Patents

Literature

118 results about "Sinusoidal grating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

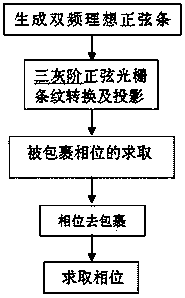

System calibration method for grating projection three-dimensional measurement

InactiveCN103528543AIncrease freedomReduce restrictionsUsing optical meansSinusoidal gratingObject point

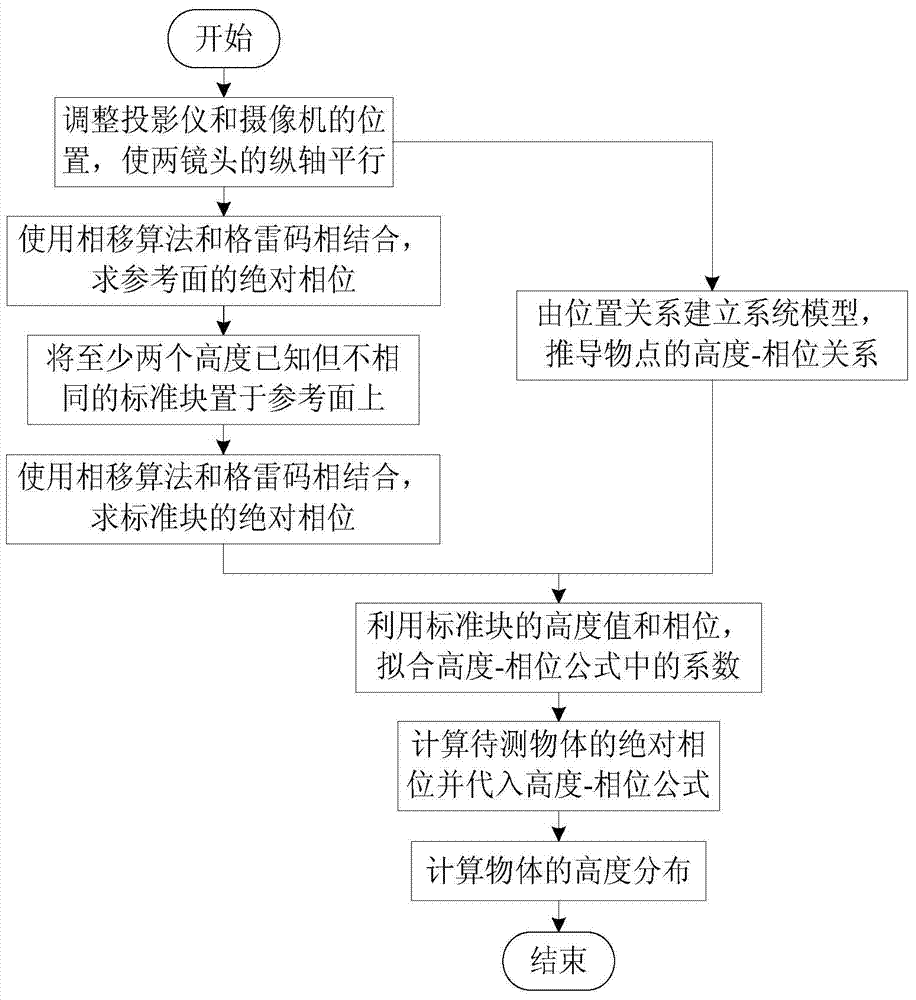

The invention relates to a system calibration method for grating stripe projection-based three-dimensional measurement. A calibration object is a system consisting of a projector and a video camera. The method is implemented by the following steps: (1) adjusting the relative positions of the projector and the video camera, so that the projector is parallel with a lens longitudinal axis of the video camera; (2) calculating the absolute phase position of a reference plane by combining a sinusoidal grating phase-shifting algorithm and a Gray code; (3) placing at least two standard blocks, of which the heights are known and different, on the reference plane and calculating the absolute phase position distribution; (4) calibrating a three-dimensional measuring system: establishing projection and imaging models, deducing an object point height-phase position relational expression of an object to be measured, and fitting the coefficients of the height-phase position relational expression by utilizing the standard blocks with known heights and the absolute phase position distribution thereof and through a least square method; (5) calculating the absolute phase position value of the object to be measured and obtaining the height distribution from a calibrated expression so as to realize height measurement of the object. The method has the advantages of high operability and high measuring precision.

Owner:SOUTHEAST UNIV

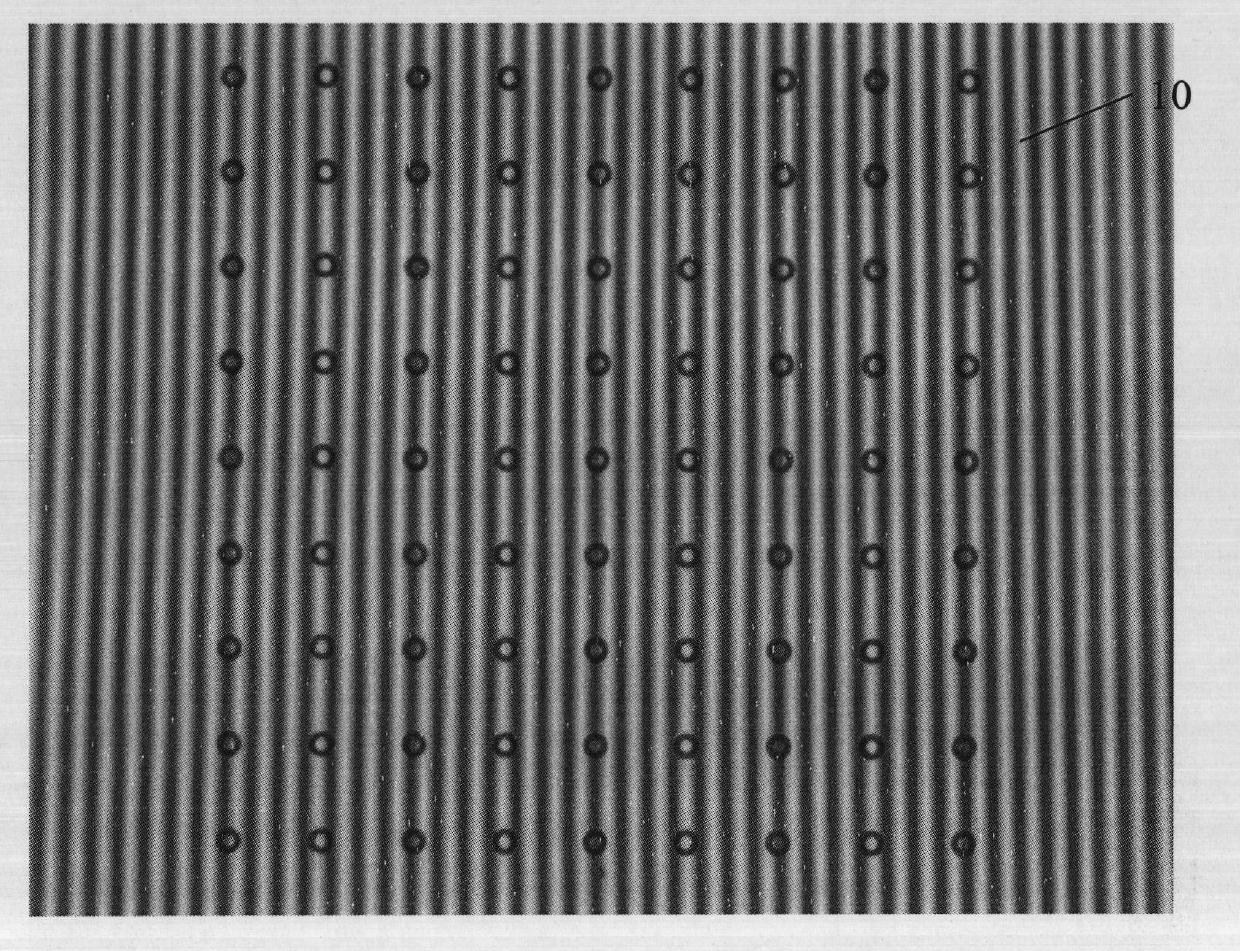

Method for calibrating three-dimensional imaging system

InactiveCN101949693AEasy CalibrationEasy Calibration TasksUsing optical meansSinusoidal gratingDiffuse reflection

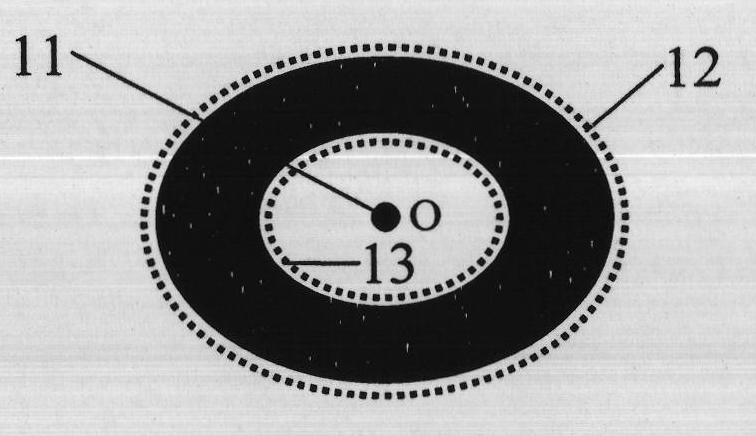

The invention discloses a method for calibrating a three-dimensional imaging system, which comprises the following steps of: 1, designing a calibration flat plate to be white and have a diffuse reflection surface and designing black annular identifiers in a square matrix arrangement mode on the calibration flat plate simultaneously, wherein the center distance between adjacent identifiers is equal; 2, placing the calibration flat plate at different positions in a measurement field, projecting non-uniform sinusoidal grating stripes with the optimal number of stripes at each placement position onto the surface of the calibration flat plate, and acquiring and calculating the absolute phase of each white pixel point inside the black annular identifiers; 3, extracting the central point position of each identifier from a corresponding absolute phase diagram to solve the relative depths of the identifiers when the calibration flat plate is at each placement position; 4, establishing a high-order polynomial (A) to express the relationship between the absolute phases and the relative depths; and 5, converting the absolute phases into actual depth data by using the calibrated polynomial coefficients so as to finish the calibration of the three-dimensional imaging system.

Owner:众趣(北京)科技有限公司

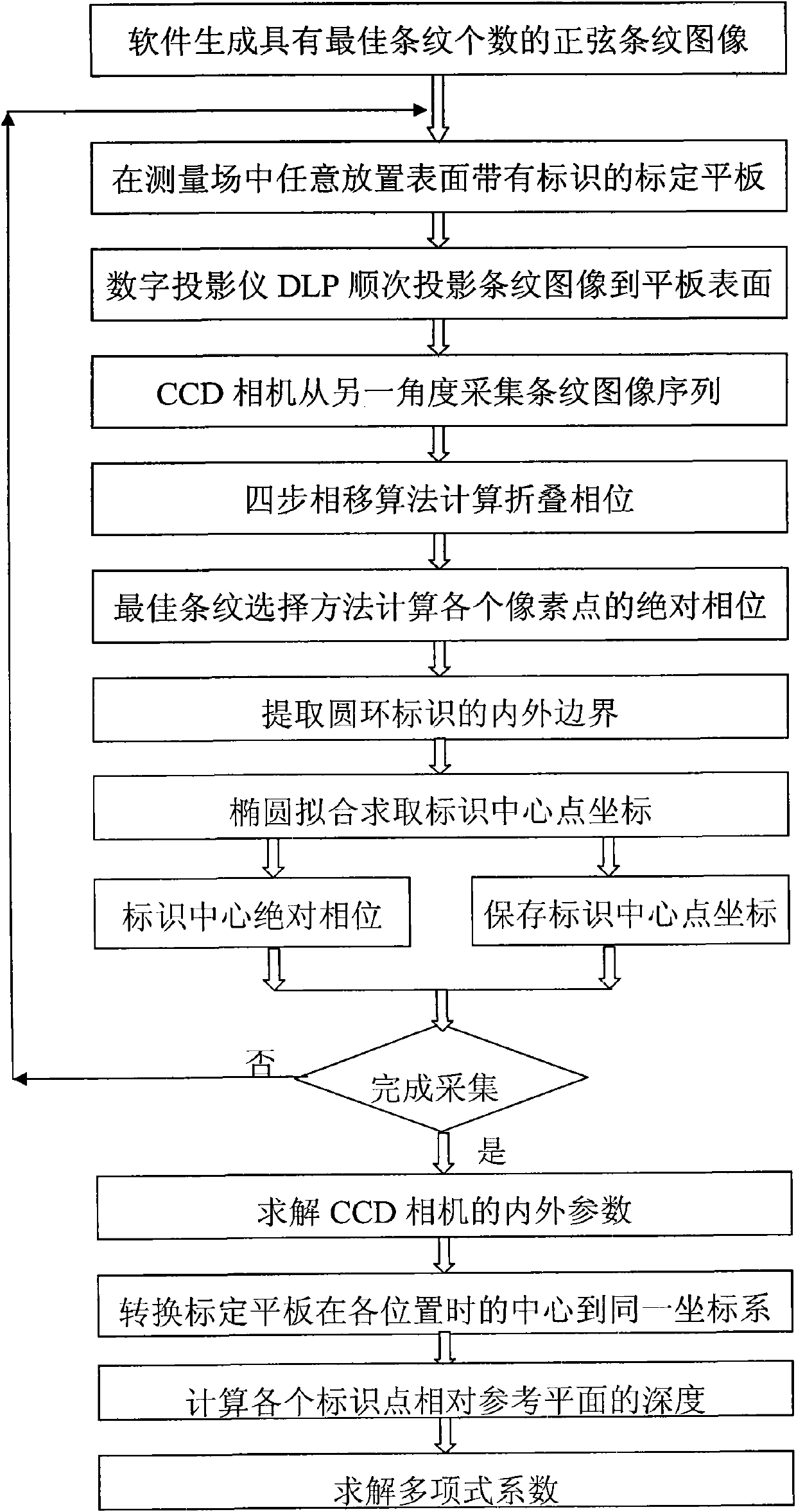

Time phase unwrapping method based on double frequency three-gray-scale sinusoidal grating fringe projection

InactiveCN103759673ASolve the problem of unpackingGuaranteed measurement accuracyUsing optical meansSinusoidal gratingWavelength

The invention discloses a time phase unwrapping method based on double frequency three-gray-scale sinusoidal grating fringe projection. The method comprises the steps that two sets and five ideal double-frequency sinusoidal grating fringes are generated by utilizing a computer, then three-gray-scale sinusoidal grating fringes corresponding to the ideal double-frequency sinusoidal grating fringes are generated by adopting the three-gray-scale space pulse width modulation technology, under condition that that a projector keeps the defocusing state, the five three-gray-scale sinusoidal grating fringes are projected to the surface of an object to be measured, two sets of wrapped phase images are solved, wherein the five double-frequency fringes comprise the two sets of wrapped phase images, the fringe order corresponding to the wrapped phase is solved, and unwrapping of the wrapped phase is achieved. The time phase unwrapping method based on the double frequency three-gray-scale sinusoidal grating fringe projection improves measurement precision and measurement speed.

Owner:NANJING UNIV OF SCI & TECH

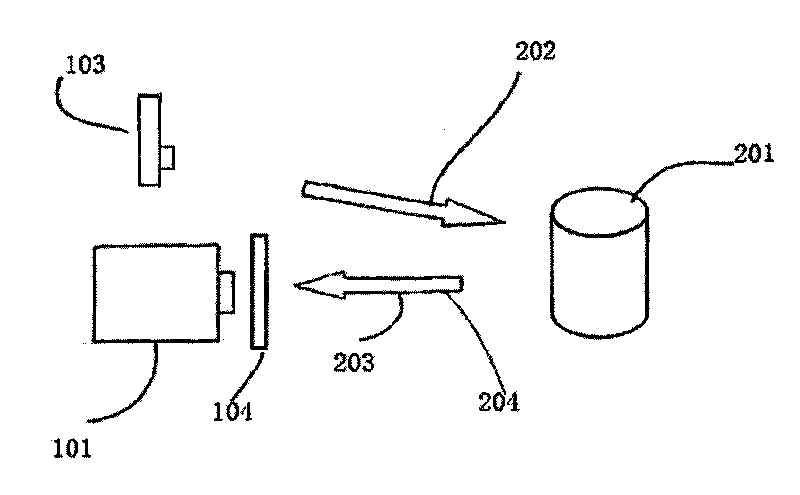

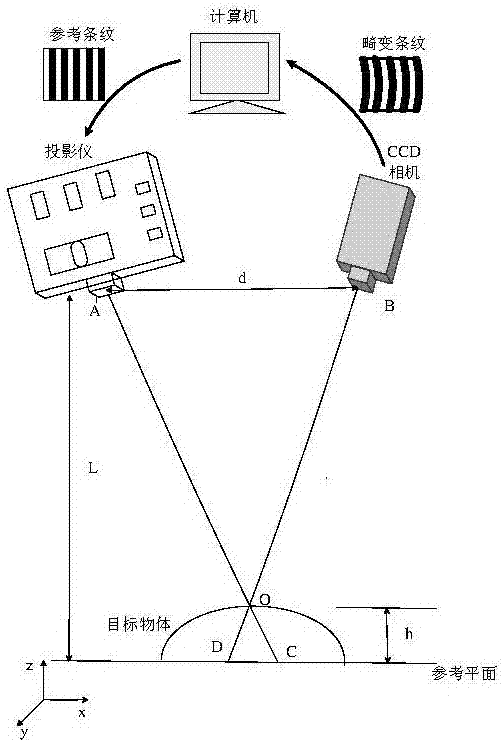

Structured light based three-dimensional reconstruction system and structured light based three-dimensional reconstruction method

InactiveCN106289109AAccurate 3D reconstructionRapid mass productionUsing optical meansSinusoidal gratingReconstruction method

The invention discloses a structured light based three-dimensional reconstruction system and a structured light based three-dimensional reconstruction method. The method includes: projecting a sinusoidal grating image towards a detected object through a projector, acquiring a deformed grating image through a camera, and performing data processing through a computer to obtain morphology of the detected object and generate a three-dimensional model. The structured light based three-dimensional reconstruction system and the structured light based three-dimensional reconstruction method have advantages of high precision, low cost, easiness in implementation and the like, functions of detected object scanning and model recovery are achieved, precision three-dimensional reconstruction can be realized, and quick batch production is realized as well.

Owner:CHANGAN UNIV

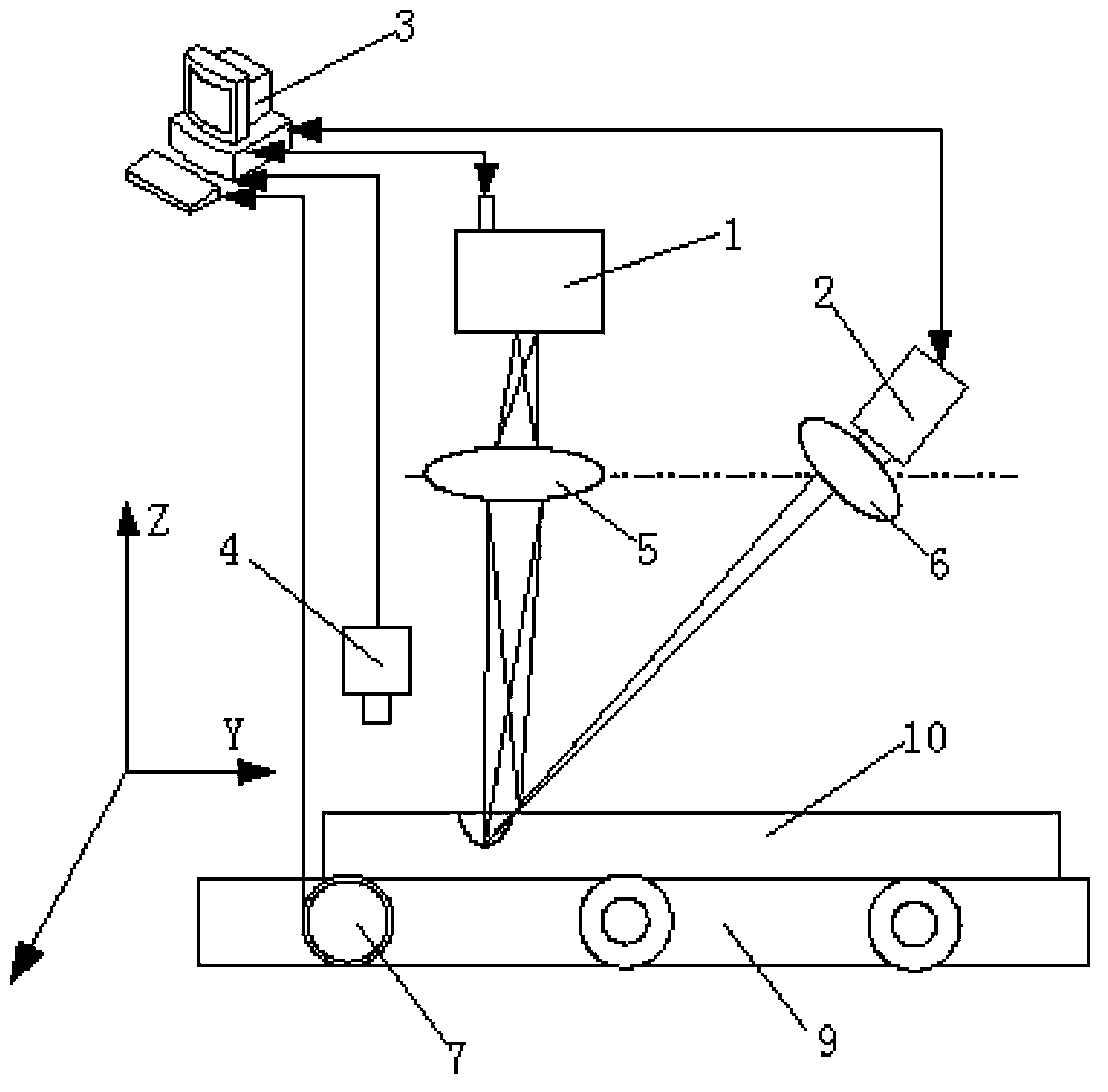

Continuous-scanning structured light three-dimensional surface shape perpendicular measuring method

ActiveCN104061879AHigh precisionFast vertical measurementUsing optical meansContinuous scanningSinusoidal grating

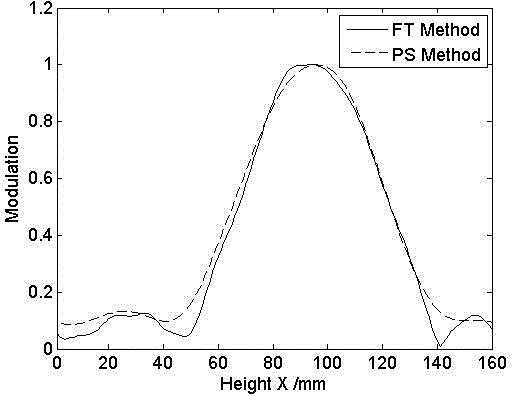

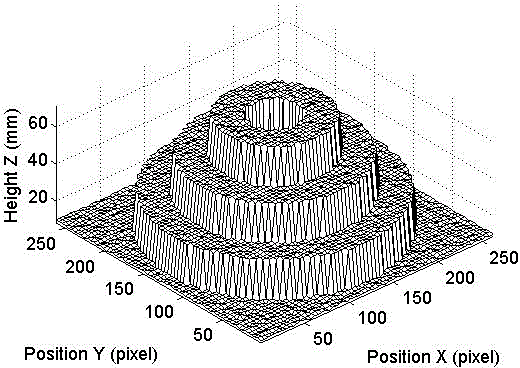

The invention provides a structured light three-dimensional surface shape perpendicular measuring method using a continuous scanning mode. When a measured objected is continuously scanned by an image surface of a structured light projector in the perpendicular direction, N frames (N>=3) N-step phase shift sinusoidal gratings are sequentially and cyclically imaged on the measured objected, a CCD camera synchronously obtains sinusoidal grating images subjected to object height modulation through a semi-transparent semi-reflective mirror in the same direction. Fourier transformation processing is conducted on the collected image set pixel by pixel along the time axis or the N-step phase shift algorithm is applied to continuous N frames (N>=3) phase shift sinusoidal grating images, so that distribution of modulation degrees of the sinusoidal grating images on the surface of the object is obtained. A three-dimensional surface shape of the object is rebuilt through a corresponding relation, which is obtained in advance through calibration, between the modulation degrees and the height. The continuous-scanning structured light three-dimensional surface shape perpendicular measuring method has the advantages of perpendicular measurement and three-dimensional surface shape high-precision measurement.

Owner:SICHUAN UNIV

Thin strip continuous casting billet surface defect sinusoidal grating phase shifting detection device and method

InactiveCN103383360ASuppress interferenceEnable digital assessmentOptically investigating flaws/contaminationUsing optical meansSinusoidal gratingGray level

The invention relates to a thin strip continuous casting billet surface defect sinusoidal grating phase shifting detection device and method. Sinusoidal grating projection and a spatial phase shifting algorithm are combined, strip steel surface defects are detected by combining defect profile measurement and height measurement, grating image gray scale distribution is directly converted to phase distribution, interference of oxide scales, water films and surface high temperature is effectively restrained, reliable and fast recognizing and positioning of surface defects of moving thin strip continuous casting billets in the high temperature state are achieved, three-dimensional shapes of the casting billet surface defects can be visually displayed, digitized assessment of the surface quality of the moving casting billets is achieved, and detection is stable, accurate and high in reliability. In addition, the thin strip continuous casting billet surface defect sinusoidal grating phase shifting detection device and method have an important meaning for improving the thin strip continuous casting billet surface defect detection automation degree, reducing production cost and improving production efficiency.

