Patents

Literature

158results about "Alkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

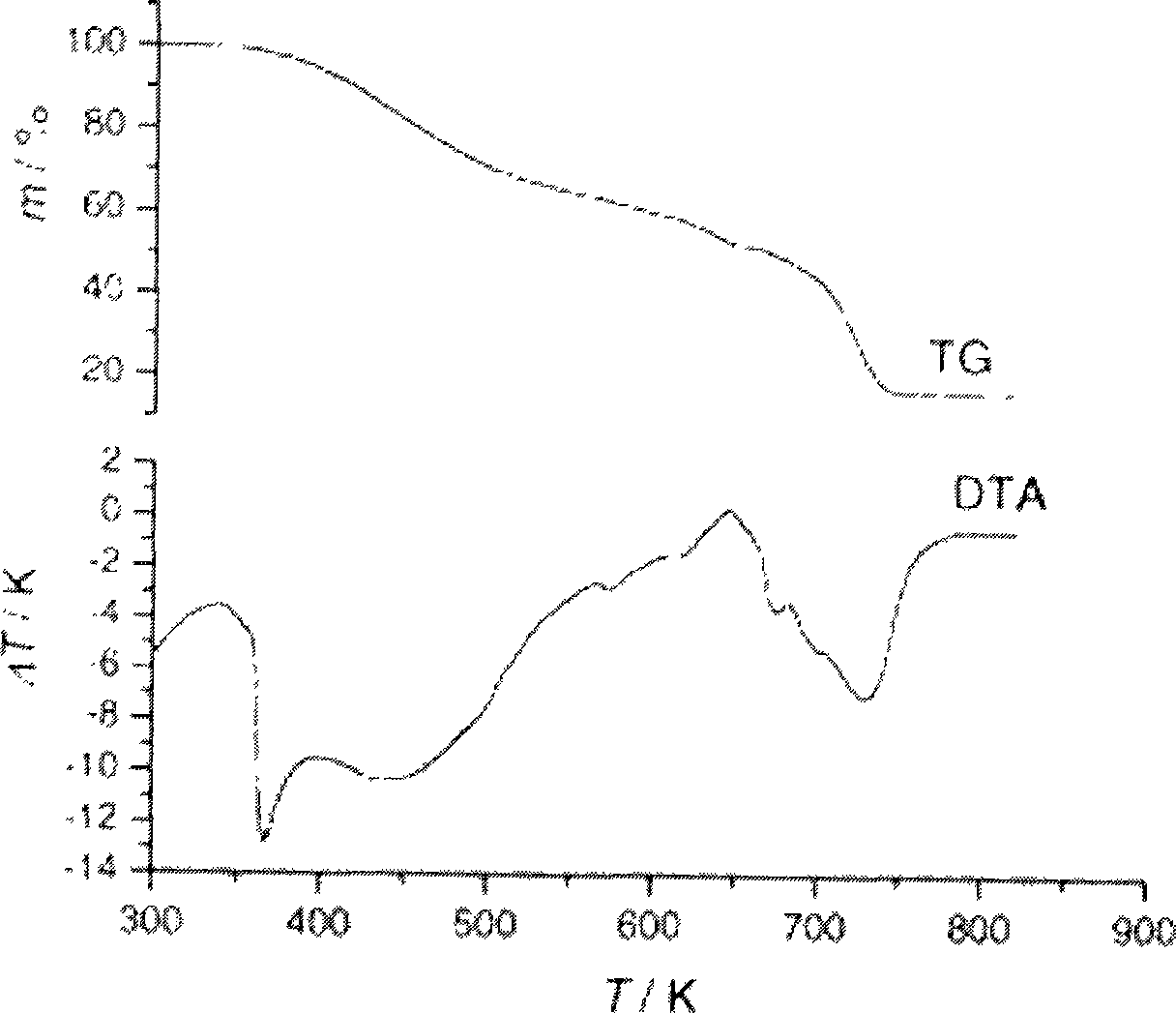

Synthesis of nanoparticles

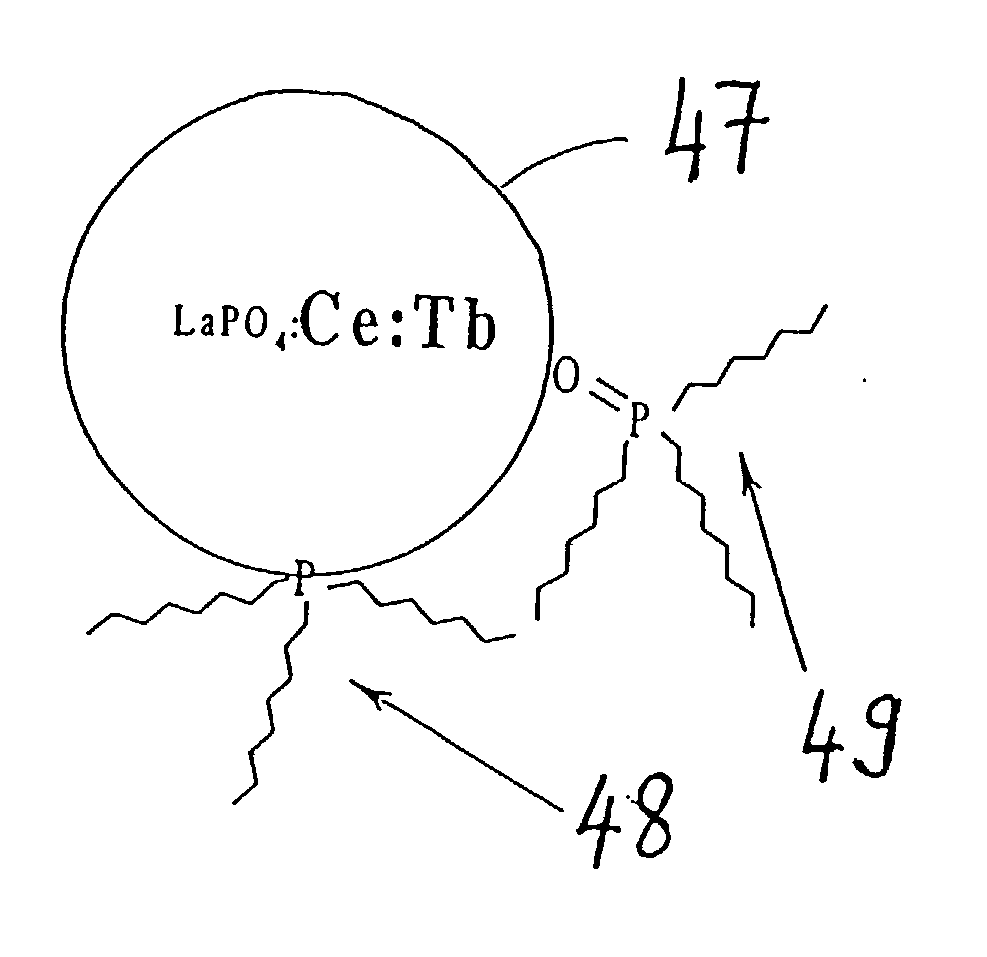

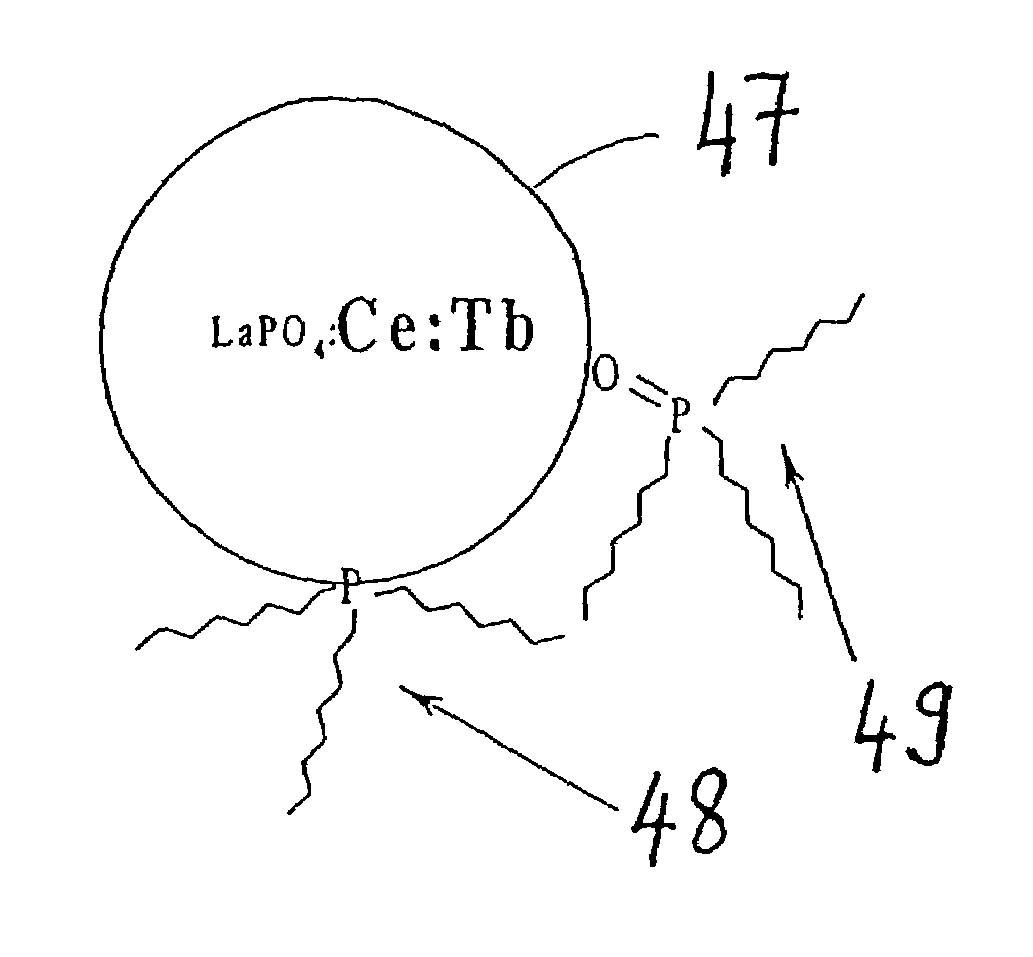

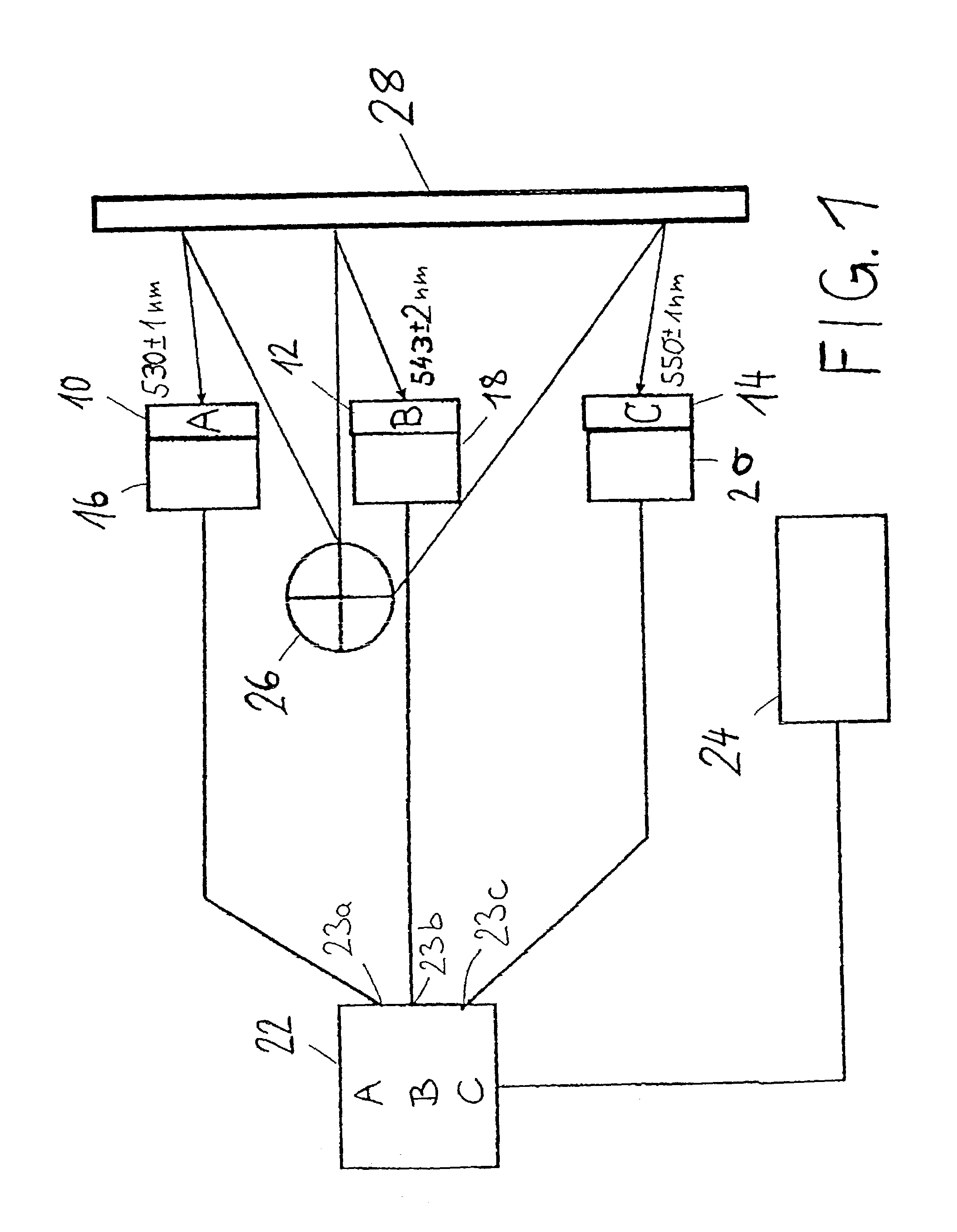

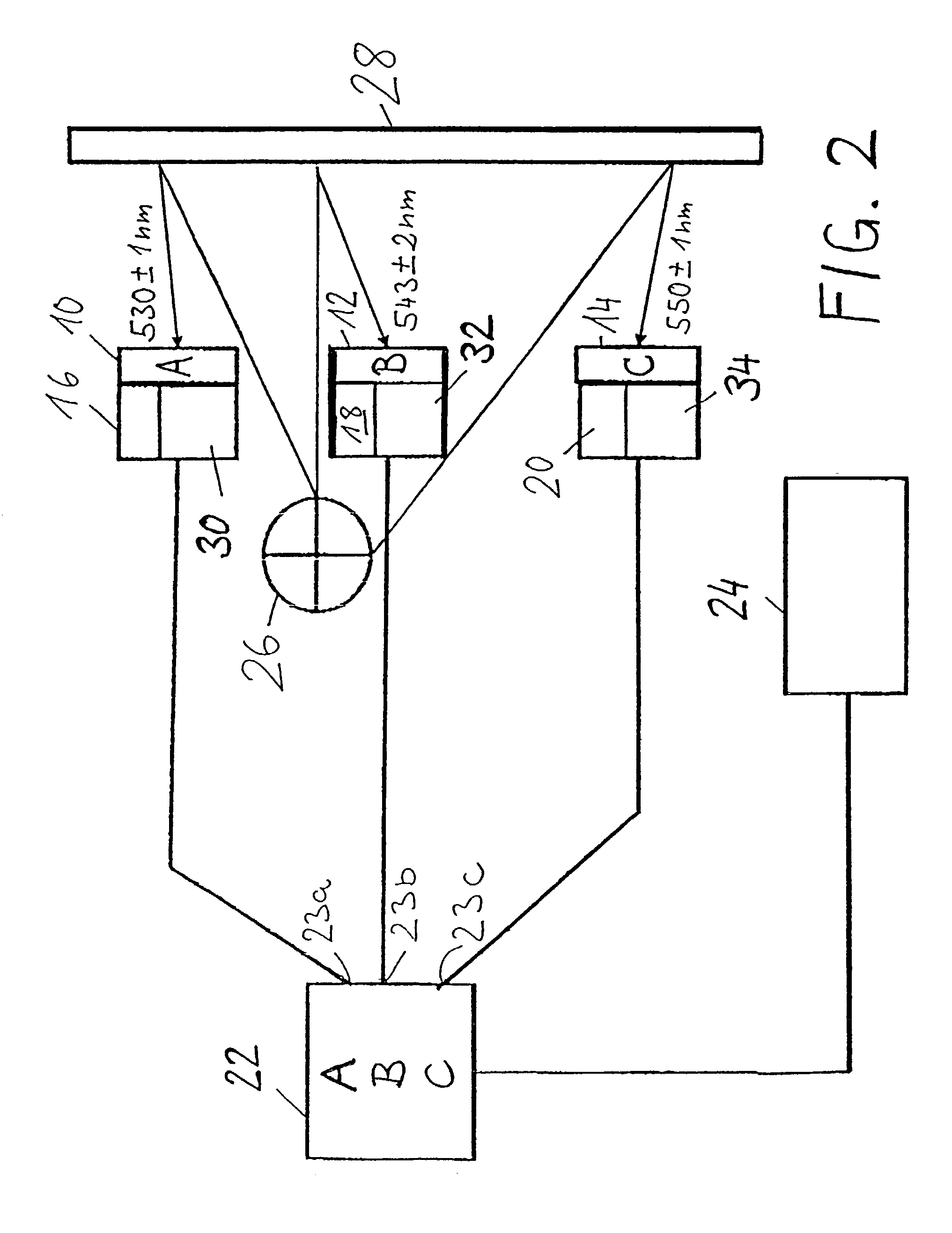

InactiveUS20030032192A1High sensitivityIncreasing efficiency of collectorOptical radiation measurementMaterial nanotechnologyDopantOrganic solvent

The present invention relates to methods for the preparation of inorganic nanoparticles capable of fluorescence, wherein the nanoparticles consist of a host material that comprises at least one dopant. The synthesis of the invention in organic solvents allows to gain a considerably higher yield compared to the prior art synthesis in water. All kinds of objects can advantageously be marked and reliably authenticated by using an automated method on the basis of a characteristic emission. Further, the size distribution of the prepared nanoparticles is narrower which renders a subsequent size-selected separation process superfluous.

