Patents

Literature

152results about How to "High softening temperature under load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ligh high strength aluminium oxide hollow ball ceramic

InactiveCN1554616AWith shrinkageWith thermal shock resistanceCeramicwarePhosphoric acidShock resistance

The light high-strength alumina ceramic ball has phosphoric acid solution as binding agent, alpha-alumina powder as basic material and hollow alumina ball as aggregate. Compared with dense refractory material, it has low density, high heat shock resistance, good heat insulating performance, low heat capacity and other features; and compared with common heat insulating material, it has high compression strength, high loaded softening temperature, low re-burning linear shrinkage and other features. It may be used as heat insulating material directly and may be also used in direct contact with flame, such as being used as lining material in high temperature furnace and kiln. In addition, its strength may be further raised in secondary sintering.

Owner:ZHEJIANG UNIV

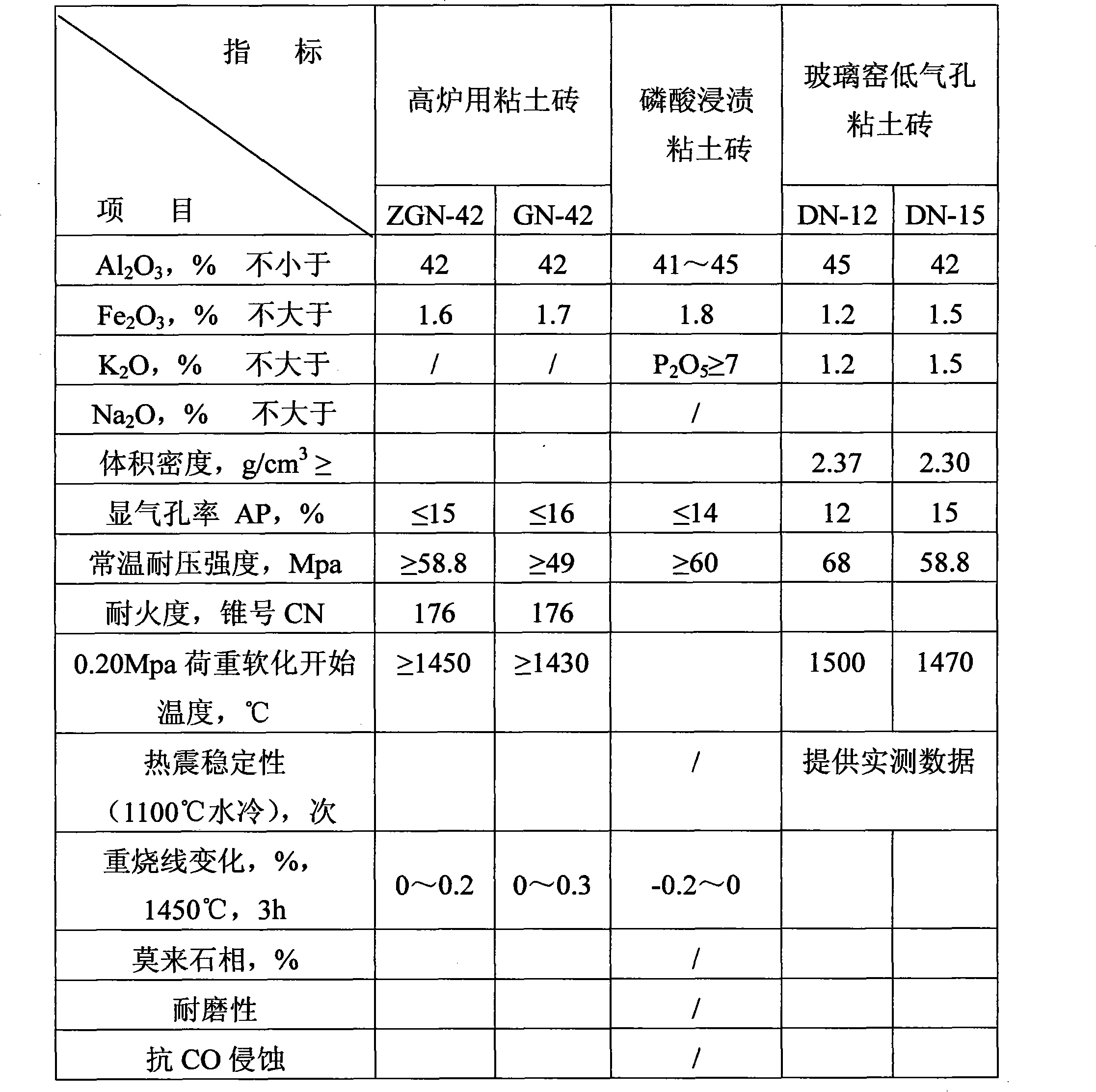

Method for producing silicon mullite abrasive brick

ActiveCN101712551AReduce kiln maintenance timesHigh softening temperature under loadTunnel kilnBrick

The invention discloses a method for producing a silicon mullite abrasive brick, comprising the following steps of: firstly, selecting 4 parts of bauxite granules, 2 parts of brown aluminum oxide granules, 0.4 part of carborundum granules, 2.5 parts of bauxite powder, 0.8 part of carborundum powder, 0.2 part of metallic silicon powder, 0.2 part of silicon powder and 0.5 part of clay powder in parts by weight; secondly, adding the bauxite granules, the brown aluminum oxide granules and the carborundum granules into an edge runner wet mill and premixing, then adding lignin liquor accounting for 4-5 percent of the total weight of materials and premixing, adding the bauxite powder, the carborundum powder, and the metallic silicon powder and mixing, adding the clay powder and the silicon powder, mixing and discharging ground ageing mixture; and thirdly, pressing the pug into semi-finished products, feeding the semi-finished products into a drying chamber, drying, feeding semi-finished products into a high-temperature tunnel kiln and sintering to form a finished brick body. The brick body has long service life, can keep synchronous running with a kiln liner in a firing zone, reduces the maintenance times for users to close down the kiln, and simultaneously has the advantages of high softening temperature for load, favorable thermal shock resisting stability, favorable wear-resisting performance and the like.

Owner:郑州真金耐火材料有限责任公司

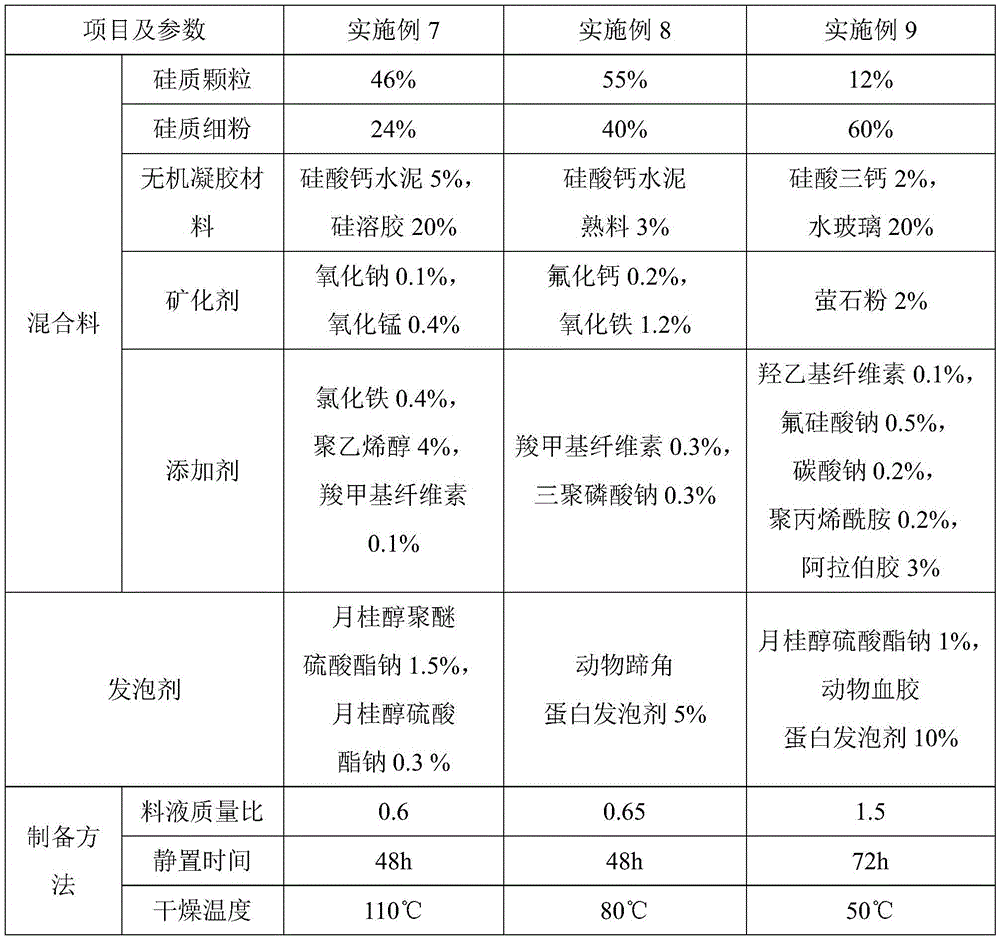

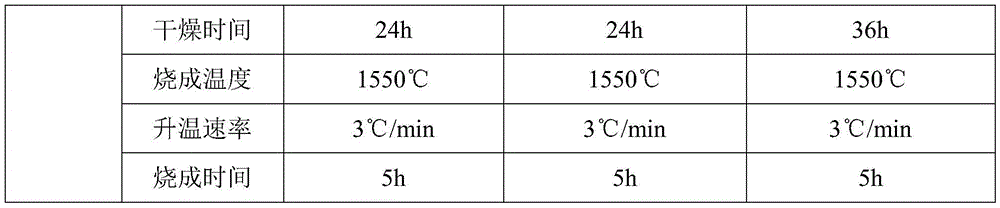

Micropore light weight silica brick and preparation method thereof

The invention discloses a micropore light weight silica brick and a preparation method thereof. The light weight silica brick is mainly prepared from a mixture and a foaming agent; a use quantity of the foaming agent is 0.1% to 10% of mass of the mixture; the mixture consists of the following components in percentage by mass: 70% to 95% of siliceous material, 1% to 25% of inorganic cementitious material, 0.1% to 15% of mineralizer, and 0.1% to 5% of additive, wherein the siliceous material consists of siliceous particles and siliceous fine powder, a particle size of the siliceous particles is 0.1 to 3mm, a particle size of the siliceous fine powder is smaller than or equal to 0.075mm, and a mass ratio of the siliceous particles to the siliceous fine powder is (1 to 65):(35 to 99). The obtained micropore light weight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical intensity, high high-temperature volume stability, high resistance to the acid atmosphere, high slagging resistance and the like, is low in preparation cost and good in heat insulation effect, meets the harsh requirements of thermal equipment for a high-temperature environment and heat insulation, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

High refractoriness under load and thermal shock resistant fireproof brick

The invention discloses a high-refractoriness under load thermal shock-resistant refractory brick, which is prepared from the raw materials of high alumina bauxite, electrically-fused corundum, synthetic mullite, sillimanite, bonding agent, additive and water according to the following mixture ratio by weight portion: 10 to 15 percent of high alumina bauxite granule, 10 to 15 percent of electrically-fused corundum granule, 35 to 45 percent of synthetic mullite granule, 10 to 15 percent of sillimanite powder, 5 to 10 percent of bonding agent, 6 to 10 percent of additive and a proper amount of water; and the brick is prepared by the method comprising the following steps: placing the weighed high alumina bauxite, electrically-fused corundum, synthetic mullite granule into a mixing mill for mixing; after the mixture is mixed uniformly, adding the sillimanite powder, the bonding agent, the additive and the proper amount of water into the mixing mill for mixing for 8 to 12 minutes and obtaining pug of which water content is controlled to be 3 percent; pressing the well mixed pug into green bricks on a brick molding press and placing molded green bodies of which the density is controlled to be 2.808kg / cm<3> into a tunnel kiln for drying; firing the green bricks at 1,460 to 1,480 DEG C and keeping the temperature for 8 to 10 hours; and obtaining finished bricks. The brick has a long service life and can prolong the service life of the kiln.

