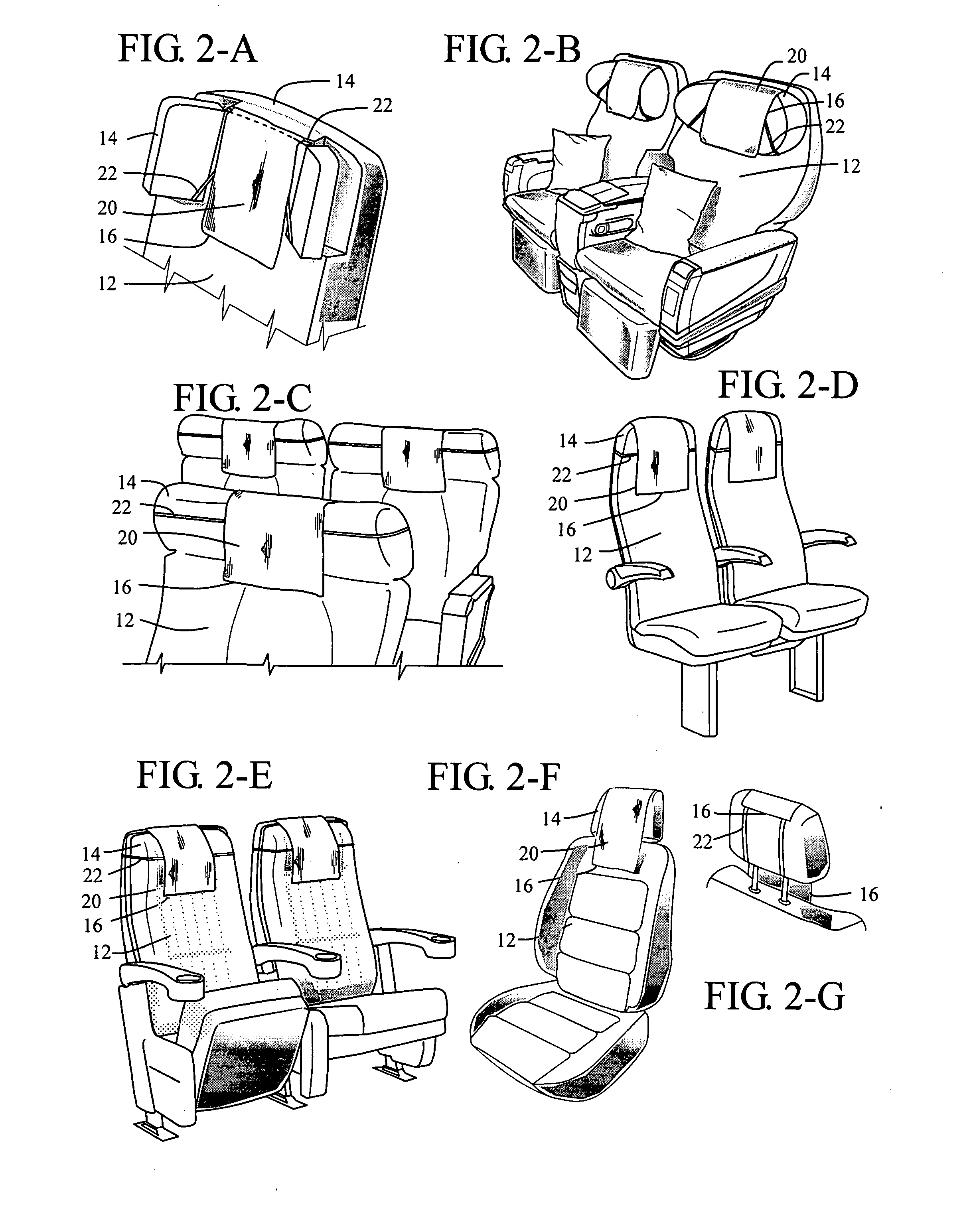

Self-fastening headrest cover

ActiveUS20070257533A1Easy to replaceEffectively availableVehicle seatsOperating chairsEngineeringHeadrest cover

A removable headrest cover for a seat is described having improved features for securing and attaching the cover to a headrest. The improved features include integrated elastic elements that serve to secure the cover to a headrest, eliminating the need for engaging receptacles on the seat. The positioning and placement of attachment points for the elastic provide versatility to the headrest cover that allows it to be used with many different seat configurations. Methods for efficiently manufacturing and packaging the cover are also described.

Owner:RESENDEZ RAUL

Board placement method and system for defective printed circuit board panel having multiple interconnected printed circuit board units

InactiveUS20070087630A1Improve precisionImprove stabilityAutomatic control devicesPrinted circuit aspectsPrinted circuit boardPlacement method

In a board placement method and system, a PCB panel having multiple interconnected PCB units and a vacant space is placed on a work surface of a reference platform. The work surface has an opening corresponding to the vacant space. The reference platform has a micro-adjusting unit, which includes a support seat disposed in the opening and movable along three directions. The support seat is used for placement of a good PCB unit. The current positions of the PCB panel and the good PCB unit are measured so as to calculate a target position of the good PCB unit and an error between the target position and the current position of the good PCB unit. The micro-adjusting unit can drive the support seat to move so as to move the good PCB unit to the target position. The good PCB unit is then fixed in the vacant space.

Owner:KU SHING SAN

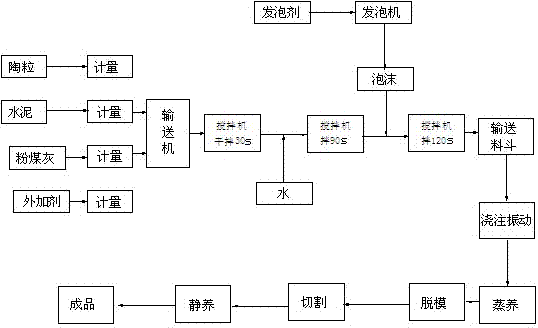

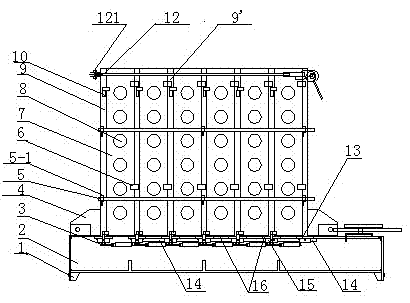

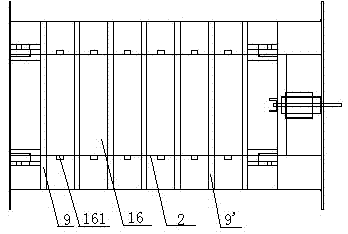

Energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould

ActiveCN102503522ALow water absorptionGood energy saving effectCeramic shaping apparatusCeramicwareCorrosion resistantEarthquake resistant

