One-fire hot charging heat treatment process of ferrite stainless steel hot-rolled hot-rolled plate

A stainless steel and ferrite technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve the problems of uneven corrosion resistance, difficult heat treatment operation, uneven coil performance, etc., to save processing time, High strength and uniform corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] One-fire hot-charging heat treatment process for ferritic stainless steel hot-rolled hot coil plate for cold rolling

[0044] The composition of ferritic stainless steel is shown in the table below:

[0045] element C Cr Ni mn Si P S N / ppm Mass content% 0.02 16.3 0.4 0.6 0.5 0.02 0.01 180

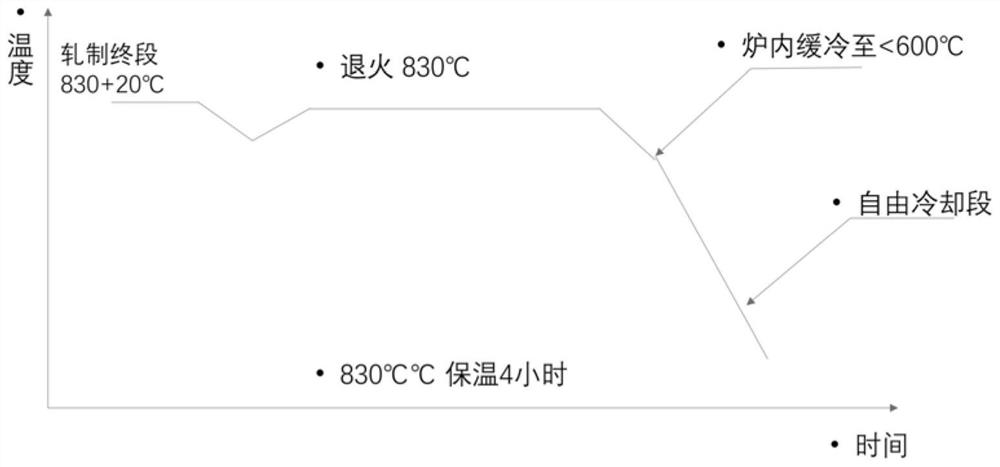

[0046] Such as figure 1 As shown, the specific heat treatment process steps are as follows:

[0047] S1. At the end of hot rolling, the temperature of ferritic stainless steel after hot coiling is controlled above 850°C;

[0048] S2, preheating the mobile bell annealing furnace to 850°C;

[0049] S3, install the furnace, and after the temperature is stabilized at 830±5°C, keep it warm for 4 hours;

[0050] S4. Stop heating until the temperature drops below 600°C;

[0051] S5, taking out the furnace and cooling to room temperature to obtain a ferritic stainless steel coil for cold rolling. After testing, the performance of the coil is unif...

Embodiment 2

[0054] One-fire hot-charging heat treatment process for ferritic stainless steel hot-rolled hot coil plate for cold rolling

[0055] The composition of ferritic stainless steel is shown in the table below:

[0056] element C Cr Ni mn Si P S N / ppm Mass content% 0.02 16.3 0.4 0.6 0.5 0.02 0.01 180

[0057] The specific heat treatment process steps are as follows:

[0058] S1. At the end of hot rolling, the temperature of ferritic stainless steel hot-rolled coils before entering the furnace is controlled at 880°C;

[0059] S2, preheating the mobile bell annealing furnace to 870°C;

[0060] S3, install the furnace, and after the temperature is stabilized at 850±5°C, keep it warm for 2.5 hours;

[0061] S4. Stop heating until the temperature drops below 600°C;

[0062] S5, taking out the furnace and cooling to room temperature to obtain a ferritic stainless steel coil for cold rolling. After testing, the performance of the coil is uniform...

Embodiment 3

[0065] One-fire hot-charging heat treatment process for hot-rolled hot-coiled ferritic stainless steel plate for structural use

[0066] Among them: the composition of ferritic stainless steel is shown in the following table:

[0067] element C Cr Ni mn Si P S N / ppm Mass content% 0.07 17.3 1.4 0.7 0.6 0.025 0.002 180

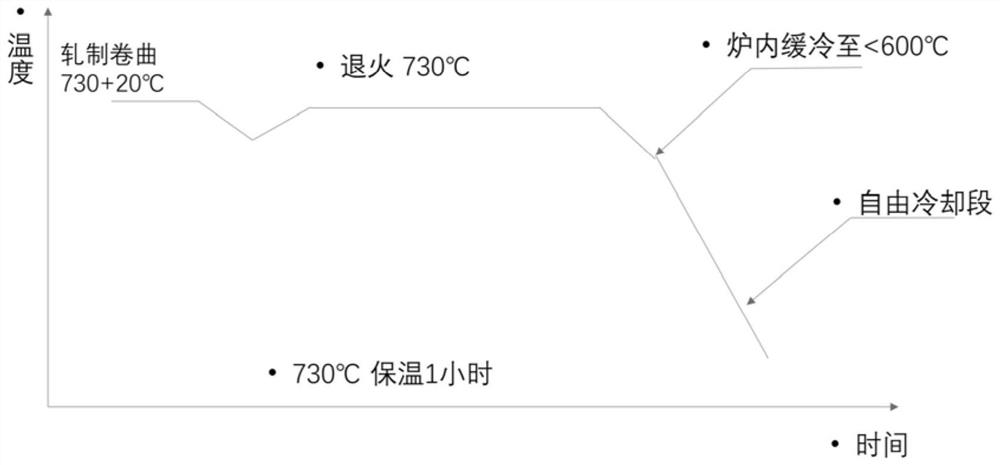

[0068] Such as figure 2 As shown, the specific heat treatment process steps are as follows:

[0069] S1. At the end of hot rolling, the temperature of ferritic stainless steel hot-rolled coils before entering the furnace is controlled at 750°C;

[0070] S2, preheating the mobile bell annealing furnace to 750°C;

[0071] S3, install the furnace, and after the temperature is stabilized at 730±5°C, keep it warm for 1 hour;

[0072] S4. Stop heating until the temperature drops below 600°C;

[0073] S5, taking out of the furnace and cooling to room temperature to obtain a ferritic stainless steel coil for structure. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com