Owner:郑州顺兴耐火材料有限公司

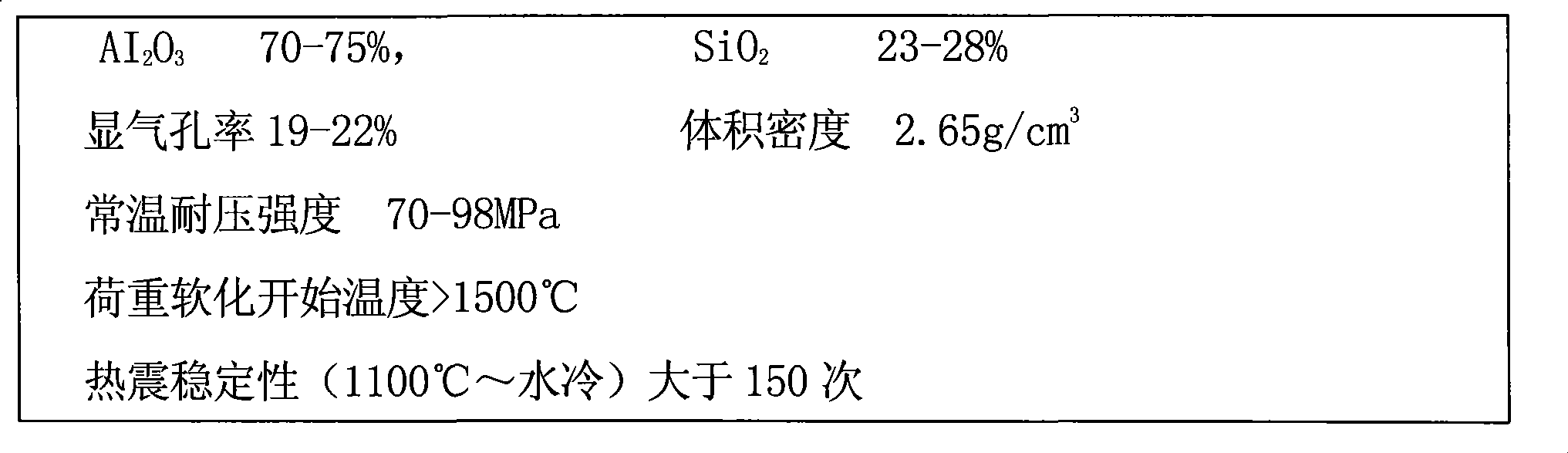

Mafic-magnalium compound spinel brick and preparation method thereof

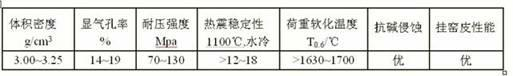

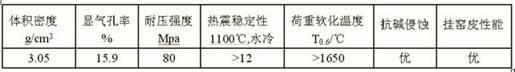

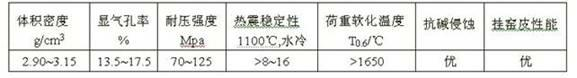

InactiveCN102020479AHigh softening temperature under loadIncrease temperatureBrickPhysical chemistry

The invention relates to a mafic-magnalium compound spinel brick and a preparation method thereof. The raw materials comprise 20-55% of high iron magnesia sand with granularity of 5-3mm, 10-45% of high iron magnesia sand with granularity of less than 2mm, 20-45% of high iron magnesia sand with granularity of less than 0.088mm, 4-35% of magnalium spinel with granularity of not more than 5mm, and 2-4% of bonding agent. The preparation method comprises the following steps of: weighing the raw materials, wet milling, shaping, drying and sintering; drying the brick blank for 8-24h at the temperature of 110-160 DEG C; heating to the temperature of 1600-1700 DEG C; warming for 3-12h at the temperature of 1600-1700 DEG C and taking out. The product comprises the main components of 73-95% of MgO, 3-15% of Al2O3 and 2-12% of Fe2O3. The mafic-magnalium compound spinel brick has good product performance, high load softening temperature, high pressure resistance intensity, good thermal shaking stability and good alkali corrosion resistance, and is an ideal material for cement kiln high temperature belts. The mafic-magnalium compound spinel brick can substitute the current magnesia-chromite fire-proof material and is a new environmentally-friendly alkali fire-proof material.

Owner:河南瑞泰耐火材料科技有限公司

High-strength steel fibre castable

The invention discloses a high-strength steel fibre castable which is prepared by the following raw materials in parts by weight: 2.5 parts of bauxite material with the granularity of 8-5mm, 2.3 parts of bauxite material of which the granularity is more than 0.075mm and is less than 5mm, 2 parts of brown aluminium oxide particle material with the granularity of 3-1mm, 0.8 part of bauxite material of which the granularity is less than or equal to 0.075 mm, 0.4 part of alumina submicron powder of which the granularity is less than or equal to 0.025 mm, 0.6 part of carborundum powder of which the granularity is less than or equal to 0.075 mm, 0.3 part of silica micropowder of which the granularity is less than 0.019 mm, 0.6 part of CA-70 cement, 0.5 part of brown aluminium oxide powder of which the granularity is less than 0.053 mm, 0.2 part of No. 446 heat-resistant steel fiber, 0.02 part of anti-explosion steel fiber, sodium tripolyphosphate accounting for 0.1% of total material weight and sodium hexametaphosphate accounting for 0.08% of total material weight. The product has high compression strength, high breaking strength, high refractoriness under load and favorable thermal shock resistance stability, has the characteristic of microdilatancy at high temperature and has the advantages of favorable wear-resisting property and the like.

Owner:郑州真金耐火材料有限责任公司

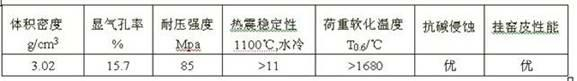

Periclase-hercynite refractory material and preparation method thereof

The invention relates to a periclase-hercynite refractory material and a preparation method thereof. The adopted technical scheme comprises the following steps: mixing 80 to 98wt% of magnesia and 2 to 20wt% of hercynite-corundum composite material, adding a binding agent accounting for 3 to 8wt% of the mixture, uniformly stirring raw materials, and molding through mechanical pressing; then dryingthe molded billet for 8 to 36 hours under the condition of 110 DEG C, then sintering under the condition of 1450 to 1650 DEG C, and preserving heat for 4 to 15 hours to obtain the periclase-hercyniterefractory material. The prepared product has the main phases of periclase and hercynite, contains a small amount of magnesia-alumina spinel and is the periclase-hercynite refractory material which not only has higher kiln crust adhesiveness, higher refractoriness and good anticorrosion capability of alkali, sulfur, chlorine, clinkers and the like, but also has higher loading softening temperature, higher high-temperature strength and better thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH

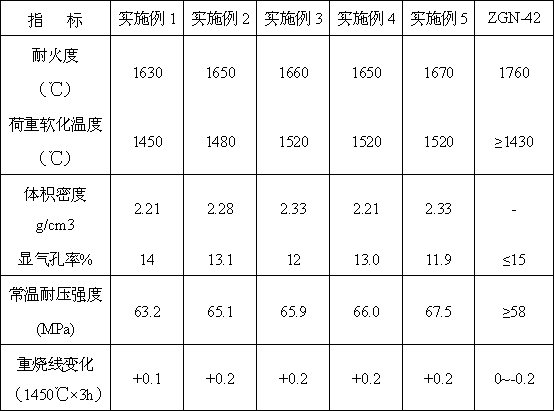

Aluminum oxide hollow sphere light insulating brick and preparation method thereof

The invention relates to an aluminum oxide hollow sphere light insulating brick and a preparation method thereof. The technical scheme of the method comprises the steps of mixing 45-55wt% of aluminum oxide hollow sphere, 30-45wt% of Al2O3 micro powder, 6-13wt% of Rho-Al2O3 micro powder with 3-6wt% of silicon micro powder, additionally adding 5-15wt% of organic polymer fine powder and 20-30wt% of water according to the weight percentage of the mixture, evenly stirring, and molding in a pouring way, maintaining for 24-48h under the condition of room temperature, demolding, drying for 20-36h under the condition of the temperature being 100-120DEG C, and keeping the temperature under the condition of 1600-1700DEG C. The method is simple in technology and low in cost. The aluminum oxide hollowsphere light insulating brick prepared by the method is characterized by being low in volume density, low in heat conductivity, high in compression strength, high in use temperature, good in insulating effect, high in load softening temperature, and low in heavy firing line change rate.

Owner:WUHAN UNIV OF SCI & TECH

Pyrophyllite brick and preparation method thereof

The invention belongs to semi-silica refractory materials, and in particular relates to a pyrophyllite brick and a preparation method thereof. The pyrophyllite brick is prepared by mixing a pyrophyllite raw material, a pyrophyllite clinker, clay, an additive and a binding agent, and performing the processes of material preparing, aging, shaping, drying and sintering. The pyrophyllite brick prepared by the method has the characteristics of high load softening temperature, stable volume and slight expansion at an operating temperature, and can ensure that a brickwork is compact in structure, small in brickwork joint and good in integrity; and meanwhile, when the pyrophyllite brick is in contact with slag, because a high-viscosity liquid-phase 'enamel layer' formed on the surface, the pyrophyllite brick can block up slag infiltration, and the erosion resistance of the pyrophyllite brick is improved.

Owner:宜兴新威利成耐火材料有限公司

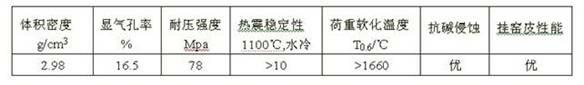

Pleonaste-hercynite bricks and preparation method thereof

The invention relates to pleonaste-hercynite bricks and a preparation method thereof. The pleonaste-hercynite bricks are prepared from the following raw materials in percentage by weight: 55 to 98 percent of high-iron magnesia with a particle size of less than or equal to 5 millimeters, 2 to 45 percent of hercynite with a particle size of less than or equal to 5 millimeters and 2 to 4 percent of binding agent. The preparation method comprises: weighing raw materials; rolling wet materials; forming; drying; firing; drying the fired bricks at 110 to 160 DEG C for 8 to 24 hours; heating the bricks to 1,550 to 1,700 DEG C; keeping the temperature for 3 to 15 hours; and taking the bricks out of kiln. The pleonaste-hercynite bricks have high performance, high refractoiness under load, high thermal shock resistance, high alkaline corrosion resistance and high kiln-crust sticking performance, are free from hydration and easy to transport, are ideal materials for the high-temperature zone of acement kiln and can be used in place of the conventional magchrome refractory material.