Owner:CHONGQING UNIV OF TECH

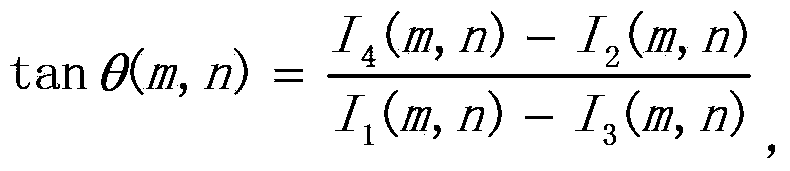

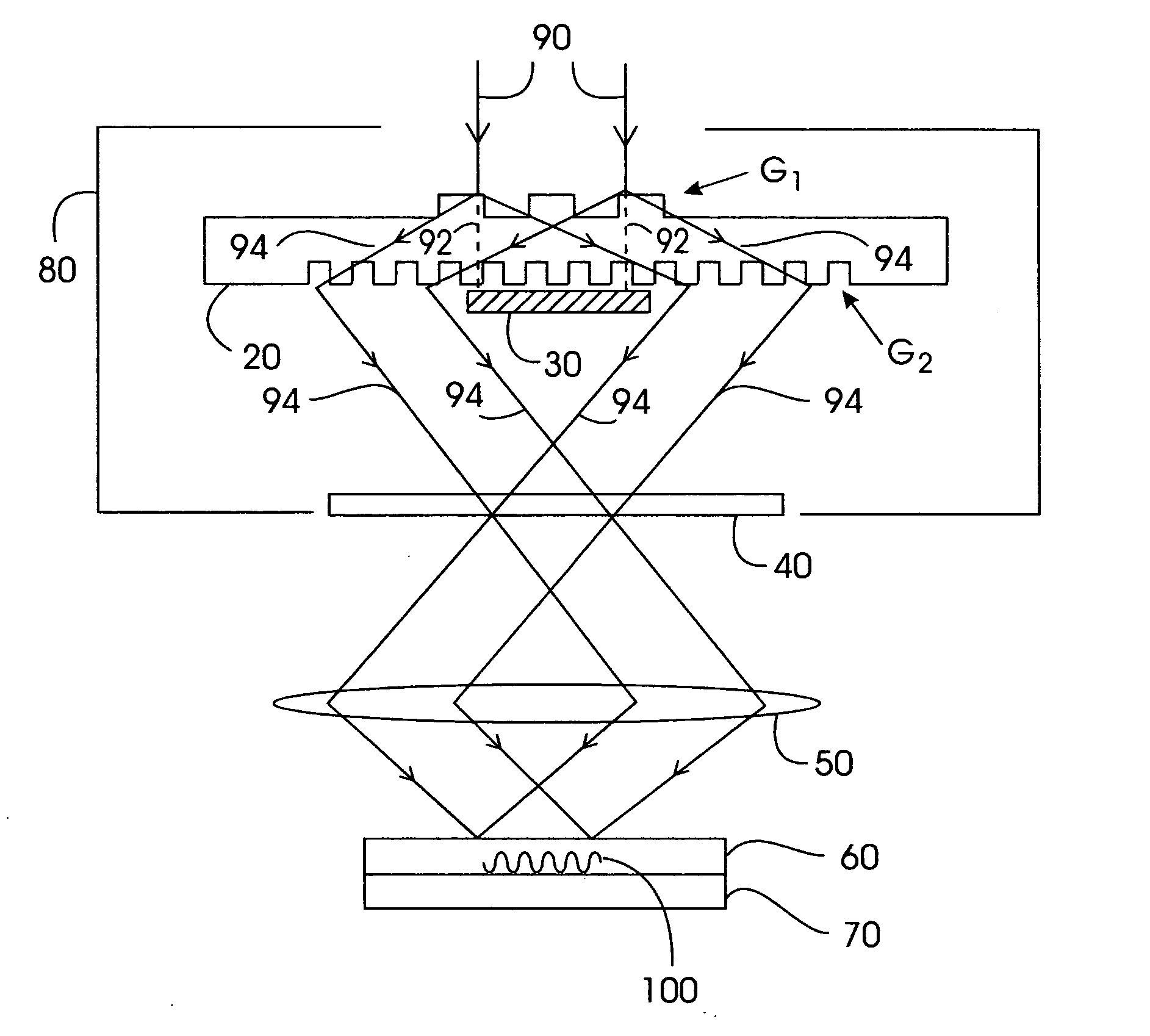

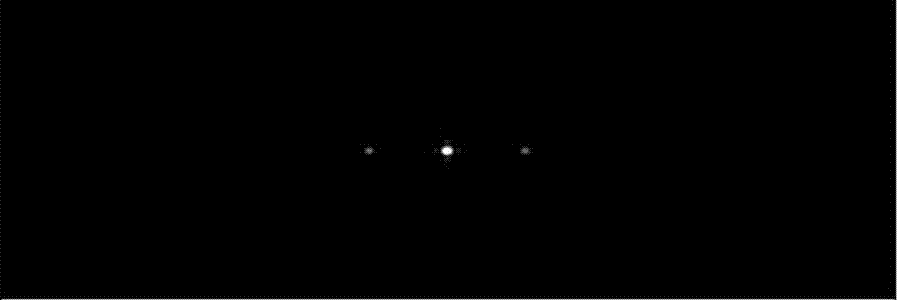

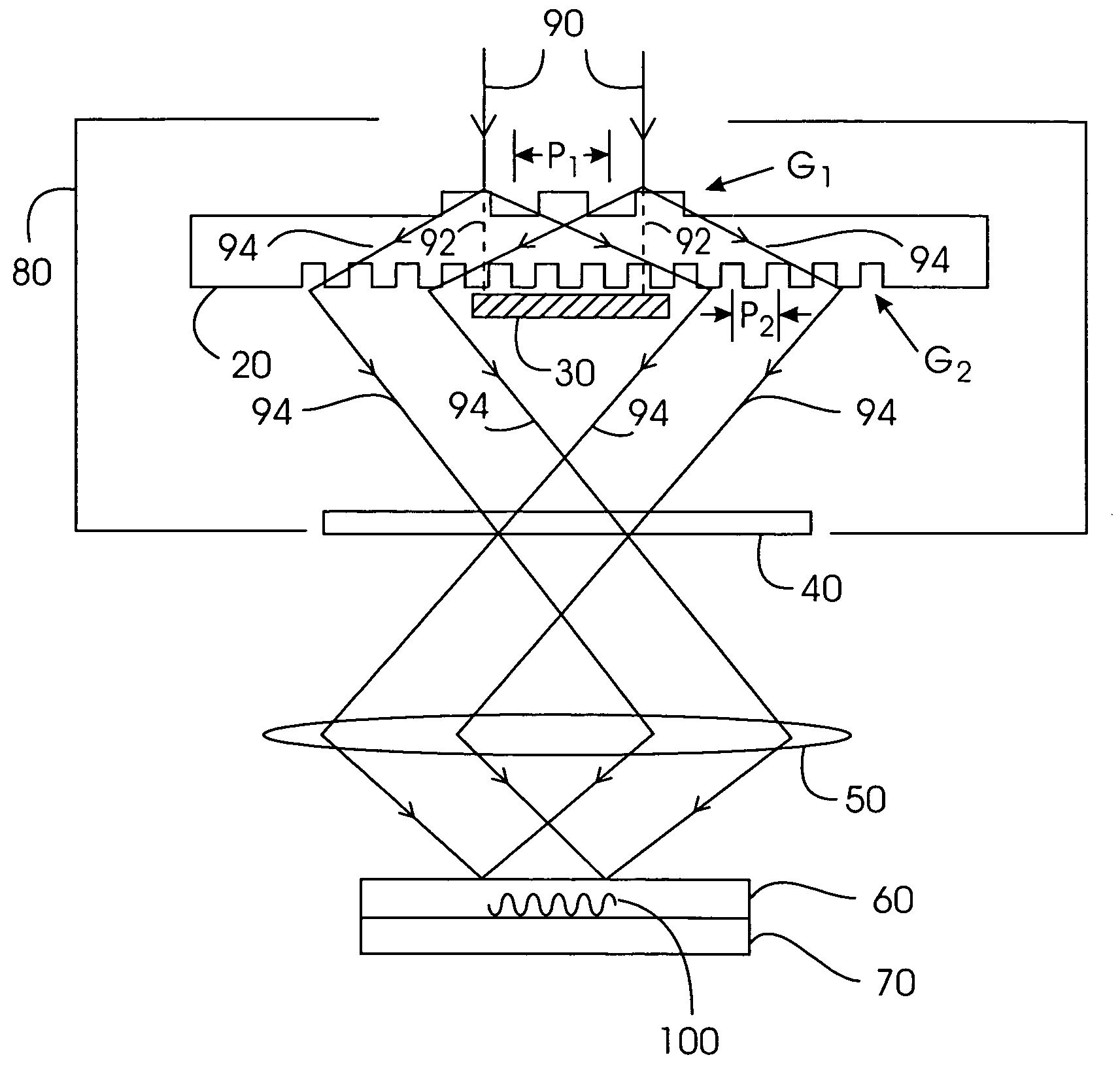

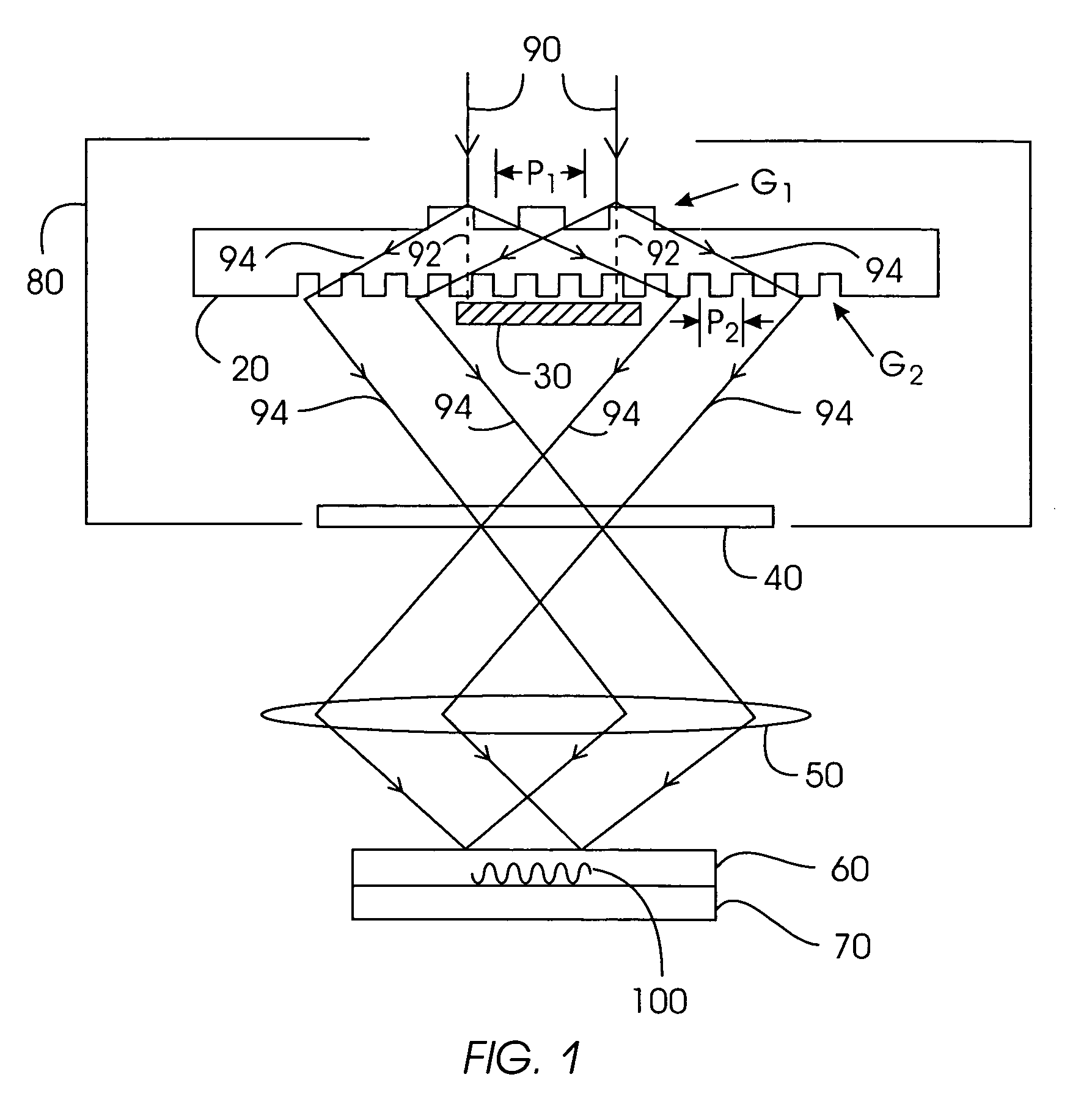

Apparatus for characterization of photoresist resolution, and method of use

InactiveUS20050168717A1Effective characterizationFacilitate automated evaluationRadiation applicationsUsing optical meansResistSinusoidal grating

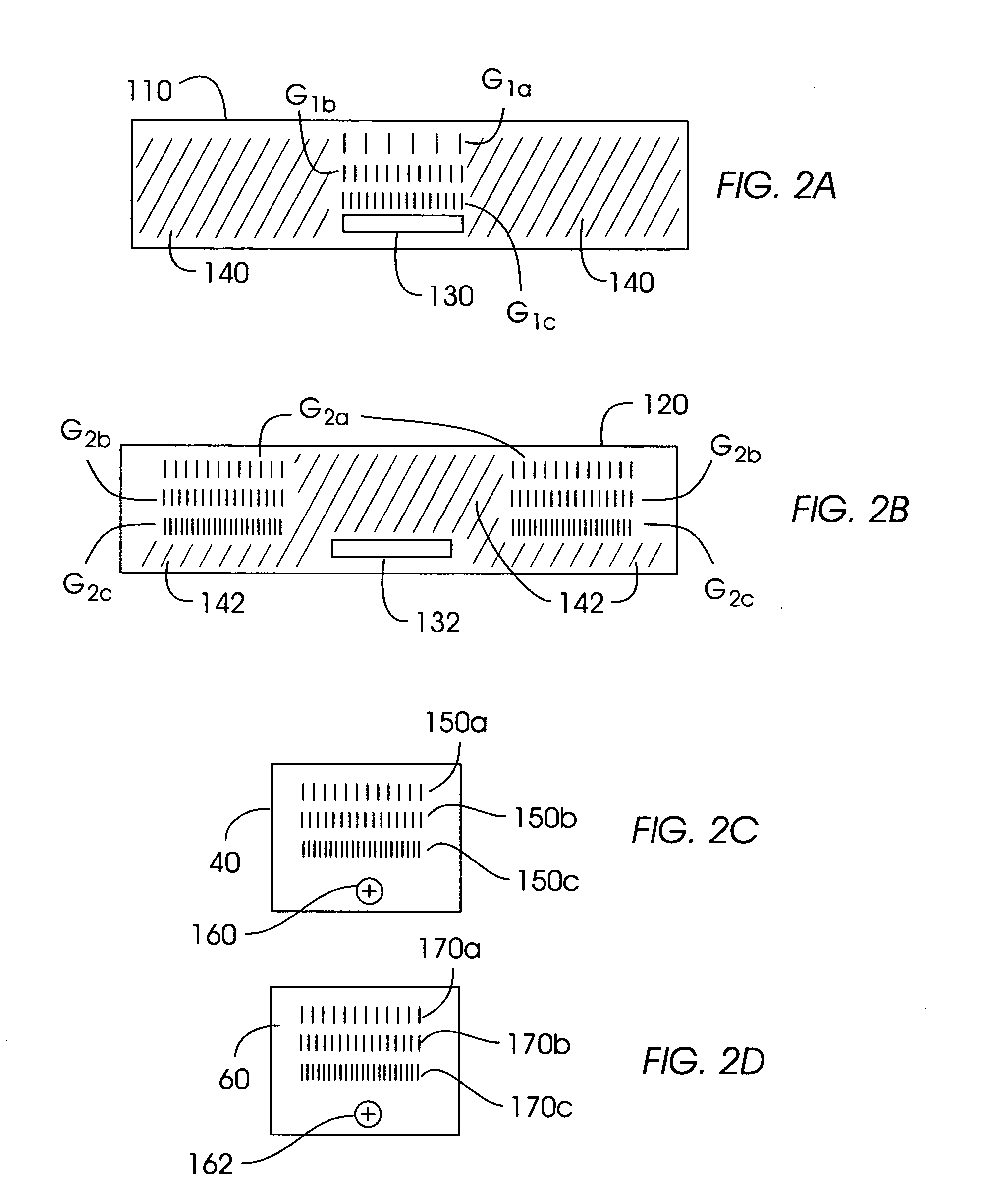

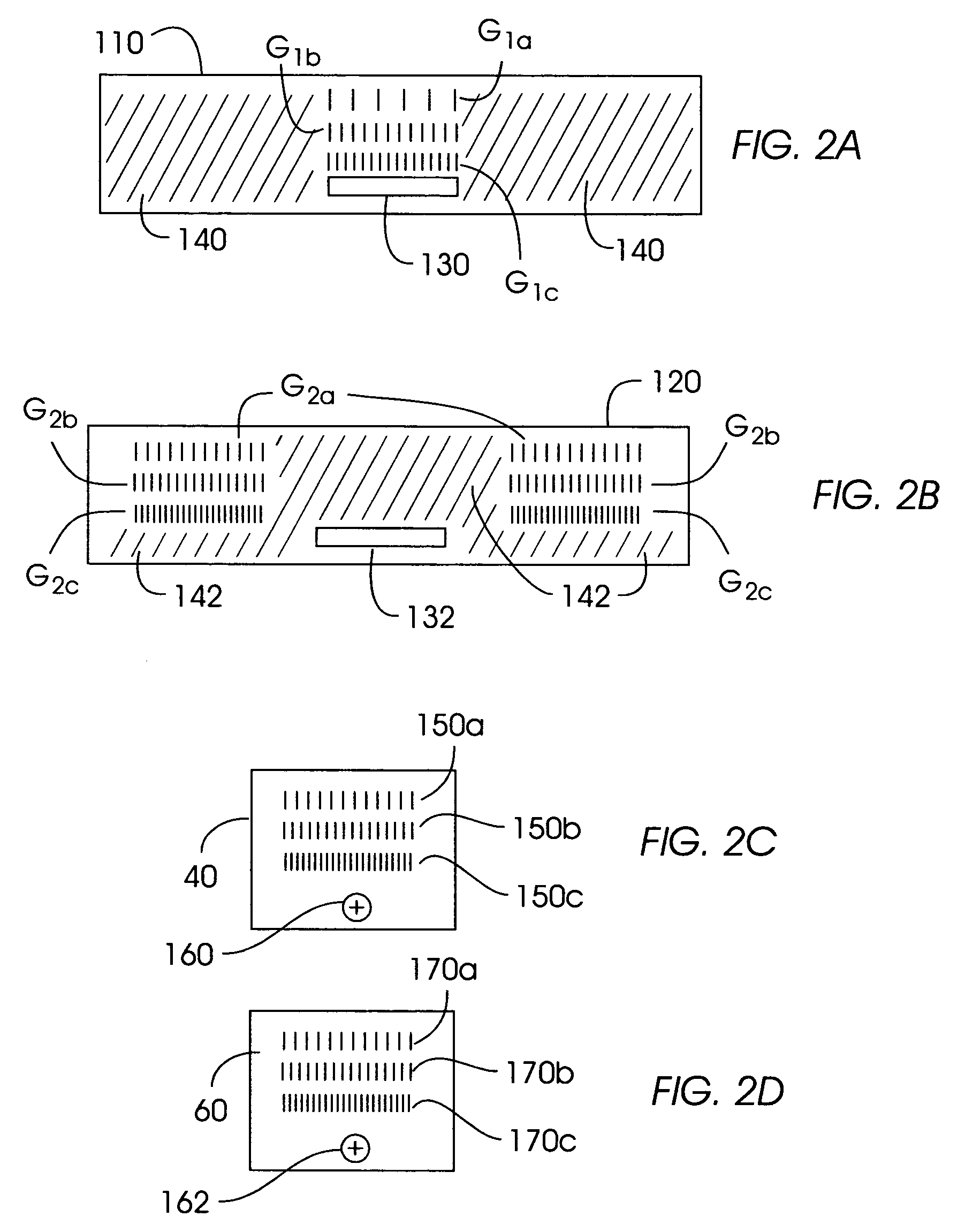

An optical apparatus used for the efficient characterization of photoresist material includes at least one grating interferometer having at least two gratings that together define an optical recombination plane. An optical stop blocks any zeroth order beam from propagating through the apparatus. A reticle positioned at the recombination plane has at least one fiducial marking therein. A lithographic imaging optical tool is positioned so that its input optical plane is substantially coincident with the optical recombination plane and its output imaging plane is substantially coincident with photoresist on a wafer. The apparatus writes in the photoresist latent, sinusoidal grating patterns, preferably of different spatial frequencies, as well as at least one fiducial mark whose pattern is determined by the marking in the reticle. After the photoresist is developed, its intrinsic spatial resolution may be determined by automated means.

Owner:GLOBALFOUNDRIES INC

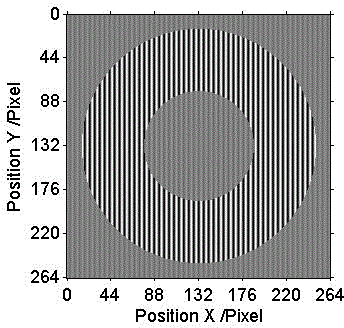

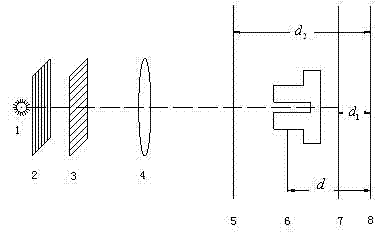

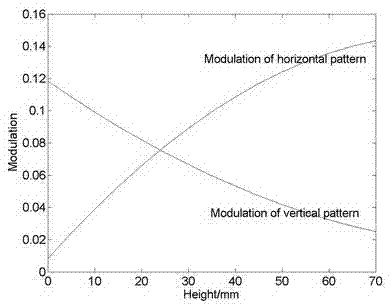

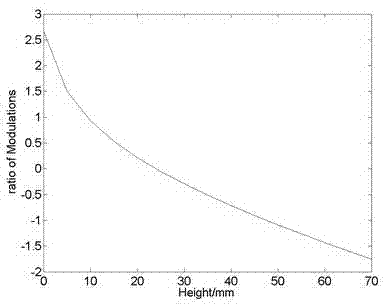

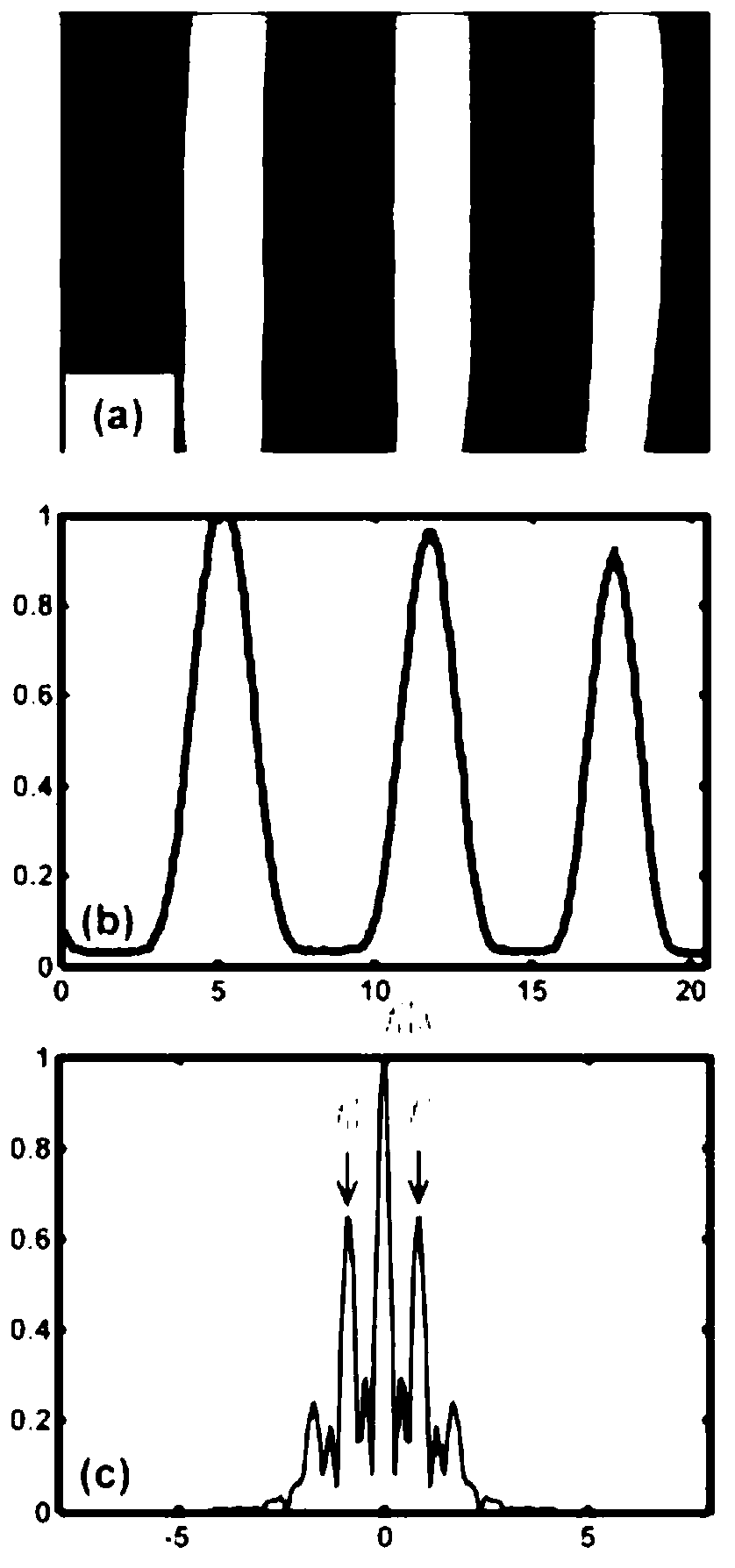

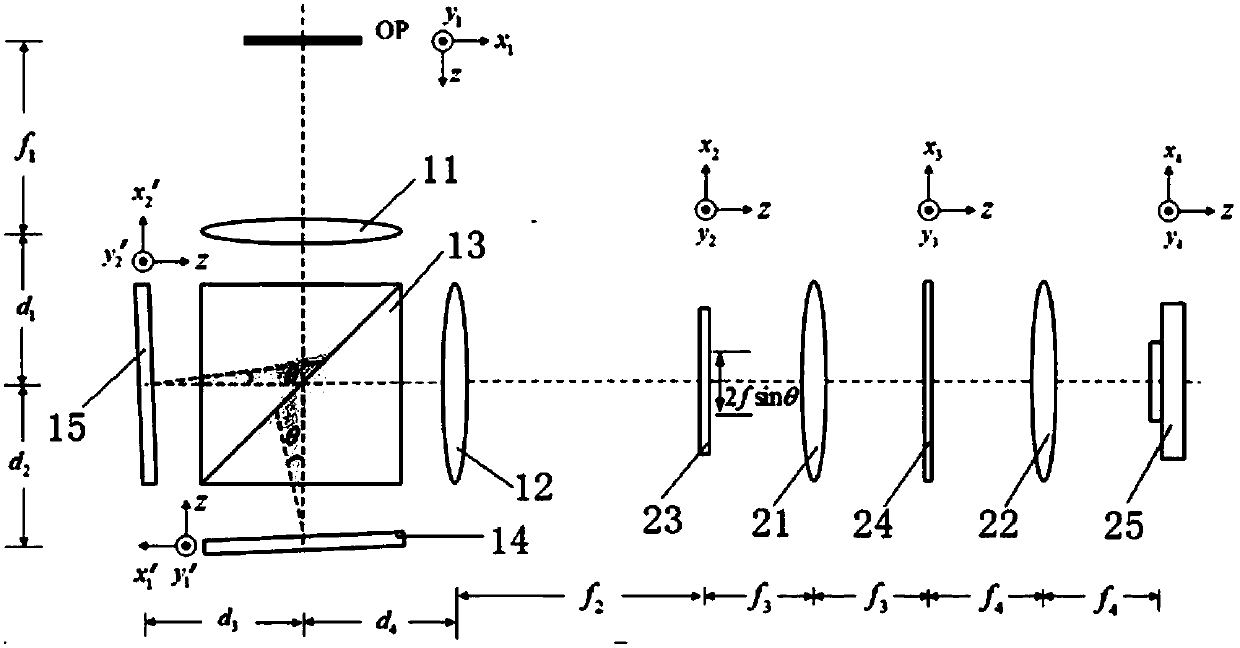

Method for realizing rapid modulation degree profilometry by use of two orthogonal sinusoidal gratings

