Patents

Literature

95results about How to "Good volume stability at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

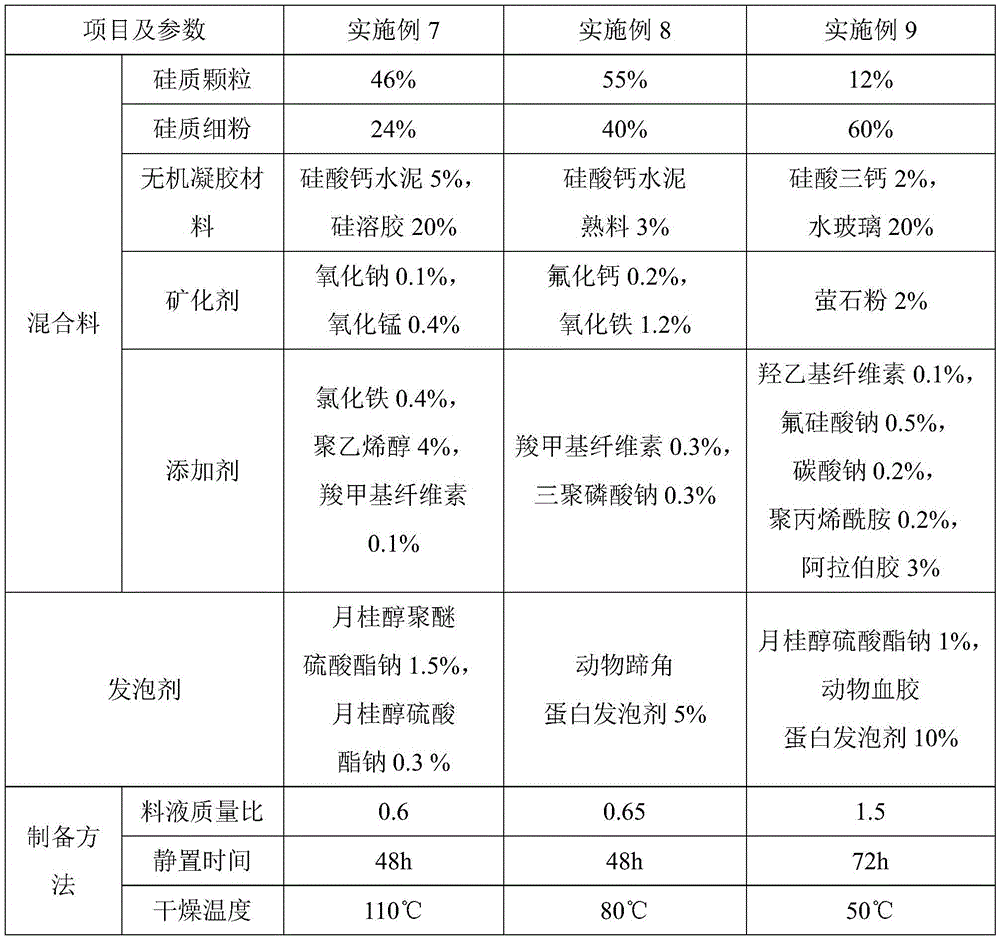

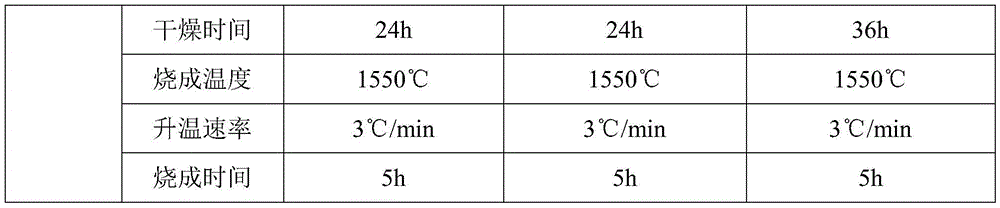

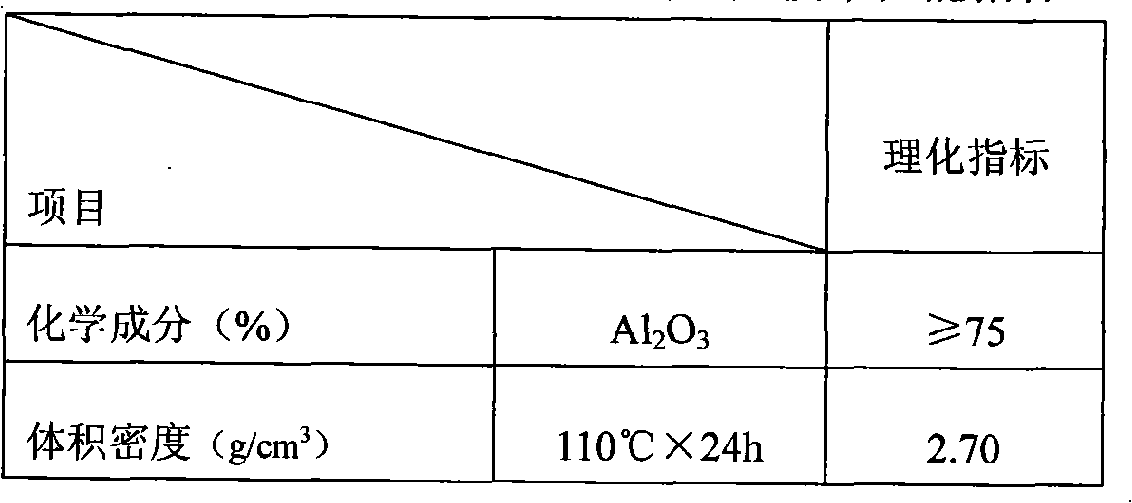

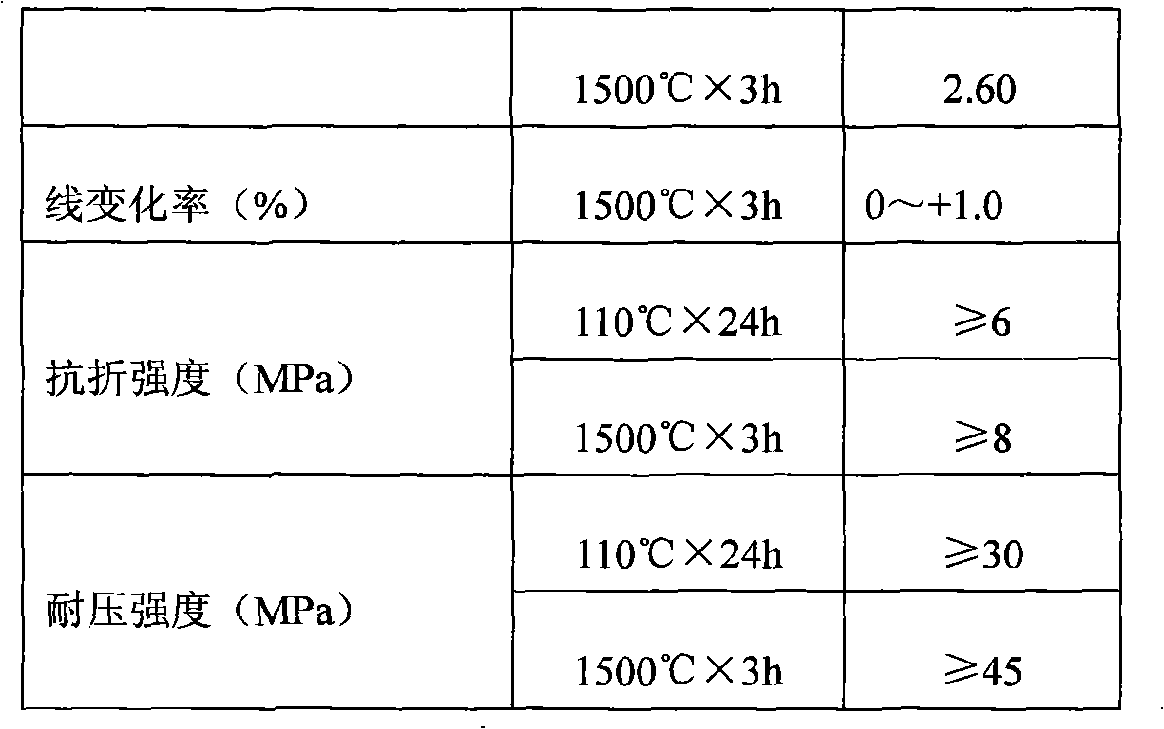

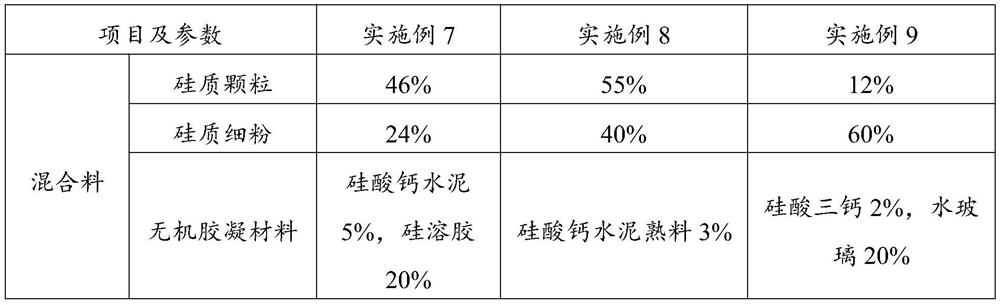

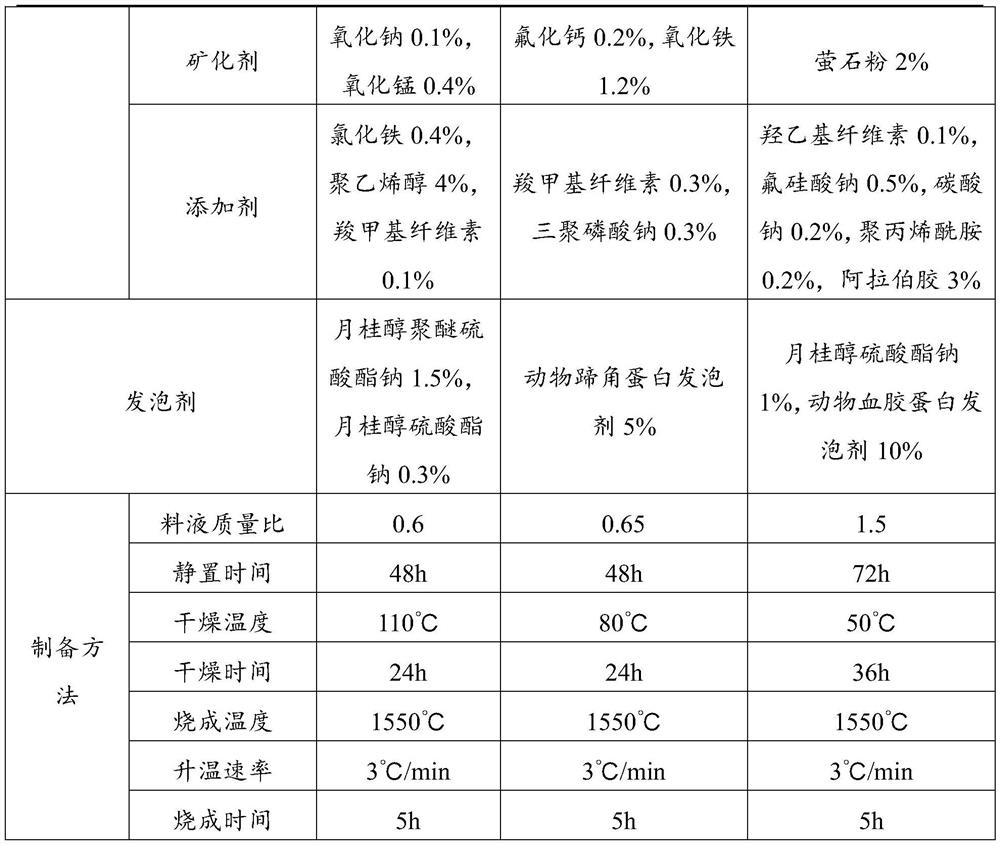

Micropore light weight silica brick and preparation method thereof

The invention discloses a micropore light weight silica brick and a preparation method thereof. The light weight silica brick is mainly prepared from a mixture and a foaming agent; a use quantity of the foaming agent is 0.1% to 10% of mass of the mixture; the mixture consists of the following components in percentage by mass: 70% to 95% of siliceous material, 1% to 25% of inorganic cementitious material, 0.1% to 15% of mineralizer, and 0.1% to 5% of additive, wherein the siliceous material consists of siliceous particles and siliceous fine powder, a particle size of the siliceous particles is 0.1 to 3mm, a particle size of the siliceous fine powder is smaller than or equal to 0.075mm, and a mass ratio of the siliceous particles to the siliceous fine powder is (1 to 65):(35 to 99). The obtained micropore light weight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical intensity, high high-temperature volume stability, high resistance to the acid atmosphere, high slagging resistance and the like, is low in preparation cost and good in heat insulation effect, meets the harsh requirements of thermal equipment for a high-temperature environment and heat insulation, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Ladle bottom castable and preparation method thereof

The invention relates to a ladle bottom castable and a preparation method thereof. The technical scheme is as follows: 60-70wt% of titanium-iron slag particles are taken as aggregate, and 25-35wt% of titanium-iron slag fine powder, 1-4wt% of zirconia micro powder and 2-5wt% of titanium oxide micro powder are taken as substrate materials; according to the content of the aggregate and the substrate materials, the substrate materials are uniformly mixed firstly, and then the uniformly mixed substrate materials are added to the aggregate to be uniformly mixed; silica sol accounting for 3-7wt% of the sum of the substrate materials and the aggregate is added, and the mixture is uniformly stirred, subjected to vibratory compaction, cured for 6-12 h under the condition of room temperature and finally subjected to heat preservation for 12-24 h under the condition of 90-110 DEG C to prepare the ladle bottom castable. The ladle bottom castable and the preparation method have the characteristics of low cost and simple process, and the prepared ladle bottom castable has good high-temperature volume stability and good corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH +1

Andalusite self-flow castable

InactiveCN102503466AGood volume stability at high temperatureImproved thermal shock stabilityFiberVolume variation

The invention discloses an andalusite self-flow castable, comprising andalusite, fused mullite, silicon carbide, mullite hollow balls, pure calcium aluminate cement, aluminum oxide micro-powder, zirconium silicate, tripolycyanamide, and polycarboxylic acid FOX-8H. The castable further comprises nano calcium carbonate, sodium hexametaphosphate and anti-explosion fiber. According to the andalusite self-flow castable disclosed by the invention, raw materials, such as the high-quality andalusite, silicon carbide, various additives and the like are selected. The andalusite self-flow castable is formed by regulating according to repeated tests and feedback after being used by a manufacturer. As the andalusite is transformed to be the mullite at a high temperature, and the vast majority of residual SiO2 in the andalusite is located in mullite crystals. Under a high temperature state, the SiO2 softened in the mullite crystals can absorb the volume variation of the mullite, which is caused by the temperature variation, so that the structure of the mullite formed by the andalusite has better high-temperature volume stability and thermal shock stability.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Raw materials and preparation method of anti-corrosion mullite brick