Owner:CENT FUR ANGEWANDTE NANOTECH

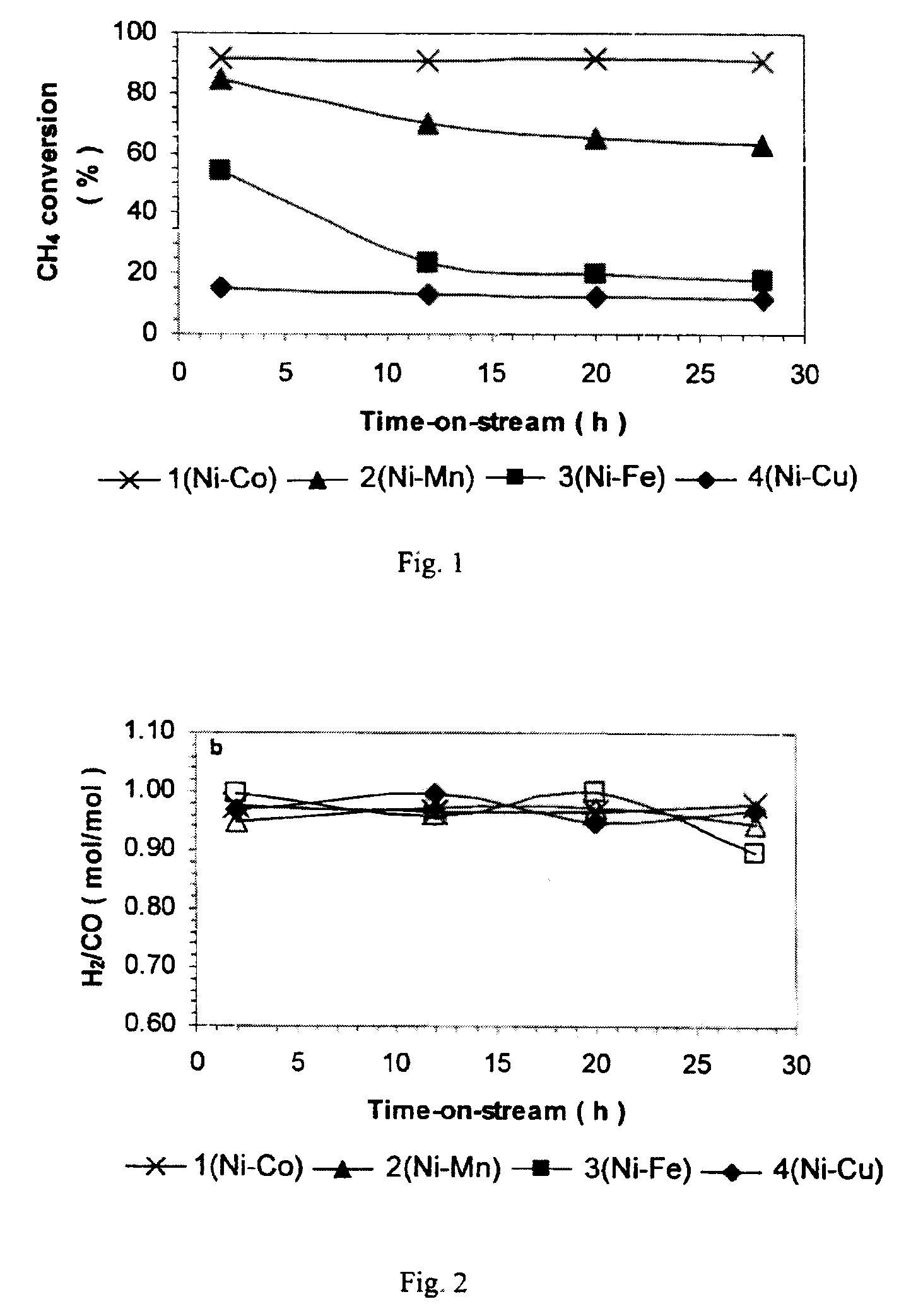

Catalyst for production of synthesis gas

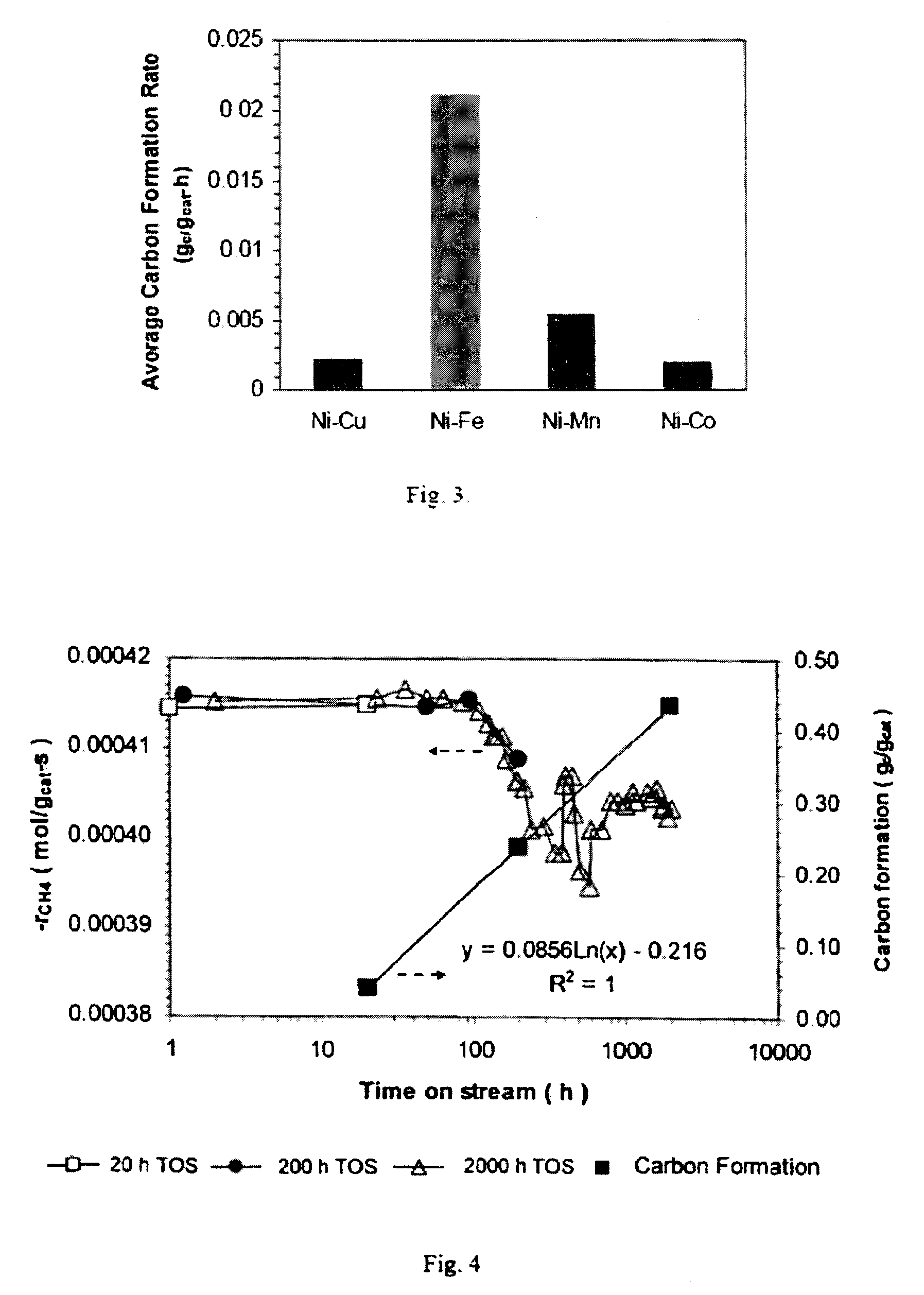

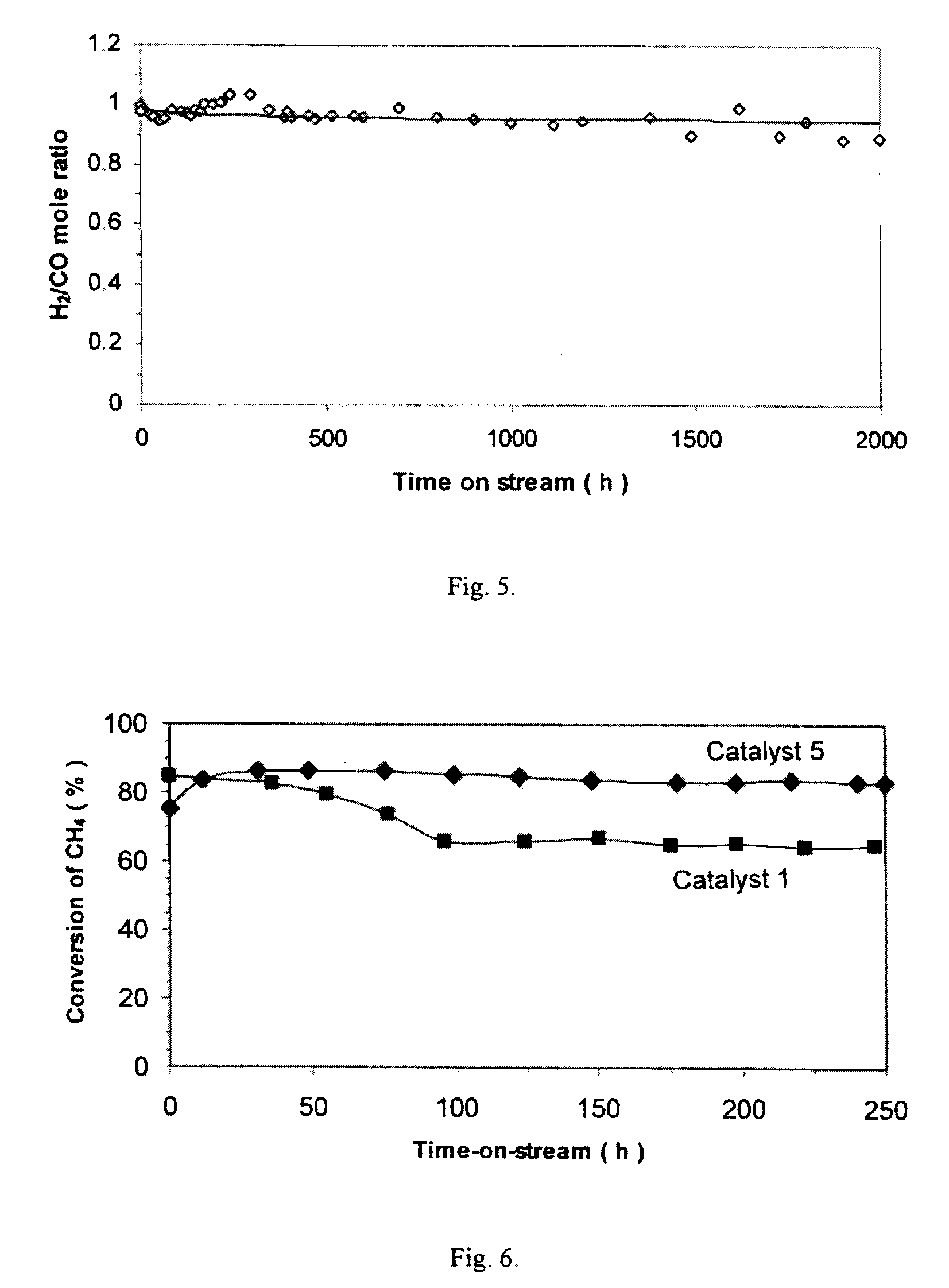

ActiveUS20090314993A1Hydrogen/synthetic gas productionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPtru catalystPhysical chemistry

The present invention relates to a novel composite metal oxide catalyst, a method of making the catalyst, and a process for producing synthesis gas using the catalyst. The catalyst may be a nickel and cobalt based dual-active component composite metal oxide catalyst. The catalyst may be used to produce synthesis gas by the carbon dioxide reforming reaction of methane. The catalyst on an anhydrous basis after calcinations has the empirical formula:Mam+Nbn+Alc3+Mgd2+O(am2+bn2+32c+d)Mm+ and Nn+ are two transition metals serving as dual-active components and selected from the group consisting of Ni, Co, Fe, Mn, Mo, Cu, Zn or mixtures thereof, a+b+c+d=1, and 0.001≦a≦0.8, 0.001≦b≦0.8, 0.1≦c≦0.99, 0.01≦d≦0.99.