The invention relates to an energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould. The energy-saving self-heat-insulation ceramsite building block is made of, by weight, 35-50% of ceramsite, 20-29% of cement, 15-30% of coal ash, 0.5-1% of fibers, 2-5% of foaming agent, 0.3-0.5% of water reducing agent, 0.1-0.3% of waterproof agent and 0.2-0.5% of catalyst, wherein the volume of the ceramsite accounts for more than 80% of that of the whole building block. The manufacturing method of the building block includes steps of material selecting, metering, stirring, pouring, vibrating, steaming, tube drawing for demoulding, cutting forming and stacking for rest. The forming mould of the building block can be used for once forming of multiple medium-sized rectangular ceramsite building blocks, and each building block can be conveniently cut into standard small ceramsite building blocks. The energy-saving self-heat-insulation ceramsite building block is high in ceramsite content and has the advantages of light weight, warm retention, heat insulation, sound insulation, sound adsorption, low water adsorption, fire resistance, freezing resistance, quake proofing, corrosion resistance and the like.

Owner:NINGBO PINGHAI BUILDING MATERIALS

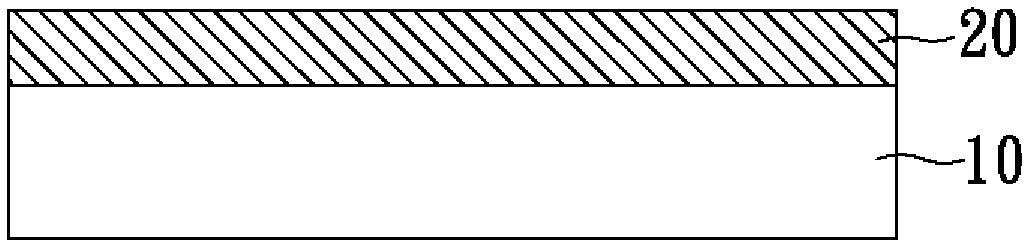

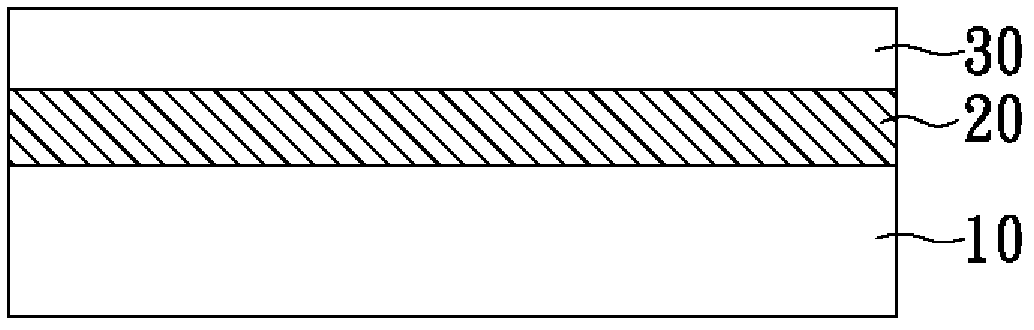

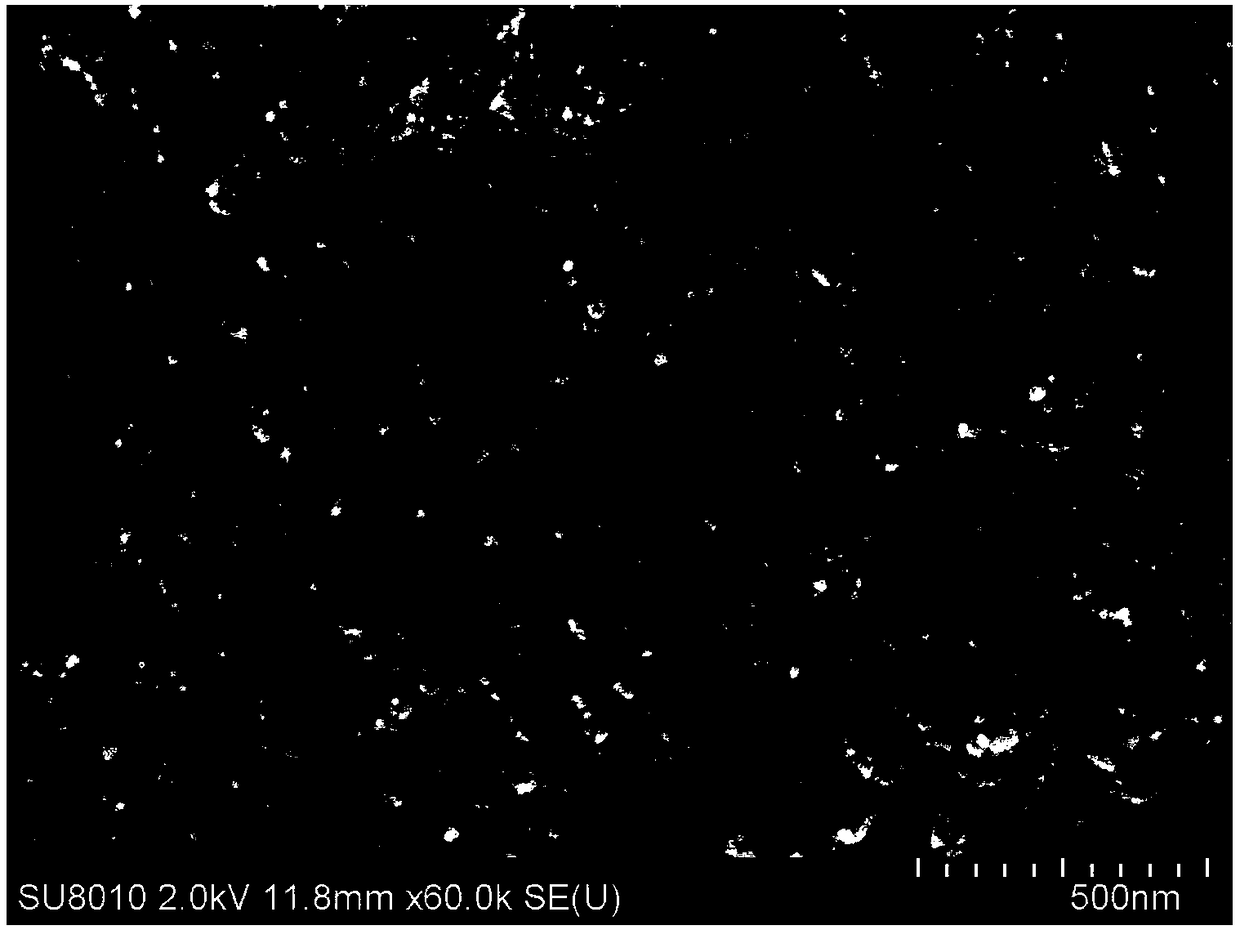

Method for manufacturing graphere layer by laser

InactiveCN103378222ACraft shortRapid mass productionMaterial nanotechnologyGrapheneOrganic solventGraphene

