A high thermal shock resistance composite kiln mouth castable

A technology of thermal shock and castables, which is applied in the field of refractory materials, can solve the problems that the in-situ spinel binding phase cannot be generated, the composition cannot be completely matched, and the service life cannot be guaranteed, so as to achieve good chemical corrosion resistance and reduce cracking and the degree of peeling, and the effect of meeting the requirements of the use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

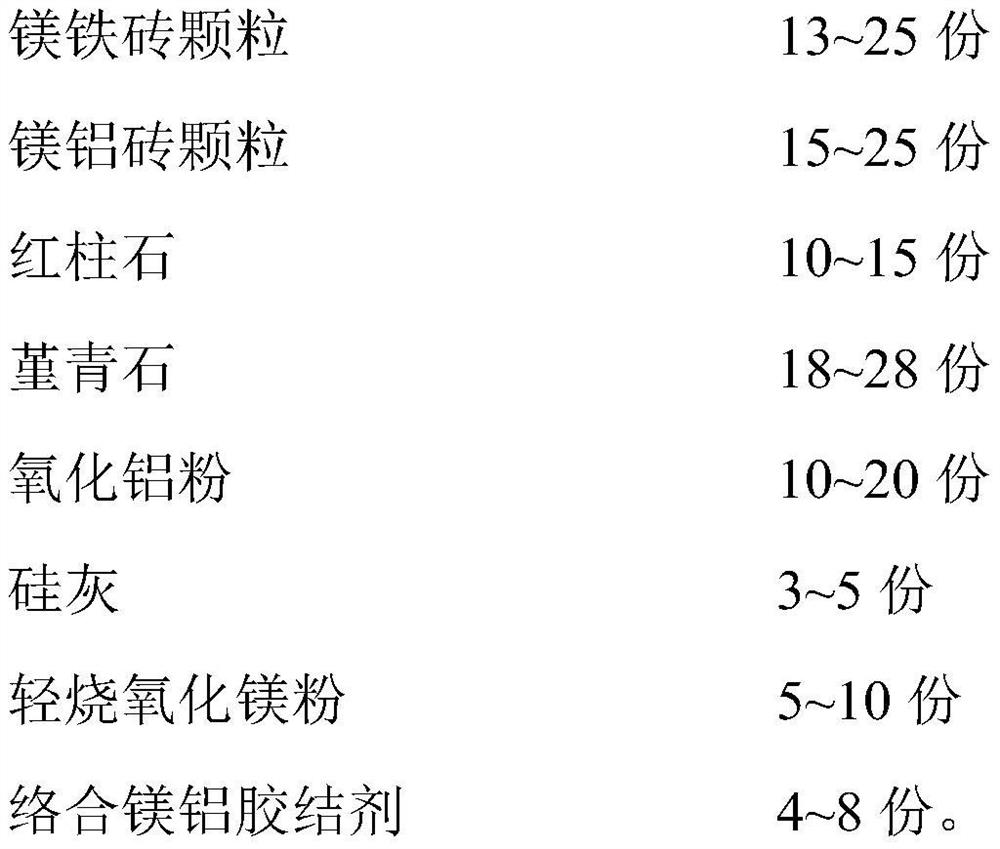

[0022] A composite kiln mouth castable with high thermal shock resistance, comprising the following components and parts by weight:

[0023]

[0024] Wherein, the magnesia-alumina brick particles are recycled magnesia-iron bricks, and the mass percentage of MgO is not less than 80%; the magnesia-alumina brick particles are recycled magnesia-alumina bricks, and the mass percentage of MgO is not less than 85% ; Al in the complex magnesium-aluminum cement 2 o 3 The mass percentage of MgO is not less than 45%, and the mass percentage of MgO is not less than 1.5%.

