Patents

Literature

60results about How to "Low requirements for use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

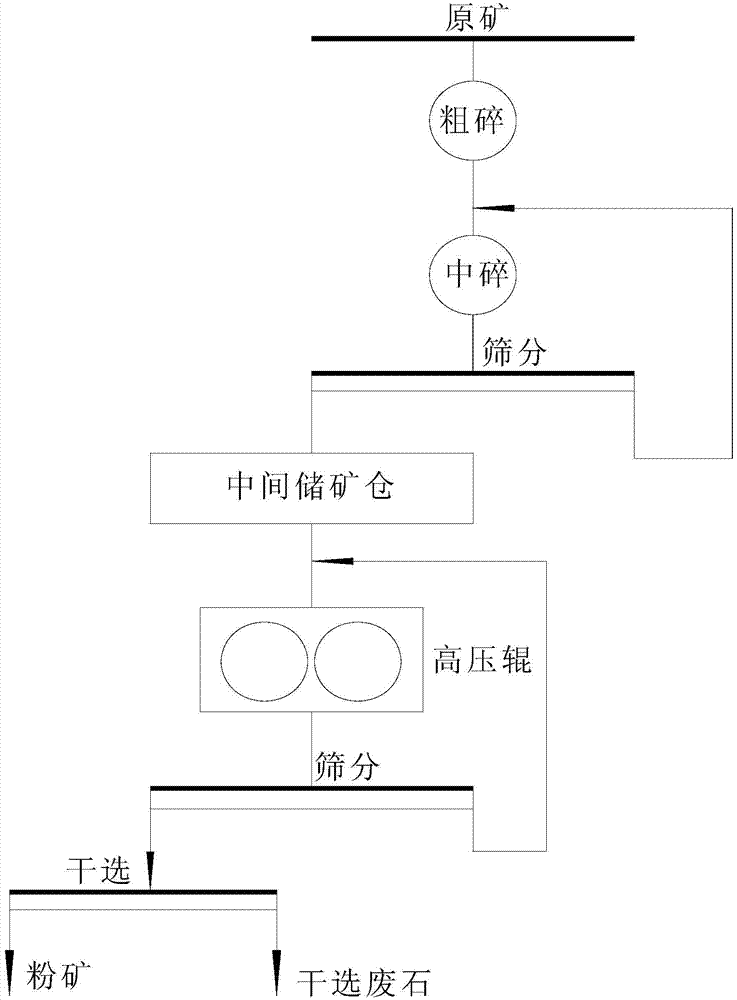

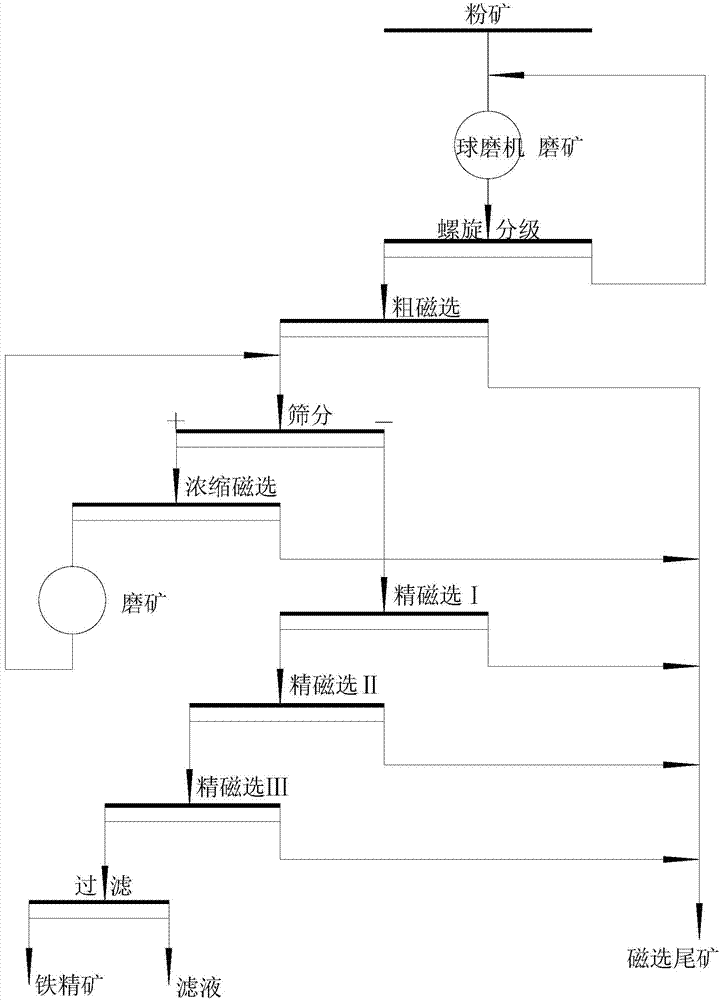

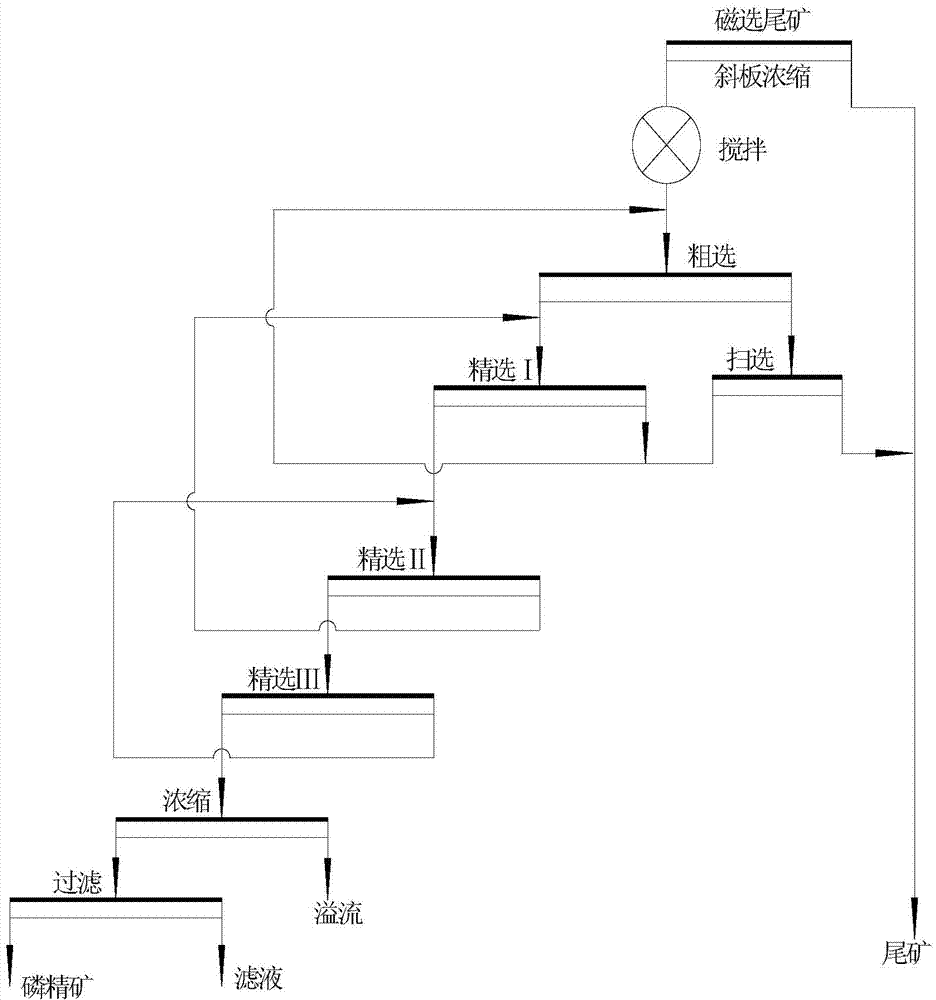

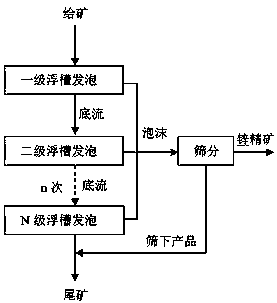

Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

The invention belongs to the technical field of efficient development of ultralow-grade ore resources and comprehensive utilization of associated minerals, and in particular relates to a combined beneficiation method and a combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals. The combined beneficiation method for the comprehensive recovery of the associated iron-phosphate minerals comprises the following steps: sequentially performing three-section and two-closed-loop crushing and screening flow on raw ores, and performing dry separation to obtain fine ores; performing two-section closed-loop ore-grinding flow on the fine ores, performing fine magnetic separation for three times, and concentrating by using a wash mill to separate iron ore concentrate and discharge tailings; performing one-time roughing, one-time scavenging and three-time concentrating on the tailings at the temperature of 10-15 DEG C to obtain phosphate ore concentrate by floatation. Compared with the prior art, the invention provides a comprehensive recovery scheme for magnetic iron ore resources and phosphate ore resources in ultralow-grade associated iron-phosphate minerals. According to the scheme, the separation cost is low, the efficiency is high, energy is saved, the space occupation is low, and the comprehensive recovery of the magnetic iron ores and the phosphate ores can be realized.

Owner:中冶沈勘工程技术有限公司

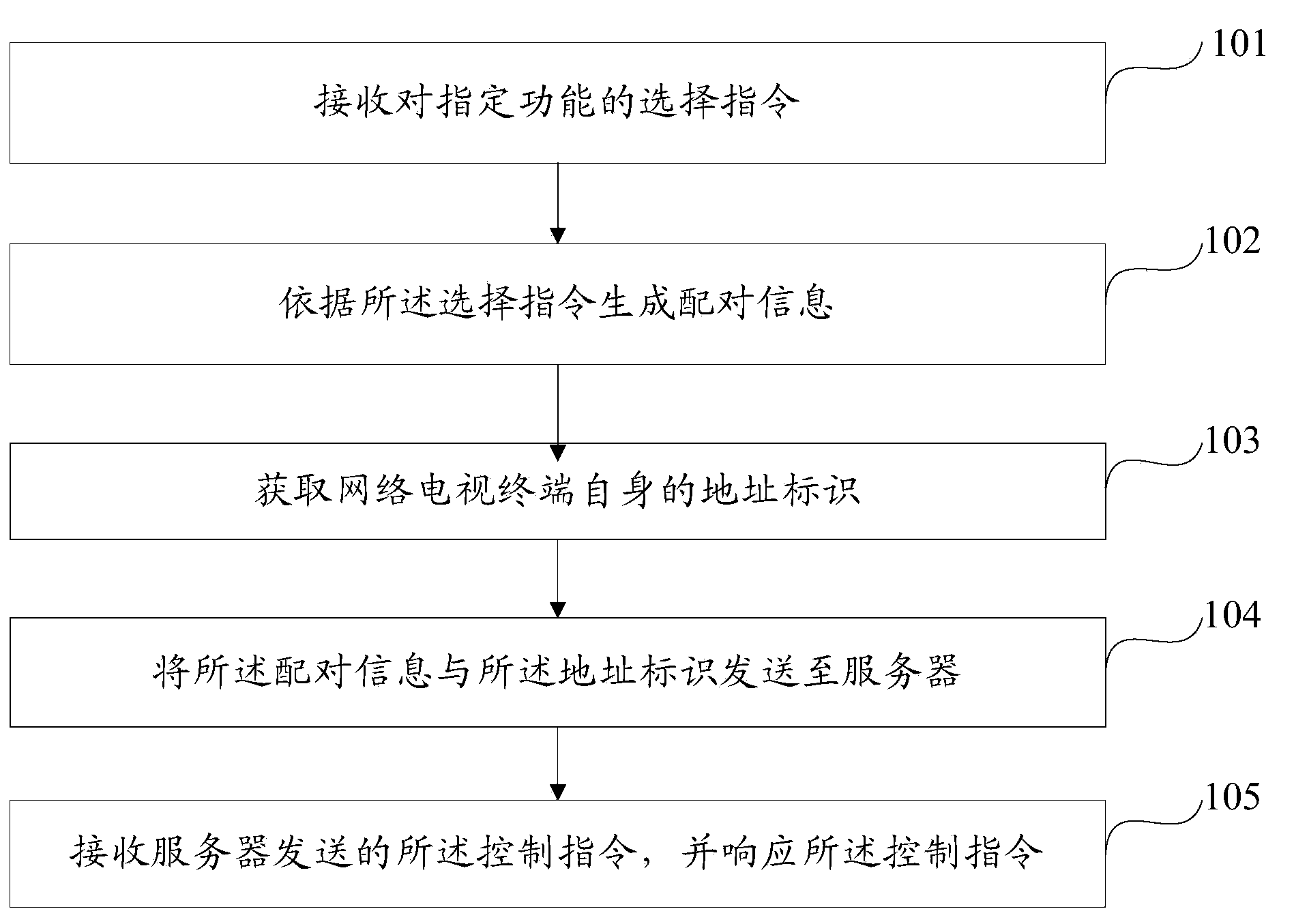

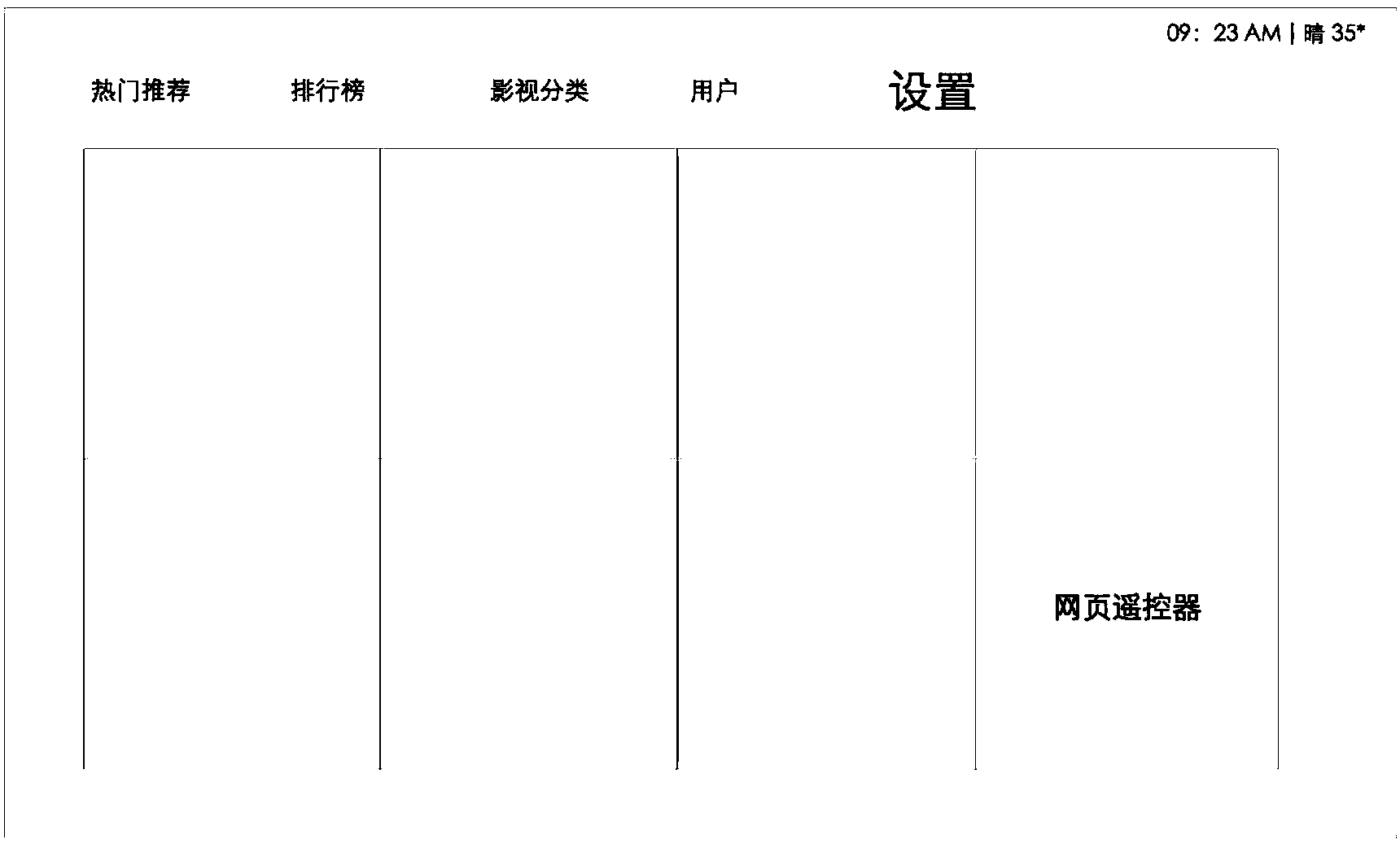

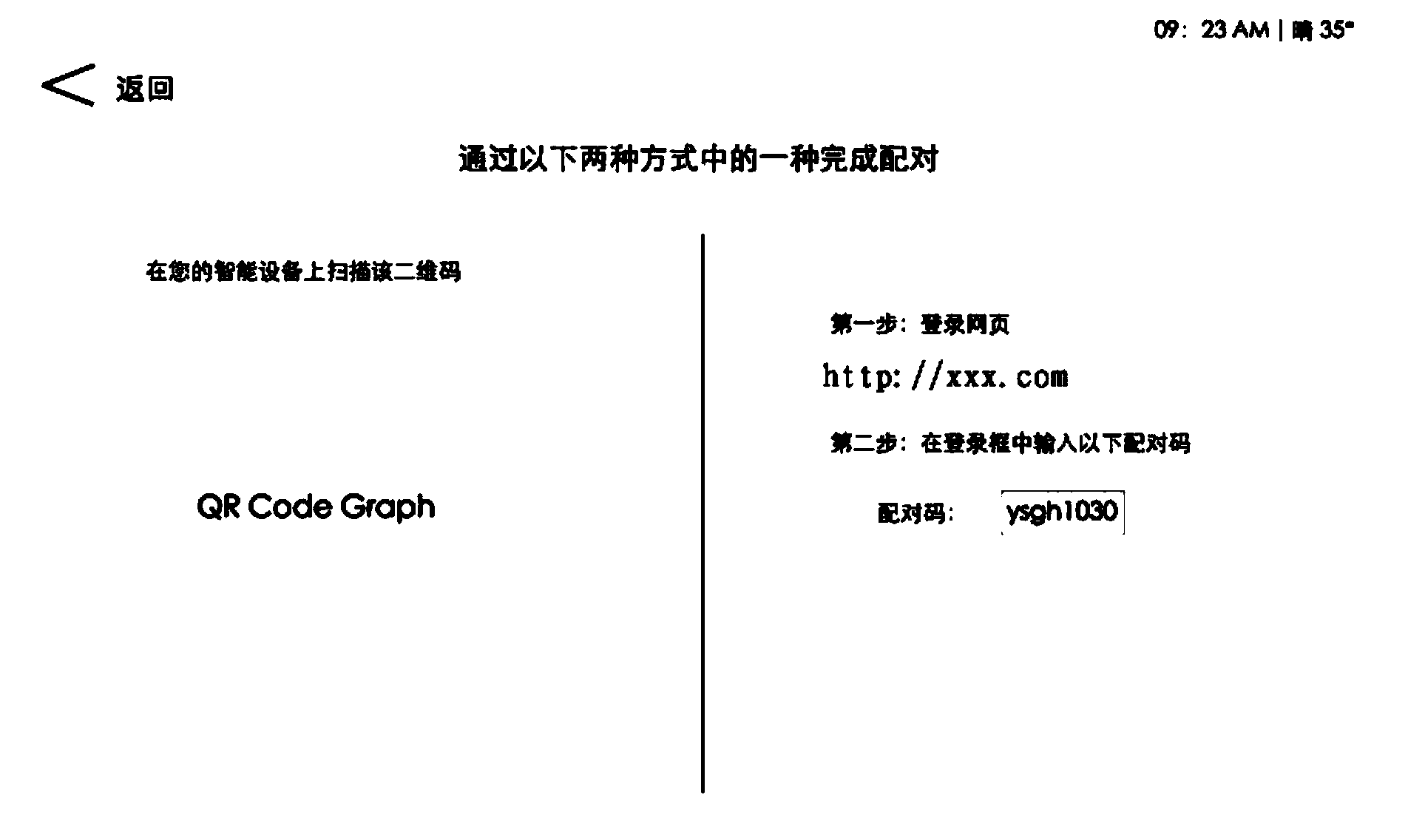

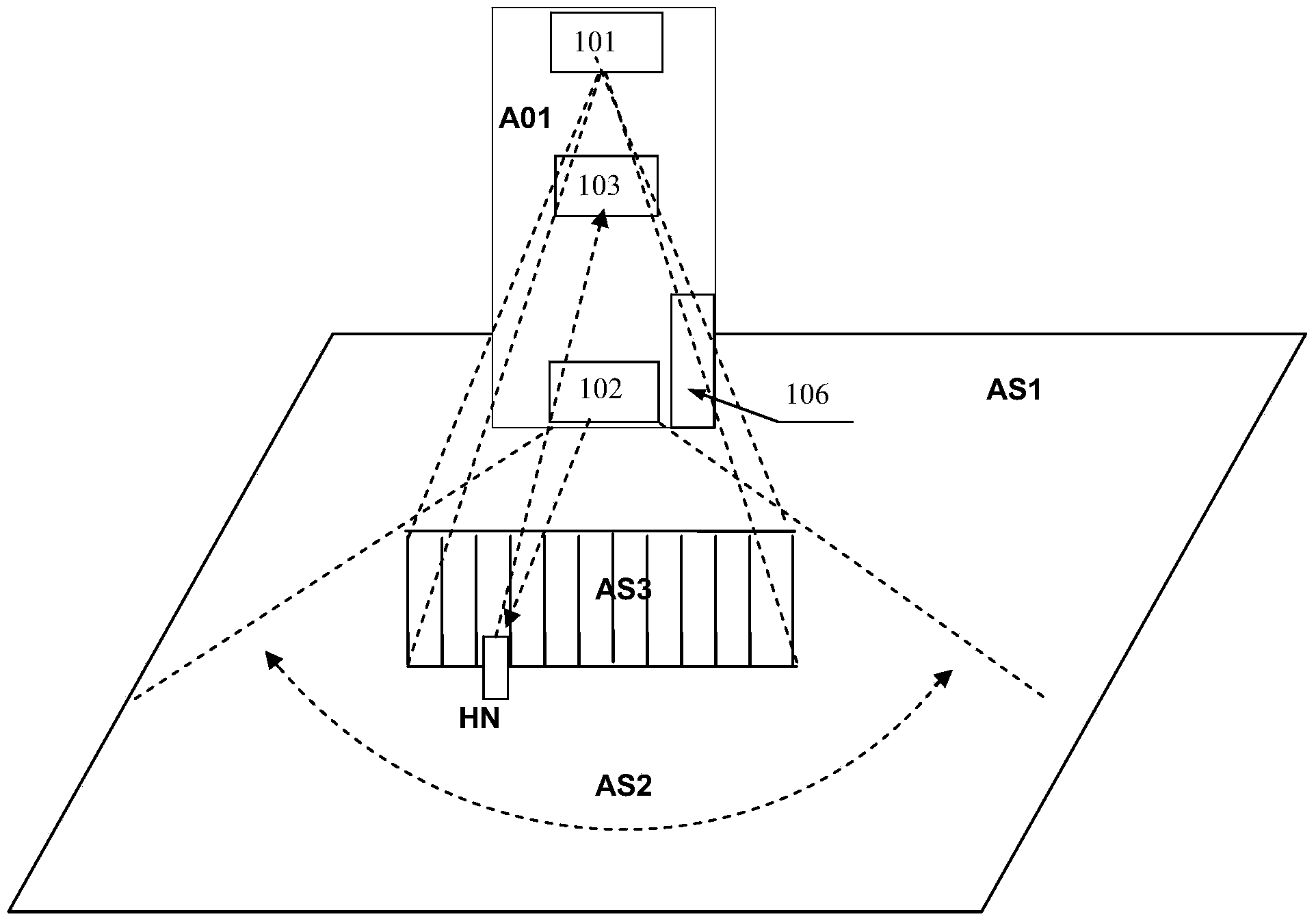

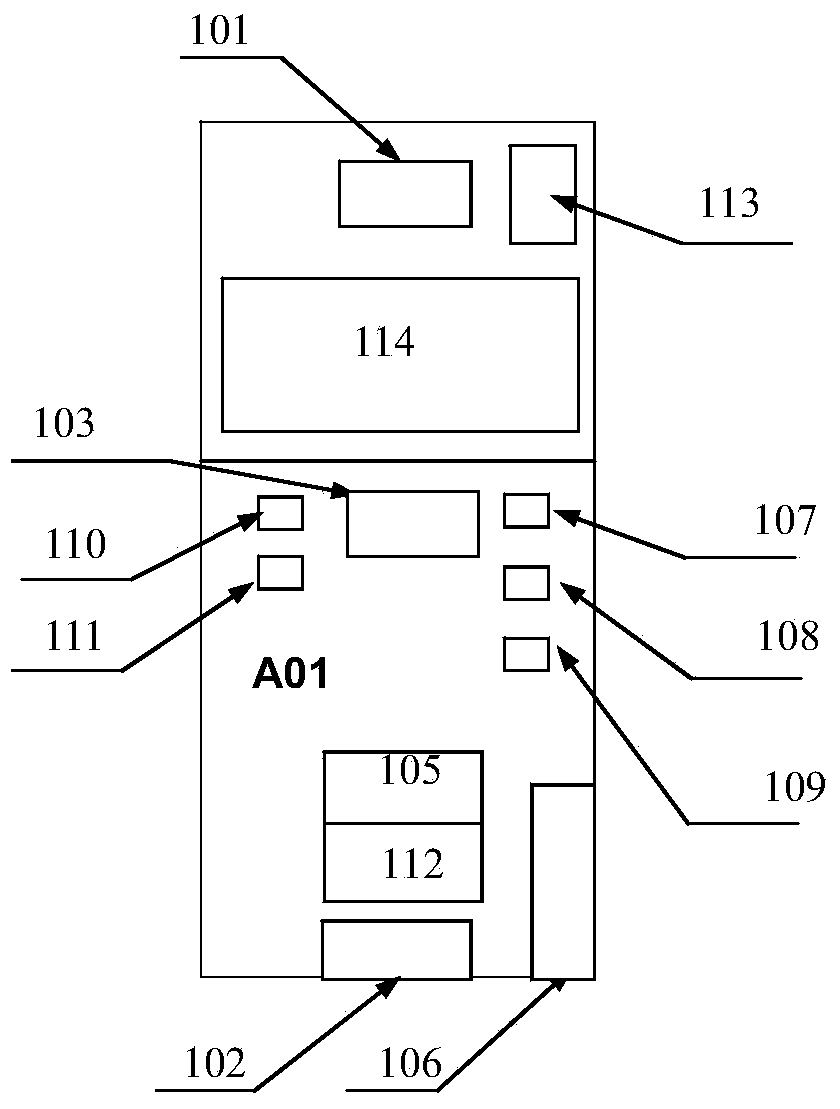

Method and device for wireless control over network television terminal

ActiveCN103458012ALow requirements for useTake advantage ofTransmissionSelective content distributionComputer networkWireless control

The embodiment of the invention provides a method and device for wireless control over a network television terminal. The method includes the steps that a selection instruction of a specified function is received; according to the selection instruction, pairing information is generated; address identification of the network television terminal is obtained; the pairing information and the address identification are sent to a server; a control instruction sent by the server is received in a responding mode. According to the embodiment, the characteristic that a network television or a network television set top box is naturally kept being connected with a network can be effectively utilized, and a connecting relation and a controlling relation are established between a networking device and the network television or the television set top box with a web page as a medium.