The present invention relates to a method for manufacturing a graphene layer, comprising the following steps: providing a substrate; forming a metal layer on a first side of the substrate; forming a carbon source layer on the metal layer; providing a laser, which irradiates a second side of the substrate and passes through the substrate to form a graphene layer on an interface between the substrate and the metal layer; and providing an organic solvent and an acid solution to remove the carbon source layer and the metal layer respectively.

Owner:阙郁伦

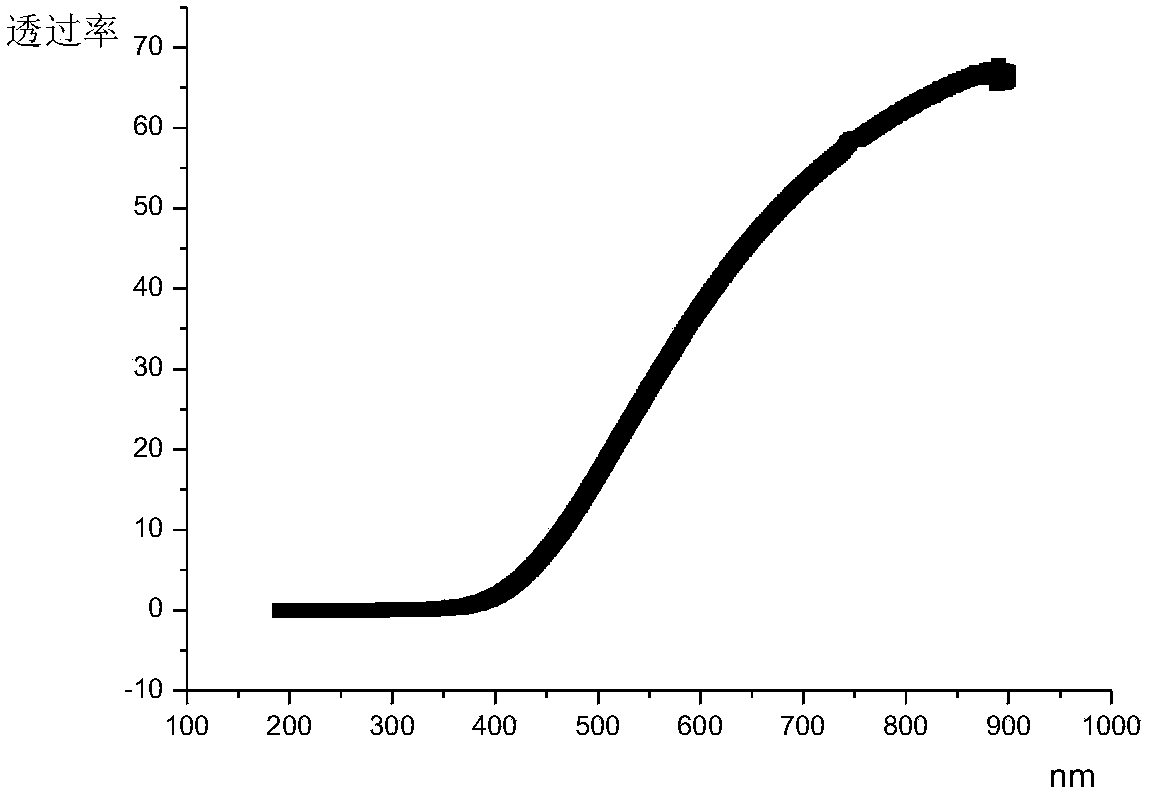

Polysilsesquioxane aerogel and preparation method thereof

The invention relates to a preparation method of a polysilsesquioxane material. The preparation method comprises the following steps that (1) in water and an organic solvent, acid is used for catalyzing a polysilsesquioxane precursor for hydrolysis to form sol; (2) organic alkali is added into a sol system for catalytic polycondensation to form gel; (3) the gel is aged and dried to obtain aerogel.The polysilsesquioxane aerogel has high tolerance degree on water, salt, acid, alkali and the like; high transmittance is realized in the visible light range; high shielding capability is realized onultraviolet light.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Preparation method and application of micro-fluidic chip based on 3D printing technique

InactiveCN104888874ASimple methodReduce manufacturing costLaboratory glasswaresPolyvinyl alcoholRapid processing

The invention provides a preparation method and application of a micro-fluidic chip based on the 3D printing technique. The preparation method comprises the following steps: (1) designing a micro-fluidic pipeline, namely printing filament through a 3D desktop printer, wherein the filament is used as the channel mold plate of the micro-fluidic chip and made of acrylon-bivinyl-styrol copolymer, polylactic resin and vinol; (2) transferring the printed filament into a watch glass and fixing the filament on a substrate, then pouring PDMS colloid, curing, demolding, punching and bonding to prepare the micro-fluidic chip. The invention further relates to the application of the micro-fluidic chip in surface enhanced Raman detection. The preparation method is simple, rapid in processing and very cheap in cost, no complex micro-processing technique such as photo etching and developing is needed and the micro-fluidic chip can be prepared under a general experiment condition; the micro-fluidic chip is convenient to popularize and can be widely applied to the fields of human health, food safety, environment detection and medical diagnosis.

