Patents

Literature

31results about How to "Meet the requirements of the conditions of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

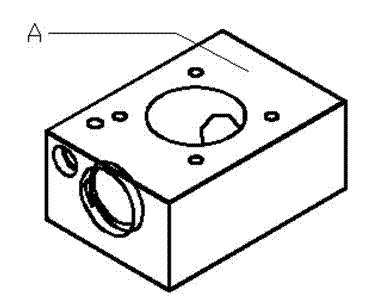

Local anodic oxidation method for surface of workpiece

The invention discloses a local anodic oxidation method for the surface of a workpiece. The method comprises the following steps of: putting the workpiece into a pretreatment solution, and treating the workpiece for 20 to 30 seconds; washing and drying the pretreated workpiece; firmly sticking a polyimide adhesive tape to the oxidation-free surface of the workpiece, and removing bubbles on the adhesive tape and the surface of the workpiece; performing anodic oxidation treatment according to the conventional oxidation flow; and tearing down the adhesive tape on the surface of the oxidized workpiece, and wiping the residual adhesive on the surface of the workpiece by using an organic solvent. The local anodic oxidation method has the advantages of reducing the machining frequency, reducing the machining cost of the workpiece and avoiding the defects of poor repeated positioning precision and low product qualification rate; and the oxidation-free surface of the workpiece is effectively shielded by the polyimide adhesive tape.

Owner:SHANGHAI REAL INDAL

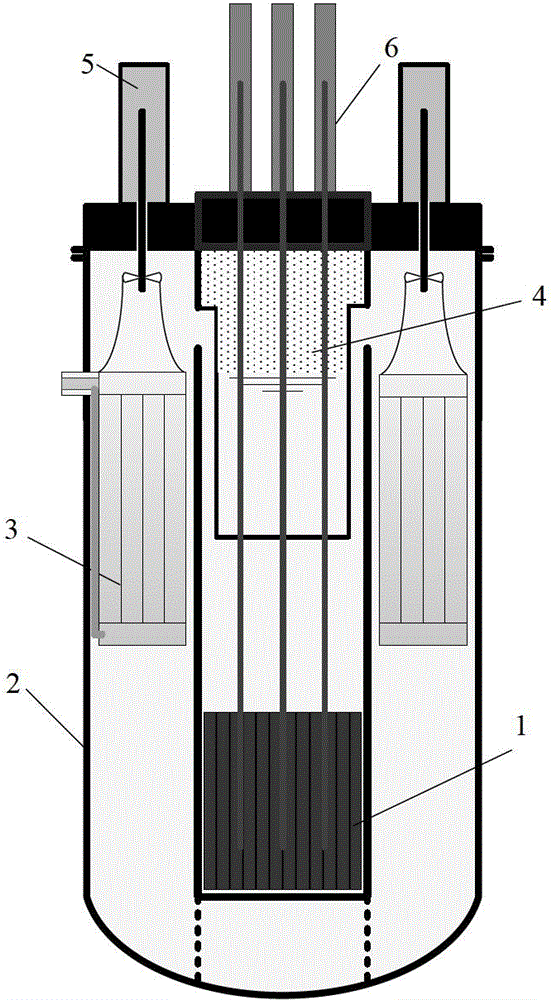

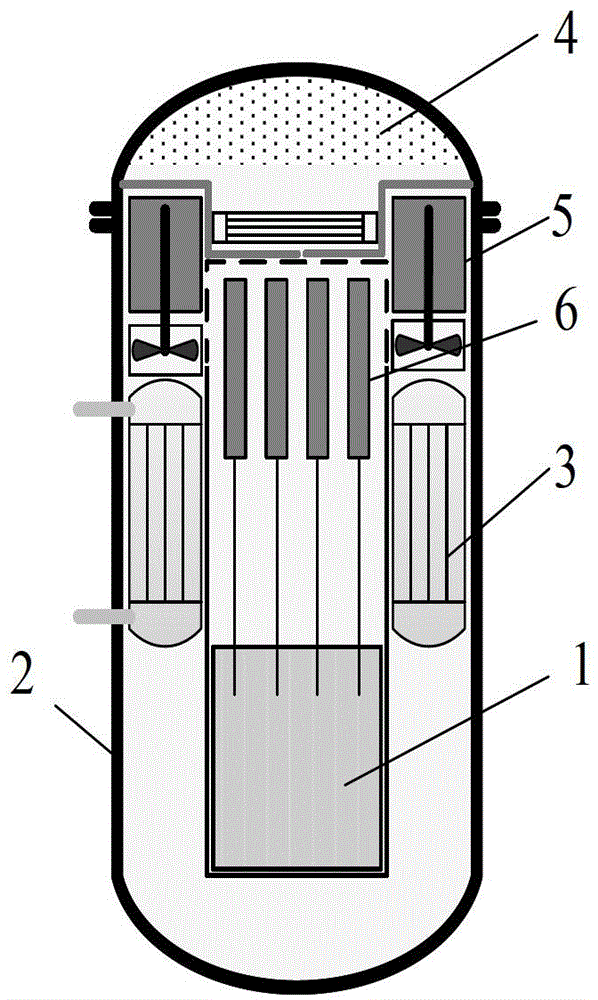

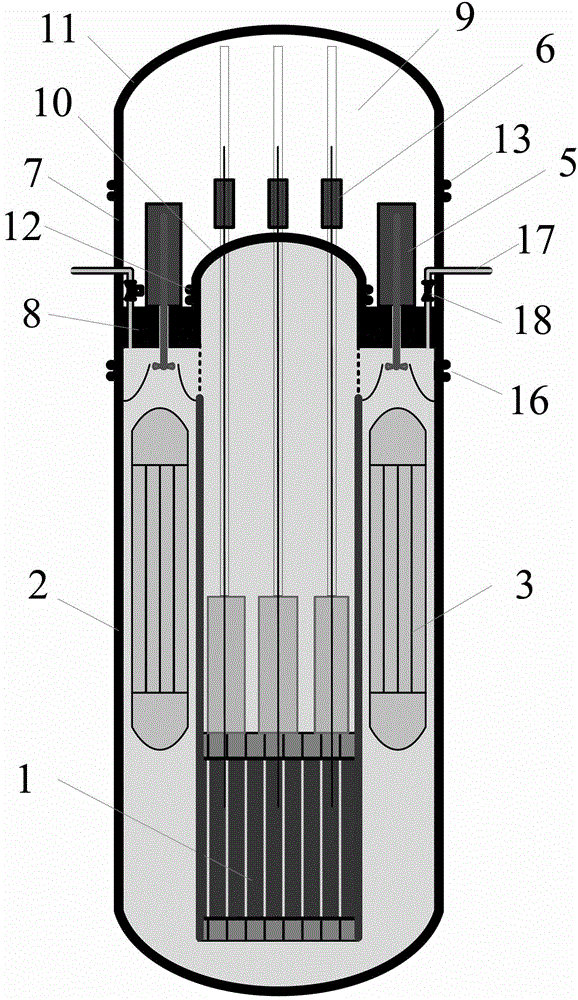

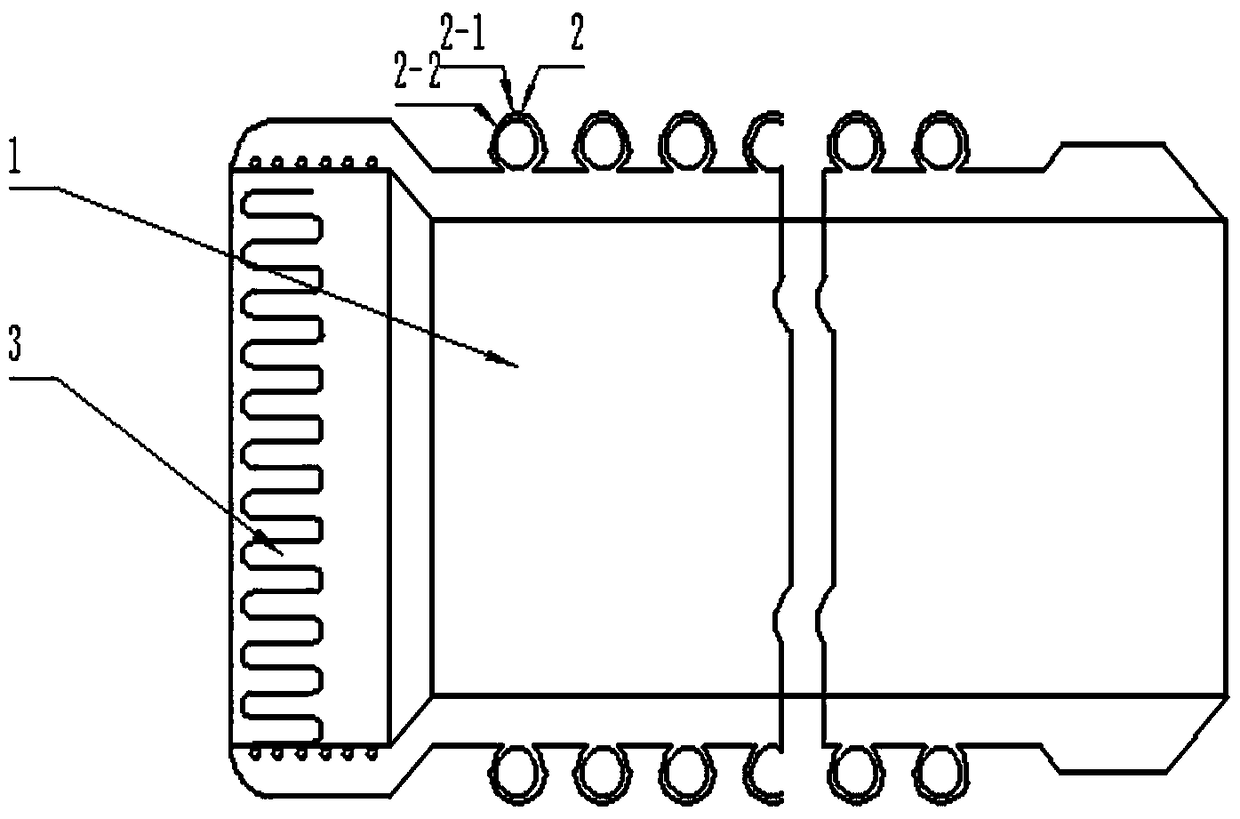

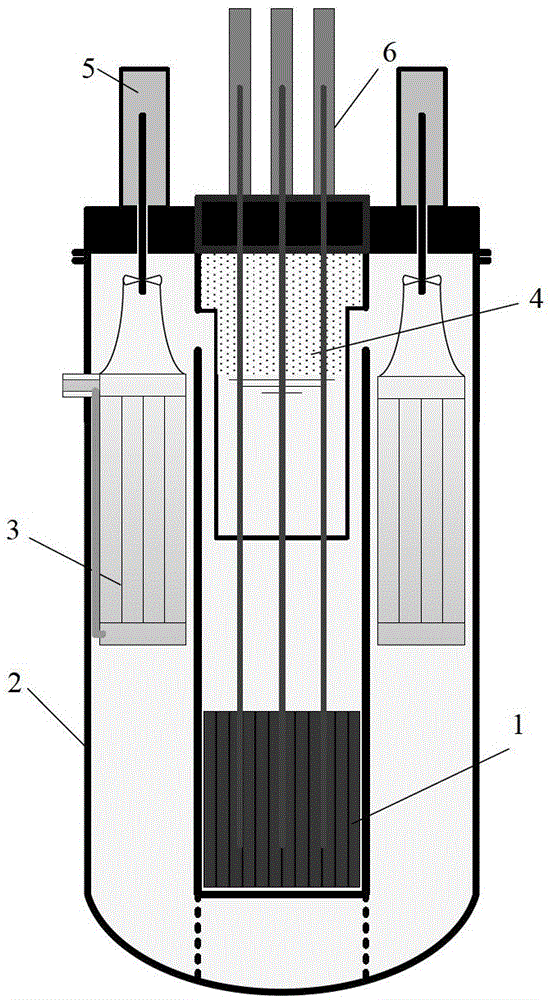

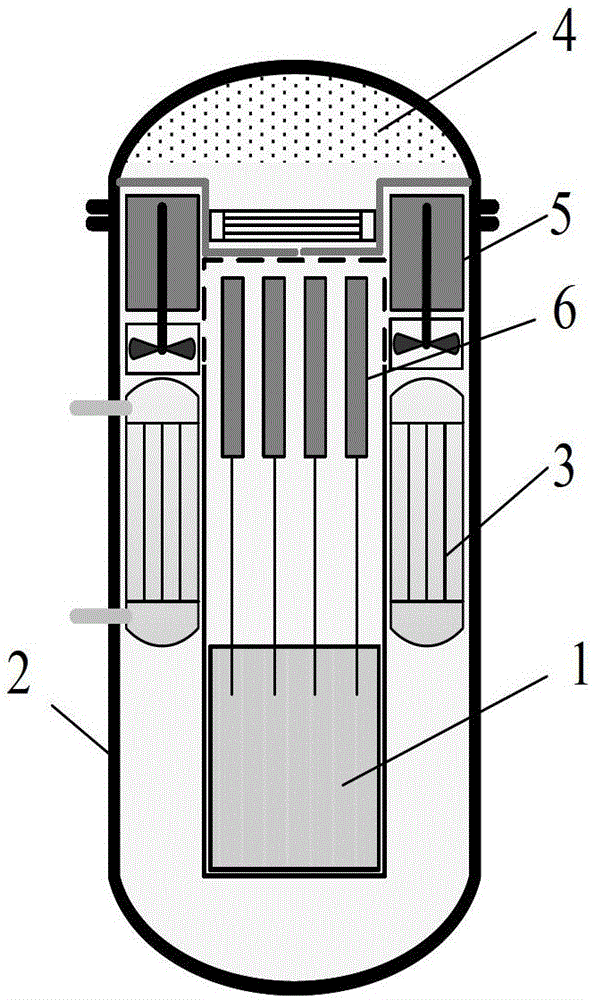

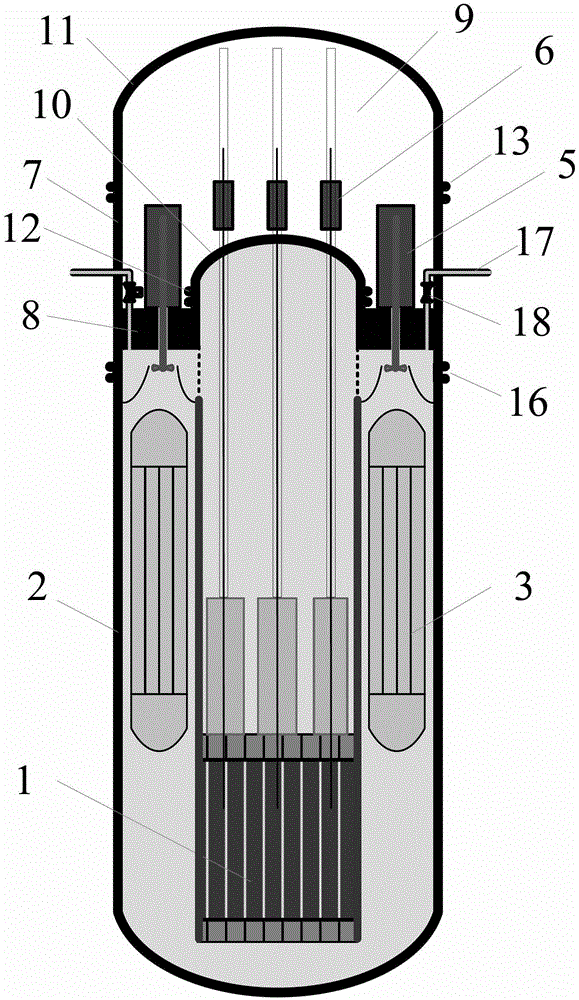

Integral reactor with top double-layer structure

ActiveCN103187108AInhibition releaseAvoid direct immersionIntegral reactorsNuclear energy generationEngineeringPressure vessel

The invention provides an integral reactor with a double-layer structure at the top, which comprises a reactor core arranged in a pressure vessel, a built-in steam generator, a main pump and a control rod drive mechanism. A pressure vessel upper cylinder and a ring-shaped equipment support platform form an integral structure, and an arc-shaped pressure vessel inner top cover is connected to the equipment support platform through a flange of the pressure vessel inner top cover and the equipment support platform; the control rod drive mechanism is arranged on the pressure vessel inner top cover, and the main pump is arranged on the equipment support platform; the reactor core and the built-in steam generator are arranged below the equipment support platform; and a pressure vessel outer top cover is arranged at the top end of the cylinder which is arranged at the upper part of the pressure vessel, and is connected with the pressure vessel upper cylinder through a flange of the pressure vessel outer top cover and the pressure vessel upper cylinder. The invention is a structural design solution to the integral reactor having higher safety and better construction property.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Nonmetallic electrothermal film made from nano composite material

Proportioning (volume percent) of the composite material is as following: solidified agent 1-2%, flame retardant 0.5-2%, insulation material 20-60%, nano graphite powder 36-75%. Nonmetallic electrothermal film is prepared through thermoplastic molding and traditional technical molding. Characters of the composite material are as following: capability of any folding for many times repeatedly, water washable, high electrothermic conversion efficiency, portable and long service life. Electrical specification of the composite material is as following: AC or DC 1.2-380V, power 1W-3kW, heating temperature 20-85 deg.C and 100-250 deg.C. The composite material is applicable to thermal wear, electric carpet, drying apparatus and other heating elements.