Owner:XIAOMI INC

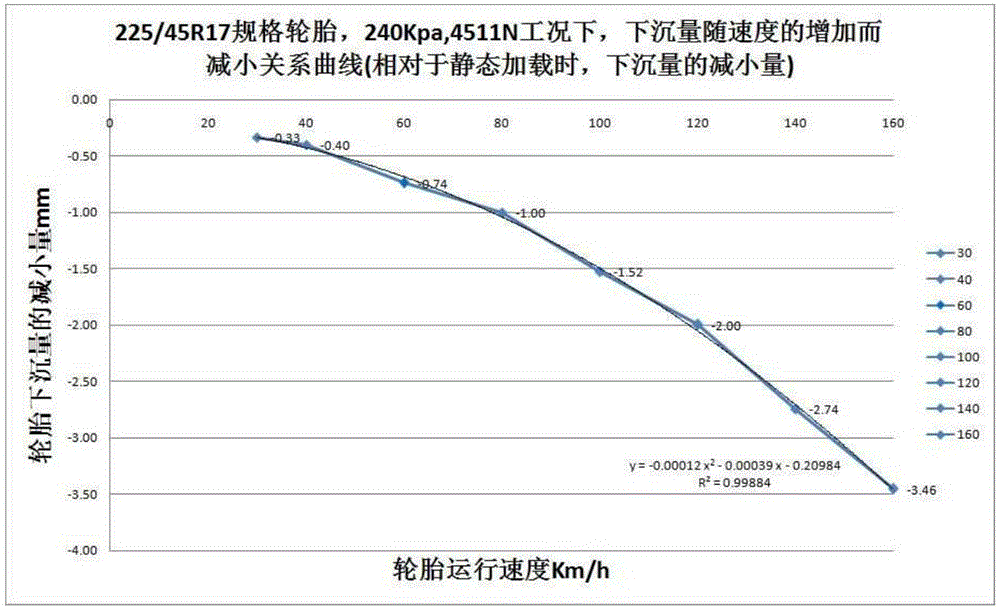

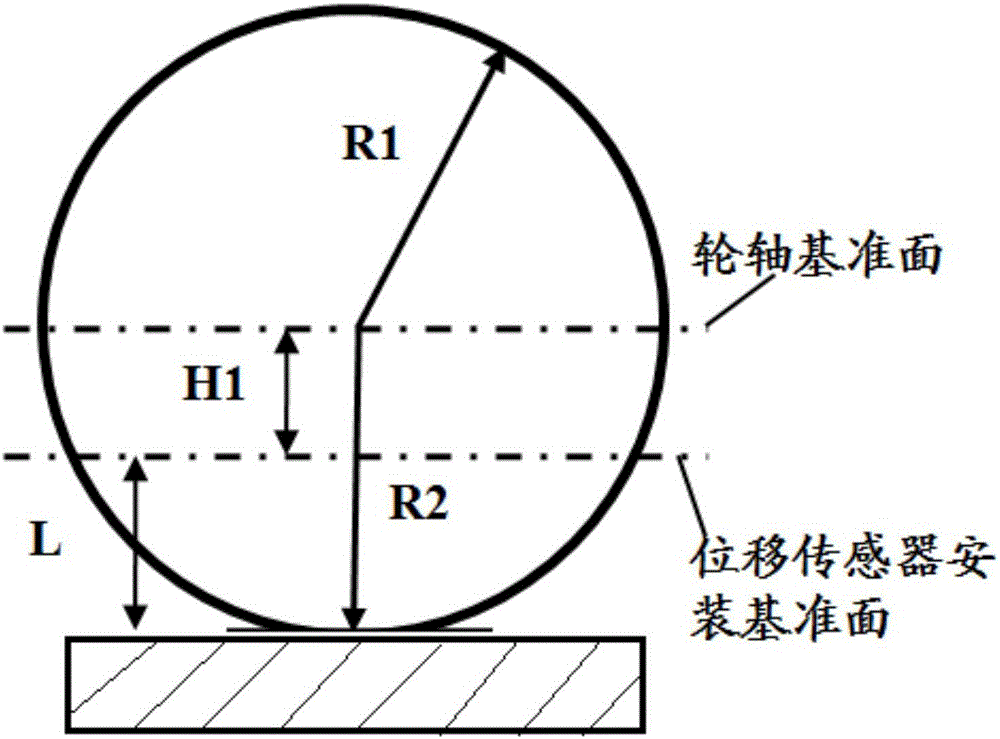

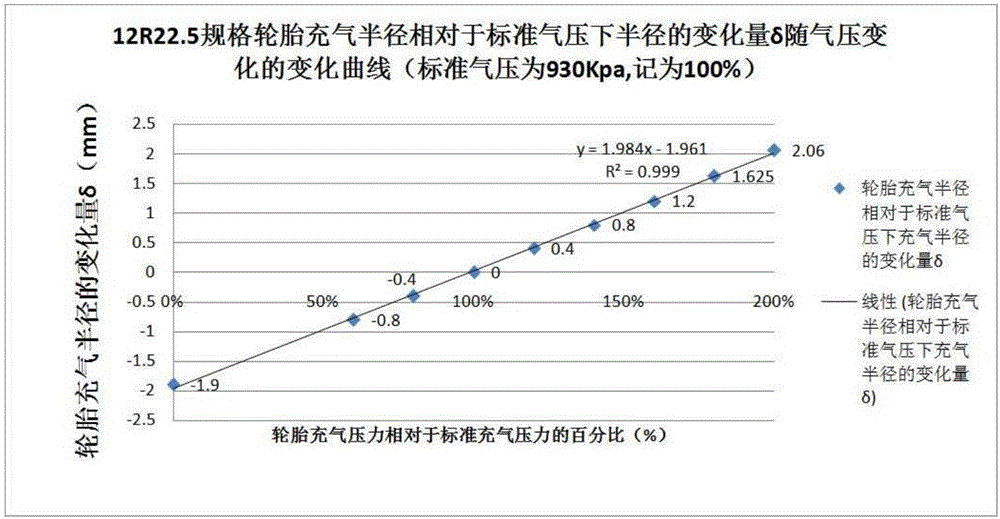

Method and system for detecting tire dynamic vertical load during traveling period of vehicle

ActiveCN106626994ASimple calculationImprove accuracyTyre measurementsElectric/fluid circuitVertical loadAtmospheric pressure

The invention discloses a method for detecting the tire dynamic vertical load during traveling period of a vehicle. The method for detecting the load comprises the steps that vehicle operation speed v is measured through a GPS vehicle speed testing component; tire real-time air pressure Pre is measured through a tire pressure monitoring system; the real-time distance L of a displacement sensor installation datum plane relative to the ground is measured through a displacement sensor; and a controller collects the v, the Pre and the L in real time and processes the v, the Pre and the L through the formulas (1) and (3), and the real-time load Load of a tire is obtained. The speed of vehicle operation and the air pressure of the tire are measured in real time by measuring change of the distance between the specific point on the tire and the ground, thus the real-time load of the tire is obtained, accurate vertical real-time load information is obtained, and the load numerical precision is high.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

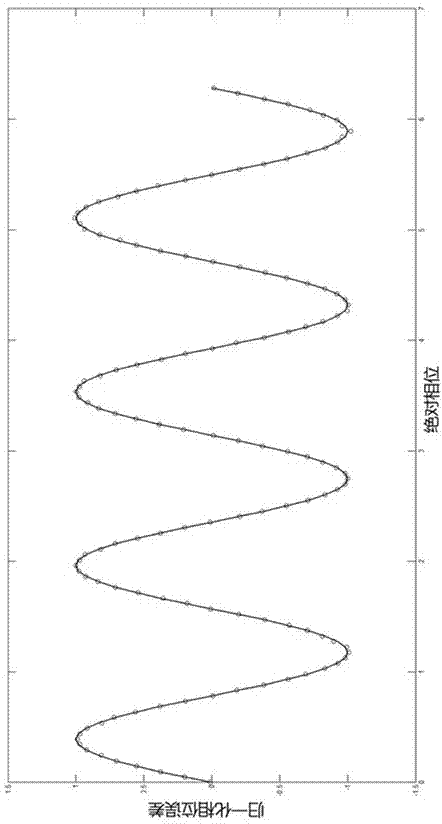

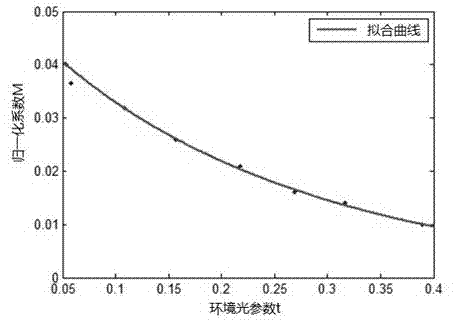

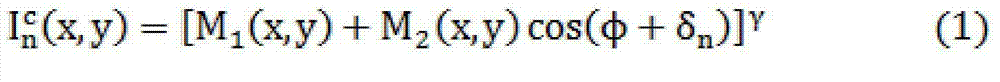

Method for solving phase error overcompensation and undercompensation in phase measurement profilometry

InactiveCN103615991AHigh measurement accuracyLow requirements for useUsing optical meansSinusoidal gratingPhase shifted

Provided is a method for solving phase error overcompensation and undercompensation in phase measurement profilometry. Based on an optical three-dimensional measurement method, a raster image is projected to an object surface, raster information modulated by an object surface profile is collected, the height of the object surface is restored, a projector, a CCD camera, an object to be measured and a computer are included, the projector projects a sinusoidal grating, the camera collects the deformed sinusoidal grating after object surface height modulation, the gamma nonlinearity of the projector and the camera and the influence of measuring environment light in the measurement process are considered, when phase errors are compensated in actual measurement, the projector projects completely black images, completely white images four-step phase shift images to the object to be measured, an environment light parameter t is calculated through the collected completely black images and completely white images, an absolute phase phi is calculated through a four-step phase shift phase solution method, the two parameters are substituted into a phase error penalty function, and a phase delta phi used for compensation can be obtained.

Owner:SOUTHEAST UNIV

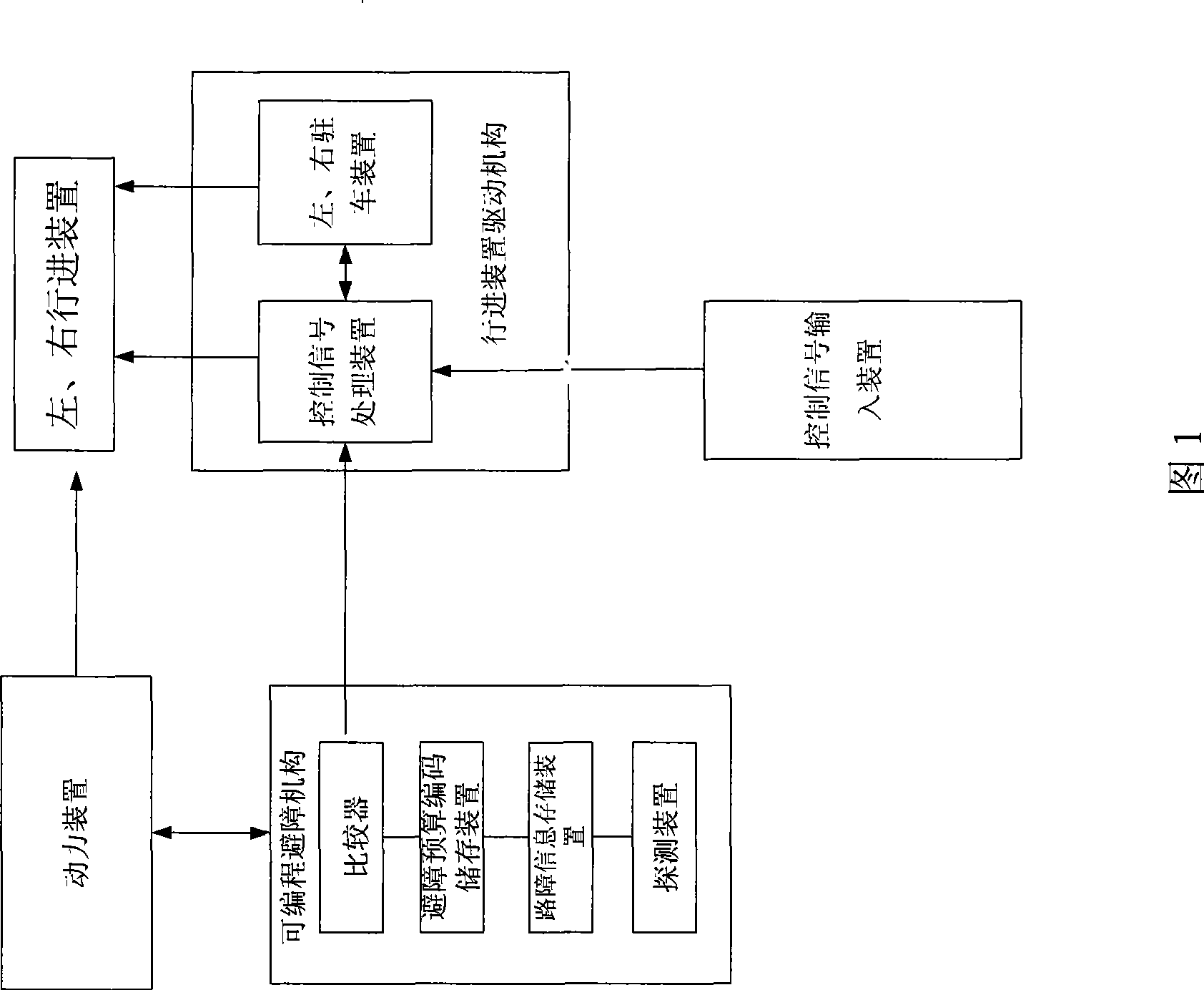

Electric vehicle with intelligent barrier avoiding function

InactiveCN101419462AWith automatic obstacle avoidance functionSimple structurePosition/course control in two dimensionsControl signalGravity center

The invention relates to an electric motor car comprising a power device, a travelling device driving mechanism which can drive a vehicle, a control signal input device and a programmable obstacle-avoiding mechanism. The programmable obstacle-avoiding mechanism comprises a detection device, a road-obstacle information storage device, an obstacle-avoiding calculating, encoding and storing device, and a comparator. The travelling device driving mechanism also comprises a control signal processing device which performs processing to obtain a translation speed value and a rotating angular speed value on the gravity center of the vehicle according to a control signal obtained through the control signal input device and an output signal of the comparator and which inputs the values obtained through calculation into the travelling device driving mechanism. Therefore, the electric motor car can automatically select an obstacle-avoiding method according to a distance away from the obstacle during the travel, which is detected by the programmable obstacle-avoiding mechanism. The system with an automatic obstacle-avoiding function has simple structure, demands low use condition, can reach high manipulation accuracy, saves the production cost, and is applicable to generalization.