Owner:SHANGHAI JIAO TONG UNIV

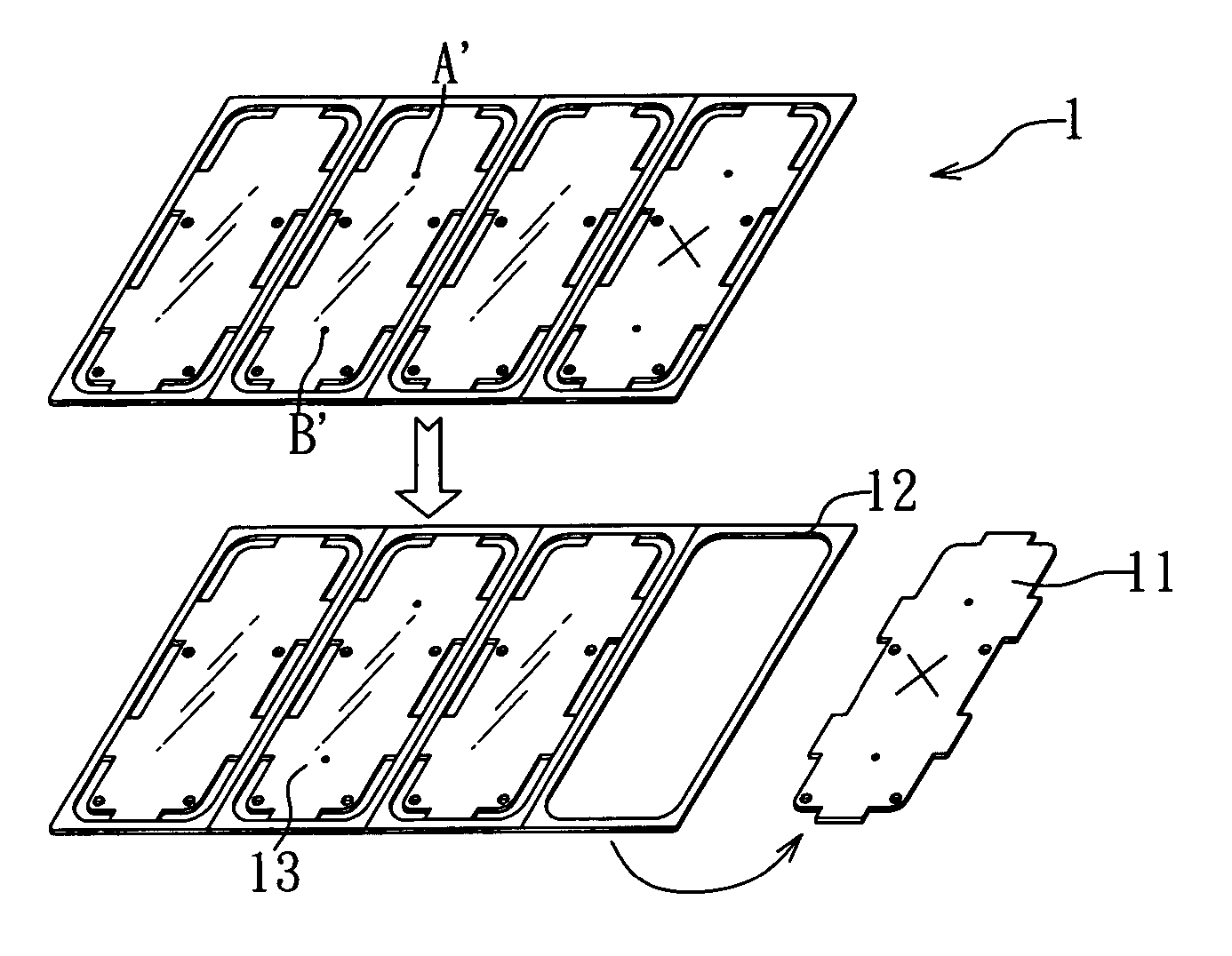

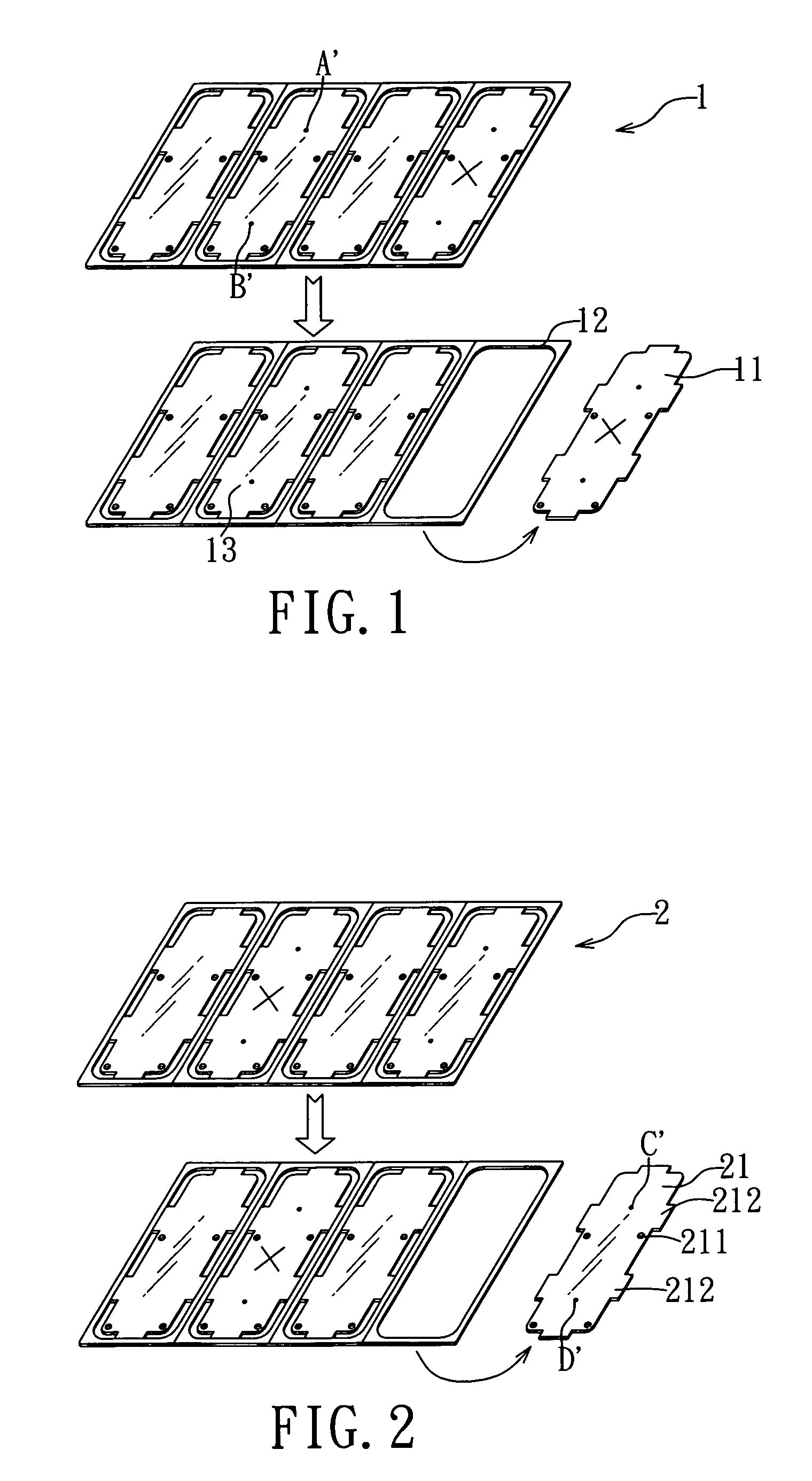