Owner:河南瑞泰耐火材料科技有限公司

Special type composite low alumina mullite brick and preparation method thereof

The invention discloses a special type composite low alumina mullite brick which is prepared by raw materials by weight percent: 10-30% of mullite with granularity of 3-1mm, 20-40% of flint clay with granularity of 3-1mm, 10-20% of flint clay with granularity of 1-0mm, 5-15% of flint clay with granularity of -200 meshes, 10-30% of sillimanite or andalusite, and 15-25% of additive. The materials weighed according to the mixture ratio are mixed and ground, processed by ageing, extruded to be molded, dried and finally sintered, so that the special type composite low alumina mullite brick can be obtained. The special type composite low alumina mullite brick has the advantages of low apparent porosity and impurity, high strength and refractoriness under load, micro-expanded product, high mullite phase and the like, and has the function of one brick for multiple purposes. The application of the special type composite low alumina mullite brick can save a great deal of maintenance costs and energy conservation cost for steel users, thus having remarkable social and economic benefits.

Owner:GONGYI WINNA SCI & TECH DEV

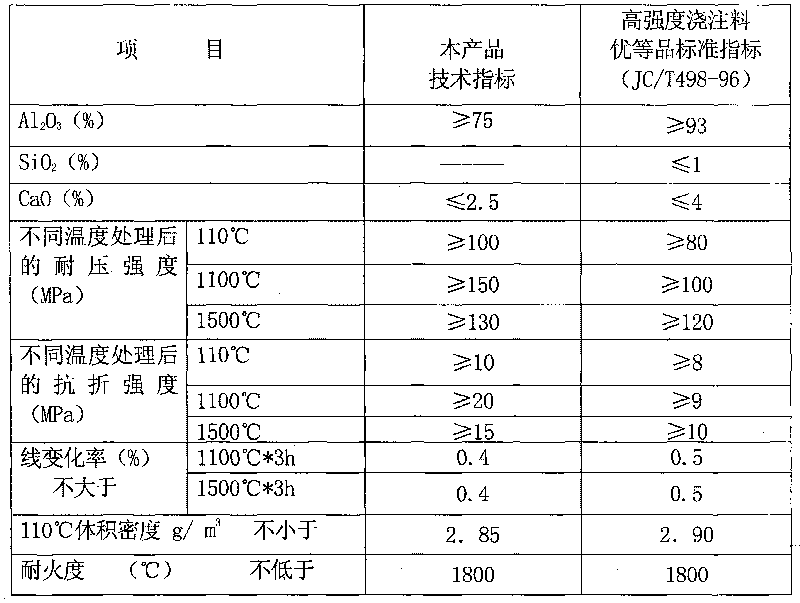

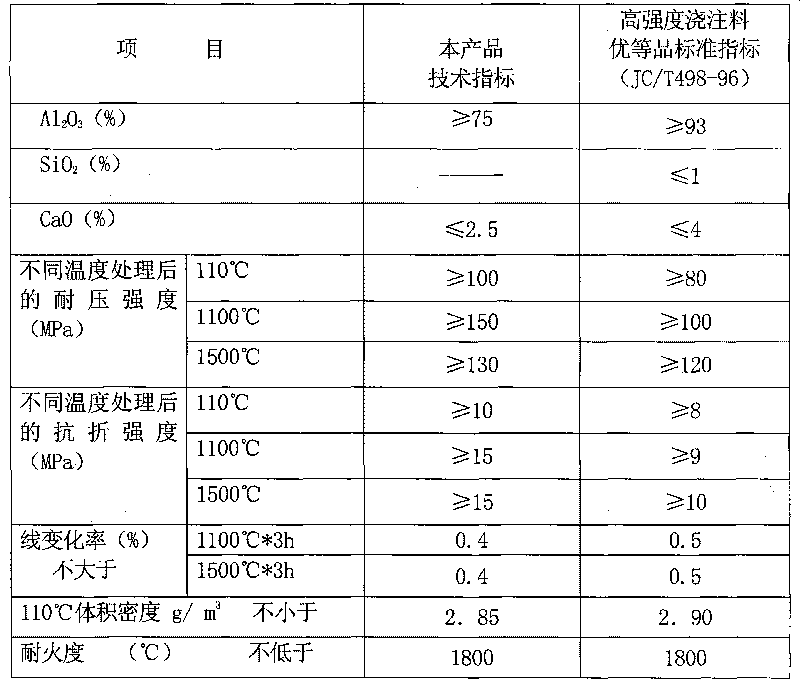

High-strength castable

The invention discloses a high-strength castable, which is prepared from the following raw materials in part by weight: 4.8 parts of bauxite aggregate, 2 parts of brown aluminium oxide granules, 0.8 part of bauxite powder, 0.4 part of alumina super-micro powder, 0.6 part of silicon carbide powder, 0.3 part of silicon micro powder, 0.6 part of CA-70 cement, 0.5 part of brown aluminium oxide powder, sodium tripolyphosphate accounting for 0.1 percent of weight of the total material, and sodium hexametaphosphate accounting for 0.08 percent of the weight of the total material. The castable has the advantages of high compression strength, high breaking strength, high load softening temperature, good thermal shock resistant stability, micro-expansion property at high temperature, good abrasion resistance and the like; the cost is reduced by about two fifth compared with that of the conventional high-strength castable; and the castable can be widely applied to kilns of cement kiln eyes, pre-heaters, grate coolers and the like with high strength requirement and severe using conditions, and is an ideal new product for replacing a high-strength corundum castable.

Owner:郑州真金耐火材料有限责任公司

Periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. according to the technical scheme, 75-95wt% of periclase-magnesium aluminate spinel composite material, 4-20wt% of magnesite and 0.5-5wt% of magnesium aluminate spinel are mixed together to obtain a mixture; a binder accounting which is 3-8wt% of the mixture is added to the mixture and mixed evenly, and then the final mixture is mechanically pressed and formed; the formed blank is dried at 110 DEG C for 8-36 hours and then fired at 1500-1650 DEG C, and furthermore, heat is preserved for 4-15 hours, and finally, the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is obtained. The preparation method of the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is simple; the periclase-magnesium aluminate spinel refractory material prepared has the characteristic of controllable distribution of magnesium aluminate spinel, and also the characteristics of good coating formation property, good thermal shock resistance and high medium erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

