Fireproof material, preparation method thereof and fireproof brick

A technology of refractory materials and granular materials, which is applied in the field of refractory materials, its preparation, and refractory bricks, can solve the problems of unsatisfactory creep resistance, unsuitable for industrial production, and high cost of mullite bricks, and achieve remarkable energy saving effects. The effect of saving maintenance cost, reducing material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

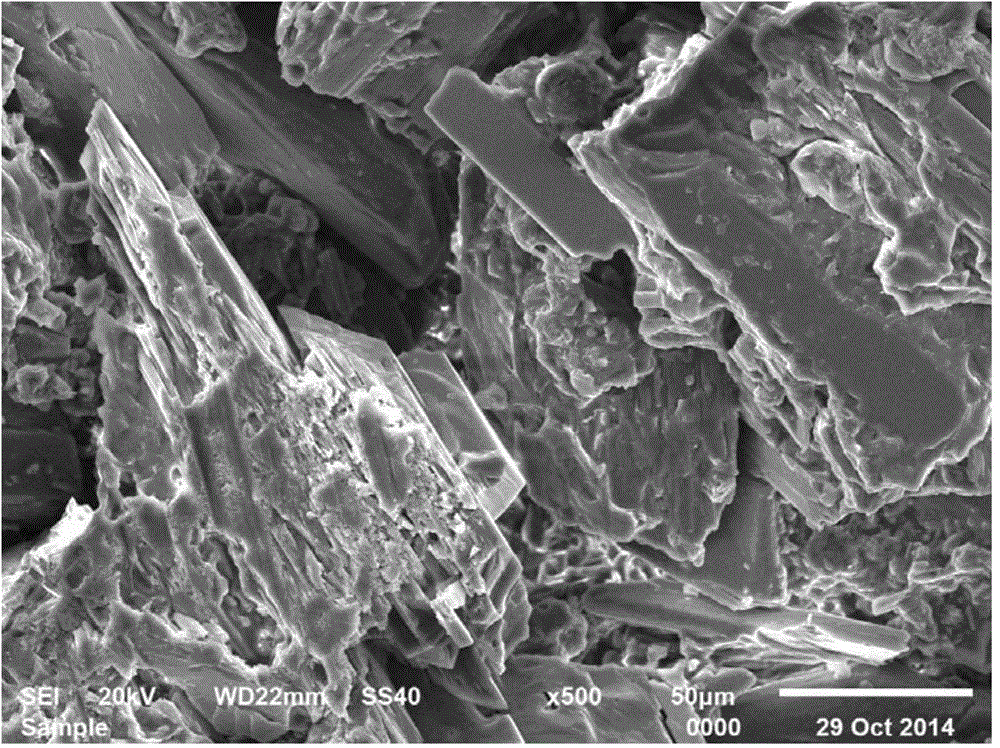

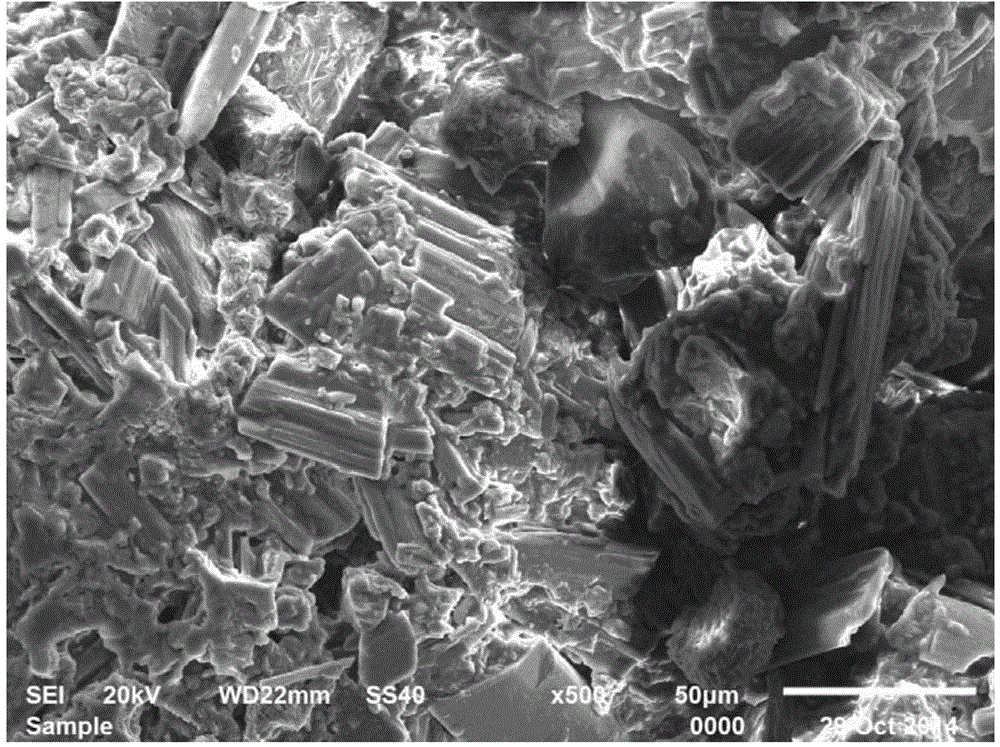

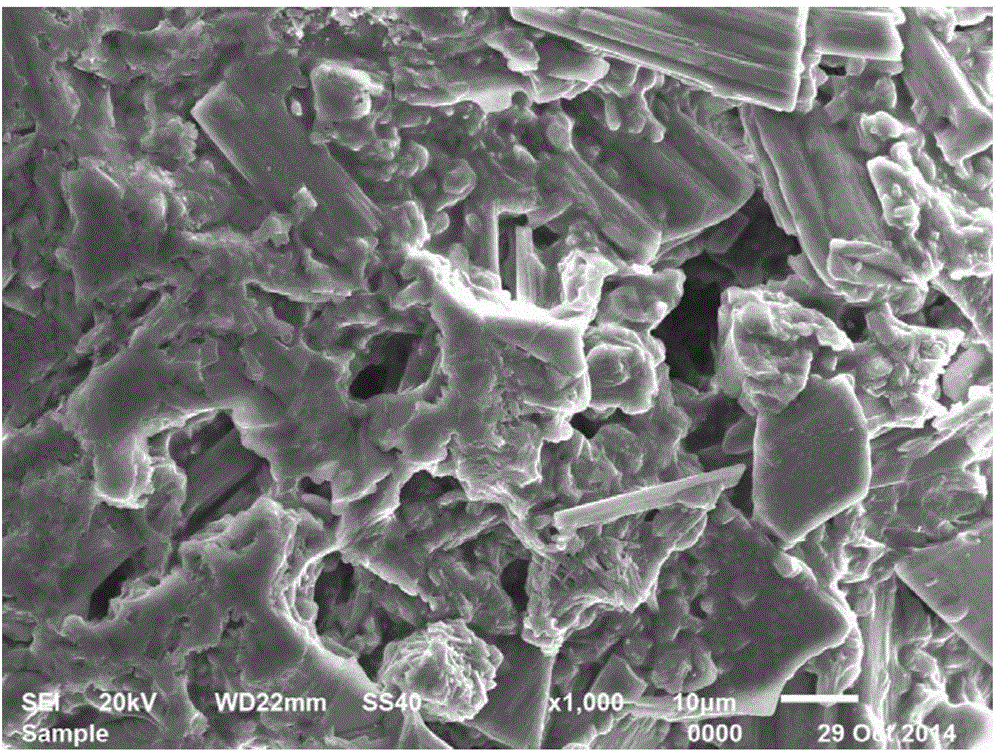

Image

Examples

preparation example Construction

[0042] The preparation raw material of the refractory material provided by the present invention includes andalusite, and the mass fraction of the andalusite in the preparation raw material is 48-62%, preferably 50-60%, more preferably 52-58%. In the present invention, the andalusite preferably includes a first andalusite granular material and a second andalusite granular material, and the particle size of the first andalusite granular material is preferably 3-1 mm, more preferably 2.5-1 mm. In the present invention, the particles with a wide particle size range are divided into several grades with a narrow particle size range. These grades are called particle grades. The particle size is 3mm, and the minimum particle size is 1mm; the particle size of the second andalusite granular material is preferably 1-0mm, more preferably 1-0.088mm; the first andalusite granular material and the second andalusite granular material The mass ratio of the materials is preferably (3-5):1, mor...

Embodiment 1

