Integral reactor with top double-layer structure

A double-layer structure, reactor technology, applied in general reactors, non-uniform reactors, reactors, etc., can solve problems such as poor project implementation, inconvenient in-service inspection and maintenance of equipment, and poor equipment reliability, and achieve high safety, The effect of good project implementation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

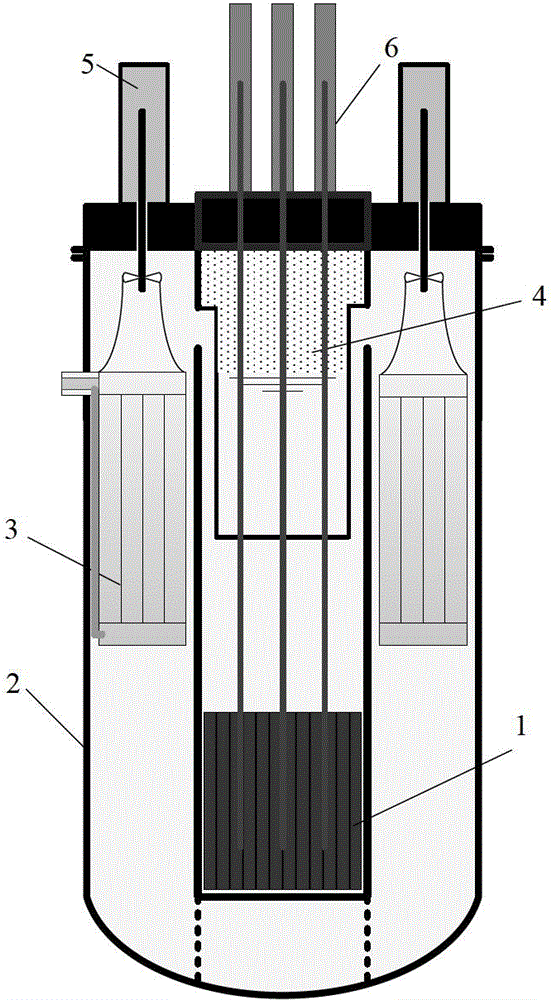

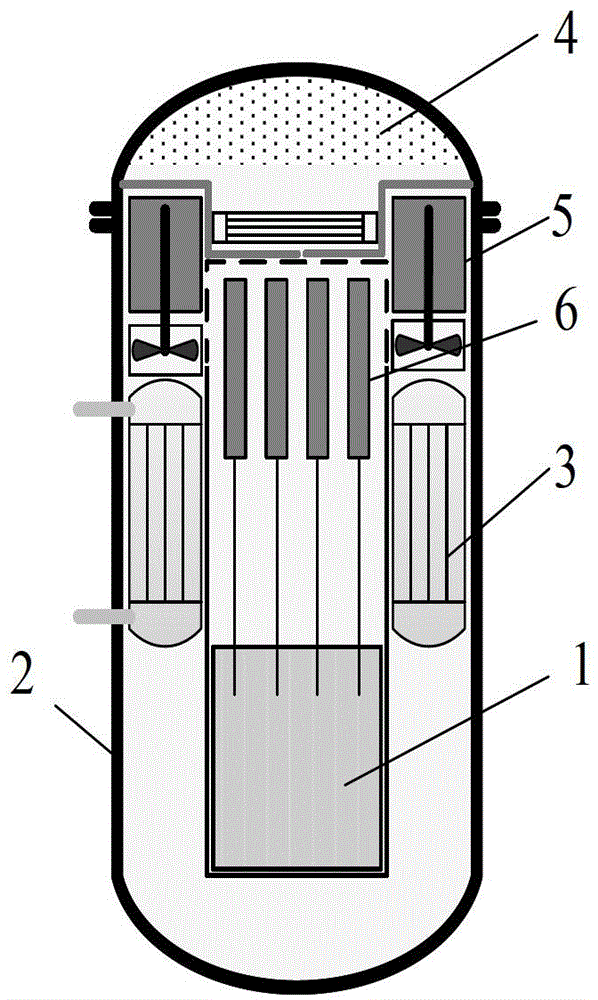

[0035] like image 3 As shown, in the integrated reactor with a double-layer structure on the top of the present invention, the reactor core 1, built-in steam generator 3, main pump 5, control rod drive mechanism 6 and other equipment are all installed in the pressure vessel 2 Inside.