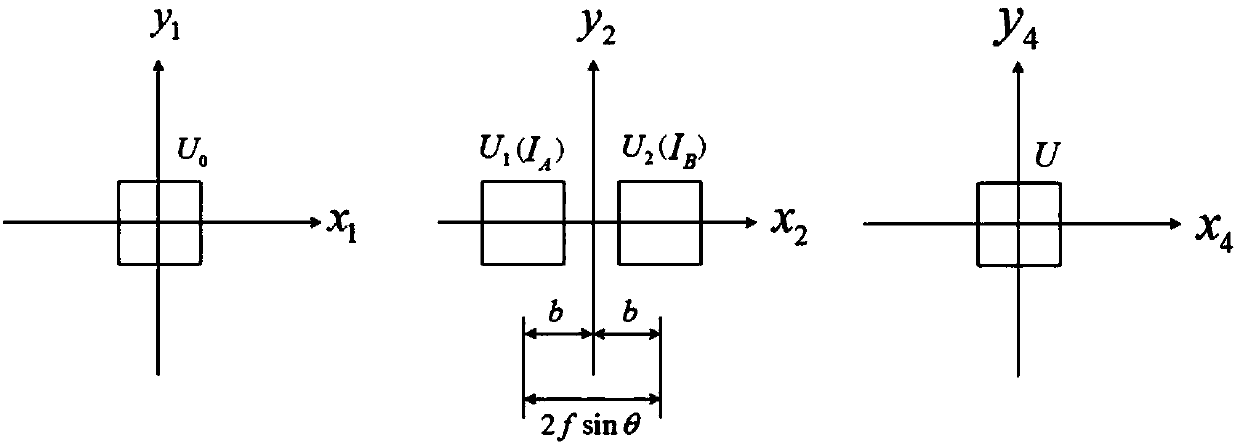

The invention discloses a method for realizing rapid modulation degree profilometry by use of two orthogonal sinusoidal gratings at a certain interval in the optical three-dimensional sensing technology. In the method, two orthogonal sinusoidal gratings at a certain interval are imaged on a measured object at the same time, and the measured object is located between the imaging surfaces of the two gratings; and a CCD (charge coupled device) camera obtains the object surface image modulated by the orthogonal gratings through a semi-transparent semi-reflecting mirror from the same direction. The images of the orthogonal gratings are separated by Fourier transform, spatial frequency-domain filtration and inverse Fourier transform so as to obtain the modulation degree distribution of the images of the two gratings on the object surface; and the object height is recovered according to the pre-calibrated corresponding relationship between the modulation degree ratio and height. In the method, the projection direction of the gratings is coaxial with the imaging direction of the CCD camera, and the method has the characteristic of vertical measurement. The method can recover the object height by acquiring only one image, and has the characteristic of real-time acquisition of three-dimensional information.

Owner:SICHUAN UNIV

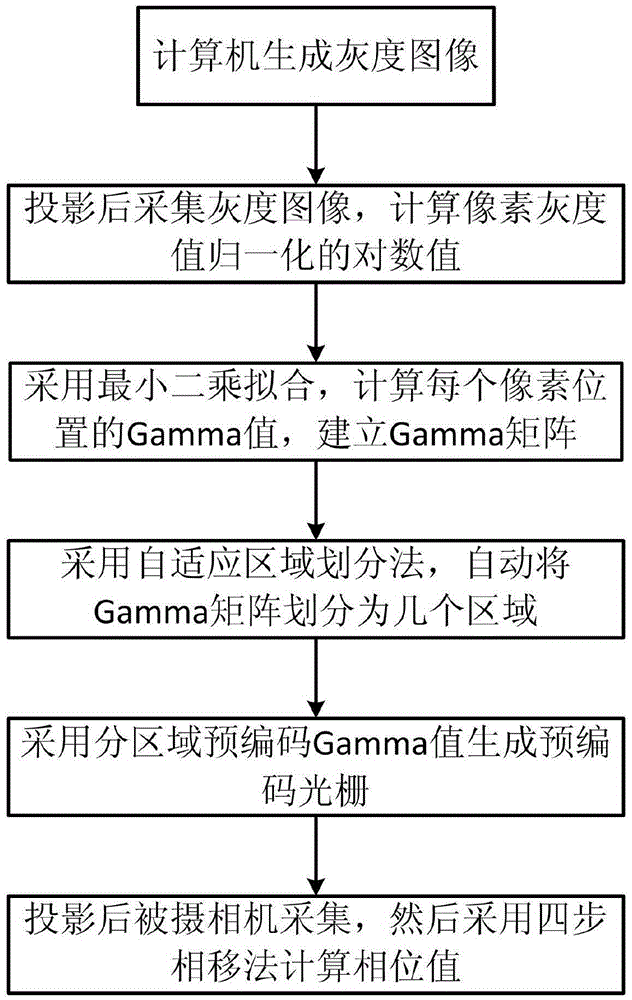

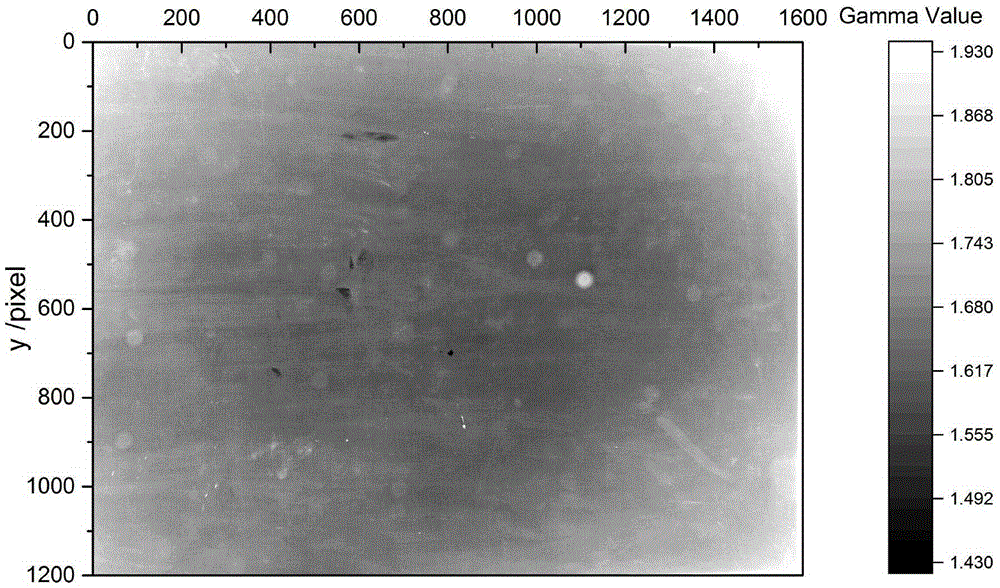

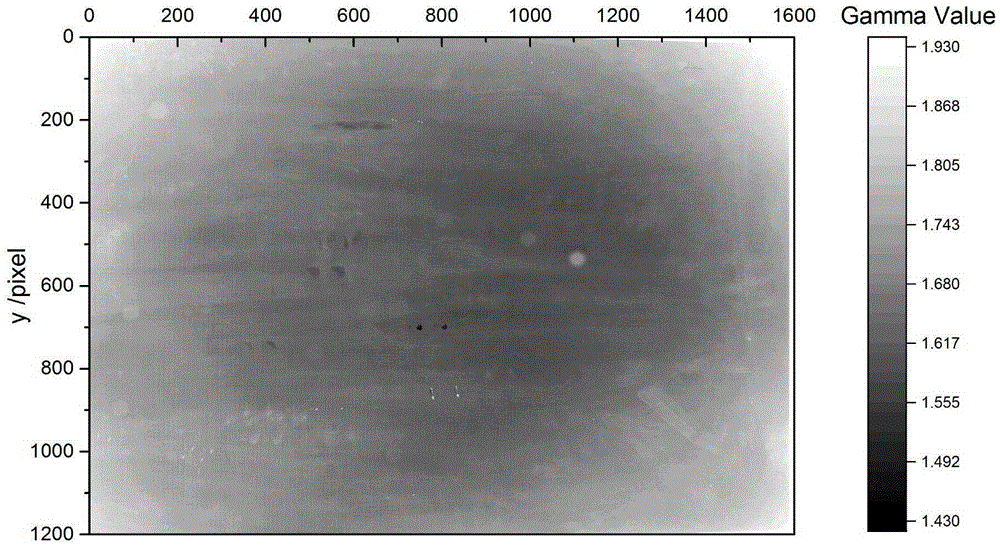

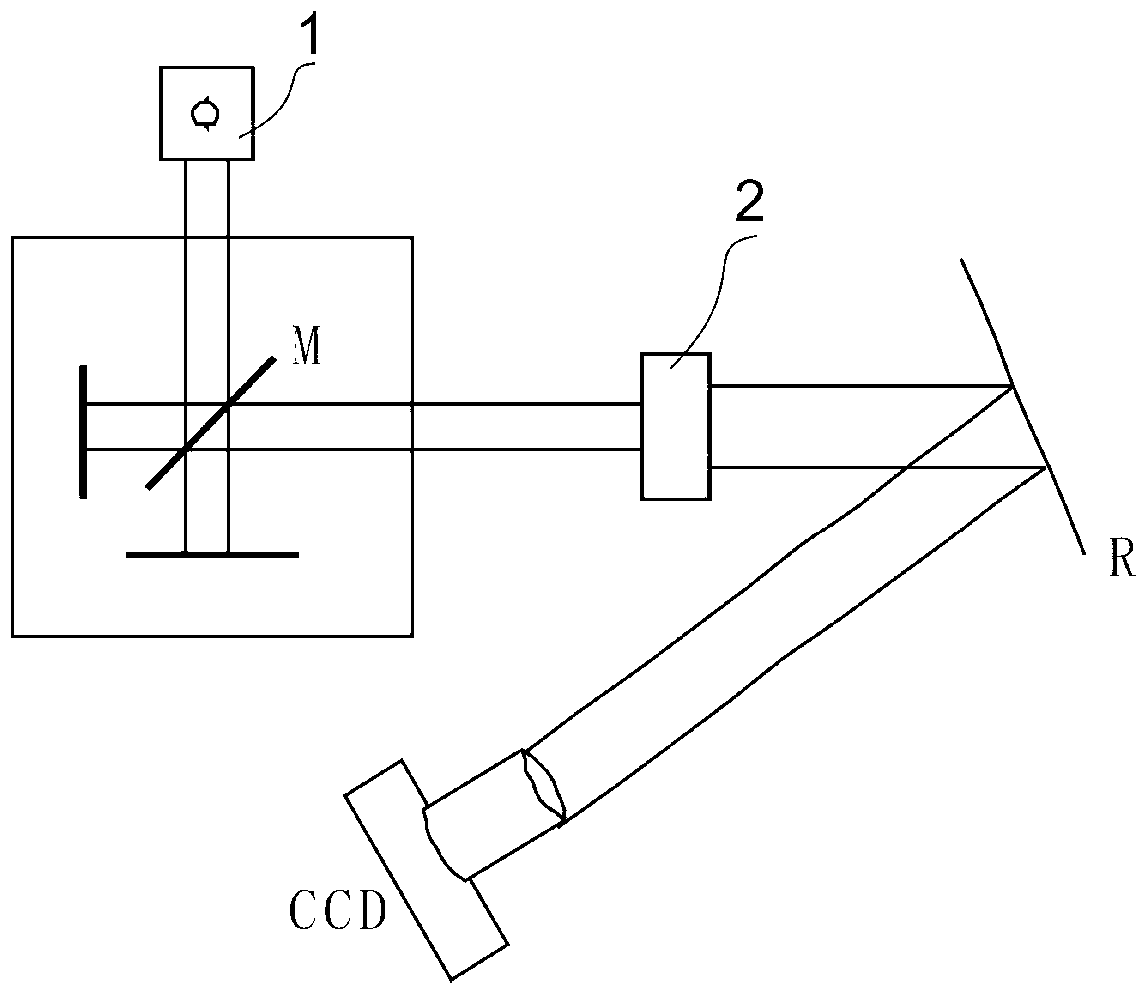

Regional Gamma precorrection phase error compensation method in large view field structured light vision measurement

The invention discloses a phase error compensation method for large view field adaptive regional Gamma precorrection. A standard N-step phase shift sinusoidal grating image is projected through a projector on the surface of a measured object; a camera is adopted to acquire the projected image; through carrying out phase demodulation on the phase shift image, the phase value of each pixel point is calculated and acquired, and thus, the three-dimensional surface information of the measured object is obtained reversely. In a large view field condition, Gamma values have large differences in a measurement range, residual errors exist when a single Gamma value is adopted for precorrection compensation, a least square fitting method is adopted to acquire the actual Gamma value at each pixel point position, the allowable maximal Gamma value change range deltaG is set to be a threshold according to the Gamma value distribution condition, the measurement region is divided, and thus, multiple Gamma values are adopted to carry out pre-coding correction on the ideal phase shift sinusoidal grating image, and phase errors caused by Gamma nonlinear distortion can be compensated.

Owner:HUAQIAO UNIVERSITY

Three-dimensional scanner measuring method and device

ActiveCN103292740AAccurate demodulationThere is no problem of unpackingUsing optical meansSinusoidal gratingVirtualization

The invention discloses a three-dimensional scanner measuring method and device. The measuring method adopts virtual sinusoidal grating formed by interferometric fringes or spatial modulated patterns to project on a reference plane and an object surface, subjects the same to phase demodulation by a phase method, and finally obtains three-dimensional information of the object surface. The three-dimensional scanner measuring method includes steps of (1) generating sinusoidal virtualization or spatial modulation light field; (2) measuring by a small-angle grating difference-frequency method; (3) forming a light path for measuring of the small-angle grating difference-frequency in the step (2) by a color separation projection system; (4) unwrapping by small-angle difference-frequency phase. The measuring device comprises a projection system, a shooting system and a computer which are arranged on the same side of the reference plane R, the projection system is arranged above the shooting system, and the computer is respectively connected with the shooting system and a printer. The three-dimensional scanner measuring method and device overcome the defects of existing three-dimensional measuring methods, has good effect and can be applicable to the integral manufacturing industry.

Owner:贵阳嘉瑜光电科技咨询中心

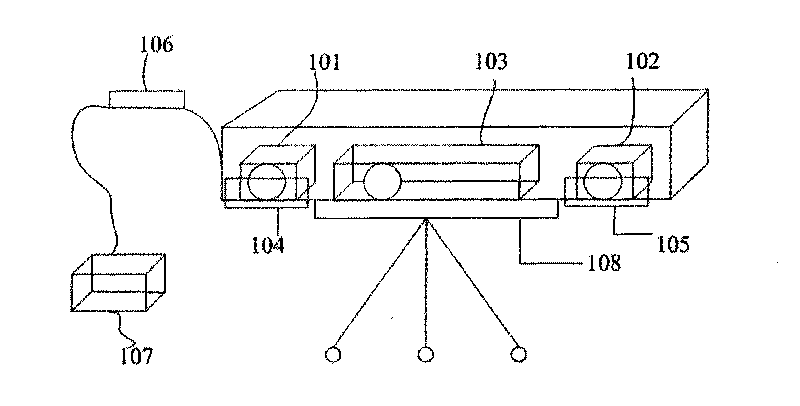

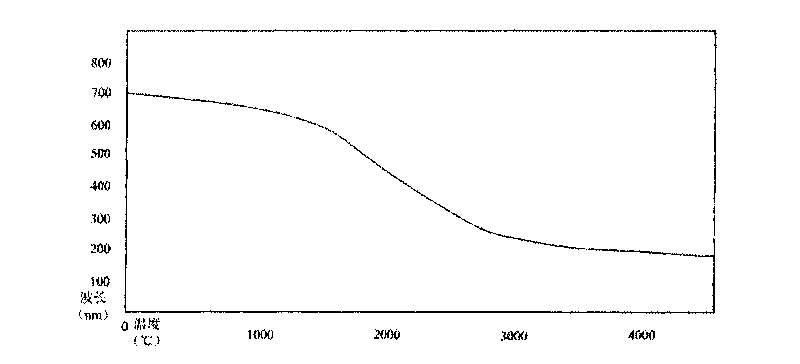

On-line detection system for hot object

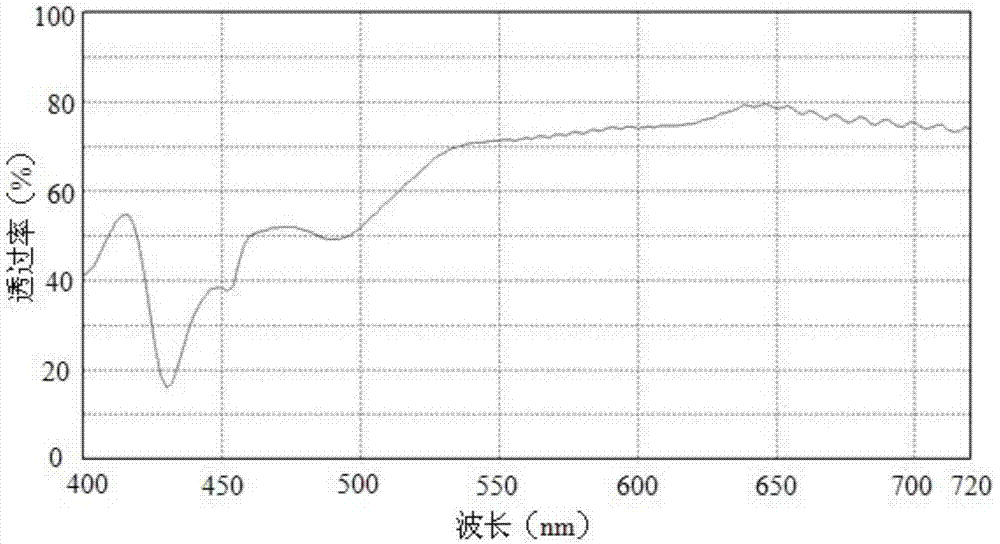

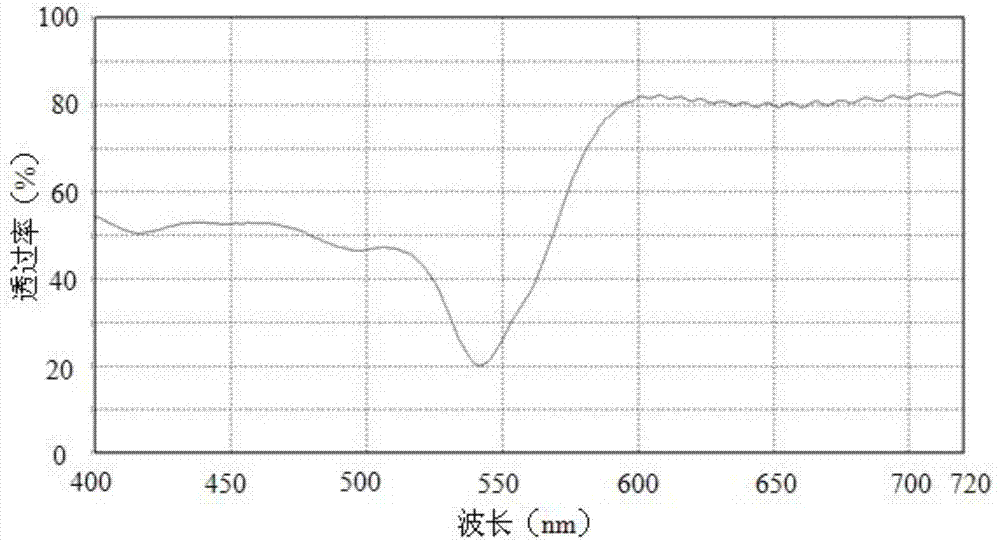

ActiveCN101726258AReduce quality impactAccurate measurementUsing optical meansSinusoidal gratingPoint cloud

The invention discloses an on-line detection system for a hot object. The on-line detection system comprises two CCD cameras, a DLP projector, two band-pass filters, an image acquisition card, a computer and a support, wherein the CCD cameras and the DLP projector are fixed on the same metal plate, optical filters are arranged in front of the CCD cameras respectively, included angles between optical center shafts of the CCD cameras and an optical center shaft of the DLP projector are between 20 and 60 DEG, the metal plate is packaged by adopting a shell, and the support is used to support under the metal plate; and the DLP projector projects a blue sinusoidal grating to a measured object in a red and hot state, the two CCD cameras are used to synchronously acquire the deformed blue sinusoidal grating reflected by the measured object, and a shot sinusoidal grating image is transmitted to the computer for data processing through the image acquisition card to obtain three-dimensional data of the measured object. The system combines the advantages of structural light measurement technology to accurately measure dense point cloud data of complex curved surfaces within the local range of workpieces; and the system can perform quick and accurate on-line measurement on objects under high temperature conditions to obtain the three-dimensional data of the surfaces of the objects.