[0083] 13% sillimanite with a particle size of 0.2-0mm, 13.8% sillimanite with a particle size of 0.074-0mm, 5% calcined α-alumina, 7% tabular alumina and 3.5% Vero mud The premixing equipment is used for premixing, and the premixing time is 25 minutes. After premixing, the mixed materials are fully mixed and evenly mixed, and the premix is made after premixing;

[0084] 1.5% microsilica powder, 1.0% pulp powder, 0.2% sodium tripolyphosphate and 1.5% water are pre-milled together in a ball mill for 2 hours to make a slurry, and the grinding medium in the ball mill is sea pebbles;

[0085] After adding 44% andalusite particles with a particle size of 3-1mm and 11% andalusite particles with a particle size of 1-0mm into the forced sand mixer, first dry mix for 2 minutes, then add mud and wet mix for 2 minutes, and finally add Obtained premix, after net mixing for 20 minutes, obtains refractory material;

[0086] The obtained refractory material is pressed into adobe by a fric...

Embodiment 2

[0102] Put 13% sillimanite with a particle size of 0.2-0mm, 15.8% sillimanite with a particle size of 0.074-0mm, 5% activated α-alumina, 7% white corundum and 3.5% Vero mud into the pre- The mixing equipment is used for premixing, and the premixing time is 25 minutes. After premixing, the mixed materials are fully mixed and evenly mixed, and a premix is made after premixing;

[0103] 1.5% microsilica powder, 1.0% pulp powder, 0.2% sodium tripolyphosphate and 1.5% water are pre-milled together in a ball mill for 2 hours to make a slurry, and the grinding medium in the ball mill is sea pebbles;

[0104] After adding 42% andalusite particles with a particle size of 3-1mm and 11% andalusite particles with a particle size of 1-0mm into the forced sand mixer, first dry mix for 3 minutes, then add mud for wet mixing for 3 minutes, and finally add Obtained premix, after net mixing for 15 minutes, obtains refractory material;

[0105] The obtained refractory material is pressed into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com