The invention discloses raw materials for preparing an anti-corrosion mullite brick, comprising calcium hexaluminate, andalusite, sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide, foaming agent and binding agent. The preparation method includes the following steps: the sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide and binding agent are added into a grinding machine to be ground after material preparation, so as to obtain base material; the calcium hexaluminate and andalusite are added into a kollermill to be mixed and milled for 5-10 minutes, water is added until the surface is wetted, so as to obtain particle aggregate, and the base material is added into the kollermill to be mixed, milled and stirred with the particle aggregate, so as to obtain mixture; and water is injected into the mixture and stirring is carried out to form muddy mixture and green brick is obtained, and the green brick is placed into a kiln to be sintered into the anti-corrosion mullite brick finished product. The mullite brick prepared by the raw materials and preparation method has the advantages of low thermal conductivity, good thermal insulation property and strong corrosion resistance.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

Steel ladle cover light mullite castable material and preparation method thereof

The invention discloses a steel ladle cover light mullite castable material including an aggregate and a matrix and including the components in parts by weight: the aggregate comprising 30-70 parts of light mullite balls, and the matrix comprising 0-15 parts of tabular corundum, 0-15 parts of mullite particles, 5-15 parts of an alumina micro powder, 5-15 parts of a mullite micro powder, 0-8 parts of a silicon micro powder, 5-15 parts of a binder, and 0.1-0.4 part of a water reducer. The invention also discloses a preparation method of the steel ladle cover light mullite castable material, wherein the preparation method comprises the following steps: firstly, mixing the matrix parts evenly; and then adding the light mullite balls, and then mixing evenly and packing. The steel ladle cover light mullite castable material has the advantages of simple production, high production efficiency, convenient field construction, low volume density, low thermal conductivity coefficient, excellent thermal shock resistance, high strength, and good high temperature volume stability and the like, and has the use temperature reaching up to 1550 DEG C.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Ladle kerb casting material and ladle kerb preparation method thereof

The invention relates to ladle kerb casting material and a ladle kerb preparation method by the ladle kerb casting material. The casting material comprises the following components in weight percentage: 60-82% of ladle lining waste having a grain size of 1-8mm, 10-20% of bauxite grain size of 0.044-1mm, 2-10% of silicon dioxide superfine(less than or equal to 0.02mum), 5-10% of magnesium oxide fine powder grain size of 0.044-0.088 and 0.01-1% of sodium polyphosphate. The preparation method comprises ladle kerb lining waste selecting, crushing, mixing evenly and adding water while stirring, casting, maintaining, baking and the like. The waste ladle kerb casting material is recycled by the preparation method so that the production cost of the fireproof materials and the steel-making cost can be obviously reduced, the economic benefit is improved and the social meaning of protecting environment and saving energy can be realized; the ladle kerb prepared by the ladle kerb casting material has the advantages of good high-temperature volume stability, enough common / medium / high temperature strength, strong anti-slag corrosion and anti erosion-corrosion, thus satisfying the requirements for maintaining the normal running of the ladles.