Owner:吴长泰 +1

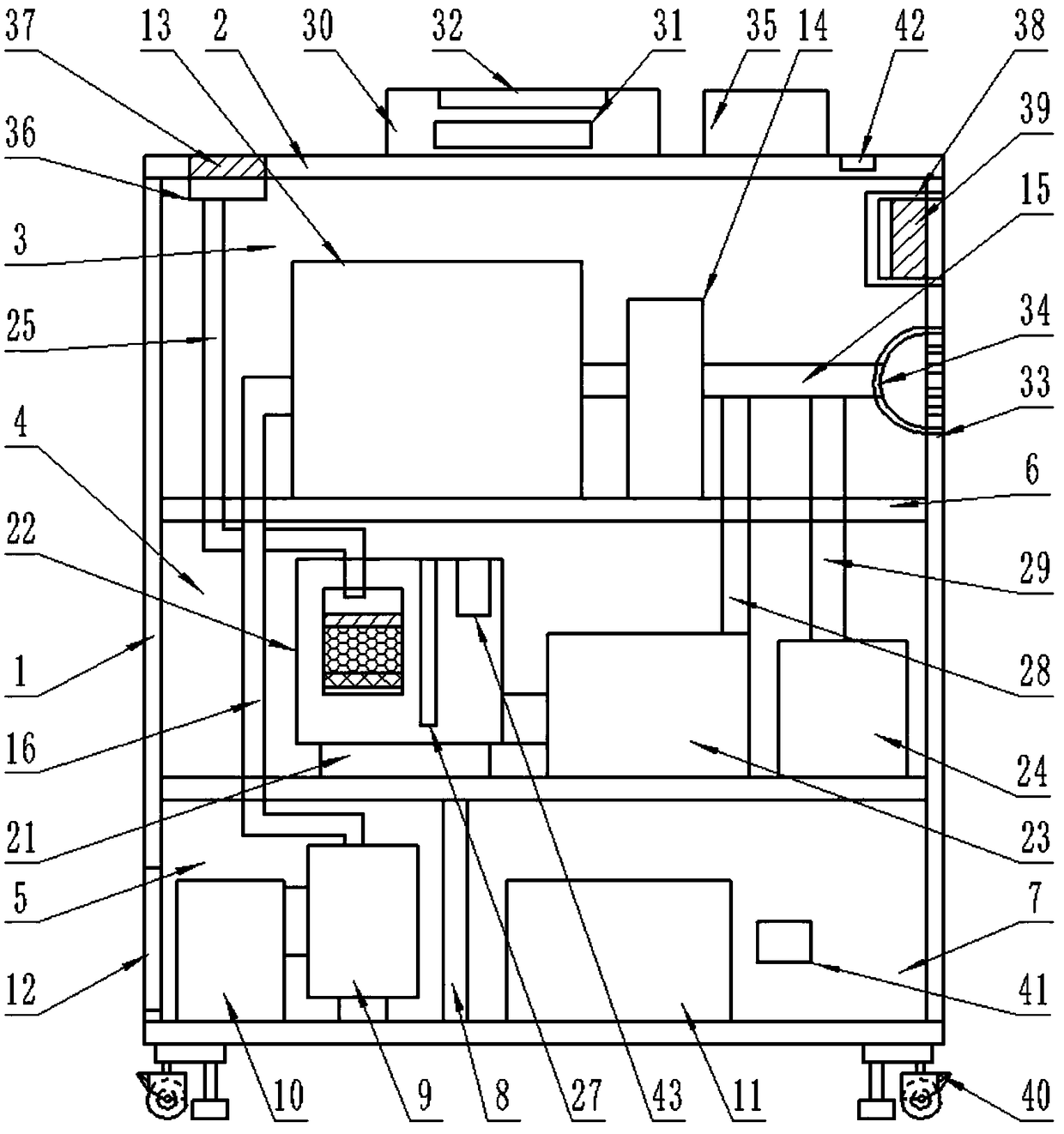

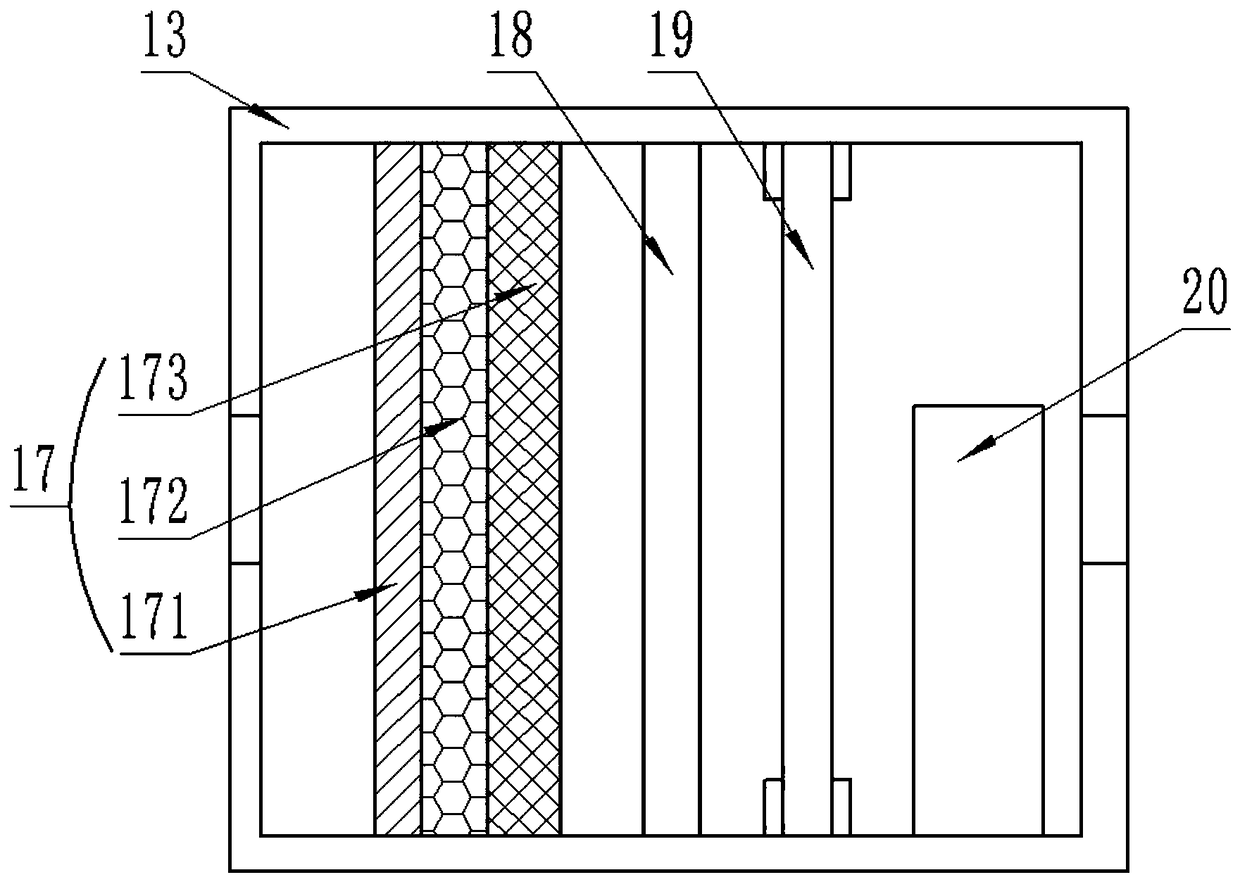

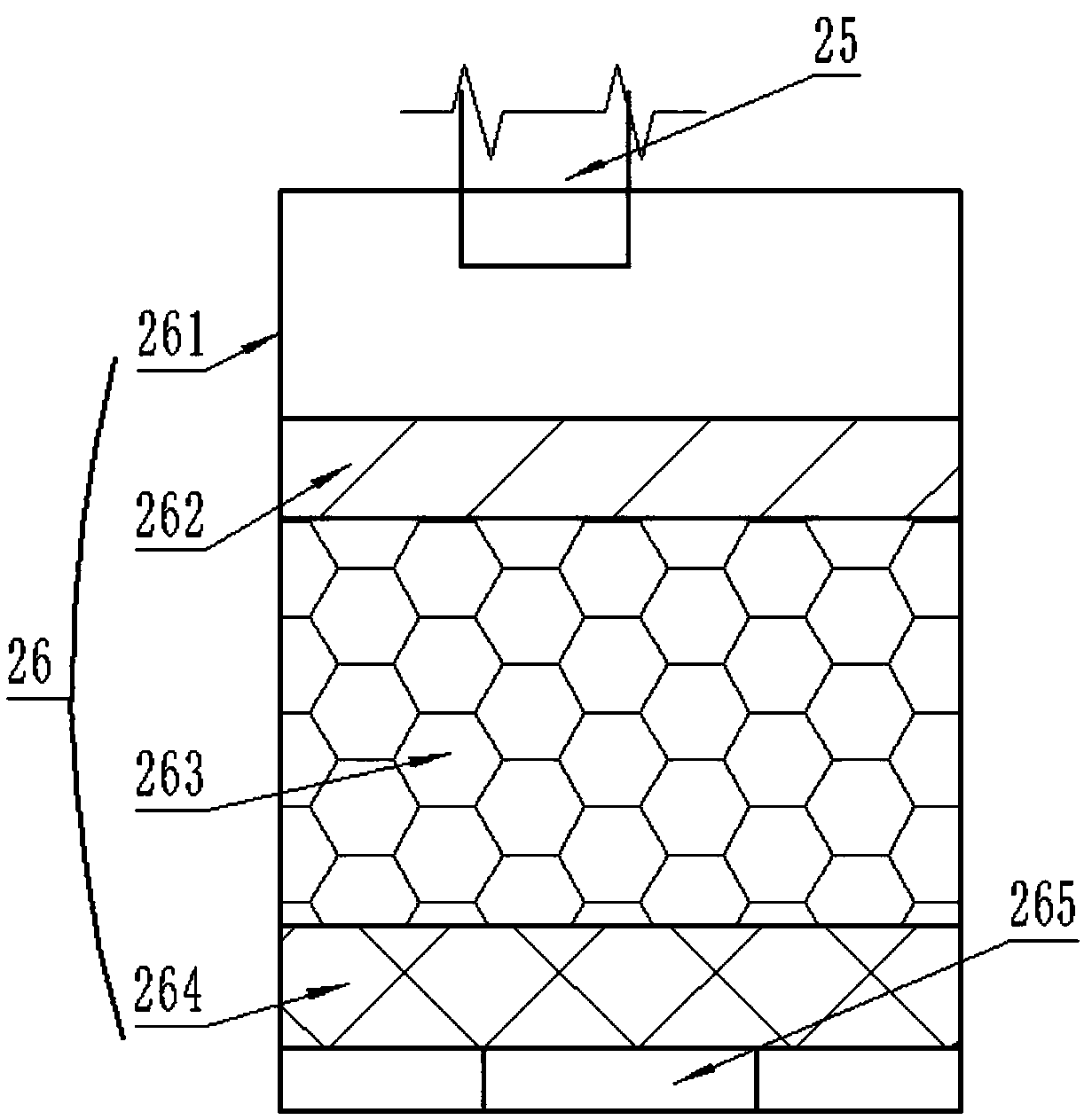

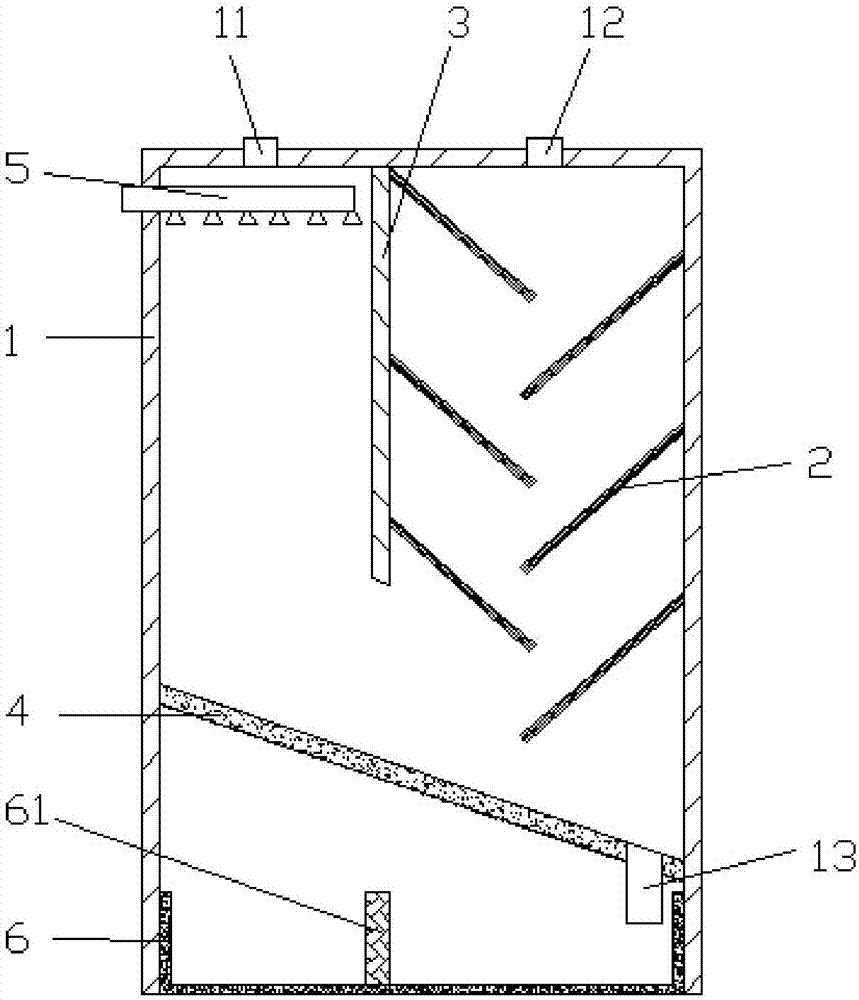

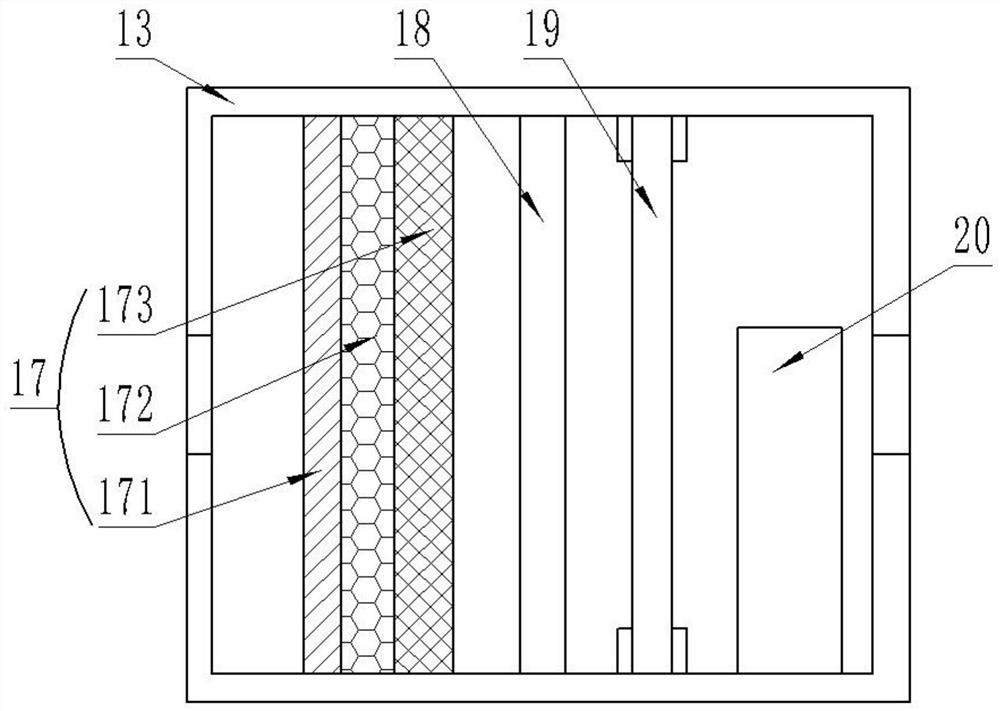

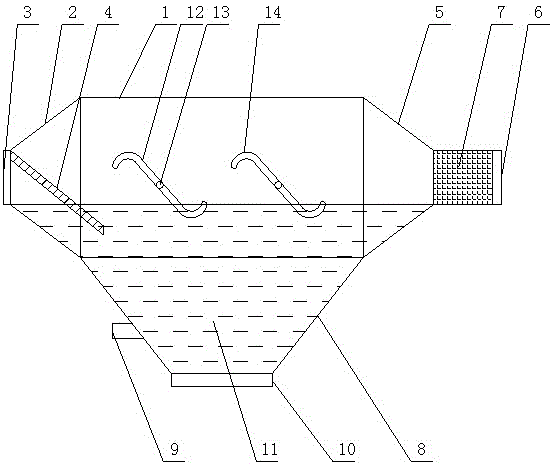

Indoor air purification, oxygenation and humidification device

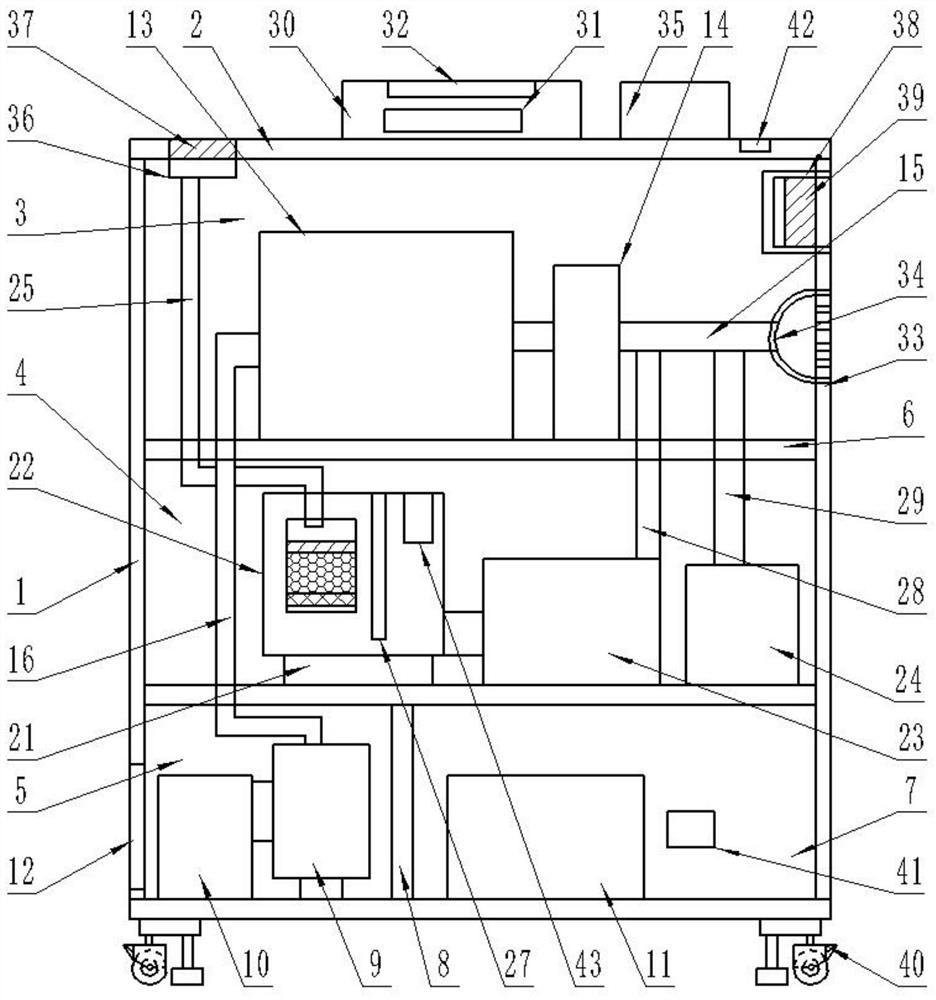

ActiveCN109140641AReasonable designSimple structureMechanical apparatusSpace heating and ventilation safety systemsOxygenAir purification

The invention discloses an indoor air purification, oxygenation and humidification device. The device comprises a device shell, a purification and sterilization mechanism and an oxygenation and humidification mechanism, wherein a cavity is formed in the device shell; a top cover is arranged at the upper end of the device shell; two flat separation plates for dividing the cavity in the device shellinto a first cavity, a second cavity and a third cavity are arranged in the device shell; a vertical separation plate for dividing the internal of the third cavity into a left side cavity and a rightside cavity is arranged in the third cavity; the purification and sterilization mechanism is arranged in the first cavity, and comprises a flat purification box, a second fan and a first connection pipe; the oxygenation and humidification mechanism is arranged in the second cavity; the humidification mechanism comprises a support base arranged on the upper surface of the flat separation plate, awater tank arranged on the support base, an atomization humidifier communicating with the bottom of the water tank, and an oxygen producer arranged on one side of the atomization humidifier; and a controller is arranged on the top cover. The indoor air purification, oxygenation and humidification device is reasonable in design, simple in structure and low in cost.