Owner:UNIVERSITY OF SASKATCHEWAN

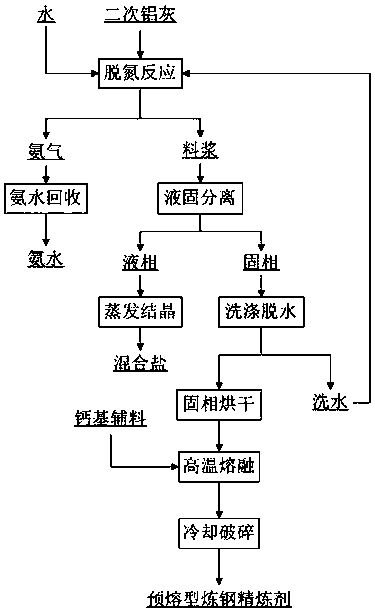

Harmless and comprehensive utilization method of secondary aluminum dross

InactiveCN107555447ARealize harmless treatmentTo achieve the purpose of "zero emission" utilizationChloride preparationFluoride preparationSlurryLiquid solid

The invention provides a harmless and comprehensive utilization method of secondary aluminum dross and relates to a harmless and comprehensive utilization method of secondary aluminum dross produced in an aluminum dross treating process. The harmless and comprehensive utilization method is characterized in that slurry is prepared from the secondary aluminum dross produced in the aluminum dross treating process and water, a stirring deamination reaction is performed, and ammonia gas formed through the reaction is condensed or absorbed by water; slurry after the reaction is subjected to liquid-solid separation, separated liquid phase is subjected to evaporative crystallization, and a chlorate and fluoride salt mixture is obtained; separated solid phase is used for producing a calcium aluminate material. With adoption of the method, the aluminum dross can be treated harmlessly, useful components in the aluminum dross are recovered efficiently, the harmless secondary aluminum dross can replace high-alumina bauxite for preparing a calcium aluminate product, production cost is reduced greatly, zero-release utilization of the aluminum dross is realized, the process is simple, the operation is convenient, the cost is low, environmental protection is realized, and the method has wide applicability.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Synthesis of nanoparticles

Owner:CENT FUR ANGEWANDTE NANOTECH

Method for making single or mixed metal oxides or silicon oxide

This invention relates to a method of manufacturing a product based on a simple or mixed metal oxide, or silicon oxide, from a charge of one or more precursors comprising one or more organic precursors. These oxides can be, for example, oxides of Ti, Al, Mg, Th, Si, Ba, Bc or Zr etc. The method comprises bringing the charge of organo-metallic precursors into contact with a reaction medium that comprises supercritical C02, at a temperature of from 31 to 100° C. and a supercritical pressure of from 3x107 to 5x107 Pa, in order to form from the precursor, a product based on a simple or mixed metal oxide, or silicon oxide, from the reaction medium by reducing the pressure of the supercritical C02 to a pressure lower than the supercritical pressure.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