Owner:HENAN GENGSHENG REFRACTORIES

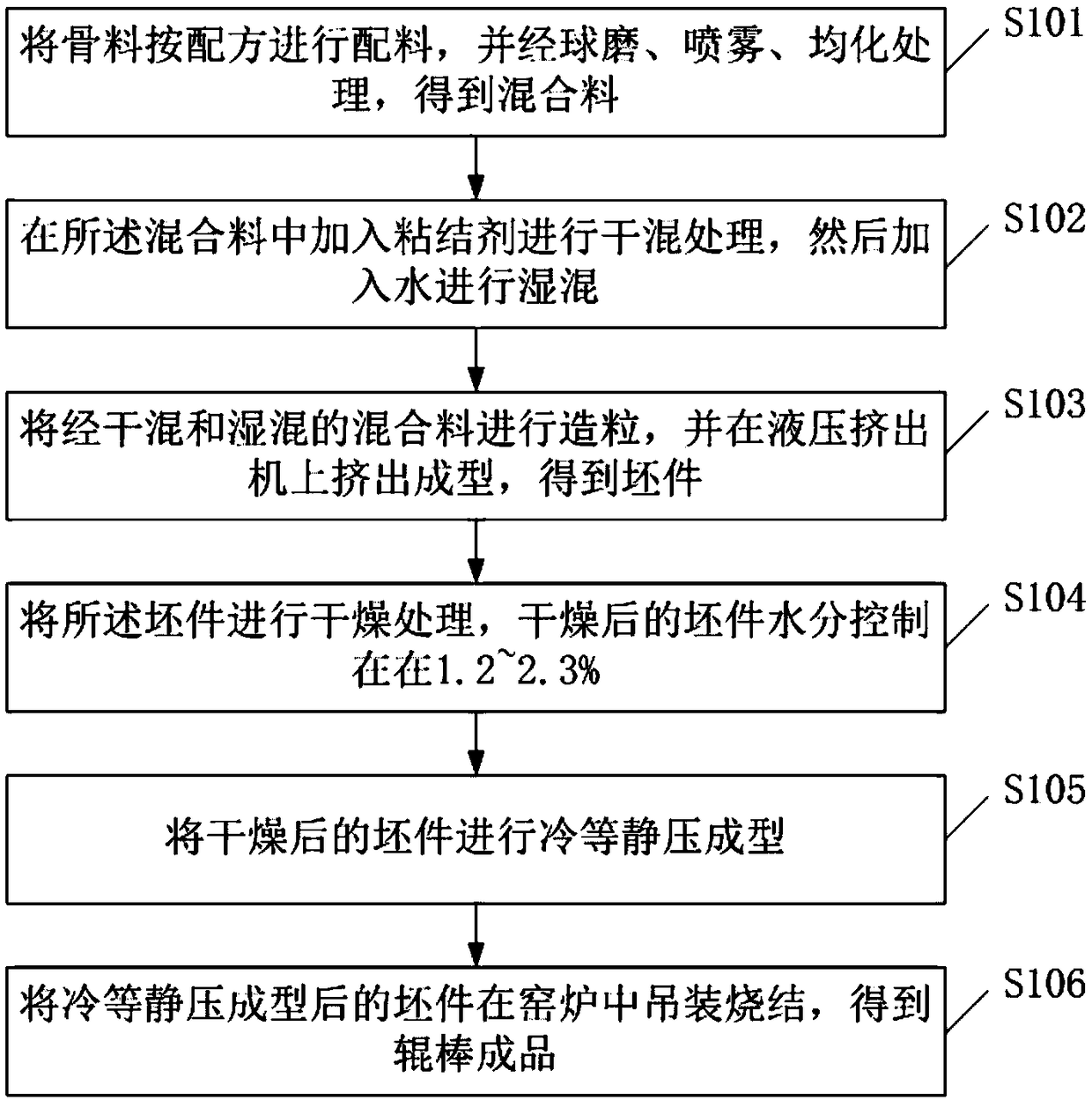

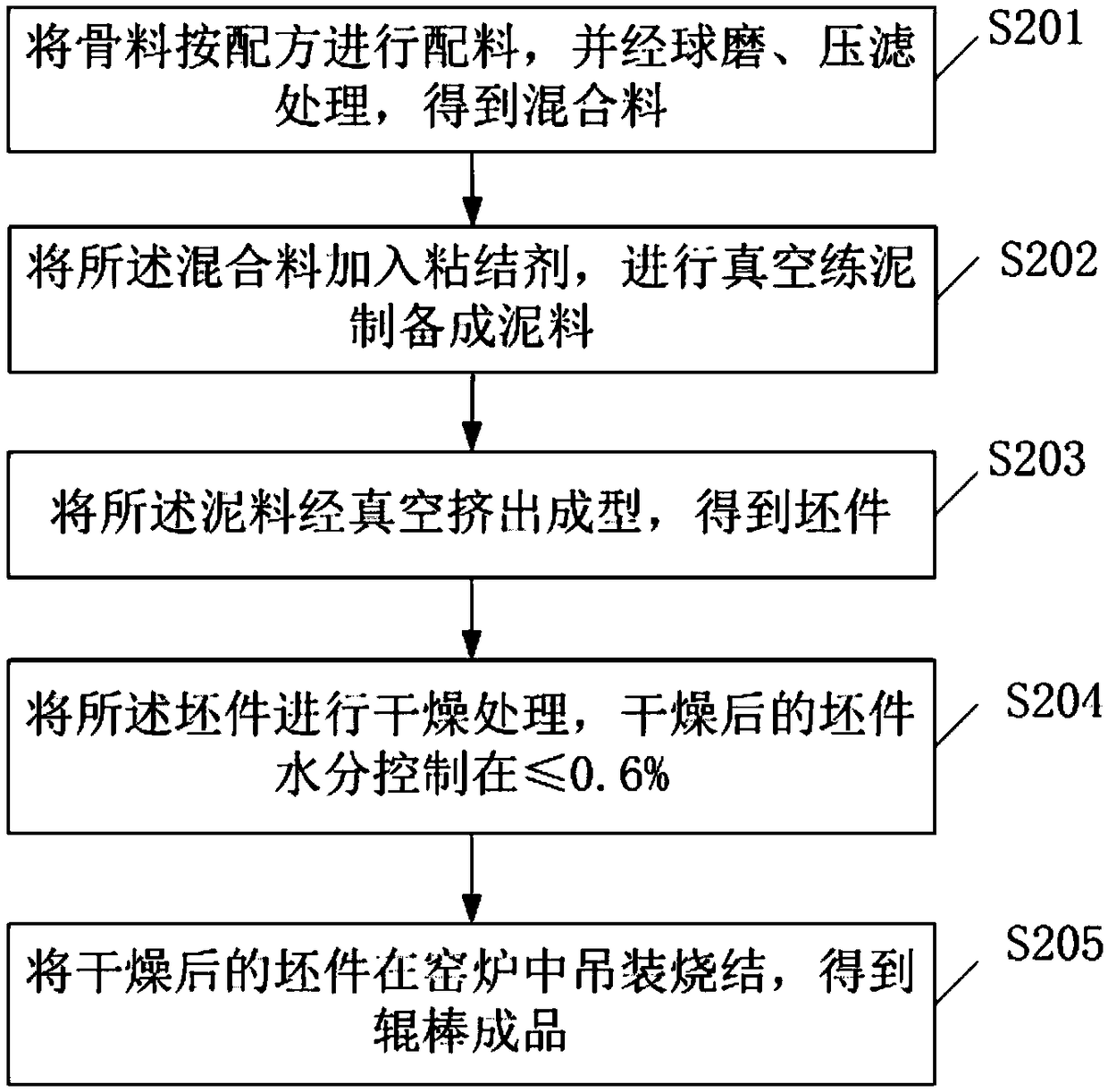

Ceramic roller with thermal shock resistance and high-temperature volume stability and preparation method thereof

ActiveCN108975923ASolve the problem of easy bending deformationImprove brick walkingMulliteThermal expansion