Owner:深圳市昶檀净化科技股份有限公司

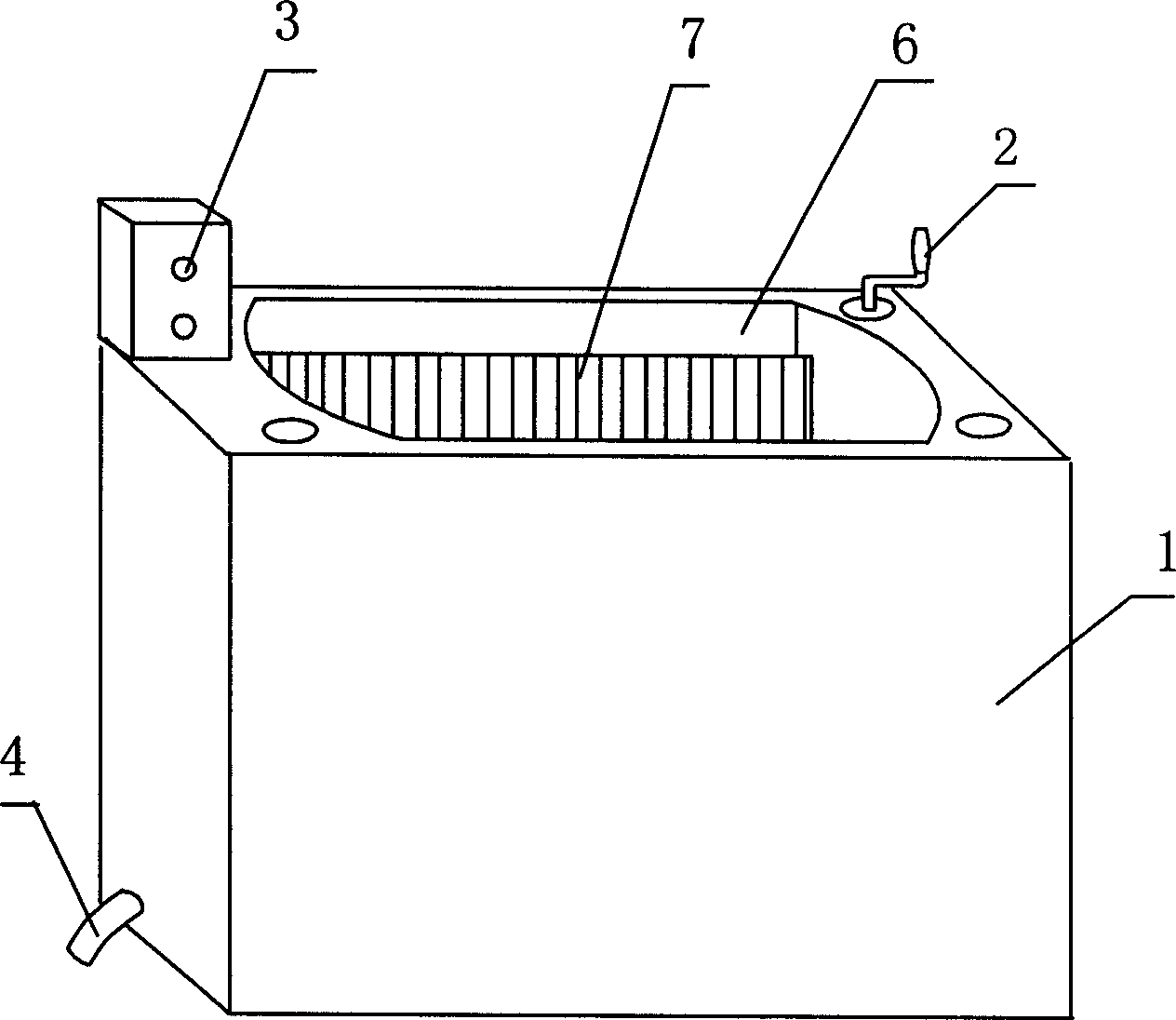

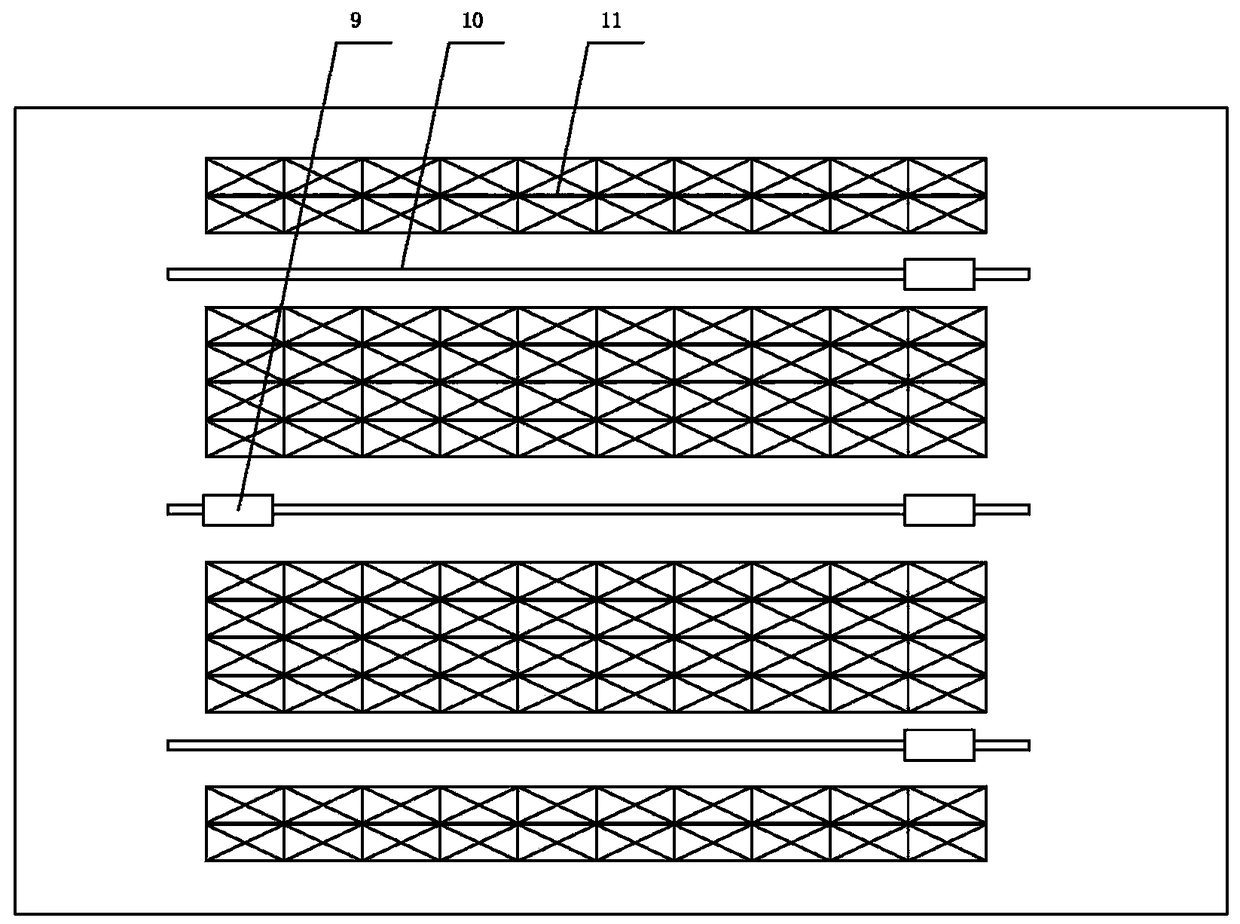

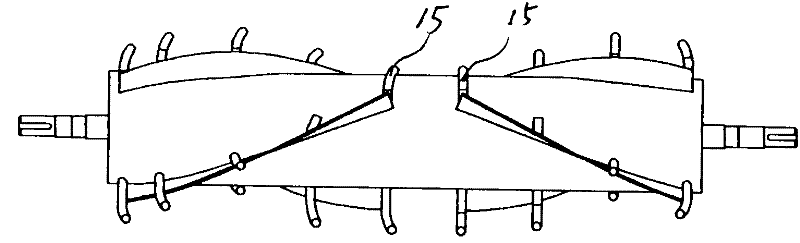

Mechanical kneading method for clothes and kneading type washing machine

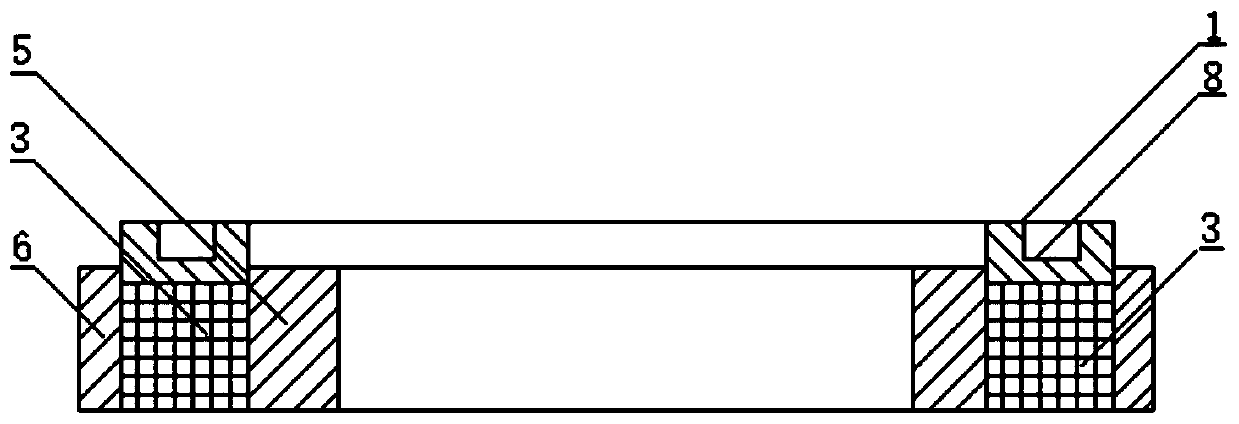

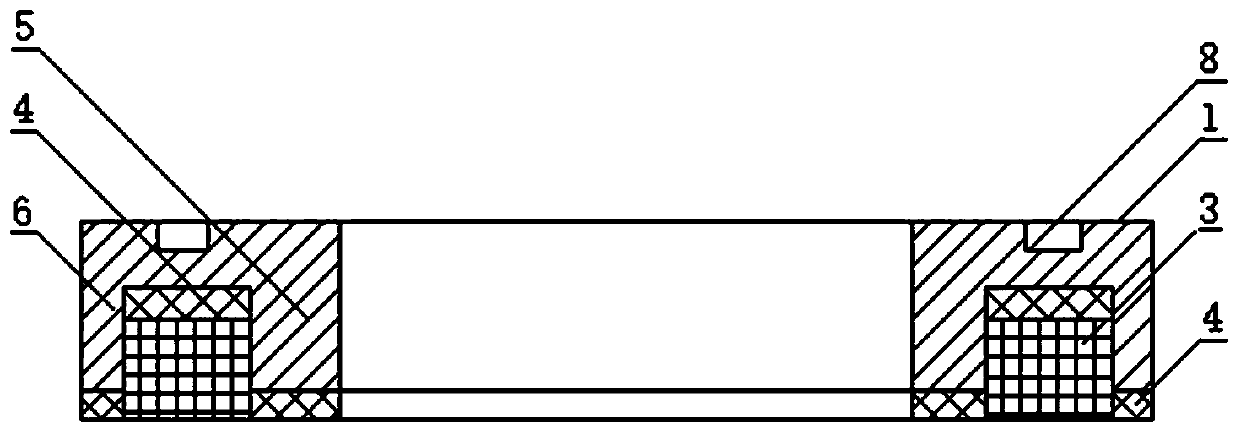

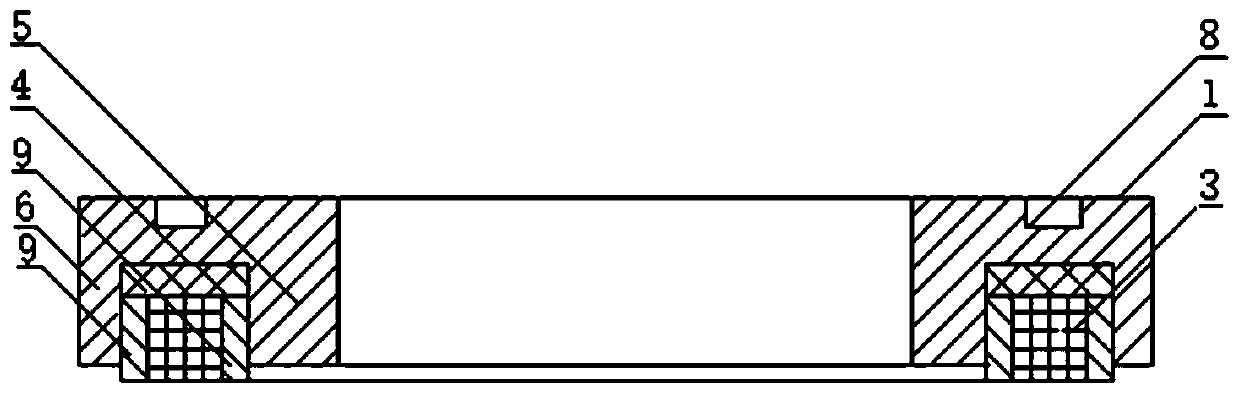

InactiveCN1730772APlay a role in dehydrationReduce consumptionOther washing machinesTextiles and paperEngineeringMechanical engineering

The present invention is mechanical clothing kneading method and kneading washer. After clothing is set inside the long and narrow washing cavity between two kneading plates, these two kneading plates are moved in opposite directions, so that the clothing is driven to rotate and washed through periodical clamping for mutual friction and releasing alternately. The kneading washer is provided with outer barrel, flat cylindrical inner barrel, belt roller connected to driver and belt. The present invention has fast washing speed, high detergency, less detergent consumption, simple structure, low cost, capacity of no-electric power running and other advantages.

Owner:罗丹

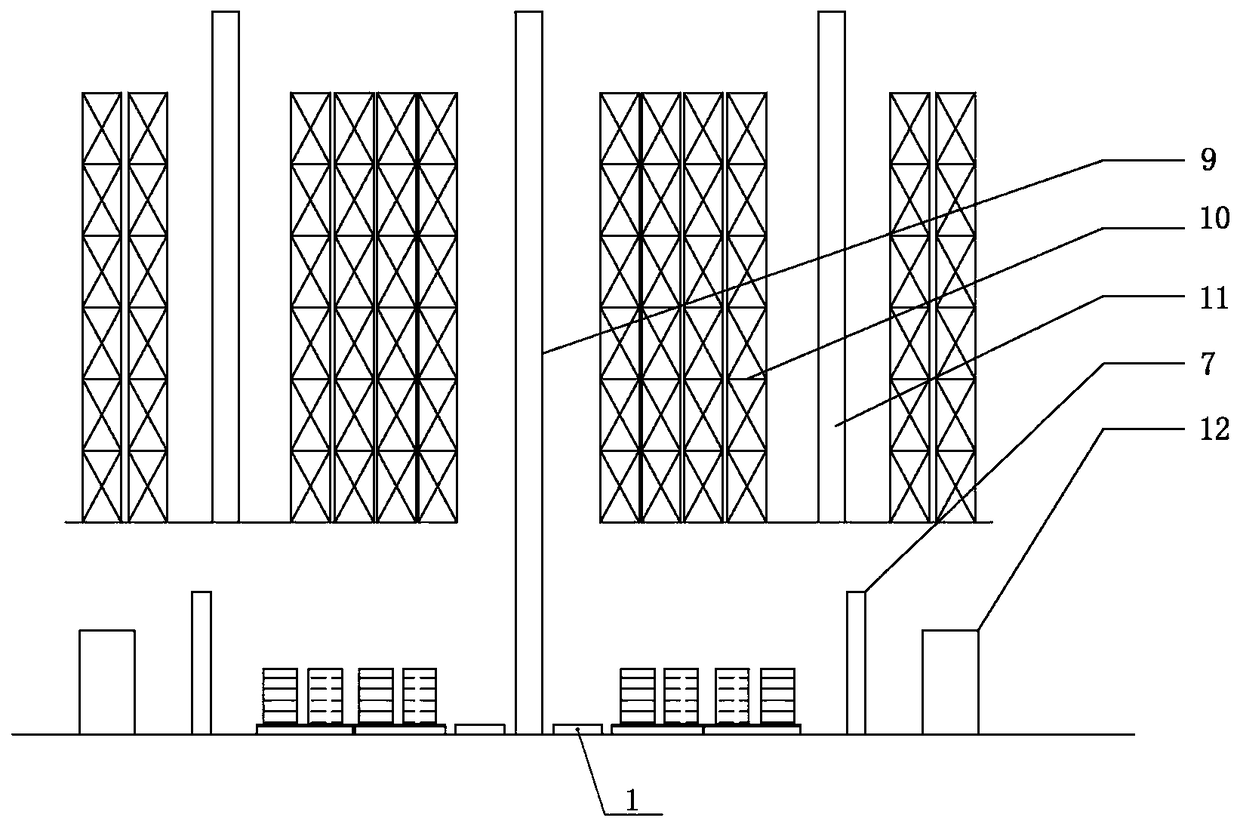

Storing-sorting-integrated whole-input-scattered-output logistics system and method

The invention discloses a storing-sorting-integrated whole-input-scattered-output logistics system and method. The logistics system comprises a storing-sorting functional area, goods sorting robots, amain conveyer belt and a controller. The storing-sorting functional area comprises a load conveying line and a plurality of automatic rotary tables, each automatic rotary table is provided with a plurality of tray positions, the trays are loaded with goods, and the trays on the load conveying line are pushed to the automatic rotary tables. The goods sorting robots are used for sorting the goods on the trays onto auxiliary conveyer belts, and the auxiliary conveyer belts are provided with automatic labeling machines and automatic weighing devices. The main conveyer belt is connected with the auxiliary conveyer belts and is used for sending the sorted goods to a designated goods output. The controller is used for controlling storing, sorting and transporting of the goods. The functions of integrating a storing area and a sorting area of the goods and whole-storing-scattered-taking of the goods are realized, movement of the goods between the storing area and the sorting area is reduced,the warehouse space is saved, energy consumption is lowered, and efficiency is improved.

Owner:深圳艾斯兰德智能装备有限公司

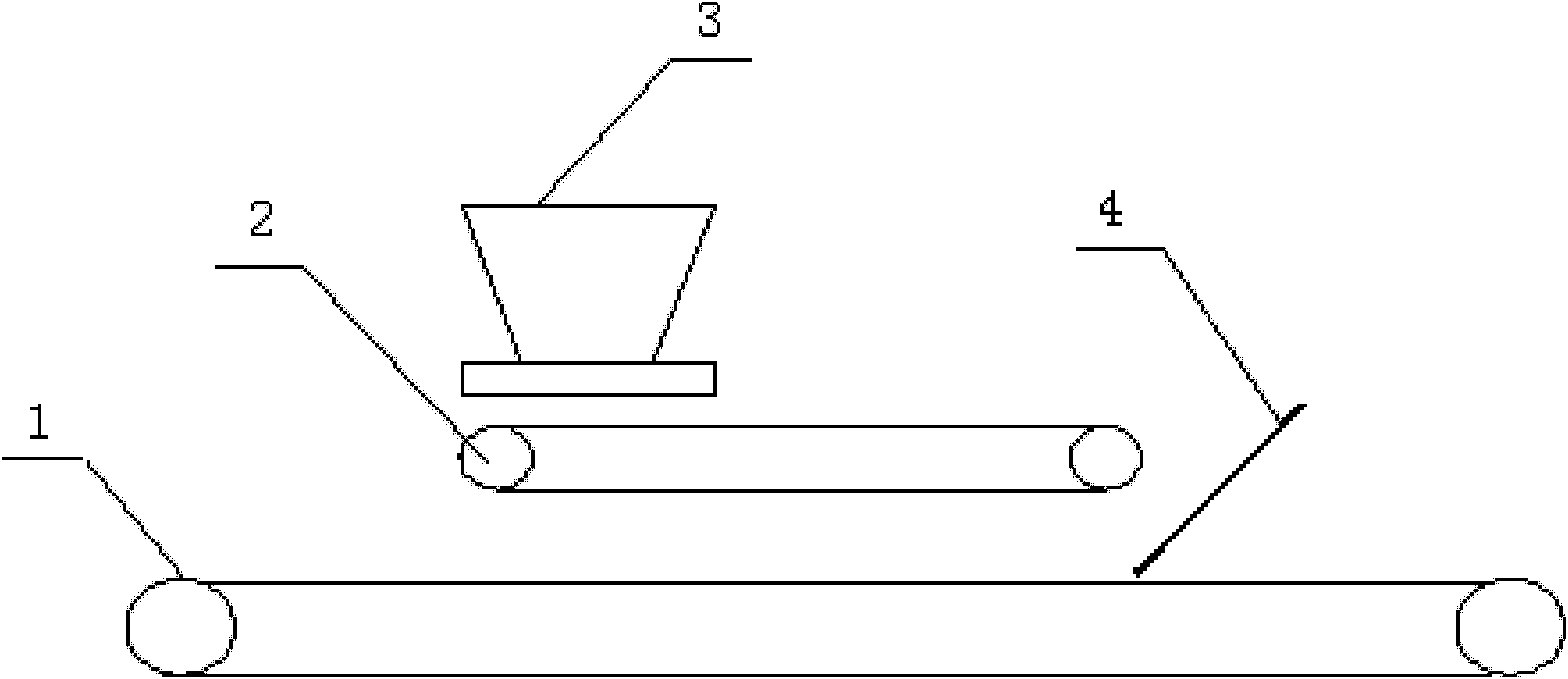

Pellet binder and adding device and adding method thereof

ActiveCN102719664ASufficient and guaranteed sourcesProduction goes straightMixer accessoriesMontmorillonitePoor quality

The invention provides a pellet binder and an adding device and an adding method thereof, wherein the pallet binder is prepared from the raw materials of yellow flower roots, sodium carboxymethylcellulose and montmorillonites. Before adding, according to the weight of the pellet mixture delivered per unit time and per unit length on a material belt, the weight of the binder to be prepared and added and the distribution amount of the binder on an electronic belt scale are correspondingly calculated. The electronic belt scale adds 4-7% by weight of the binder into the pellet mixture, the proportion of the binder being calculated according to the binder weight set to be delivered. The pellet binder has an adequate raw-material source and the auxiliary raw materials contain no harmful components such as ash content, silicon and the like. The pellet binder does not reduce the total iron content, can substitute or partially substitute a bentonite binder, raising the grade of finished product minerals by over 1.0% and reducing SiO2 content by 0.8%. The pellet binder, with a simple preparation method, is suitable for mass production and can satisfy production requirements of various poor-quality concentrates.

Owner:ANGANG STEEL CO LTD

Catalyst for synthesizing morphine through diethylene glycol ammoniation, and preparation method

InactiveCN1915497AHigh catalytic activityGood choiceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActive componentMorpholine

A catalyst for preparing morpholine from diglycol by ammoniation is prepared from Al2O3.3H2O as carrier and the Cu, Ni and Zn as active component through high-temp calcining of Al2O3.3H2O to obtain the pre-activated carrier, preparing the mixed nitrate solution of Cu, Ni and Zn proportionally, depositing reaction in the solution of sodium carbonate, filtering, washing, adding said pre-activated carrier, washing, filtering, drying, and calcining.

Owner:GUANGXI UNIV

Safe and environment-friendly dust remover

The invention discloses a safe and environment-friendly dust remover. The dust remover comprises a shell and a bottom plate, wherein the shell is internally provided with a vertical division plate which divides the shell into an air inlet cavity and an air outlet cavity, and the bottom plate is arranged below the vertical division plate inside the shell; a lower part of the air inlet cavity is communicated with a lower part of the air outlet cavity to form an air flow channel, the top of the air inlet cavity and the top of the air outlet cavity are respectively provided with an air inlet and an air outlet of the air flow channel; the top of the air inlet cavity is provided with an atomizing device, the air outlet cavity is uniformly and internally provided with slantwise division plates which are arranged in a stagger manner, the high ends of the slantwise division plates are arranged on a side wall or the vertical division plate of the shell, and the low ends of the slantwise division plates are hung in the air and used for elongating the air flow channel; and the bottom plate of the shell has a slantwise shape in design, and one side wall of the shell at the low end of the bottom plate is provided with a sewage draining exit. According to the dust remover, the structure is simple, the use is safe, the requirement for conditions of usage is not high, and the dust removing effect is good.

