Method and system for detecting tire dynamic vertical load during traveling period of vehicle

A vertical load and vehicle driving technology, which is applied in tire measurement, vehicle parts, tire parts, etc., can solve the problems of high requirements for use conditions, poor feasibility, and high cost, and achieve low requirements for use conditions, hardware requirements and cost The effect of low, high accuracy of the load value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

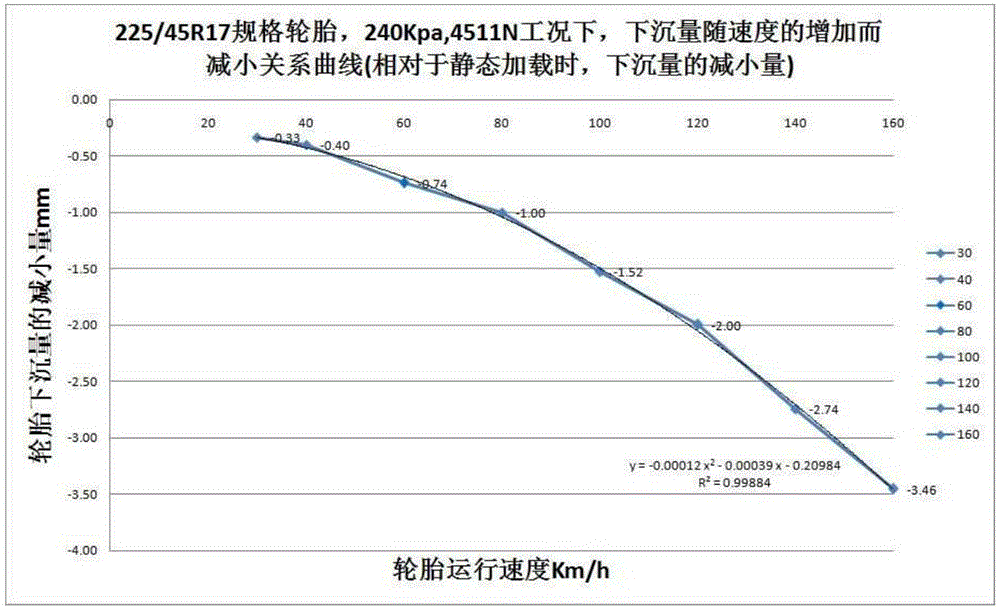

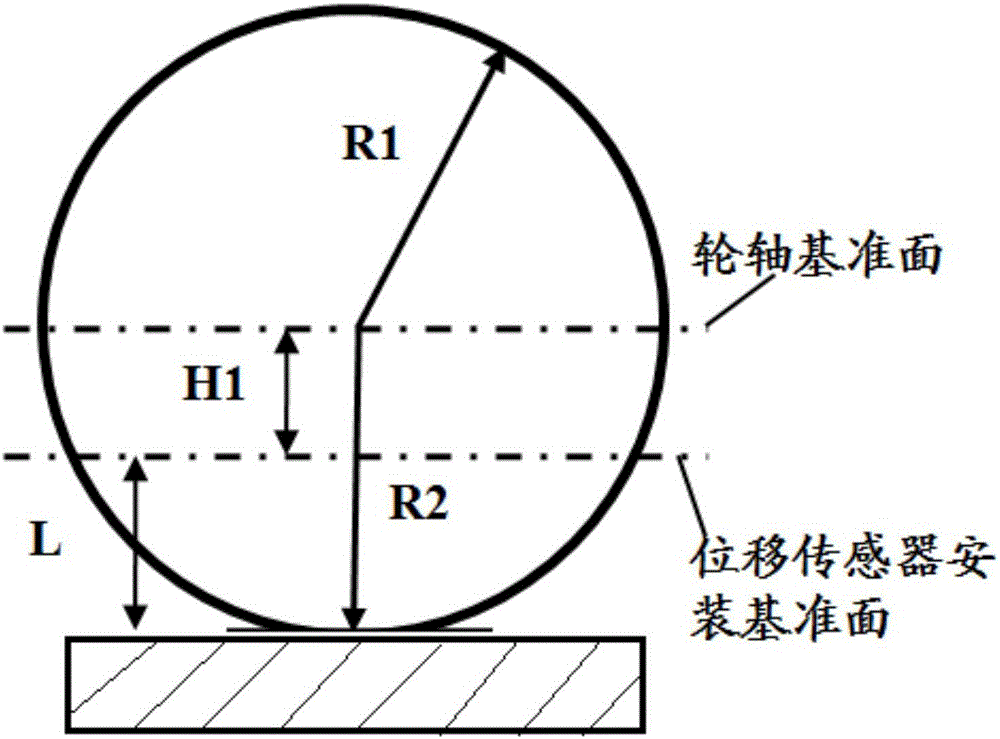

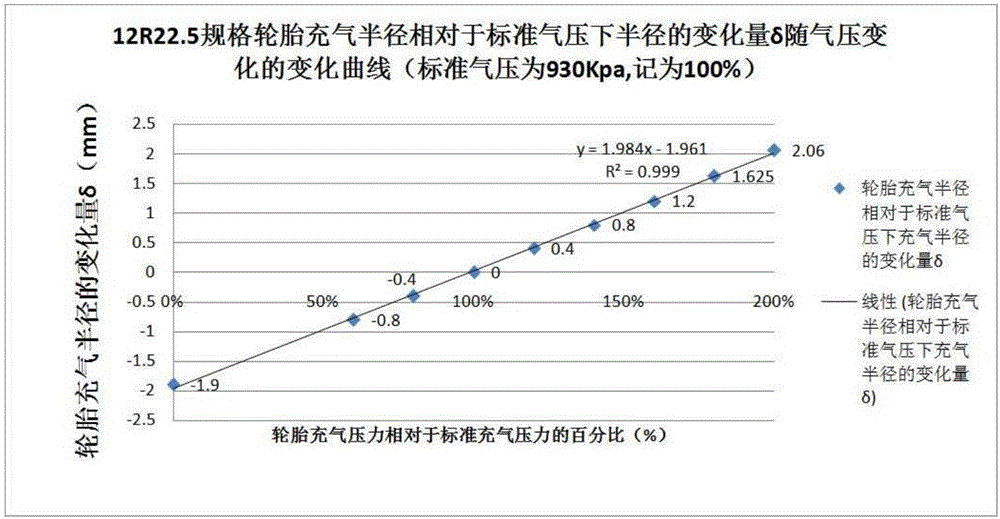

[0038] The tire dynamic vertical load detection system during vehicle running involved in the present invention mainly consists of two parts: one is the measurement of vehicle and tire related technical parameters during vehicle running, and the other is the tire dynamic vertical load model, which involves The technical parameters of the vehicle are the real-time speed of the vehicle, the real-time air pressure of the tire, and the ground distance of the displacement sensor.

[0039] see figure 2 The system for detecting the dynamic vertical load of tires during vehicle running includes a GPS speed test component for measuring the vehicle running speed v, a tire pressure monitoring system for measuring the real-time air pressure Pre of the tire, and a real-time pressure monitoring system for measuring the displacement sensor installation reference plane relative to the ground The displacement sensor of the distance L and the server used to collect v, Pre and L in real time an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com