Method and device for improving liquefied natural gas gasification energy-saving efficiency

A technology of liquefied natural gas and energy-saving efficiency, which is applied in the field of improving the energy-saving efficiency of liquefied natural gas gasification and gasification of liquefied natural gas receiving stations, can solve the problems of titanium alloy pipeline equipment load being difficult to meet the use requirements, cold energy not being utilized, and high price. , to achieve the effect of improving long-term continuous operation capacity, reducing cleaning and maintenance, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

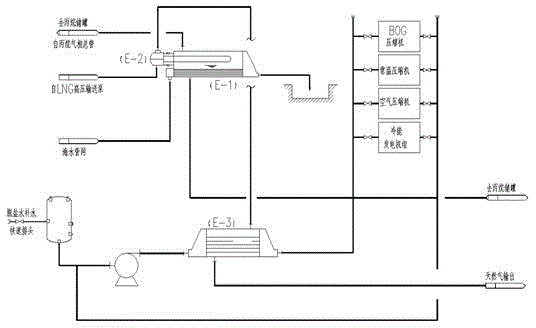

[0024] Such as figure 1 shown.

[0025] A method and device for improving the energy-saving efficiency of gasification of liquefied natural gas. Firstly, the liquefied natural gas vaporized by the gasifier E-2 is introduced into an independent superheater E-3 for superheating, and the liquefied natural gas that is vaporized by the gasifier E-1 is sucked The heated seawater is directly discharged, and the requirements for the use of seawater are lowered, so it can be used even in winter; secondly, the natural gas in the superheater is heated to the required temperature with fresh water, and the fresh water becomes low-temperature cold water after heat absorption by liquefied natural gas; the low-temperature cold water Introduced into the cold energy utilization equipment, the cold energy is fully utilized and then returned to the superheater to heat natural gas, realizing the recycling of fresh water, improving the working efficiency of the whole system, and increasing the ener...

Embodiment 2

[0027] A liquefied natural gas receiving station process device capable of circulating cooling system equipment, which includes:

[0028] A seawater system, which is composed of a seawater intake, a seawater pump, a seawater pipeline, a heat exchange tube bundle at the lower part of a gasifier, a drainage channel and a pipeline system, is used to provide the heat required for heating and vaporizing liquefied natural gas, and the seawater flow rate, temperature Very easy to adjust;

[0029] A propane system, which consists of a propane tank, a propane pump and a pipeline system, is used to absorb the heat of seawater in the seawater system to provide the required heat energy for the primary gasification of liquefied natural gas; during normal operation, the propane system is gasifying The gasifier is closed, neither input nor discharged. The propane in the gasifier is heated and vaporized by the lower seawater heat exchange tube bundle, and the vaporized propane rises to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com