Owner:成都智宸科技有限公司

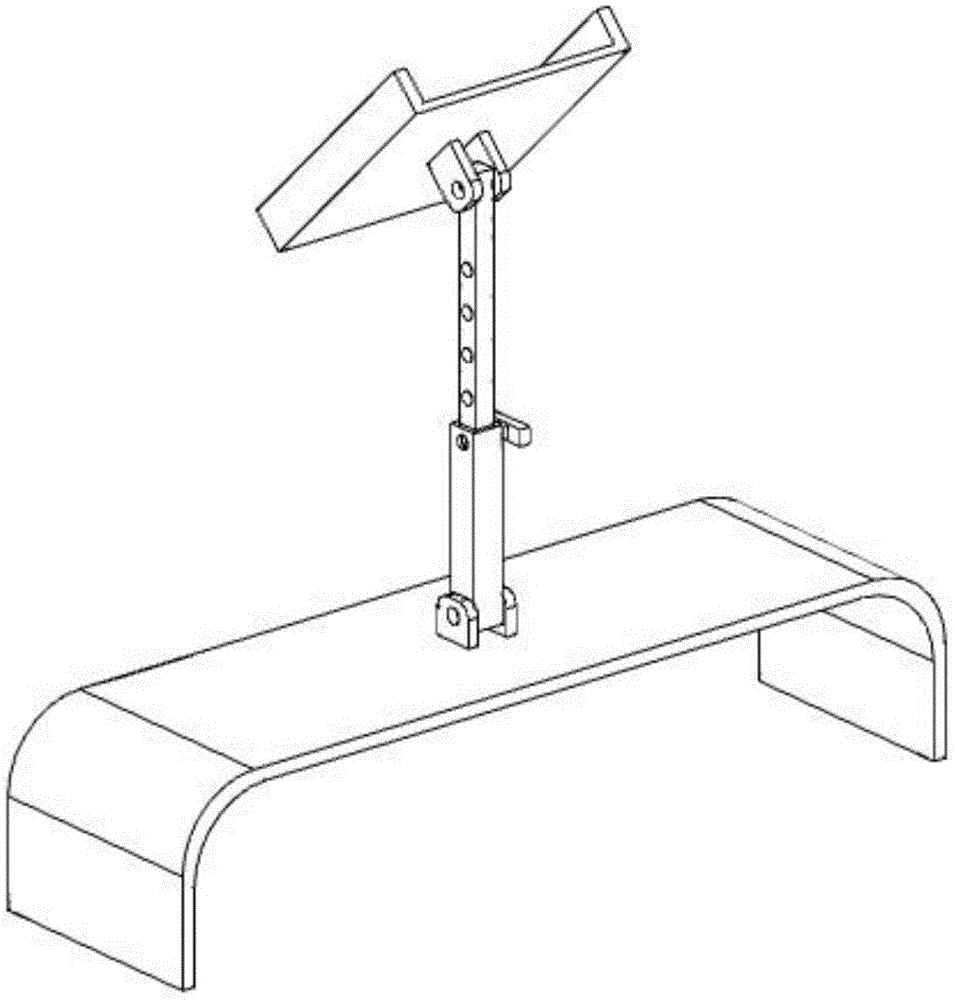

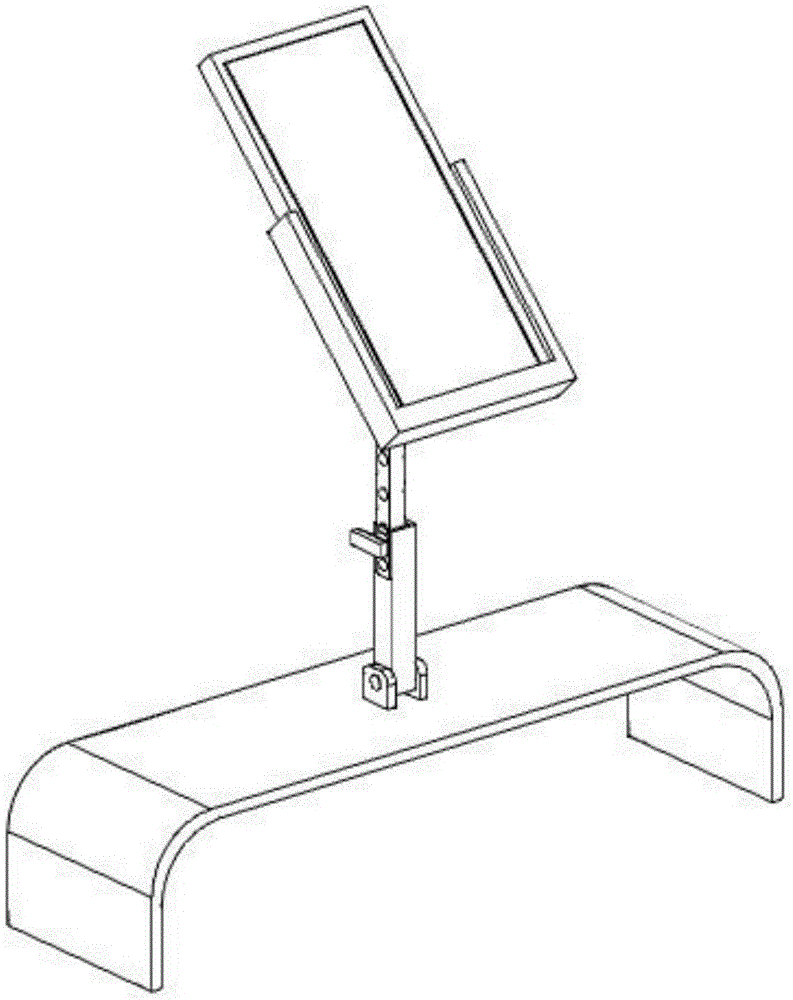

Portable digital equipment support

Owner:SHANGHAI DIANJI UNIV

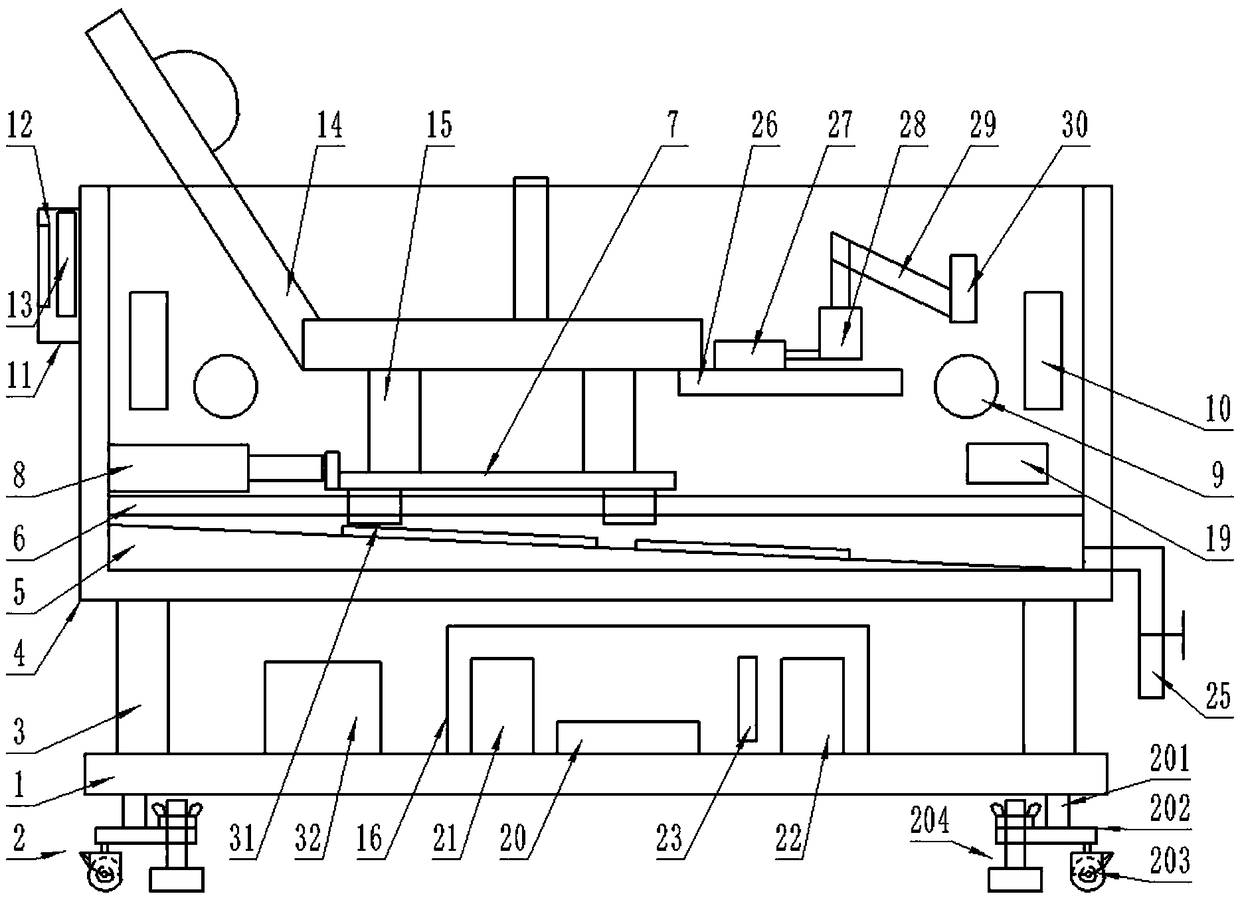

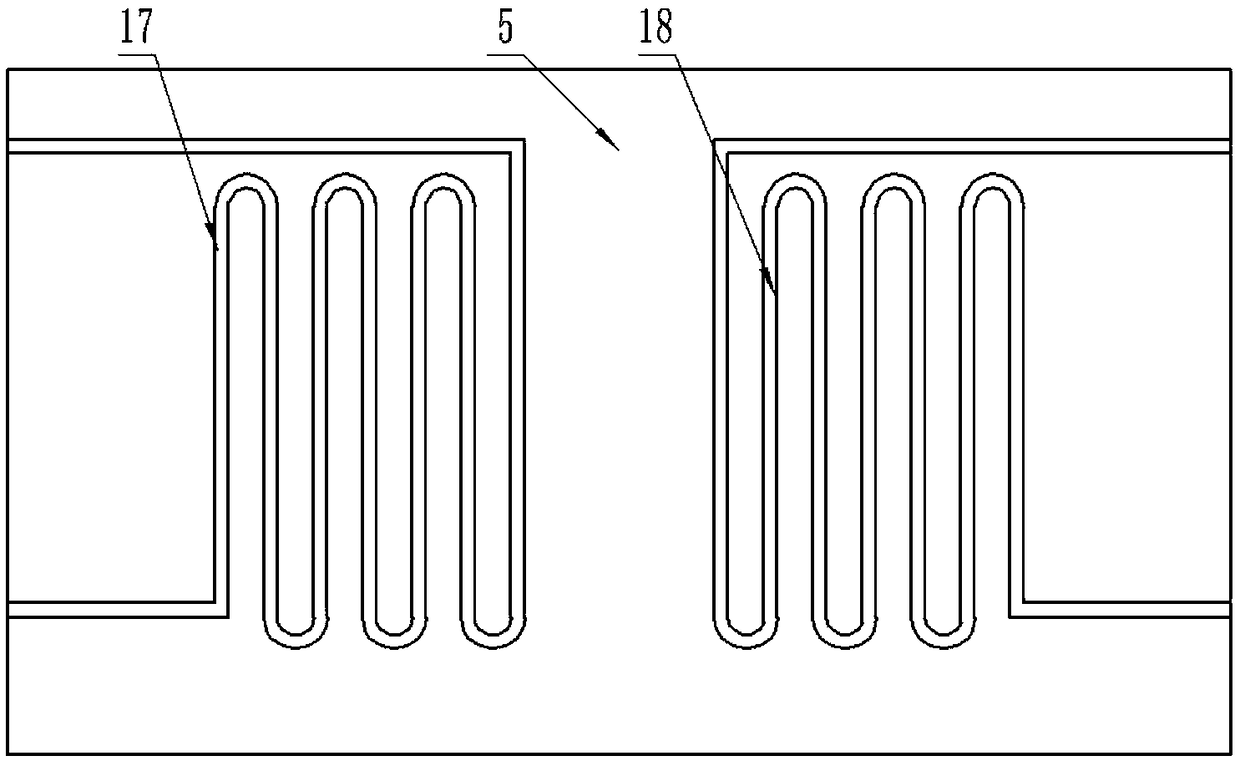

Limb support device for puerpera

InactiveCN109009834AReasonable designSimple structureOperating tablesDiagnosticsEngineeringHeat pipe

The invention discloses a limb support device for a puerpera. The limb support device comprising: a mobile support mechanism including a carrier plate, four bearing mechanisms disposed on the four corners of the lower surface of the carrier plate respectively, and four support rods disposed on the four corners of the upper surface of the carrier plate respectively; a birthing pool disposed on theupper ends of the four support rods, wherein the inner bottom surface of the birthing pool is sloped, two horizontal guide rods are disposed in the birthing pool along the length direction of the birthing pool and are adjacent to the inner bottom surface of the birthing pool, and a movable mechanism is disposed in the birthing pool; a birthing bed body selectively disposed in the birthing pool; and a heating mechanism including a heating box disposed on the upper surface of the carrier plate and located below the birthing pool, a first heat pipe and a second heat pipe which are disposed in thebirthing pool, and a temperature sensor disposed in the birthing pool. The limb support device for the puerpera is not only reasonable in design and simple in structure, but also low in cost.

Owner:HUNAN POLYTECHNIC OF ENVIRONMENT & BIOLOGY

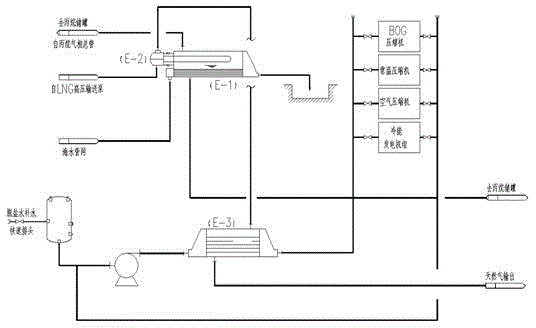

Method and device for improving liquefied natural gas gasification energy-saving efficiency

InactiveCN104964157ALow requirements for useAchieve recyclingPressure vesselsContainer discharging from pressure vesselsSuperheaterProcess engineering

A method and device for improving liquefied natural gas gasification energy-saving efficiency is characterized in that firstly, introducing liquefied natural gas which is gasified through a gasifier E-2 into an independent superheater E-3 for superheating, and then directly discharging seawater of which the heat is absorbed through a gasifier E-1, wherein the requirement on the using condition of the seawater is lower, and the seawater can be used even in winter; secondarily, heating natural gas to a required temperature by using fresh water in the superheater, and changing the fresh water into low-temperature cool water after absorbing the heat of the fresh water by the liquefied natural gas; thirdly, introducing the low-temperature cool water into a cold energy utilization device, and enabling the low-temperature cool water to return back into the superheater to heat the natural gas after the cold energy is utilized thoroughly, so as to realize the cyclic utilization of the fresh water, and improve the working efficiency of the whole system, and the energy-saving efficiency is improved by over 50 percent.

Owner:JIANGSU SUNPOWER TECH

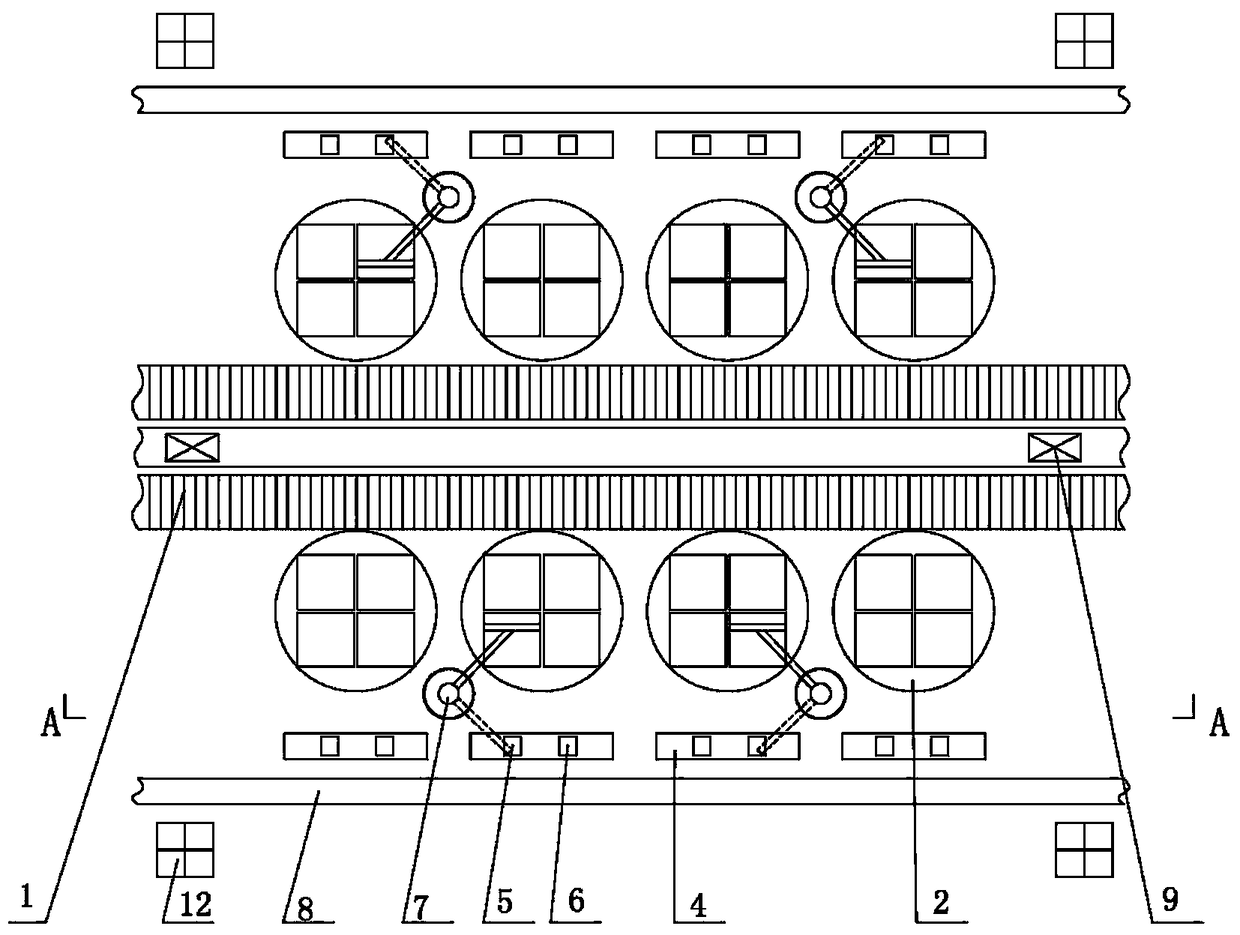

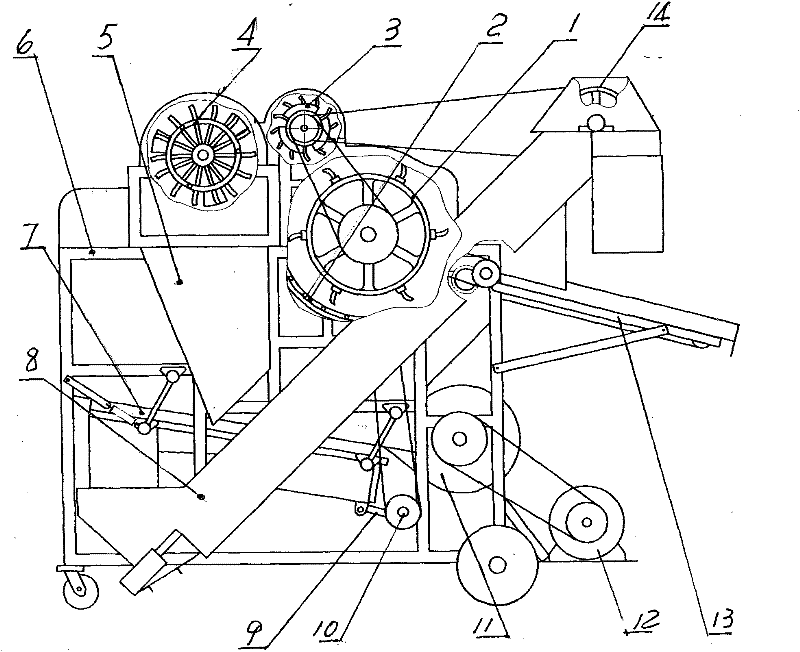

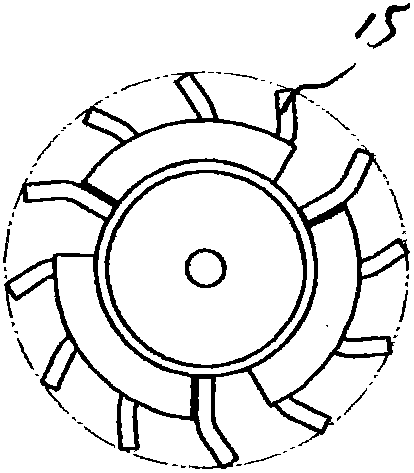

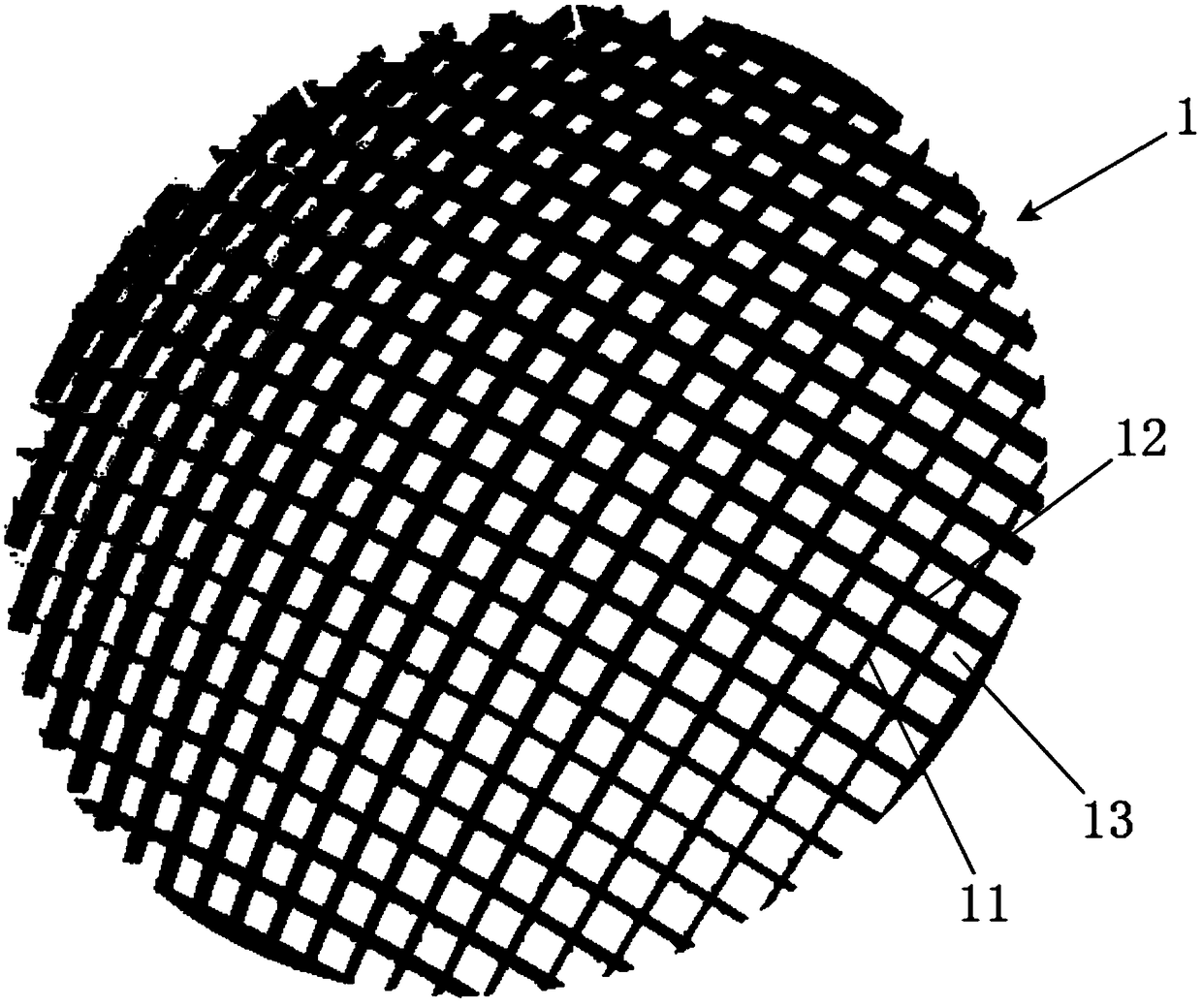

Peanut picker

ActiveCN102349397AHigh removal rateLow requirements for useThreshersEngineeringMechanical engineering

The invention discloses a peanut picker and aims to provide a peanut picker capable of dry type picking and wet type picking and having high complete picking rate, which comprises a first picking roll, a sorting sieve, a fan, a recycling device, a feeding device and a power device, and is also provided with a second picking roll and a third picking roll, wherein the second picking roll is arranged between the first picking roll and the third picking roll, and the shells of the second picking roll connected to the first picking roll and the third picking roll are respectively provided with axial long holes which are respectively communicated with the axial long hole on the shell of the first picking roll and the axial long hole on the shell of the third picking roll; spirally distributed arc-shaped bent teeth along the axial direction on a left half circumferential surface and a right half circumferential surface of the circumferential surface of the second picking roll have the opposite spiral directions with the spirally distributed arc-shaped bent teeth on the circumferential surfaces of the left picking roll and the right picking roll; and the front end of a cage grid at the lower part of the third picking roll is opposite to a lower slant receiving hopper. The invention is used for a peanut picker.

Owner:河南瑞锋机械有限公司

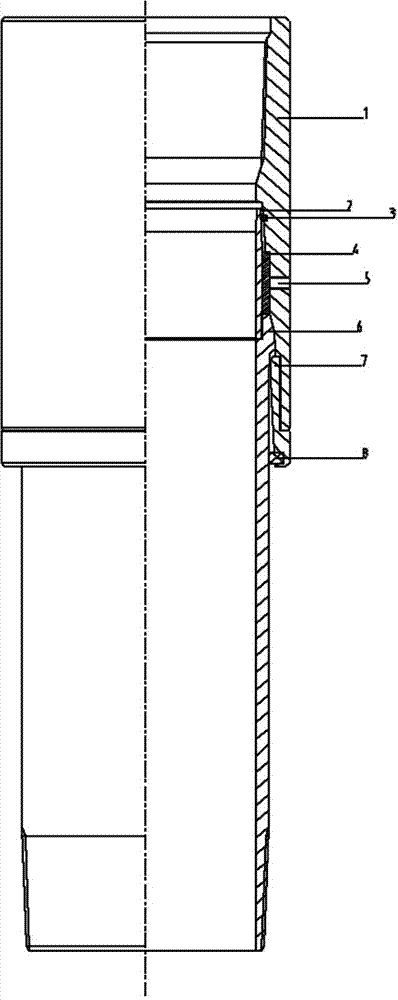

Casing pipe bending moment compensator special for thermal recovery horizontal well

InactiveCN103790562AImprove securityLow costDrilling rodsFluid removalThermodynamicsHorizontal wells

The invention relates to a casing pipe bending moment compensator special for a thermal recovery horizontal well. The casing pipe bending moment compensator special for the thermal recovery horizontal well is connected with a steam injection section of a cased hole completion pipe pillar and can meet the requirements for a steam injection process of a recovery well casing pipe pillar. The casing pipe bending moment compensator special for the thermal recovery horizontal well comprises an outer barrel, a hot-melt limiting ring and a lower inner barrel, wherein an upper inner barrel is connected with the lower inner barrel, the upper inner barrel and the hot-melt limiting ring are put in the outer barrel together and then connected with the outer barrel through a blocking ring in a thread bucking mode, the outer circle of the upper portion of the upper inner barrel is a conical surface, and the outer circle of the upper portion of the lower inner barrel and the inner circle of the middle of the outer barrel are convex and concave spherical matching surfaces. When the hot-melt limiting ring is melted by the high temperature of injected steam, a pipe string formed by the upper inner barrel and the lower inner barrel can be bent to adapt to the actual variation of a well body of an oil layer section, the unfavorable situation that in the prior art the bending moment of the casing pipe pillar can not be compensated, and the safety of the cased hole completion pipe pillar is improved. The casing pipe bending moment compensator special for the thermal recovery horizontal well is simple in structure, reliable in work and complete in function, keeps the inner drift diameter of the casing pipe unchanged after the bending moment of the casing pipe is compensated, is low in cost and is high in adaptability.