Owner:贵州航天天科机电制造有限责任公司

Castable material for aluminum melting furnace

InactiveCN101597168AMeet the requirements of the conditions of useEasy to sinterBreaking strengthCoesite

The invention relates to a castable material for an aluminum melting furnace. The castable material comprises the following components of 70-88 percent of I-level bauxite, 5-15 percent of clay, 3-10 percent of kyanite and 4-8 percent of binding agent, wherein the I-level bauxite with the grain size of 5-3 mm accounts for 35-45 percent, the I-level bauxite with the grain size of 3-1 mm accounts for 20-30 percent, the I-level bauxite with the grain size of 1-0 mm accounts for 15-25 percent, and the I-level bauxite with the grain size lower than 0.09 mm accounts for 15-25 percent. All the physical performance indexes of the refractory castable material inner lining produced according to the grain size and the mixture ratio are as follows: the breaking strength is 15.6MPa, the compression strength is 41.3MPa, the linear change rate is 0.18 percent, the volume density is 2.81 g.cm, and the actual application shows that all the physical performance indexes can fully meet the requirements of service conditions of the inner lining of the aluminum melting furnace, no crack phenomenon occurs, the problem of alumetizing is eliminated, and the service life can reach more than 4 years.

Owner:刘杰

Waterproof gypsum environmental-friendly building block

The invention relates to the technical field of building partition materials, in particular to a waterproof gypsum environmental-friendly building block. The waterproof gypsum environmental-friendly building block is produced through the steps of stirring beta semi-hydrated gypsum, a water reducing agent, an inorganic material and a composite water-proofing agent, adding water and performing casting, wherein the percentage by weight of the raw materials is that the weight of the inorganic material is 9-15% of that of the beta semi-hydrated gypsum, the weight of the water reducing agent is 0.4-0.7% of that of the beta semi-hydrated gypsum, the weight of the composite water-proofing agent is 0.7-1.2% of that of the beta semi-hydrated gypsum, and the weight of the water is 58-70% of that of the beta semi-hydrated gypsum. Compared with the prior art, the environmental-friendly building block disclosed by the invention is produced through the following steps of mixing and stirring the beta semi-hydrated gypsum, the inorganic material, the water reducing agent and the composite water-proofing agent, then adding the water, and performing casting and shaping so that the problems that the coagulation time is too long, productivity is difficult to form, the intensity is low, the cost is high, and efflorescence and mildewing occur, are solved.

Owner:宋国梁

High alumina castable

InactiveCN105461318AMeet the requirements of the conditions of useEasy to sinterCoesiteCompressive strength

The invention relates to a high alumina castable. The high alumina castable comprises 60-85% of high alumina bauxite, 1-10% of clay, 1-10% of flint clay, 10-30% of zircon sand and 3-7% of a binder. The high alumina bauxite comprises 30-40% of bauxite with the granularity of 5-3mm, 25-35% of bauxite with the granularity of 3-1mm, 20-30% of bauxite with the granularity of 1-0mm, and 10-20% of bauxite with the granularity of 0.09mm or below. The physical performance indexes of the above fireproof castable lining produced according to above granularities and proportions are as follows: the bending strength is 15.5MPa, the compressive strength is 40.5MPa, the linear change rate is 0.20%, and the bulk density is 2.75g.cm<-3>. Practical use proves that the physical performances of the high alumina castable completely meets use condition requirements of fused aluminum furnace linings, has no cracks, and eliminates the aluminising problem, and the service life of the high alumina castable can reach 5 years or above.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

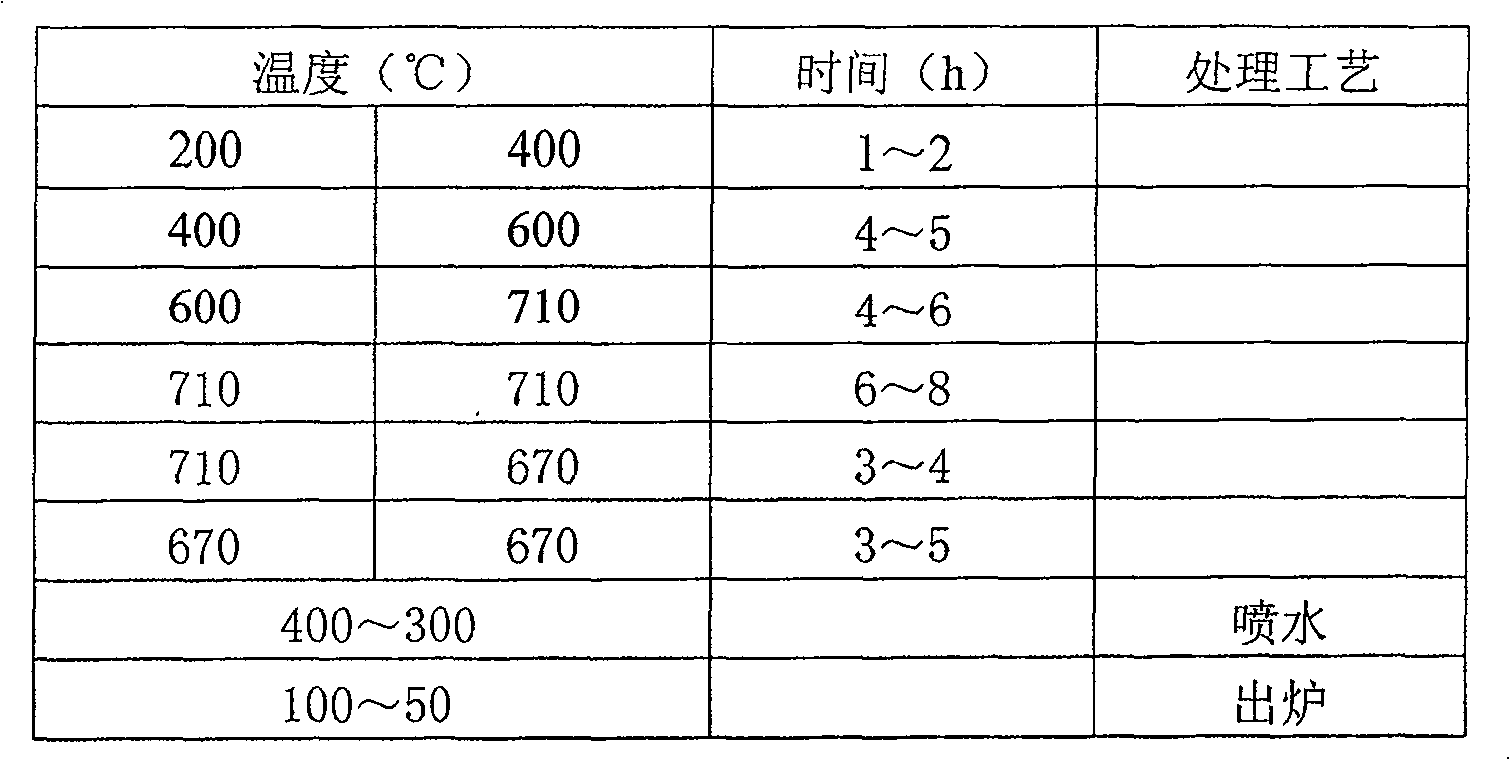

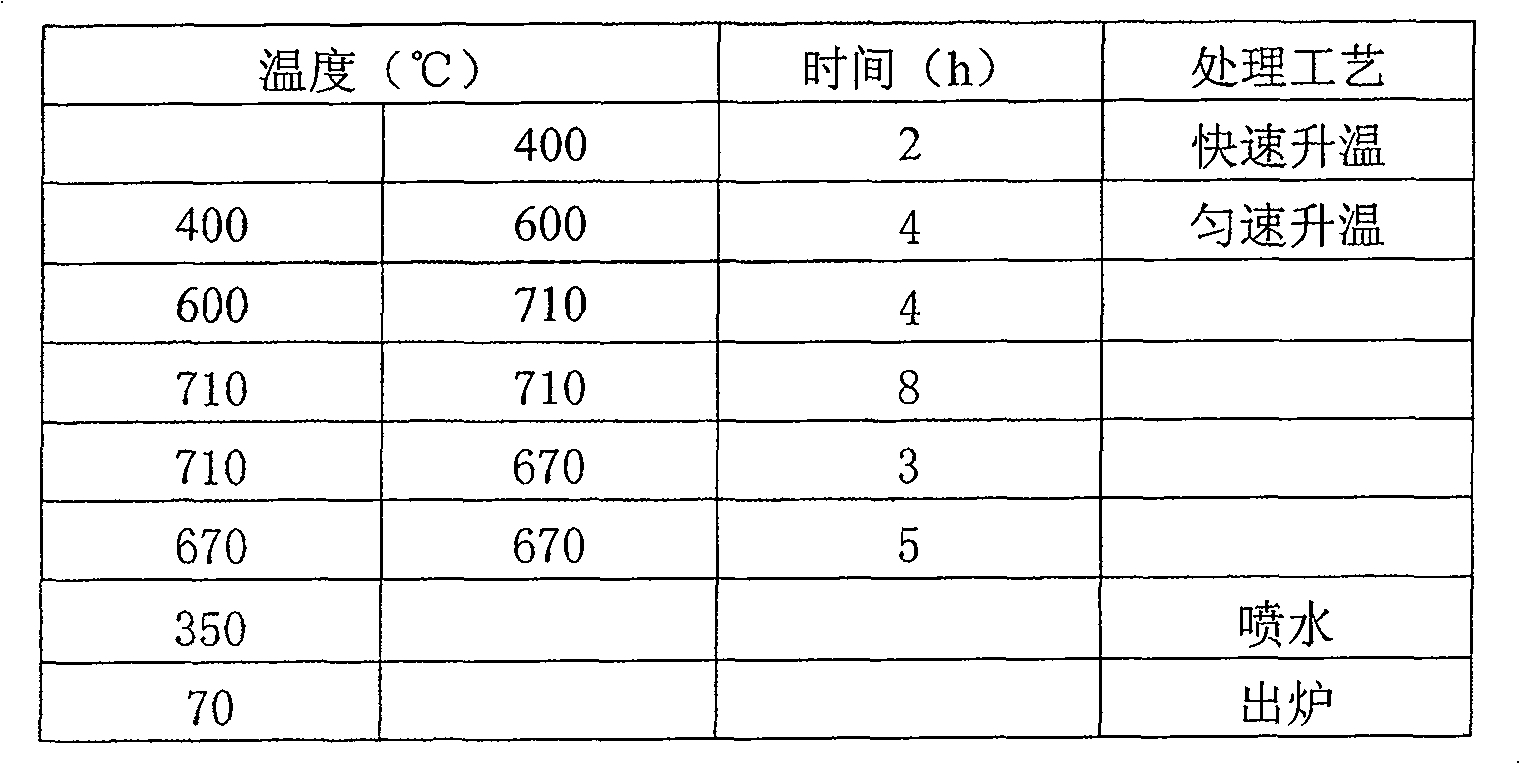

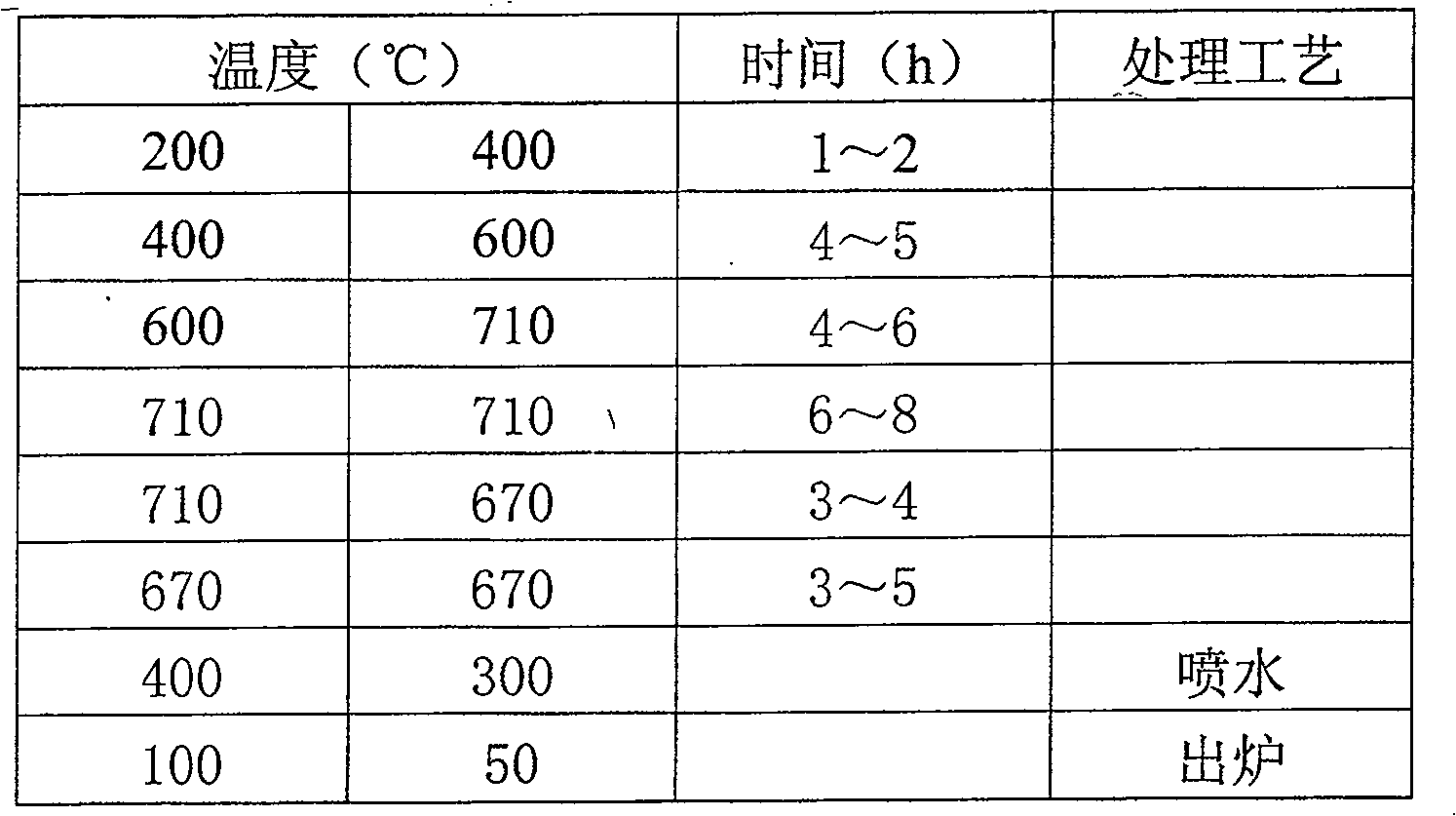

Method for producing cold rolling domestic appliance plate using cover type oven

InactiveCN100529140CMeet the requirements of the conditions of useFurnace typesHeat treatment furnacesProcess systemsChemical composition