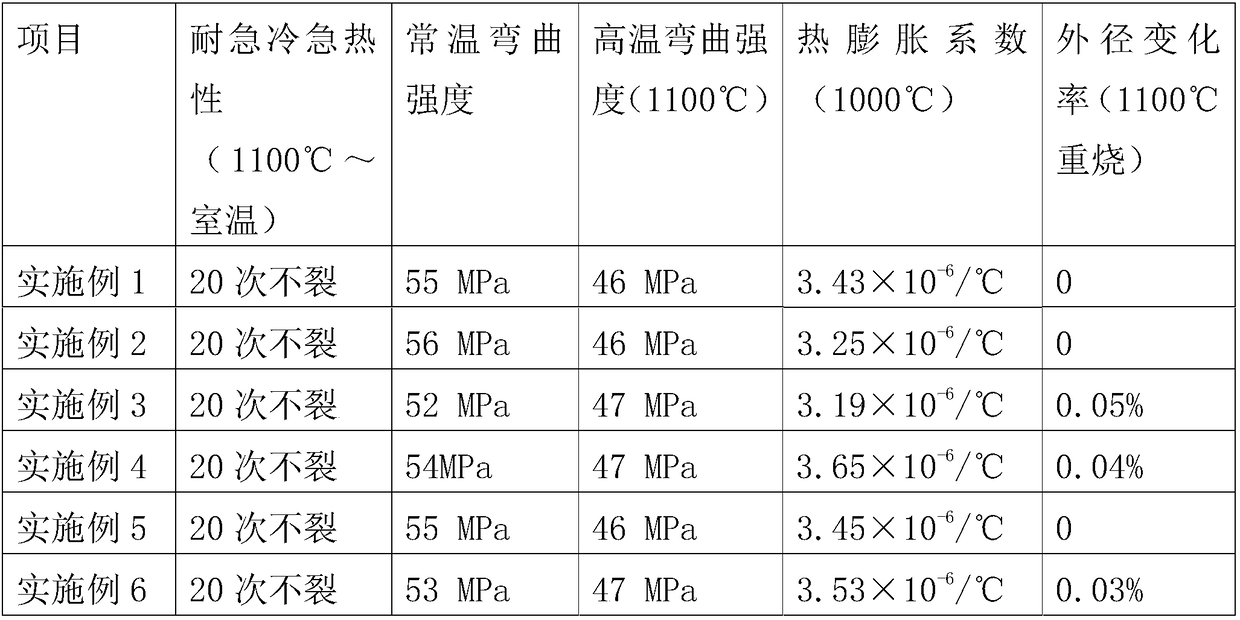

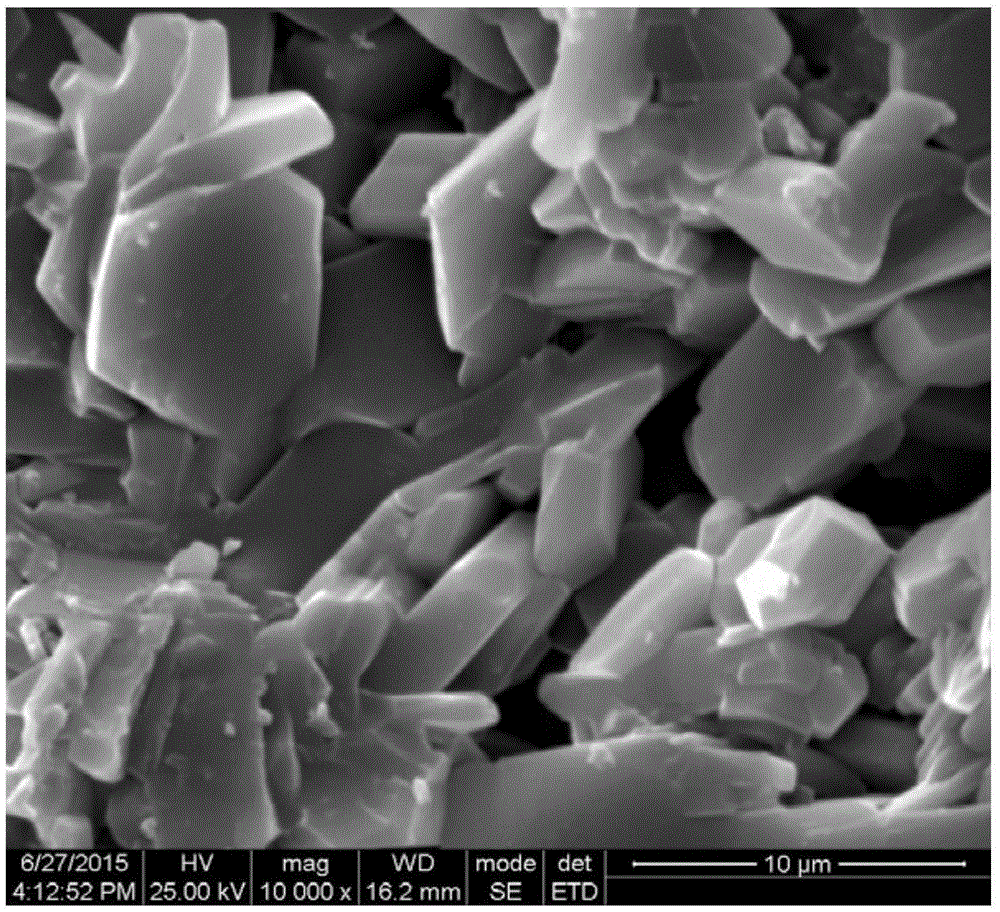

The invention discloses a ceramic roller with the thermal shock resistance and the high-temperature volume stability. The ceramic roller is prepared by selecting kaolin, refractory clay, cordierite, talcum powder, magnesite, silica powder, alumina powder, a corundum-mullite roller clinker, zirconium silicate, barium carbonate and cobalt oxide as main raw materials. According to a finished productof the ceramic roller, the thermal shock resistance (1100 DEG C to room temperature) is greater than or equal to 20 times for no cracking, the bending strength at normal temperature is greater than orequal to 50 MPa, the bending strength at high temperature (1100 DEG C) is greater than or equal to 45 MPa, the thermal expansion coefficient is 3.0-4.0*10<-6> / DEG C (1000 DEG C), and the outer diameter change rate of the roller (1100 DEG C refiring) is less than or equal to 0.1%. The ceramic roller has the advantages that the problem that the bending deformation of a corundum-mullite ceramic roller is easily generated in a quenching zone or an area with great temperature difference can be solved, the thermal shock resistance is good, the high-temperature volume stability is high, the thermalexpansion coefficient is low, the deformation resistance is strong, and the ceramic roller can be widely applied to the quenching zone of a roller kiln.

Owner:JIN GANG NEW MATERIALS +1

Heat-insulating and fire-resistant calcium alumino-titanate material and preparation method thereof

The invention relates to a heat-insulating and fire-resistant calcium alumino-titanate material and a preparation method thereof. According to the technical scheme, the method comprises the steps thatfine calcium alumino-titanate powder and coke powder are pre-mixed in a mass ratio of (8-9):1, and then placed in a tube furnace, heat preservation is conducted at the temperature of 1600-1700 DEG Cin the nitrogen atmosphere, and cooling, crushing and magnetic separation are conducted in sequence; heat preservation is conducted at the temperature of 1400-1450 DEG C, cooling and crushing are conducted, grinding is conducted until the particle size is smaller than or equal to 0.088 mm, and a mixture is obtained; sodium dodecyl benzene sulfonate accounting for 2-3 wt% of the mixture, dextrin accounting for 3-8 wt% of the mixture, sodium polyacrylate accounting for 0.2-0.5 wt% of the mixture and water accounting for 35-40 wt% of the mixture are added into the mixture, stirring, forming, maintaining and drying are conducted in sequence, heat preservation is conducted at the temperature of 1400-1500 DEG C, and the heat-insulating and fire-resistant calcium alumino-titanate material is obtained. The preparation method has the advantages of being low in cost, simple in process and high in yield. The heat-insulating and fire-resistant calcium alumino-titanate material has the advantages of being small in bulk density, high in compression strength, high in high-temperature breaking strength, small in heat conductivity coefficient and high in thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH +1

Silicon carbide brick and preparation method thereof

The invention relates to a silicon carbide brick and a preparation method thereof. According to the silicon carbide brick, silica is used as a main raw material, and is divided into silica powder, silica coarse powder and silica fine powder according to grain diameters. The graphene silicon carbide brick is prepared from silica powder, silica coarse powder, silica fine powder, graphene, composite mineralizer and binding agents including nano-sized chromic oxide and nano-sized titanium oxide. The silicon carbide brick is a graphene silicon carbide brick with excellent thermal shock resistance, strong slag and alkaline metal corrosion resistance, excellent washing resistance, excellent heat-isolation and insulation performance and good high-temperature volume stability; the contact inside the silicon carbide brick is closer due to the graphene, so that the stress generated by expansion when the brick is burnt can be reduced, and the brick is prevented from loosening or cracking; and due to the high strength of the graphene, the excellent mechanical performance of the silicon carbide brick is guaranteed, and the acid and alkali corrosion resistance of the silicon carbide brick can be improved.