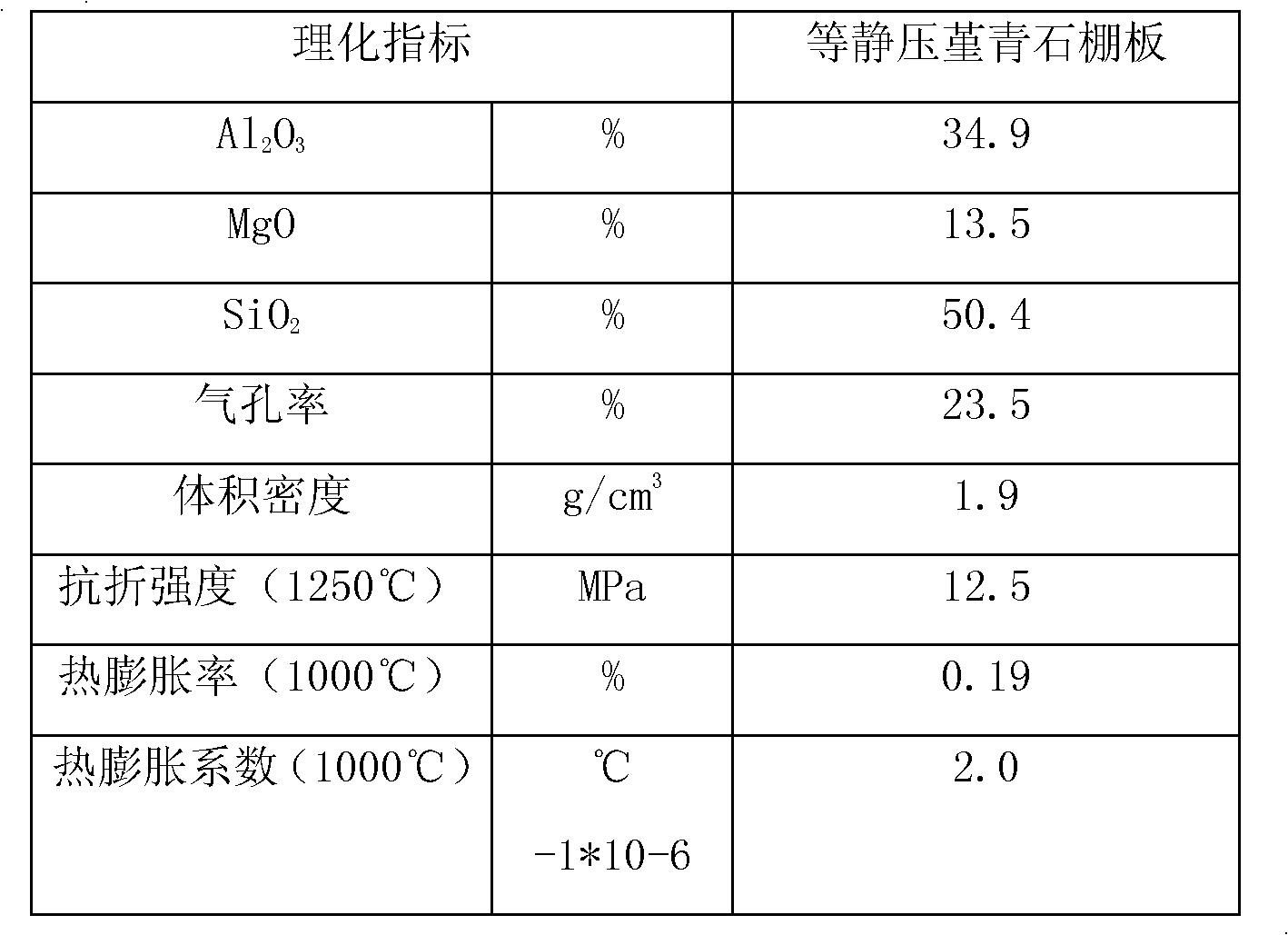

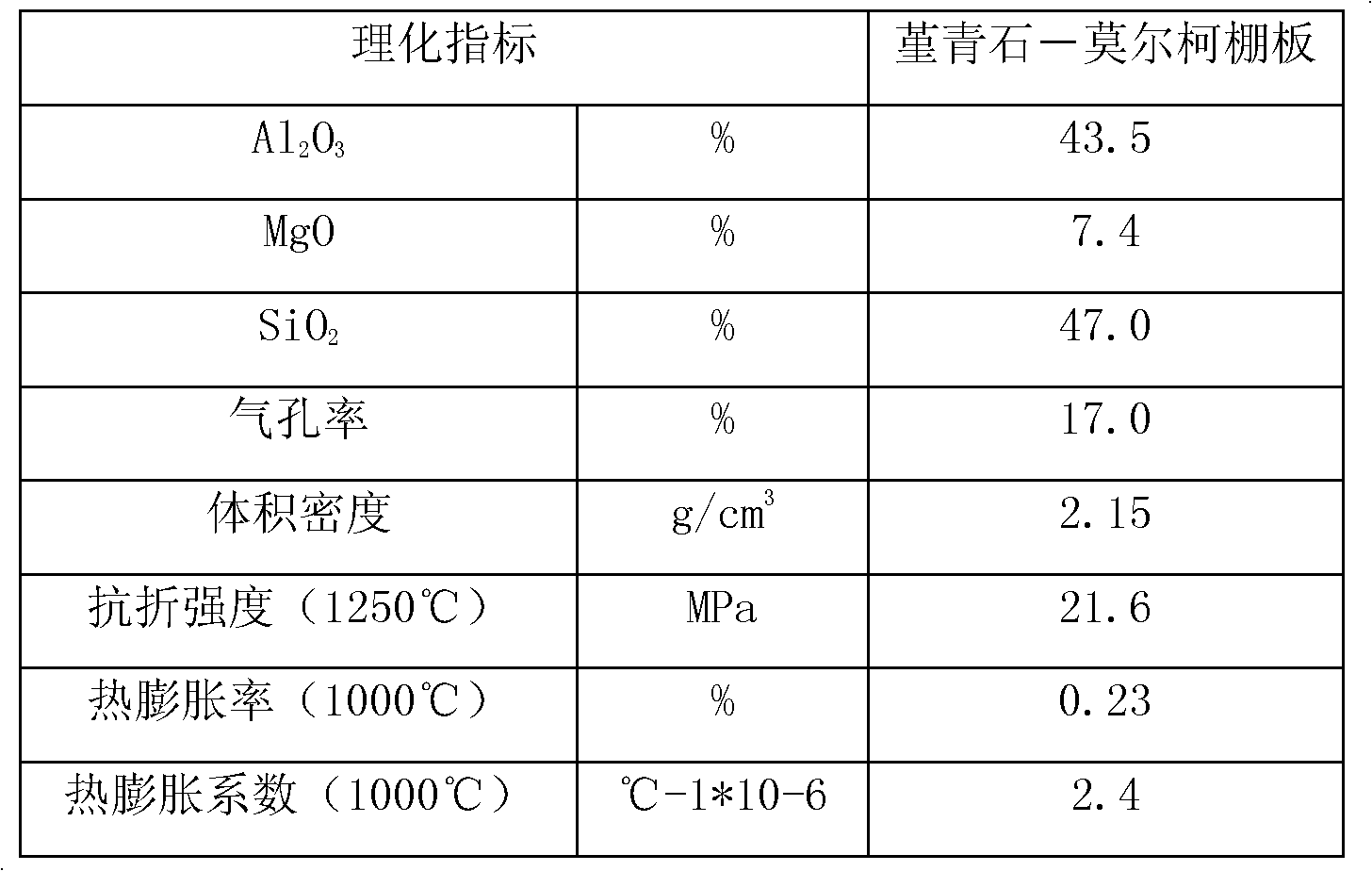

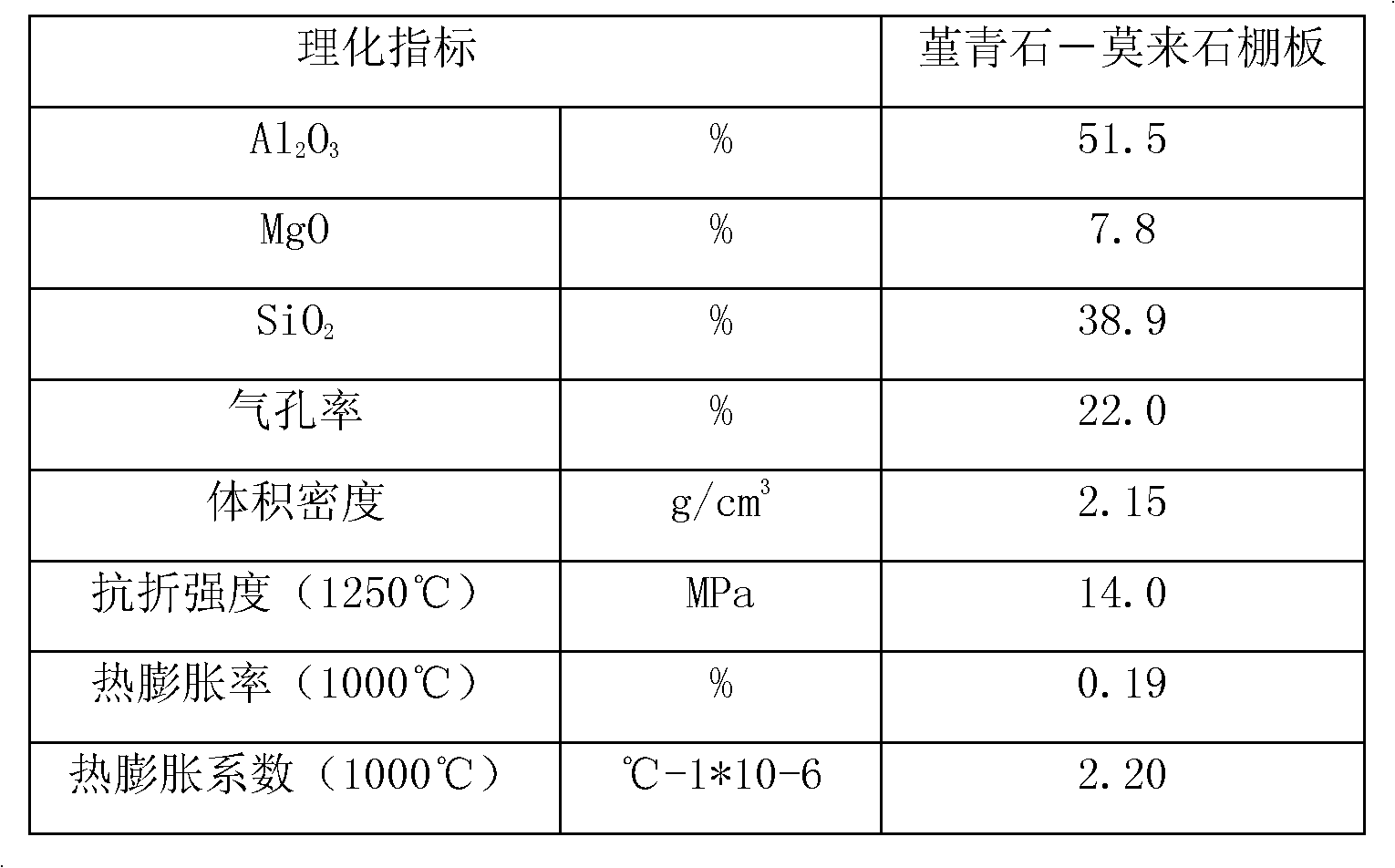

Method for preparing refractory shed plate

InactiveCN102153349AHigh softening temperature under loadHigh temperature strengthCollocationRefractory

The invention relates to a method for preparing a refractory shed plate, belonging to the technical field of refractory materials. The method comprises the steps of dosing, molding and sintering; coarse and fine material collocation; isostatic pressing and high temperature sintering. In the preparing process, the product has the advantages of difficulty in cracking and deformation, high production efficiency, high yield and low manufacturing cost; and the prepared product has the advantages of uniform organization structure, no internal crack, high strength at high temperature, high refractoriness under load, good thermal shock resistance and long service life; and kiln furniture consumption is largely reduced.

Owner:ZIBO GT INDAL CERAMICS

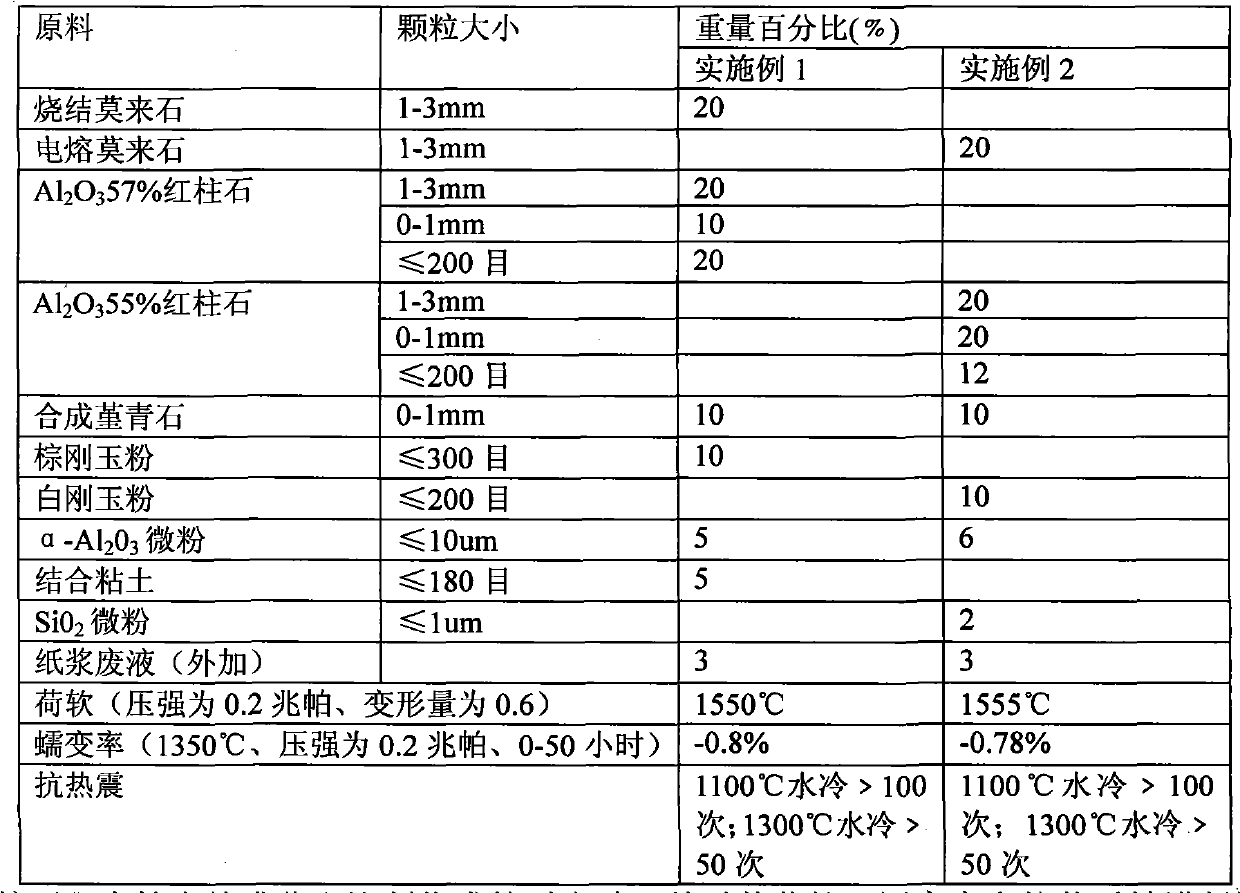

High purity andalusite brick for high blast temperature and long time type hot blast stove and preparation method thereof

The invention discloses a high pure andalusite brick for an air heating furnace with high blast temperature and long service life, and a preparation method thereof. The high pure andalusite brick is prepared by the following steps: andalusite, sillimanite sand, activated alumina powder and kaolin are taken as raw materials, andalusite powder, the activated alumina powder and kaolin powder which have the raw material particle size of between 0.088 and 0 mm are premixed into powder first, then the remaining particle materials, sulphite liquor and the prepared powder are mixed evenly to produce pug, the produced pug is pressed into a green brick, and the green brick is transferred into a high-temperature tunnel kiln for calcination to obtain a product. As a refractory material of a large-scale air heating furnace, the product has low creep rate and good thermal shock stability during use, and can apparently improve the blast temperature and the service life of the air heating furnace, thereby saving a large amount of maintenance cost and energy-saving cost for iron and steel users, and obtaining remarkable social and economical benefits.