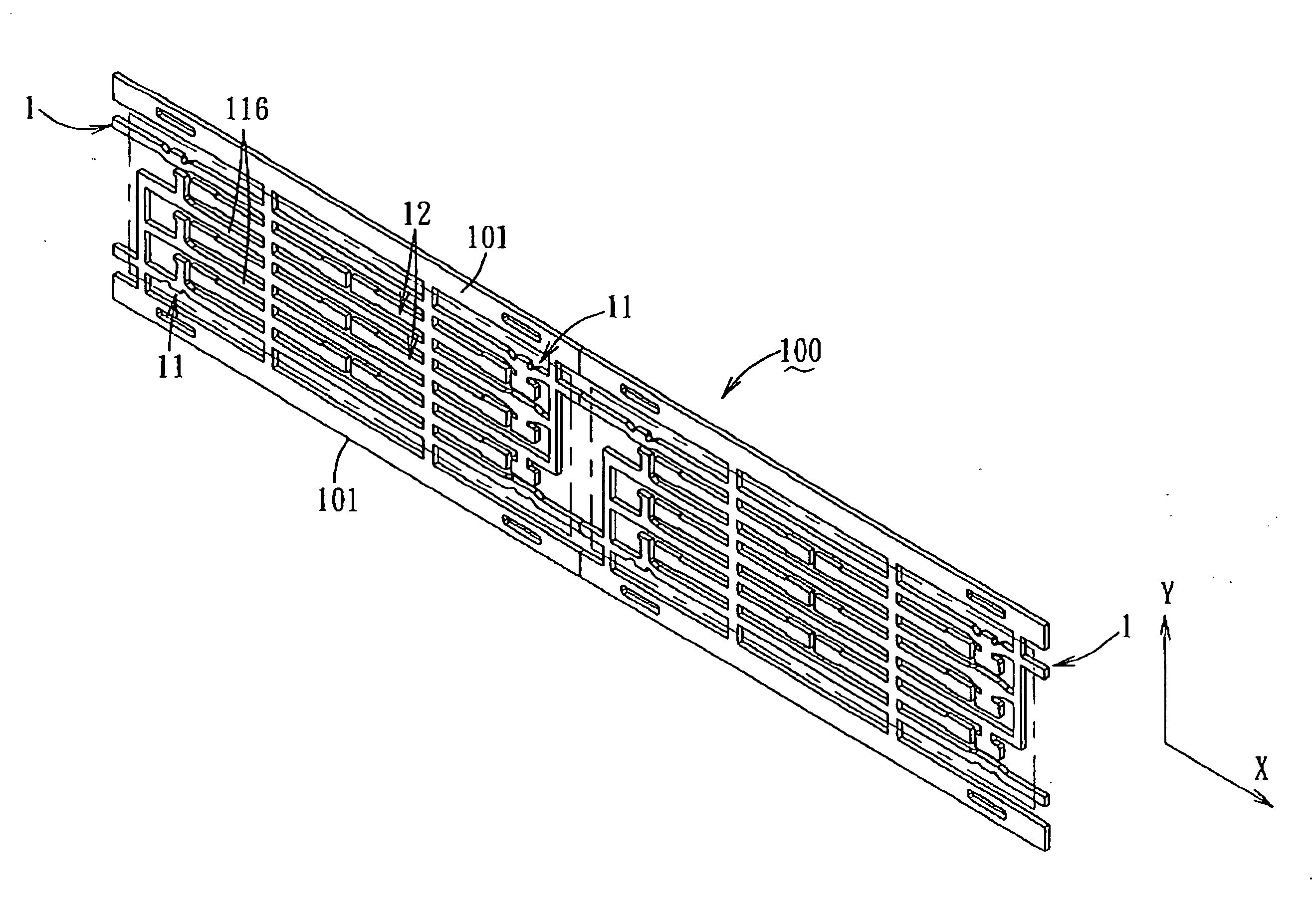

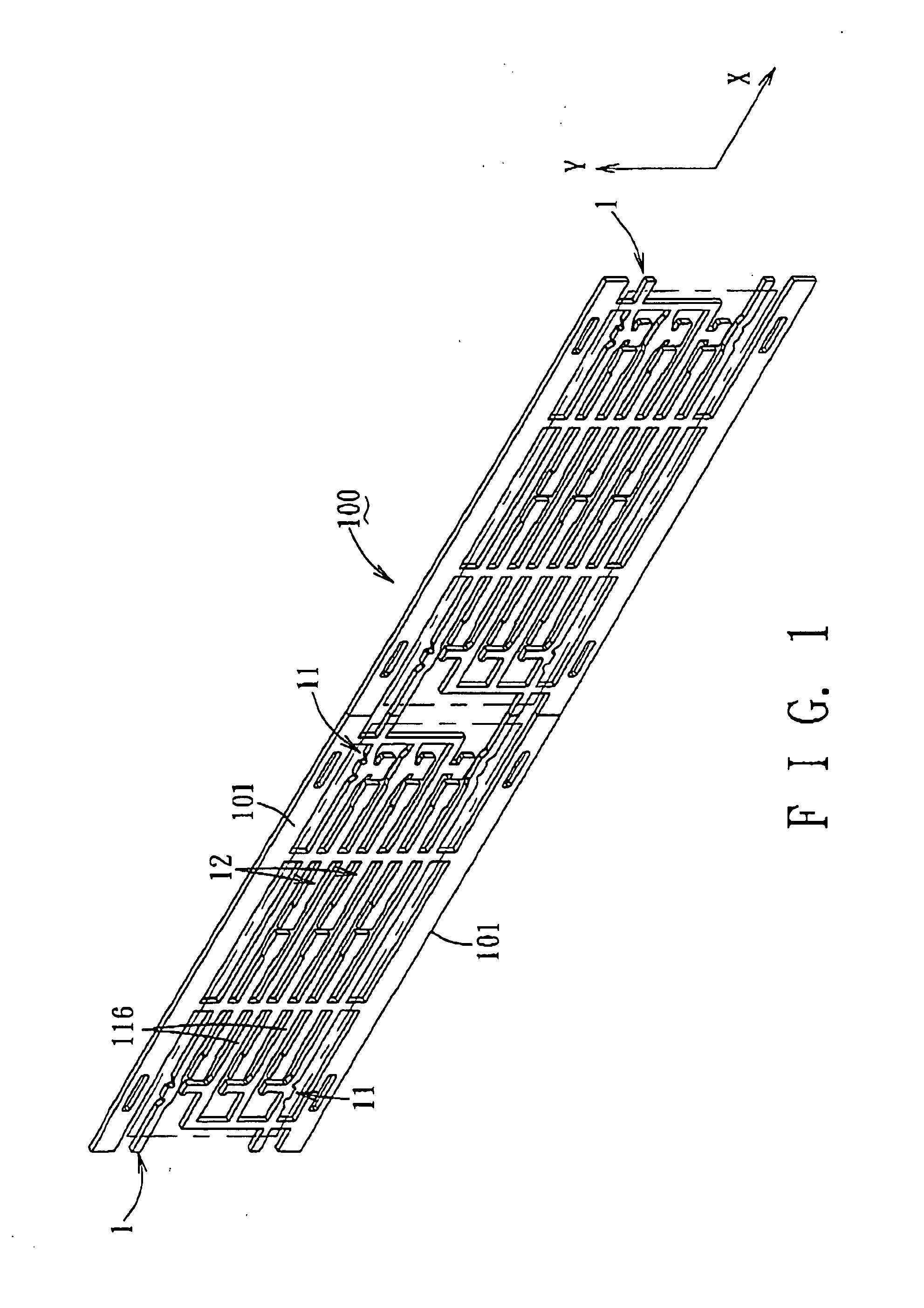

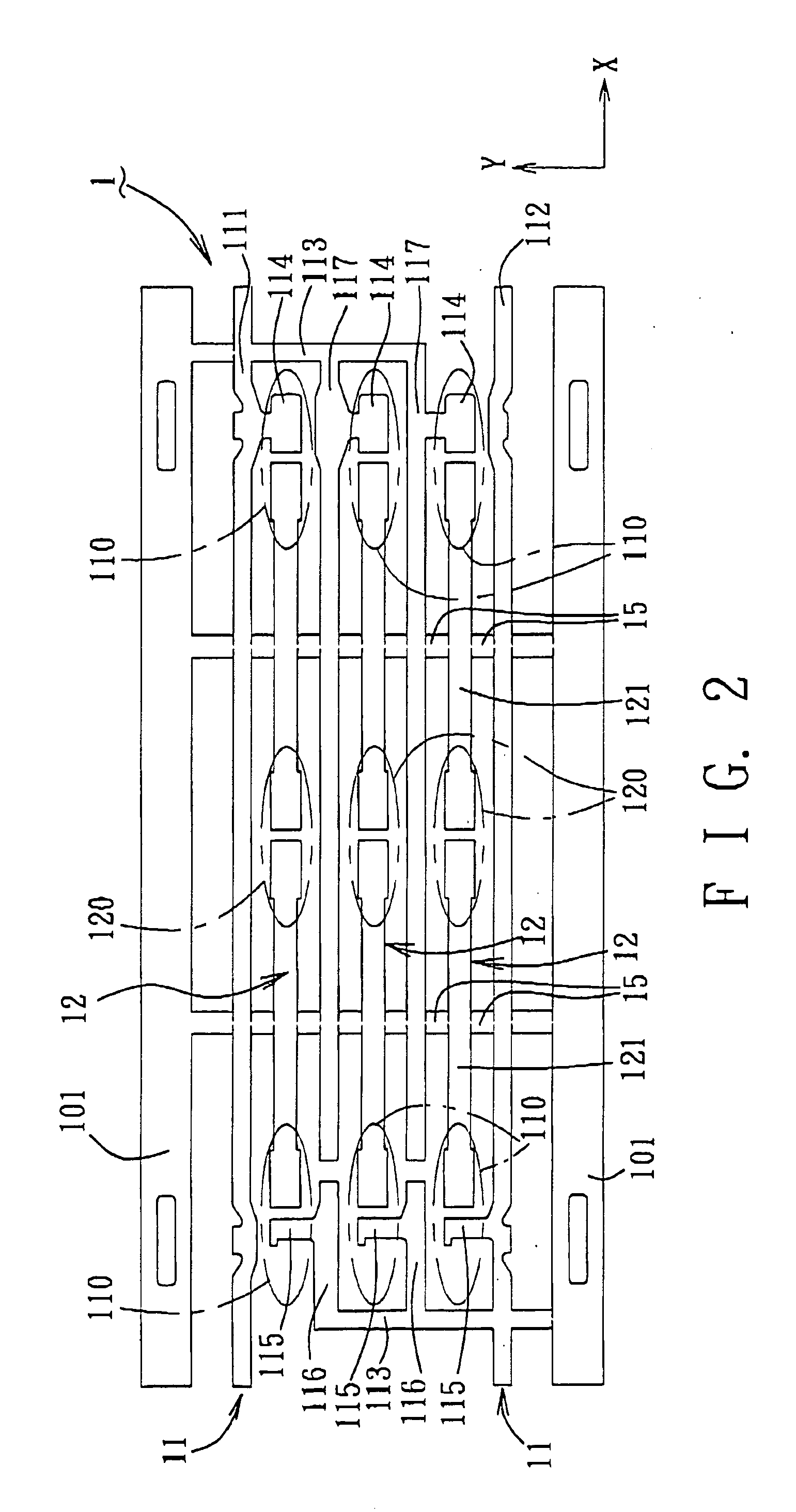

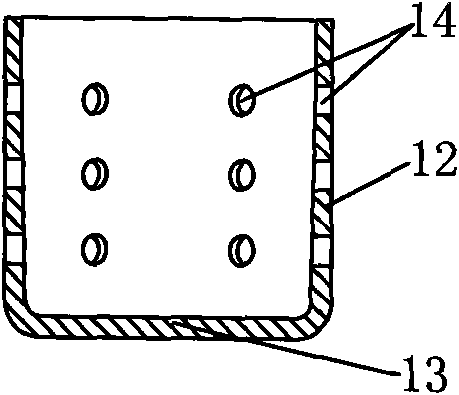

Lead frame assembly, lead frame and insulating housing combination, and led module having the same

