A reactor temperature control integrated device with precise temperature control

A reactor and precise technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as increased input costs, achieve long service life, stable and timely temperature control, and structural good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

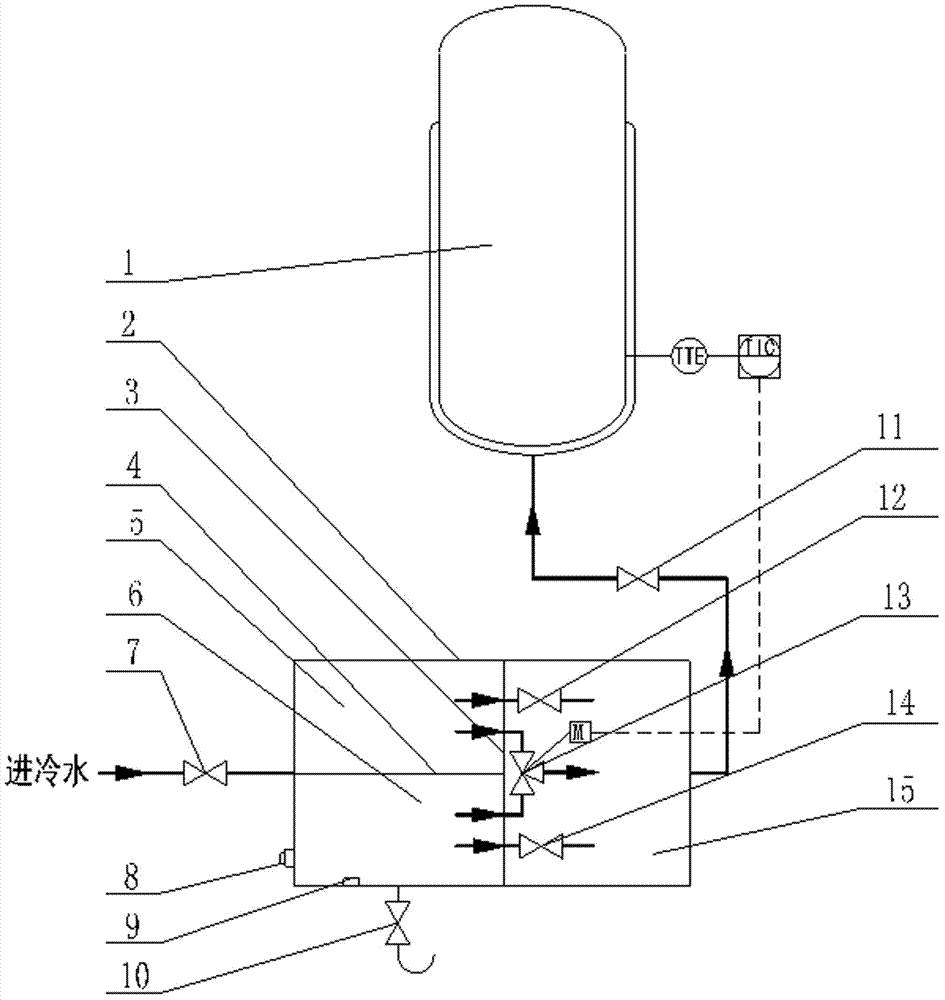

[0041] The reactor temperature control integrated device with precise temperature control in this embodiment, such as figure 1 As shown, it includes a water tank 2, a cold water inlet valve 7, a three-way temperature control valve 13, a constant temperature water outlet valve 11 and a reactor 1. The inside of the water tank 2 is divided into a cold water cavity by a first partition 3 and a second partition 4 5. The hot water cavity 6 and the constant temperature cavity 15, the first partition 3 and the second partition 4 are arranged perpendicular to each other, the hot water cavity 6 is connected with an exhaust valve 10, and the constant temperature cavity 15 is provided with a temperature sensor 9 The outlet of the cold water inlet valve 7 is communicated with the cold water cavity 5 and the hot water cavity 6 of the water tank 2 respectively through the pipeline, and the cold water cavity 5 and the hot water cavity 6 are connected with two of the three-way temperature contr...

Embodiment 2

[0060] The reactor temperature control integrated device with precise temperature control in this embodiment is roughly the same as that in Example 1, except that the mass percentage of each component in the separator in step (i) of the processing technology of the separator is: C: 0.46%, Si: 0.58%, Mn: 0.67%, S: ≤0.030%, P: ≤0.030%, Cr: 0.13%, Ni: 0.43%, Cu: 0.34%, V: 0.13%, Mo: 0.02%, Ti: 0.46 %, B: 0.05%, Zn: 1.34%, Pd: 0.04%, Pt: 0.04%, Au: 0.08%, W: 1.05%, Ta: 0.23%, Nd: 0.05%, Ce: 0.03%, Eu: 0.04 %, Lu: 0.04%, Ag: 0.24%, Ga: 0.06%, Al0.93%, Y: 0.16%, Sn: 1.25%, Zr: 0.13%, Re: 0.04%, Os: 0.09%, Hf: 0.12 %, Bi: 0.13%, the balance is Fe;

[0061] In step (vi) of the processing technology of the separator, the protective layer is composed of mixture A and mixture B, and the weight ratio of mixture A and mixture B is 3:1;

[0062] The mass percentage of each component of the mixture A is: sodium silicate: 0.27%, melamine phosphate: 0.19%, pentaerythritol: 0.12%, aluminum sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com