Owner:HUAZHONG UNIV OF SCI & TECH

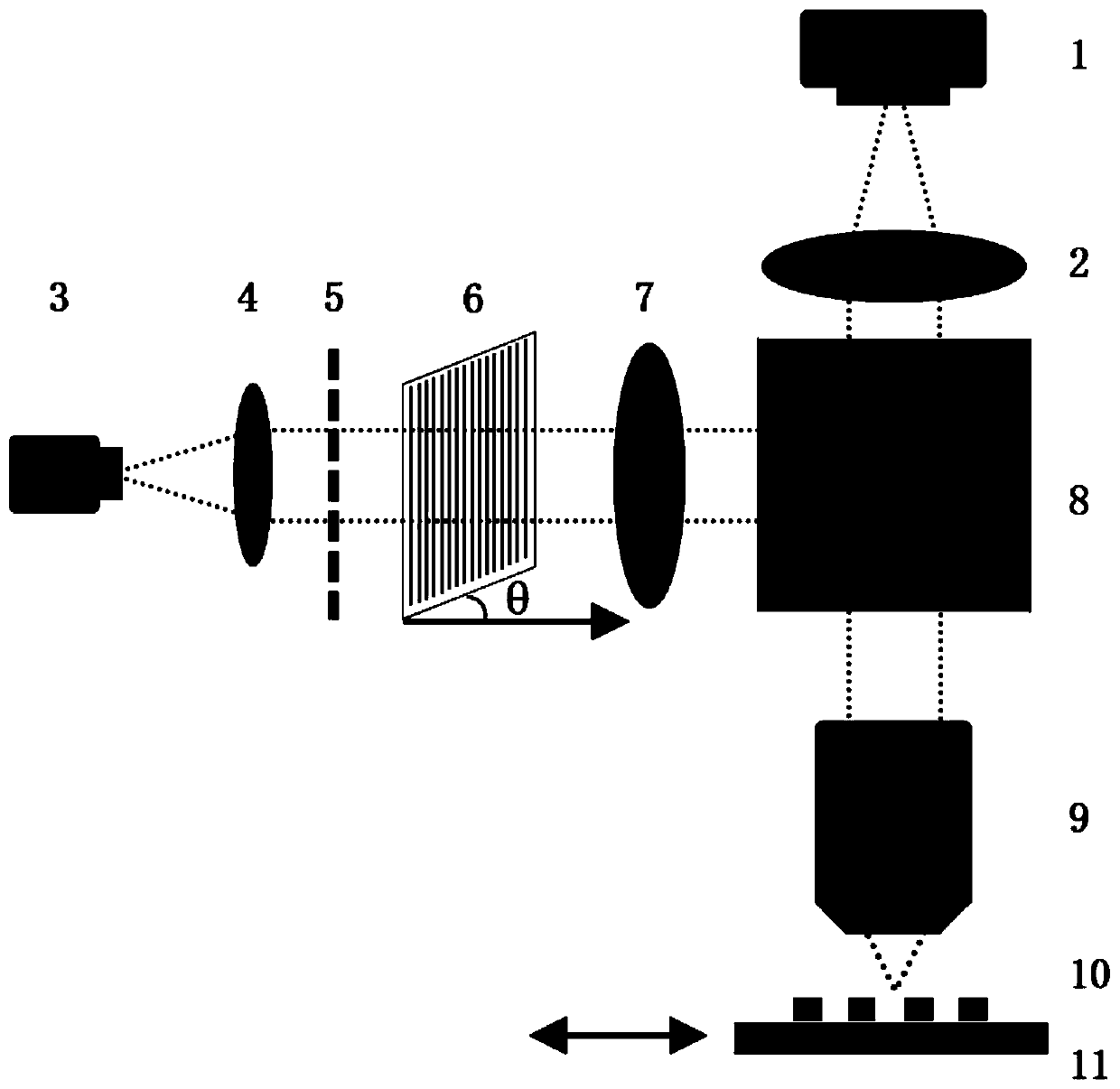

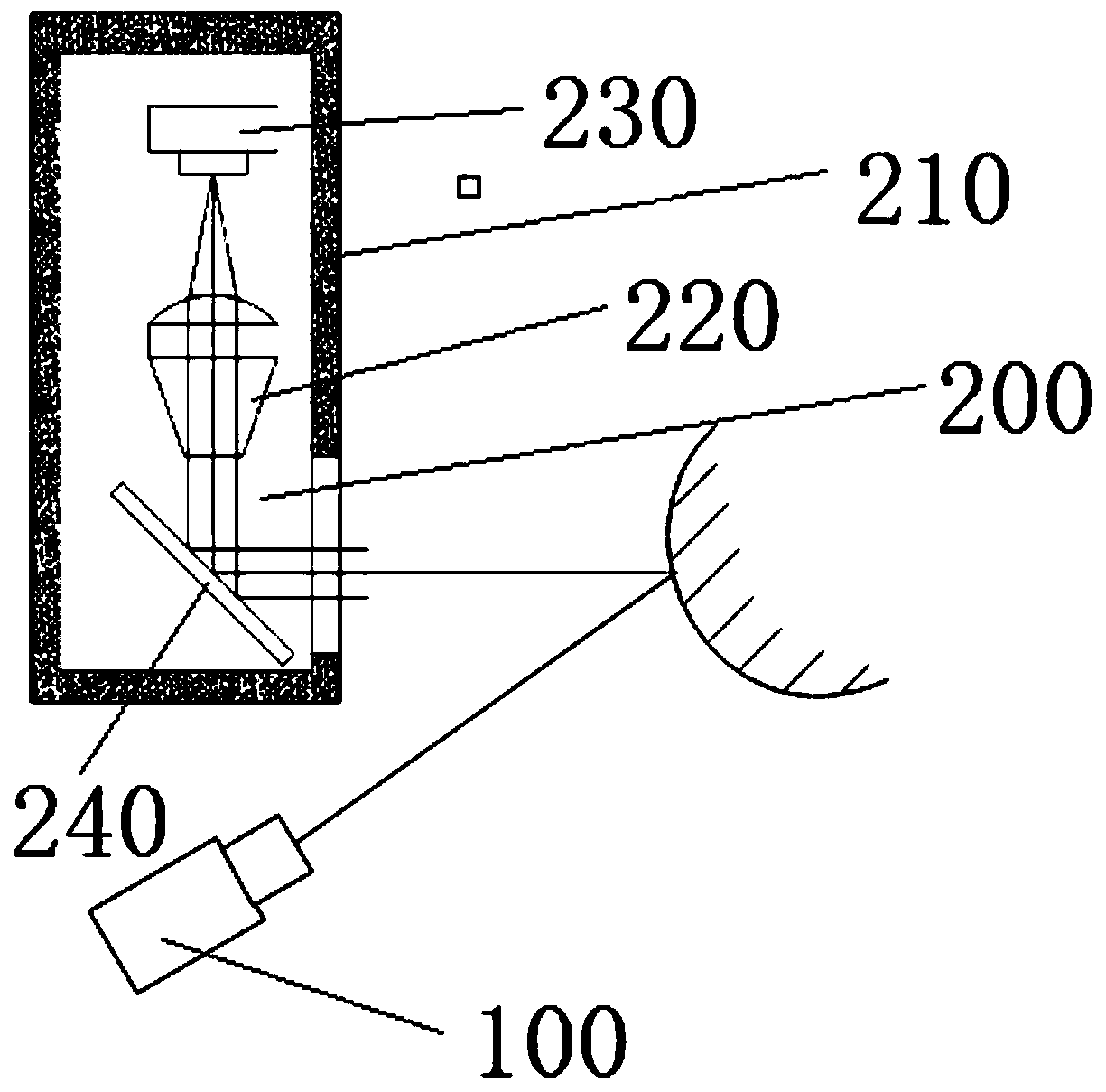

High-speed detection method for three-dimensional topography of micro-nano structure based on structured light

ActiveCN109341574AEnables continuous measurementHigh precisionUsing optical meansSinusoidal gratingMicro nano

The invention is a high-speed detection method for three-dimensional topography of micro-nano structure based on structured light. Sinusoidal grating stripes projected by a structured light projectiondevice form an angle [theta] with optical axis, are then projected onto the surface of the object to be tested, and an image is acquired by a CCD camera. The acquired image is calculated through a Fourier transform filtering algorithm to obtain a modulation distribution of the sinusoidal grating on the surface of the object, so that a modulation curve of each pixel point at different horizontal scanning positions can be obtained. Finally, the topography recovery can be realized by extracting a position of the maximum value of the modulation. The high-speed detection method for the three-dimensional topography of the micro-nano structure based on the structured light can not only realize continuity measurement of the non-periodic micro-nano structure, but also retain advantages of verticalmeasurement, and has high detection precision and efficiency.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

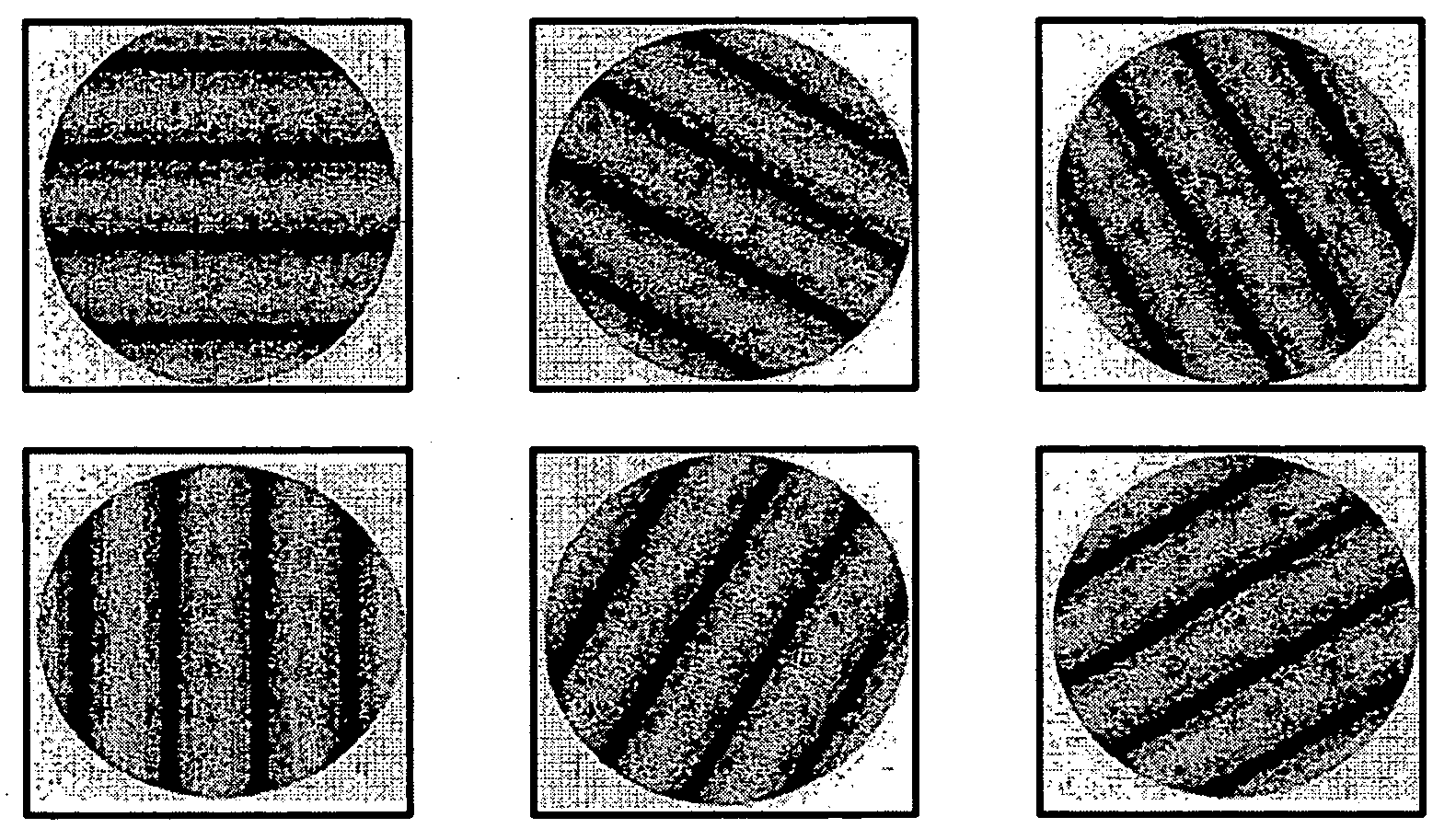

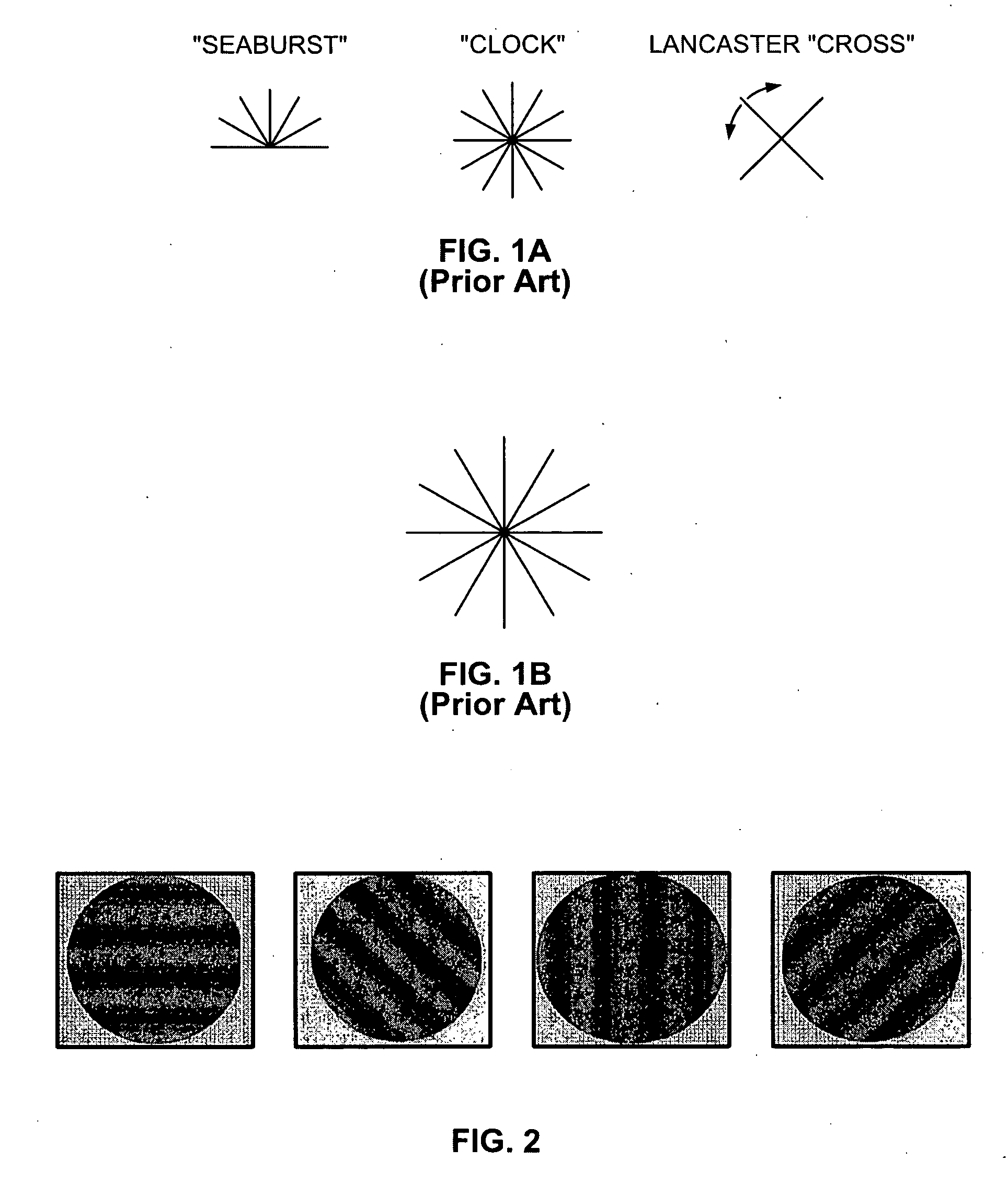

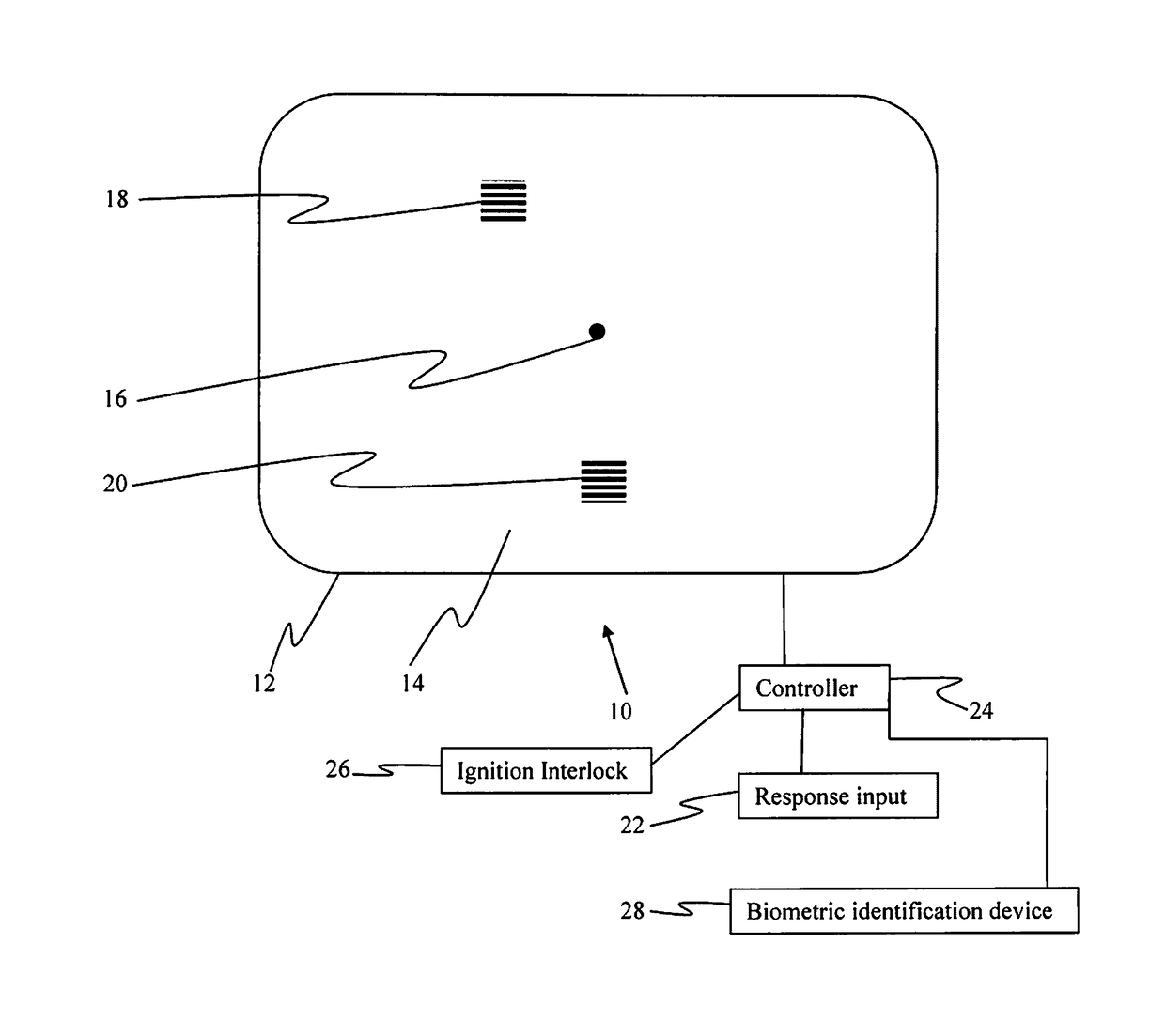

Astigmatic axis independent spatial frequency and contrast sensitivity target and method

A set of visual targets and a method for using these targets to evaluate the spatial frequency response and contrast sensitivity of the human visual system. The invention includes four choice test, six choice test, sinusoidal bulls eye and fundamental sinusoidal letters or optotype targets. The four and six choice targets feature sinusoidal gratings oriented vertically, horizontally and at angles thereto. The sinusoidal bull's eye target features concentric circular light and dark areas with brightness varying in a sinusoidal fashion. The fundamental sinusoidal optotype target features an optotype, such as a letter, that is made up of strokes, each of which have a width that is equal to a single sinusoidal period.

Owner:THE HILSINGER

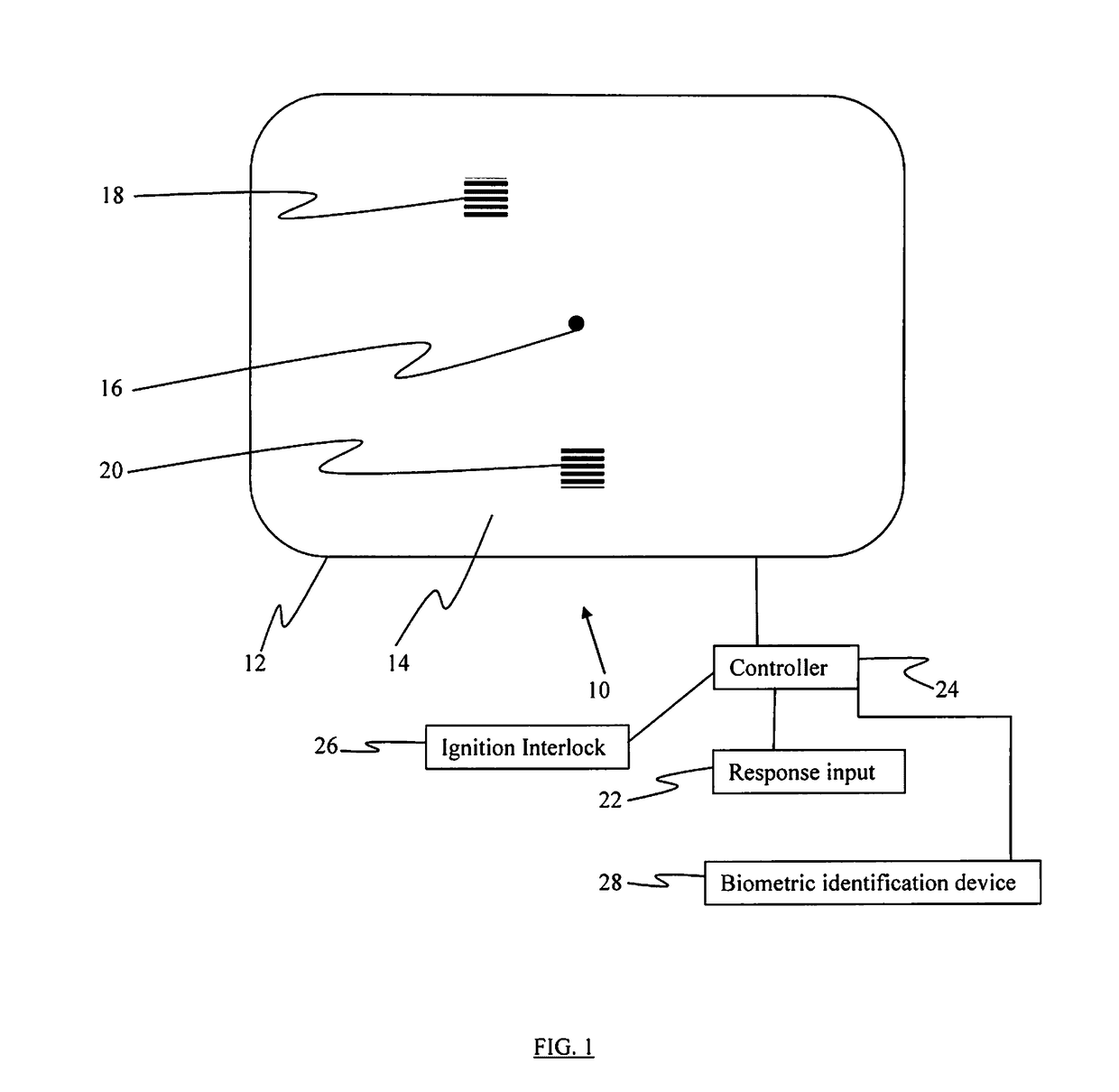

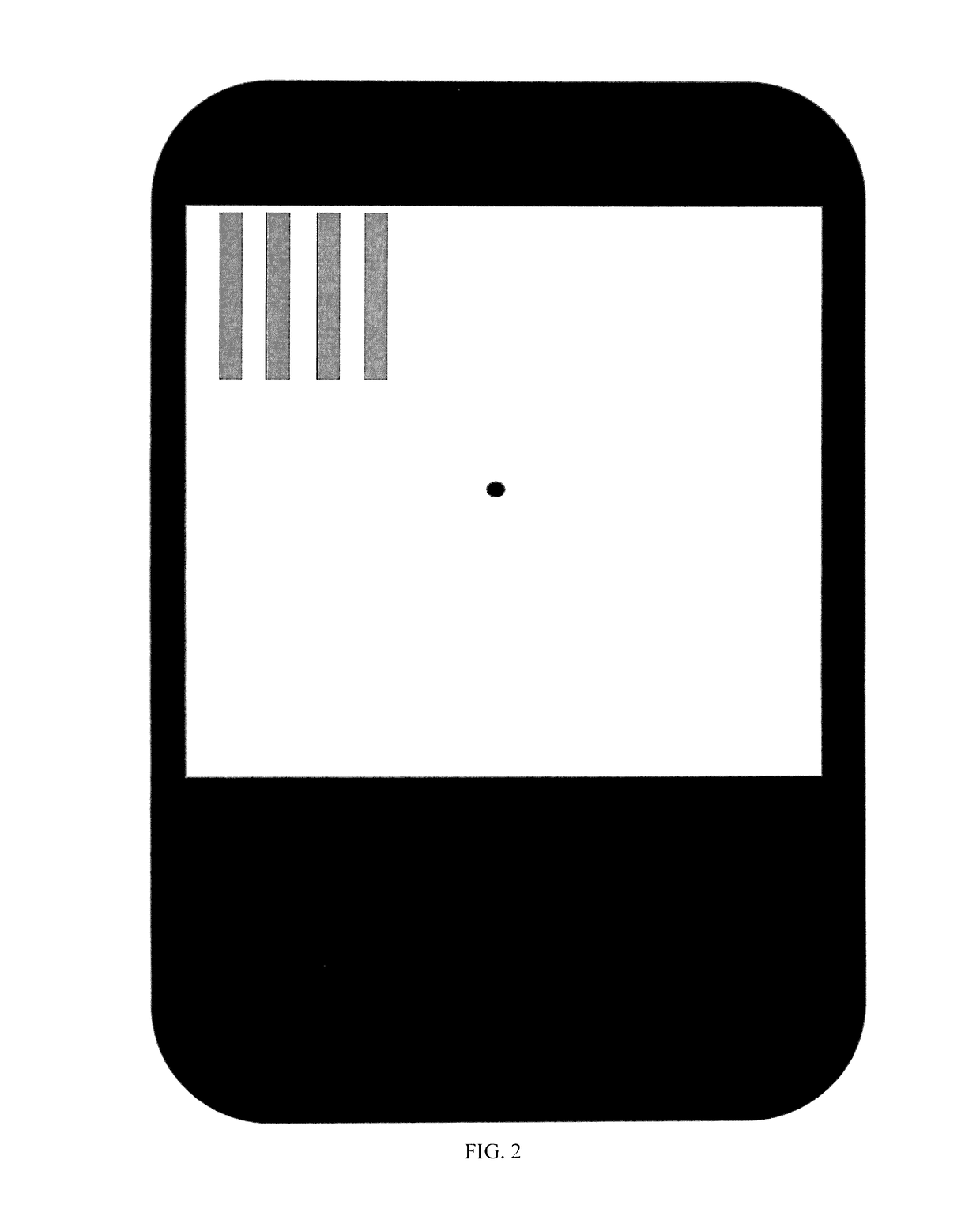

Method and device for detection and assessment of marijuana impairment

ActiveUS20170105669A1Reduce stepsQuickly and accurately assessMedical automated diagnosisDiagnostic recording/measuringSinusoidal gratingCannabis

A method of identifying individuals impaired by a psychoactive substance such as cannabis. The method includes presenting monocularly to a subject being tested; to each eye separately, a sinusoidal grating pattern of fixed spatial frequency with achromatic contrast or color contrast between grating stripes being temporally alternately modulated at a temporal frequency that ranges between 10 Hz and 60 Hz with a pattern of the contrast being such that the subject being tested can see a frequency doubling in the grating pattern.