The invention relates to a method for producing cold-rolled home appliance panels with a bell furnace, mainly through controlling the chemical composition of steel and adjusting the annealing process system of the bell furnace to produce home appliance panels with high yield ratio and high elongation. The mass percentage of its chemical composition is: C0.03~0.15, Si≤0.034, Mn0.17~0.65, P≤0.025, S≤0.02, Als0.02~0.055, N≤0.006, Nb≤0.03. The annealing process system is: temperature 200-400°C, time 1-2h; 400-600°C, 4-5h; 600-710°C, 4-6h; 710°C, 6-8h; 710-670°C, 3-4h ; Keep warm at 670°C for 3-5 hours; spray water at 400-300°C; bake at 100-50°C. The performance index of the cold-rolled home appliance plate produced by the above method reaches: yield strength 304MPa; tensile strength 379MPa; elongation 30%; hardness HRB63. And the income per ton can be increased by more than 100 yuan.

Owner:ANGANG STEEL CO LTD

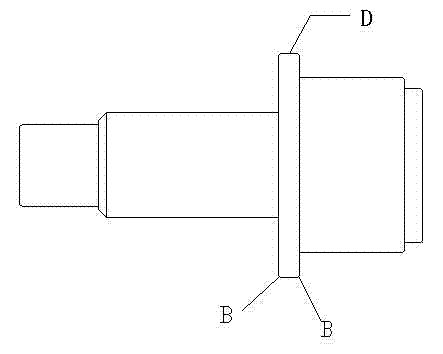

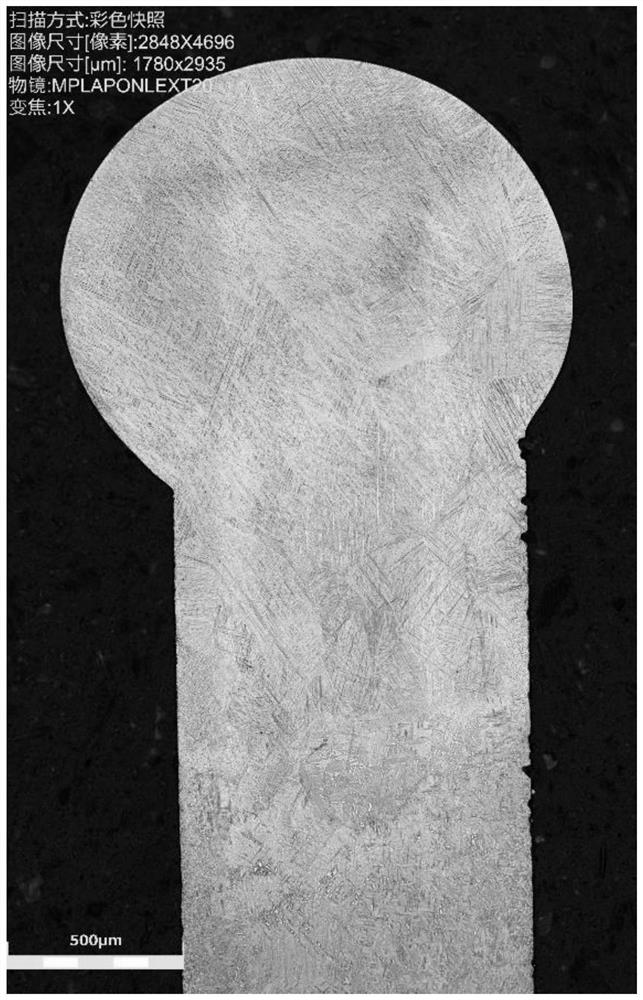

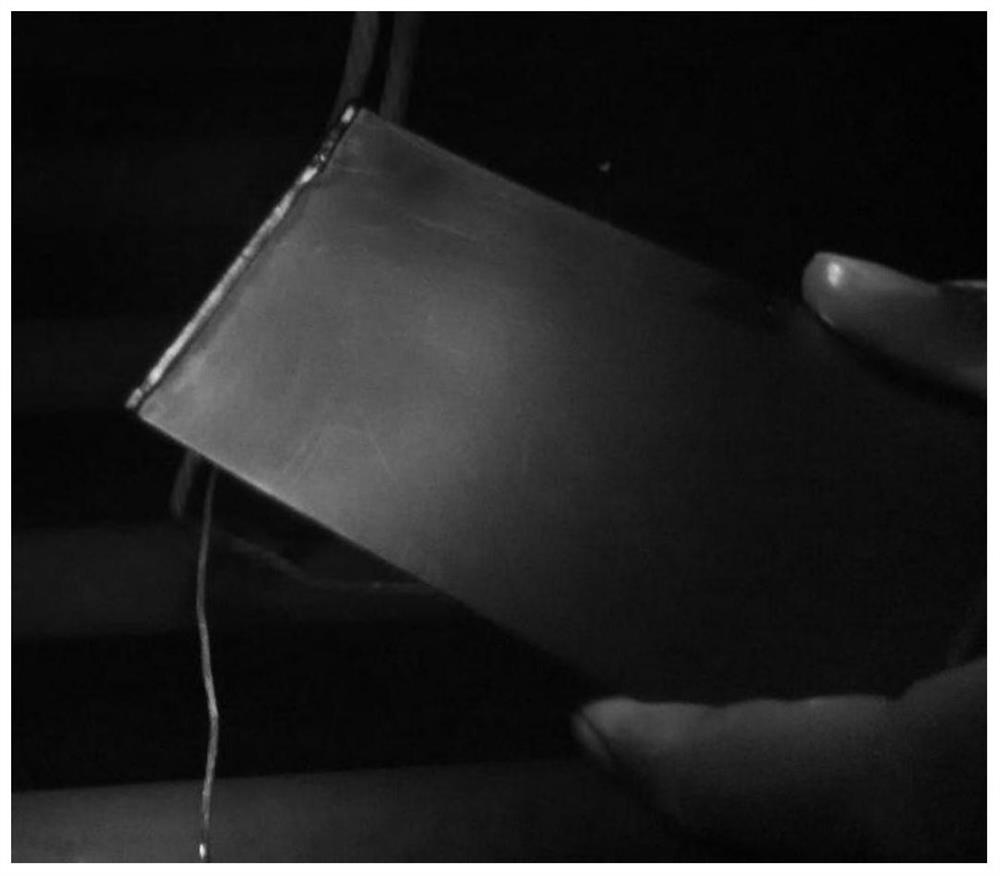

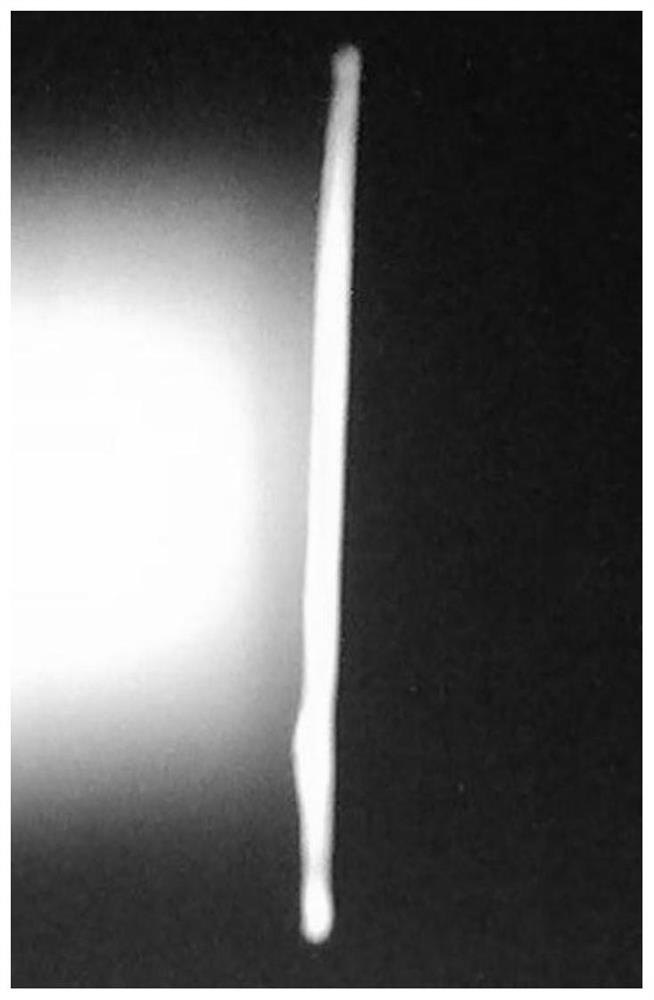

Titanium alloy compressor blade welding repair method

ActiveCN112453824ARealize conformal clampingIncrease cooling intensityProcess efficiency improvementEngineeringTitanium alloy

The invention relates to a titanium alloy compressor blade welding repair method, which comprises the following steps of 1) machining before welding; 2) conducting blade inspection; 3) clamping a blade; (4) planning a welding process: determining the number of welding beads for welding repair according to the missing size of a blade profile, planning a welding repair track according to the outlinesize and the shape of the to-be-welded repair surface of the blade, and requiring the welding track to move along the center line of the welding repair surface, wherein all welding parameters are inlinear transition, so that the welding quality and the forming precision of a transition section are improved; 5) removing welding thermal stress by adopting heat treatment; 6) machining by a weldingmachine; 7) conducting welding defect detection. According to the titanium alloy compressor blade welding repair method provided by the invention, a visual system is adopted for planning the welding track; micro-beam pulse plasma arcs are adopted as heat source input, and welding wires are filled in cooperation with a pulse wire feeding mode, so that heat input in the welding process is reduced; and a flexible clamping tool is adopted to achieve conformal clamping of the blade, so that the cooling strength of a welding repair part is improved.

Owner:杨媛媛

HDPE winding structure wall B type pipe with lining as fireproof layer and manufacturing process thereof

InactiveCN108591630ALow costExpand the scope of useRigid pipesPipe connection arrangementsHigh-density polyethyleneEngineering

The invention provides a HDPE winding structure wall B type pipe with a lining as a fireproof layer and a manufacturing process thereof, and solves the problem of possible generation of fire due to exposure of pipes in an environment capable of contacting with open fire due to change of use environments. An inner layer is designed as the fireproof layer, but a whole pipe body is not designed as afireproof pipe, so that the requirements of use conditions can be met, no waste can be achieved, and the low cost is guaranteed. The application range of high-density polyethylene drainage pipes is widened, so that the effects of simple construction and cost reduction are indirectly achieved, and wide popularization and application value is achieved.

