Safe and environment-friendly dust remover

A safe and environmentally friendly dust collector technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as hopper bridging, reduced dust removal efficiency, and inability to remove dust, so as to reduce dust, facilitate maintenance, and improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

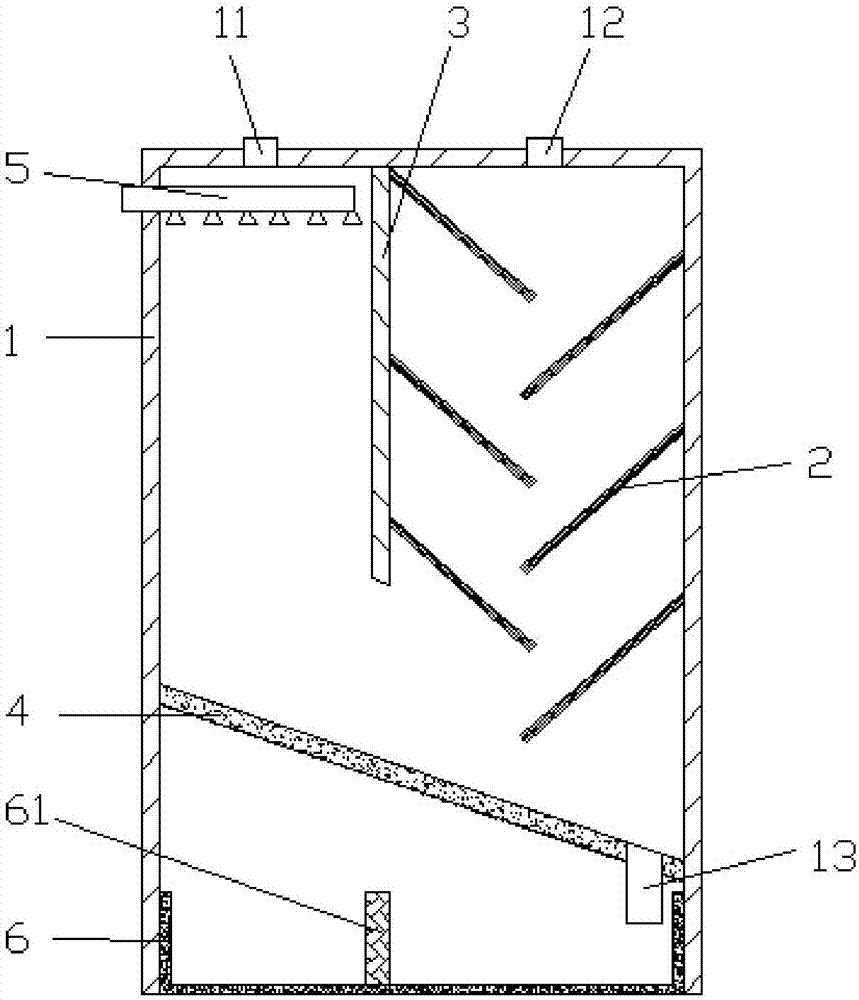

[0017] The purpose of this embodiment is to provide a safe and environmentally friendly dust collector, such as figure 1 As shown, the dust collector includes a housing 1, and the housing 1 is provided with a vertical partition 3 that divides the housing 1 into an air inlet chamber and an air outlet chamber, and a bottom plate 4 arranged under the vertical partition in the housing The air inlet cavity and the lower part of the air outlet cavity are connected to form an air flow channel, and the top of the air intake cavity and the air output cavity are respectively provided with an air inlet 11 and an air outlet 12 of the air flow channel; the top of the air intake cavity is provided with Spraying device 5, in the described air outlet cavity, staggered inclined pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com