Owner:CHINA PETROLEUM & CHEM CORP +1

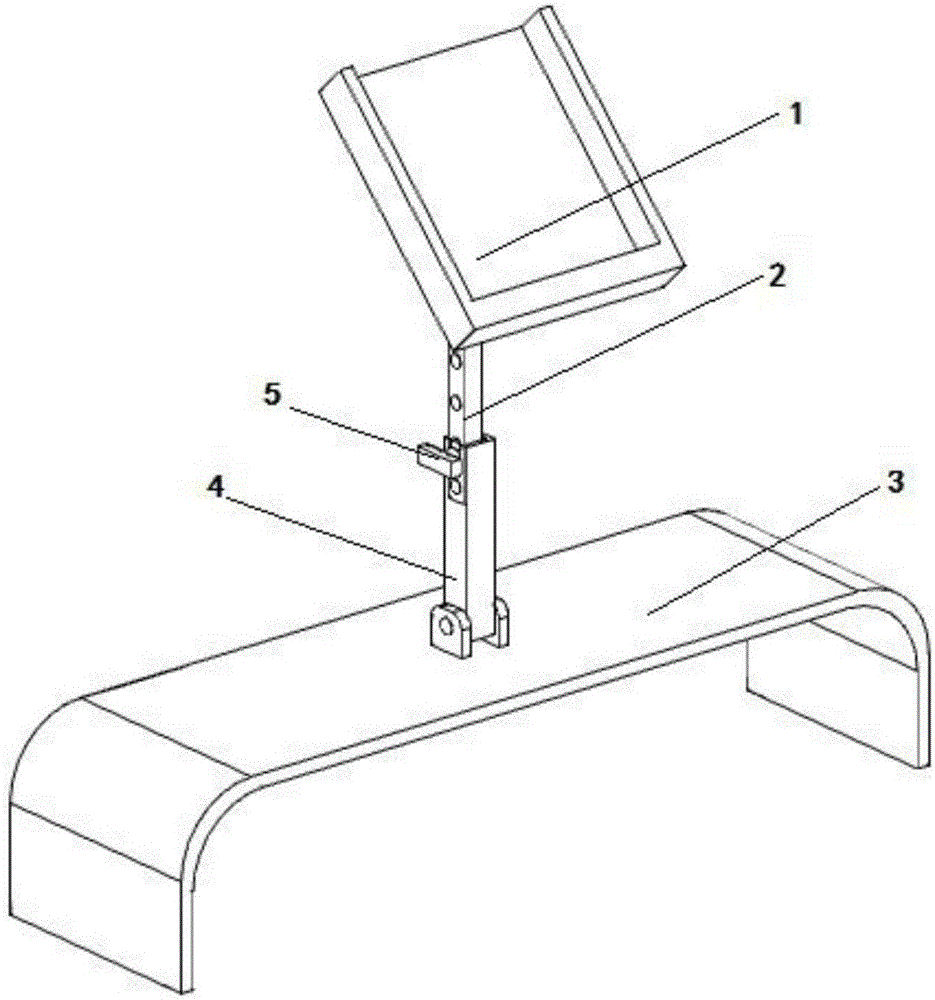

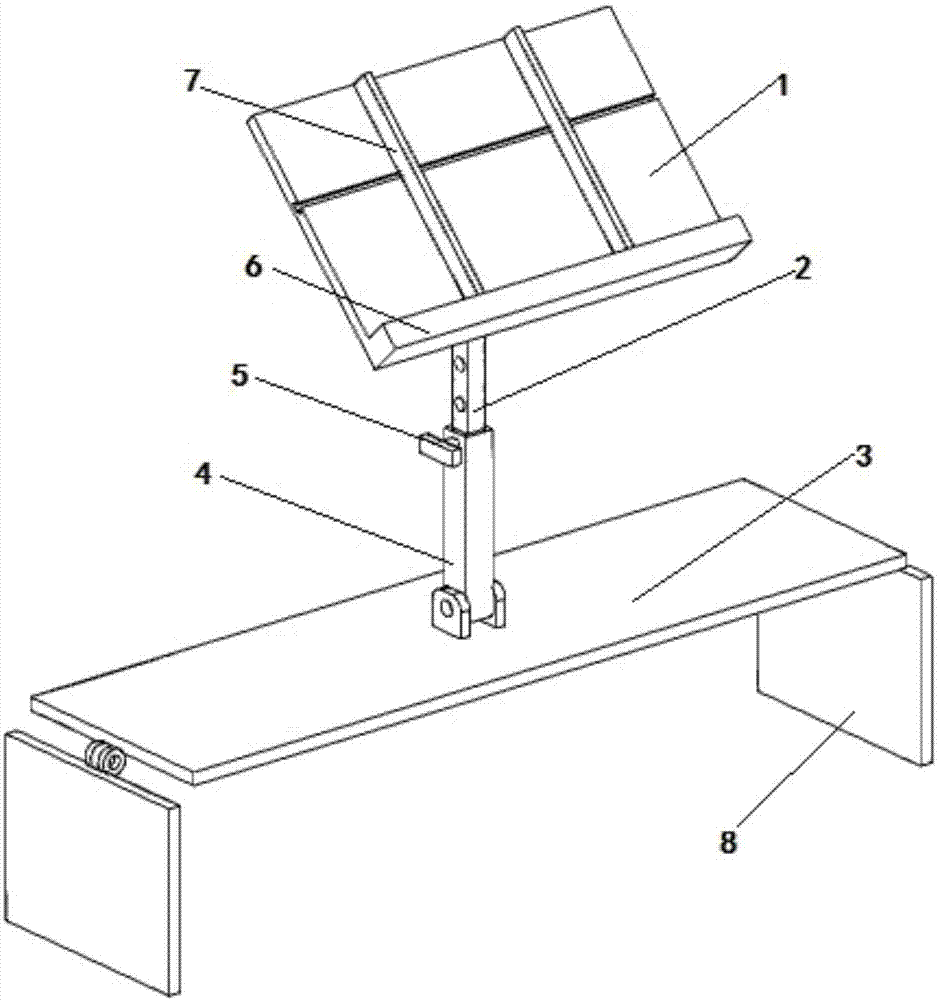

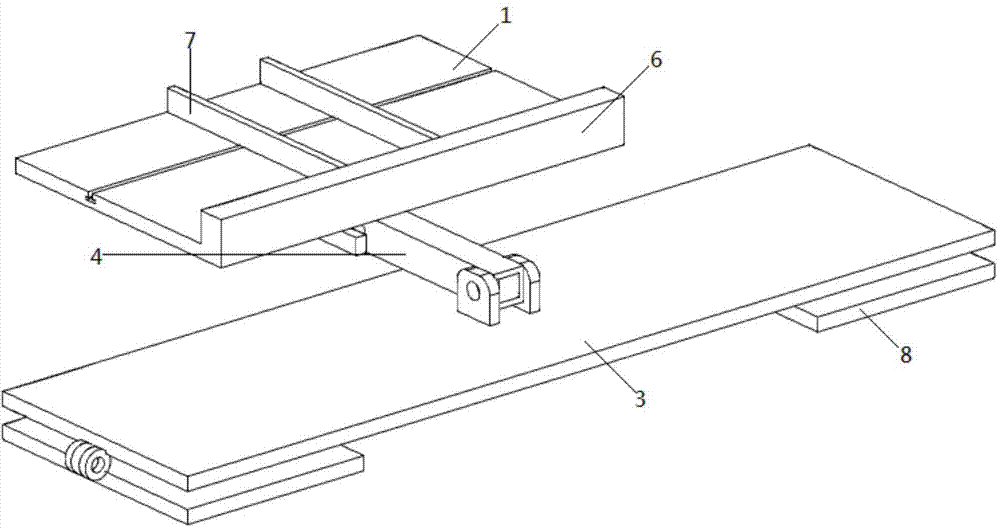

Self-fixing digital equipment support

InactiveCN103661135ASimple structureLow manufacturing costRailway componentsVehicle componentsEngineeringSlide plate

The invention discloses a self-fixing digital equipment support. The self-fixing digital equipment support comprises a leg supporting frame. The two sides of the leg supporting frame are connected with leg fixing plates through return springs. A height positioning square tube is installed in the middle of the leg supporting frame in a hinged mode. A height support is installed inside the height positioning square tube in a sliding mode. An equipment carrying platform is installed at the upper end of the height support in a hinged mode. A clamping device elastic assembly is arranged at the bottom of the equipment carrying platform. Symmetric equipment clamping and positioning slide plates are installed on the equipment carrying platform in a sliding mode, and the equipment clamping and positioning slide plates are connected with the two side edges of the equipment carrying platform and elastically connected with the corresponding side edge of the equipment carrying platform through springs which are fixed at the two ends inside the clamping device elastic assembly. A positioning screw is installed on the height positioning square tube in a rotating mode. The height positioning square tube is provided with a plurality of positioning holes. The self-fixing digital equipment support is simple in structure, convenient to use, and beneficial for people to carrying and using at any time; besides, the self-fixing digital equipment support is low in manufacturing cost, high in market value, and capable of achieving a good using effect by the utilization of a simple structure, as a result, manufacturing cost and requirements for service conditions of the self-fixing digital equipment support are greatly reduced.

Owner:安徽省智汇电气技术有限公司

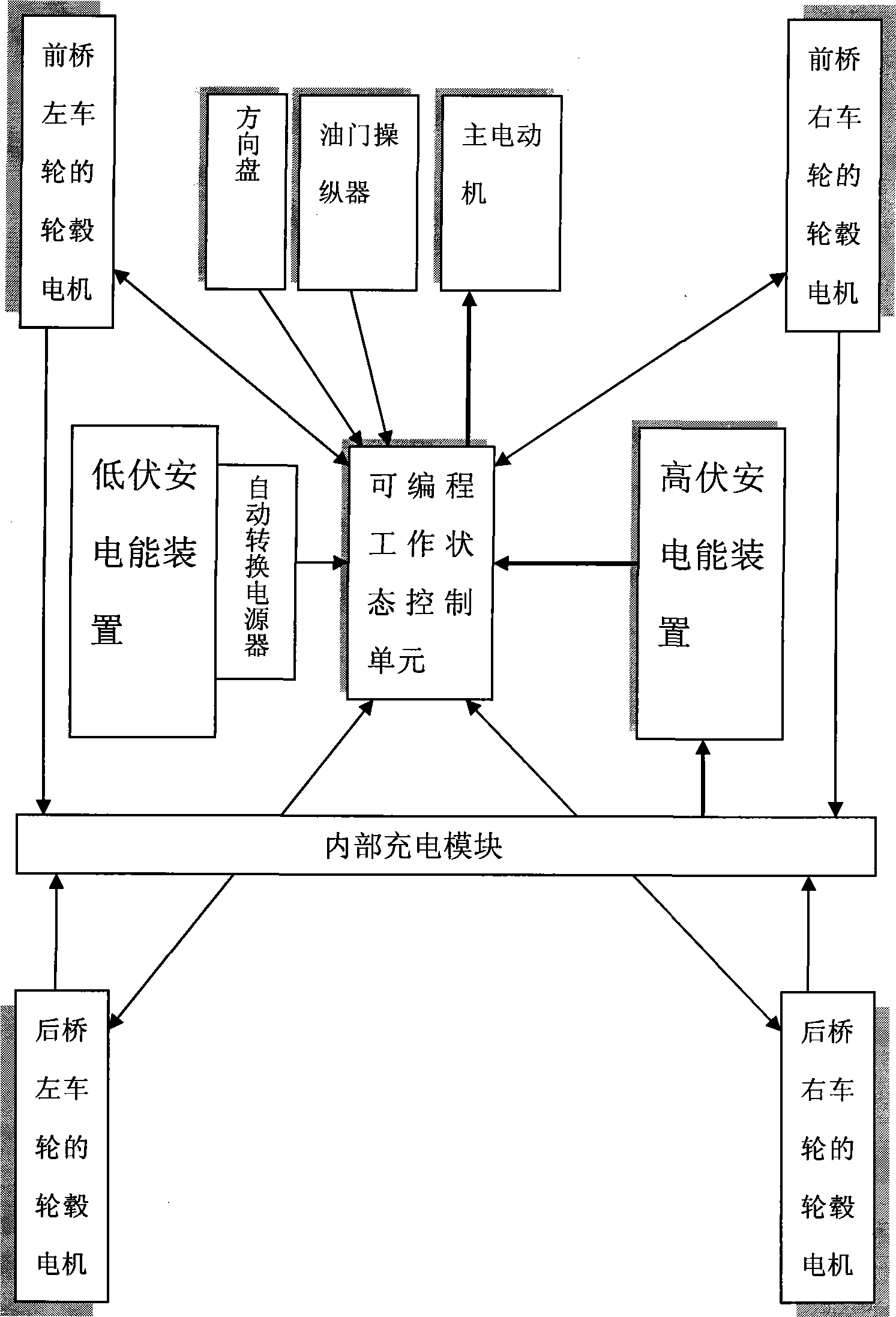

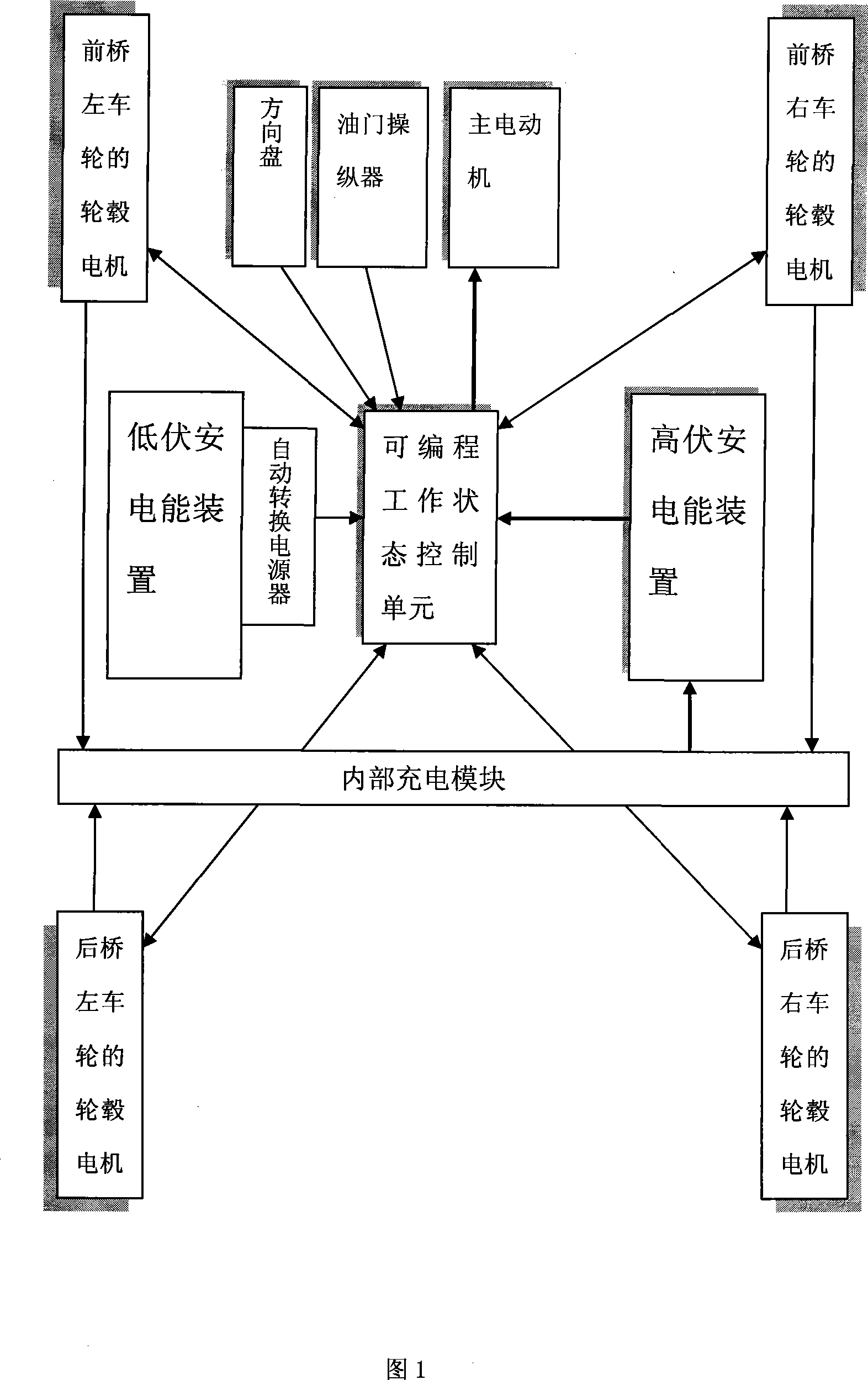

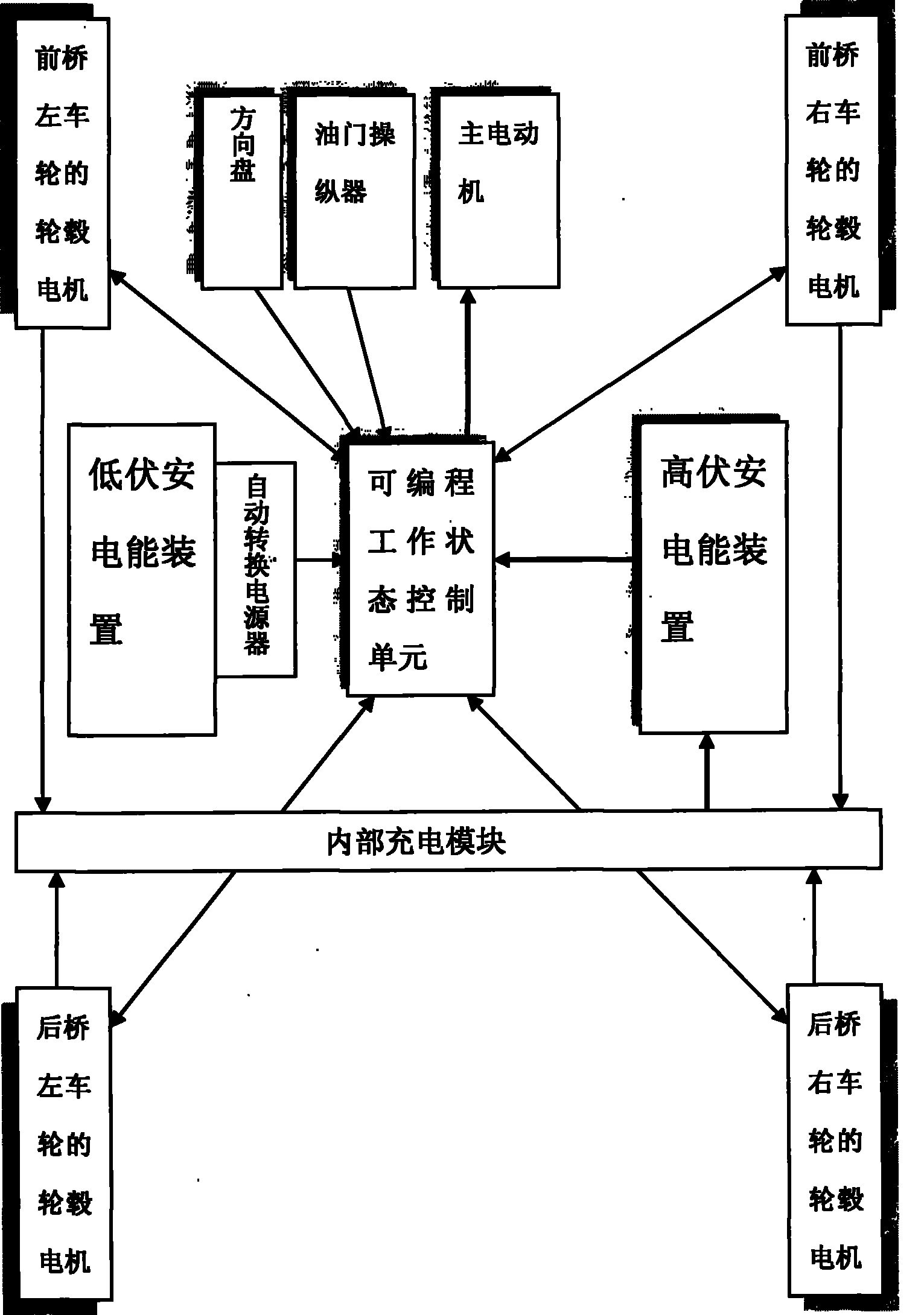

Electric automobile using a plurality of electric apparatuses to drive running

InactiveCN101412378ASimple structureLow requirements for useSpeed controllerElectric energy managementElectricityVehicle frame

The invention relates to an electric automobile. The electric automobile comprises an automobile body, an automotive chassis, automotive wheels, a parking mechanism, a control signal input device and a power-drive mechanism, wherein the power-drive mechanism comprises a main drive unit for providing a driving force for the electric automobile in a high-torque operation state, and an auxiliary drive unit for providing a driving force for the electric automobile in a low-torque operation state. The electric automobile also comprises a programmable operating mode control unit for controlling operating conditions of the main drive unit and the auxiliary drive unit according to a control signal input by the control signal input device and the working currents in the main drive unit and the auxiliary drive unit. Therefore, the electric automobile can freely select driving modes with the control of the programmable operating mode control unit, thereby improving the use rate of vehicle-mounted batteries. The electric automobile with the electric drive units has advantages of simple structure, low requirements on use conditions, low manufacture cost and easy promotion and application.

Owner:SHENZHEN ODET INTELLIGENT TECH DEV +3

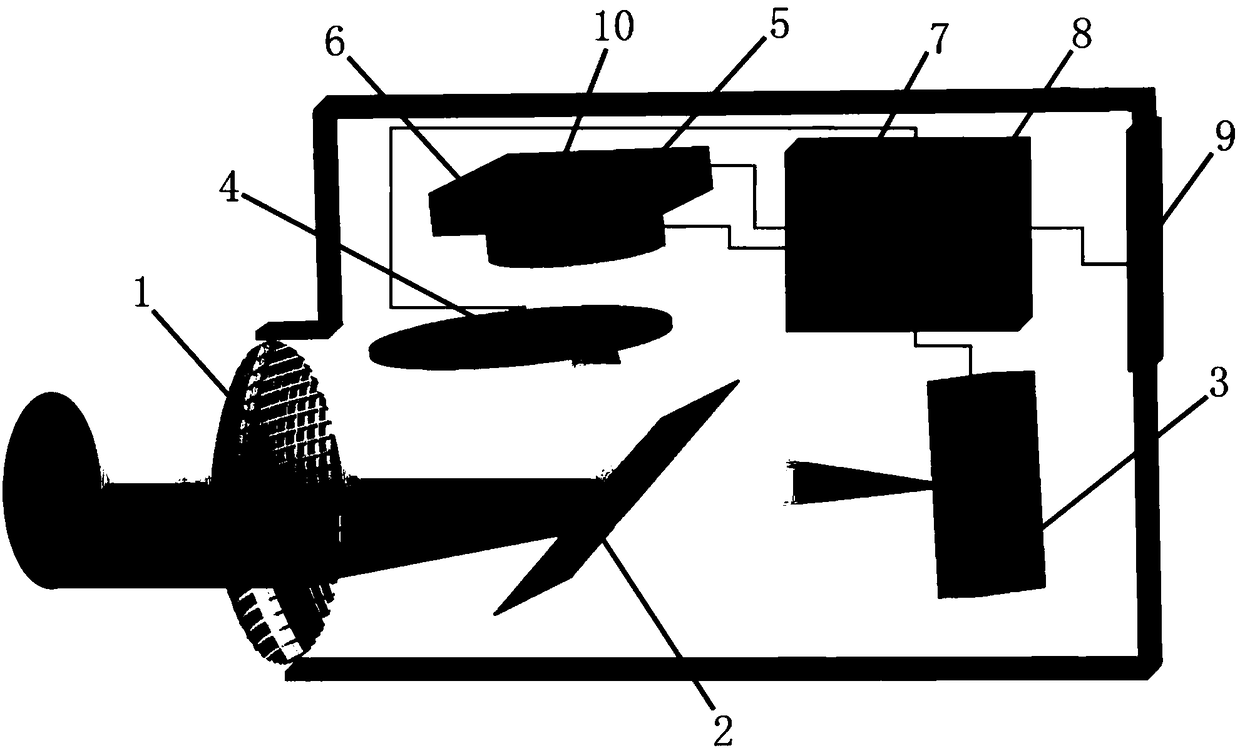

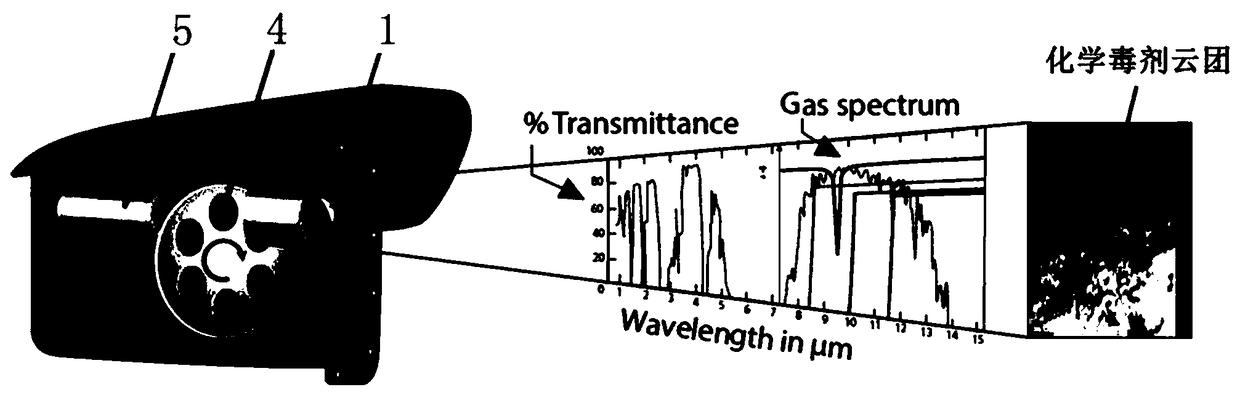

Novel single-pawn portable chemical toxicant passive telemetering imager

InactiveCN109253974AEasy to operateIncrease luminous fluxMaterial analysis by optical meansFiberToxicant

The invention discloses a novel single-pawn portable chemical toxicant passive telemetering imager. The problem that the existing chemical toxicant passive telemetering imager is hard to be applied tothe real-time detection of the field environment of battlefield due to large volume, complex structure and inconvenient carrying is solved. The chemical toxicant passive telemetering imager comprisesa lobster eye lens, a dichroscope, a first visible light CCD detector, a multi-element optical component array, an infrared image intensifier, a second visible light CCD detector, an accumulator, a liquid crystal display screen, and a microprocessor; and light fiber is arranged between the infrared image intensifier and the second visible light CCD detector. The chemical toxicant passive telemetering imager is simple in structure, scientific and reasonable in structure, and convenient for use, the defect that the imager is small in light amount, low in sensitivity and unused under complex environment in the non-dispersion infrared technology is overcome, and the comprehensive performance is close to the Fourier transform infrared spectroscopy, but the size and the cost are greatly reduced; the imager disclosed by the invention has the advantages of being convenient for operation, strong in environment adaption, high in light collecting efficiency, large in field of visual, and high indirection sensitivity.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