Owner:HEBEI TONGTAO PIPE CO LTD

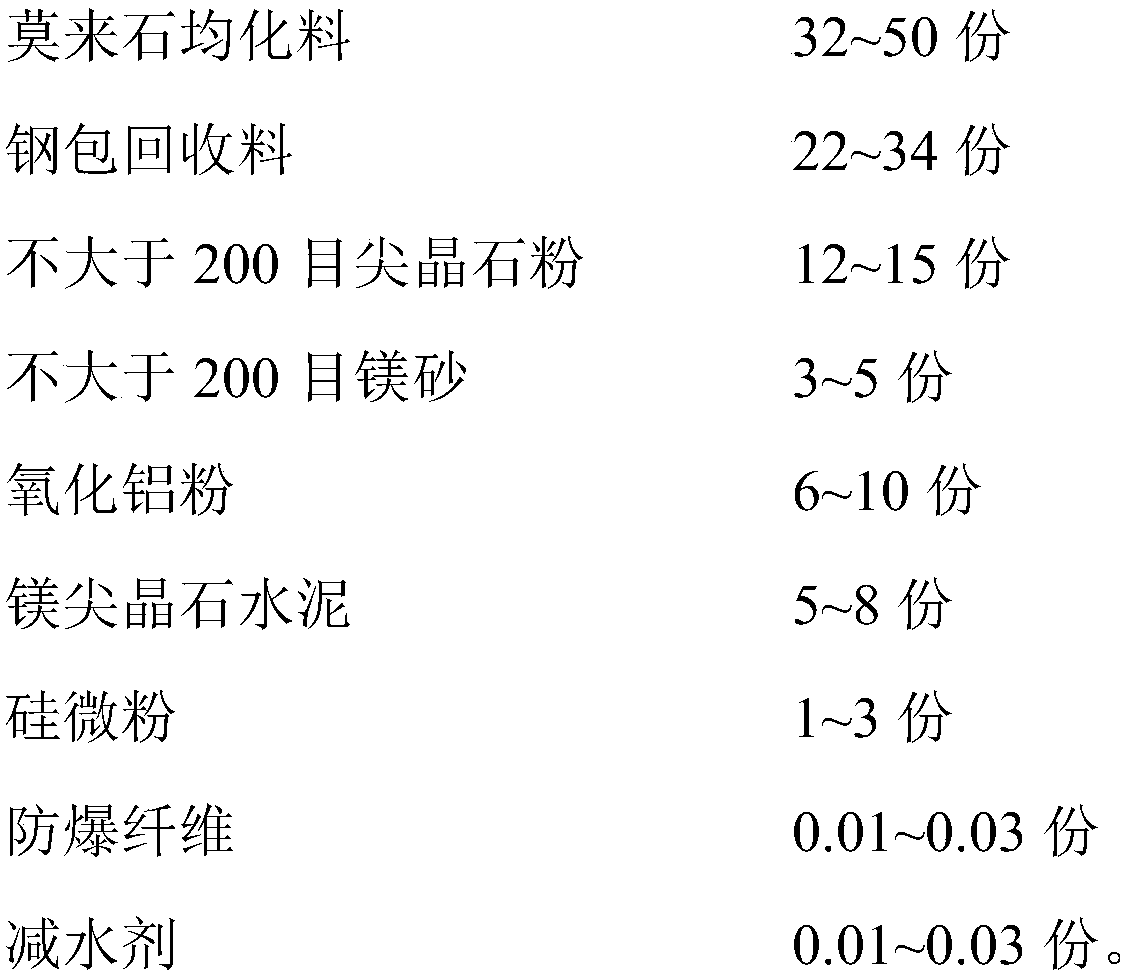

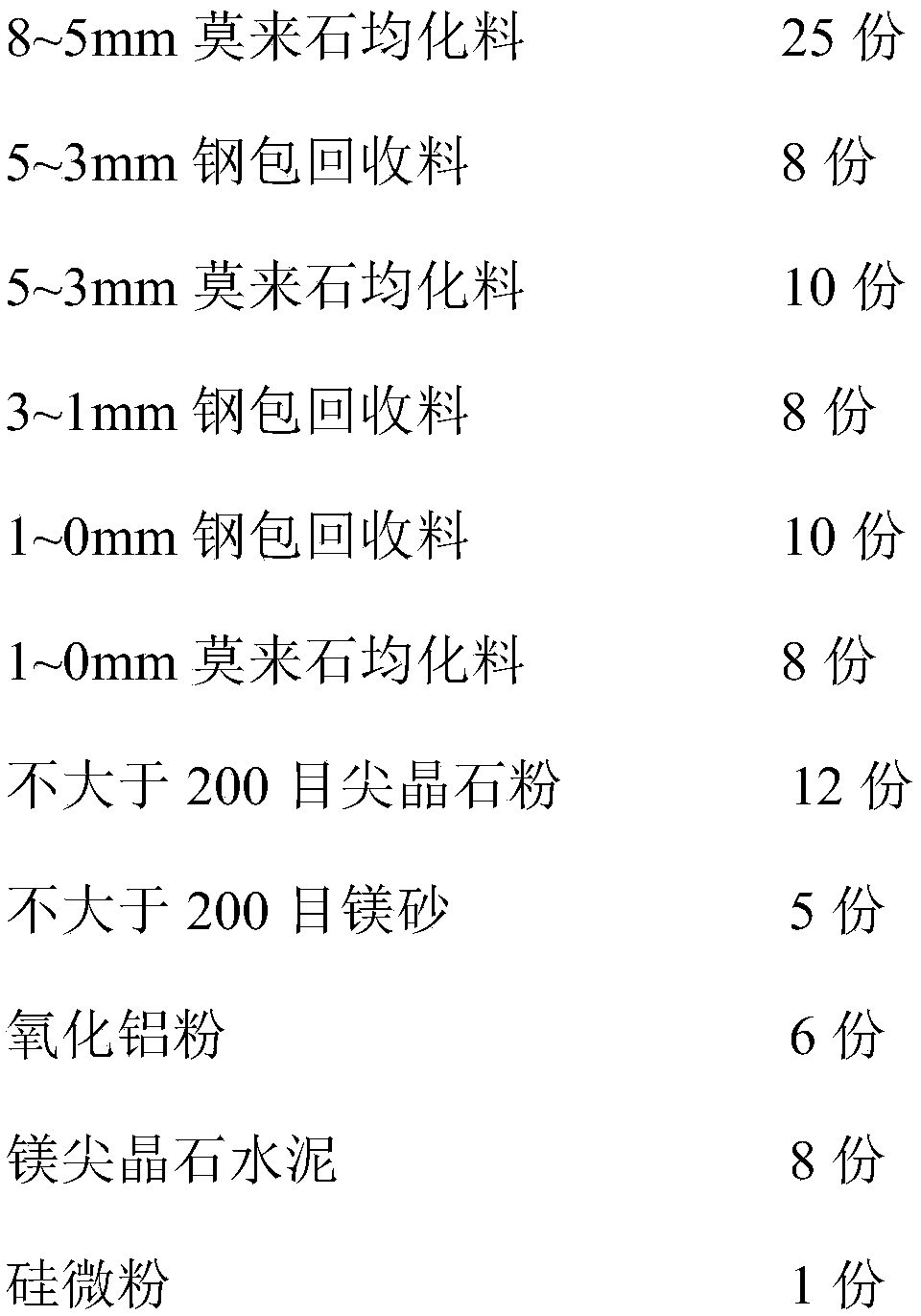

Special castable for kiln mouth

The invention relates to a special castable for a kiln mouth. The special castable comprises the following components by weight: 18-25 parts of 8-5mm mullite homogenate, 8-12 parts of 5-3mm ladle reclaimed material, 6-10 parts of 5-3mm mullite homogenate, 8-12 parts of 3-1mm ladle reclaimed material, 6-10 parts of 1-0mm ladle reclaimed material, 8-15 parts of 1-0mm mullite homogenate, 2-15 parts of spinel powder no more than 200 meshes; 3-5 parts of magnesia no more than 200 meshes, 6-10 parts of alumina powder, 5-8 parts of magnesia spinel cement, 1-3 parts of silicon micropowder, 0.01-0.03 part of explosion-proof fiber and 0.01-0.03 part of water reducing agent. The special castable adopts the ladle reclaimed materials, has low raw material cost, strong resistance to gas pickling of K2O,Na2O and other alkaline gas, strong wear resistance and thermal shock resistance stability, and satisfies the requirements of operation conditions of the kiln mouth use condition. The service life ismore than one year.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