Owner:浙江长兴银兴窑业有限公司

Iron-storage type casting material for iron tapping channel, and preparation method thereof

The invention discloses an iron-storage type casting material for an iron tapping channel. The casting material is composed of brown corundum, dense corundum, silicon carbide, ball asphalt, alpha-Al2O3, pure calcium aluminate cement, silica micropowder, silicon metal powder, Guangxi white mud, aluminium metal powder, an explosion-proof fiber and FDN. The invention also provides a preparation method of the iron-storage type casting material for the iron tapping channel. The method comprises the steps of mixing the above-mentioned raw materials according to a proportion; stirring the mixture for 10 minutes in a stirring machine; discharging the mixture and packaging. Compared with a conventional technology, the method has the beneficial effects that the casting material is manufactured by employing Al2O3-SiC-C material and a carbon-containing polymer, and has good high-temperature wear resistance, good slag-resistant chemical corrosion performance, high and good oxidation resistance, good thermal shock-resistant stability, good high-temperature volume stability, good explosion resistance, high iron content, high safety coefficient and high slag resistance, sticks no slag iron, is convenient for production, and reduces labor intensity.

Owner:王振江

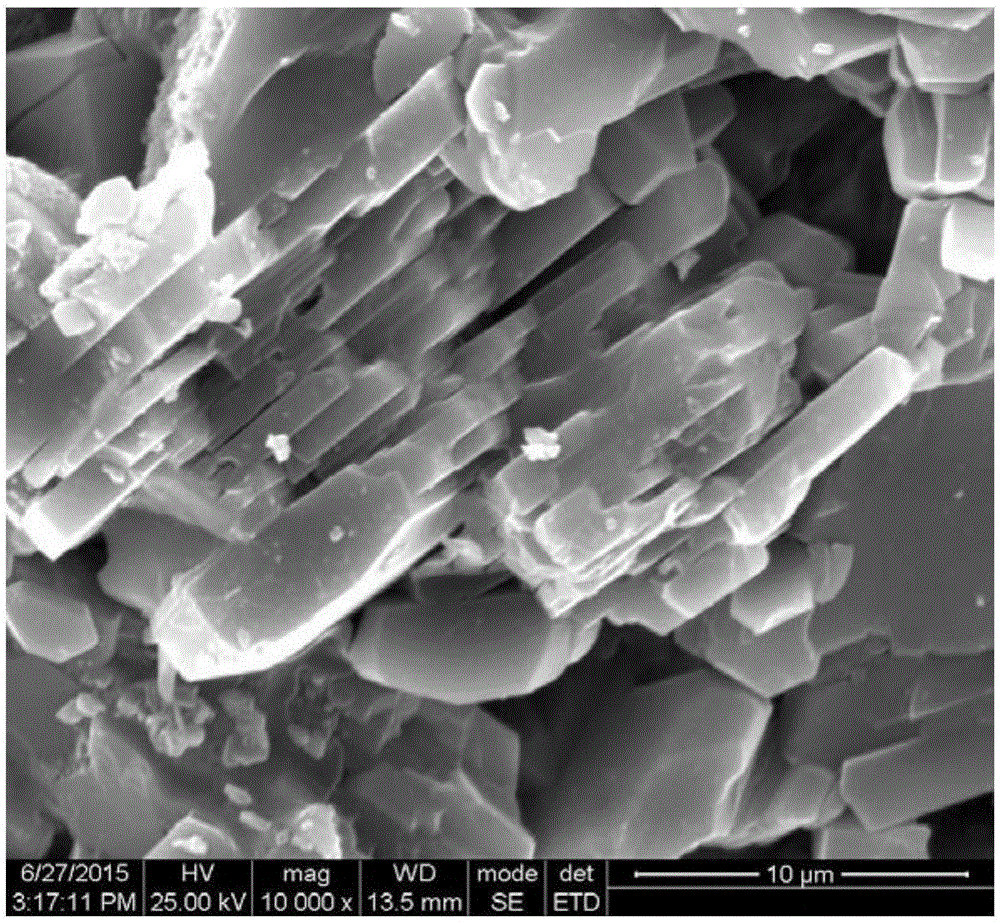

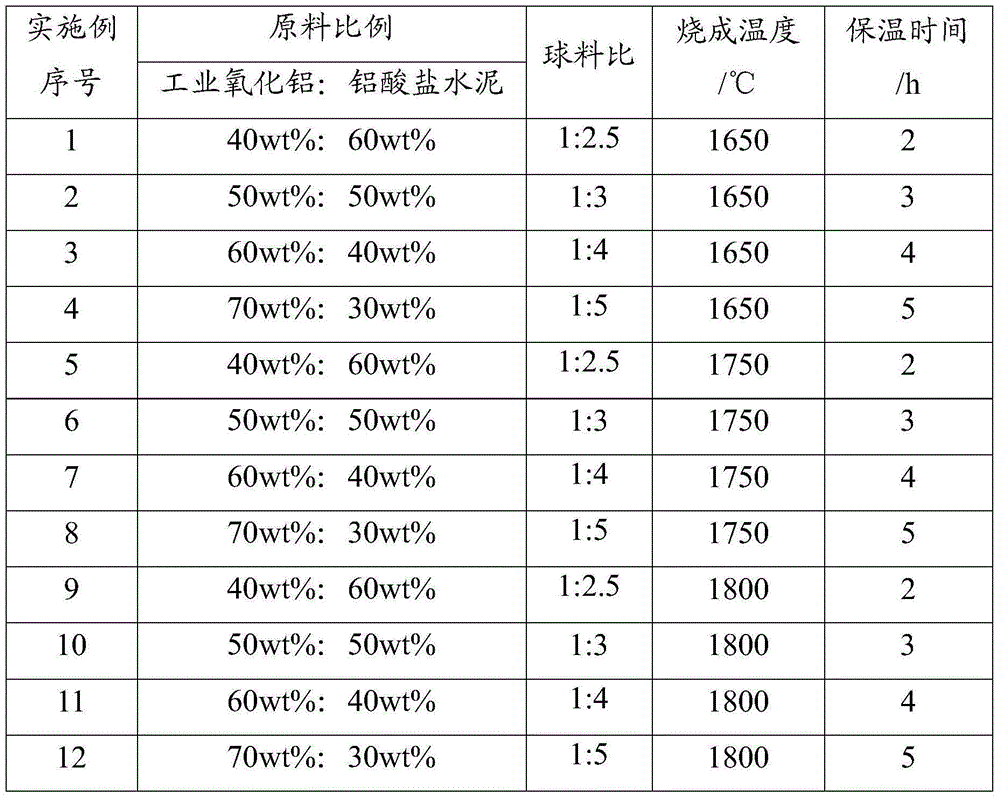

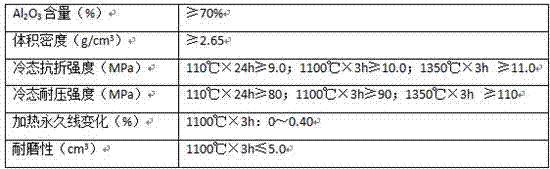

Calcium hexaluminate and preparation method thereof

InactiveCN105036167ALower sintering temperatureIncrease productivityAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRefractoryVolume density

The invention discloses a preparation method of calcium hexaluminate. The method includes the following steps that firstly, 40-80 wt% of industrial aluminum oxide powder and 20-60 wt% of aluminate cement are evenly mixed, mixed powder is obtained, the mixed powder is subjected to secondary balling fabrication processing, and green balls are obtained; secondly, after the green balls are dried, the green balls are sintered for 1-5 hours at the temperature of 1650-1800 DEG C, and then the calcium hexaluminate is obtained through smashing and screening. The preparation method of the calcium hexaluminate has the advantages that the technology is simple, cost is low, the production cycle is short, and large-scale industrial production can be achieved. The prepared calcium hexaluminate is high in purity and stable in performance. After the calcium hexaluminate is added into an amorphous fire-resistant material product, the volume density of a fire-resistant material can be effectively reduced, and accordingly the fire-resistant material has the advantages of being good in high-temperature volume stability, heat-preserving and heat-isolation performance, alkali resistance and the like.

Owner:浙江自立新材料股份有限公司

Anticorrosion silicon carbide shelf plate and preparation method thereof

The present invention relates to an anticorrosion silicon carbide shelf plate and a preparation method thereof, wherein the anticorrosion silicon carbide shelf plate comprises the following raw materials by mass: silicon carbide particles, silicon carbide coarse powder, silicon carbide fine powder, silicon carbide micro-powder, graphene, a composite antioxidant, a composite binding agent, molybdenum disulfide and a lubricating grease. According to the present invention, the product has characteristics of excellent thermal shock resistance, strong anti-oxidation property, strong slag erosion resistance, strong alkali metal erosion resistance, excellent erosion resistance, excellent thermal insulation and good high temperature volume stability; and the highly uniform dispersion inside the shelf plate can be achieved, the sintering can be promoted, the shelf plate can have the uniform structure, and the strength and the thermal shock resistance of the product can be improved.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Kilneye plastic refractory

The invention discloses special kilneye plastic refractory for cement kilneye, which comprises sillimanite, andalusite, silicon carbide, pure calcium aluminate cement, boron carbide, nanosilicon dioxide, active micro silicon powder and alumina micro powder. The kilneye plastic refractory further comprises aluminum powder, explosion-proof fiber, P530 high efficiency water reducing agent and plasticizing agent. The kilneye plastic refractory selects the raw materials of high-grade sillimanite, andalusite, various additives and the like and is prepared through adjustment based on various experiments and the feedback of factories. As the temperature of mullite converted by sillimanite and andalusite at high temperature is different, densities of substance before and after conversion are different, the volume is changed, and the structure of the mullite formed by sillimanite and andalusite has good high temperature volume stability.