Owner:VALENTI DENISE A

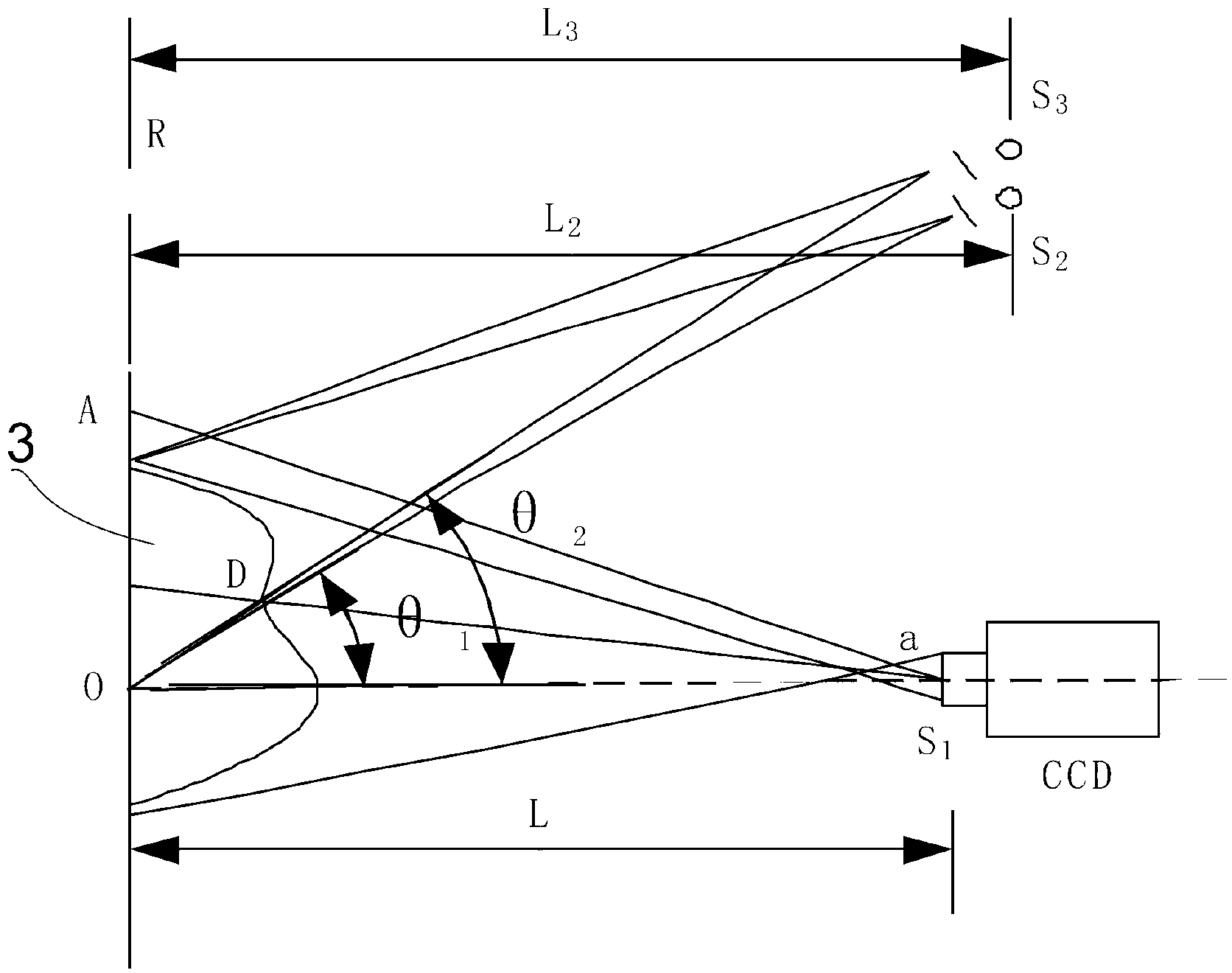

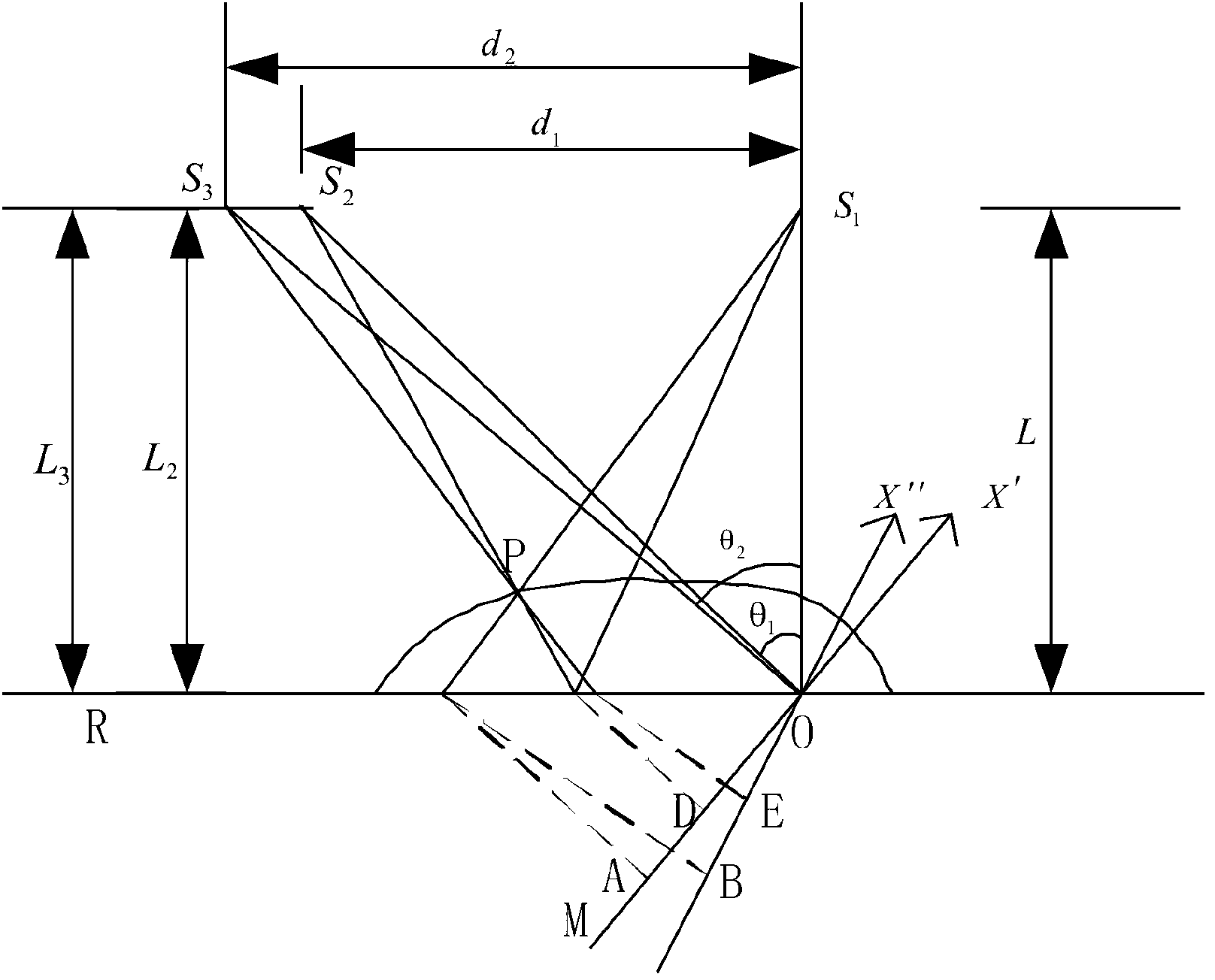

Lonky detection method of aspheric surface with heavy calibre

The invention relates to a lonky detection method of an aspheric surface with a heavy calibre. A compensating sinusoidal grating is designed by using phase information of a ray trace and a sine fringe and displayed on a transmissive type liquid crystal display screen; the transmissive type liquid crystal display screen is also a phase shifter so that the compensating sinusoidal grating displayed on the transmissive type liquid crystal display screen generates phase shift. Light emitted from an off-axis point light source passes through the compensating grating after being reflected by a mirror surface. A video camera records a phase-shift fringe pattern carrying deviation information of the mirror surface relative to an ideal face shape of the mirror surface. Actual lateral aberration and corresponding ideal lateral aberration of the tested mirror surface can be determined by analyzing the phase-shift fringe pattern, the deviation gradient of the tested mirror surface can be obtained on the basis of a geometrical principle of the lonky detection and the deviation of the tested mirror surface is obtained by integration of the tested mirror surface so that a three-dimensional surface shape of the tested mirror surface is rebuilt. According to the invention, it is unnecessary to manufacture a special compensating grating as to each type of aspherical mirror. The lonky detection method has the advantages of flexibility, convenience and high detection accuracy, and has an important application prospect in detection of the aspheric surface with the heavy calibre.

Owner:SICHUAN UNIV

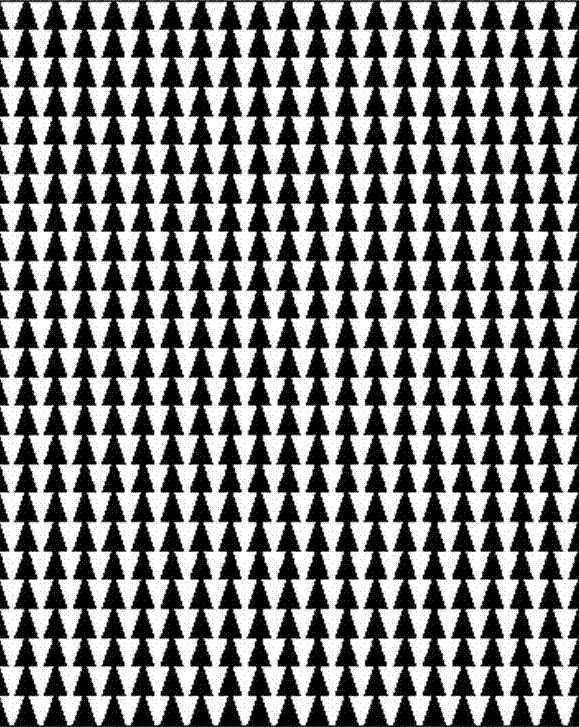

Trapezoid primitive optical grating with single-stage diffraction properties

InactiveCN104765086AEasy to makeReduce data volumeDiffraction gratingsIsosceles trapezoidSinusoidal grating

The invention provides a trapezoid primitive optical grating with single-stage diffraction properties. According to the core concept, primitives of the certain shape are distributed in a certain mode so that the penetration rates or reflective rates in the optical grating period direction can be distributed according to a trapezoid function. According to the specific manufacturing process of two design modes, the trapezoid primitives are sequentially stacked together in the one-dimensional direction on the bottom face of an optical grating substrate, or one trapezoid primitive and another inverted trapezoid of the same parameter as the trapezoid primitive are sequentially stacked together in a spaced mode to form the function with the specific trapezoid penetration rate or reflective rate in the optical grating period direction; copying is performed on the other dimension direction of the bottom face of the optical grating substrate by using the optical grating period as the interval length; each trapezoid primitive is in an isosceles trapezoid shape, the upper bottom edge and the lower bottom edge of the isosceles trapezoid are related to the optical grating period, and the height of the trapezoid is determined according to the practical application situation. The obtained trapezoid primitive optical grating can completely ignore high-order diffraction, the positive and negative one-order absolute diffraction efficiency theoretical value of the trapezoid primitive optical grating is 6.93%, the diffraction efficiency of the trapezoid primitive optical grating is larger than that of a sinusoidal grating with the same period and duty ratio as the trapezoid primitive optical grating, and the trapezoid primitive optical grating will bring new changes to spectral analysis, light source monochromatization and other aspects.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Apparatus for characterization of photoresist resolution, and method of use

InactiveUS7046342B2Effective characterizationFacilitate automated evaluationRadiation applicationsUsing optical meansResistSinusoidal grating

An optical apparatus used for the efficient characterization of photoresist material includes at least one grating interferometer having at least two gratings that together define an optical recombination plane. An optical stop blocks any zeroth order beam from propagating through the apparatus. A reticle positioned at the recombination plane has at least one fiducial marking therein. A lithographic imaging optical tool is positioned so that its input optical plane is substantially coincident with the optical recombination plane and its output imaging plane is substantially coincident with photoresist on a wafer. The apparatus writes in the photoresist latent, sinusoidal grating patterns, preferably of different spatial frequencies, as well as at least one fiducial mark whose pattern is determined by the marking in the reticle. After the photoresist is developed, its intrinsic spatial resolution may be determined by automated means.

Owner:GLOBALFOUNDRIES INC

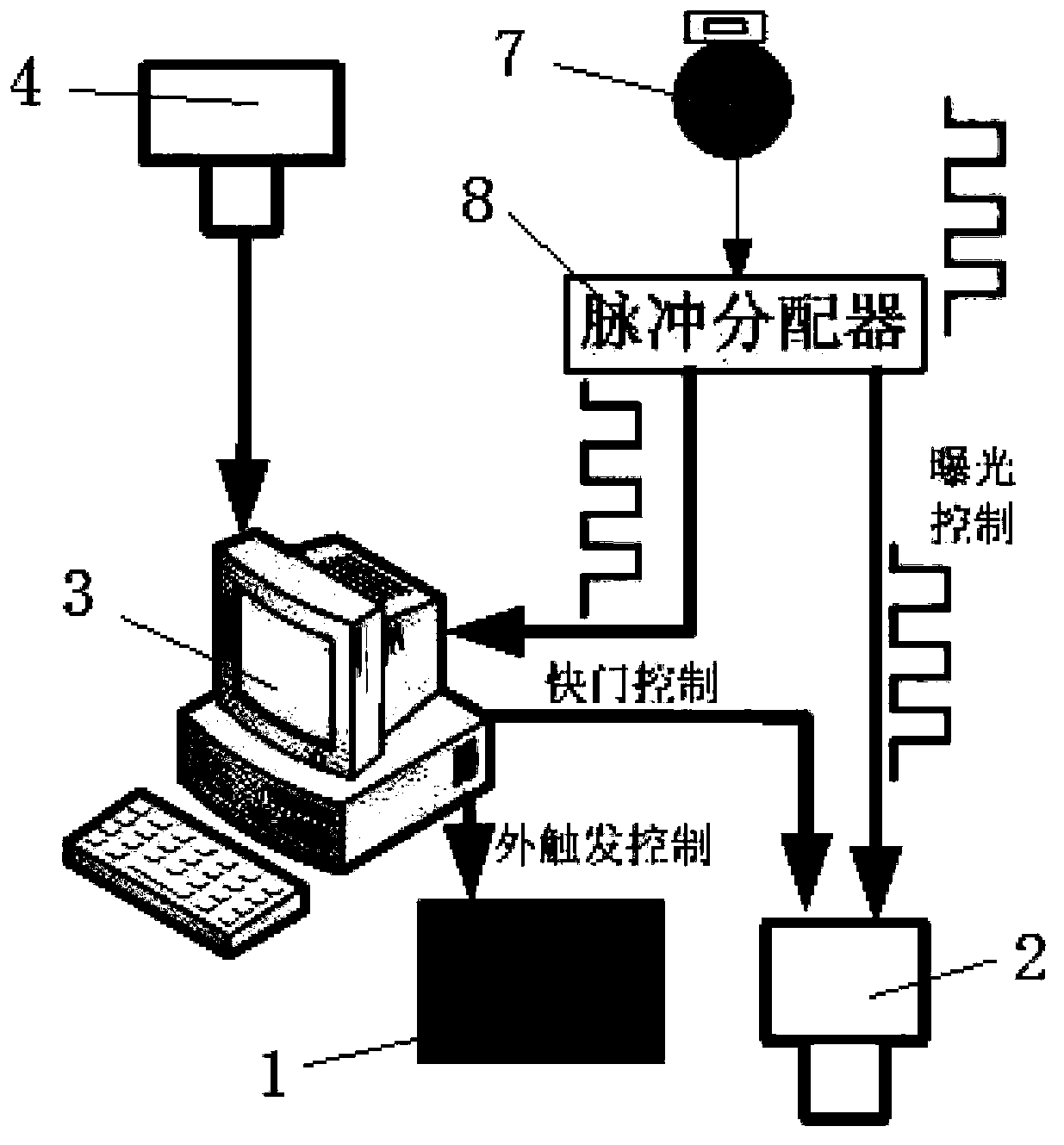

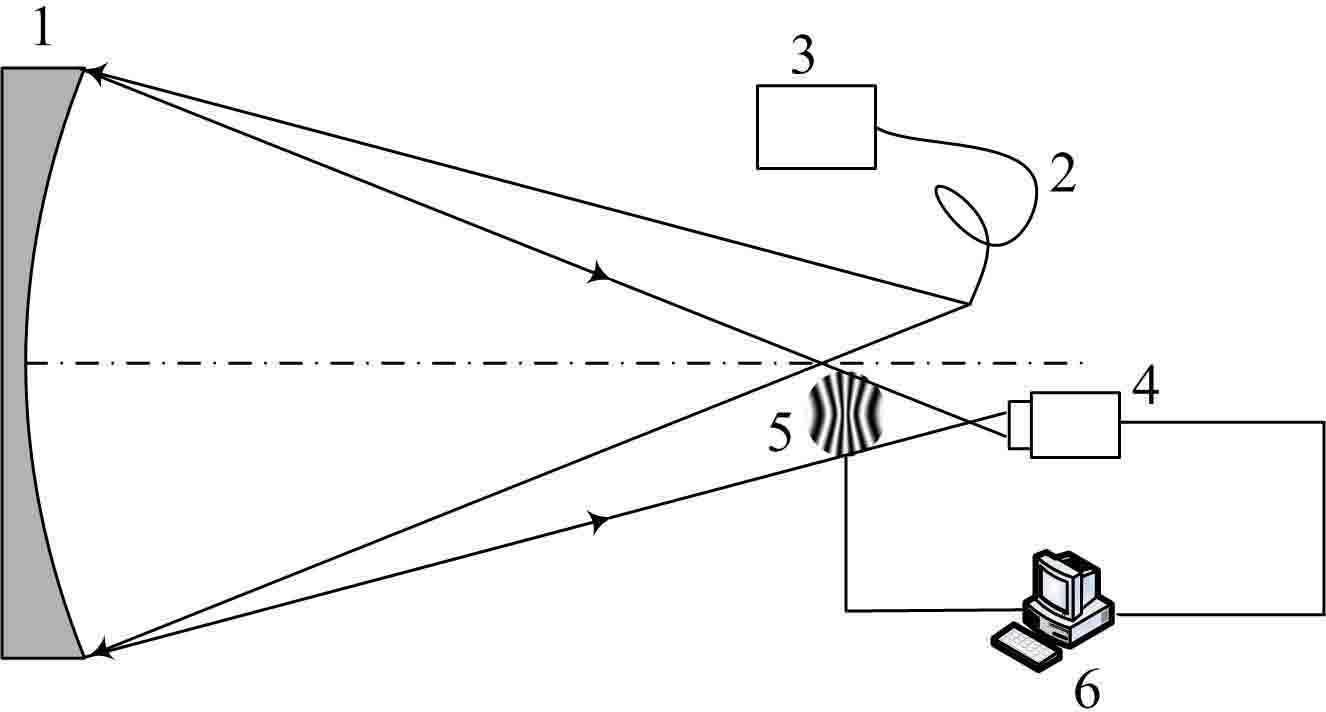

Scanning vibrating mirror vibration parameter measurement system and measurement method

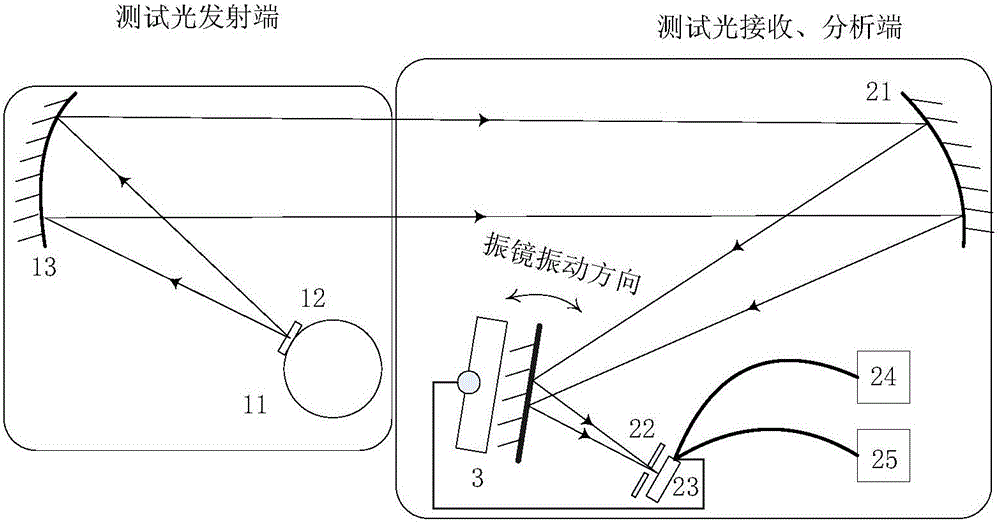

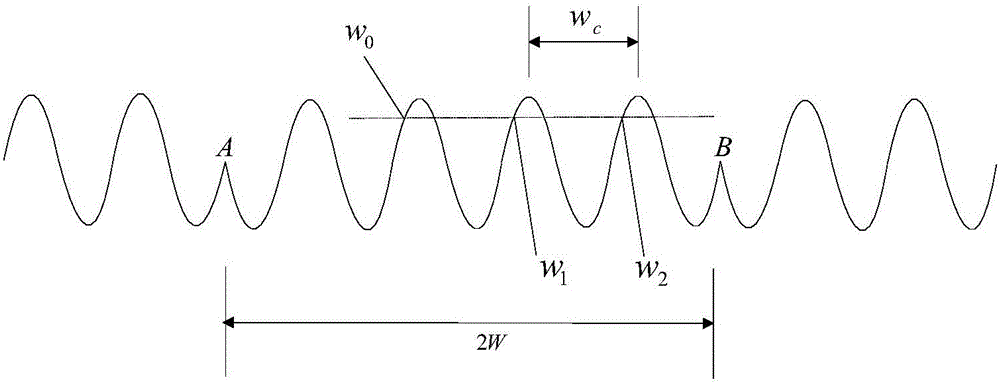

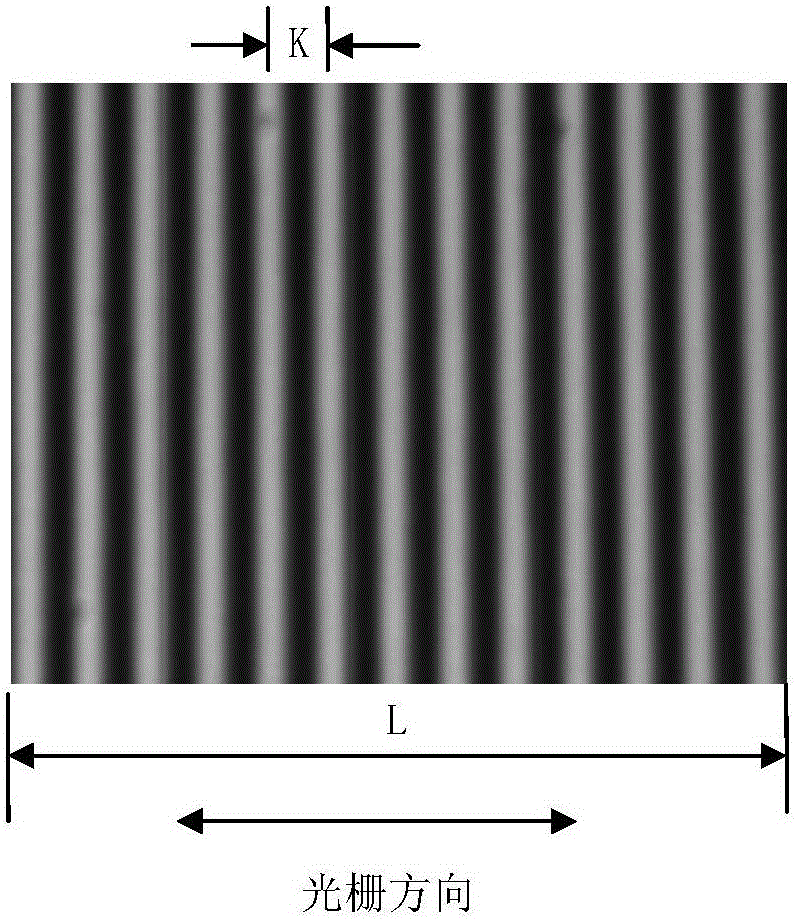

ActiveCN106092302ARealize non-contact measurementHigh sensitivitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansSinusoidal gratingLight beam

The invention relates to a scanning vibrating mirror vibration parameter measurement system and measurement method, and aims at solving the problems in the prior art that the angle measurement range is small, the frequency response is low and the precision is low. The measurement system comprises an integrating sphere light source, a first off-axis parabolic mirror, a second off-axis parabolic mirror, a single point detector, a signal acquisition unit and timing equipment. The light outlet of the integrating sphere light source is provided with a sinusoidal grating. The first off-axis parabolic mirror is arranged on the emergent light path of the integrating sphere light source. The second off-axis parabolic mirror is arranged on the emergent light path of the first off-axis parabolic mirror is arranged. A scanning vibrating mirror to be measured is arranged on the emergent light path of the second off-axis parabolic mirror. The single point detector is arranged at the convergent point of the reflecting beam of the scanning vibrating mirror to be measured so as to receive sinusoidal grating images. The timing equipment is used for synchronizing signal acquisition time of the motor of the scanning vibrating mirror to be measured and the single point detector and giving the corresponding time of each angular position of the scanning vibrating mirror to be measured. The signal acquisition unit is used for reading the output signals of the single point detector.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

