Plastic cooling liquid water pipe and preparation method thereof

A cooling liquid and water pipe technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of complex production process routes, non-recyclable materials, low water vapor barrier rate, etc., to reduce production and operation costs, save flow The effect of simplifying the process, reducing equipment investment and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

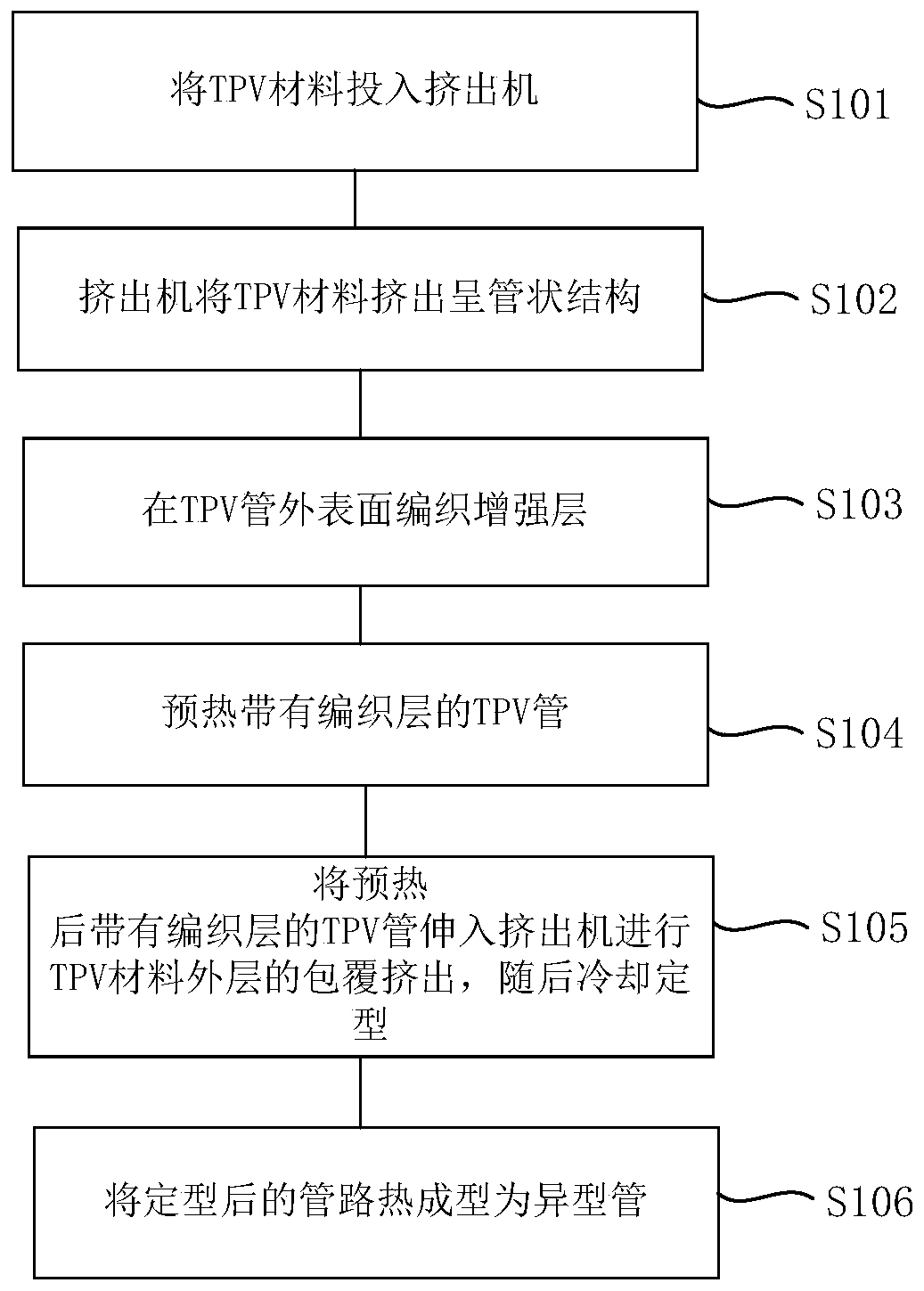

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment one, the first polyolefin pipe is a PP (Polypropylene, polypropylene) pipe, and the second polyolefin pipe is a TPV (Thermoplastic Vulcanizate, thermoplastic vulcanizate) pipe. To the outside are: PP layer, TPV layer. PP material has good coolant resistance and temperature resistance, TPV material not only has the stiffness and excellent processing performance of plastic, but also has the flexibility of rubber material.