Owner:南京联合荣大工程材料有限责任公司

Sandwich type long nozzle sealing piece and manufacturing method thereof

The invention relates to a sandwich type long nozzle sealing piece and a manufacturing method of the sandwich type long nozzle sealing piece. According to the technical scheme, raw materials including 15-55wt% of mullite, 45-85wt% of corundum, 10-50wt% of water glass and 15-35wt% of complex binding agents are evenly mixed and molded by casting, and a rough body (1) formed after casting is shaped like a horn mouth and is naturally dried; then graphite paper (2) is pasted on the inner surface and the outer surface of the dried rough body (1) to form the sandwich type long nozzle sealing piece. The complex binding agent is a mixed solution of resin and ethyl alcohol, and the mass ratio between the resin and the ethyl alcohol is 1 / (4-1). The resin is phenolic resin or epoxy resin or furan resin or polyester resin. The thickness of the graphite paper is 0.2-1.5 mm. The manufactured sandwich type long nozzle sealing piece has the advantages of being good in sealing performance, high in strength, good in high-temperature volume stability, good in erosion resistance and easy to detach.

Owner:WUHAN UNIV OF SCI & TECH +1

Lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate and preparation method thereof

InactiveCN102161591BImprove thermal shock resistanceHigh purityThermal insulationAluminium hydroxide

The invention discloses a lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate for lightweight refractory castables and a preparation method thereof. The lightweight calcium hexaluminate-magnesia alumina spinel composite microporous refractory aggregate is obtained by taking 3 to 7 weight percent of lime, 12 to 18 weight percent of magnesite and 75 to 85 weight percent of industrial aluminum hydroxide as initiative materials, adding a binding agent in an amount which is 3 to 6 percent of the total weight of the initial materials, performing wet co-grinding and machine molding, drying a green body and then calcining the green body, and crushing a product obtained after calcination. The lightweight microporous aggregate has the advantages of high stability in reducing atmosphere and alkaline environment, excellent thermal shock resistance and thermal insulation property and the like, so that the service life of the material is prolonged and the loss of energy consumption is reduced.

Owner:HENAN UNIV OF SCI & TECH

Recycled alumina-chrome brick for Ausmelt furnace inner liner, and making method thereof

The invention relates to a recycled alumina-chrome brick for an Ausmelt furnace inner liner, and a making method thereof. A technical scheme is characterized in that the recycled alumina-chrome brick comprises 66-76wt% of ferrochrome slag particles as aggregates, and also comprises 20-30wt% of ferrochrome slag fine powder, 1-2wt% of vanadium trioxide fine powder and 2.1-2.9wt% of yttria fine powder as a matrix. The method comprises the following steps: mixing above proportions of components of the matrix for 0.5-1h, adding the mixed matrix to the above proportion of the aggregates, and mixing the matrix and the aggregates for 5-8min; and adding alumina sol accounting for 5-7% of the total weight of the matrix and the aggregates, mixing for 8-10min, ageing the obtained mixture at 25-35DEG C for 0.3-0.5h, carrying out mechanical pressing, drying the obtained material at 100-110DEG C for 12-24h, and carrying out heat insulation at 1550-1650DEG C for 3-6h to obtain the recycled alumina-chrome brick for the Ausmelt furnace inner liner. The method has the characteristics of low cost and simple process; and the recycled alumina-chrome brick for an Ausmelt furnace inner liner, made in the invention, has good high temperature volume stability and strong slag corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Anti-oxidation silicon carbide deck and production method thereof

The invention relates to an anti-oxidation silicon carbide deck and a production method thereof. The anti-oxidation silicon carbide deck comprises, by mass, 30-40% of silicon carbide particles, 15-20% of silicon carbide coarse powder, 14-19% of silicon carbide fine powder, 5-10% of silicon carbide micro-powder, 10-15% of graphene, 2-4% of a composite antioxidant, 6-8% of a composite binder, 0.7-1.5% of beeswax and 0.2-0.5% of molybdenum disulfide. Lightweight silica bricks having the advantages of excellent thermal shock resistance, strong oxidation, slag and alkali metal erosion resistance, excellent washing resistance and heat insulation performance, and good high-temperature volume stability can be highly and uniformly dispersed in the deck, promote sintering, make the deck have a uniform microstructure, and improve the strength and the thermal shock resistance of the deck.

Owner:浙江长兴银兴窑业有限公司

Fireproof material filler and preparation method therefor

The invention relates to fireproof material filler and a preparation method therefore. The fireproof material filler is composed of nano aluminum oxide, nano silicon dioxide, nano zirconium oxide, nano zinc oxide, erbium oxide, cerium oxide and maltodextrin. The filler provided by the invention can be used for improving the thermal shock resistance of the fireproof material, is strong in oxidization resistance, slag resistance and alkali metal corrosion resistance, is excellent in scouring resistance, heat isolation and insulation and is good in high-temperature volume stability; the filler can be highly and uniformly dispersed inside to promote sintering and has more uniform organization structures, so that the strength and thermal shock resistance of a product are improved.

Owner:长兴泓矿炉料有限公司

Sialon bonded andalusite/sillimanite/SiC refractory material and preparation method

The invention discloses a sialon bonded andalusite / sillimanite / SiC refractory material and a preparation method, and belongs to the field of a refractory material. The refractory material comprises the following raw materials: andalusite, sillimanite, alpha-Al2O3 powder, polycrystalline silicon waste and aluminum powder, and dextrin and phenolic resin are taken as binding agents. The refractory material is produced by the following steps: weighing raw materials and mixing to obtain mud, compressing and moulding, and sintering in a nitrogen atmosphere at 1200-1600 DEG C. According to the product disclosed by the invention, characteristics of andalusite and sillimanite are developed and a sialon bonded phase is generated through the polycrystalline silicon waste; the refractory material has the following excellent physical performance indexes: apparent porosity is 9-18%, volume density is 2.5-3.0g / cm<3>, cold crushing strength is 100-300MPa and high temperature bending strength is 20-70MPa, thermal shock resistance, creep resistance, CO resistance and alkaline steam erosion resistance are excellent. The product disclosed by the invention is high in cost performance, and is applicable to the middle upper part of furnace body of a blast furnace. The refractory material is not only favorable for prolonging service life of the blast furnace but also realizes recycling of the polycrystalline silicon waste.

Owner:UNIV OF SCI & TECH BEIJING +1

Zirconium silicate-mullite composite wear-resisting castable and preparation method thereof

ActiveCN107344858AGood volume stability at high temperatureGood thermal shock resistanceWear resistanceCalcium aluminate cements

The invention discloses zirconium silicate-mullite composite wear-resisting castable and a preparation method thereof. The castable is prepared from the following components in parts by mass: 18 to 24 parts of mullite with the size of 1mm to 8mm, 5 to 10 parts of andalusite particles with the size of 3mm to 5mm, 5 to 10 parts of compound ore powder with the grain diameter less than 0.075mm, 5 to 8 parts of ZrO2 with the grain diameter less than 1mum, 3 to 8 parts of silicon micro-powder with the grain diameter less than 1mum, 3 to 5 parts of Al2O3 micro-powder with the grain diameter less than 1.2mum, 3 to 7 parts of calcium aluminate cement, 0.15 to 0.2 part of sodium hexametaphosphate, 0.08 to 0.12 part of a flatting agent, 0.5 to 1.6 parts of heat-resisting steel fibers and 0.2 part of explosion-proof fibers. The zirconium silicate-mullite composite wear-resisting castable disclosed by the invention has the characteristics of high strength, high temperature resistance, good thermal shock resistance, wearing resistance and uneasiness of being cracked; in the aspect of the preparation method, a traditional construction manner is changed and a self flow mode is adopted; the problems of castable segregation and the like, which are possibly caused by vibration construction, are avoided; the zirconium silicate-mullite composite wear-resisting castable is applicable to abnormal-shape parts which are not easy to vibrate, such as coal injection pipes and kiln openings.

Owner:长兴兴鹰新型耐火建材有限公司

Corrosion-resistant refractory brick and preparation method thereof

The invention discloses a corrosion-resistant refractory brick which is prepared from the following raw materials in parts by weight: 15 to 30 parts of silicon powder, 20 to 40 parts of magnesium aluminated spinel, 5 to 10 parts of activated aluminum oxide, 6 to 12 parts of iron trioxide, 4 to 8 parts of graphene, 1 to 3 parts of fluorite powder, 0.2 to 1 part of boron nitride, 2 to 5 parts of binding agent and 5 to 10 parts of nanometer magnesia. A preparation method of the corrosion-resistant refractory brick comprises the steps of weighing all the raw materials according to the matching, mixing and shaping, then utilizing a mould-pressing vibration shaping machine to manufacture a green brick, roasting, then putting into a dipping tank to be vacuumized, adding impregnant after press maintaining and calcinating. The refractory brick disclosed by the invention has the beneficial effects of excellent performance, strong slag and alkali metal corrosion resistance, excellent washing resistance and thermal insulation performance and good high-temperature volume stability. The preparation method disclosed by the invention is simple, rich in raw materials and suitable for factory production.