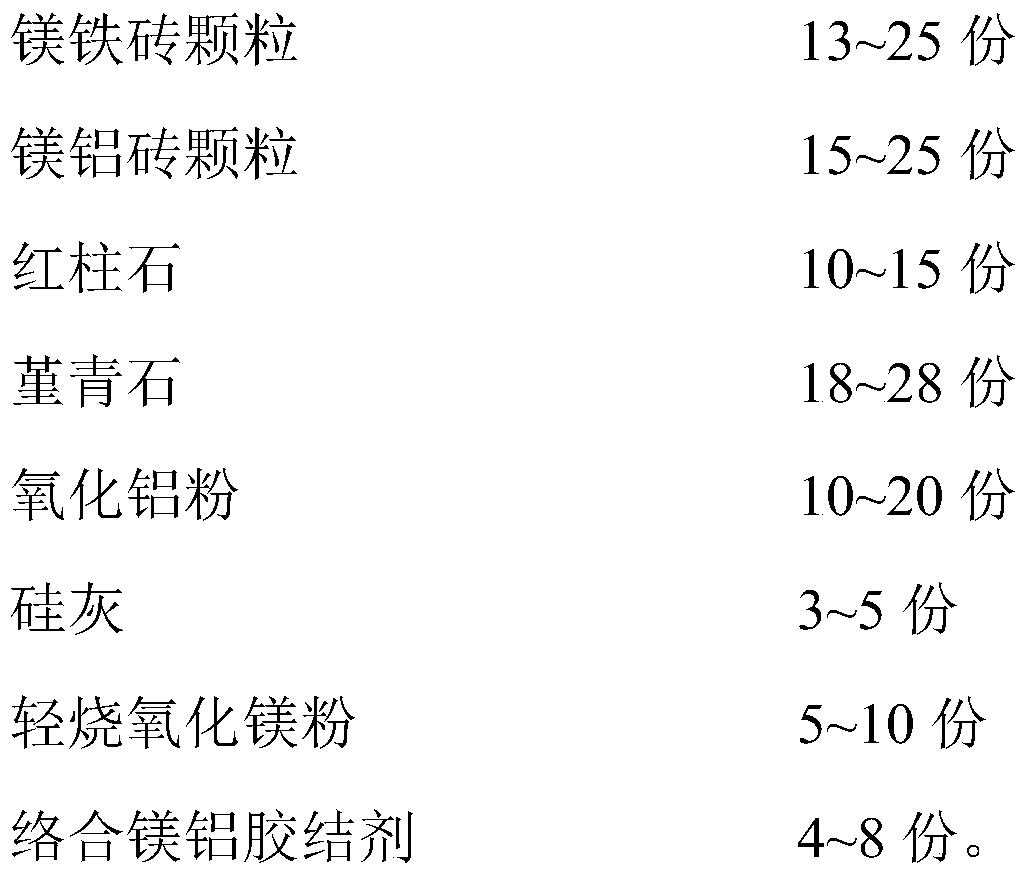

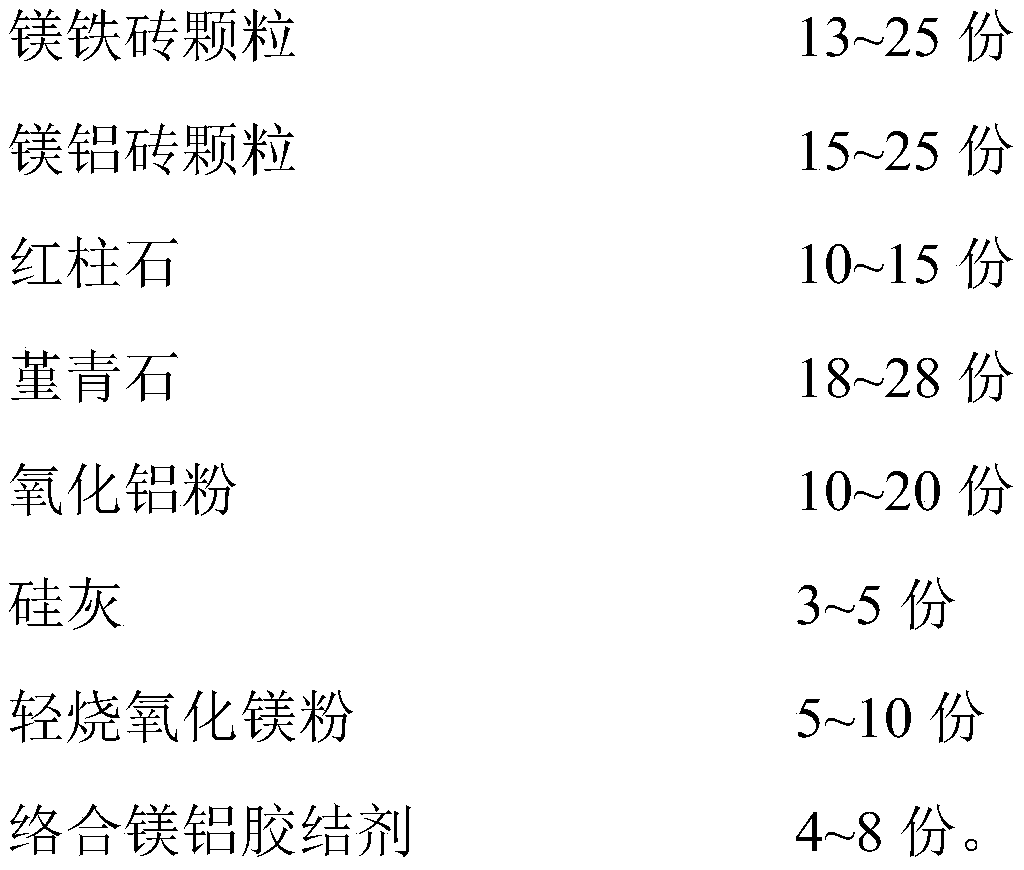

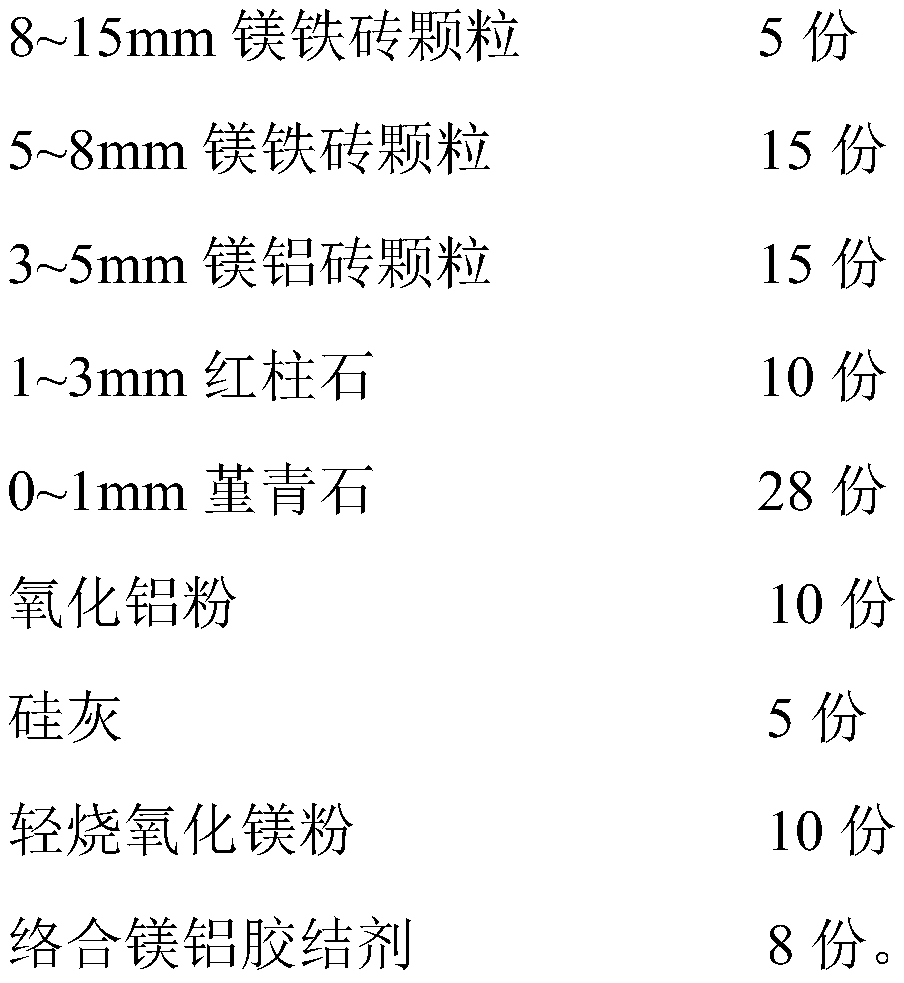

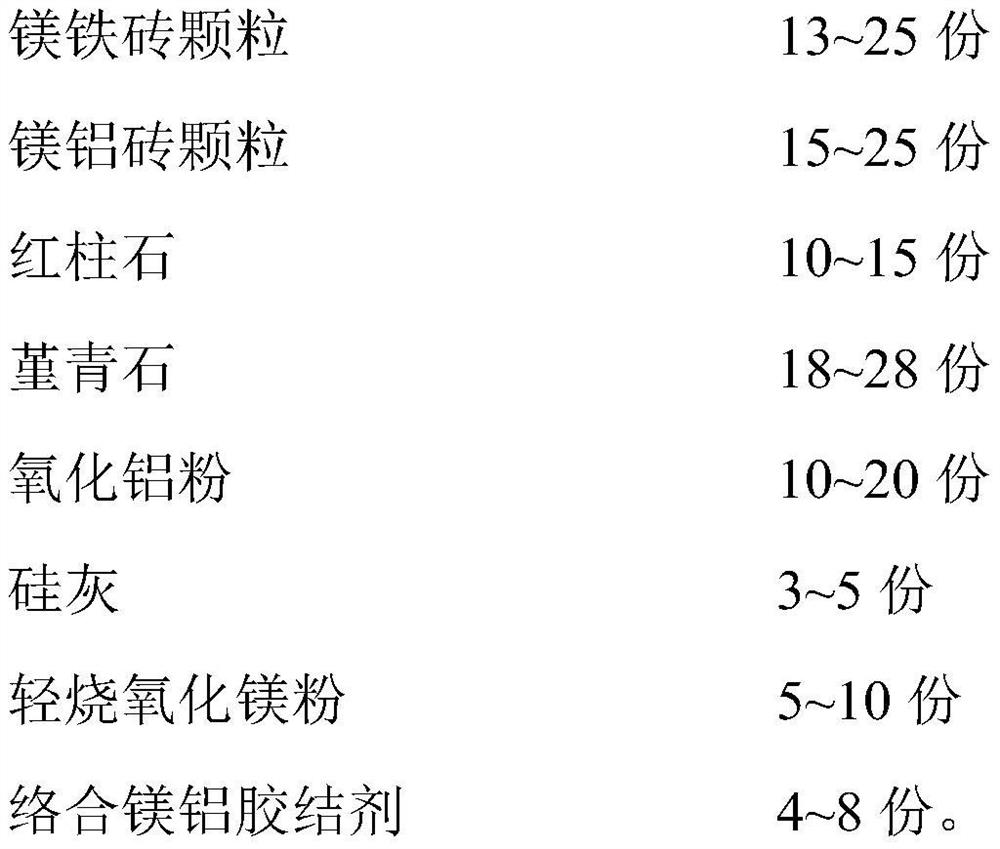

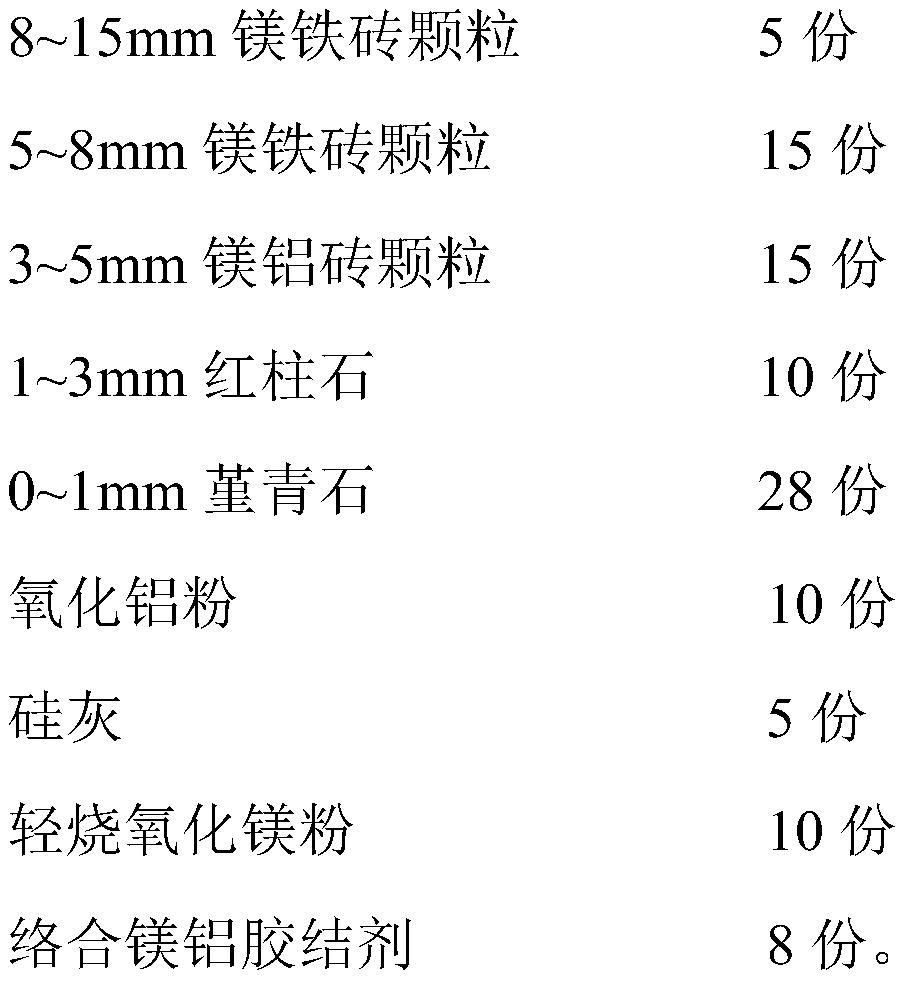

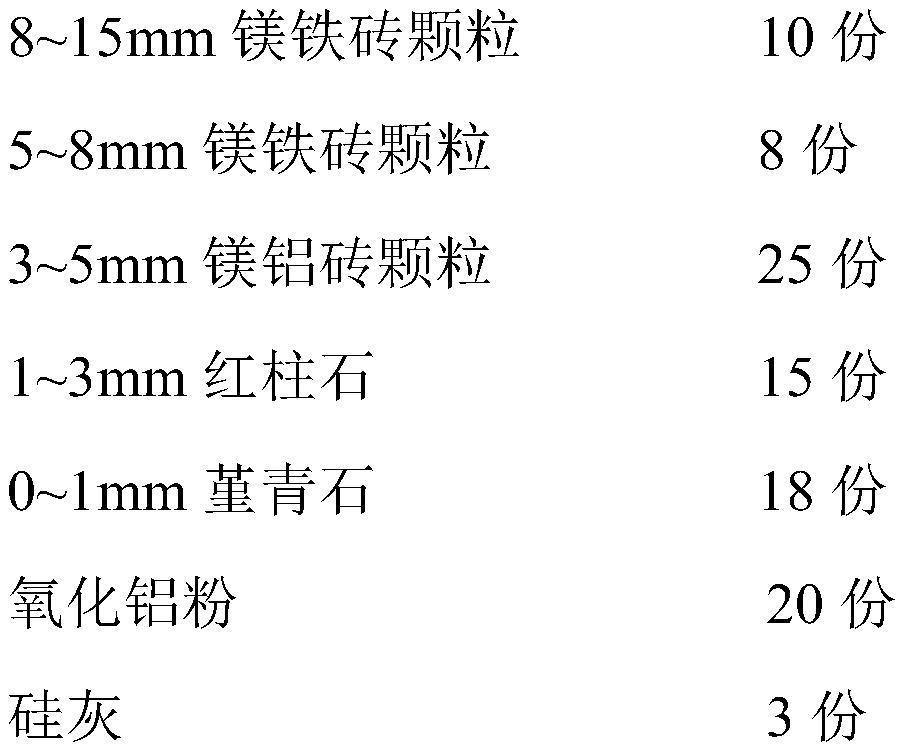

High-thermal shock resistance composite kiln mouth castable

The invention relates to a high-thermal shock resistance composite kiln mouth castable comprising, by weight, 13-25 parts of magnesium-iron brick granules, 15-25 parts of magnesium-aluminum brick granules, 10-15 parts of andalusite, 18-28 parts of cordierite, 10-20 parts of alumina powder, 3-5 parts of silica fume, 5-10 parts of light calcined magnesia powder, 4-8 parts of a complexing magnesium-aluminum adhesive. By means of the formula, the product has great thermal shock resistance, high mechanical strength and great chemical corrosion resistance, is low in porosity and is long in service life.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Crop straw medium density fiberboard using natural rubber and manufacturing method thereof

InactiveCN101367227BIncrease profitInhibition releaseFlat articlesDomestic articlesFiberStearic acid

The crop straw medium density fiberboard using natural rubber, the raw materials include crop straw fiber, adhesive, waterproof and lubricant, flame retardant, and the adhesive is natural rubber, including vegetable glue and animal glue. Water repellants and lubricants are natural waxes, stearic acid or stearate salts. Flame retardants are non-toxic and harmless flame retardants. The proportion of various raw materials by weight is: crop straw fiber 75% to 93%, binder 1% to 8% (dry), waterproof and lubricant 0.5% to 8%, flame retardant 5.5% to 23.5% . Various raw materials are mixed, sizing, paving, pre-pressing, hot-pressing, and trimming to make finished products, and microwaves are used for auxiliary heating in the hot-pressing stage. The crop straw medium density fiberboard made of natural rubber of the present invention can be completely degraded under natural conditions after being discarded and damaged, and will not cause any irreversible damage to the environment, so that the production and use of crop straw medium density fiberboard can be realized. Complete sustainability and recyclability, with significant practical and historical significance.

Owner:张东旭

Method for producing cold rolling domestic appliance plate using cover type oven

InactiveCN101008067AMeet the requirements of the conditions of useOvercoming the difficulty of producing home appliance boards with a yield ratio up to the standardFurnace typesHeat treatment furnacesChemical compositionMetallurgy

Owner:ANGANG STEEL CO LTD

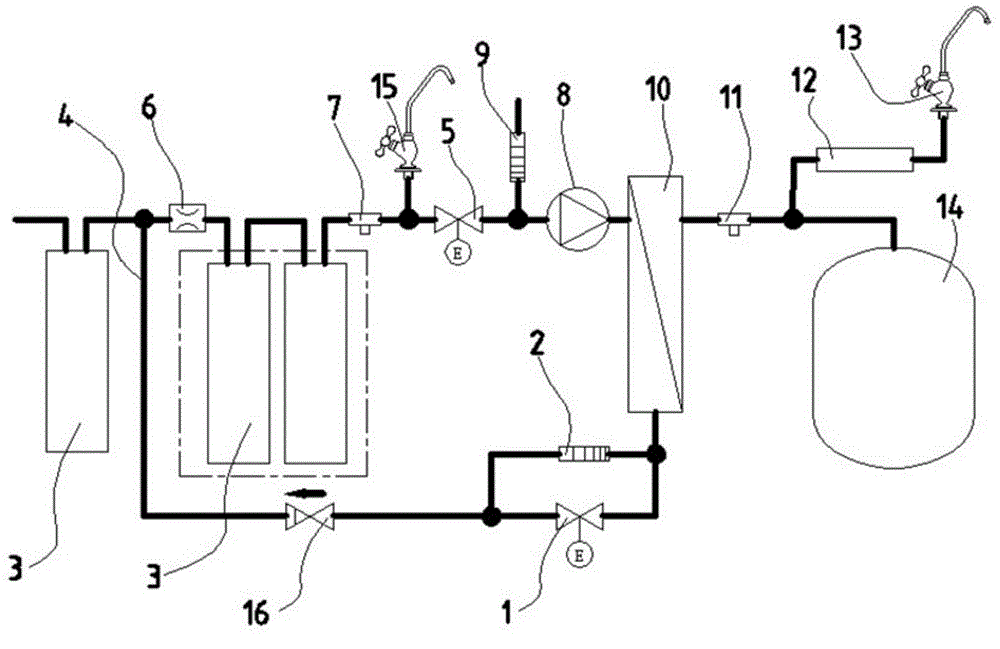

Photocatalysis wastewater degradation reactor capacity expanding method capable of incidentally preventing lamp region from causing water burst

ActiveCN103319034AMeet the requirements of the conditions of useGood maintenance effectMultistage water/sewage treatmentStreamflowNormal state

The invention relates to a photocatalysis wastewater degradation reactor capacity expanding method capable of incidentally preventing lamp region from causing water burst, belonging to the technical field of wastewater treatment. Existing relevant technologies has the problem of the water burst of an electrodeless lamp installing cavity, namely, a quartz tube cavity, and also has the problems of microwave energy waste, slightly small single-tank wastewater treatment capacity, catalyst agent loss, difficulty in distinguishing degradation reaction endpoints, incapability of immediately finding catalytic agent agglomeration, corrosion of secondary ozone reverse channeling to a magnetron, and the like. Aiming at the series problems, the capacity expanding method mainly comprises the steps of: connecting a miniature diaphragm pump used for replenishing air at a normal state and with low power consumption and low flow to an air channel leading into the quartz tube cavity in a bypass manner; restraining a microwave irradiation airspace by using a metal cage so as to conveniently largely expand the capacity of a reactor; intercepting a catalytic agent by stages by using a multi-stage filter; sensing a degradation endpoint by using an ozone sensor, and automatically switching off a power supply at the degradation endpoint; self-detecting the agglomeration trend of the catalytic agent; separating a waveguide tube by using a wave-transparent airtight partitioning plate, and blocking a secondary ozone reverse channeling channel.

