Preparation method and application of micro-fluidic chip based on 3D printing technique

A microfluidic chip and 3D printing technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of high processing technology requirements, complicated preparation process, long preparation cycle, etc., and achieve production The effect of shortening the preparation cycle, low preparation cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to a method for preparing a microfluidic chip based on 3D printing technology, the method comprising the following steps:

[0040] Step 1, using three-dimensional drawing software to design the microfluidic pipeline, the pipeline design is as follows: figure 1 As shown, the microfluidic channel lines are printed by fused deposition 3D, and the diameter range of the lines is 0.5-1mm, and the printed lines and filaments are cut into chip channels;

[0041] Step 2, then transfer to a watch glass, pass a little PDMS colloid, fix it on the substrate, such as figure 2 , pouring PDMS colloid in a surface dish, placing it in an 80-degree oven for 2 hours, curing and demoulding, drilling and bonding, and preparing a microfluidic chip;

[0042] The application of the microfluidic chip prepared above in surface-enhanced Raman detection specifically includes the following steps:

[0043] In the first step, the schematic diagram of the microfluidic chip pr...

Embodiment 2

[0052] This embodiment relates to a method for preparing a microfluidic chip based on 3D printing technology, the method comprising the following steps:

[0053] Step 1: Use 3D drawing software to design microfluidic pipelines, use fused deposition to 3D print microfluidic channel lines, the diameter of the lines ranges from 0.5 to 1mm, and cut the printed lines and filaments into chip channels;

[0054] Step 2, then transfer to a watch glass, pass a little PDMS colloid, fix it on the substrate, pour the PDMS colloid in the watch glass, place in a 60°C oven overnight, cure and demould, punch holes and bond, and prepare a microfluidic chip;

[0055] The application of the microfluidic chip prepared above in surface-enhanced Raman detection specifically includes the following steps:

[0056] In the first step, the monolithic column solution is injected into the microfluidic chip, and a point light source is used to expose the small cuboid area designed by the microfluidic chip t...

Embodiment 3

[0061] This embodiment relates to a method for preparing a microfluidic chip based on 3D printing technology, the method comprising the following steps:

[0062] Step 1: Use 3D drawing software to design microfluidic pipelines, use fused deposition to 3D print microfluidic channel lines, the diameter of the lines ranges from 0.1 to 1mm, and cut the printed lines and filaments into chip channels;

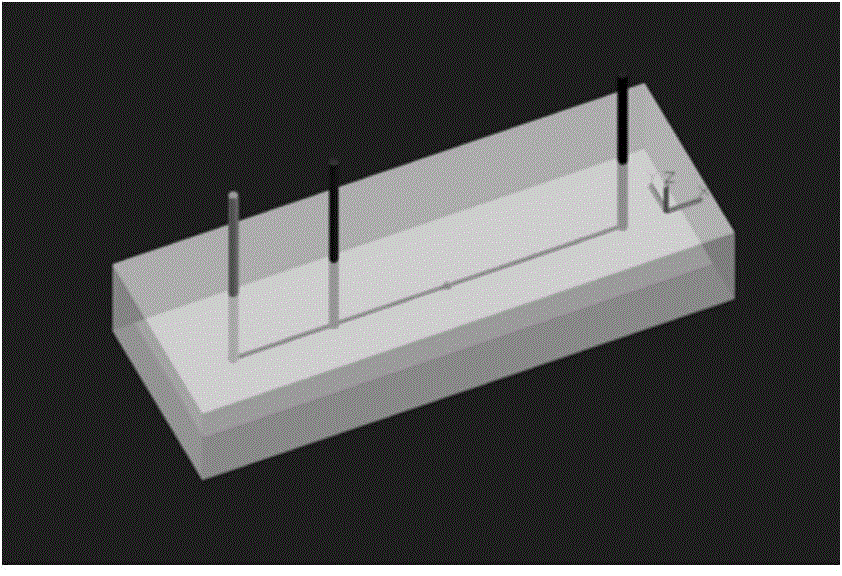

[0063] Step 2, then transfer to a watch glass, apply a small amount of 502 glue on the line, fix it to the substrate, pour PDMS colloid in the watch glass, place it in a 60°C oven for 6 hours, cure and demould, punch holes and bond, and prepare micro Fluidic chip, the schematic diagram of the microfluidic chip prepared based on 3D printing is as follows: image 3 shown.

[0064] The application of the microfluidic chip prepared above includes the following steps:

[0065] In the first step, the monolithic column solution is injected into the microfluidic chip, and a point light sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com