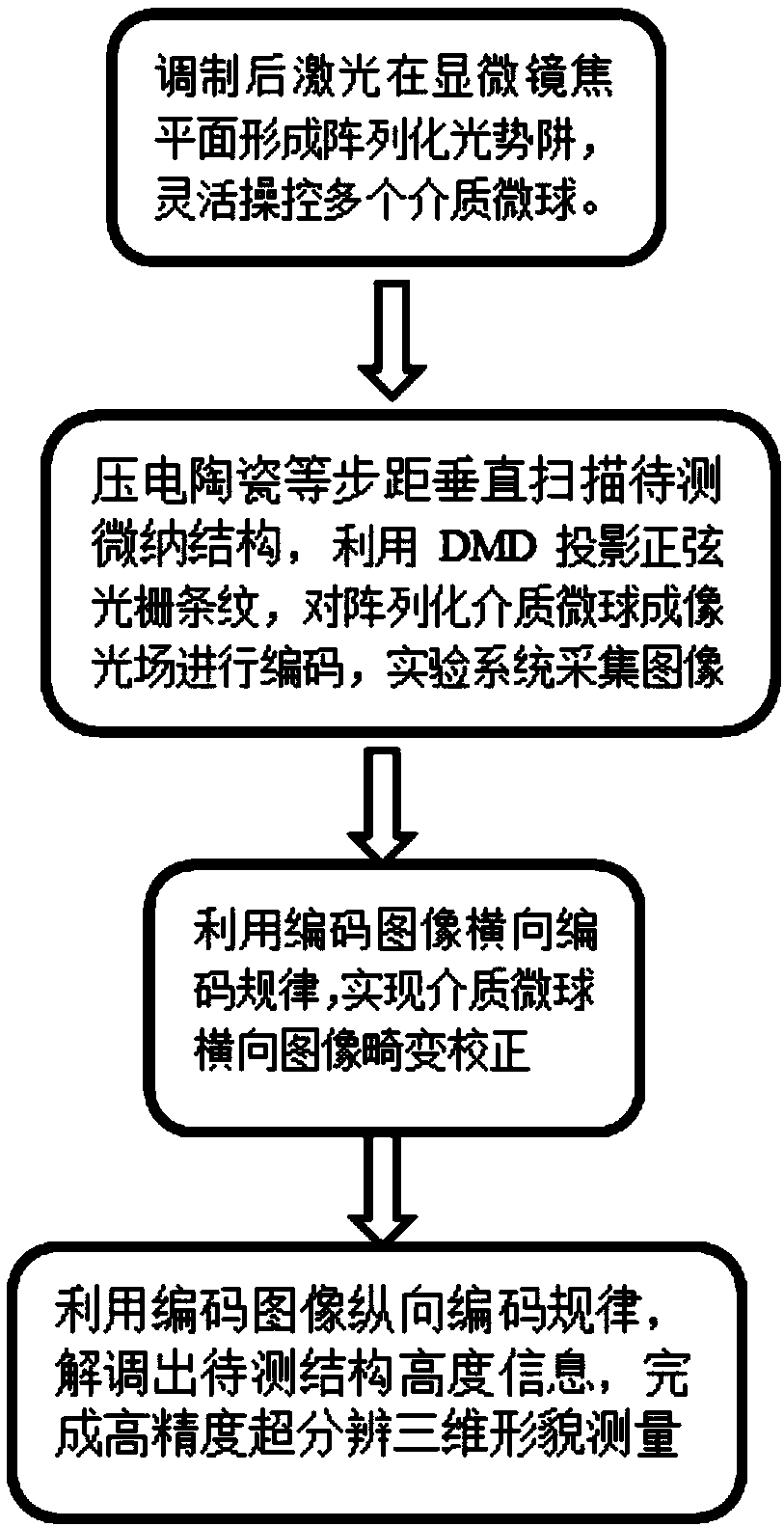

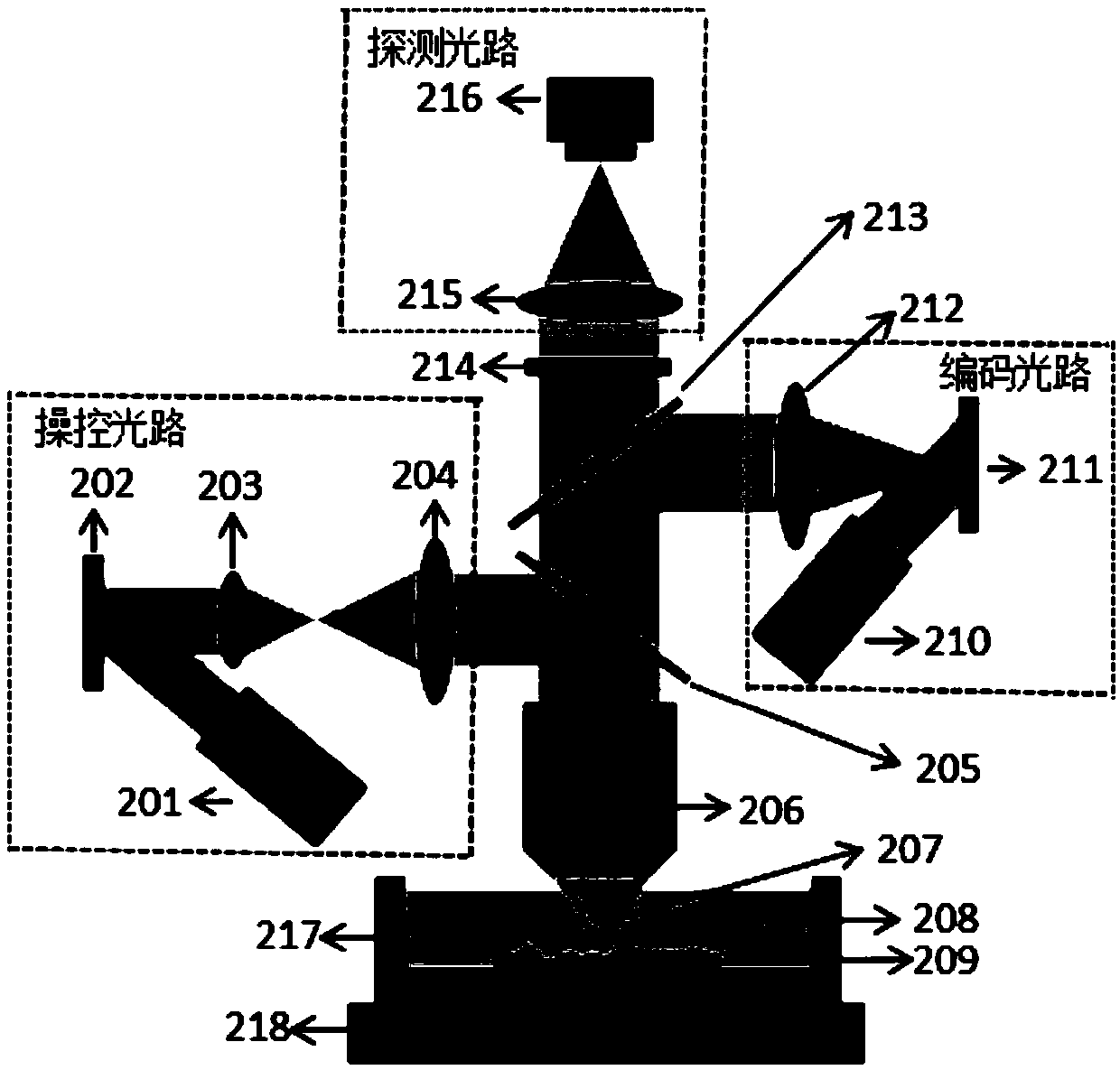

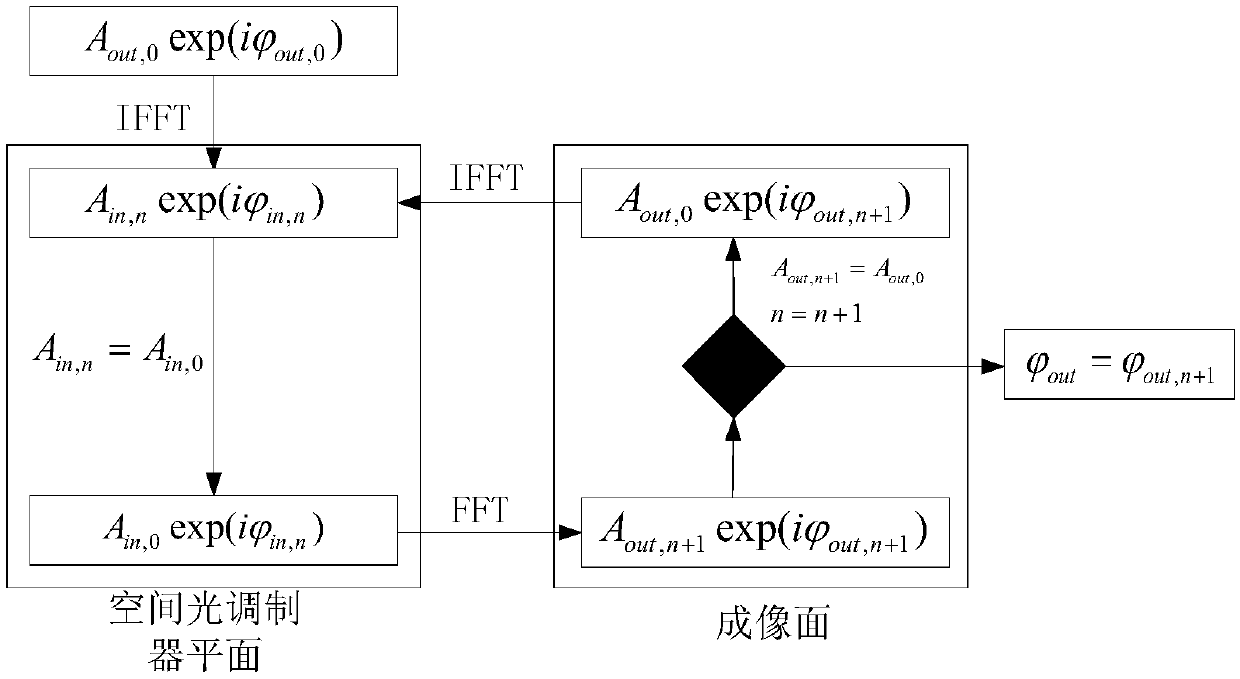

Super-resolution three-dimensional shape measurement method based on optical tweezers dielectric microspheres

ActiveCN108917651AFlexible handlingPrecise control of bead positionUsing optical meansSinusoidal gratingDielectric

The invention discloses a super-resolution three-dimensional shape measurement method based on optical tweezers dielectric microspheres. The dielectric microspheres are taken as a core, an optical tweezers principle is adopted for controlling the dielectric microspheres in an array mode, a three-dimensional space position of the dielectric microspheres is flexibly controlled, and an optimal imaging effect is obtained. Meanwhile, DMD projection sinusoidal grating stripes are used for encoding a dielectric microsphere imaging space, light field distribution characteristics of the dielectric microsphere imaging space are utilized, and a dielectric microspheres coded image modulated by a to-be-measured structure is resolved, so that transverse graph correction and longitudinal height reconstruction are achieved. According to the method, three-dimensional shape measurement of micro-nano devices with the characteristic dimension of less than 100 nm can be realized in a far-field region through a face imaging mode, and meanwhile, the method has the advantages of high flexibility, high resolution, parallelism, fast measurement and the like.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

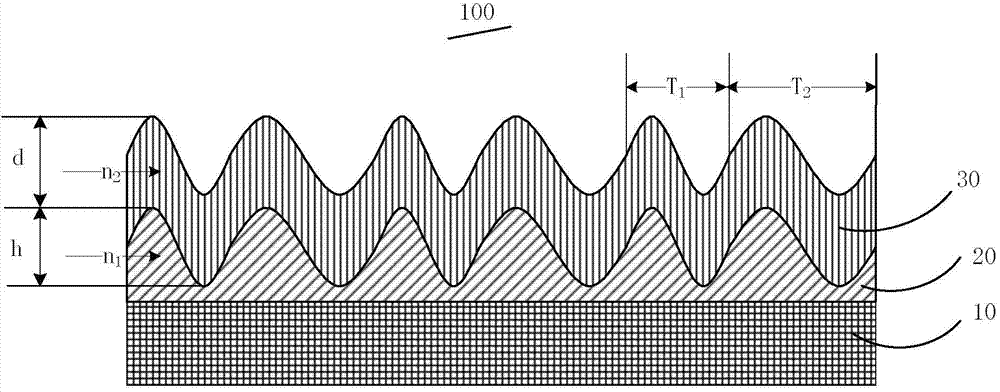

Anti-fake grating, anti-fake trademark, hot stamping film and composite film

InactiveCN103901517AImprove anti-counterfeiting performanceIncrease the scope of applicationStampsSynthetic resin layered productsInformation layerHot stamping

The invention provides an anti-fake grating which has the multi-channel color changing effect. The anti-fake grating comprises a substrate layer, a grating information layer and a dielectric layer, wherein the substrate layer, the grating information layer and the dielectric layer are sequentially stacked. The grating information layer is a sub-wavelength grating with the one-dimensional sinusoidal relief type quasi-reflection size, the sub-wavelength grating is a double-cycle grating which comprises a small-cycle sinusoidal grating and a large-cycle sinusoidal grating, the cycle of the small-cycle sinusoidal grating ranges from 320 nm to 420 nm, and the cycle of the large-cycle sinusoidal grating ranges from 600 nm to 900 nm. The anti-fake grating has the multi-channel color changing effect, can well combine public anti-fake identification with expert identification, and can effectively improve the anti-fake capability and application range of anti-fake labels. The invention further provides an anti-fake trademark, a hot stamping film and a composite film.