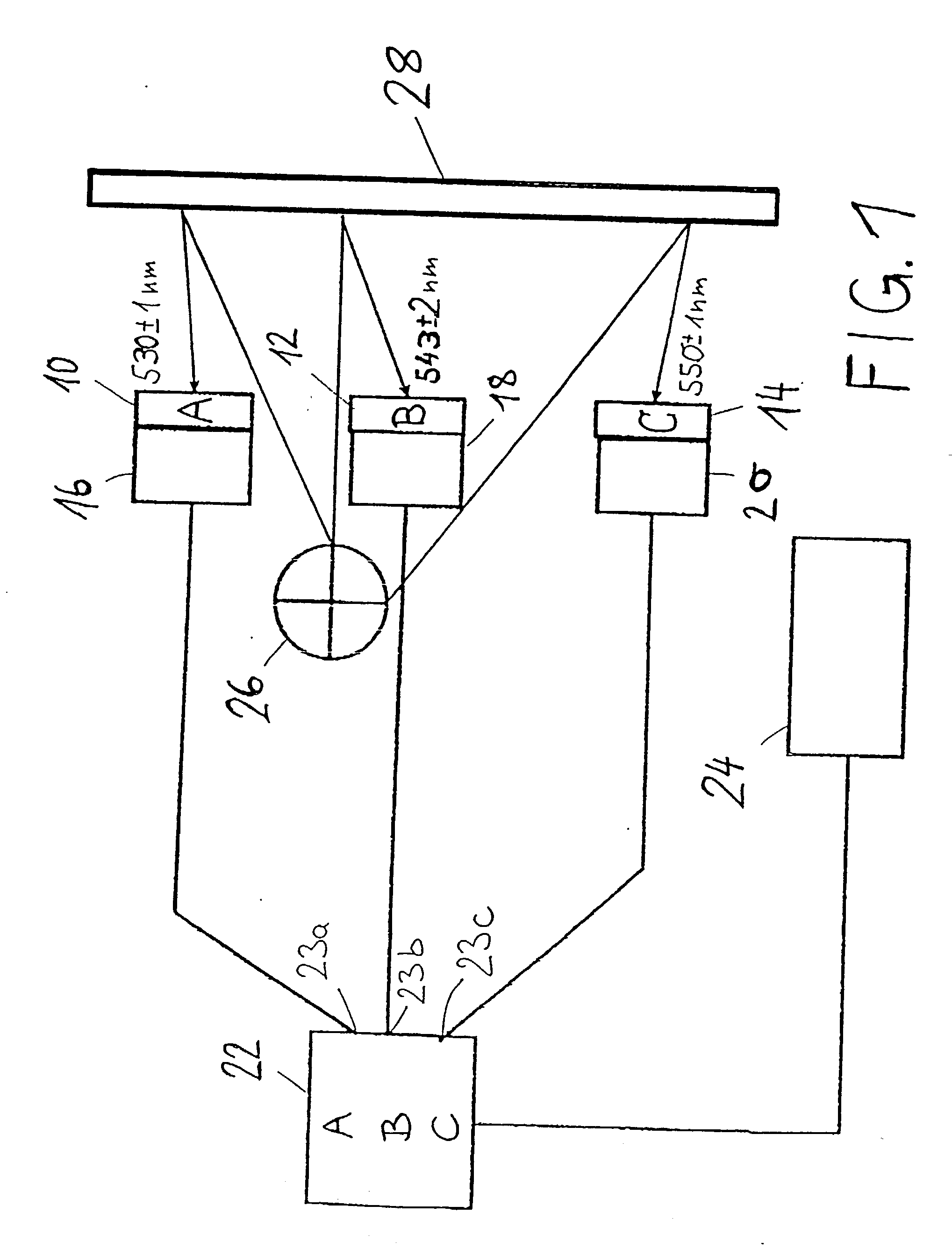

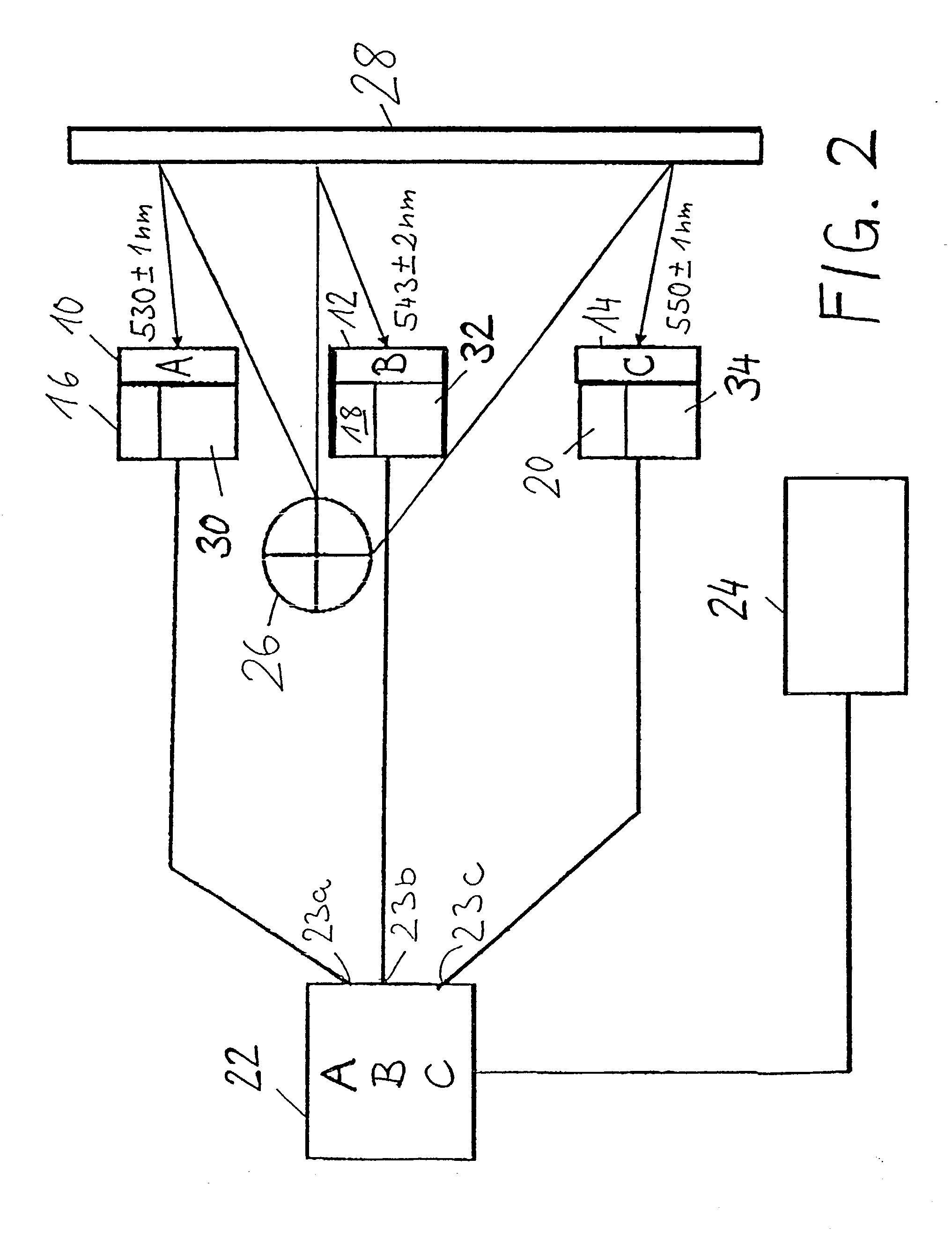

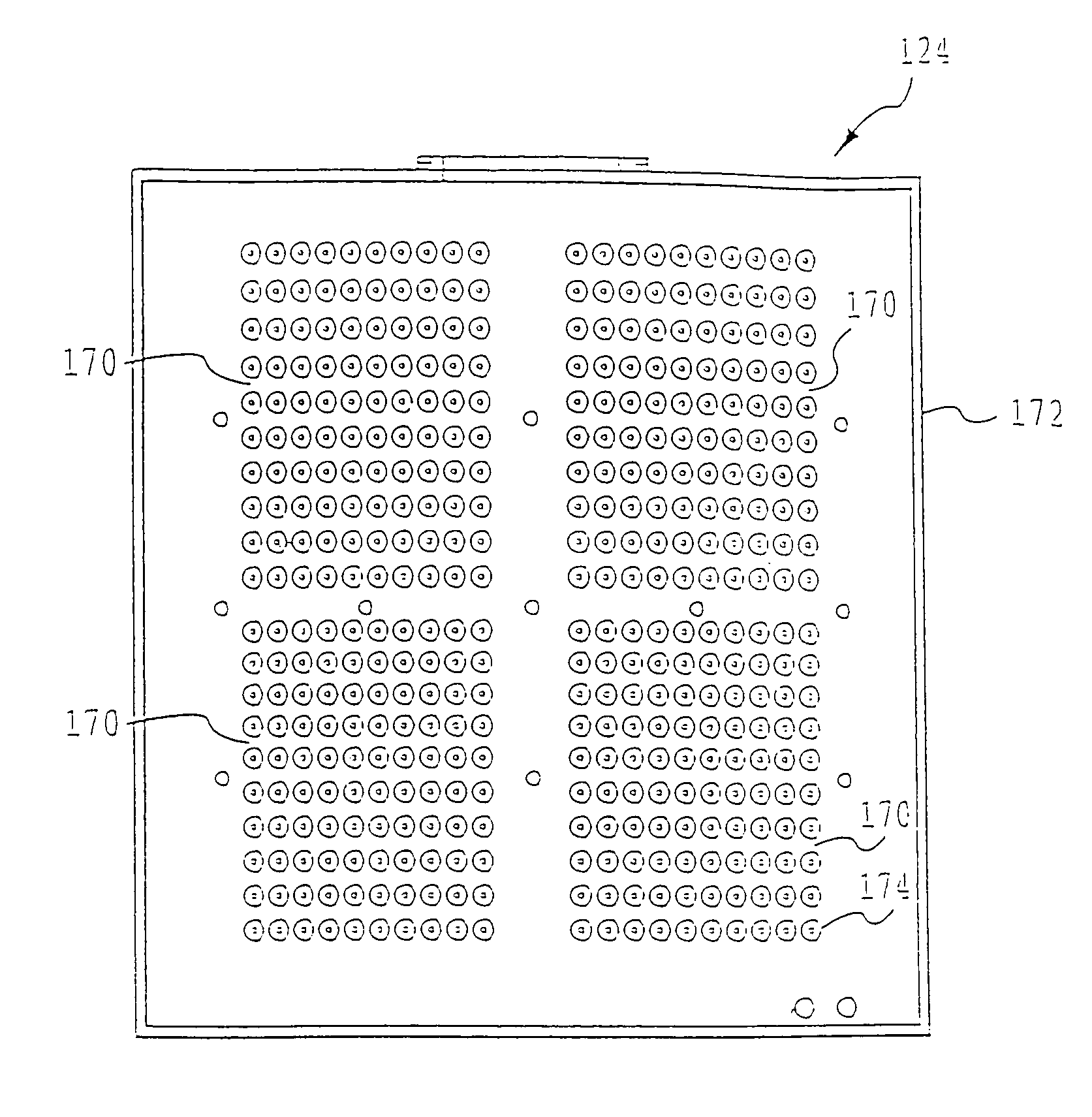

Direct-write deposition of phosphor powders

InactiveUS7476411B1Improve automationHigh resolution displayRare earth metal oxides/hydroxidesMaterial granulation and coatingApparent densityPhosphor

A liquid suspension of phosphor particles and method for depositing the liquid suspension. The suspension advantageously has a low viscosity with a high solids-loading of phosphor particles. The apparent density of the phosphor particles is well-controlled to enable the particles to be dispersed in the liquid vehicle. The suspension is useful in direct-write tools such as ink-jet devices.

Owner:SICPA HLDG SA

Comprehensive utilization method for red mud

InactiveCN101275182AEfficient use ofIncrease added valueAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateChemical composition

The invention belongs to the technical field of comprehensive utilization of red mud. The technical proposal of the invention is that: adding coke, anthracite which is 7-75% of mass of red mud, calcium compound which is 0-16% or aluminiferous compounds which is 0-645% into the red mud, placing in an electrical furnace after mixing; melting to deoxidize at the temperature ranging from 1400 to 1800 DEG C, and keeping temperature for 0.5 to 4 hours, crushing the red mud for separation after naturally cooling. The main chemical ingredients of the red mud is that: SiO<2> is 10-23wt%, Fe<2>O<3> is 7-40wt%, Al<2>O<3> is 6-20wt%, CaO is 3-45 wt%, Mgo is 0.5-3 wt%, K<2>O is 0.1-0.4 wt%, Na<2>O is 2-11 wt%, TiO<2> is 1-6 wt%, cauterized loss is 8-12wt%. Under high temperature, SiO<2> and Fe<2>O<3> in the red mud of the invention are deoxidized into ferro-silicon alloy, Al<2>O<3> and CaO are generated to calcium aluminate, Na<2>O and K<2>O are volatilized at high temperature to be refined, cooled and deposited to obtain the calcium aluminate material and ferro-silicon alloy by crushing separation, so the invention has the characteristics of wide application range and high additional value.

Owner:WUHAN UNIV OF SCI & TECH

Processing method for recycling aluminum dross

ActiveCN101913634ANo pollutionReduce pollutionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSocial benefitsPtru catalyst

The invention discloses a processing method for recycling aluminum dross, which comprises the following steps: adding crushed limestone and catalyst to aluminum dross, thoroughly homogenizing and mixing the three materials, carrying out catalyzed calcination on the thoroughly homogenized and mixed materials in a calcination reaction furnace, and directly grinding the calcined products or grinding the calcined products after cooling, thus obtaining the calcium aluminate powder product. The processing method has a simple operational process, and can not cause new environmental pollution, thereby according with the policy for industry development. The invention recycles the aluminum dross, simultaneously reduces environmental pollution caused by the aluminum dross, improves the environmental management on surrounding areas, and also provides a reasonable and effective way to recycle waste aluminum dross. Thus, the invention has obvious economic benefits and social benefits.

Owner:HENAN KETAI WATER PURIFYING MATERIALS

Method for producing calcium aluminate with waste aluminum gray

InactiveCN101172635ASimple processWide applicabilityAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationElectric arc furnaceCalcium aluminates

The invention relates to a method of utilizing wasted aluminum ash to produce calcium aluminate. The method comprises the steps as follows: wasted aluminum ash and calcium oxide are adopted as the raw materials; coke as the reducing agent and scrap iron as the settling agent are added, and smelted under high temperature in an electric arc furnace; the calcium aluminate produced after the melting is poured and cooled, and mulled and sieved, and utilized as the desulfurizer in making steel. The invention of simple technique does not require to process the wasted aluminum ash, which can instead bauxite to produce high-purity calcium aluminate, so that the invention reduces the production cost of the calcium aluminate, recycles the wasted aluminum ash which causes environmental pollution easily, and brings about remarkable comprehensive benefits socially and economically.

Owner:SHANGHAI JIAO TONG UNIV

Method for producing ferro-silicon alloy and calcium aluminate material with red mud and aluminum ash

InactiveCN101429582AEfficient use ofNo emissionsProcess efficiency improvementElectric furnaceSteelmakingRed mud

The invention relates to a method for preparing ferro-silicon alloy and a calcium aluminate material through utilizing red mud and aluminum ash. The method comprises the following technical proposal: 25 to 70 weight percent of the red mud and 30 to 75 weight percent of the aluminum ash are mixed, are added with 15 to 50 weight percent of a calcic compound or are not added with the calcic compound, are mixed, are put to an electric furnace, are melted and reduced at a temperature of between 1,400 and 1,800 DEG C, are kept at the temperature for 1 to 4 hours and are naturally cooled, broken and separated, to obtain the ferro-silicon alloy and the calcium aluminate material. The method uses the aluminum ash and the red mud as raw materials, utilizes waste and has a simple process and low cost. In the reaction process, metal aluminum and aluminum nitride are utilized as reducing agents; the process is exothermic, thereby reducing electricity consumption, having no emission of CO2 and reducing environmental pollution; and the ferro-silicon alloy and the calcium aluminate material have wide application range and high added values. The prepared calcium aluminate material can be used as a corhart and a raw material for producing calcium aluminate cement and can also be used as premelt slag in steel industry; and the ferro-silicon alloy can be used as a deoxidant and an alloy agent for steelmaking.