[0036] Wherein, the core 1 and the built-in steam generator 3 are arranged under the equipment supporting platform 8 .

[0037]The upper cylinder body 7 of the pressure vessel and the ring-shaped equipment support platform 8 form an integral structure, and the arc-shaped pressure vessel inner top cover 10 is connected to the through hole in the center of the equipment support platform 8 through the pressure vessel inner top cover and the flange 12 of the equipment support platform edge. The control rod driving mechanism 6 is arranged above the inner top cover 10 of the pressure vessel, and the driving line of the control rod assembly passes through the inner top cover 10 of the pressure vesse...

Embodiment 2

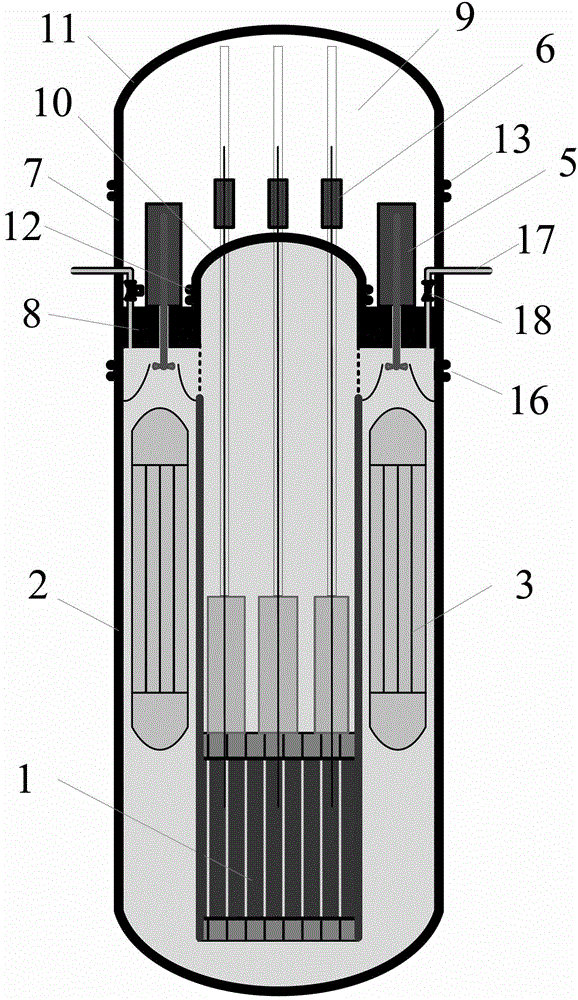

[0045] like Figure 6 As shown, another integrated reactor with a double-layer structure on the top of the present invention, its core 1, built-in steam generator 3, main pump 5, control rod drive mechanism 6 and other major equipment are directly installed on the pressure Inside container 2.

[0046] Wherein, the core 1 and the built-in steam generator 3 are arranged under the flat roof 19 .

[0047] The upper cylinder body 7 of the pressure vessel and the flat top cover 19 form an integral structure, and the flat top cover 19 doubles as an equipment support platform. The upper flange 16 of the pressure vessel is arranged on the cylindrical body below the flat top cover 19 to facilitate the disassembly of the flat top cover 19 . The main pump 5 and the control rod driving mechanism 6 are arranged on the flat top cover 19 , and the driving line of the main pump shaft, the impeller and the control rod assembly passes through the flat top cover 19 .

[0048] The pressure vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com