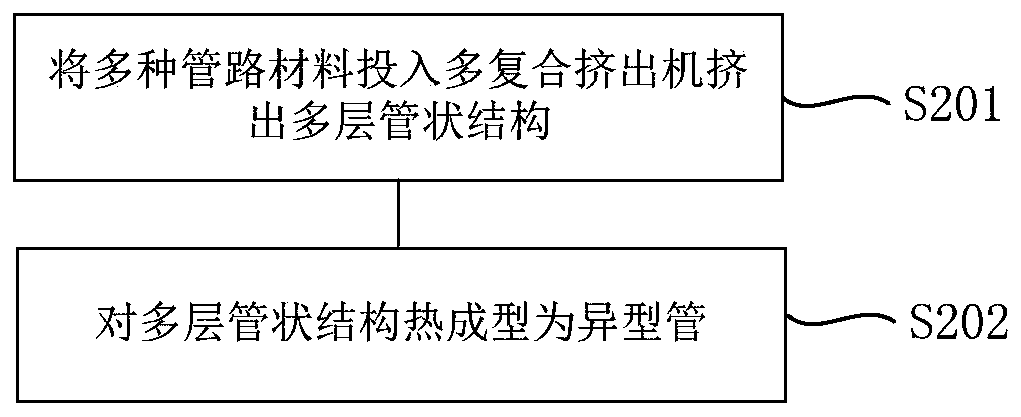

[0038] During processing, PP materials and TPV materials can be added to a multi-compound extruder for extrusion, and a certain extrusion temperature can be controlled to form a double-layer tubular structure.

Embodiment 2

[0040] In the second embodiment, the first polyolefin pipe is a HDPE (High Density Polyethylene, high-density polyethylene) pipe, the second polyolefin pipe is a TPV pipe, and there is an adhesive between the first polyolefin pipe and the second polyolefin pipe. Adhesive layer group, the plastic cooling liquid water pipe in the present embodiment 2 is in order from inside to outside: HDPE layer, adhesive layer, TPV layer. HDPE material has good heat resistance and cold resistance, and also has high rigidity and toughness.

[0041] The adhesive layer group can strengthen the connection strength between HDPE and TPV, and in this embodiment, the adhesive layer group is a layer of plastic material for bonding.

[0042] During processing, HDPE material, binder and TPV material can be added to a multi-compound extruder for extrusion, and a certain extrusion temperature can be controlled to form a multi-layer tubular structure.

Embodiment 3

[0044]In the third embodiment, the first polyolefin pipe is an HDPE pipe, the second polyolefin pipe is a TPV pipe, and there is an adhesive layer group between the first polyolefin pipe and the second polyolefin pipe. The adhesive layer group includes a first adhesive layer and a second adhesive layer, and a barrier layer is also arranged between the first adhesive layer and the second adhesive layer. Adding a barrier layer between the first adhesive layer and the second adhesive layer can make the plastic coolant water pipe have better tensile strength and anti-aging properties.

[0045] Wherein, the barrier layer may be EVOH (Ethylene vinyl alcohol copolymer, ethylene / vinyl alcohol copolymer) tube, PA6 (nylon 6) tube or other barrier material layers. The plastic coolant water pipe in the third embodiment is sequentially arranged from inside to outside: HDPE layer, adhesive layer, EVOH / PA6 layer, adhesive layer, and TPV layer.

[0046] During processing, the HDPE material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst pressure | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com