Self-fixing digital equipment support

A digital device and self-fixing technology, applied to railway car body parts, transportation and packaging, vehicle parts, etc., can solve the problems of user discomfort, low safety factor, user fatigue, etc., and achieve low manufacturing cost, simple structure, The effect of good market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

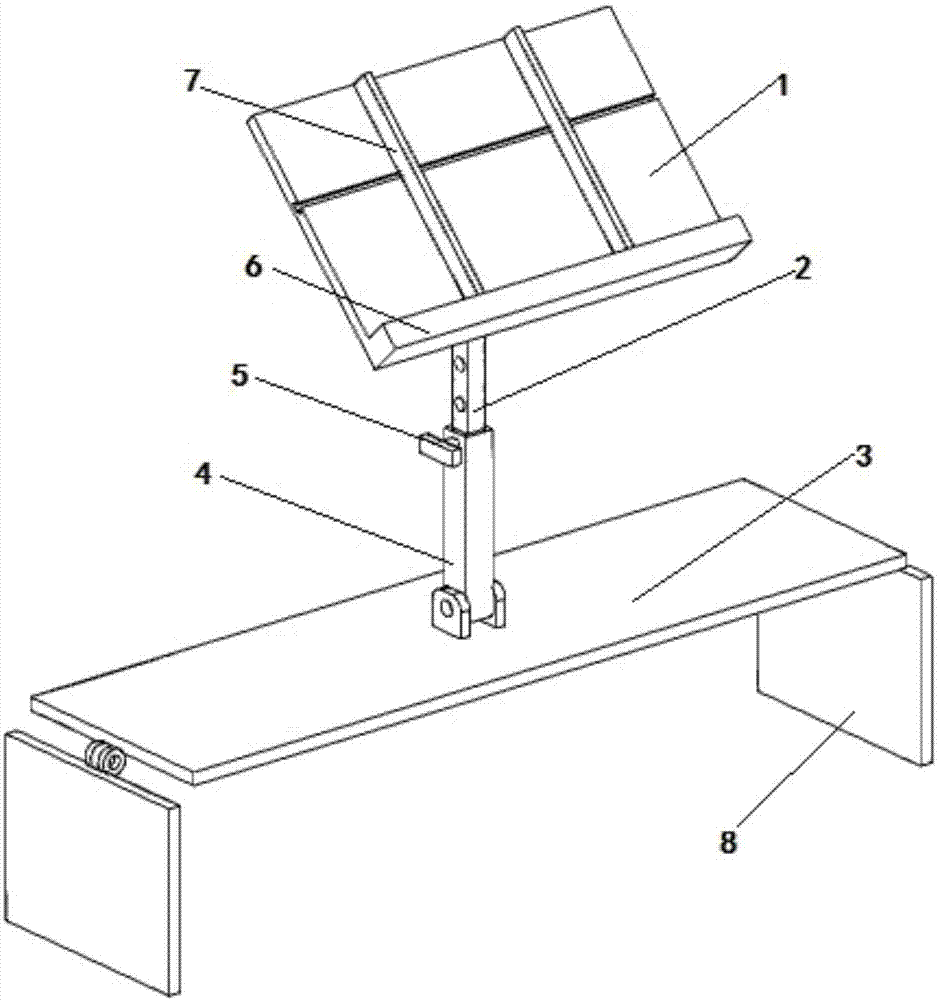

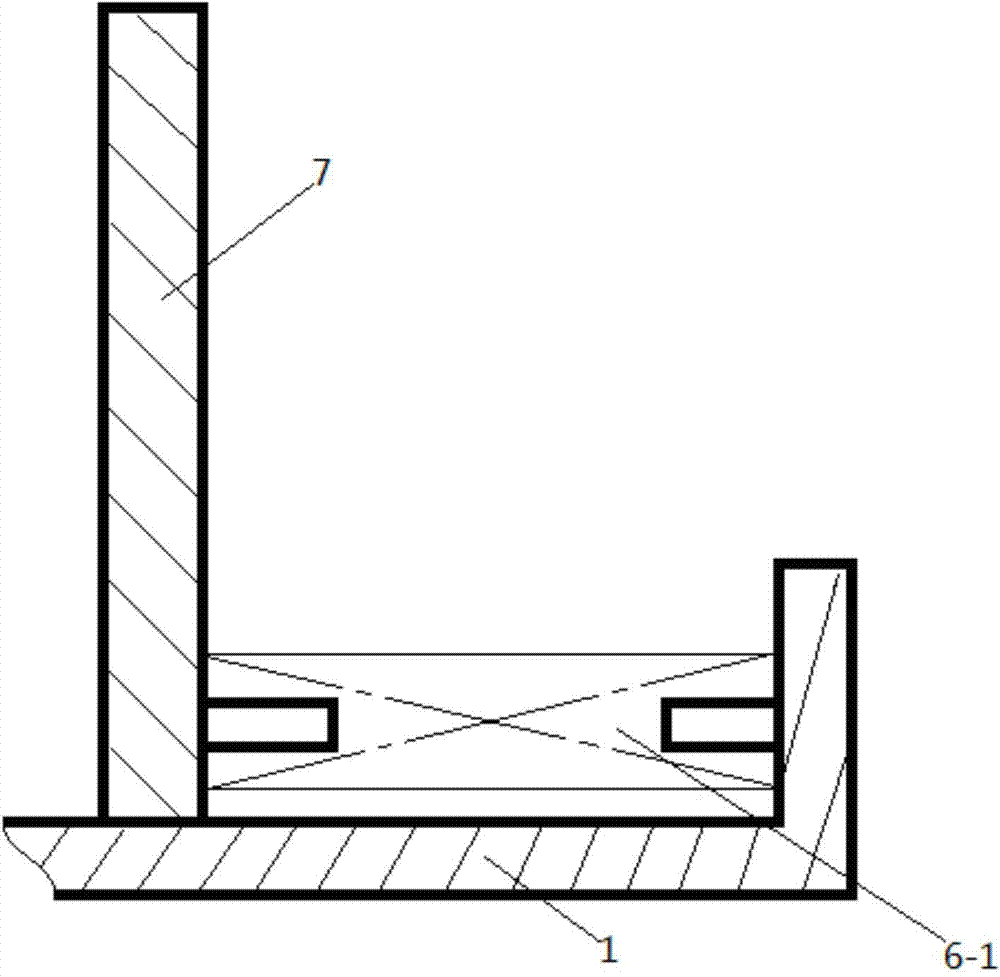

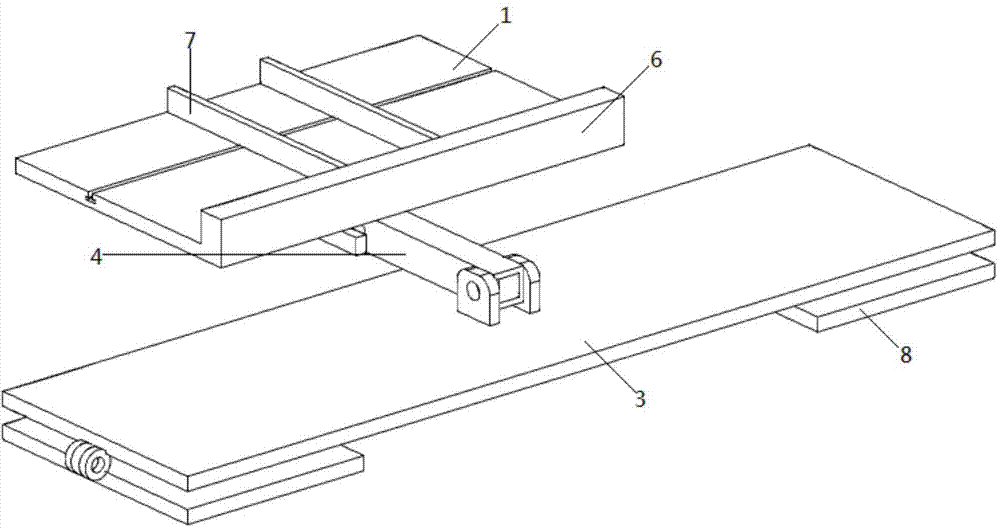

[0015] Referring to the accompanying drawings, the self-fixing digital equipment support includes a leg support frame 3, leg support plates 8 are connected to the return springs on both sides of the leg support frame 3, and a height positioning square tube 4 is hingedly installed in the middle of the leg support frame 3 , the height positioning square tube 4 is slidably installed with a height bracket 2, the upper end of the height bracket 2 is hingedly installed with an equipment carrying platform 1, the bottom of the equipment carrying platform 1 is provided with a clamping device elastic component 6, and the equipment carrying platform 1 is slidingly installed with a symmetrical The equipment clamping and positioning slide plate 7 is connected to the side edges on both sides of the equipment carrying platform 1, and the spring 6-1 fixed between the equipment clamping positioning slide plate 7 and the corresponding side is elastically fixed at both ends of the elastic componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com