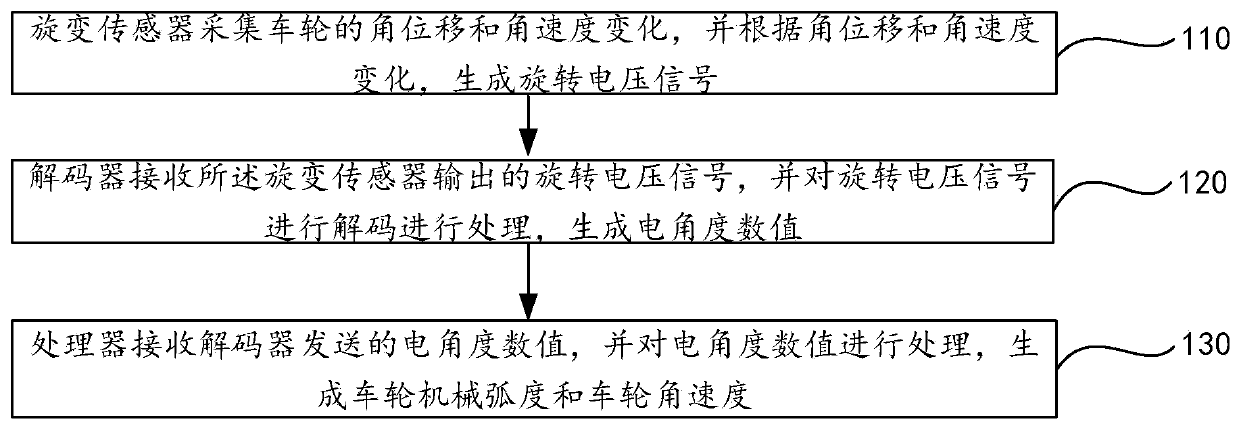

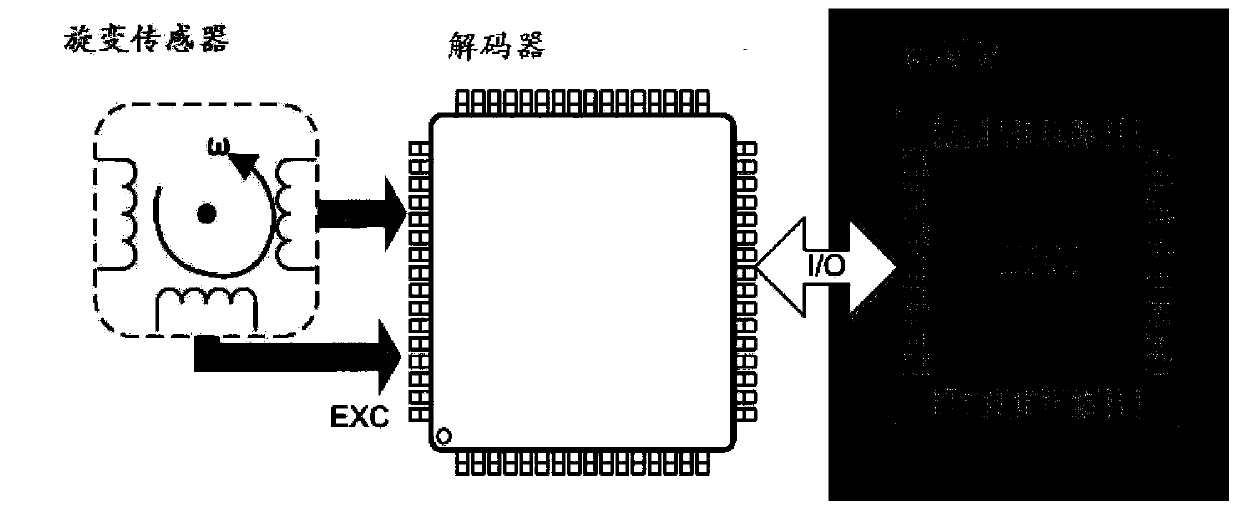

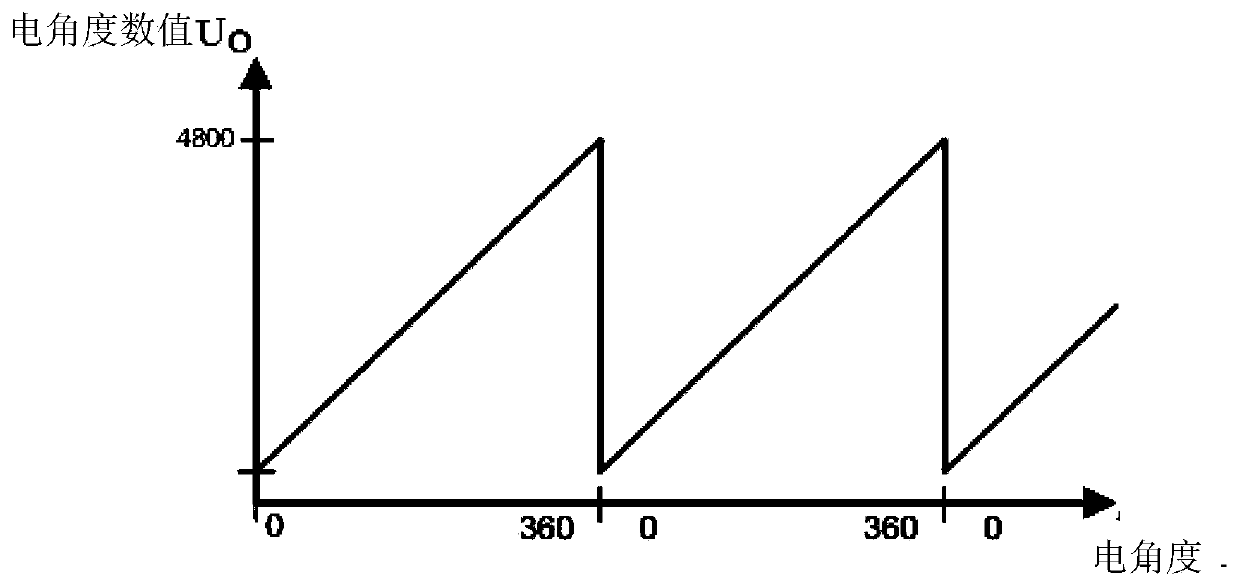

Parameter acquisition method based on rotational variable sensor

ActiveCN109878531ALow requirements for useGuaranteed measurement accuracyElectricityAngular velocity

The invention provides a parameter acquisition method based on a rotational variable sensor, which comprises the following steps: the rotational variable sensor acquires angular displacement and angular velocity change of a wheel, and generates a rotation voltage signal according to the angular displacement and the angular velocity change; a decoder receives the rotation voltage signal output by the rotational variable sensor and processes the rotation voltage signal to generate an electric angle value; a processor receives the electric angle value sent by the decoder and processes the electric angle value to generate the mechanical radian of the wheel and the angular speed of the wheel. Therefore, the measurement precision is ensured, the requirement on environmental use conditions is reduced; meanwhile, the open circuit state and the short circuit state of the rotational variable sensor can be detected, and the safety performance of automatic driving is improved.

Owner:BEIJING ZHIXINGZHE TECH CO LTD

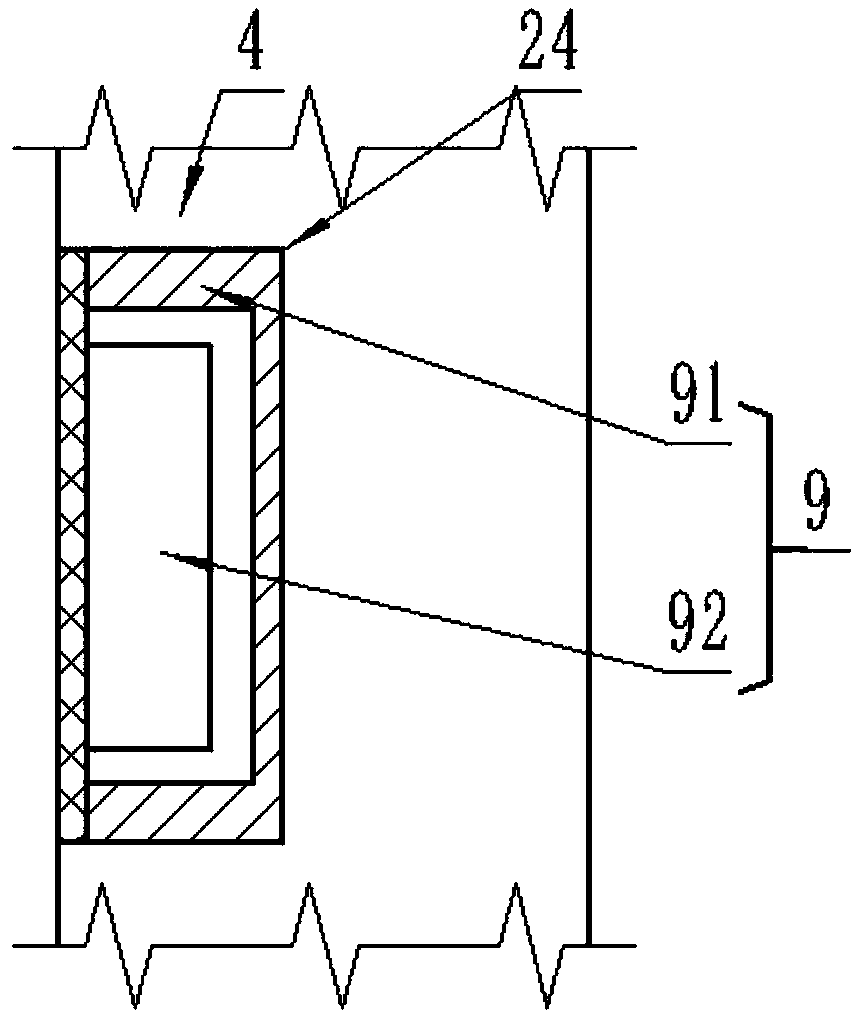

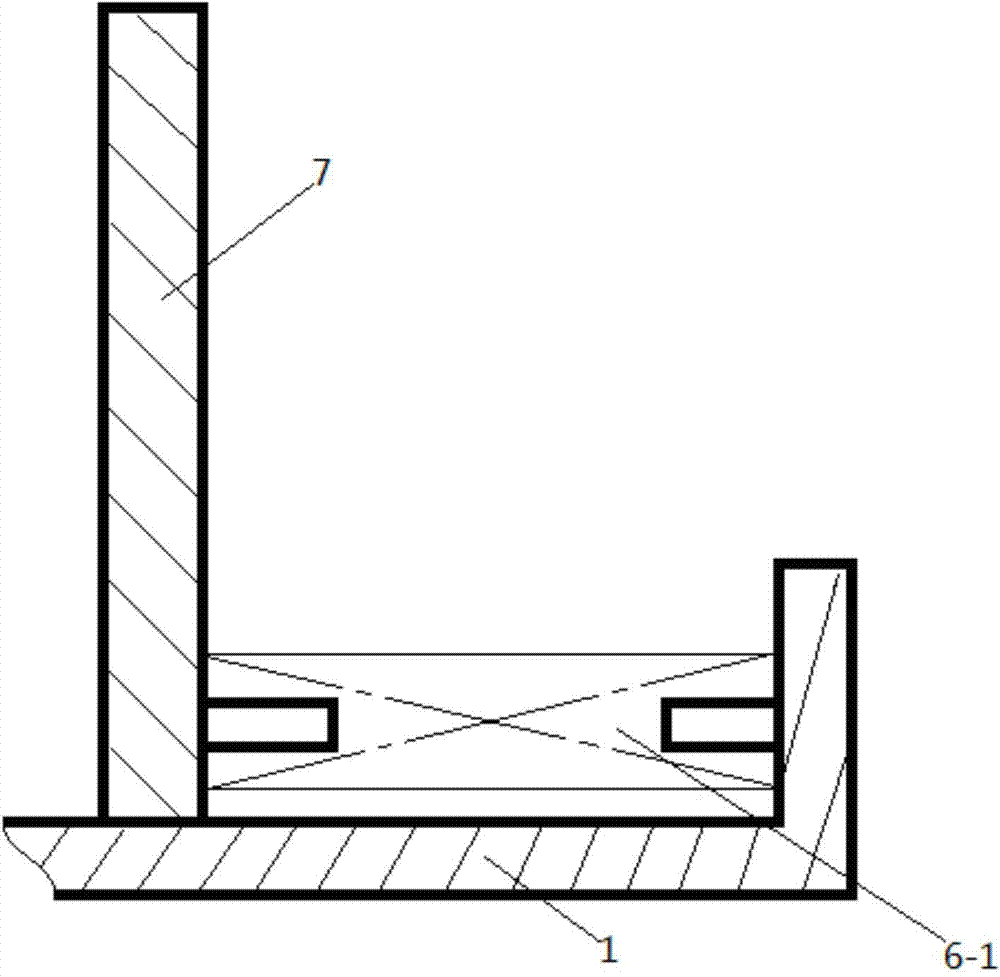

Negative pressure fixing seat

PendingCN110115676AReduce the conditions of useLarge fixed loadEngine sealsPneumatic massageMedium termEngineering

The invention relates to a negative pressure fixing seat. The negative pressure fixing seat is suitable for medium-term and short-term fixation, cupping and pressure drug delivery on an irregular plane. The negative pressure fixing seat is provided with an annular base, wherein an annular sealing material is arranged in the annular base, the sealing material is one of a plastic deformation material, a mud plastic solid, a solid-liquid mixture and a fluid material, the surface of the sealing material is provided with 0-1 protective thin layer, and the annular base is integrally connected with anegative pressure shell plate or is in compressed connection with the negative pressure shell plate through a pressing ring. The negative pressure fixing seat has the advantages that the fixed load is large, the requirements on the use condition of the surface of the plane are low, the use condition of an original cupping device is lowered, the use functions and range of the original cupping device are increased, the cost is low, the fixation is firm, reinforcement can be performed in the middle, repeated use can be achieved, the fixation position is flexible, the surface of the fixed plane is not damaged, the fixing pressure is controllable, and the fixing time is long.

Owner:张子辰

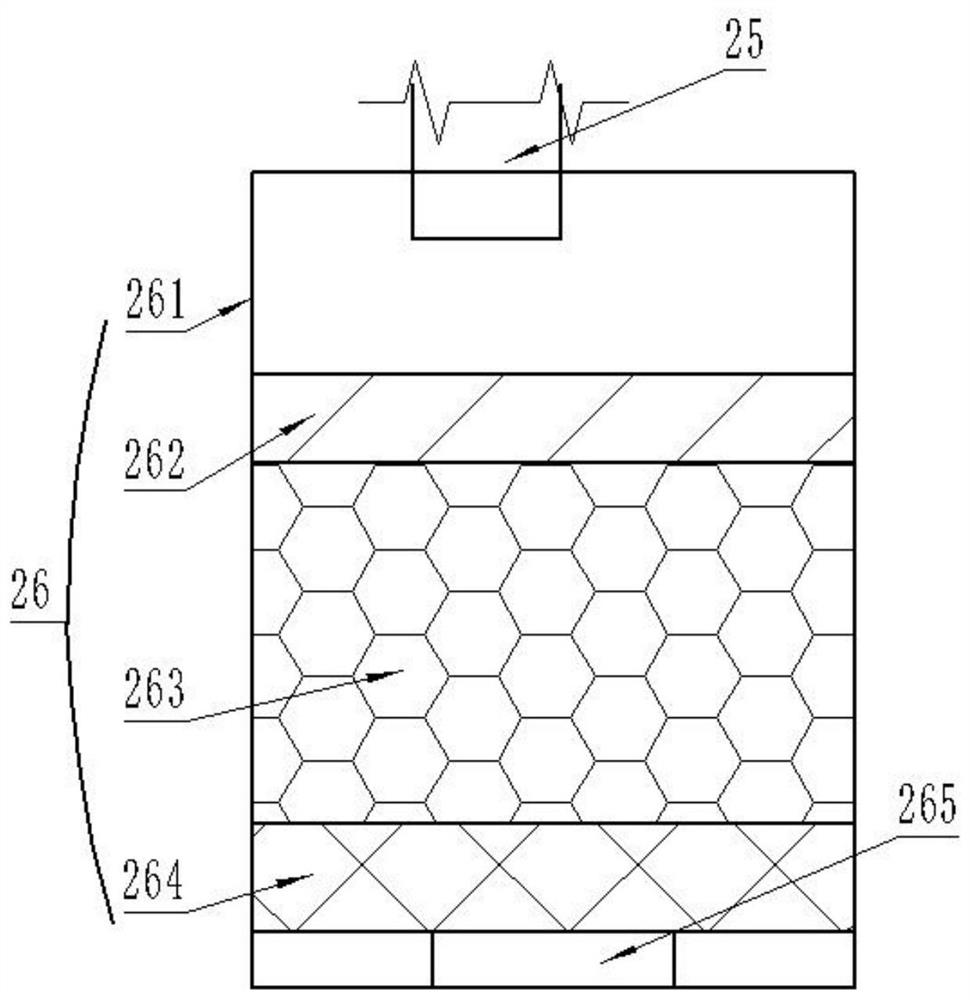

Beneficiation combined method and system for comprehensively recovered associated iron phosphate minerals

InactiveCN108906313AReduce production handling costsReduce processingMagnetic separationWet separationPrillIronstone

The invention discloses a beneficiation combined method and a system for comprehensively recovered associated iron phosphate minerals. The method comprises the steps of internally crushing the iron phosphate minerals through a crusher; sequentially carrying out 0.35mm to 0.45mm particle-size coarse crushing, 0.1mm to 0.15mm intermediate crushing, and 0.05mm to 0.09mm fine crushing; screening the fine-crushed powder ore, and obtaining undersize dried powdered ore and plus sieve powdered ore; placing the undersize dried powdered ore into a screening machine with a 0.4T to 1.2T high-intensity magnetic field, screening to obtain magnetic iron ore particles and powder, carrying out magnetic separation to screening a first dried iron ore concentrate, a first dried middling ore, and a first driedtailing, and returning the plus sieve powered ore back to the fine crushing step. The powered ore is dry-screened through sequentially carrying out the technological processes such as coarse crushing, intermediate crushing, fine crushing, screening, and dry screening on raw ore, so that the grinding particle size fineness is improved, the aim of more crushing and less grinding is achieved, the energy consumption and other raw material consumption during the mineral processing process are greatly reduced, the beneficiation cost is reduced, and the economic benefit is improved.

Owner:李建辉

An indoor air purification oxygenation and humidification device

ActiveCN109140641BReasonable designSimple structureMechanical apparatusSpace heating and ventilation safety systemsAir decontaminationOxygen enhanced

The invention discloses an indoor air purification, oxygenation and humidification device. The device comprises a device shell, a purification and sterilization mechanism and an oxygenation and humidification mechanism, wherein a cavity is formed in the device shell; a top cover is arranged at the upper end of the device shell; two flat separation plates for dividing the cavity in the device shellinto a first cavity, a second cavity and a third cavity are arranged in the device shell; a vertical separation plate for dividing the internal of the third cavity into a left side cavity and a rightside cavity is arranged in the third cavity; the purification and sterilization mechanism is arranged in the first cavity, and comprises a flat purification box, a second fan and a first connection pipe; the oxygenation and humidification mechanism is arranged in the second cavity; the humidification mechanism comprises a support base arranged on the upper surface of the flat separation plate, awater tank arranged on the support base, an atomization humidifier communicating with the bottom of the water tank, and an oxygen producer arranged on one side of the atomization humidifier; and a controller is arranged on the top cover. The indoor air purification, oxygenation and humidification device is reasonable in design, simple in structure and low in cost.

Owner:深圳市昶檀净化科技股份有限公司

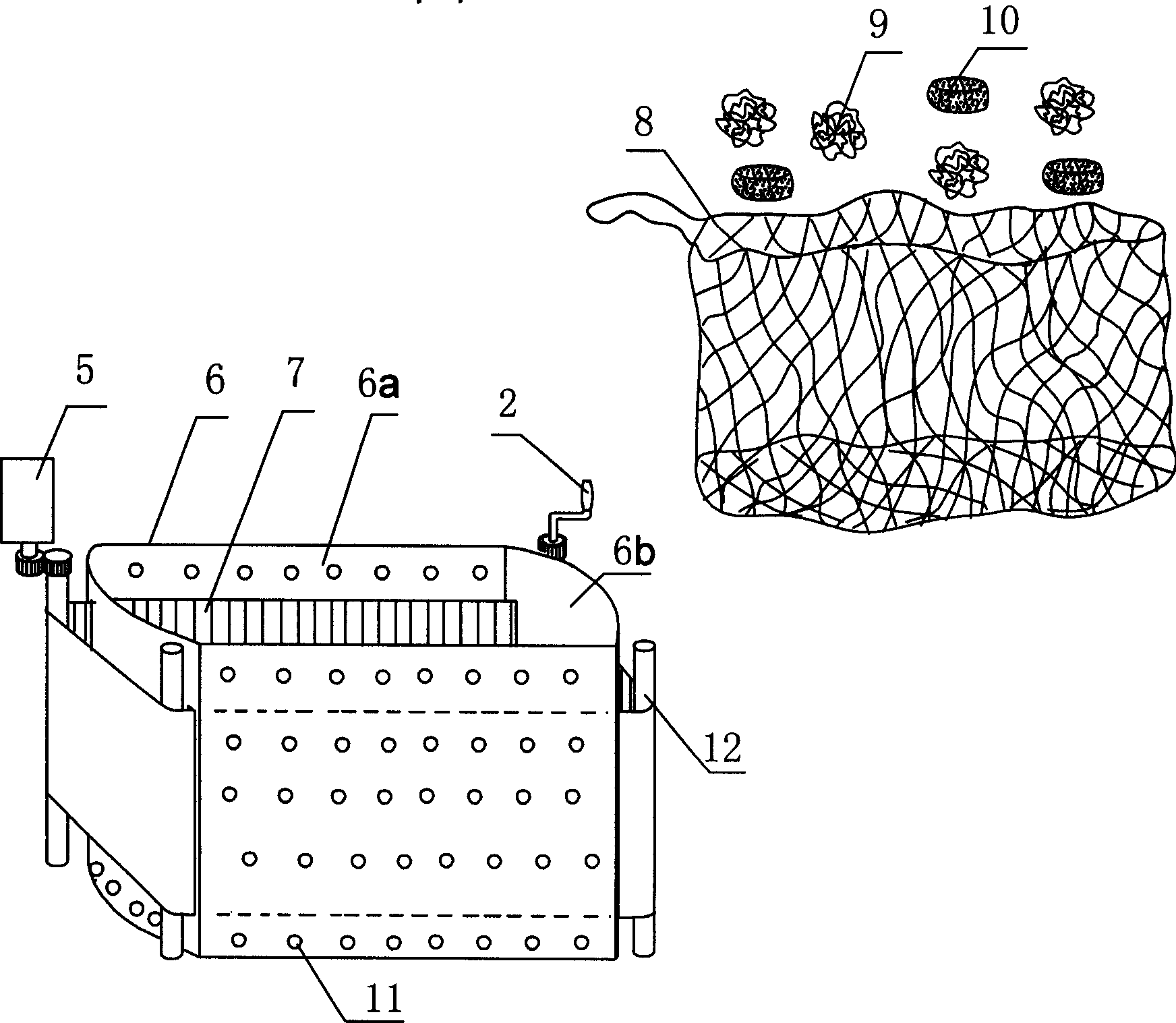

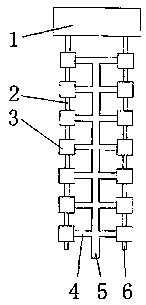

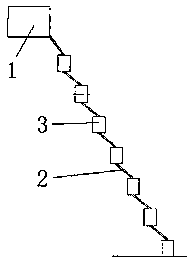

Suspension ladder gravity flow impact foaming mine tailing recycling technology, and device thereof

The invention discloses suspension ladder gravity flow impact foaming mine tailing recycling technology, and a device thereof. The device comprises a mine tailing ore pulp tank, an ore pulp pipeline,an unpowered floating tank, a foam path, and a discharge pipe; the mine tailing ore pulp tank is connected with a first ore pulp opening of the unpowered floating tank through the ore pulp pipeline; the unpowered floating tank is provided with a blocking plate which is used for blocking zinc mine tailing ore pulp and forming of foam through agitating overturning, and a floating tank foam outlet used for discharging foam. The suspension ladder gravity flow impact foaming mine tailing recycling technology is capable of solving problems in the prior art that in conventional flotation selection recycling of zinc metal in mine tailing, recycling process is complex, and cost is high; production technology process of recycling of zinc metal in mine tailing is simplified; excellent practical operation effect is achieved; operation is convenient; full ore pulp foaming is ensured; zinc metal recovery rate is increased; production cost is reduced; low cost mine tailing zinc metal recycling is realized; technology process is simple; using condition requirement is low; and zinc metal recovery rate is high.