Owner:WUHAN UNIV OF SCI & TECH

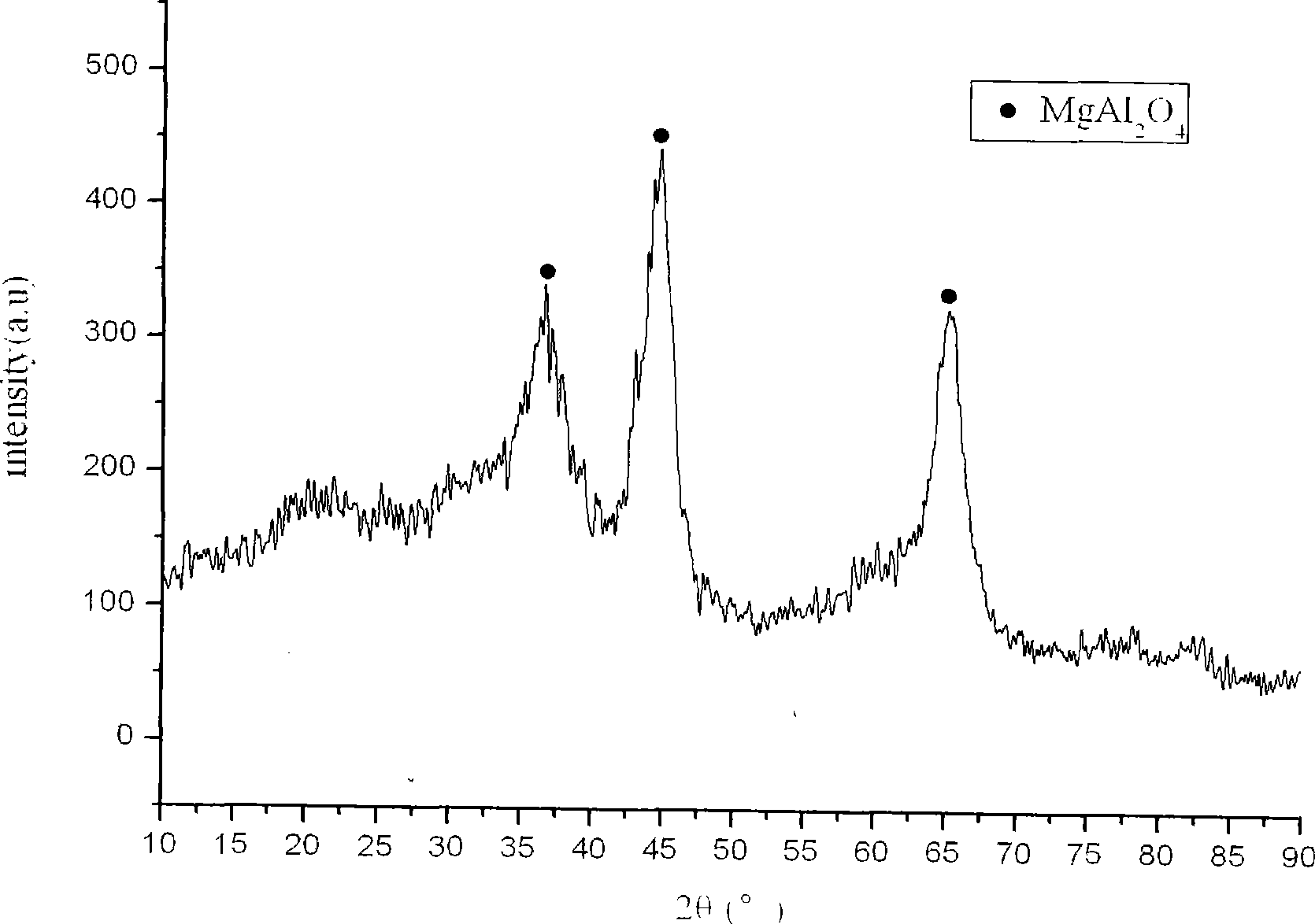

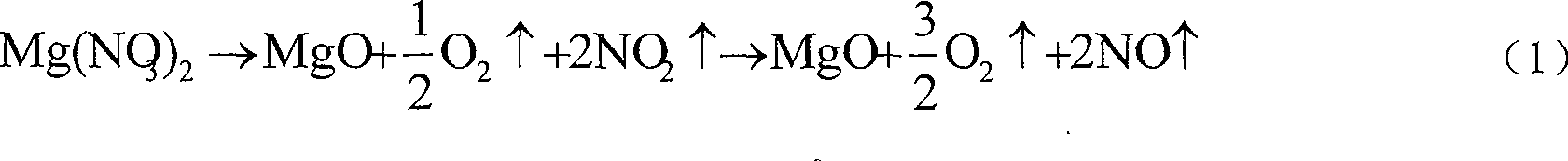

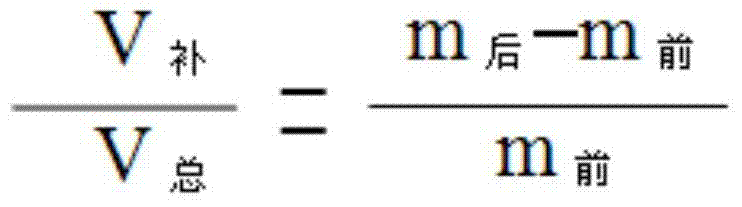

Environment-friendly low-temperature solid-phase synthesis method of magnesia-alumina spinel powder

InactiveCN101445261ALow priceAvoid emissionsAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSynthesis methodsOxygen

An environment-friendly low-temperature solid-phase synthesis method of magnesia-alumina spinel powder belongs to the solid-phase low-temperature synthesis method of complex oxide powder. The method comprises the following steps: selecting magnesium nitrate powder or other crystalline hydrate powder with purity more than 95% and alumina powder or various alumina precursor powders as the raw materials; decomposing magnesium nitrate at low temperature by conventional milling, mixing and low-temperature solid-phase co-firing process to obtain high-activity magnesium oxide and oxygen; and synthesizing the magnesia-alumina spinel powder from the high-activity magnesium oxide and oxygen at 350 to 600 DEG C. Compared with the prior solid-phase synthesis method, the calcination temperature is reduced by 500 to 700 DEG C, thereby greatly reducing the energy consumption and obviating emission of greenhouse gas CO2. Compared with liquid-phase synthesis and sol-gel process, the calcination temperature is reduced by hundreds of centigrade, the unavoidable environment pollution of the liquid-phase process is obviated, and the method can achieve low material cost, simple facility and short production flow. The method can be used for synthesizing high-temperature ceramics, high-temperature electric-insulation refractory materials, catalyst carriers and transparent materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for producing calcium hexaluminate with waste aluminum ash

InactiveCN101353177ASimple processWide applicabilityAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationElectric arc furnaceDross

The invention relates to a method for producing calcium aluminate by waste aluminium dross. In the method, according to weight proportion the waste aluminium dross accounting for 80-97% and calcium oxide accounting for 3-20% are taken as raw materials (the total proportion thereof is 100%), uniformly mixed with a reducing agent accounting for 5-5% of the total weight of the raw materials and a precipitating agent accounting for 10-15% of the total weight of the raw materials and smelted in an electric arc furnace to obtain calcium hexaluminate, and the smelted calcium hexaluminate is poured out, cooled, crushed and separated. The method has simple and convenient process and can replace bauxite to produce high-purity calcium aluminate without treating the waste aluminium dross, thus the production cost of the calcium aluminate is reduced, and the waste aluminium dross which easily causes environmental pollution is utilized.

Owner:SHANGHAI JIAO TONG UNIV

Method for recycling alkali and aluminum in process of treating bayer red mud by calcification-carbonization method

ActiveCN103934258APromote incomeReduce energy consumptionSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

The invention relates to the field of environment protection, and in particular relates to a method for recycling alkali and aluminum in a process of treating bayer red mud by a calcification-carbonization method. The method comprises the steps of mixing the bayer red mud with calcium aluminate or lime and the calcium aluminate to obtain a mixture, performing calcification dealkalization transformation on the mixture in high-concentration alkali liquid with the caustic alkali concentration being 100-300g / L, totally converting silicon-containing phases in the red mud into calcified slag generated in a dealkalization process in the form of hydrate garnet, carbonizing the calcified slag to obtain carbonized slag, then o carrying out low-temperature aluminum smelting and aluminum precipitation to obtain a calcium aluminate product, and recycling the calcium aluminate product in the red mud calcification dealkalization transformation process. Part of alkali and aluminum-containing liquid phases subjected to calcification dealkalization transformation can be reused as supplement alkali in a bayer production process. The method disclosed by the invention can realize recycling of alkali and aluminum in the red mud and harmless treatment of the bayer red mud, and is an energy-saving and environment-friendly red mud utilization method.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Amorphous calcium aluminate and preparation method thereof

ActiveCN102765738AChange the speed of condensationRaise the labelAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateSteelmaking

The invention discloses an amorphous calcium aluminate, which can be used in both steelmaking industry and cement additive industry. The invention also discloses a preparation method of the amorphous calcium aluminate. The method comprises the steps of: raw material selection, mixing, smelting by a furnace, tapping, cooling and pelletization. The cooling step is carried out for a while, starting from a certain temperature, to form the amorphous calcium aluminate; and the certain temperature is optimally to be 2000 DEG C.

Owner:ZHENGZHOU SHENGTONG METALLURGY MATERIAL

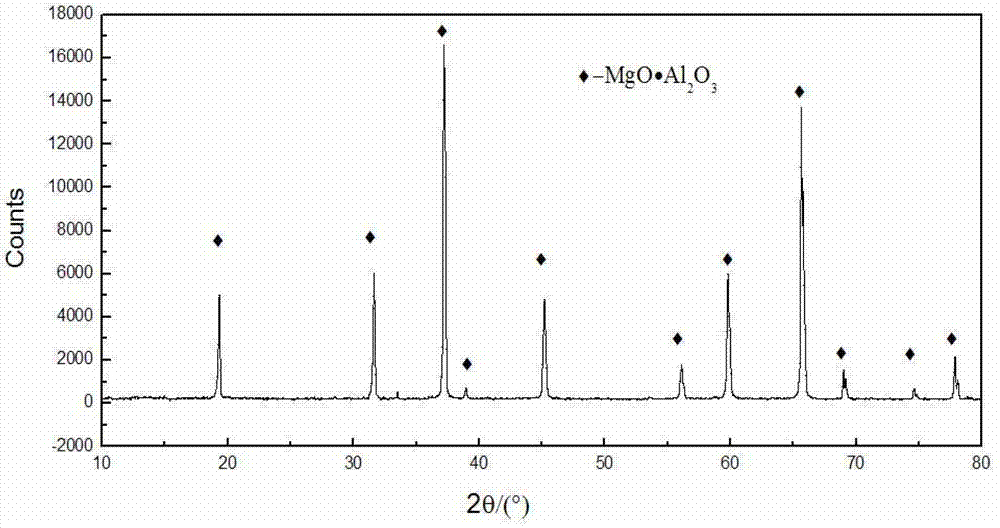

Preparation method for magnesia-alumina spinel

ActiveCN103204528ASimple structureStable structureCatalyst carriersAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCrystal structureSpinel

The invention relates to a preparation method for magnesia-alumina spinel. The preparation method comprises the steps of: firstly, evenly mixing alumina-containing compound and magnesium-containing compound according to the mole ratio of Al:Mg being 3.2:1-3.92:1; then adding acid solution, and stirring evenly into size; then neutralizing the size with alkali liquor; and finally, filtering the neutralized product, washing, drying and roasting a filter cake to obtain the magnesia-alumina spinel. According to the preparation method for the magnesia-alumina spinel, the alkali liquor can be added after the acid solution is added, the aluminum source can be directly doped into crystal lattices of the aluminum-magnesium crystals in the crystal nucleus growth process of the aluminum-magnesium crystals, so that the strength of the prepared magnesia-alumina spinel compound is larger, the crystal structure is more stable, thereby better meeting the strength requirement of a hydrogenated desulfurization catalyst to a carrier.