Owner:诺特达新材料科技(上海)有限公司

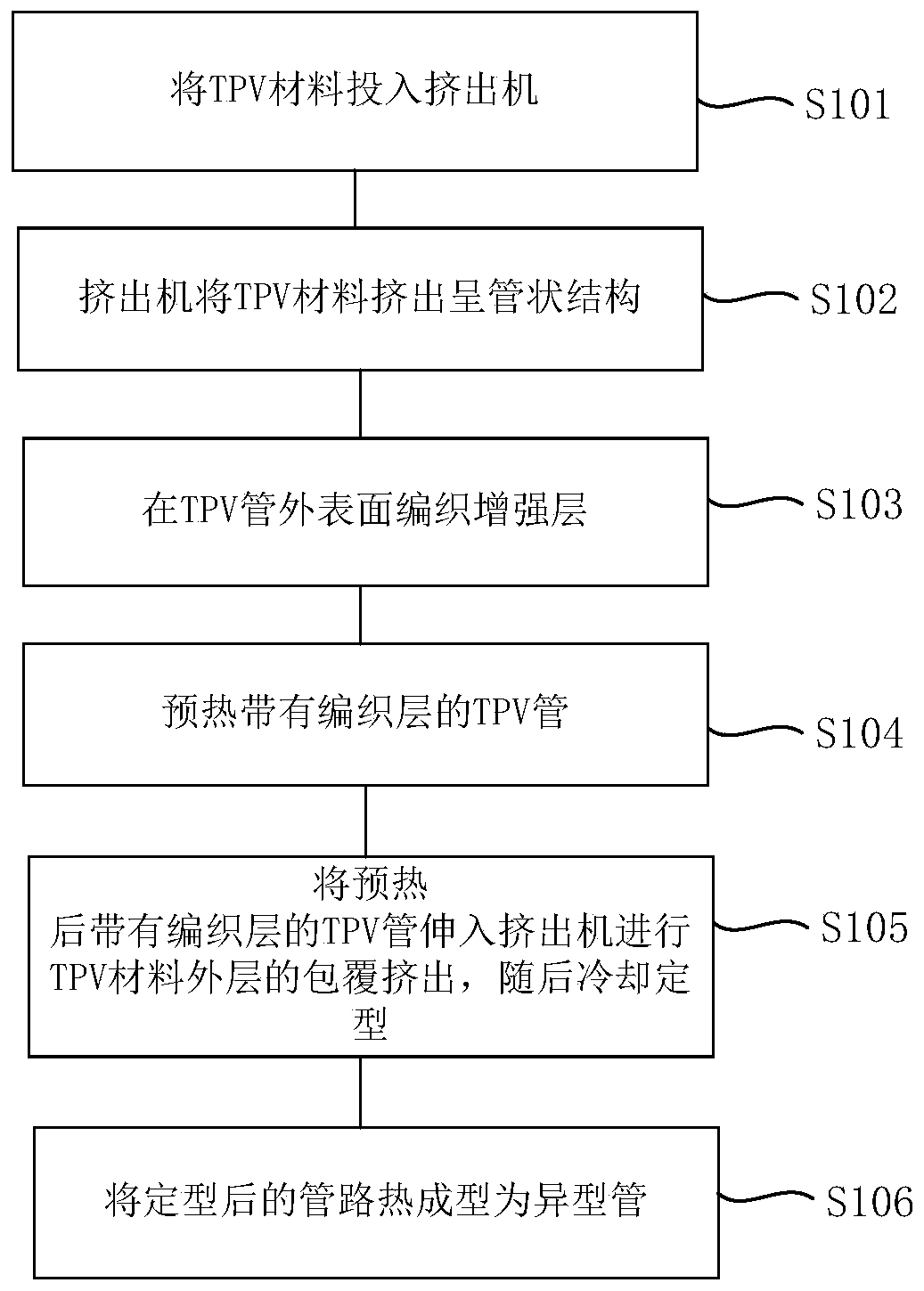

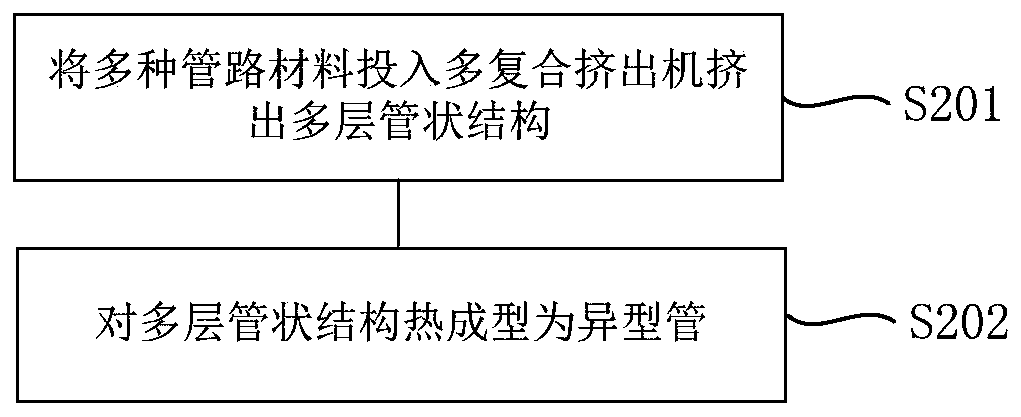

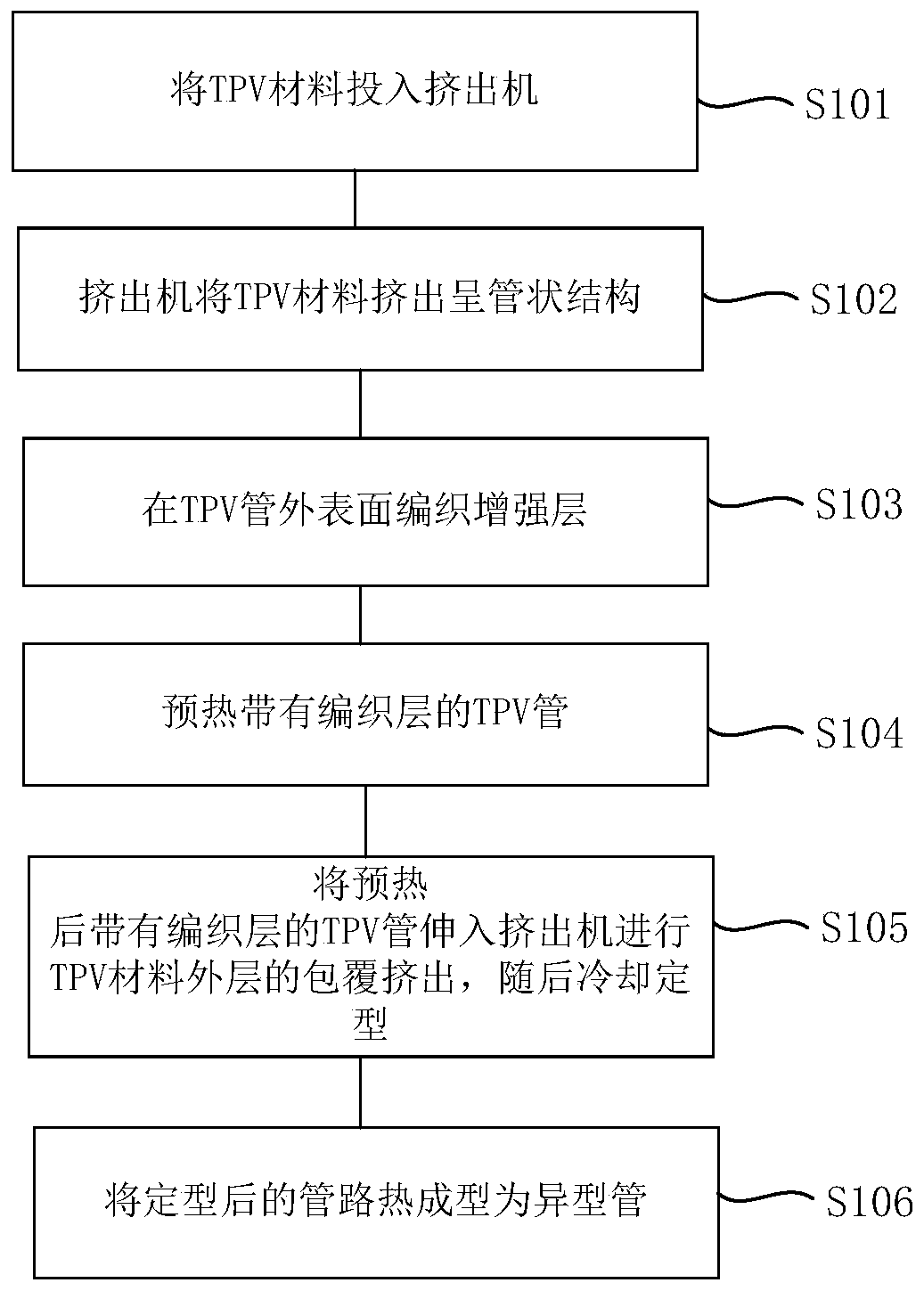

Plastic cooling liquid water pipe and preparation method thereof

The invention provides a plastic cooling liquid water pipe and a preparation method thereof, relating to the technical field of cooling pipes. The plastic cooling liquid water pipe comprises a first polyolefin pipe and a second polyolefin pipe, wherein the first polyolefin pipe is coated with the second polyolefin pipe, and when the first polyolefin pipe and the second polyolefin pipe are made ofthe same material, a reinforcing layer is further arranged between the first polyolefin pipe and the second polyolefin pipe. The plastic cooling liquid water pipe provided by the invention can be recycled, is light in weight, low in cost and low in permeability, and more conforms to the development trend of a safe, environment-friendly and weight-reducing whole vehicle.

Owner:TIANJIN PENGYI GRP CO LTD

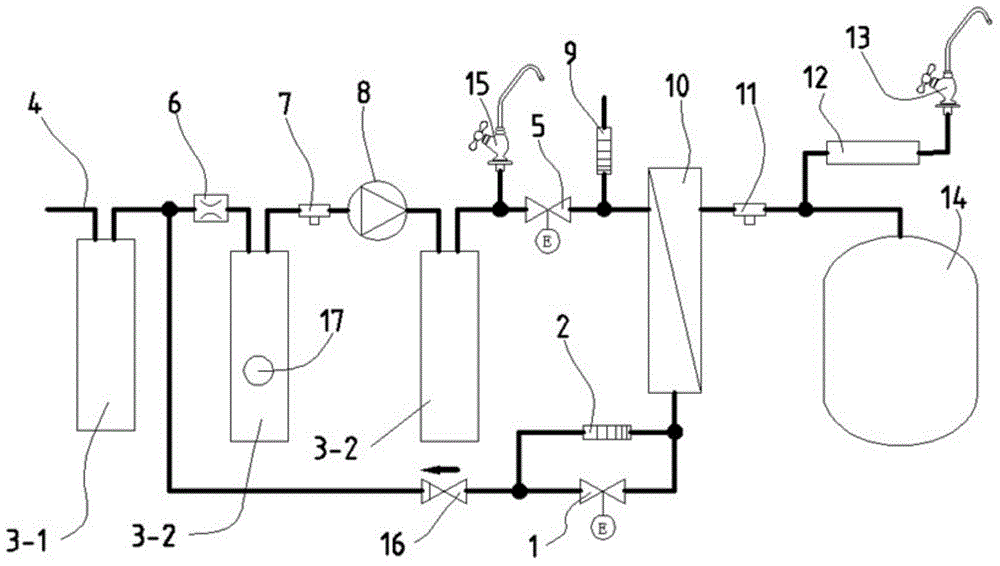

Photocatalytic Wastewater Degradation Reactor Capacity Expansion Method for Self-inspection of UV Radiator State

ActiveCN103435200BMeet the requirements of the conditions of useGood maintenance effectMultistage water/sewage treatmentMicrowaveUltraviolet lights

The invention relates to a capacity expanding method for a photocatalysis waste-water degrading reactor capable of realizing UV radiator state self-inspection, and belongs to the technical field of waste water processing. In present correlated background technologies, there are the problems that: the function state of an electrodeless lamp is difficult to know timely; an electrodeless lamp placing chamber, that is a quartz tube chamber, has a water bursting problem; microwave energy is wasted; single pot waste-water processing capacity is smaller; catalysts loss; degradation terminal point is difficult to determine; secondary ozone flows crossly and corrodes magnetrons; and the like. The capacity expanding method aims at the problems. The capacity expanding method comprises the main steps: introducing one end of an optical fiber to the periphery of a quartz tube, making the tip of the optical fiber direct to inner cavity of the quartz tube, and making the other end of the optical fiber press close to and direct to the detection window of a ultraviolet light intensity detector. The capacity expanding method also comprises other multiple steps. The capacity expanding method of the invention helps to realize package solution on the series of the problems.

Owner:重庆尧群环保科技有限公司

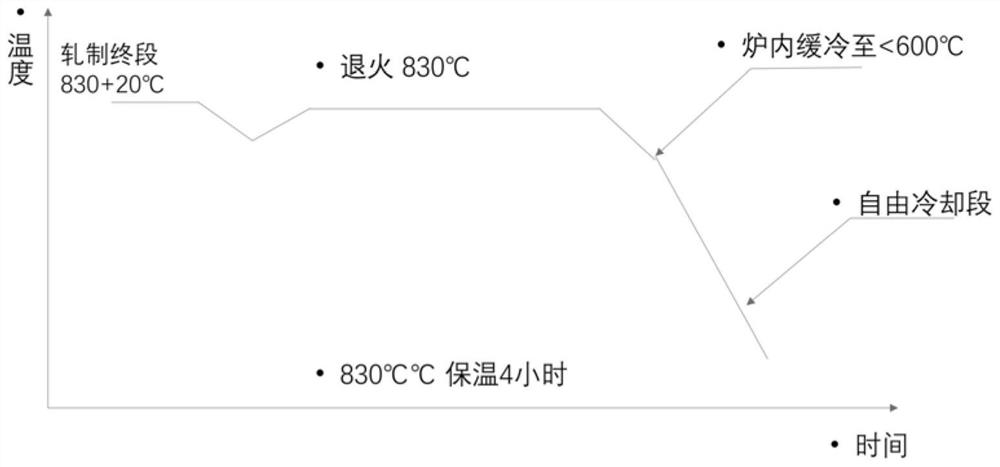

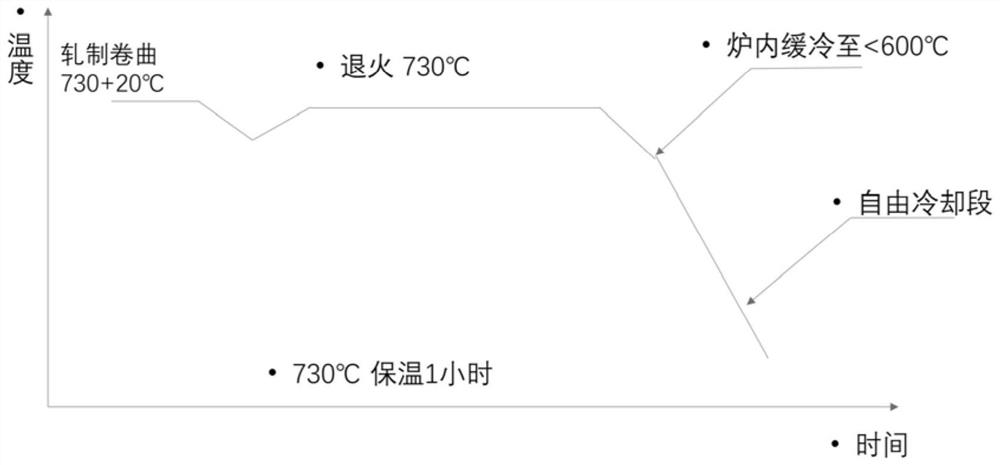

One-fire hot charging heat treatment process of ferrite stainless steel hot-rolled hot-rolled plate

ActiveCN114214485AHas qualityEnergy savingFurnace typesHeat treatment process controlHeat energyHeat treating

The invention discloses a one-fire hot charging heat treatment process for a ferrite stainless steel hot-rolled hot-rolled plate, and belongs to the technical field of stainless steel production. According to the heat treatment process, after hot rolling, a hot coiled plate is directly loaded into a preheated movable cover type annealing furnace or tempering furnace to be subjected to heat treatment, so that the technical defect that hot rolling and annealing are separated in the prior art is overcome, and the coiled plate subjected to cold coil heating heat treatment is non-uniform in performance; and the structural ferritic stainless steel with the yield strength of 400-500 MPa, which cannot be realized by a traditional annealing method, is produced, and a large amount of heat energy is saved. Through a simple and convenient one-fire hot charging heat treatment continuous process, the ferrite stainless steel coiled plate can respectively meet the performance requirements of cold rolling and structural steel by controlling two heat treatment temperatures and time. The process method is suitable for large-scale production, less in furnace occupation time, low in energy consumption and beneficial to rapid switching of heat treatment temperature and time of steel coils with different components, product quality is improved, and an efficient rolling process is matched.

Owner:辽宁石源科技有限公司

Capacity expanding method for photocatalysis waste-water degrading reactor capable of realizing UV radiator state self-inspection

ActiveCN103435200AMeet the requirements of the conditions of useGood maintenance effectMultistage water/sewage treatmentMicrowaveUltraviolet lights

The invention relates to a capacity expanding method for a photocatalysis waste-water degrading reactor capable of realizing UV radiator state self-inspection, and belongs to the technical field of waste water processing. In present correlated background technologies, there are the problems that: the function state of an electrodeless lamp is difficult to know timely; an electrodeless lamp placing chamber, that is a quartz tube chamber, has a water bursting problem; microwave energy is wasted; single pot waste-water processing capacity is smaller; catalysts loss; degradation terminal point is difficult to determine; secondary ozone flows crossly and corrodes magnetrons; and the like. The capacity expanding method aims at the problems. The capacity expanding method comprises the main steps: introducing one end of an optical fiber to the periphery of a quartz tube, making the tip of the optical fiber direct to inner cavity of the quartz tube, and making the other end of the optical fiber press close to and direct to the detection window of a ultraviolet light intensity detector. The capacity expanding method also comprises other multiple steps. The capacity expanding method of the invention helps to realize package solution on the series of the problems.