ActiveUS20100072509A1Facilitate fast mass productionRapid mass productionSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A unitary lead frame assembly having a plurality of lead frame sets each comprises a first lead frame unit. The first lead frame unit has a pair of first and second frame portions extending along a first direction and spaced apart from each other along a second direction different from the first direction. The lead frame set further comprises at least two second lead frame units disposed between the first and second frame portions and spaced apart from each other along the second direction. Each of the second lead frame units cooperates with the first lead frame unit to define at least one first die-bonding area therebetween.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

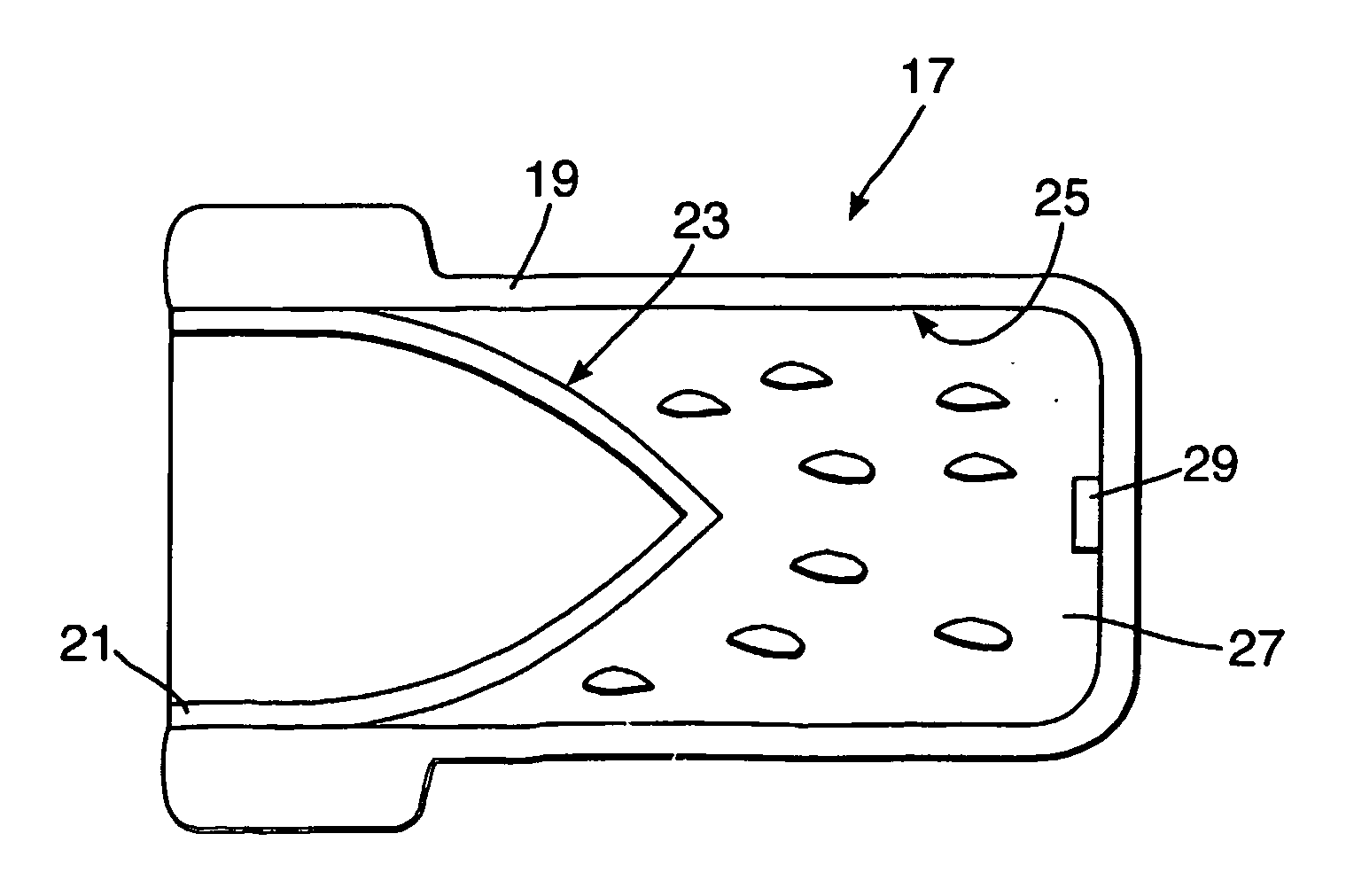

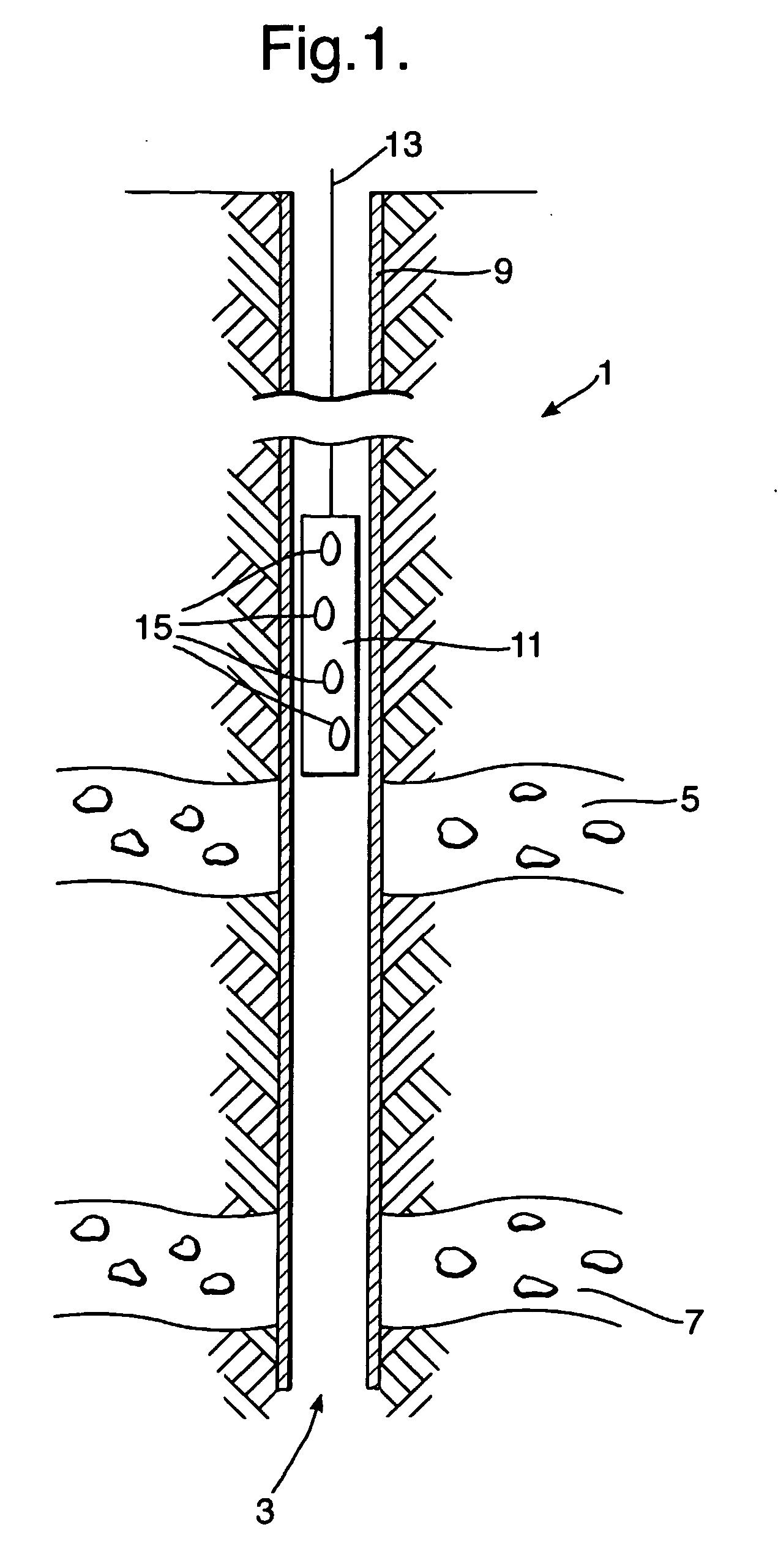

Perforators

ActiveUS20070051267A1Mitigate effectEnhanced recoveryAmmunition projectilesExplosive chargesEngineeringTemperature and pressure

A composite material case (19) and liner (21) is described for use in a perforator (17) for completing wells such as oil, gas and water wells (1). The materials selected are intended to exhibit stability during prolonged periods at the raised temperatures and pressures present in a well (1).

Owner:QINETIQ LTD

Label of radio frequency identification by thermal transfer printing antenna

InactiveUS20070096917A1Rapid mass productionLow costAntenna feed intermediatesBurglar alarm by hand-portable articles removalMetal foilEngineering

A thermal transfer printing antenna RFID label by a thermal transfer printer includes mainly a conductive metal foil, a thermal transfer RFID antenna substratum and a RFID chip. A conductive metal foil is used as a material to thermal transfer the antenna circuits onto the substratum by a thermal transfer printer, forming the antenna substratum, which is then adhered with the RFID chip by a flip chip bonder or a wire bonder. The process can obtain a quick mass production and a lower cost for the label.

Owner:YANG SAN LIEN

Side hole progressive die

InactiveCN101733325AAvoid precision errorsGood quality and stabilityShaping toolsStripping-off devicesHigh volume manufacturingPunching

The invention discloses a side hole progressive die comprising two sets or more than two sets of deep drawing devices and a side punching device. The side punching device is arranged behind the deep drawing device and comprises an upper die, a lower die, an elastic structure, a side punching structure and a discharge structure; the side punching structure and the discharge structure are arranged between the upper die and the lower die; and the elastic structure is positioned in the upper die and acts on between the discharge structure and the upper die. With the adoption of the technical scheme, the side hole progressive die can well finish deep drawing since two sets or more than two sets of the depth-drawing devices are arranged; the side hole progressive die can greatly improve the processing efficiency and make rapid large-batch production to ensure timely supply compared with the traditional processing mode of adopting multidie single procedure as the deep drawing die and the side punching die are combined together; and meanwhile, the labor cost is greatly reduced, and the labor of operators is lightened. In addition, the side hole progressive die avoids the precision error brought by the moving of a workpiece blank between different working positions, thereby having higher processing precision and better quality stability.

