Method for solving phase error overcompensation and undercompensation in phase measurement profilometry

A technology of phase measurement profile and phase error, which is applied in the field of phase error overcompensation and undercompensation, and phase error compensation in phase measurement profilometry, and can solve problems such as overcompensation, phase error, and undercompensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

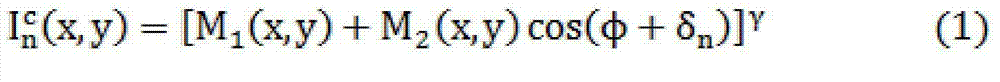

[0049] Take the 3D measurement using the four-step phase shift method as an example.

[0050] In the phase error compensation preprocessing, the projector projects all black, all white, four-step phase shift and sixteen-step phase shift images to the measured object, and collects the corresponding images. The purpose of projecting a sixteen-step phase-shifted image is to calculate an accurate absolute phase.

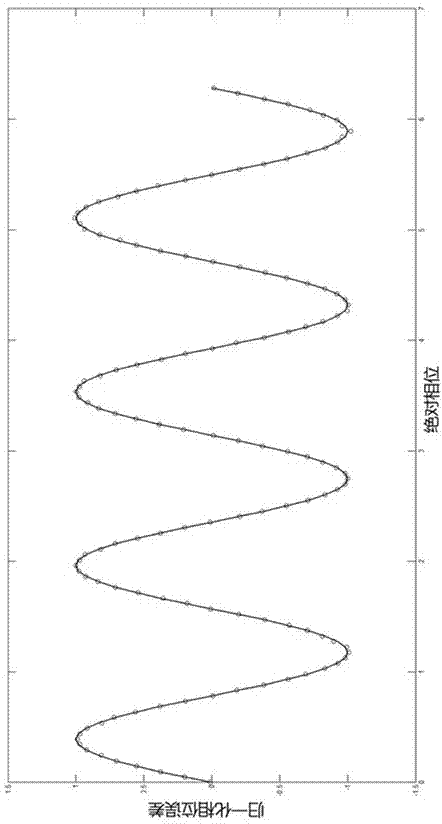

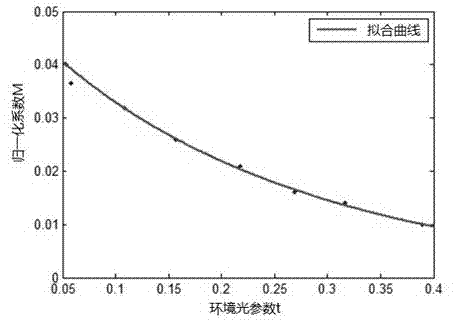

[0051] According to formula (19), the phase error consists of two parts, where It is the phase error coefficient related to the system gamma value and ambient light, and sin4φ is the harmonic normalized phase error related to the absolute phase measurement in theory. The two parts are determined separately.

[0052] In this embodiment, for the harmonic normalized phase error sin4φ, considering the random error in the measurement, it is determined by the method of curve fitting, and the specific steps are as follows:

[0053]1) Solve the absolute phase of the acquired ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com