Owner:重庆尧群环保科技有限公司

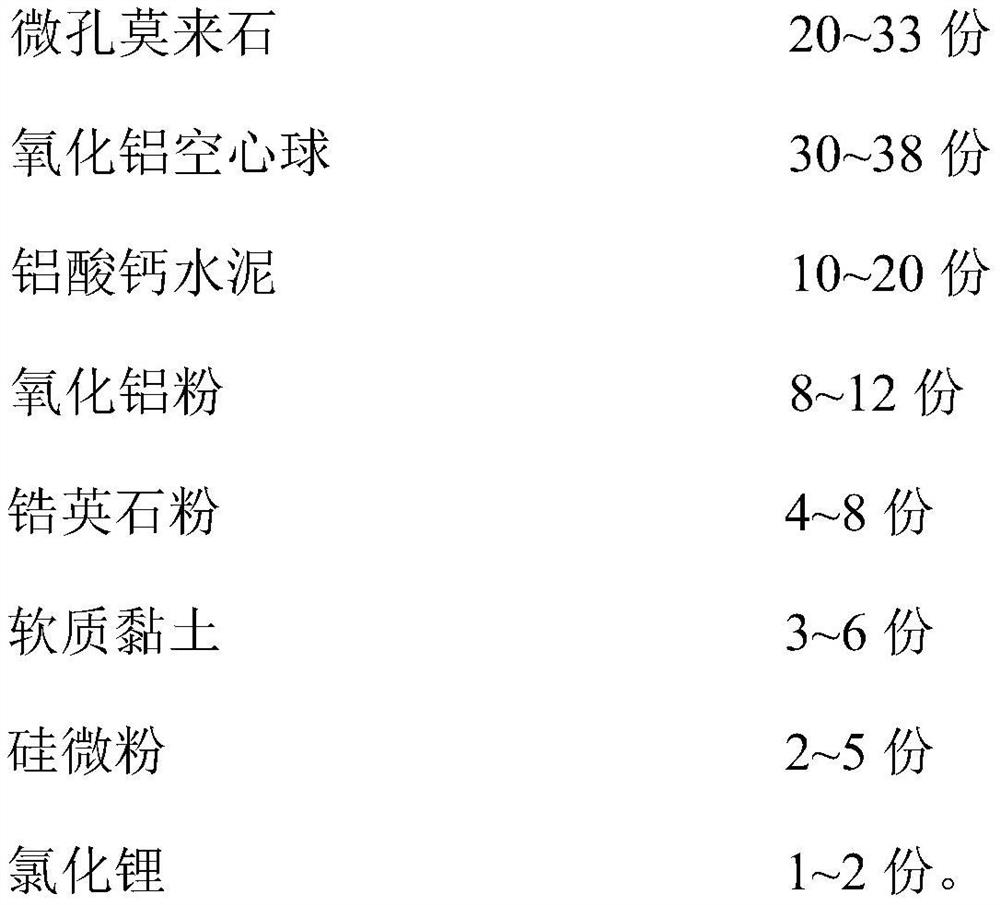

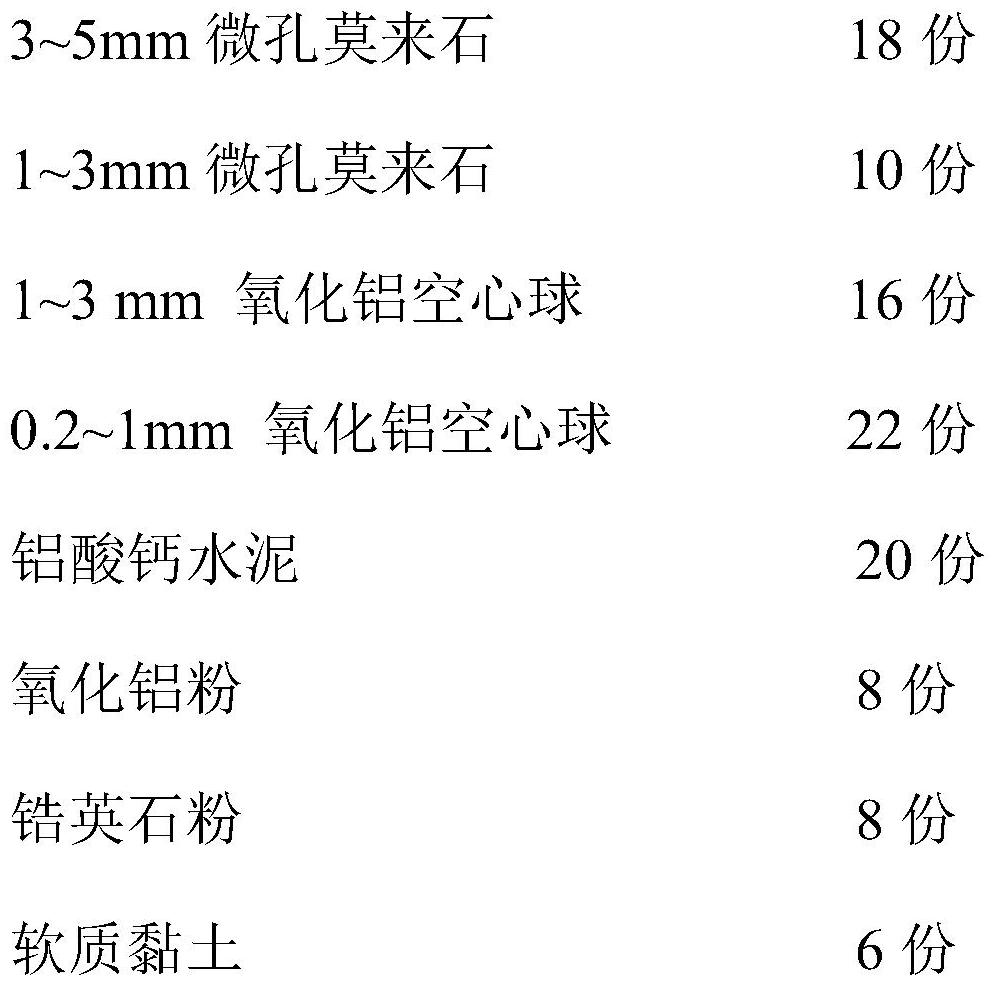

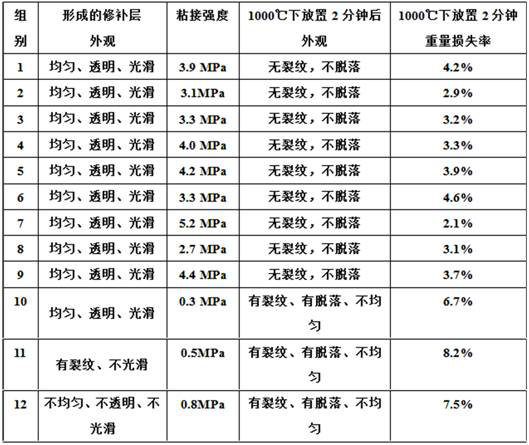

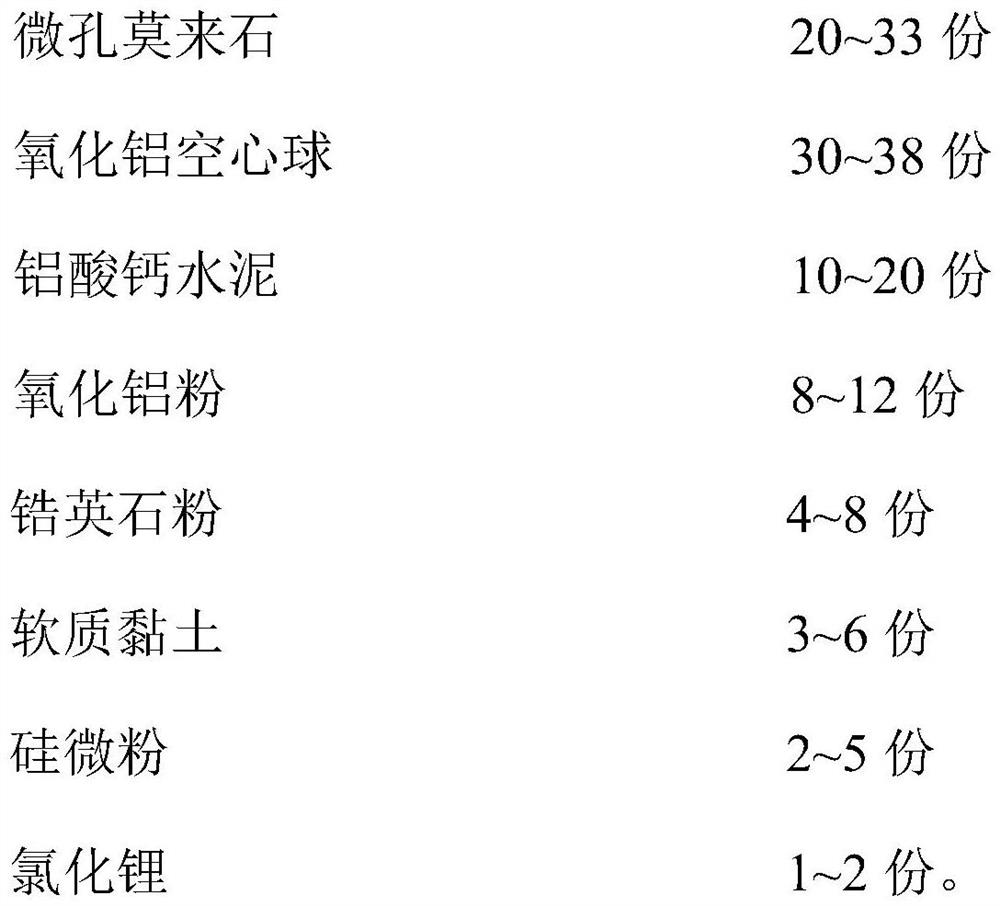

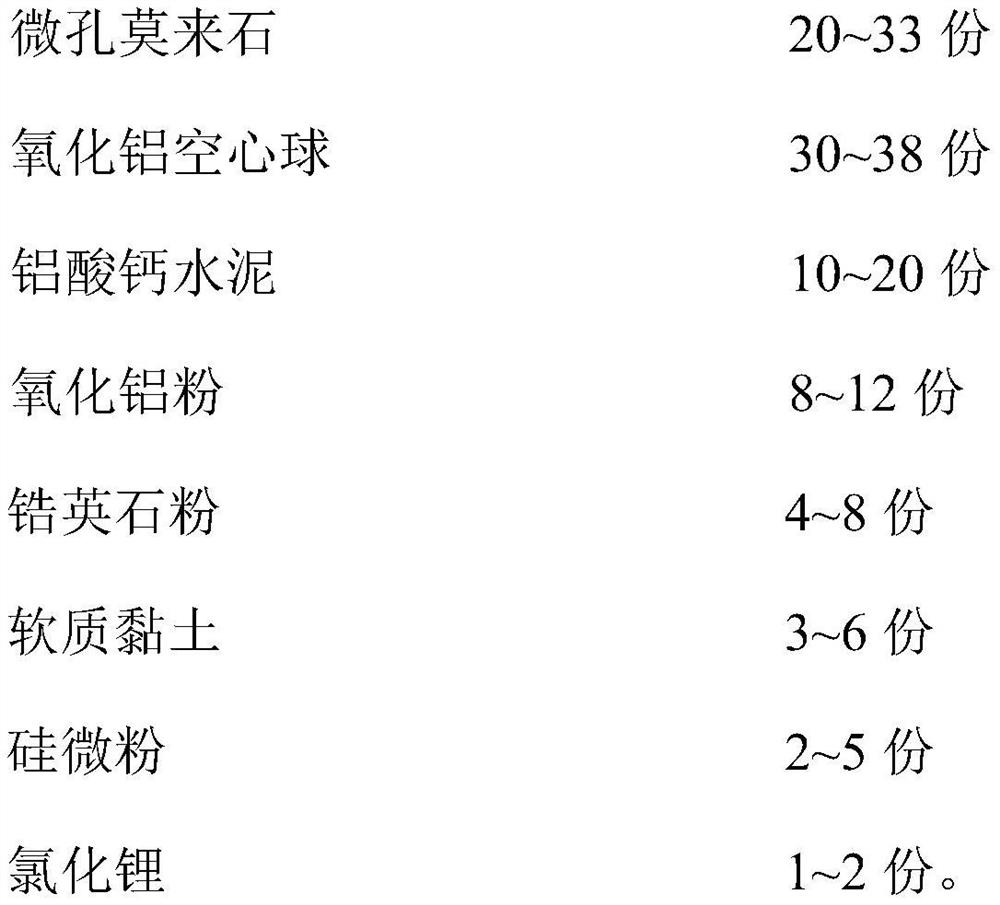

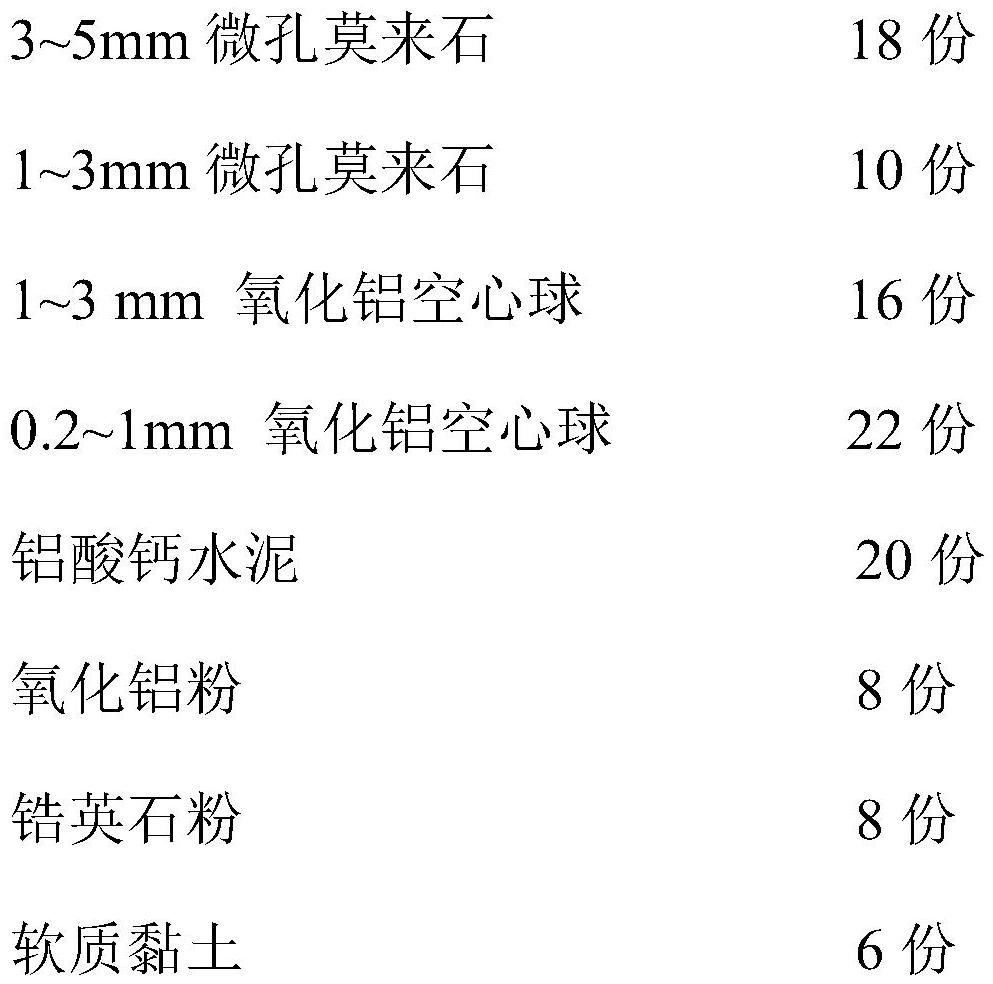

Spray paint for cement kiln preheater

ActiveCN111960831BEasy to transportLow thermal conductivityLinings repairLithium chlorideThermal insulation