Owner:GUANGXI GAOFENG MINE IND +1

Dedusting equipment

The invention discloses dedusting equipment, which includes a dedusting cylinder. One end of the dedusting cylinder is provided with an air inlet cylinder, and the other end is provided with an air outlet cylinder. The bottom of the dedusting cylinder is equipped with a conical barrel. The air inlet cylinder is provided with an air inlet, and the air outlet cylinder is provided with an air outlet. A water injection port is disposed on one side of the conical barrel, and the bottom of the conical barrel is equipped with a discharge bottom cover. The air inlet cylinder, the air outlet cylinder, the conical barrel and the dedusting cylinder are internally provided with a dedusting medium. The dedusting cylinder is internally provided with a plurality of stirring shafts, which undergo anticlockwise operation through a rotating shaft at the center. The dedusting equipment provided by the invention has the advantages of simple structure, safe use and low use condition requirement, can be suitable for the needs of different industries, and especially has thorough dedusting effects.

Owner:季江记

Electric automobile using a plurality of electric apparatuses to drive running

InactiveCN101412378BSimple structureLow requirements for useSpeed controllerElectric energy managementVehicle frameControl signal

The invention relates to an electric automobile. The electric automobile comprises an automobile body, an automotive chassis, automotive wheels, a parking mechanism, a control signal input device and a power-drive mechanism, wherein the power-drive mechanism comprises a main drive unit for providing a driving force for the electric automobile in a high-torque operation state, and an auxiliary drive unit for providing a driving force for the electric automobile in a low-torque operation state. The electric automobile also comprises a programmable operating mode control unit for controlling operating conditions of the main drive unit and the auxiliary drive unit according to a control signal input by the control signal input device and the working currents in the main drive unit and the auxiliary drive unit. Therefore, the electric automobile can freely select driving modes with the control of the programmable operating mode control unit, thereby improving the use rate of vehicle-mounted batteries. The electric automobile with the electric drive units has advantages of simple structure, low requirements on use conditions, low manufacture cost and easy promotion and application.

Owner:SHENZHEN ODET INTELLIGENT TECH DEV +3

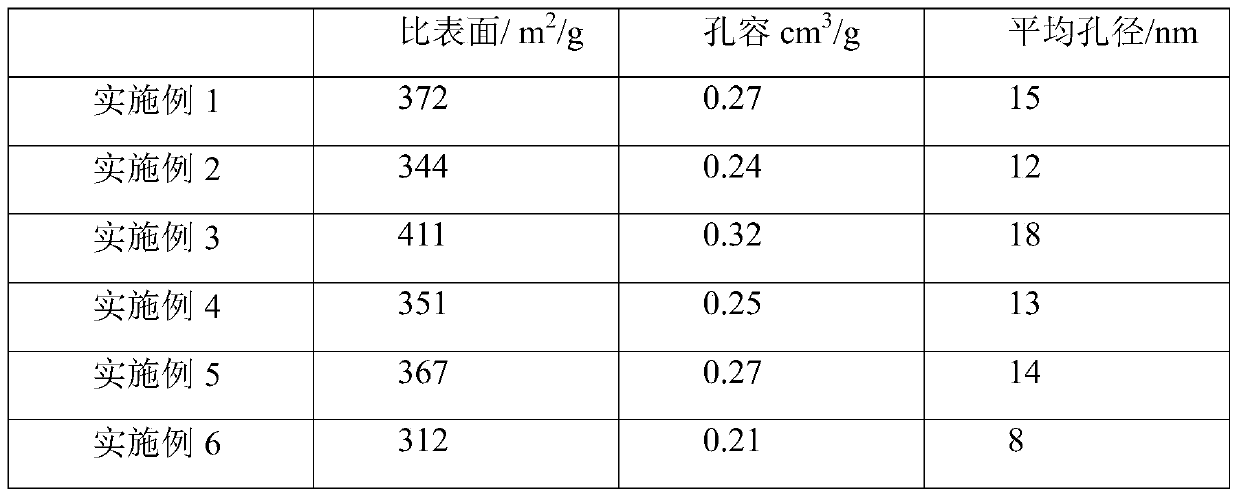

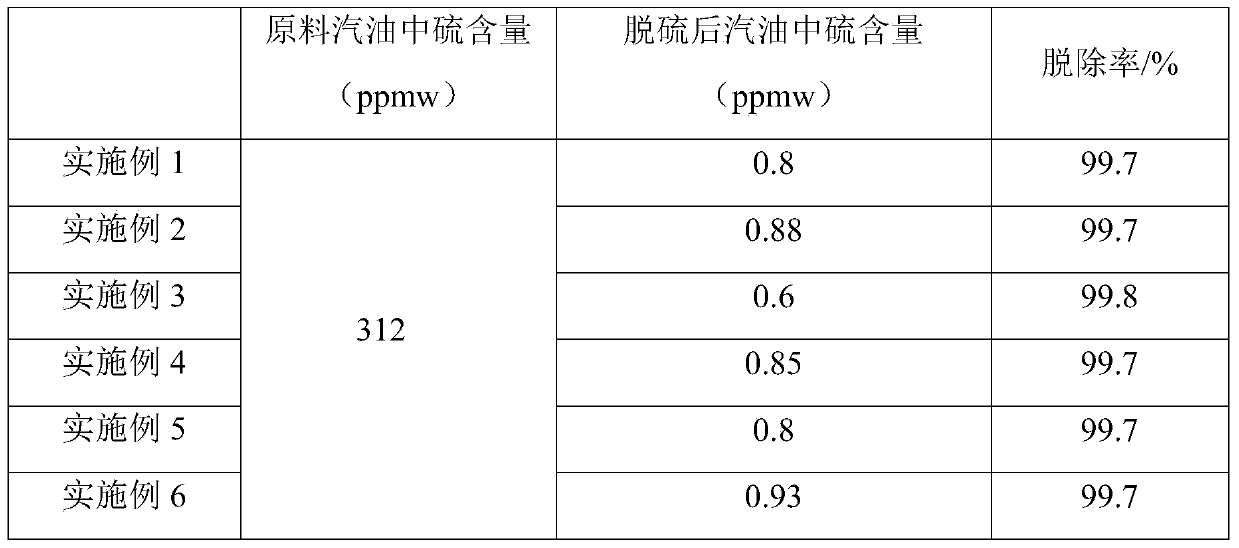

A novel desulfurization adsorbent and its preparation method

ActiveCN105797674BImprove desulfurization effectUniform loadOther chemical processesAlkali metal oxides/hydroxidesPhosphatePhysical chemistry

Owner:QINGDAO HUICHENG PETROCHEM TECH

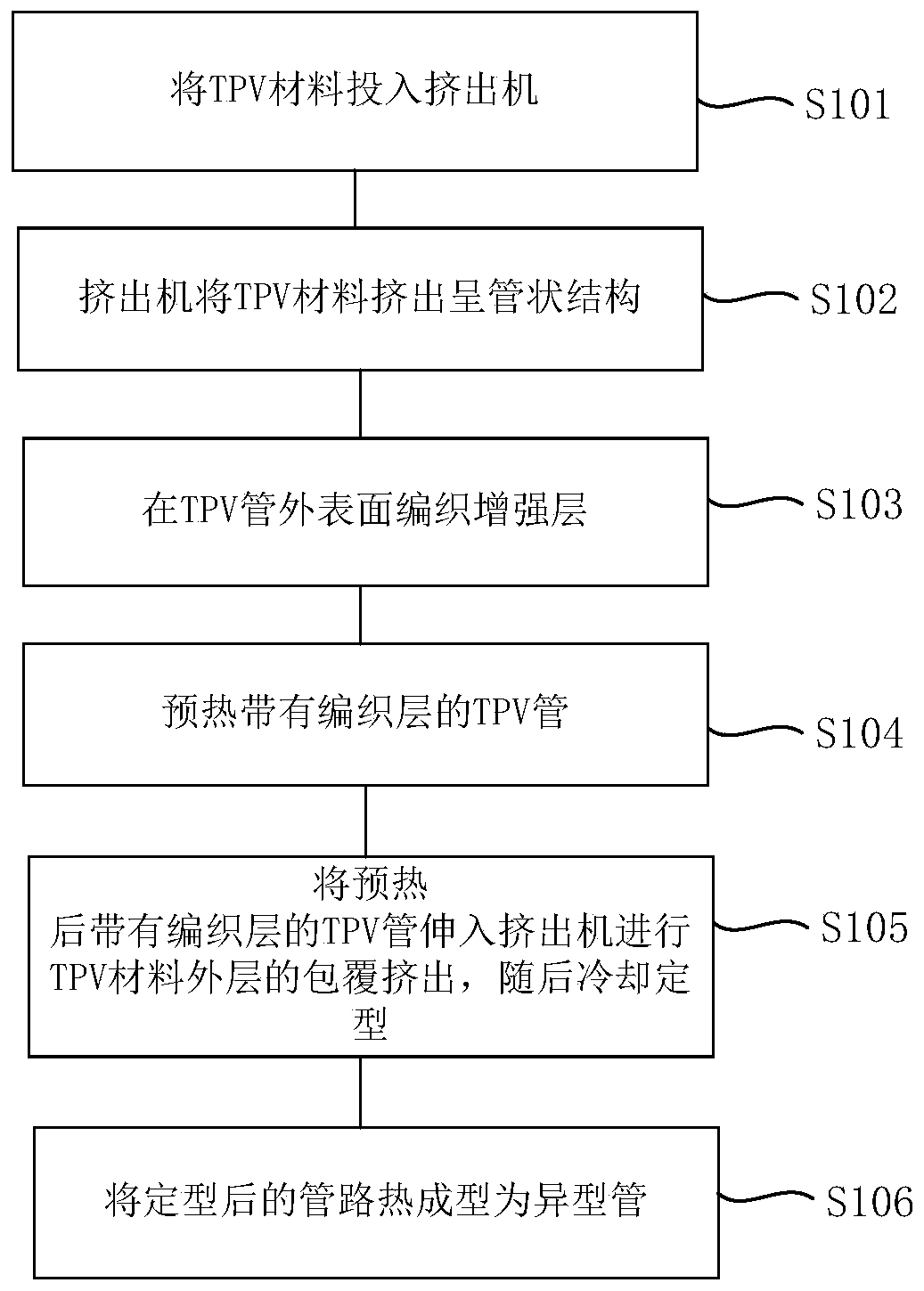

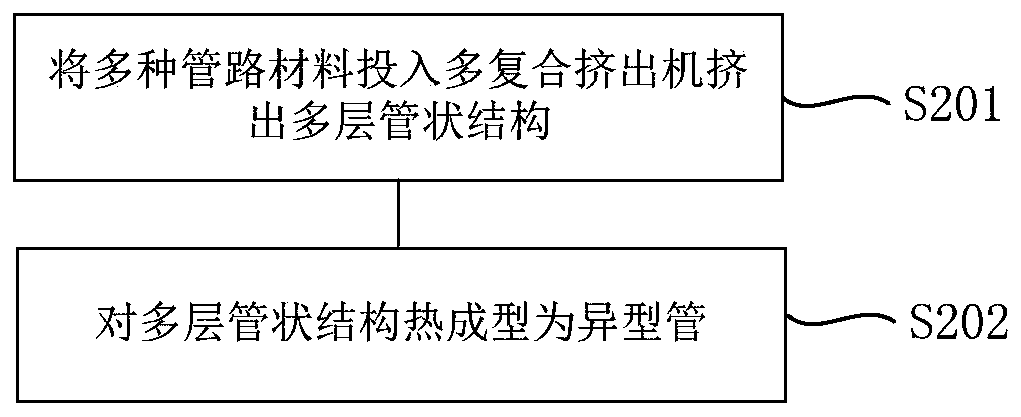

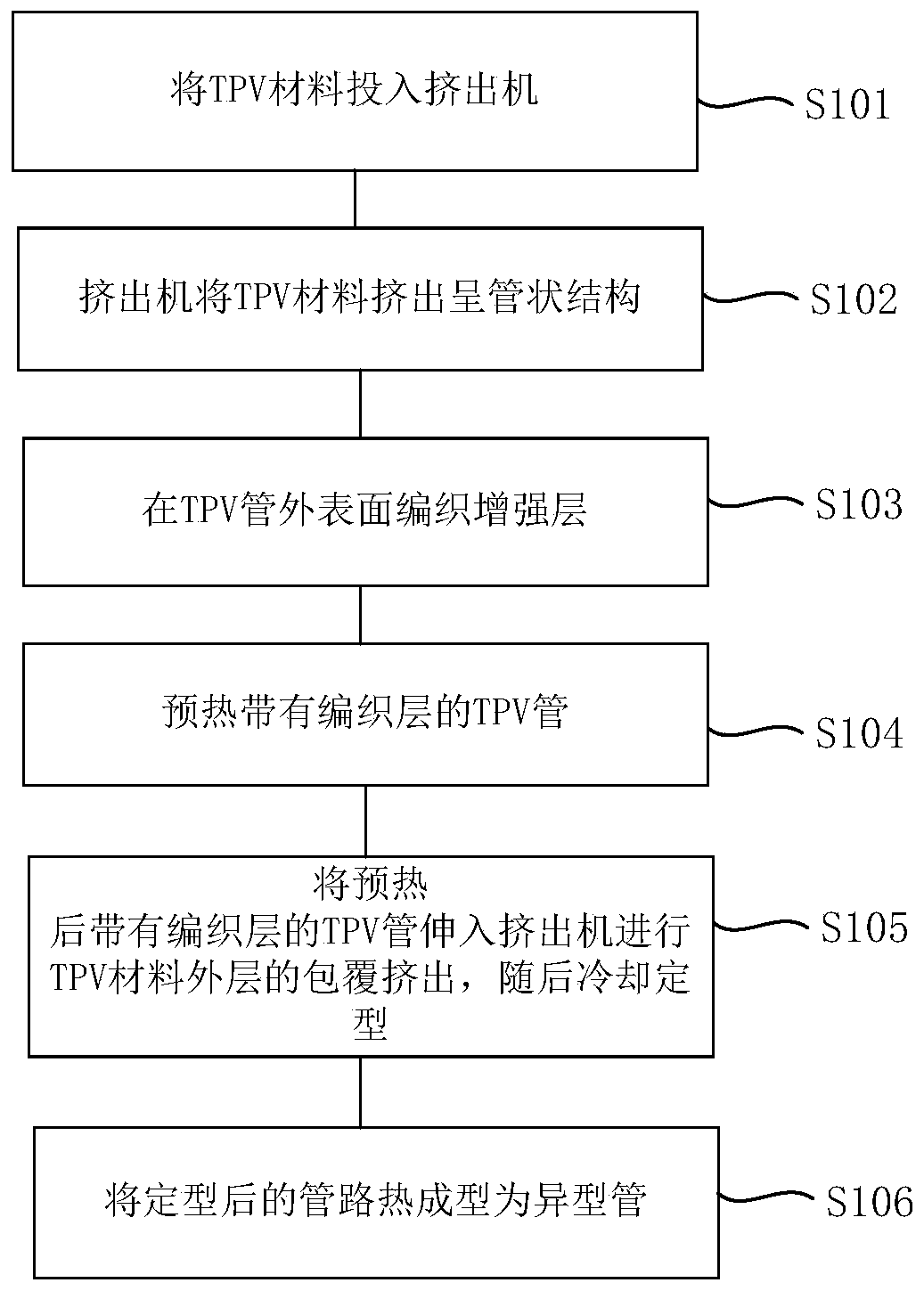

Plastic cooling liquid water pipe and preparation method thereof

The invention provides a plastic cooling liquid water pipe and a preparation method thereof, relating to the technical field of cooling pipes. The plastic cooling liquid water pipe comprises a first polyolefin pipe and a second polyolefin pipe, wherein the first polyolefin pipe is coated with the second polyolefin pipe, and when the first polyolefin pipe and the second polyolefin pipe are made ofthe same material, a reinforcing layer is further arranged between the first polyolefin pipe and the second polyolefin pipe. The plastic cooling liquid water pipe provided by the invention can be recycled, is light in weight, low in cost and low in permeability, and more conforms to the development trend of a safe, environment-friendly and weight-reducing whole vehicle.

Owner:TIANJIN PENGYI GRP CO LTD

Light and shadow music device

InactiveCN103645834ALow requirements for use conditionsWide range of applicationsInput/output for user-computer interactionGraph readingClose rangeCommunication unit

The invention discloses a light and shadow music device. The device comprises a central processing unit and a display, a light and shadow imaging unit, an image recognition unit, a sounding unit, a shaking induction unit, a close-range induction unit, a levelness induction unit, a light ray intensity induction unit, a plane transmission analysis unit and a wireless communication unit which are connected with the central processing unit respectively.

Owner:白振辉

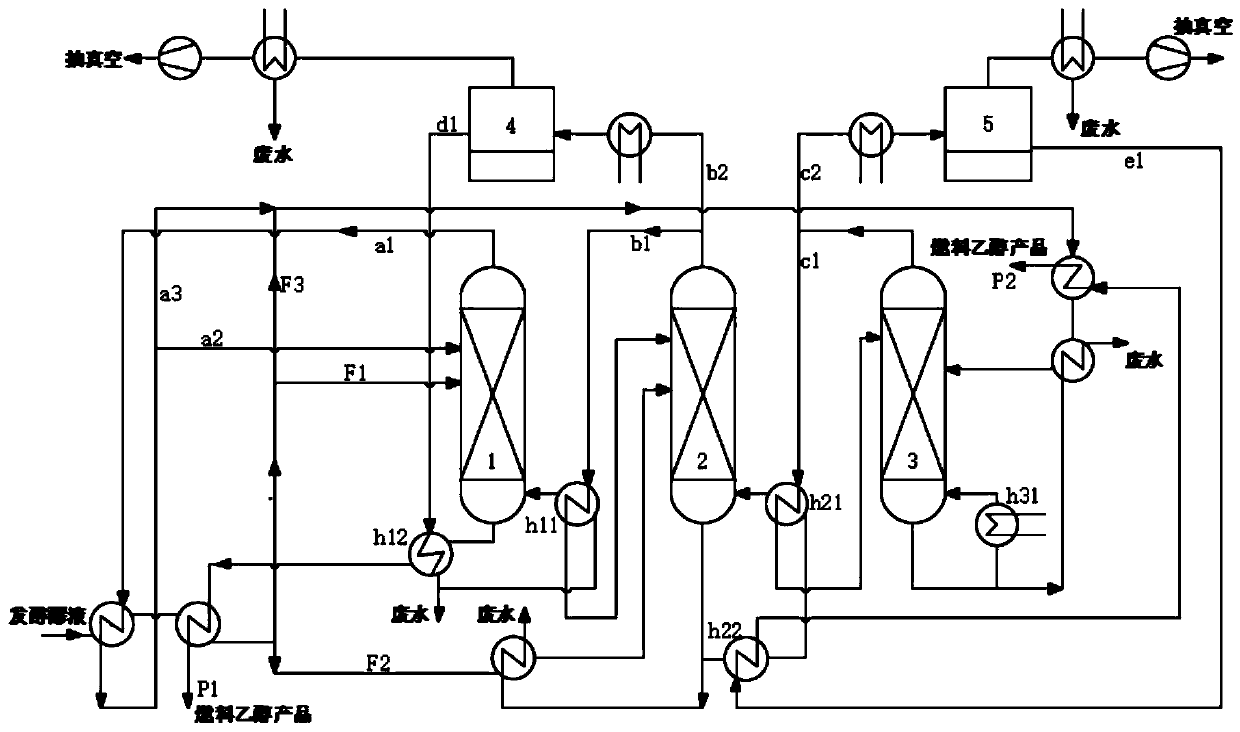

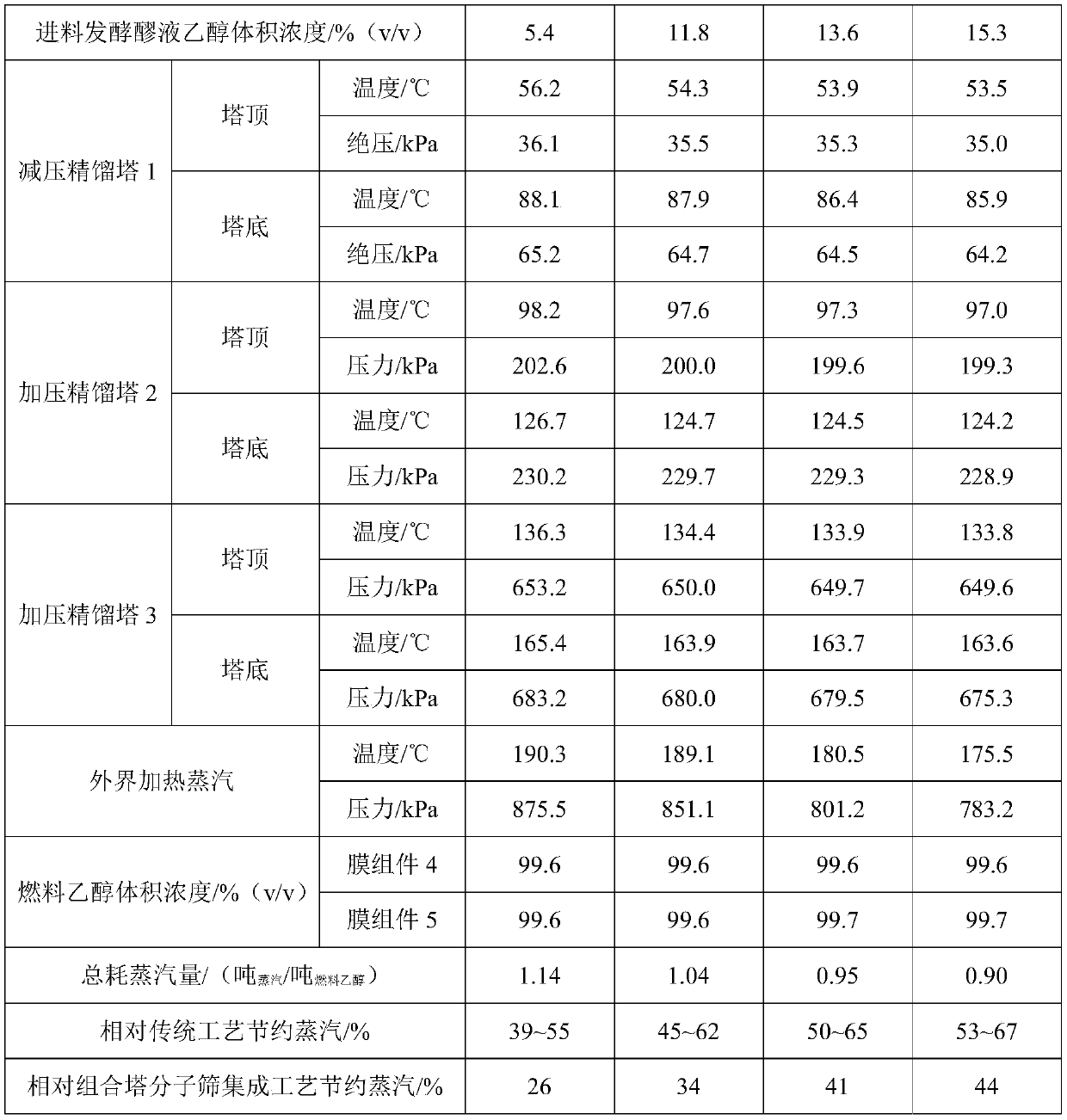

Three-column two-membrane coupled reinforced refining method for fuel ethanol

ActiveCN110483248AIncrease profitImprove matchOrganic compound preparationChemical industryProcess systemsDistillation

The invention discloses a three-column two-membrane coupled reinforced refining method for fuel ethanol. In the method, a rectification-purification process system includes a three-column rectification section formed by connecting a decompression distillation column and two pressurized coarse distillation columns which adopt a mash parallel feeding manner, and a purification section includes a membrane separation device. Materials of the rectification section and the purification section are highly matched with a heat system to reduce steam consumption for a unit product; through combination of vapor permeation and membrane separation, the concentration requirement of fed ethanol is reduced, the number of column trays of the pressurized coarse distillation columns is reduced, and the reflux ratio is reduced, so that biomass fermented mash is rectified and purified to prepare high-purity ethanol meeting the requirement of fuel ethanol, and the production purposes of environmental protection, energy conservation and high efficiency are achieved. The method disclosed by the invention has the advantages of greatly saving steam consumption, being high in one-time discharging quality, high in system automation degree, small in occupied area of the device, convenient to maintain equipment, reliable and durable in membrane consumable material, high in resource utilization rate and thelike.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com