Owner:GONGYI TONGDA ZHONGYUAN REFRACTORY TECH

Prefabricated member for lime rotary kiln and preparation method of prefabricated member

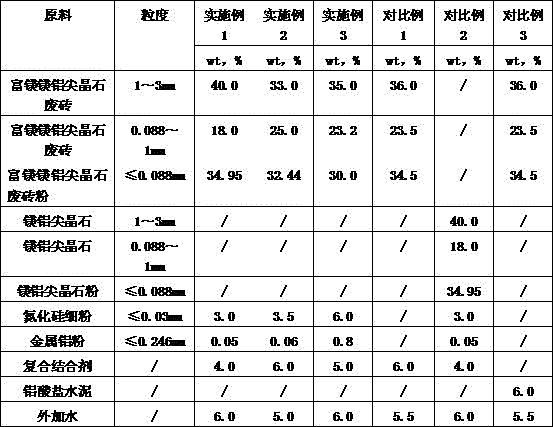

The invention discloses a prefabricated member for a lime rotary kiln adopting magnesium-rich magnesium-aluminum spinel waste bricks as main raw materials and a preparation method of the prefabricated member. The invention adopts a technical scheme as follows: the prefabricated member is prepared from the following components in percentage by weight: 35 to 40 percent of 1 to 3 mm magnesium-rich magnesium-aluminum spinel waste bricks, 18 to 25 percent of 0.088 to 1 mm magnesium-rich magnesium-aluminum spinel waste bricks, 30 to 35 percent of magnesium-rich magnesium-aluminum spinel waste bricks less than or equal to 0.088 mm, 3 to 6 percent of silicon nitride fine powder less than or equal to 0.03 mm, 0.05 to 1 percent of metal aluminum powder less than or equal to 0.246 mm, and 4 to 6 percent of composite binding agent; and the added water accounts for 5 to 6 percent of the total weight of the main raw materials; the composite binding agent is prepared from 20 to 40 weight percent of silica powder and 60 to 80 weight percent of aluminate cement, wherein the weight percentage content of SiO2 in the silica powder is more than or equal to 93 percent, and the weight percentage content of Al2O3 in the aluminate cement is more than or equal to 68.75 percent. The preparation method comprises the steps of crushing, screening, grinding, burdening, forming, drying, heat treatment and the like. The prefabricated member adopts the waste bricks as the main raw materials, so that the price is low; and by introducing silicon nitride, the metal aluminum powder and the composite binding agent, the performance and the quality of the prefabricated member can be remarkably improved.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