Owner:SHENYANG SANJUKAITE CATALYST

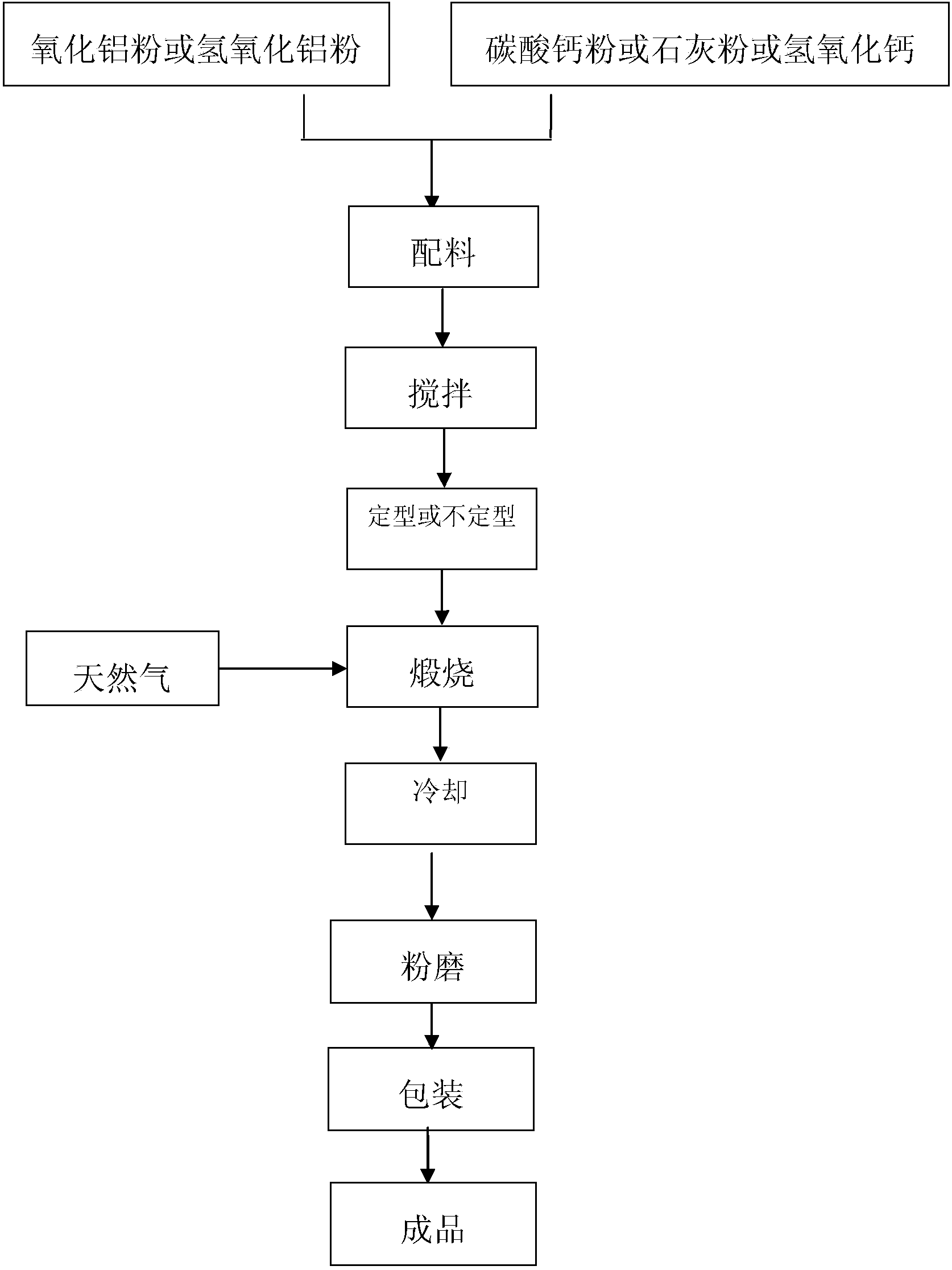

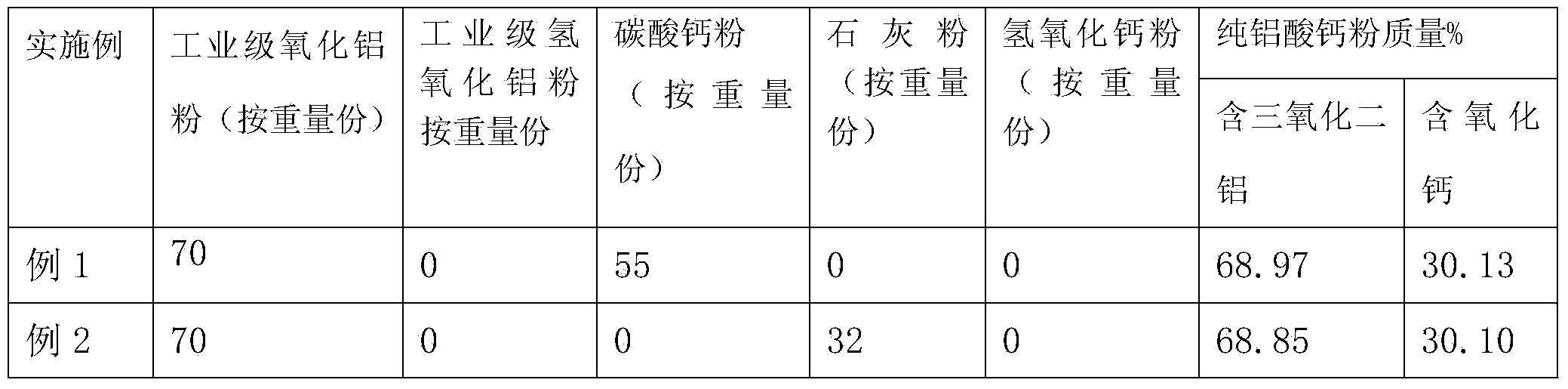

Method for preparing pure calcium aluminate powder for water treatment

InactiveCN103880051AAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCalcium hydroxideAluminium hydroxide

The invention discloses a method for preparing pure calcium aluminate powder for water treatment. The method comprises the following steps: (1) according to 100kg of pure calcium aluminate powder to be produced, uniformly stirring the following raw materials in parts by weight: 0-70kg of industrial grade alumina powder or 0-107kg of aluminum hydroxide powder, 0-76kg of calcium carbonate powder, 0-44kg of lime powder and 0-61kg of calcium hydroxide powder, thus obtaining a mixture; (2) moulding the mixture or directly using the mixture; (3) pushing the moulded mixture or the directly used mixture into a natural gas kiln, sintering at the sintering temperature of 1350-1400 DEG C for 1-2 hours, cooling after the mixture is sintered into clinker, and milling to obtain the pure calcium aluminate powder in which the mass percent of aluminum oxide is 57-69 percent, the mass percent of calcium oxide is 30-42 percent and the mass percent of the acid dissolution rate is 95-99.5 percent. The pure calcium aluminate powder for water treatment can be prepared by adopting the industrial grade alumina powder or industrial grade aluminum hydroxide powder and calcium carbonate powder or lime powder or calcium hydroxide powder.

Owner:GUANGXI AL STONE ECO FRIENDLY MATERIAL CO LTD

Method for manufacturing high-purity magnesium-aluminum spinel

ActiveCN101671046AHigh melting pointImprove thermal conductivityAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationState of artSpinel

The invention provides a method for manufacturing high-purity magnesium-aluminum spinel, and relates to a method for manufacturing a high-quality fireproof material used in all kinds of thermal equipment widely applied in industries such as metallurgy, cement, glass and ceramics. The method comprises the following steps: mixing 50 to 95 weight percent of Gamma-Al2O3 and 50 to 5 weight percent of dead burnt MgO evenly; carrying out ultrafine grinding and mechanical classification; carrying out pelletizing, shaping and drying; and finally, obtaining finished products by calcining for 8 to 20 hours inside an ultrahigh temperature vertical kiln at a temperature of between 1,820 and 1,930 DEG C. The manufacturing method solves the problems in the prior art of low material density and low production capacity. The magnesium-aluminum spinel obtained by the manufacturing method has the characteristics of high melting point, low coefficient of heat expansion, excellent thermal conductivity, strong chemical corrosion resistance, and the like.

