Negative pressure fixing seat

A negative pressure and negative pressure shell plate technology, used in the field of short-term fixation, cupping, and pressure drug delivery, can solve the problems of high requirements for use conditions, small fixed load, damage, etc., to achieve low requirements for use conditions and controllable fixed pressure. , Fixed position and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

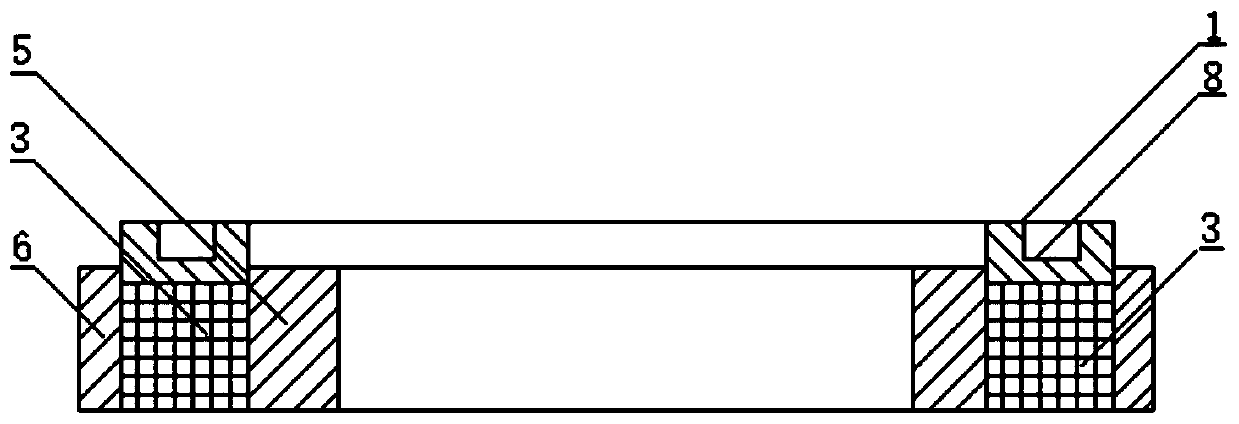

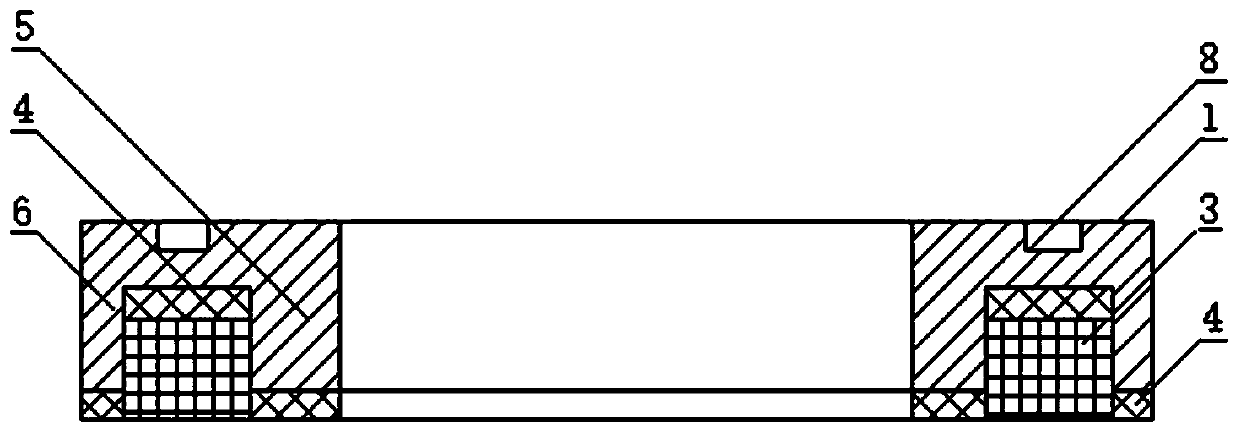

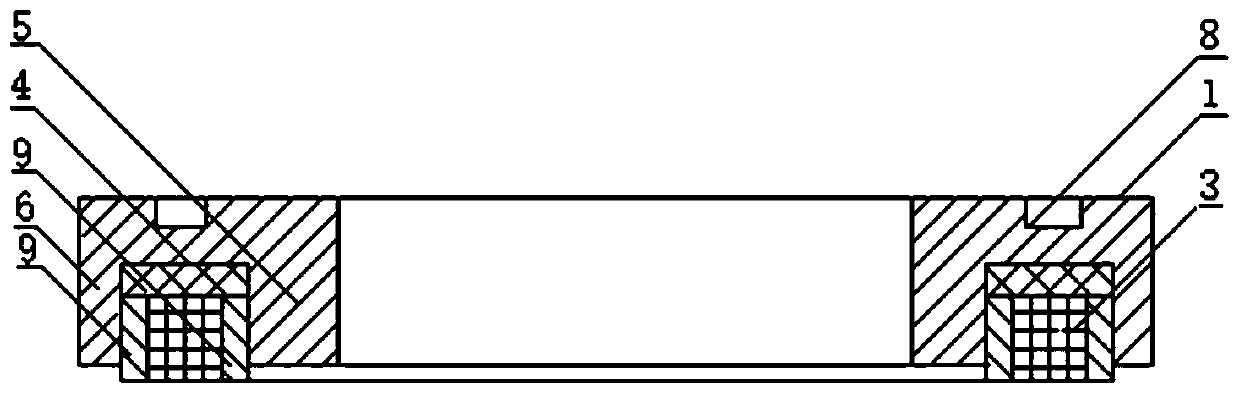

[0023] attached by figure 1 , attached Figure 5 , attached Figure 13 It can be seen that the embodiment 1 of the negative pressure fixing seat is as follows: it has an annular base 1, and an annular sealing material 3 is located between the inner ring 5 and the outer ring 6 in the annular base, and its bottom surface is at the bottom of the annular base. 1, the inner ring 5 and the outer ring 6 are connected by connecting rods or plates, and the sealing material 3 is one of four materials: plastic deformation material, muddy plastic solid material, solid-liquid mixture, and fluid material. On the surface of the sealing material 3, there are 0-1 protective thin layers of elastic material which have little effect on the plastic deformation and sealing of the sealing material 3, and part or all of the material of the annular base 1 is elastic material. The negative pressure shell plate 2 is connected with the sealing material 3 through three elastic deformation layers 4 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com