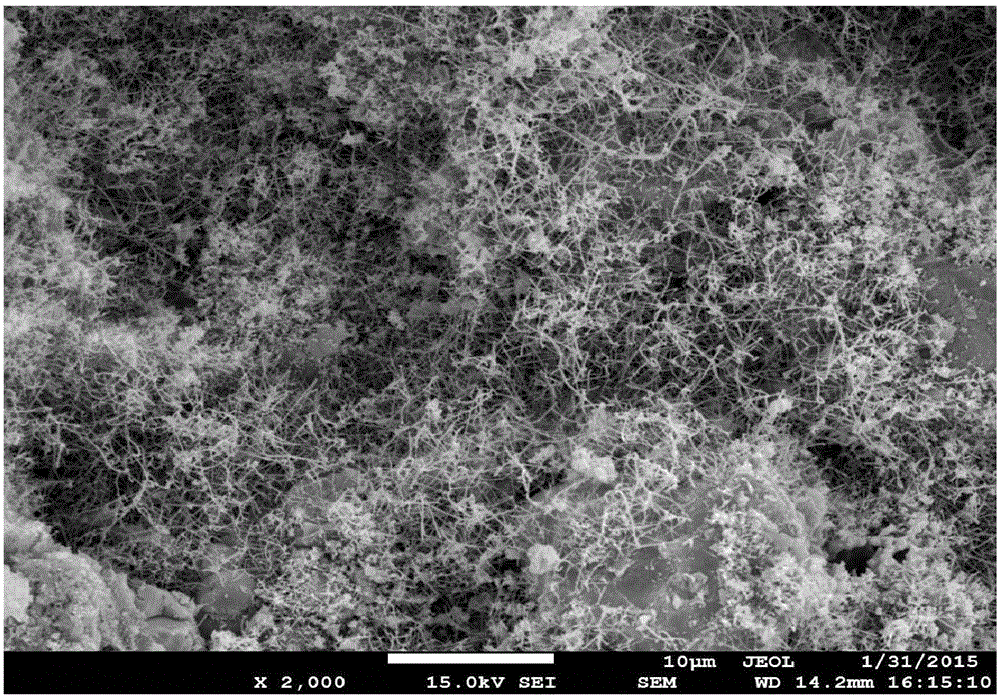

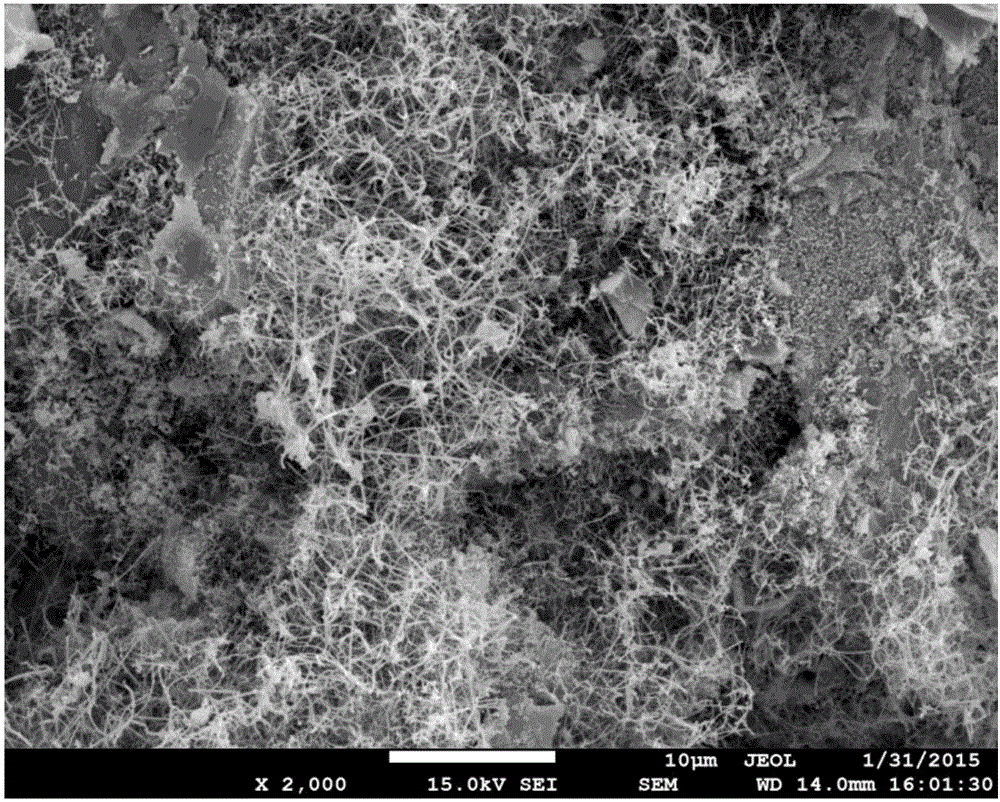

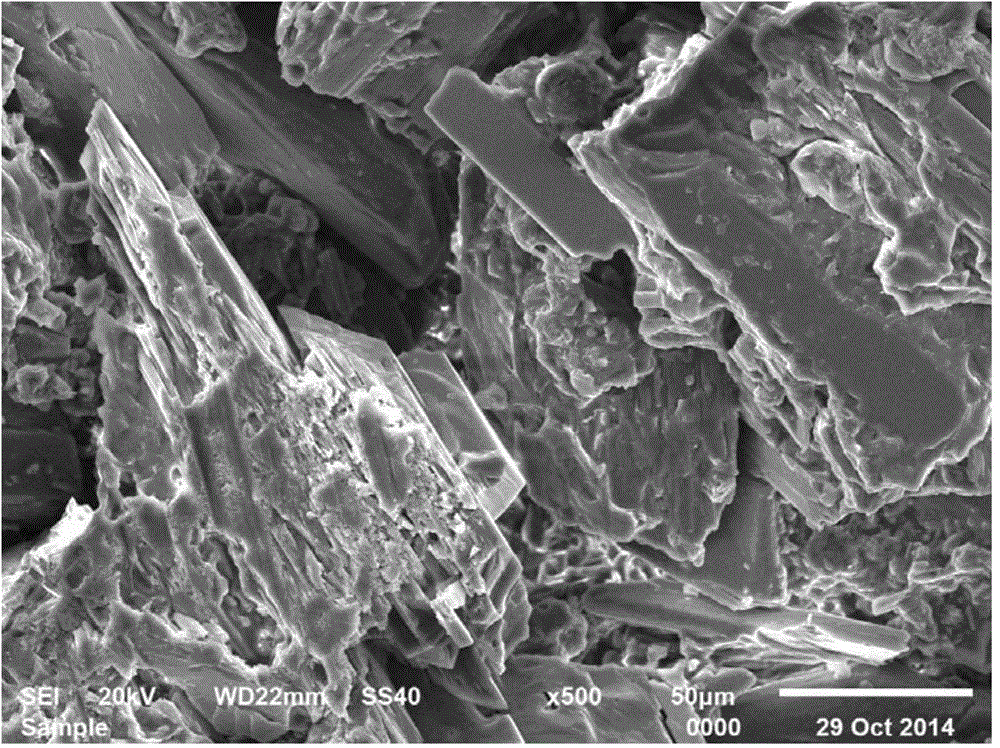

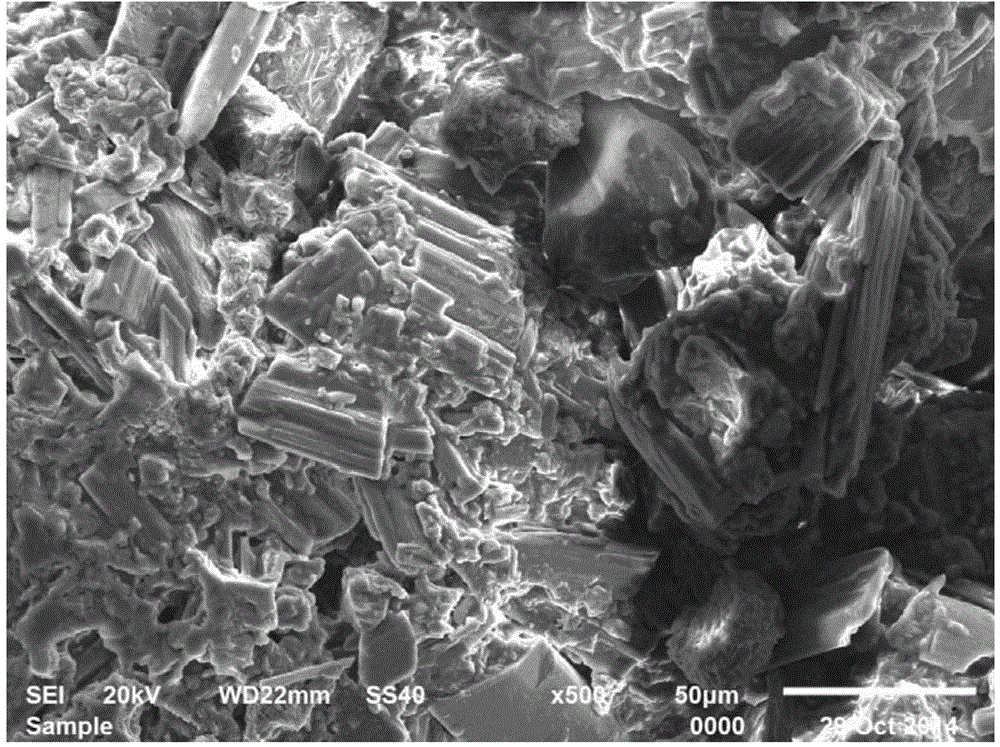

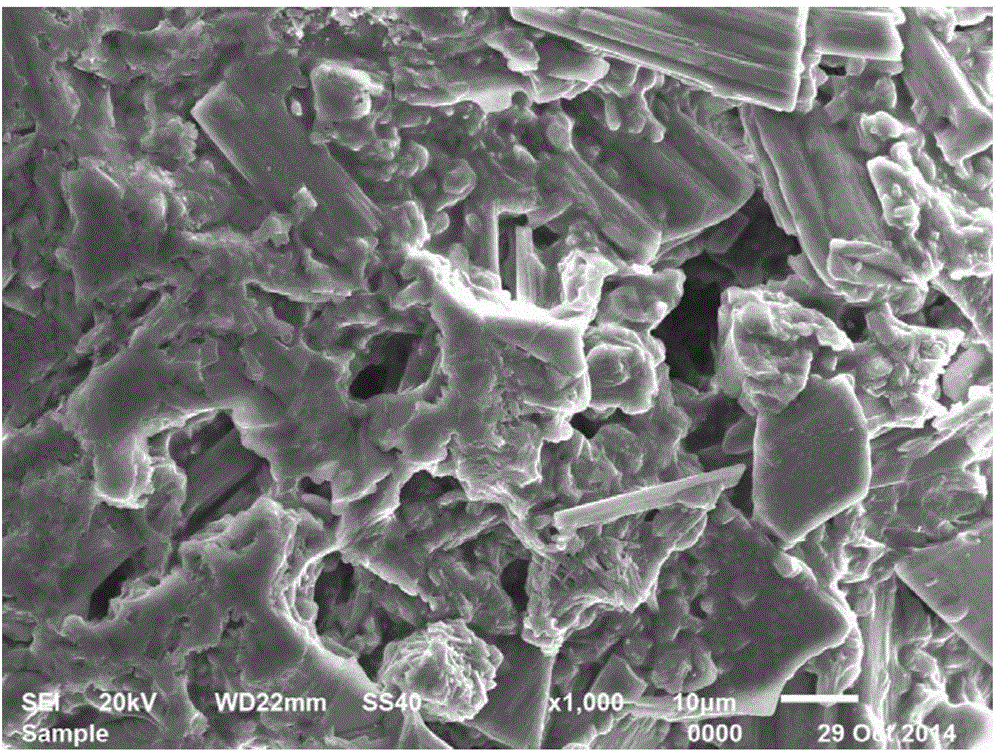

Silicon carbide whisker in-situ composite corundum high-temperature ceramic material and preparation method thereof

The invention discloses a silicon carbide whisker in-situ composite corundum high-temperature ceramic material and a preparation method thereof, and belongs to the technical field of high-temperature ceramic materials. The silicon carbide whisker in-situ composite corundum high-temperature ceramic material is prepared from a composite raw material and a binder, wherein the composite raw material is prepared from the following raw materials in percentages by weight: 82-91.5% of alundum powder, 7-15% of carbonized rice husk powder, 0.5-2% of a catalyst and 0.2-1% of silica micro-powder or silicon powder; and the mass of the binder is 3-5% of total mass of the composite raw material. The used raw materials are low in price and wide in source; the preparation technology is simple; and the prepared product has the advantages of being good thermal shock resistance, high in high-temperature strength and good in volume stability and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

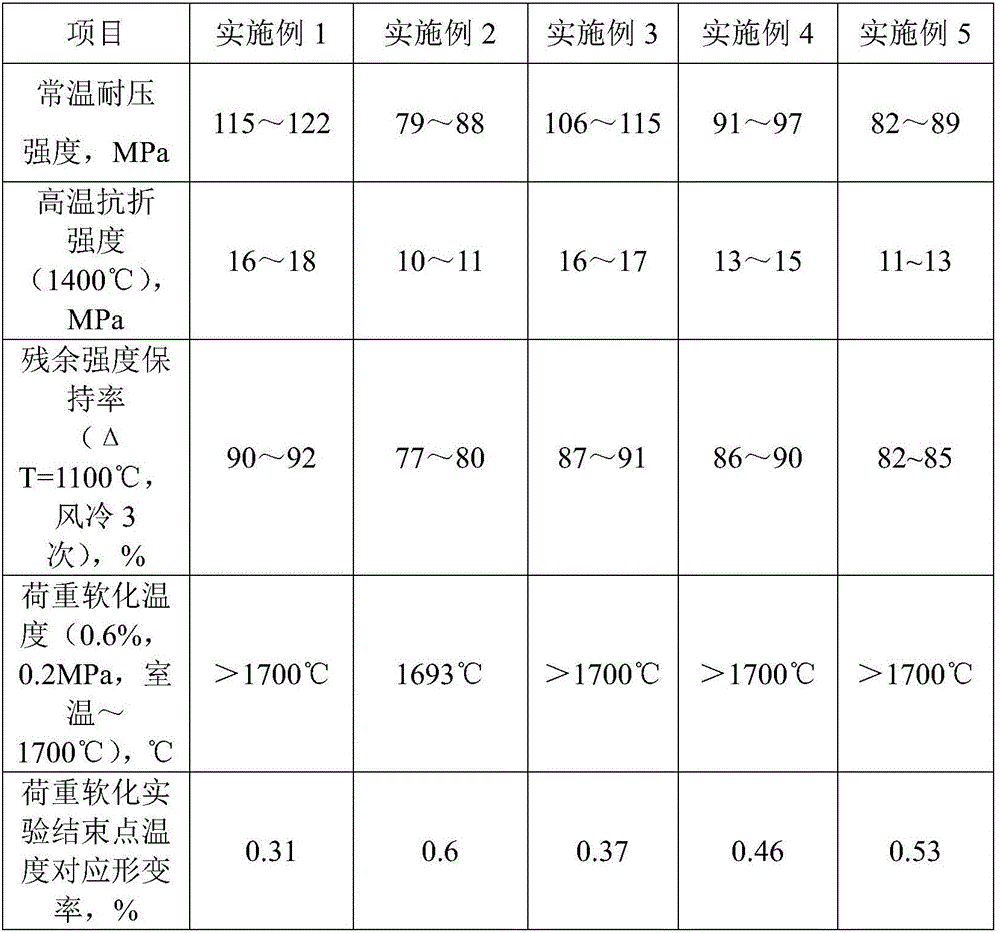

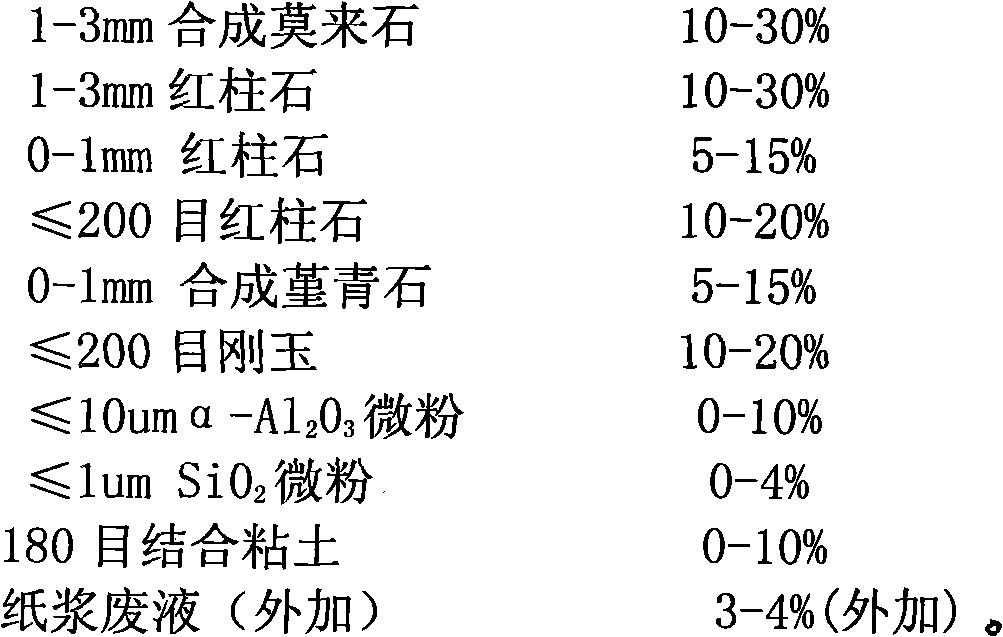

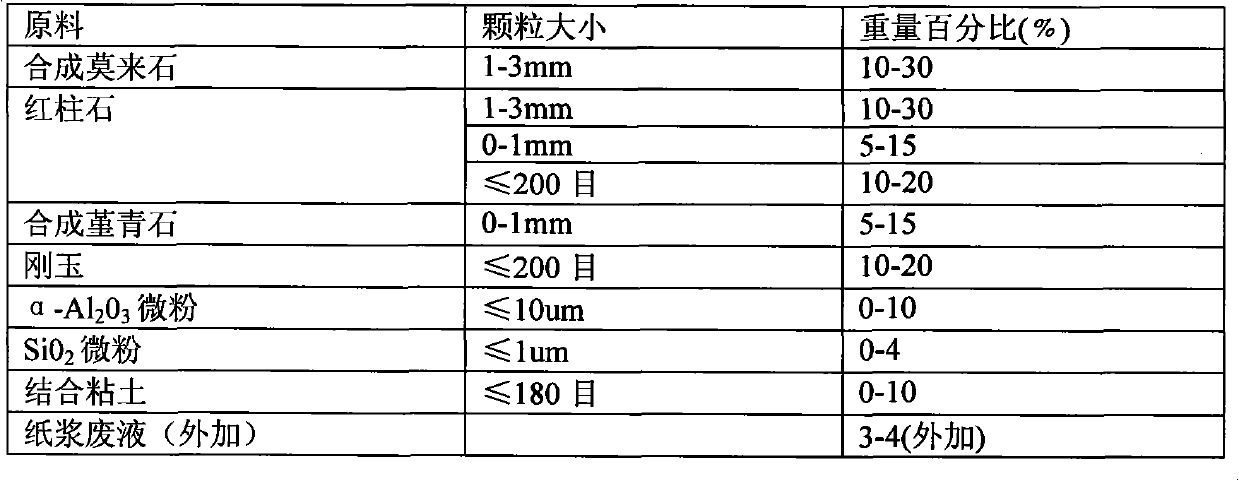

High-stress-strain low-creepage high-thermal-shock-resistance refractory brick and manufacturing method thereof

The invention discloses a manufacturing method of a refractory brick. According to the manufacturing method, low-and-medium-grade andalusite (the contents of Al2O3 are 53%, 55% and 57%) are used as main raw materials, large and intermediate andalusite particles are replaced with large mullite particles and intermediate cordierite particles, and corundum, alpha-Al2O3 micropowder and SiO2 micropowder and combining clay and waste paper pulp are added. The preparation method comprises the following steps of: mixing the ingredients in a wet pan mill evenly and then discharging out of the mill; forming by a frictional brick press; drying the formed green blanks in a dryer; calcining the dried blanks in a calcining kiln, wherein the highest calcining temperature ranges from 1370DEG C to 1400DEG C. The refractory brick obtained by adopting the method can effectively solve the problems of the conventional refractory brick, such as high manufacturing cost, low load softness, large creepage, poor anti-seismic property and short service life; the appearance defects of the refractory brick are fewer, and the refractory brick can be widely applied in a ceramic burner of an ironmaking blast-furnace hot blast stove.

