A novel desulfurization adsorbent and its preparation method

A new type of desulfurization and adsorbent technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc. In addition to other problems, it can achieve the effect of remarkable desulfurization effect, low sodium oxide content and simple regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

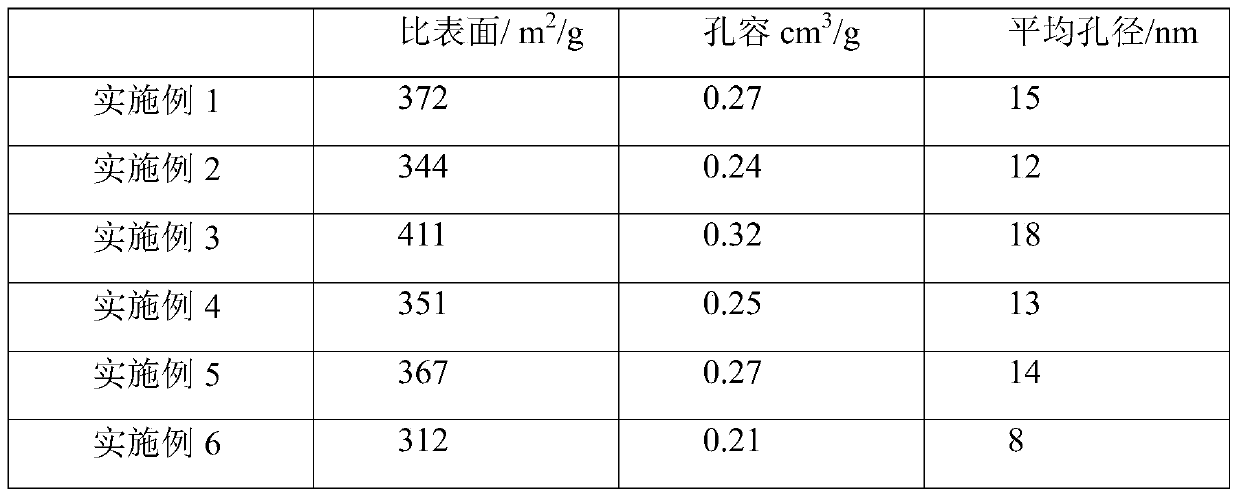

[0021] (1) Mix the flue gas dust collected from petrochemical enterprises with 50% sulfuric acid solution at a liquid-solid ratio of 3:1. After reacting at 110°C for 1 hour, the mixed solution is separated from solid and liquid by a centrifuge. The solid obtained after solid-liquid separation is washed with water to pH = 7, and dried at 120°C to obtain a high-quality carrier material with high specific surface area, large pore volume, and wide pore size distribution range. For physical properties of the carrier material see figure 1 .

[0022] (2) The self-made support obtained above is placed in the vanadium oxalate solution that has been completely dissolved by the method of supersaturated impregnation, and the amount of impregnation is V 2 o 5 Calculated as 3%, put the uniformly stirred sample under an infrared lamp, stir intermittently until the impregnation solution is completely dry, and finally dry the solid at 120°C for 4 hours, and then roast it in a muffle furnace ...

Embodiment 2

[0026] (1) Mix the flue gas dust collected from petrochemical enterprises with 50% sulfuric acid solution according to the liquid-solid ratio of 3.2:1. After reacting at 120°C for 1 hour, the mixed solution is separated from solid and liquid by centrifuge. The solid obtained after solid-liquid separation is washed with water to pH = 7, and dried at 120°C to obtain a high-quality carrier material with high specific surface area, large pore volume, and wide pore size distribution range. For physical properties of the carrier material see figure 1 .

[0027] (2) The self-made support obtained above is placed in the vanadium naphthenate solution that has been completely dissolved by the method of supersaturated impregnation, and the amount of impregnation is V 2 o 5 Calculated as 3.2%, put the evenly stirred sample under an infrared lamp, stir intermittently until the impregnation solution is completely dry, and finally dry the solid at 120°C for 4 hours, and then roast it in a ...

Embodiment 3

[0031] (1) Mix the flue gas dust collected from petrochemical enterprises with 50% sulfuric acid solution at a liquid-solid ratio of 2.9:1. After reacting at 100°C for 1 hour, the mixed solution is separated from solid and liquid by a centrifuge. The solid obtained after solid-liquid separation is washed with water to pH = 7, and dried at 120°C to obtain a high-quality carrier material with high specific surface area, large pore volume, and wide pore size distribution range. For physical properties of the carrier material see figure 1 .

[0032] (2) The self-made carrier obtained above is placed in the fully dissolved ammonium metavanadate solution by supersaturated impregnation, and the amount of impregnation is V 2 o 5 Calculated as 4%, put the uniformly stirred sample under an infrared lamp, stir intermittently until the impregnation solution is completely dry, and finally dry the solid at 120°C for 4 hours, and then roast it in a muffle furnace at 600°C for 4 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com