Owner:SHENZHEN SHENDA AURORA TECH

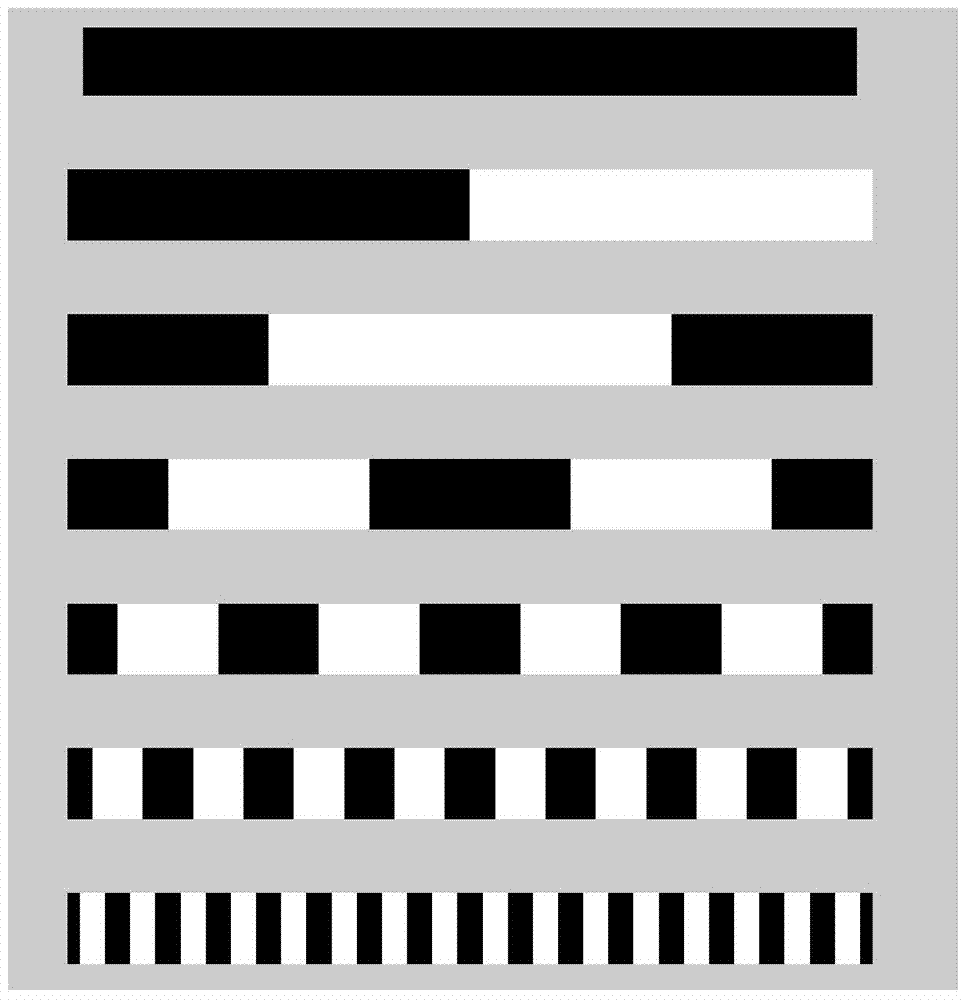

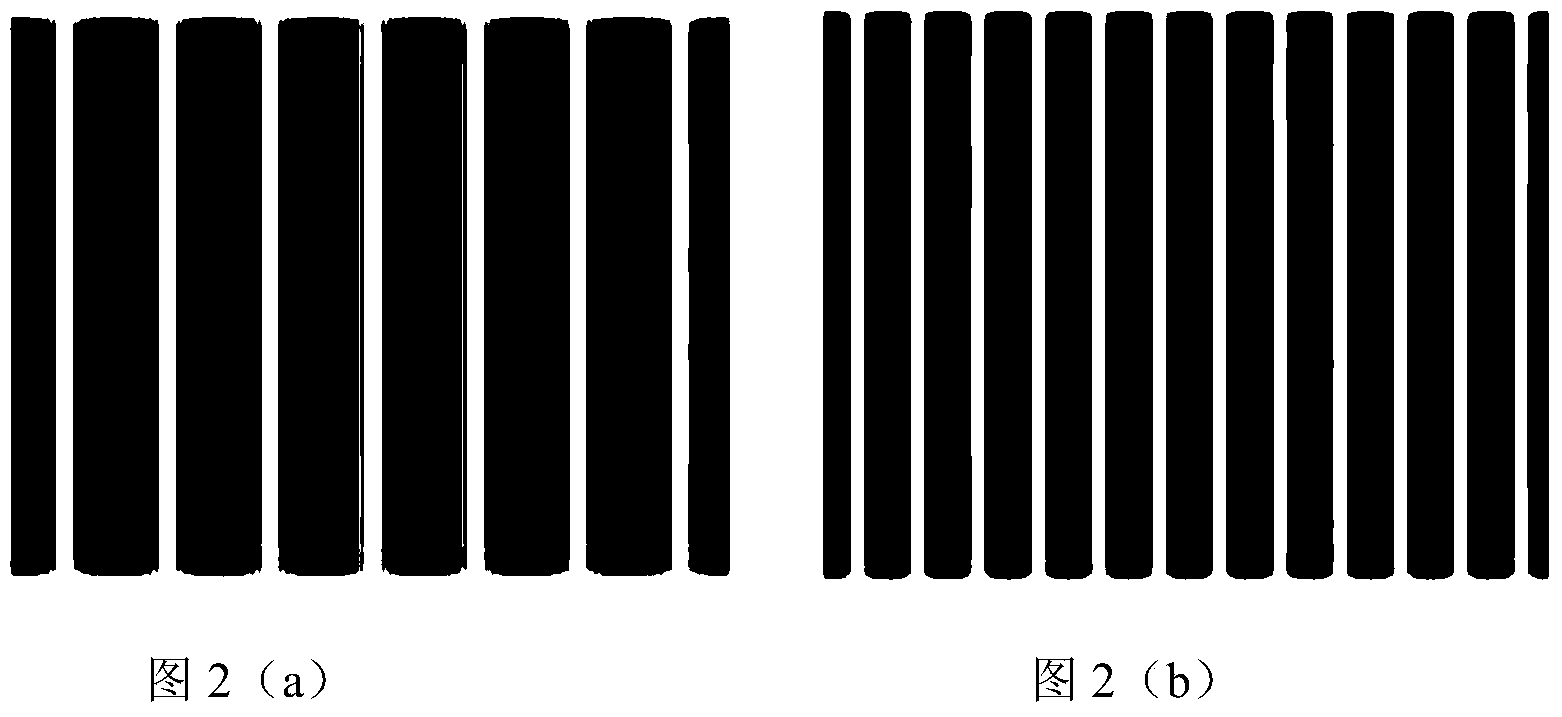

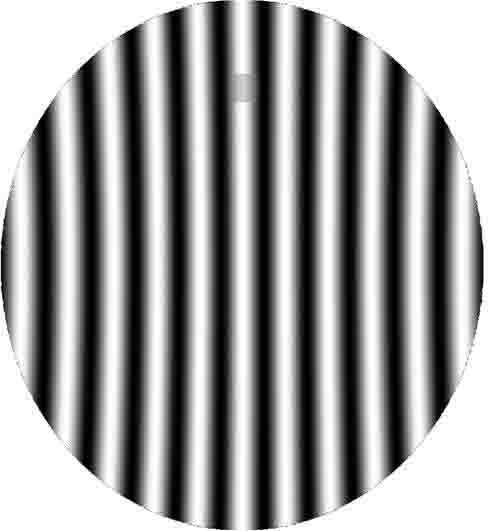

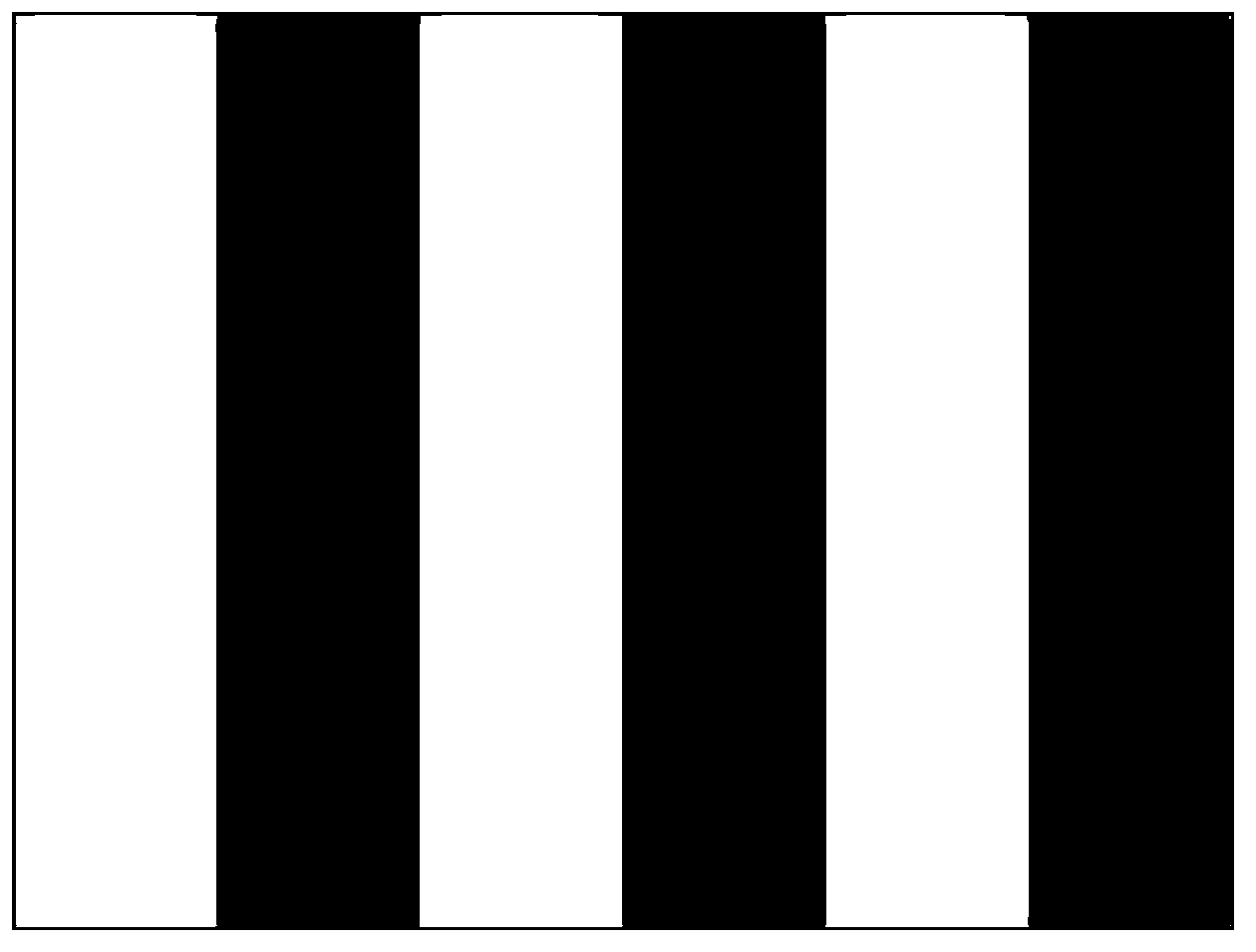

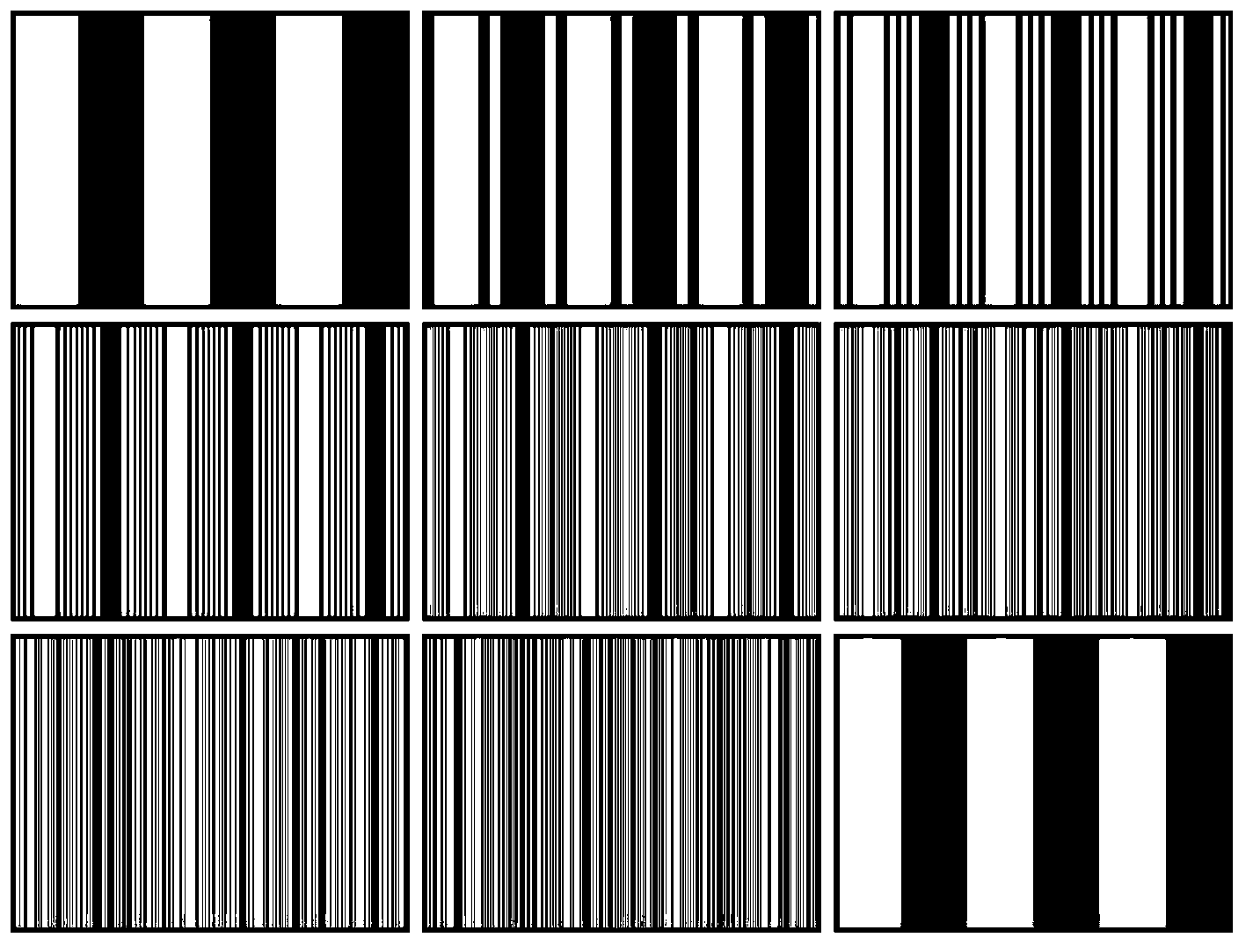

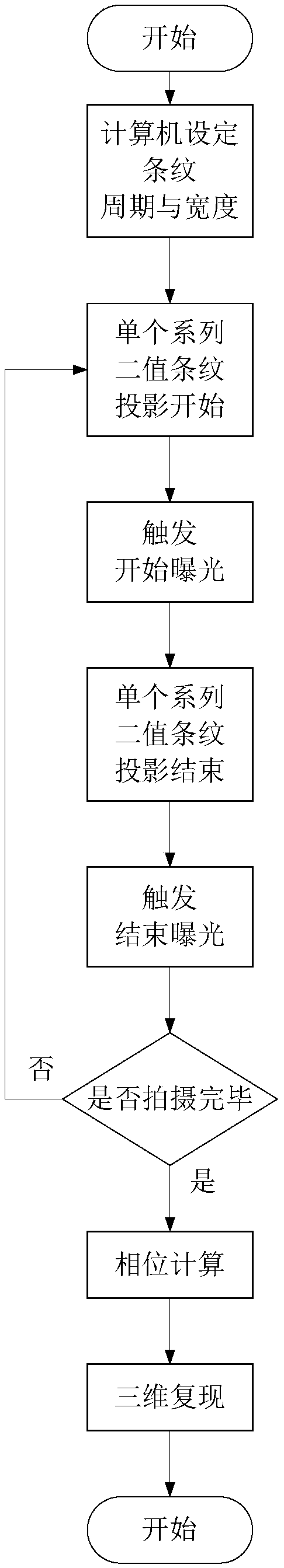

Binary stripe stack based sinusoidal grating generation method

The invention discloses a binary stripe stack based sinusoidal grating generation method. The method provided by the invention comprises the following steps of: firstly generating a sinusoidal grating picture, and decomposing one sinusoidal grating picture into 8 binary pictures through a binary method, wherein each point of each binary picture represents a bit of each point of the original sinusoidal grating after binary, and the value only can be 1 or 1; and through projecting the 8 binary pictures, finally combining the 8 binary pictures into one sinusoidal grating picture. Through the method provided by the invention, a composite plane sinusoidal grating protecting picture E can be obtained, the range of the pixel value of each point of the projecting picture E is from 0 to 255, and is in sinusoidal distribution, and thus errors caused by the nonlinear response of a projector and a camera can be prevented.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

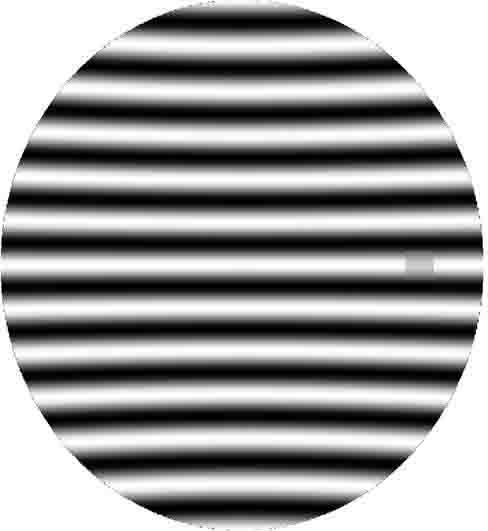

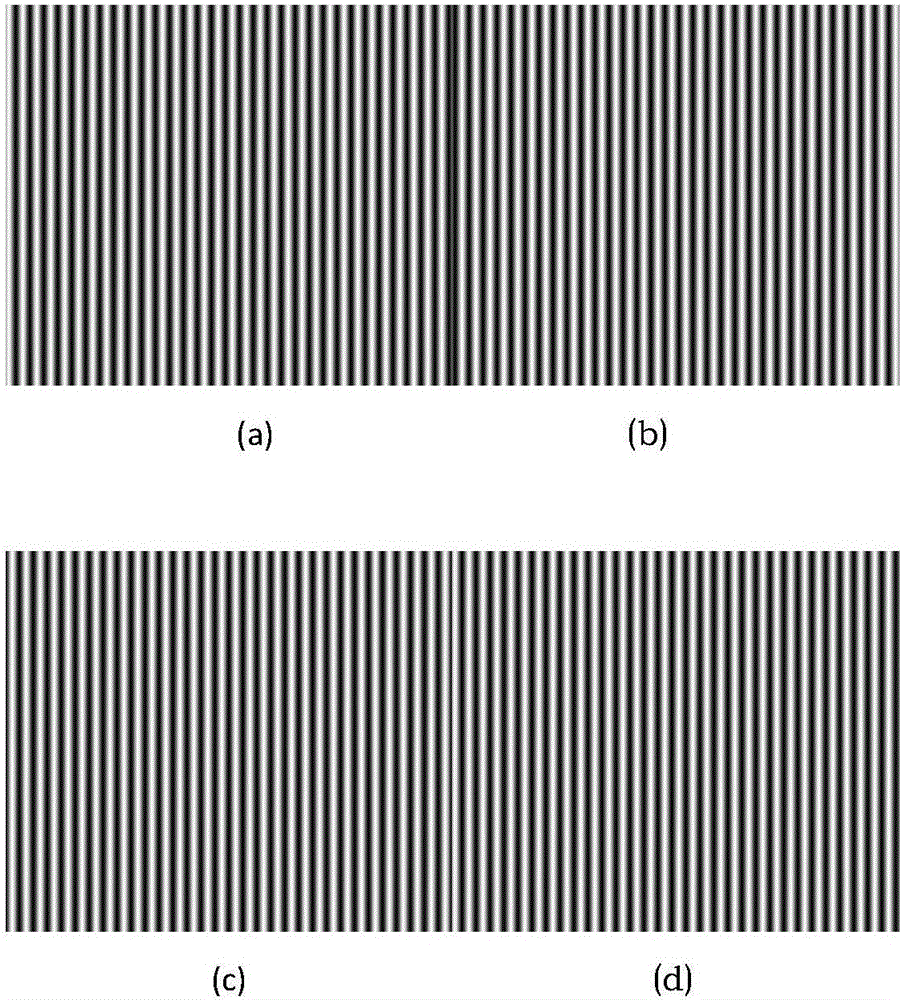

Rapid phase unwrapping method based on period encoding

ActiveCN106441161AHigh-resolutionHigh measurement accuracyUsing optical meansSinusoidal gratingCalculation error

The invention belongs to the technical field of structured light three-dimensional visual measurement in computer vision and particularly relates to a rapid phase unwrapping method based on period encoding. The method includes the steps that encoding gratings are manufactured, wherein the encoding gratings comprise four horizontal standard sinusoidal gratings with 90-degree phase shifting, four horizontal gratings for determining wrapping phase period information, four vertical standard sinusoidal gratings with 90-degree phase shifting, and four vertical gratings for determining wrapping phase period information; a projector is used for sequentially projecting encoding grating images on a tested object, and a camera is used for capture and save; each set of obtained images are solved, wrapping phases in the line direction and the column direction are obtained, and a first layer of period signals and the like are determined. The method is suitable for high-resolution projected gratings, the measuring resolution is improved, and a foundation is laid for improvement of the measuring precision. Each position is independently subjected to phase unwrapping, calculation errors cannot be accumulated, and the calculation precision is high.

Owner:HARBIN ENG UNIV

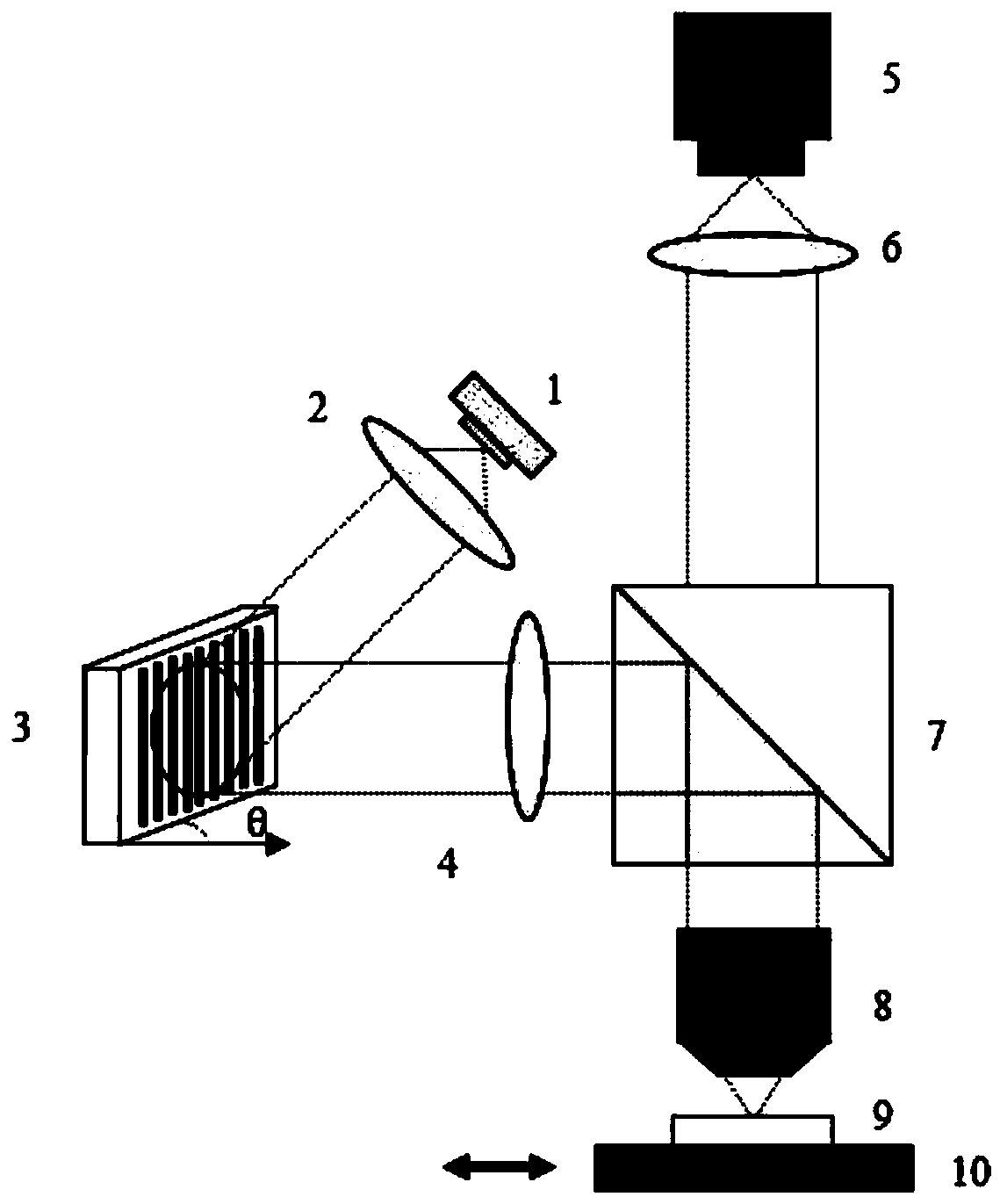

Structure light micro-nano structure three-dimensional detection method based on composite grating

ActiveCN109916331ARealize online 3D detectionHigh-speed and high-precision 3D shape detectionUsing optical meansSinusoidal gratingMicro nano

The invention discloses a structure light micro-nano structure three-dimensional detection method based on a composite grating. The composite grating formed by a horizontal sinusoidal grating and a sinusoidal grating inclined at a certain angle theta projects structure light on a surface of a tested object. During a process of horizontal scanning of the object to be tested, CCD synchronously collects modulated fringe image sequences from a conjugate light path through a beam splitting prism. A grating line direction of a horizontal grating is vertical to a horizontal scanning direction, and ahorizontal displacement of an entire field modulation degree of the object is extracted and calcualted to realize high-precision pixel matching of the image sequences. An imaging focal plane positionof an inclined grating is inclined and fixed. During a horizontal scanning process, phase shift and vertical scanning can be realized continuously, automatically and synchronously. The inclined grating is used for single point modulation degree extraction of the object, and height information is acquired to realize high precision micro-nano three-dimensional detection. In the invention, the objectto be tested is horizontally scanned so that a large-range and high-efficient three-dimensional measuring process can be realized, and the method has a good application prospect in the micro-nano detection field.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

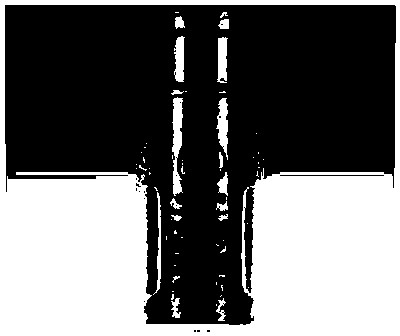

Three-dimensional visual measuring system based on high-speed triangle wave fringe projection principle

InactiveCN108680142AThe principle is simpleSimple structurePhotogrammetry/videogrammetrySinusoidal gratingDigital micro mirror device

The invention relates to a three-dimensional visual measuring system based on high-speed triangle wave fringe projection principle. The system mainly comprises a DMD (Digital Micro-mirror Device) projector, a high speed industrial camera and a computer, wherein the DMD projector consists of a DMD micromirror array, an LED (Light Emitting Diode) light source, a triggering circuit and a main controlcircuit. During the work, a black and white pattern is projected at the surface of an object to be measured by the DMD projector; meanwhile, the high speed camera is triggered for performing image shooting. The computer performs data processing and three-dimensional resolving on the shot image; the morphology information at the surface of the object to be measured is obtained. A specific black and white pattern is projected; a plurality of patterns are superimposed into a triangle wave fringe; the high-speed projection is realized. Compared with that of a traditional sinusoidal grating projection method, the speed is improved by 12 times or higher. Meanwhile, a triangular wave phase resolving method of a phase shifting method is used; after the provided high-speed measuring principle is concretely implemented, the high-speed three-dimensional measurement can be realized.

Owner:BEIHANG UNIV

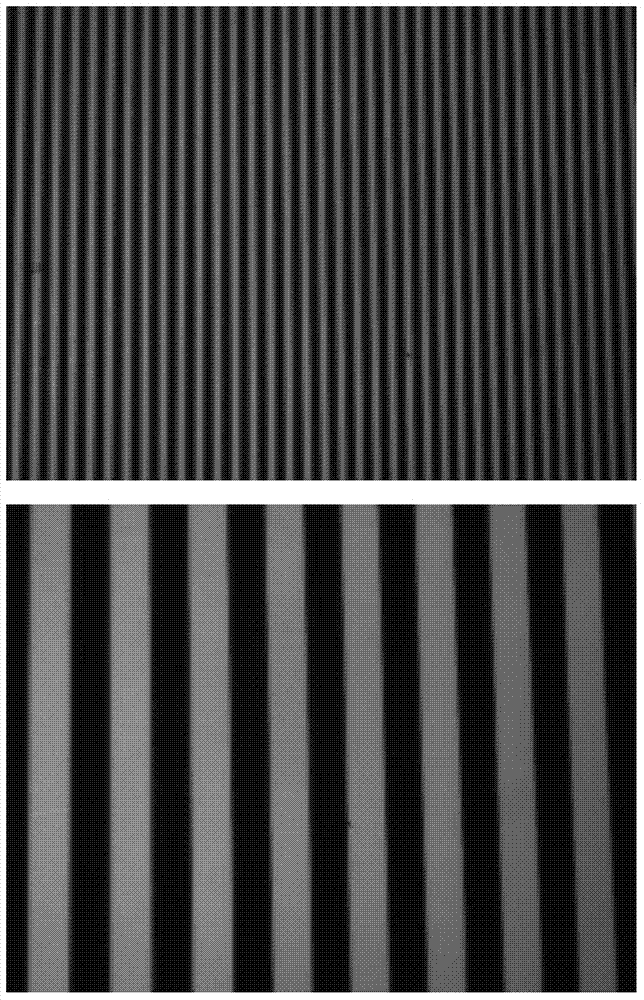

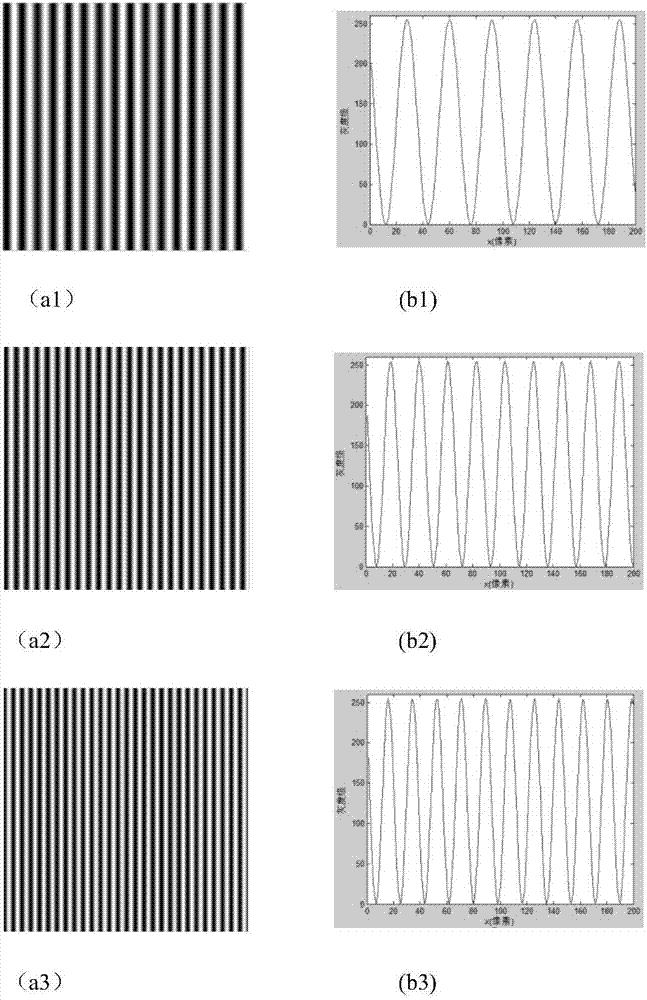

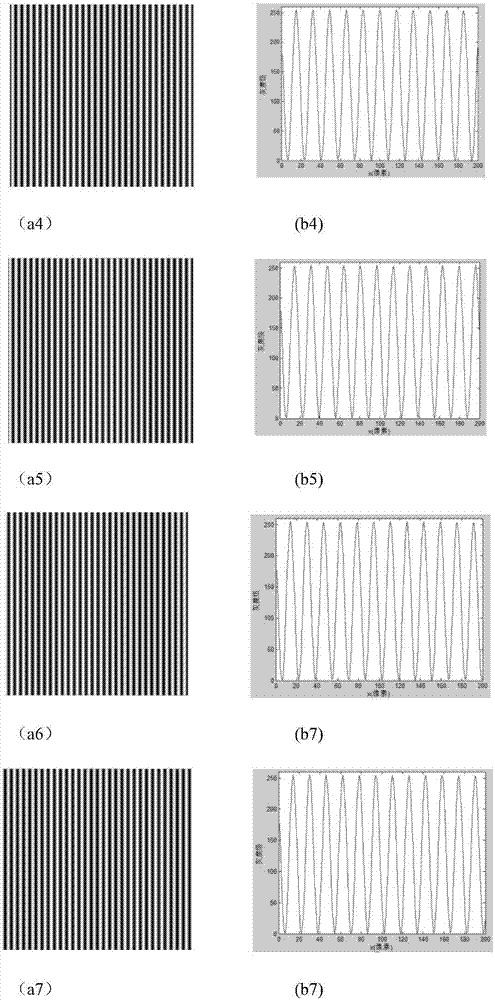

Adaptive lighting optimization method based on sinusoidal grating projection

InactiveCN106996754AAddress the disadvantages of lossReduce adverse effectsUsing optical meansSinusoidal gratingFundamental frequency

The invention relates to an adaptive lighting optimization method based on sinusoidal grating projection. The method comprises the steps that a projector is used to project seven computer-generated sinusoidal grating stripes with different frequency numbers on the surface of a three-dimensional target object; reference strips are modulated by the three-dimensional object depth and distort, and corresponding seven distortion strips are acquired respectively; the fundamental frequency components of 7 pairs of distortion strips and reference strips are extracted in the frequency domain through Fourier transform, so as to acquire the decompression phase continuously distributed in the space; pixel matching between the projector and a camera is established; seven distortion images collected by the camera are used as images before processing, and the processed images are projected onto the surface of the object through inverse proportion supplementary lighting of the projector; and for each kind of different grating projection, the best iterative image result is selected, and the optimal adaptive lighting mode is selected by comparing the number of dark / saturation pixels of the seven adaptive lighting image results.

Owner:TIANJIN UNIV

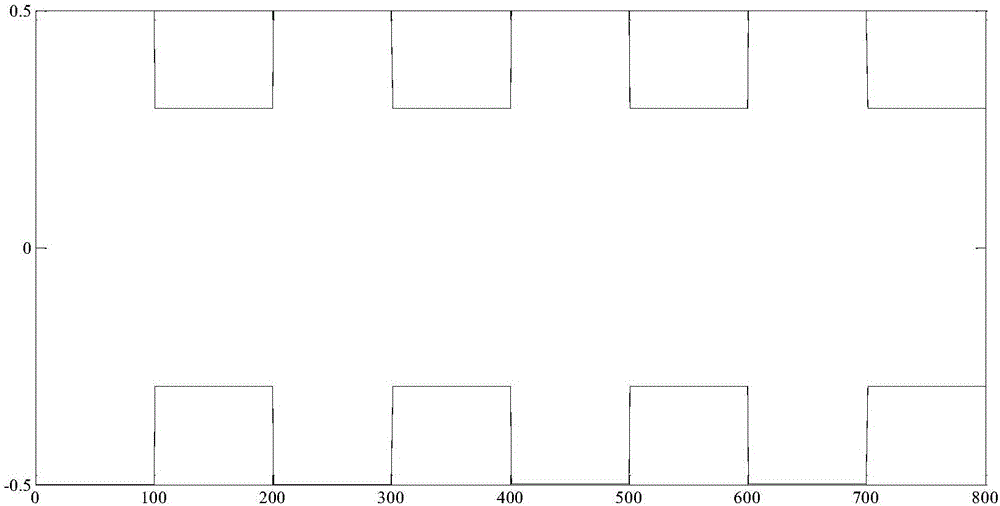

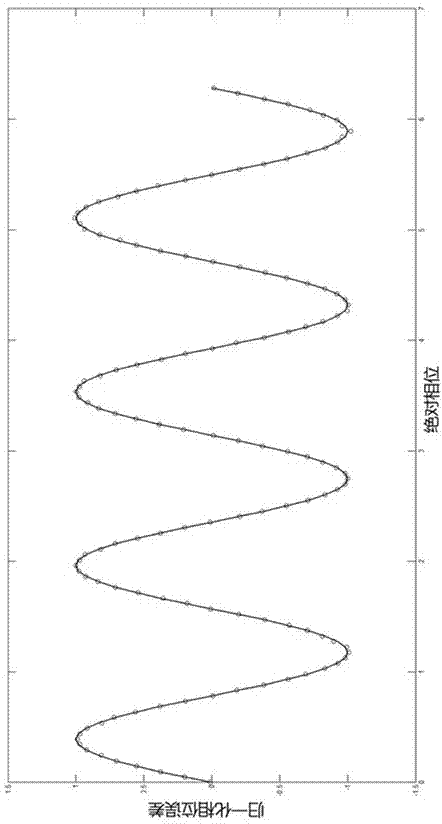

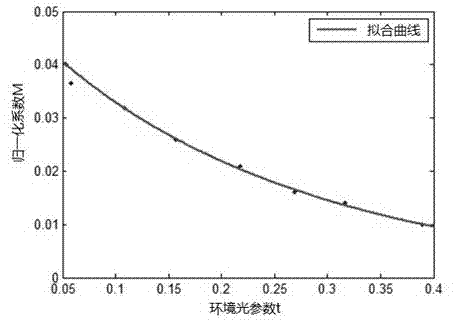

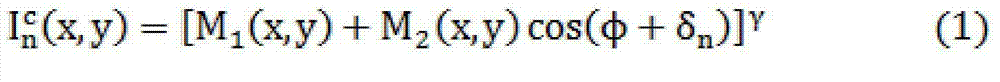

Method for solving phase error overcompensation and undercompensation in phase measurement profilometry

InactiveCN103615991AHigh measurement accuracyLow requirements for useUsing optical meansSinusoidal gratingPhase shifted

Provided is a method for solving phase error overcompensation and undercompensation in phase measurement profilometry. Based on an optical three-dimensional measurement method, a raster image is projected to an object surface, raster information modulated by an object surface profile is collected, the height of the object surface is restored, a projector, a CCD camera, an object to be measured and a computer are included, the projector projects a sinusoidal grating, the camera collects the deformed sinusoidal grating after object surface height modulation, the gamma nonlinearity of the projector and the camera and the influence of measuring environment light in the measurement process are considered, when phase errors are compensated in actual measurement, the projector projects completely black images, completely white images four-step phase shift images to the object to be measured, an environment light parameter t is calculated through the collected completely black images and completely white images, an absolute phase phi is calculated through a four-step phase shift phase solution method, the two parameters are substituted into a phase error penalty function, and a phase delta phi used for compensation can be obtained.