The invention relates to a spray paint for a cement kiln preheater, which comprises the following components and parts by weight: 20-33 parts of microporous mullite, 30-38 parts of alumina hollow balls, 10-20 parts of calcium aluminate cement, 8-12 parts of alumina powder, 4-8 parts of zircon powder, 3-6 parts of soft clay, 2-5 parts of silicon micropowder, and 1-2 parts of lithium chloride. The spray paint for cement kiln preheater prepared by the invention has strong corrosion resistance and good thermal shock stability, and has low bulk density and thermal conductivity, good thermal insulation performance, and satisfies the needs of cement kilns. The service conditions of the preheater require that the expected service life of the preheater is more than two years, which effectively guarantees the stability of the production and operation of the cement kiln.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Locomotive driver operation standard voice recognition device and voice recognition method thereof

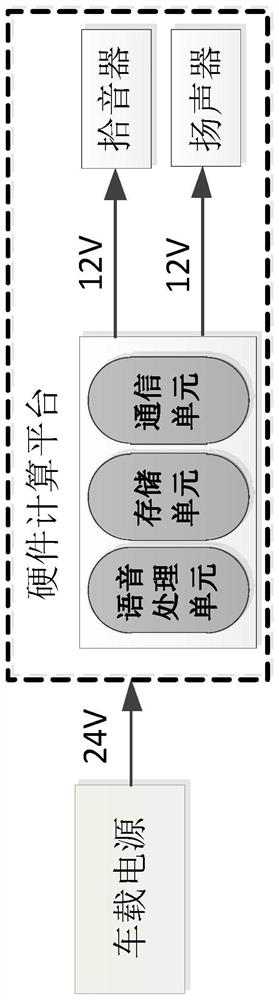

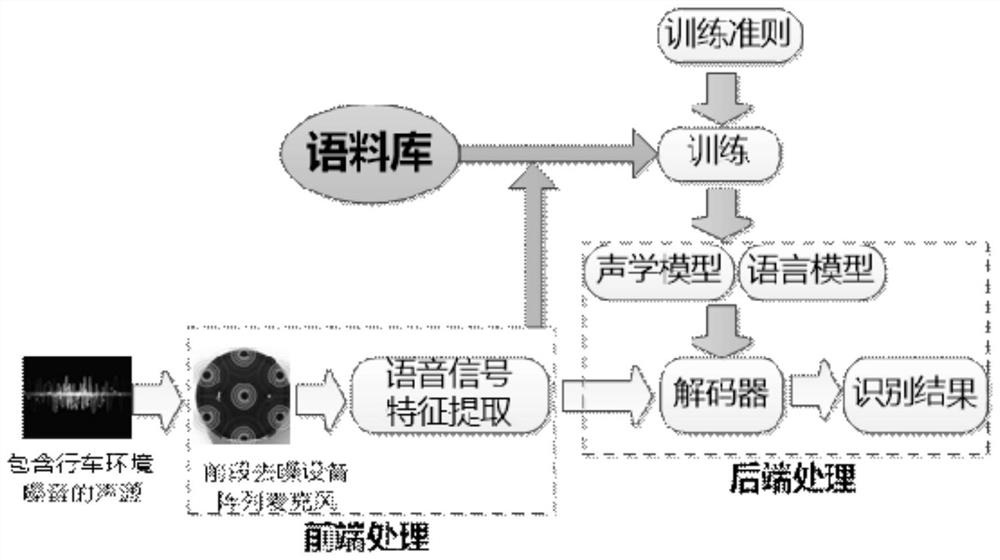

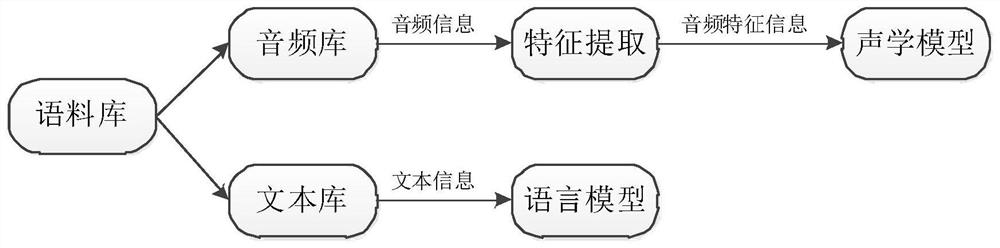

PendingCN112216269AMeet your connectivity needsEffective detection of code of conductSpeech recognitionCommunication unitFeature extraction

The invention discloses a locomotive driver operation standard voice recognition device, which comprises a pickup, a loudspeaker and a hardware computing platform. The pickup collects voice data of alocomotive cab, the loudspeaker broadcasts voice to feed back a driver, and the hardware computing platform comprises a voice processing unit, a storage unit and a communication unit. The voice processing unit comprises a feature extraction module and a voice recognition module, the storage unit stores a voice recognition result of the voice recognition step and related data of the voice recognition result, and the communication unit is used for realizing communication between the hardware computing platform and external equipment.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Method for expanding photocatalytic wastewater degradation reactor for resisting water burst in lamp zone

ActiveCN103319031AMaintain normal performanceGuaranteed normal service lifeMultistage water/sewage treatmentStreamflowAir channel

The invention relates to a method for expanding a photocatalytic wastewater degradation reactor for resisting water burst in a lamp zone and belongs to the technical field of wastewater treatment. The problem that water bursts in a tube cavity of a quartz tube, namely an electrodeless lamp accommodating cavity and the problems that the microwave energy is wasted, the single-pot wastewater treatment amount is small, the catalytic agent is lost, the degradation endpoint is difficultly distinguished, a magnetron is corroded by reverse channeling of secondary ozone and the like exist in the existing related technology, and the scheme aims to solve the series of problems. According to the scheme, the method mainly comprises the following steps: connecting a micro diaphragm pump used for supplementing air in a normal state at low power consumption and low flow to an air channel communicated with the tube cavity of the quartz tube in a bypass mode; separating the microwave irradiation area; expanding the size of the reactor, gradually intercepting the catalyst particles by employing an external cascade filter; sensing the reaction process by employing an ozone sensor, and immediately closing the related power supply when the degradation endpoint is reached; and separating a waveguide tube by employing a wave-transparent airtight separation plate so as to prevent the reverse flow of secondary ozone from corroding the magnetron.

Owner:重庆尧群环保科技有限公司

Piggybacking method for expanding capacity of photocatalytic wastewater degradation reactor to prevent water inrush in lamp area

ActiveCN103319034BMeet the requirements of the conditions of useGood maintenance effectMultistage water/sewage treatmentStreamflowNormal state

The invention relates to a photocatalysis wastewater degradation reactor capacity expanding method capable of incidentally preventing lamp region from causing water burst, belonging to the technical field of wastewater treatment. Existing relevant technologies has the problem of the water burst of an electrodeless lamp installing cavity, namely, a quartz tube cavity, and also has the problems of microwave energy waste, slightly small single-tank wastewater treatment capacity, catalyst agent loss, difficulty in distinguishing degradation reaction endpoints, incapability of immediately finding catalytic agent agglomeration, corrosion of secondary ozone reverse channeling to a magnetron, and the like. Aiming at the series problems, the capacity expanding method mainly comprises the steps of: connecting a miniature diaphragm pump used for replenishing air at a normal state and with low power consumption and low flow to an air channel leading into the quartz tube cavity in a bypass manner; restraining a microwave irradiation airspace by using a metal cage so as to conveniently largely expand the capacity of a reactor; intercepting a catalytic agent by stages by using a multi-stage filter; sensing a degradation endpoint by using an ozone sensor, and automatically switching off a power supply at the degradation endpoint; self-detecting the agglomeration trend of the catalytic agent; separating a waveguide tube by using a wave-transparent airtight partitioning plate, and blocking a secondary ozone reverse channeling channel.

Owner:诺特达新材料科技(上海)有限公司

Water-saving reverse osmosis water purifier

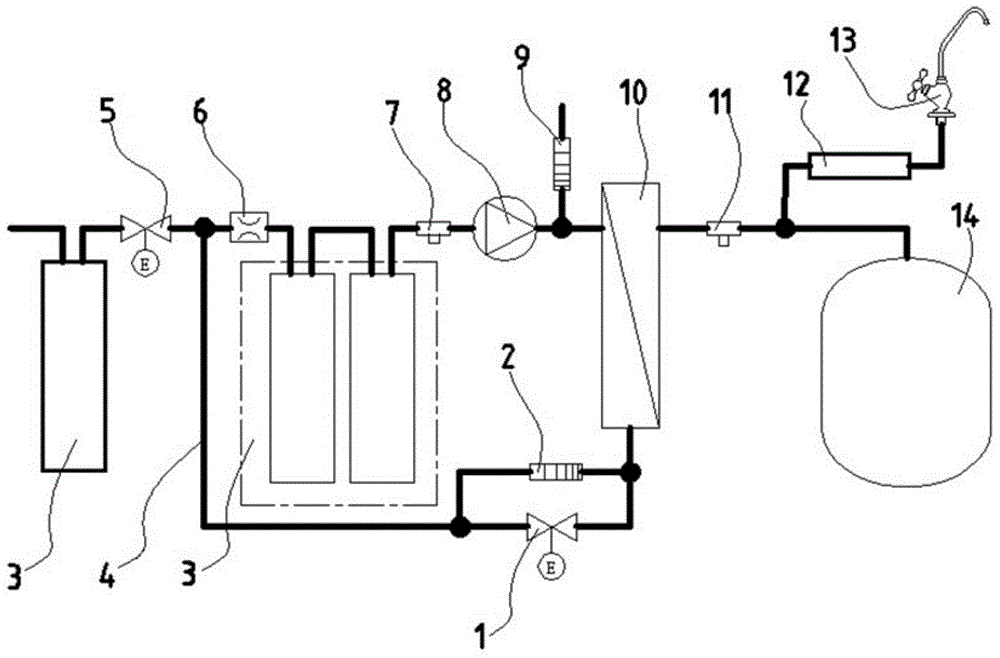

ActiveCN103693799BRinse discharge water reductionAvoid easy cloggingWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater savingWater source

The invention discloses a water-saving reverse osmosis water purifier, comprising a flush valve, a large-flow throttle valve, a pretreatment filter core, a return pipe, a booster pump, a small-flow throttle valve and a reverse osmosis processor, wherein the inlet of the pretreatment filter core is communicated with a water source; the outlet of the pretreatment filter core is communicated with the inlet of the reverse osmosis processor; the booster pump is arranged inside a water inlet pipeline of the reverse osmosis processor; one end of the return pipe is communicated with a concentrated water outlet of the reverse osmosis processor; the other end of the return pipe is communicated with the water inlet pipeline of the booster pump; the large-flow throttle valve is arranged on the return pipe; the inlet of the flush valve is communicated with the concentrated water outlet of the reverse osmosis processor; the outlet is communicated with the water inlet pipeline of the booster pump; the inlet of the small-flow throttle valve is communicated with the water inlet pipeline of the reverse osmosis processor or a concentrated water discharge pipeline of the reverse osmosis processor or the return pipeline; and the outlet of the small-flow throttle valve is idle. The washing water generated when the water-saving reverse osmosis water purifier is washed can be completely recycled. Therefore, the rinse discharge water of a reverse osmosis processor can be reduced to zero.

Owner:江苏正本净化节水科技实业有限公司

A high thermal shock resistance composite kiln mouth castable

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

An integrated reactor with a double-layer structure on the top

ActiveCN103187108BInhibition releaseAvoid direct immersionIntegral reactorsNuclear energy generationEngineeringPressure vessel

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

A kind of acidic inorganic repairing agent and its preparation method, repairing method

The invention provides an acidic inorganic repairing agent and its preparation method and repairing method, comprising: silica sol, silicon dioxide, boron nitride, and glass glaze; wherein, the pH value of the silica sol is 2-5. The acidic inorganic repairing agent of the invention can avoid the problem of pyrolysis of organic resins, is suitable for use at high temperatures, and has a stable and long-lasting repairing effect on ceramics and their composite materials that are not resistant to alkali.

Owner:北京玻钢院复合材料有限公司

Spray coating for cement kiln preheater

The invention relates to a spray coating for a cement kiln preheater. The spray coating comprises the following components in parts by weight: 20-33 parts of microporous mullite, 30-38 parts of alumina hollow spheres, 10-20 parts of calcium aluminate cement, 8-12 parts of alumina powder, 4-8 parts of zirconite powder, 3-6 parts of soft clay, 2-5 parts of silica powder and 1-2 parts of lithium chloride. The spray coating for the cement kiln preheater, prepared by the invention, has relatively strong erosion resistance and good thermal shock stability; the volume density and the heat conductivity coefficient are low, the heat preservation and insulation performance is good, the use condition requirements of the cement kiln preheater are well met, the expected service life of the preheater exceeds two years, and the stability of cement kiln production operation is effectively guaranteed.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Acidic inorganic repairing agent as well as preparation method and repairing method thereof

The invention provides an acidic inorganic repairing agent as well as a preparation method and a repairing method thereof. The acidic inorganic repairing agent comprises silica sol, silicon dioxide, boron nitride and glass glaze, wherein the pH value of the silica sol is 2-5. The acidic inorganic repairing agent provided by the invention can avoid the problem of high-temperature decomposition of organic resin, is suitable for high-temperature use, and has a stable and lasting repairing effect on non-alkali-resistant ceramics and composite material products thereof.

Owner:北京玻钢院复合材料有限公司

Photocatalysis wastewater degradation reactor capacity expansion method capable of protecting magnetron from being corroded

InactiveCN103319030AMeet the requirements of the conditions of useGood maintenance effectWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisAutomatic controlWastewater

The invention relates to a photocatalysis wastewater degradation reactor capacity expansion method capable of protecting a magnetron from being corroded and belongs to the technical field of wastewater treatment. An existing related technology has the problems that a contact agent is lost, microwave energy is wasted, the processing amount of single-pot wastewater of a reactor is small, a degradation finished point is difficult to recognize, a contact agent agglomerate can not be dissipated in situ, the contact agent agglomeration can not be observed in time, the secondary ozone reverse fluid channeling corrosion magnetron and the like. The scheme aims at the series problems. The method comprises the main steps: closing up a microwave irradiation by a metal cage; expanding the size of the reactor; gradually intercepting the contact agent by utilizing a multi-grade filter; dissipating the contact agent agglomerate in situ by utilizing low-frequency ultrasonic waves sent from the bottom of the reactor, meanwhile, cleaning a quartz tube; monitoring a reaction progress by utilizing an ozone sensor and automatically controlling a related power supply switching mechanism by utilizing a sensing electric signal; carrying out self detection on an agglomerate main induction parameter; separating a waveguide pipe in an air-tight manner by utilizing a wave-transparent plate including the quartz tube and the like to avoid the zone reverse fluid channeling and prevent the magnetron from being corroded.

Owner:李榕生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com