Owner:新昌县永佳耐火材料厂

Preparation method for mullite-roller bed bar waste-cordierite product for hot-blast stove ceramic burner

The invention relates to a mullite-roller bed bar waste-cordierite product for a hot-blast stove ceramic burner, and a preparation method thereof. The product comprises mullite, roller bed wastes, cordierite, sintered alpha-Al2O3, Guangxi clay and silica micropowder. The preparation method for the mullite-roller bed bar waste-cordierite product comprises the steps: 1, mulling the raw materials; 2, pressing into a high-density semi-finished product; 3, placing the semi-finished product into a dryer for drying; and 4, sintering a biscuit dried in the step 3. By replacing andalusite raw materials with roller bed wastes, not only can wastes be reasonably utilized, but also the production cost of the product can be lowered, and the properties of the product are excellent.

Owner:ZHENGZHOU ANNEC IND

Composite silicon brick and preparation method thereof

The present invention relates to a composite silicon brick and a preparation method thereof, wherein silica rock is adopted as a main raw material, the main raw material silica rock is divided into silica rock particles, silica rock powder, silica rock coarse powder and silica rock fine powder according to the particle size, and the composite composition comprises silica rock particles, silica rock powder, silica rock coarse powder, silica rock fine powder, graphene, nanometer silica, a composite mineralization agent, a binder and nanometer zirconia. According to the present invention, the composite silicon brick has characteristics of excellent thermal shock resistance, strong slag erosion resistance, strong alkali metal erosion resistance, excellent erosion resistance, excellent thermal insulation and good high temperature volume stability; with the graphene, the internal contact of the brick is close so as to reduce the stress generated by expansion during the firing and prevent the product from loosening or cracking; and with the high strength of the graphene, the excellent mechanical property of the silicon brick is ensured, and the acid-alkali corrosion resistance of the silicon brick can be enhanced.

Owner:唐山市开平区鑫惠保温耐火材料厂

Refractory lining material and preparation method thereof

The invention relates to a refractory lining material and a preparation method thereof. The refractory lining material is composed of following components, by mass: 10-20 parts of SnO2 sol, 30-50 parts of a core-shell-structured carrier, 50-70 parts of magnesite and 20-40 parts of mullite. The preparation method includes the following steps: uniformly mixing the SnO2 sol and the core-shell-structured carrier, finely grinding the magnesite and the mullite and adding the magnesite and the mullite to the SnO2 sol and the core-shell-structured carrier with mixing, and performing regular mixing, pressing moulding, drying and calcination to obtain the refractory lining material. The refractory lining material has a compact stacked structure, is good in not only kiln coating forming property but also thermal shock stability, has excellent anti-permeation erosion property, can block diffusion of air and flue gas pollutants into the refractory lining material and is effectively prevented from being oxidized at a high temperature. The refractory lining material is long in service life, is low in production cost, is good in high-temperature size stability, is strong in alkaline resistance and is free of any environment pollution after combustion.

Owner:云南天朗能源科技有限公司

Method for laying bottom of prefabricated block ladle by using small building blocks

The invention discloses a method for laying the bottom of a prefabricated block ladle by using small building blocks. The method comprises the following steps of: vertically laying the bottom with small upright prefabricated blocks after an inner lining of the wall of the ladle is laid; reserving a gap of 40 to 50mm between the periphery of the bottom and the wall; and filling the gap with corundum-spinel castable and laying two layers of bricks along an annular joint of the bottom and the wall after the bottom is laid. The method has the advantages that: 1, the upright small prefabricated blocks are fired at high temperature, have high strength and low residual moisture, are suitable for rapid baking and quicken the turnover of the ladle; 2, because the bottom of the ladle is formed by laying a plurality of upright small fabricated blocks, the thermal stress can be uniformly dispersed during use and the bottom of the ladle has high high-temperature volumetric stability; 3, a comprehensive laying process is flexibly used to prolong the comprehensive ladle life of the ladle; 4, the bottom of the ladle is convenient to disassemble and maintain, and partial maintenance or replacement is realized; and 5, the use safety of the ladle is improved and a steel drilling accident of the bottom is prevented.

