Casing pipe bending moment compensator special for thermal recovery horizontal well

A technology of horizontal wells and compensators, which is applied in the direction of casing, drilling pipe, and production fluid, etc., can solve the problems of stress concentration, failure to provide bending moment compensation, downhole sand production, etc., and achieve strong applicability, significant economic benefits, Effects requiring low usage conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

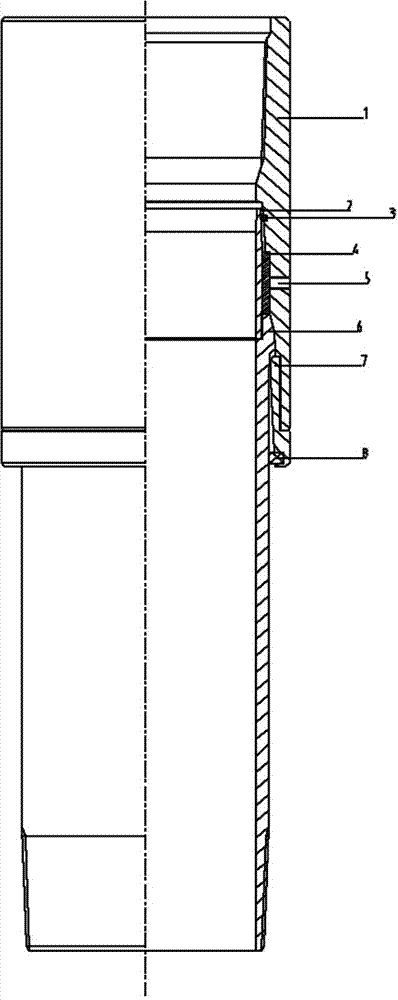

[0007] The present invention is described in detail below in conjunction with accompanying drawing, see figure 1 , the special casing bending moment compensator for thermal recovery horizontal wells includes an outer cylinder 1, a hot-melt limit ring 4 and a lower inner cylinder 6, connecting the upper inner cylinder 2 with the lower inner cylinder 6, together with the heat-melt limit ring 4 After being put into the outer cylinder 1 together, the stop ring 7 is used to connect the outer cylinder 1 with threads; , Concave spherical mating surface. The pipe string formed by the upper inner cylinder 2 and the lower inner cylinder 6 can take the spherical mating surface as the axis and bend arbitrarily in all directions within a preset angle to adapt to the actual wellbore changes of the oil zone. Both ends of the outer cylinder 1 are provided with inner threaded buckles, and the inner circle is sequentially processed from top to bottom to protect the inner cylinder with steps, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com