Owner:SOUTHEAST UNIV

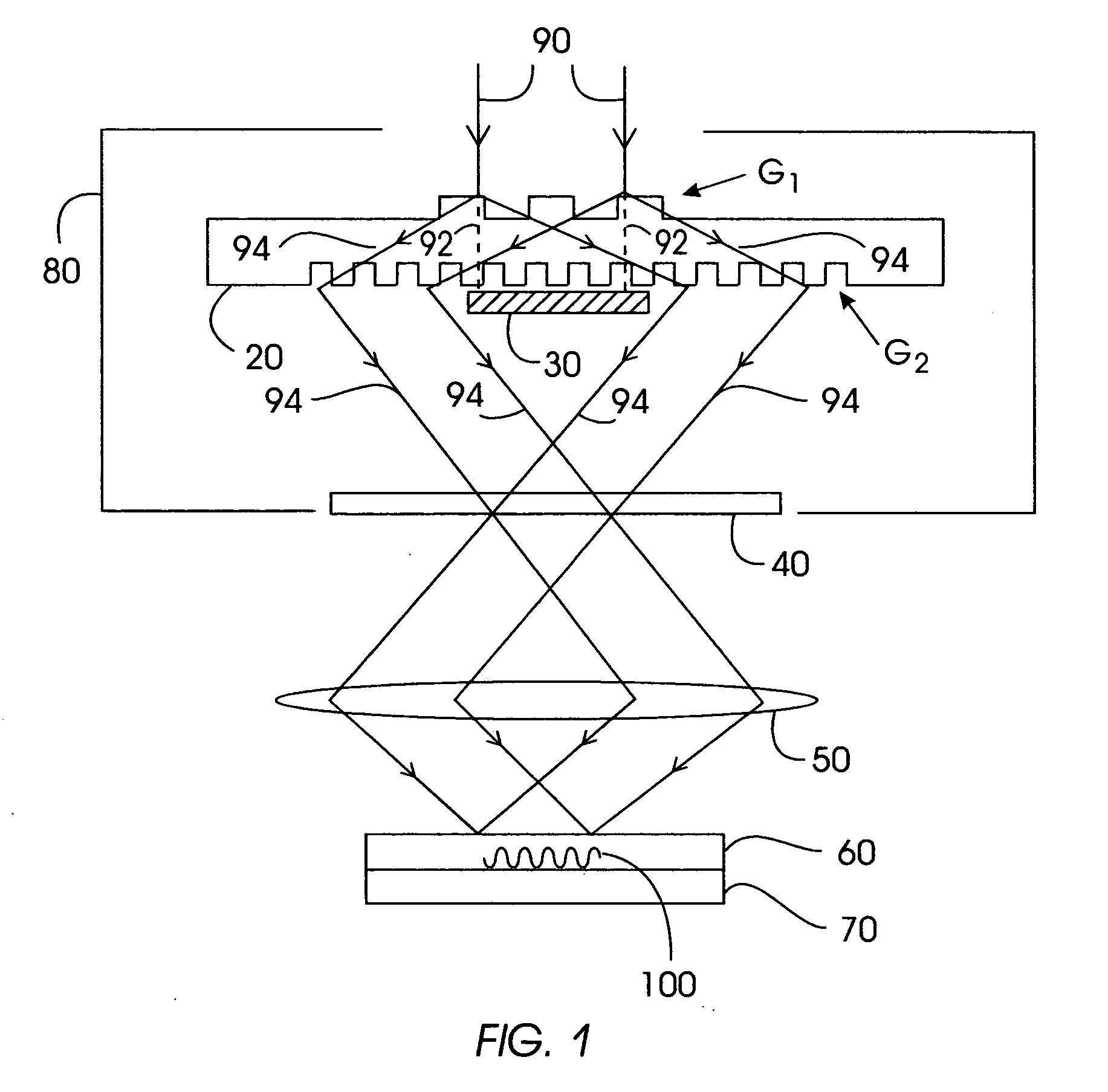

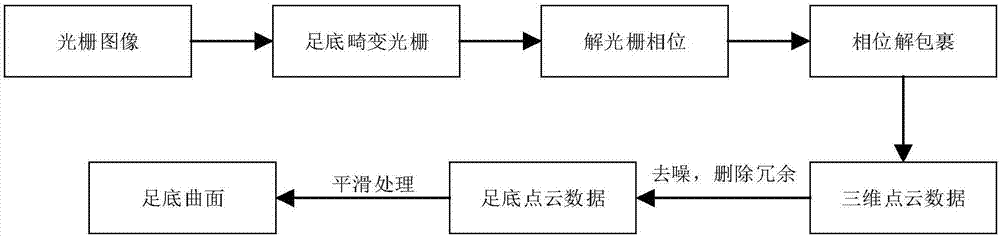

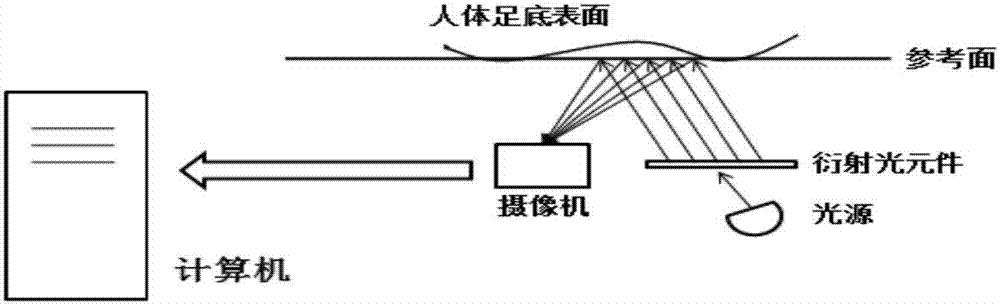

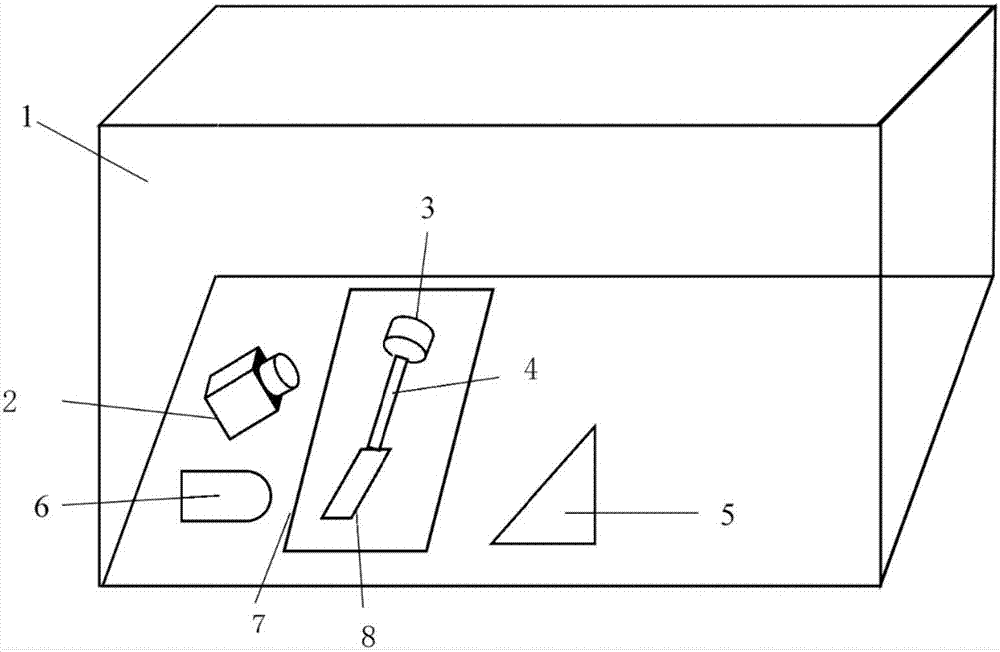

Three-dimensional planta pedis scanning device and method based on single-camera four-step grating phase shift method

ActiveCN107970026AReduced range of motionReduce data volumeDiagnostic recording/measuringSensorsSinusoidal gratingHuman body

The invention discloses a three-dimensional planta pedis scanning device and a scanning method based on a single-camera four-step grating phase shift method. A sinusoidal grating, a servo motor and agear, which are linked, are arranged on a transverse supporting plate on a side plate of a box body; a laser light source, which is adaptive to the sinusoidal grating, is arranged at the bottom of thebox body; an image reflective mirror surface is arranged in the middle of the box body; a single camera is arranged at the other end of the box body; the sinusoidal grating is irradiated on planta pedis of a human body; a physical grating, under the control of the servo motor, is moved by a certain distance; four distorted gratings that a phase difference is [phi] / 2 are formed on the surface of the planta pedis; by virtue of an industrial camera, four distorted grating images are acquired; and the gratings are subjected to phase analysis, so that three-dimensional data information of the planta pedis is obtained. According to the scanning device and the scanning method provided by the invention, the grating images are acquired by virtue of the high-precision industrial camera, and with the adoption of the four-step phase shift method, random noise can be filtered out and precision can be improved; and the system, which just uses one camera, can reduce system cost and implement high-precision scanning.

Owner:XI AN JIAOTONG UNIV

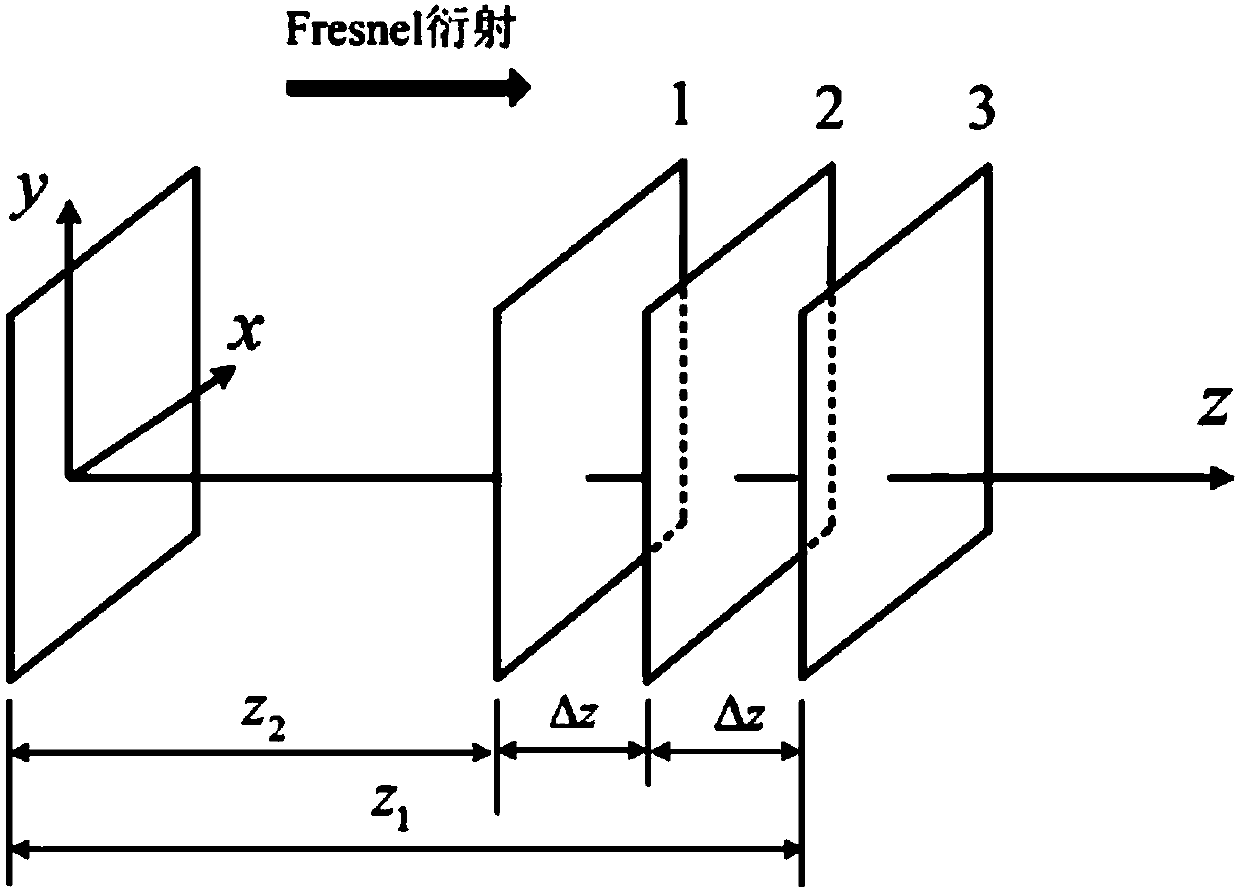

Phase recovery system based on light intensity transmission measurement and calculation

PendingCN107942523AGuaranteed resolutionOvercome the limitation of low resolutionOptical elementsSinusoidal gratingSpatial light modulator

The invention provides a phase recovery system based on light intensity transmission measurement and calculation. The system comprises a first 4f system and a second 4f system; the first 4f system ismainly composed of a first Fourier transform lens, a second Fourier transform lens, a light splitting prism, a first spatial light modulator and a second spatial light modulator; and the second 4f system is mainly composed of a third Fourier transform lens, a fourth Fourier transform lens, a transparent imaging screen, a sine grating and a CCD. According to the invention, optical measurement and calculation are combined, a differential image is obtained directly via an optical system instead of collecting under-focus and over-focus images and using the under-focus and over-focus images as approximation of intensity differential terms, it can be ensured that the resolution of the differential image matches the CCD, errors caused by mechanical movement of the CCD in a traditional system areovercome, and the problem that images collected by an SLM based single-frame measurement system are low in resolution is solved.

Owner:ANHUI UNIVERSITY

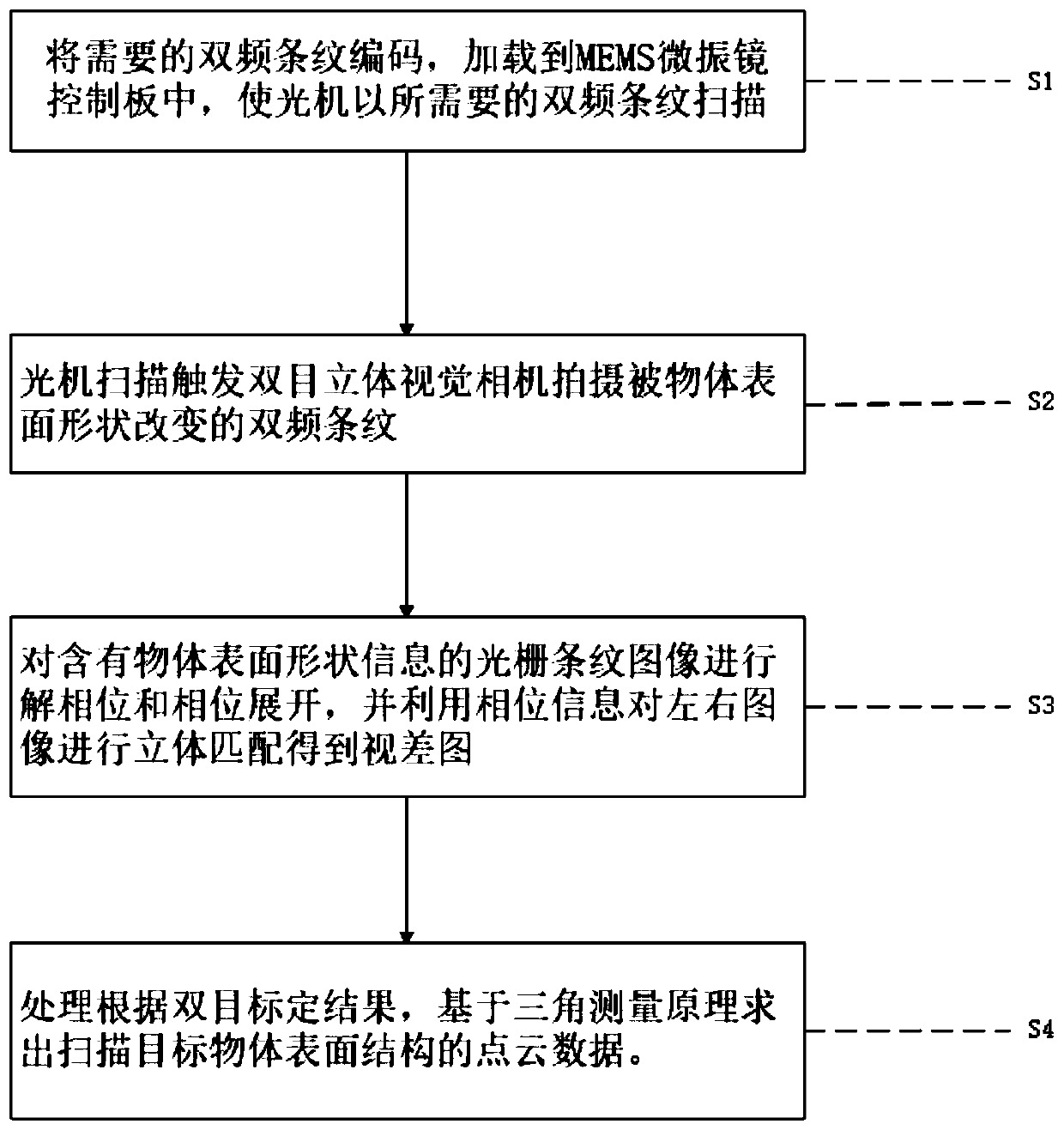

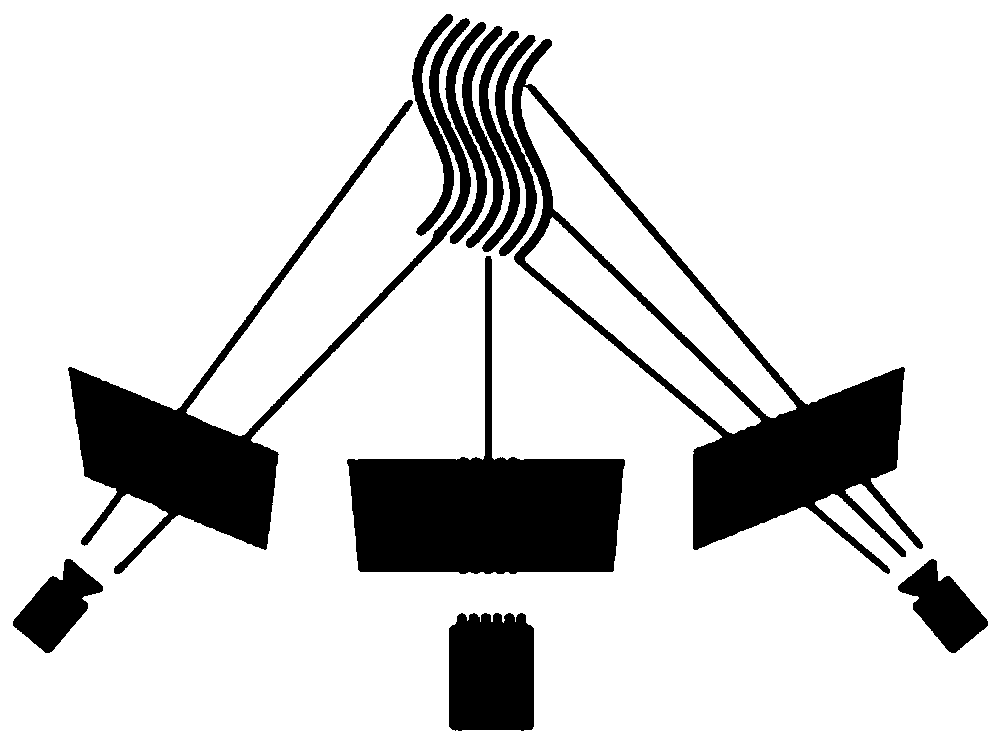

Three-dimensional reconstruction accuracy improvement method and device based on laser grating scanning

InactiveCN109798845AReduce noiseReduce continuityUsing optical meansSinusoidal gratingThree dimensional measurement

The invention provides a three-dimensional reconstruction accuracy improvement method and device based on laser grating scanning. The method includes the steps: encoding needed double-frequency stripes, loading the encoded double-frequency stripes into an MEMS (micro-electro mechanical system) micro vibration mirror control panel, scanning the panel by an X-ray machine according to the double-frequency stripes, and triggering the binocular stereoscopic camera to shoot the double-frequency stripes changed by an object surface shape by scanning of the X-ray machine; performing phase unwrapping on grating stripe images containing object surface shape information, and stereoscopically matching the left images and the right images by the aid of phase information to obtain parallax maps; calculating point cloud data for describing target object surfaces based on three-dimensional measurement principles according to binocular calibration results. Principal value phase image noise or discontinuous conditions are decreased, accuracy of an unwrapped phase is improved, the difference between two groups of initial phases is designed into 45 degrees by projecting two groups of four sinusoidal grating stripe images, a four-step phase shift algorithm is executed twice to obtain two principal value phase images, measuring errors can be greatly reduced, and the method can be effectively used for actual measurement.

Owner:QINGDAO XIAOYOU INTELLIGENT TECH CO LTD

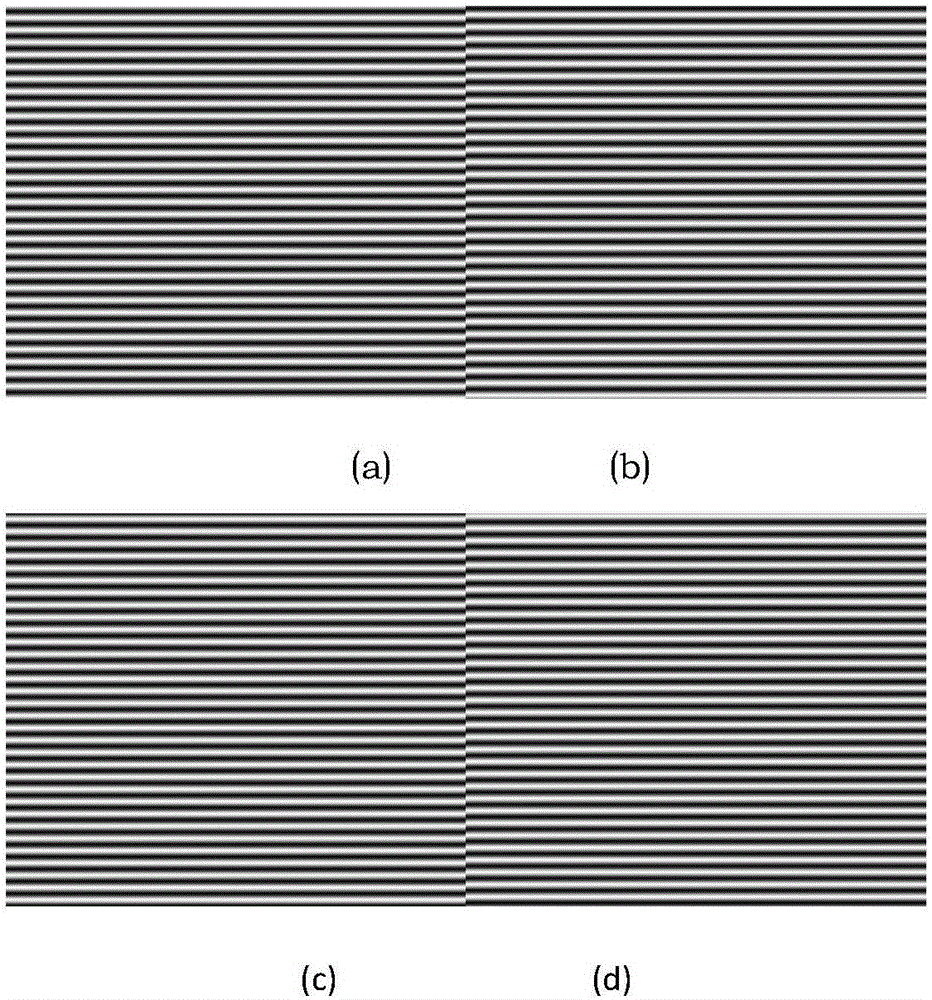

Generation method of sinusoidal grating based on regional defocusing

InactiveCN102798344AEasy to implementGenerate accuratelyUsing optical meansSinusoidal gratingHarmonic

The invention discloses a generation method of a sinusoidal grating based on regional defocusing, comprising the following steps of: performing 2*2 regionalization on the connected pixels via construction; performing different binary assignments on the pixels in the regions; generating a high-accuracy triangular wave grating via defocusing; and then performing secondary defocusing on the triangular wave grating to obtain the sinusoidal grating meeting accuracy requirements. The generation method is convenient to realize, accurate in grating generation and suitable for a high-accuracy non-contact three-dimensional real-time measurement system, thus effectively solving the defects existing in the prior art. Via division and assignment for the regions of 2 pixels*2 pixels and slight defocusing, the error brought by the gamma nonlinearity problem of a projector during direct generation for the triangular wave grating is effectively eliminated, the regions of 2 pixels*2 pixels can be regarded as an integer after the step 1 and the step 2, and a triangular wave grating image meeting requirements is generated; and via the secondary defocusing in the step 3 for the high-accuracy triangular wave grating image, higher harmonic in the high-accuracy triangular wave grating image is filtered out, so that a satisfactory sinusoidal grating image is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com