Embodiment 2

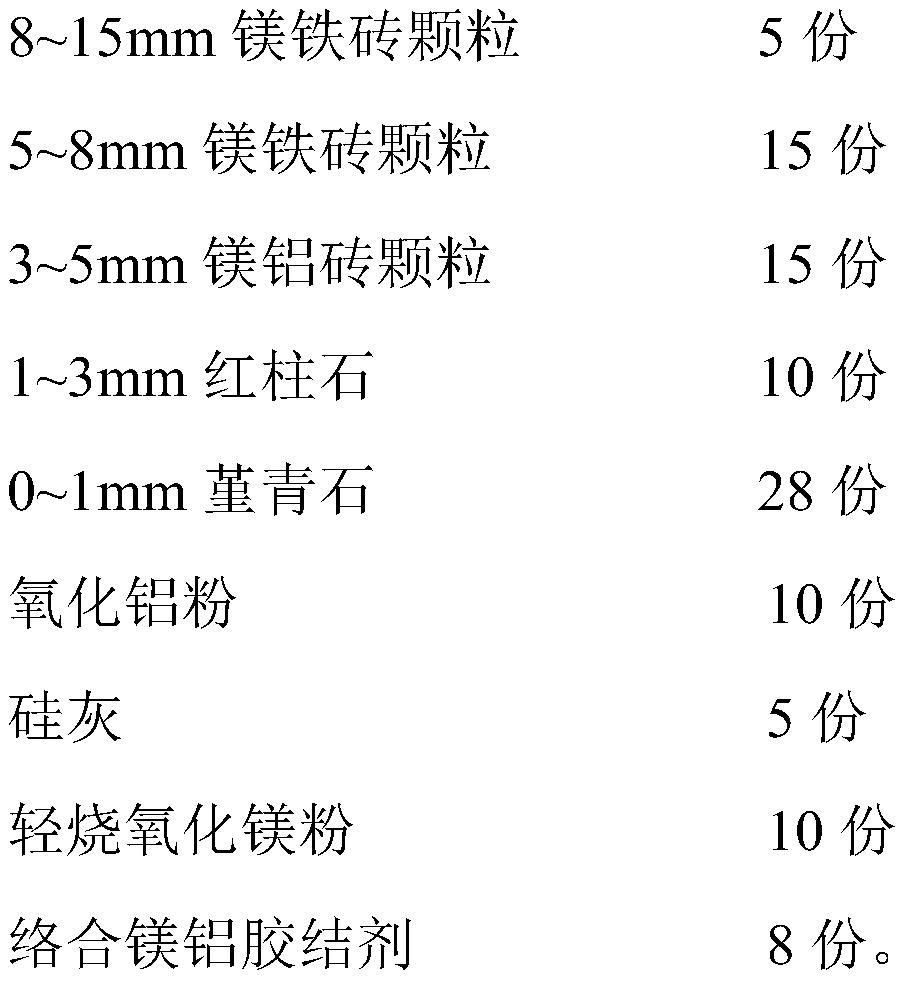

[0026] A composite kiln mouth castable with high thermal shock resistance, comprising the following components and parts by weight:

[0027]

[0028]

[0029] Wherein, the magnesia-alumina brick particles are recycled magnesia-iron bricks, and the mass percentage of MgO is not less than 80%; the magnesia-alumina brick particles are recycled magnesia-alumina bricks, and the mass percentage of MgO is not less than 85% ; Al in the complex magnesium-aluminum cement 2 o 3 The mass percentage of MgO is not less than 45%, and the mass percentage of MgO is not less than 1.5%.

Embodiment 3

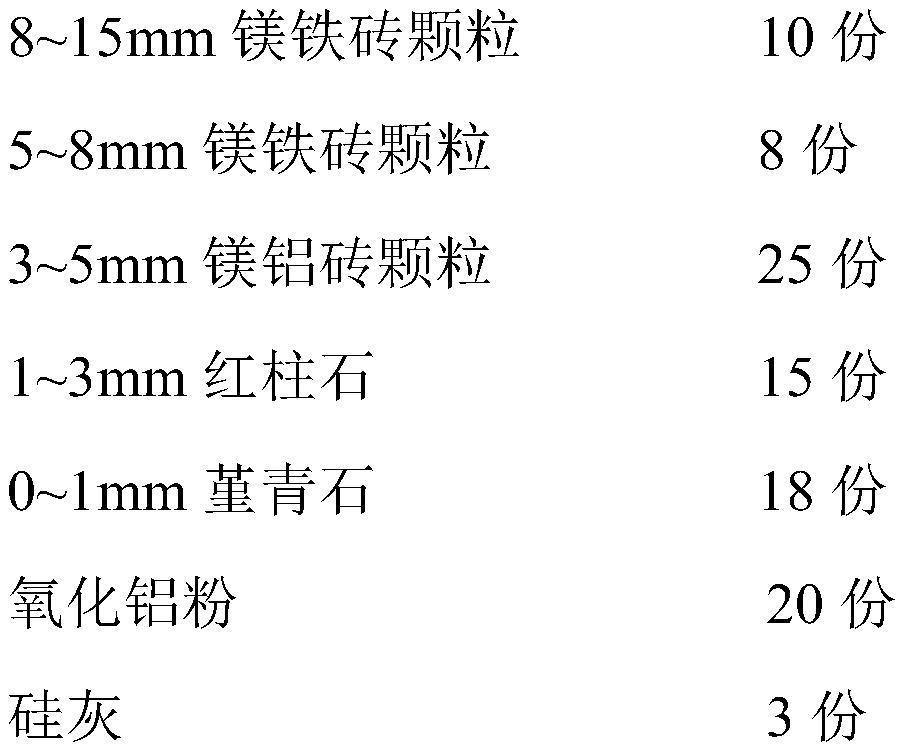

[0031] A composite kiln mouth castable with high thermal shock resistance, comprising the following components and parts by weight:

[0032]

[0033] Wherein, the magnesia-alumina brick particles are recycled magnesia-iron bricks, and the mass percentage of MgO is not less than 80%; the magnesia-alumina brick particles are recycled magnesia-alumina bricks, and the mass percentage of MgO is not less than 85% ; Al in the complex magnesium-aluminum cement 2 o 3 The mass percentage of MgO is not less than 45%, and the mass percentage of MgO is not less than 1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com