Owner:ZHENGZHOU ANNEC IND

Zirconium mullite red brick and preparation technology thereof

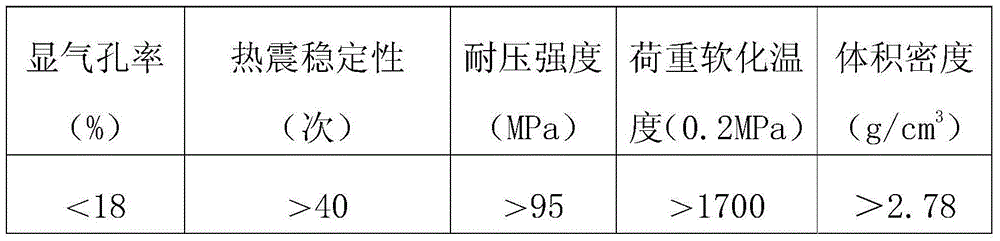

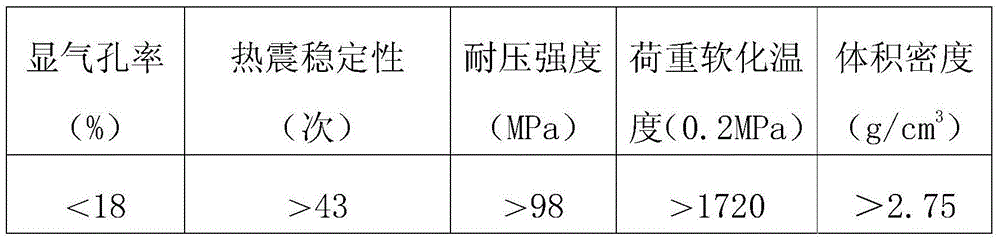

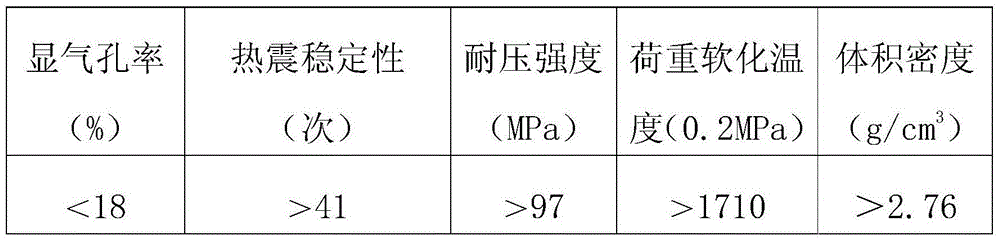

The invention relates to a refractory material, in particular to a zirconium mullite red brick and a preparation technology thereof. According to the zirconium mullite red brick provided by the invention and a product prepared due to the adoption of the preparation technology, a refractory brick is prepared by adding a phosphoric acid solution; according to the refractory brick, the temperature of a kiln shell can be effectively reduced, the refractory brick is long in service life, resistant to abrasion and high in anti-erosion ability, and particularly the times of thermal shock resistance reach more than 40; the operating temperature range of the product is between 1400 DEG C and 1550 DEG C, and the maximum allowable temperature is 1600 DEG C; at a high-temperature operating state, the product has high strength, erosion resistance, high-wearing feature, high thermal shock resistance, low heat conductivity coefficient and higher refractoriness under load.

Owner:ZHEJIANG RUITAI REFRACTORY TECH

High-strength thermal-shock-resistant refractory brick

The invention discloses a high-strength thermal-shock-resistant refractory brick. The high-strength thermal-shock-resistant refractory brick is characterized by being prepared from the following raw materials in parts by weight: 16-20 parts of fused corundum powder, 12-16 parts of tabular corundum, 48-52 parts of aluminum oxide micro powder, 2-6 parts of magnesia fine powder, 2-6 parts of zirconium dioxide powder, 1-4 parts of silicon carbide, 1-4 parts of silica powder, 2-6 parts of sodium silicate, 2-6 parts of andalusite powder, 1-2 parts of a titanium boride additive, 5-15 parts of sillimanite fine powder, 5-8 parts of Guangxi clay, 10-15 parts of waste iron trough materials and 10-15 parts of waste silicon mullite bricks. The material proportion of the refractory brick is optimized, and the refractory brick is good in high temperature resistance, corrosion resistance and thermal shock resistance, improves refractoriness under load, is not liable to have cracks and damages in use, and prolongs the service life.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

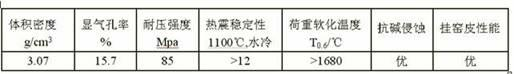

Fireproof product for cement rotary kiln transition belt

InactiveCN1919797AImprove performanceHigh compressive strength at room temperatureCement rotary kilnCoesite

The invention discloses a fireproof composition product of cement rotary kiln transmitting belt through dried method, which comprises the following parts: 50-79% alumina clinker aggregate with Al2O3 not less than 90% and bulk density not less than 3.0g / cm3, 5-20% silicon carbide, 3-15% clay with Al2O3 not less than 32%, 3-15% alumina, wherein the silicon carbide, clay and alumina are added at 0.1-10mm fined powder pattern, which possesses 63-75% Al2O3,8-32.5% SiO2 and 4.5-19% SiC for sintered components.

Owner:YIXING REFRACTORY EQUIP & MATERIAL FACTORY

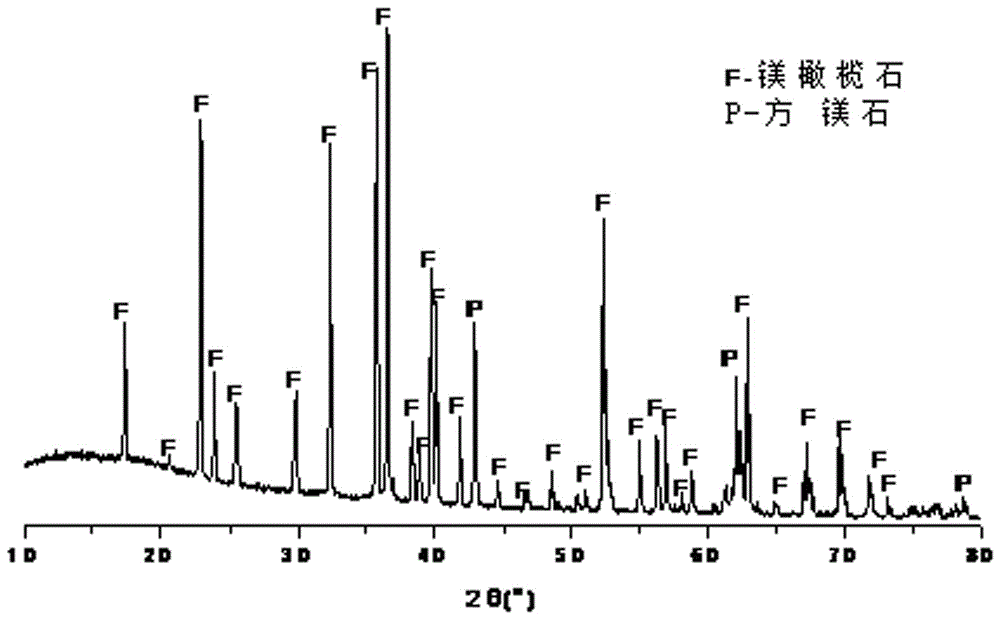

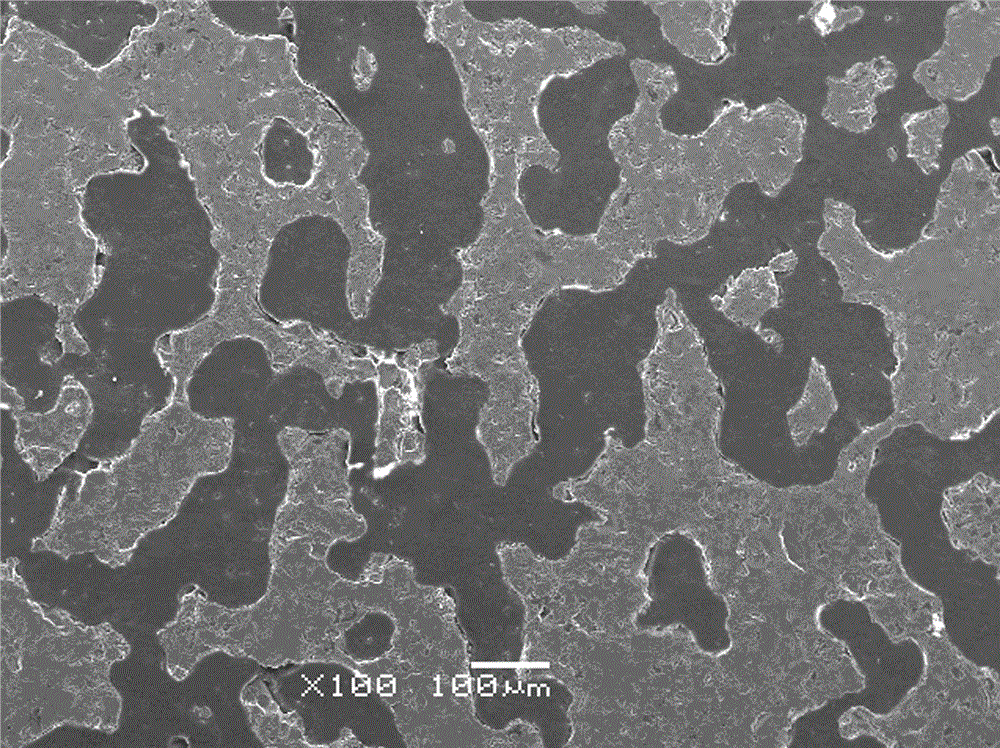

Porous periclase-forsterite multiphase material and preparation method thereof

InactiveCN106431435AHigh softening temperature under loadVolume stabilityCeramicwareThermal insulationPericlase

The invention relates to a porous periclase-forsterite multiphase material and a preparation method thereof. The method comprises steps as follows: 48wt%-85wt% of a magnesium oxide raw material and 15wt%-52wt% of a silicon dioxide raw material are evenly mixed to form a mixed raw material, an additive accounting 3wt%-12wt% of the sum of mass percentages of raw materials is added, mixed mud is obtained after even stirring and poured in a mold to be mechanically pressed under 80-130 MPa, a blank is obtained, baked at 100-180 DEG C for 3-10 h and calcined at 1,500-1,750 DEG C for 1-16 h in a high-temperature furnace, and the porous periclase-forsterite multiphase material is prepared. A sintering in-situ pore forming technology is adopted, the production process is pollution-free, and the obtained product has the characteristics of high refractoriness under load, stable size, staggered pore structure, good thermal insulation effect and capability of being used at the high temperature of 1,500-1,700 DEG C for a long time.