Owner:上海定达机电设备有限公司

Leaf vegetable release-controlling fertilizer

InactiveCN101215202APromote growthIncrease plant heightSuperphosphatesAlkali orthophosphate fertiliserSocial benefitsLeafy vegetables

The invention discloses a controlled release fertilizer of leafy vegetable, which is composed of the following components with the following weight proportion, (NH4)2HPO4 taking 14-16, (NH4)2SO4 taking 3-5, NH4Cl taking 13-20, K2SO4 taking 35-40, calcium superphosphate taking 8-15, diatomite taking 7-12 and high molecular polymer taking 20-25. The controlled release fertilizer of leafy vegetable effectively holds the rule of the fertilizer efficiency releasing and the fertilizer requirement of the leafy vegetable and achieves the anastomosis of the releasing peak of the azophoska fertilizer and the peak of leafy vegetable absorbing azophoska, thereby being more beneficial to the absorbability and the utilization of the fertilizer, decreasing fertilizing frequency, saving time and fertilizing amount, having perfect economic benefit and social benefit.

Owner:SHANDONG UNIV

Vertical electric numerical control knife rest

ActiveCN102513556AImprove transmission efficiencyImprove rigidityMetal-working apparatusNumerical controlLocking mechanism

The invention relates to a vertical electric numerical control knife rest, belonging to the field of numerical control knife rest. The numerical control knife rest is provided with a power delivery mechanism, a preliminarily locating mechanism, a precisely locating mechanism and a locking mechanism; a square knife table and a base are arranged up and down; screw sets are arranged in the centers of the base and the square knife table; the screw sets match with the base by a steel-backed bearing; a driving disc is connected with the side of one end of the screw set; a connecting disc is arranged outside the driving disc; a worm gear and a worm drive pair are installed at the side of the other end of the screw set; a movable gear disc is arranged between the inner side of the square knife table and the outer side of the screw set; the movable gear disc matches with the screw sets by a helical structure; and the movable gear disc is connected with the square knife table through the connecting disc. The vertical electric numerical control knife rest is suitable for economical numerical control lathe; and the vertical electric numerical control knife rest is rotated by using a torque motor, pre-located by a preliminarily locating pin, precisely located by a triple gear and locked in a lifting manner by rectangular threads. The knife rest solves the problem that the knife rest in theprior art has poor rigidity, poor waterproof property, low power delivery efficiency, high preliminarily locating fault rate, complex structure and poor processing and assembling process, and the like.

Owner:SHENYANG MASCH TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com