Owner:ZHENGZHOU ZHENDONG TECH

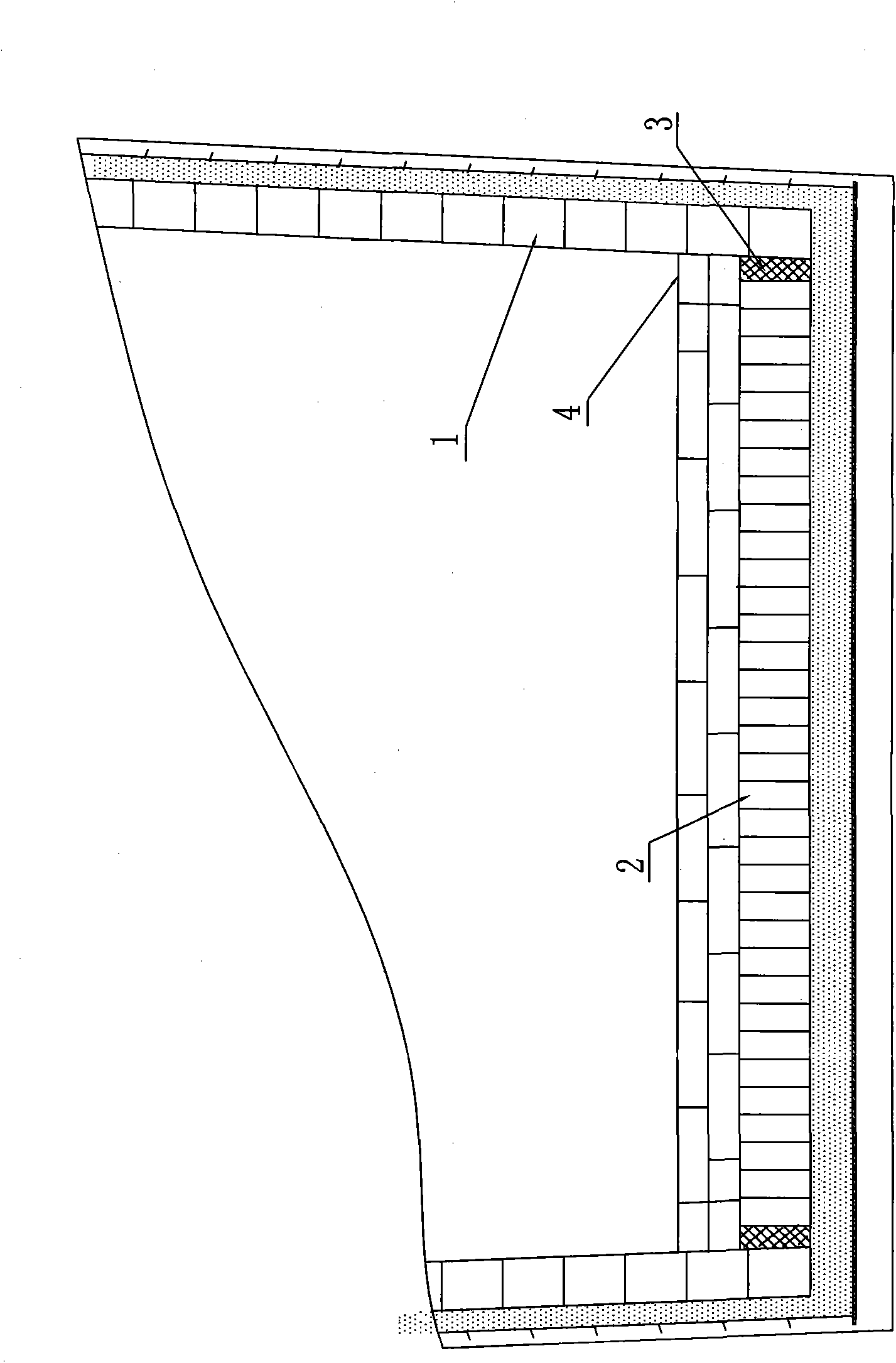

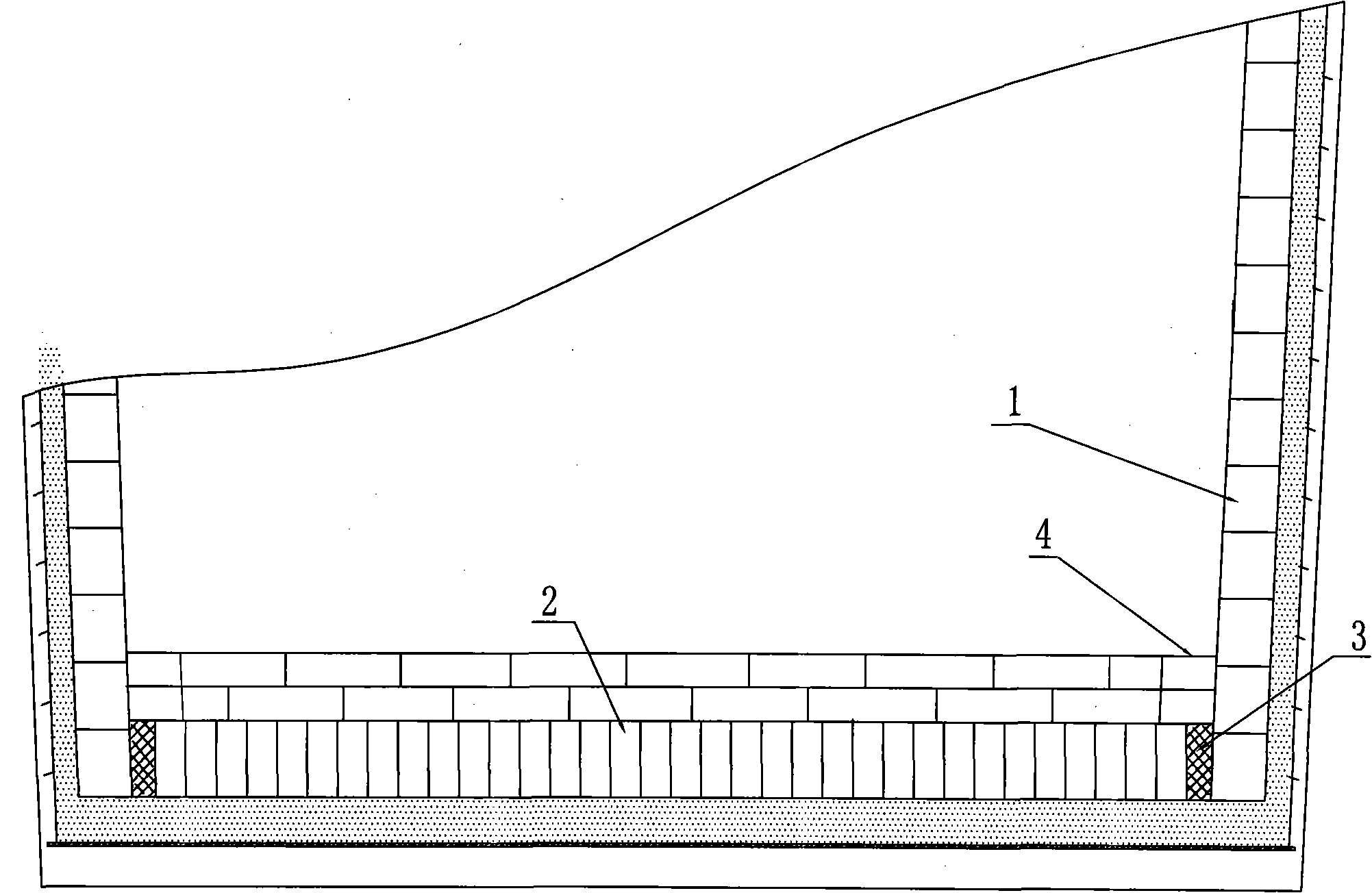

Microporous lightweight silica brick and preparation method thereof

The invention discloses a microporous lightweight silica brick and a preparation method thereof, the lightweight silica brick is mainly prepared from a mixture and a foaming agent, and the dosage of the foaming agent is 0.1-10% of the mass of the mixture; the mixture is prepared from the following components in percentage by mass: 70%-95% of a siliceous material, 1%-25% of an inorganic cementing material, 0.1%-15% of a mineralizing agent and 0.1%-5% of an additive; wherein the siliceous material is composed of siliceous particles and siliceous fine powder, the particle size of the siliceous particles is 0.1-3 mm, the particle size of the siliceous fine powder is smaller than or equal to 0.075 mm, and the mass ratio of the siliceous particles to the siliceous fine powder is (1-65): (35-99). The obtained microporous lightweight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical strength, good high-temperature volume stability, strong acid atmosphere and slag erosion resistance and the like, is low in preparation cost and good in heat insulation effect, meets harsh high-temperature environment and heat insulation requirements of thermal equipment, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Low-carbon-residue high-temperature-creep-resisting lost foam casting water-based paint with nanophase ceramic powder solution enhancement function and preparation method of water-based paint

InactiveCN105562592AImprove breathabilityLow thermal conductivityFoundry mouldsFoundry coresWater basedSuspending Agents

The invention relates to the technical field of lost foam casting, in particular to low-carbon-residue high-temperature-creep-resisting lost foam casting water-based paint with a nanophase ceramic powder solution enhancement function and a preparation method of the water-based paint. According to the paint, high-alumina bauxite and microporous light mullite which are different in particle size are mixed as refractory aggregate, and good air permeability, the low heat conduction coefficient and good high-temperature volume stability are achieved; by means of a mixed suspending agent prepared from a transparent nanophase ceramic powder solution, clay powder, sodium carboxymethylcellulose and other materials, the suspension property of the materials is improved, and the effects of enhancement, toughening and the like are achieved; and added nano ceric oxide has the oxygen storage capacity, oxygen can be released in the pouring process, the oxidization combustion efficiency of plastic is improved, and carbon residues are reduced. The prepared paint is compact and smooth in coating, resistant to high-temperature creep, stable in forming, not likely to collapse or break and easy to clean, and a prepared casting is fewer in impurity on the surface and better in quality.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Wear resistant pouring material for garbage treatment kiln and preparation method thereof

The invention discloses a wear resistant pouring material for a garbage treatment kiln and a preparation method thereof, wherein the wear resistant pouring material includes the following components by mass: 30-50 parts of 15-0mm A88 spinel, 15-25 parts of 10-5mm A95 spinel particles, 5-10 parts of composite inorganic powder with the particle size of 0.076-0.088mm, 5-8 parts of zirconium gel powder with the particle size of 2-100mu m, 3-8 parts of silicon micro powder with the particle size less than 1 mu m, 3-5 parts of Al2O3 micro powder with the particle size less than 1.2 mu m, 1-3 parts of Portland 625 cement, 3-8 parts of magnesium sol, 0.12 part of sodium pyrophosphate, 0.15 part of a defoaming agent, 0.3 part of explosion-proof fiber and 0.2 part of aluminum carbonate; and the composite wear resistant pouring material has the characteristics of uniform structure, high strength, high temperature resistance, good thermal shock resistance and easy construction.

Owner:万燕杰

Inorganic silicate heat insulating refractory and preparation method thereof

The invention discloses an inorganic silicate heat insulating refractory and a preparation method thereof. The inorganic silicate heat insulating refractory comprises the following components in part by weight: 5-20 parts of attapulgite, 50-80 parts of meerschaum, 500-700 parts of water, 5-20 parts of ceramic fiber, 5-20 parts of bentonite, 5-20 parts of sodium sulfosuccinate, 5-20 parts of aluminum dihydrogen phosphate, 5-20 parts of sodium silicate, 1-10 parts of light magnesium carbonate, 1-10 parts of titanium oxide, 15-70 parts of expanded perlite, 5-20 parts of cement and 15-20 parts of sodium methyl silicate. The preparation method for the inorganic silicate heat insulating refractory comprises the following steps: stirring the water, the sodium sulfosuccinate and the ceramic fiber at the rotating speed of 20-30 rpm for 5-8 minutes; adding the meerschaum, stirring the mixture at the rotating speed of 50-70 rpm for 30-35 minutes and then adding the aluminum dihydrogen phosphate, the attapulgite, the bentonite, the sodium silicate, the light magnesium carbonate and the titanium oxide; and after 25 minutes, adding rest components and stirring for 10-15 minutes to obtain the required sizing.

Owner:赵莉

Method for preparing light periclase-magnesium aluminate spinel composite material in in-situ decomposition manner

The invention relates to a method for preparing a light periclase-magnesium aluminate spinel composite material in an in-situ decomposition manner. The technical scheme is as follows: firstly 85wt% to 98wt% of magnesium-aluminum hydrotalcite, 2wt% to 12wt% of water and 0 to 4wt% of binding agent are mixed, uniformly stirred and then molded; then a molded green body is dried for 4h to 24h under the condition of 110DEG C, thermally insulated for 1-8h under the condition of 1000DEG C to 1800DEG C and then cooled to obtain the light periclase-magnesium aluminate spinel composite material, wherein the granularity of the magnesium-aluminum hydrotalcite is less than or equal to 0.5mm, and the content of Mg(4-6)Al2(OH)(12-16)(CO3).4H2O is more than or equal to 90 percent by weight. The preparation process is simple. By adopting the method, the light periclase-magnesium aluminate spinel composite material with a uniform organization structure can be obtained. The prepared composite material has the characteristics of small volume density, high strength, excellent corrosion resistance, good high-temperature volume stability and excellent thermal-shock stability, can be used as a raw material for producing high-temperature ceramics and fire-resistant materials and can also be used as a light excellent fire-resistant material.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com