Owner:ZHENGZHOU UNIV

Silicon oxide refractory castable and using method thereof

The invention discloses a silicon oxide refractory castable and a using method thereof. The castable consists of aggregate, powder, a coagulant and an external binding agent, wherein the aggregate consists of calcined silica, scrap for a waste silica brick recyclable material and a mixture of the calcined silica and the scrap, and the total amount accounts for 60-70 percent of the sum of mass of the aggregate and powder; the powder consists of calcined silica powder and silica powder or superfine quartz sand, and the total amount accounts for 30-40 percent of the sum of mass of the aggregate and powder; the coagulant is fettling magnesite grain powder, and the total amount accounts for 2-4 percent of the sum of mass of the aggregate and powder; and the external binding agent is an aqueous solution of phosphoric acid and aluminium dihydrogen phosphate, and the total amount respectively accounts for 3-5 percent and 8-12 percent of the sum of mass of the aggregate and powder. The silicon oxide refractory castable has high-temperature performances of high load softening temperature, high high-temperature strength, wide application temperature range, stable high-temperature size and excellent thermal shock resistance and is wide in raw material distribution, high in yield, low in cost and convenient to popularize and apply.

Owner:成都蜀冶新材料有限责任公司

Bauxite base slight expansion high-alumina brick for ladle and method for producing the same

InactiveCN101417883ASolve the problem that agglomeration is difficult to disperse and homogenizeImprove microstructureBrickSillimanite

The invention relates to a bauxite-based slight expansive high-alumina brick for ladles and a preparation method thereof and the material components and weight percentage are as follows: bauxite clinker between 5mm to 3mm accounting for 10 percent to 15 percent, bauxite clinker between 3mm to 1mm accounting for 20 percent to 30 percent, bauxite clinker between 1mm to 0mm accounting for10 percent to 20 percent, andanlusite less than 0.5mm accounting for 0 to 20 percent, sillimanite less than 0.088mm accounting for 0 to 15 percent, kyanite less than 0.2mm accounting for 0 to 10 percent, bauxite clinker less than 0.088mm accounting for 20 percent to 40 percent, Alpha-Al2O3 less than 320 mesh accounting for 0 to 5 percent and applied sulfurous acid paper pulp waste liquid accounting for 3 percent to 5 percent. The preparation method comprises the following steps: a. the bauxite clinker is crushed; b. the powders are magnetically selected; c. calendering is carried out on the bauxite clinker, the andanlusite, the sillimanite, the kyanite, the Alpha-Al2O3 and the applied sulfurous acid paper pulp waste liquid after mixing according to a ratio; d. the pug after calendering is shaped; e. the shaped pug is dried for 48hours; and f. the pug is sintered at the temperature of 1500 DEG C and the temperature is preserved for 6 to 8 hours. The preparation method can leads to the slight expansion of high-alumina bricks in use to avoid the flaking of bricks and the service life of bricks can be improved by 30 percent to 50 percent.

Owner:YANGQUAN XIAQIAN REFRACTORY MATERIAL

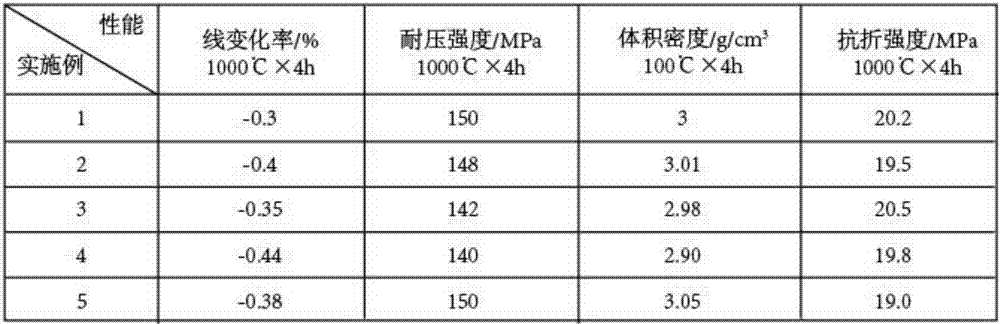

Preparation method of magnesium aluminate spinel brick

ActiveCN105837229AHigh compressive strength at room temperatureImproved thermal shock stabilityMagnesium AluminatePelletizing

The invention provides a preparation method of a magnesium aluminate spinel brick, wherein the preparation method comprises the specific steps: A, mixing evenly magnesia particles, a corundum fine powder and a binder, then granulating, carrying out heat treatment, and screening to obtain a material A and a material B; B, mixing a magnesia fine powder, a corundum fine powder, a magnesium aluminate spinel fine powder and a binder evenly, carrying out heat treatment, then crushing and screening to obtain a material C and a material D; C, mixing evenly the material A, the material B, the material C, the material D, a magnesium aluminate spinel fine powder, a magnesia fine powder, a corundum fine powder and a binder, and then carrying out heat treatment, to obtain the magnesium aluminate spinel brick. The method is beneficial for close contact of all kinds of raw material particles, but also makes full use of structural characteristics of materials at different temperatures; the prepared magnesium aluminate spinel brick has excellent characteristics of high room-temperature compressive strength, high thermal shock stability, high load softening temperature, and low reburning line change rate.

Owner:江苏诺明高温材料股份有限公司

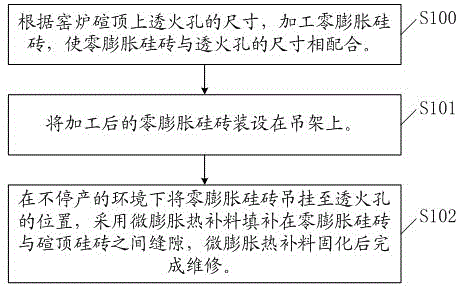

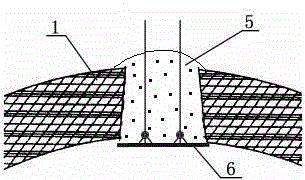

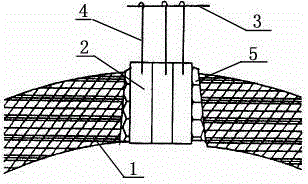

Method for maintaining crown of kiln

InactiveCN104556634ASolve the problem of difficult repair and sealingOvercome the Difficulties of Water Leakage and MeltingGlass furnace apparatusBrickComputer science

The invention discloses a method for maintaining a crown of a kiln. The method comprises the following steps: (1), processing zero inflated silica bricks according to the size of flame leaking holes on the top of the crown of the kiln, wherein the zero inflated silica bricks are matched with the flame leaking holes in size; (2), mounting the processed zero inflated silica bricks on a hanging bracket; and (3), under the environment of non-stop production, hanging the zero inflated silica bricks to the positions of the flame leaking holes, filling the gaps between the zero inflated silica bricks and the crown of the kiln by using a micro-inflated hot repairing mix and curing the micro-inflated hot repairing mix to accomplish maintenance. By adopting the method disclosed by the invention, the repair work can be directly carried out without stop production, corrosion and flake phenomena difficultly occur, and the method is simple to operate and the sealing property is good.

Owner:XINJIANG HUAXING GLASS

Fireproof material, preparation method thereof and fireproof brick

The invention provides a fireproof material. The fireproof material is prepared from the following components in percentage by mass: 48-62 percent of andalusite, 20-35 percent of sillimanite, 4-8 percent of aluminum oxide, 5-15 percent of corundum, 2-6 percent of combined clay, 1-3 percent of silica powder, 0.5-1.5 percent of paper pulp powder and 0.1-0.3 percent of a water reducing agent. In the fireproof material prepared from the high-purity andalusite and sillimanite, the high-purity corundum and the high-purity aluminum oxide are also added for strengthening a base material so that a main crystal phase mullite in the base material is columnar, long column-shaped or needle-shaped and a special network structure is formed; meanwhile, the needle-column-shaped mullite in the base material forms an interlaced network structure with the andalusite and the sillimanite, so the fireproof material disclosed by the invention is extremely good in thermal shock resistance and stability, relatively high in refractoriness under load (higher than 1700 DEG C) and relatively low in creep rate (0.125%). The invention also provides a preparation method of the fireproof material and a fireproof brick.

Owner:HUNAN XIANGGANG RUITAI TECH

Method for manufacturing silicon mullite brick by adopting bauxite tailings

The present invention particularly relates to a method for manufacturing a silicon mullite brick by adopting bauxite tailings so as to solve a problem of high raw material cost of the existing silicon mullite brick. According to the method for manufacturing the silicon mullite brick by adopting bauxite tailings, bauxite tailings is adopted to replace mullite with expensive cost to be adopted as a main raw material, and is matched with silicon carbide and other materials, and high-pressure molding and medium temperature firing are performed to obtain the silicon mullite brick. The method has characteristics of comprehensive resource utilization, energy saving and environmental protection. The obtained silicon mullite brick has advantages of high compressive strength at a room temperature and low cost, wherein a compressive strength of the product achieves 115-137 MPa, thermal shock resistance under a 1100 DEG C water cooling condition achieves 60-110 times, room temperature wear resistance achieves 9-13 cm<3>, and content, bulk density, apparent porosity, and refractoriness under load of alumina are higher than the national standards.

Owner:孝义市和中兴矿产有限公司

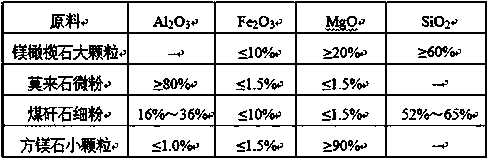

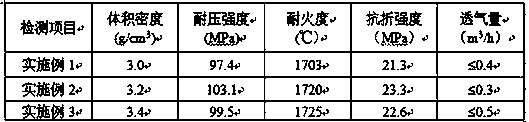

Quartz sand-containing fireproof brick and preparation method thereof

InactiveCN108017397AHigh softening temperature under loadImprove corrosion resistanceCeramicwareBrickMullite

The invention provides a quartz sand-containing fireproof brick, which comprises the following raw materials by mass: 19-27% of large-particle forsterite, 13-25% of small-particle periclase, 3-11% ofsulfamic acid fine powder, 14-29% of quartz sand, 9-28% of coal gangue fine powder, 15-27% of mullite micro-powder, 1-3% of a magnesia combustion aid, 0.5-2% of expanded graphite, 4-9% of a compositeanti-seepage agent, 1-4% of a composite binder, and the balance of paper pulp water. According to the present invention, the quartz sand-containing fireproof brick has advantages of reasonable component ratio, high corrosion resistance, good dimensional stability and high refractoriness under load. The invention further provides a preparation method of the quartz sand-containing fireproof brick, wherein the method has the simple steps, and is suitable for industrial production.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Erosion-resistant high-temperature refractory brick for waste liquid incineration and preparation method thereof

InactiveCN109251018AErosion effect is goodHigh softening temperature under loadThermal shockMolten slag

An erosion-resistant high-temperature refractory brick for waste liquid incineration includes the following materials by the weight percentage: 10-35% of 5 mm-3 mm tabular corundum particles, 20-98% of 3 mm-1 mm tabular corundum particles, 5-25% of 1 mm-0 mm tabular corundum particles, 20-98% of 320 mesh tabular corundum powder, 5-30% of 80 mesh zirconia, 2-15% of chromium oxide green and 2-13% ofhigh temperature alpha-alumina micro-powder. The erosion-resistant high-temperature refractory brick has the advantages of high load softening temperature, good thermal shock resistance, high corrosion resistance at room temperature and high temperature, good wear resistance, good thermal conductivity, and excellent resistance to waste liquid erosion, and is especially suitable for solution molten slag corrosion invasion of a high temperature melting furnace.

Owner:宜兴市海科耐火材料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com