Owner:JIANGSU JINGXIN NEW MATERIAL

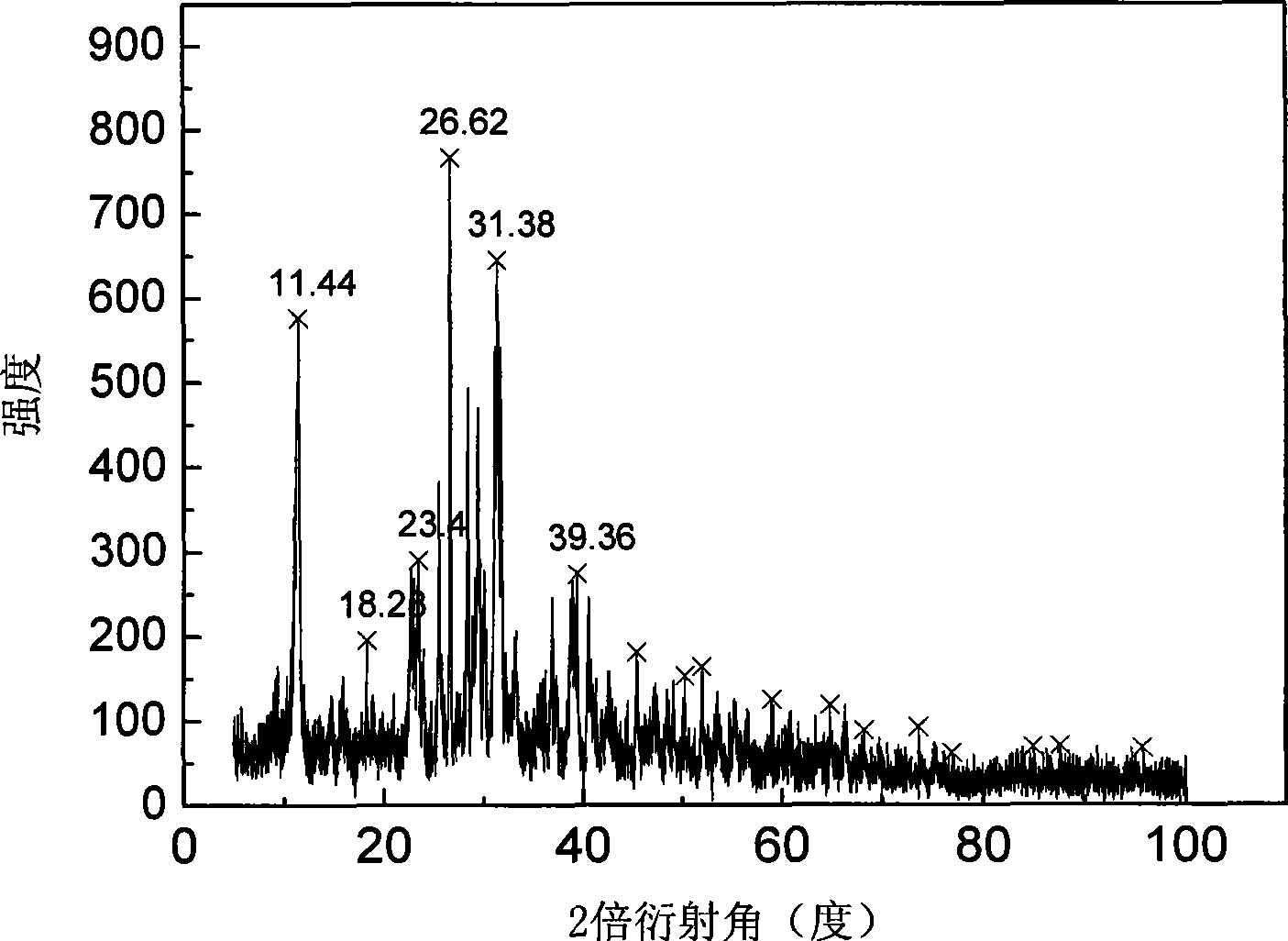

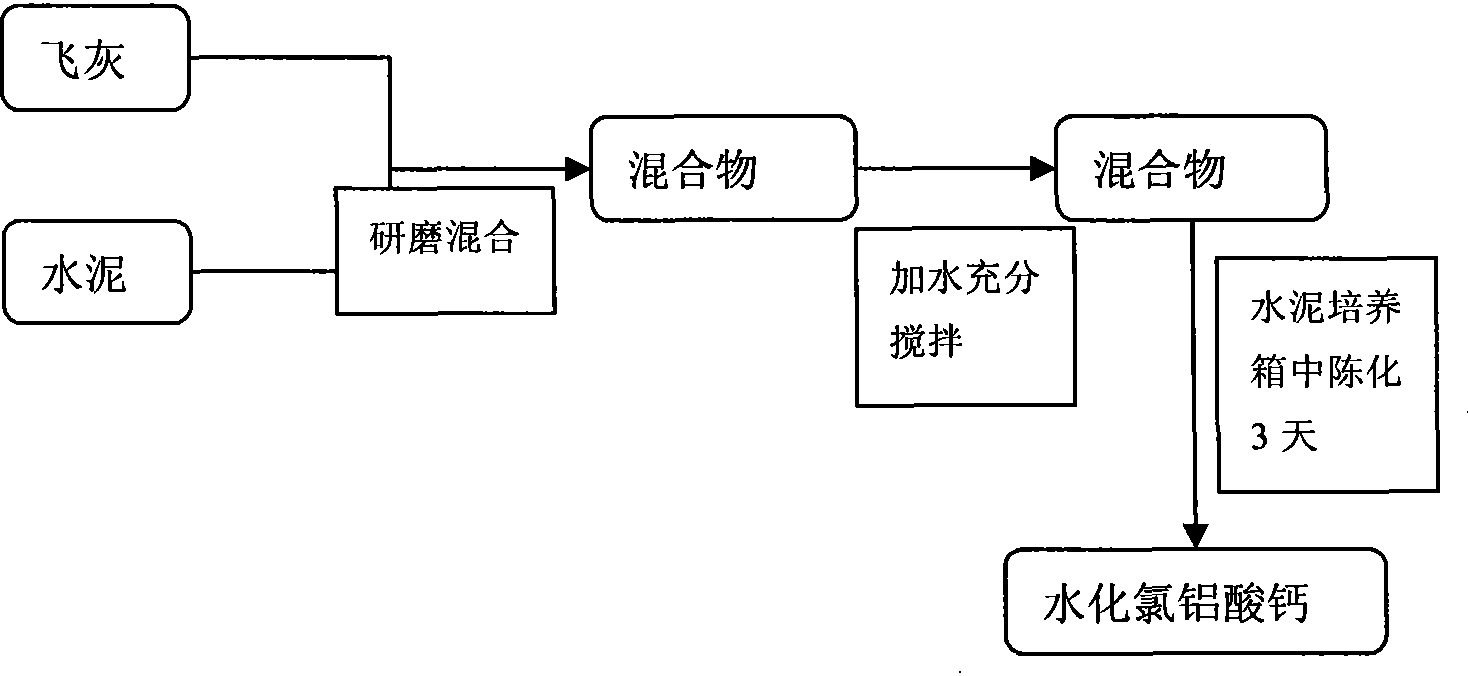

Method for synthesizing hydrated calcium chloroaluminate from municipal refuse incineration fly ash

InactiveCN101519220AAchieve the effect of treating waste with wasteLayered structure is obviousAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHydration reactionMemory effect

The invention relates to a method for synthesizing hydrated calcium chloroaluminate, which belongs to the technical field of environmental engineering solid waste utilization. The method comprises the following steps: mixing and stirring municipal refuse incineration fly ash, aluminate cement and deionized water according to the weight ratio of 70:30:33; putting the mixture into a cement incubator for incubating for 72 hours under a condition that the humidity is between 95 and 99 percent; and drying and grinding the mixture to obtain micro-particles mainly comprising the hydrated calcium chloroaluminate. Through mixed hydration reactions between solid phases under the action of water, a compound with the characteristics of pollutant binding capacity, LDHs special structure, anion exchangeability, memory effect, and the like is synthesized. The method provides a new way for the treatment and the disposal of hazardous waste of fly ash, and achieves the effect of treating wastes by wastes simultaneously.

Owner:SHANGHAI UNIV +1

A method for recovering alkali and aluminum in course of treatment of bayer red mud by using calcification-carbonation method

ActiveUS20170036920A1Comprehensive utilization of valuable elementLow costSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

A method for recovering alkali and aluminum during treatment of Bayer red mud using a calcification-carbonation method, including steps of mixing the Bayer red mud with calcium aluminate or with calcium aluminate and lime, performing calcification dealkalization conversion in a high-concentration alkaline liquor, and carbonizing the calcified residues produced during dealkalization to obtain carbonized residues; and then performing low-temperature aluminum dissolution, aluminum precipitation and the like to obtain calcium aluminate products, which is returned to the calcification dealkalization conversion of the red mud for recycling. Part of an alkali-containing and aluminum-containing liquid phase after calcification dealkalization conversion can be used as supplementary alkali in the Bayer production course for recycling. The method is energy-saving and environmentally-friendly, and allows recovering alkali and aluminum from the red mud and harmless treatment of the Bayer red mud.

Owner:NORTHEASTERN UNIV

Method of producing electric melting magnesium aluminum spinel

InactiveCN1919739AQuality improvementAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationElectric arc furnaceSlag

The invention discloses a manufacturing method of electric melting magnesium aluminate spinel in the material technological domain, which comprises the following steps: sintering; placing non-disposed aluminum ash in the rotary kiln; placing aluminum ash in the groove; adding dilute acid; stirring; draining acid liquid; centrifuging; removing surface water at 200 deg.c; mixing aluminum, carbon element material and hammer slag with weight rate at 100:6-9:8-14 evenly; adding in the arc furnace; controlling pressure and current; reducing; reinforcing electric field; adding light-sintering magnesium sand with 65% Al2O3 and 30% MgO; refining; cooling the fused liquid; obtaining the magnesium aluminate spinel with Al2O3 between 63% and 67%; grinding the magnesium aluminate spinel; dehydrating; drying; proceeding magnetic cobbing.

Owner:SHANGHAI JIAO TONG UNIV

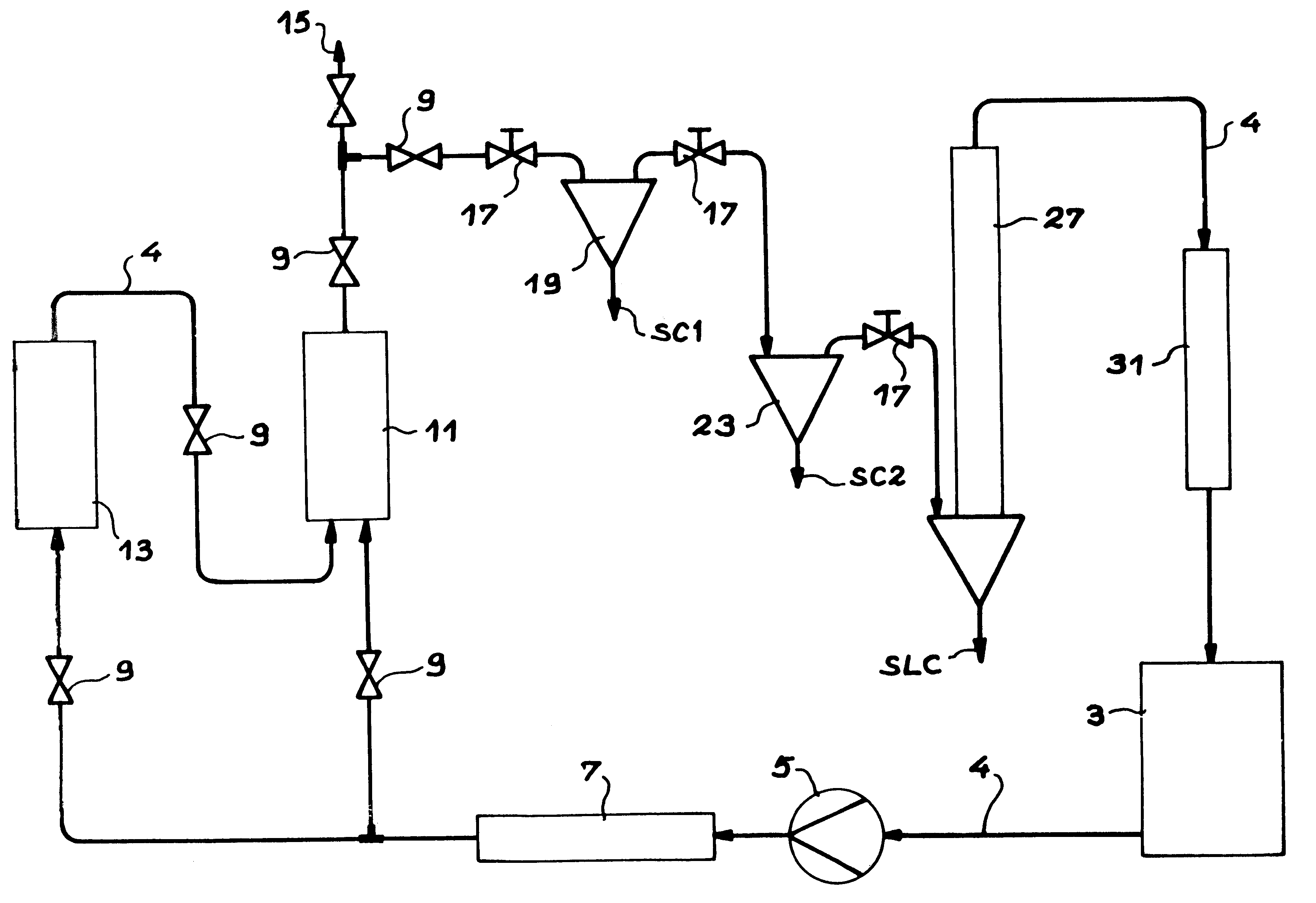

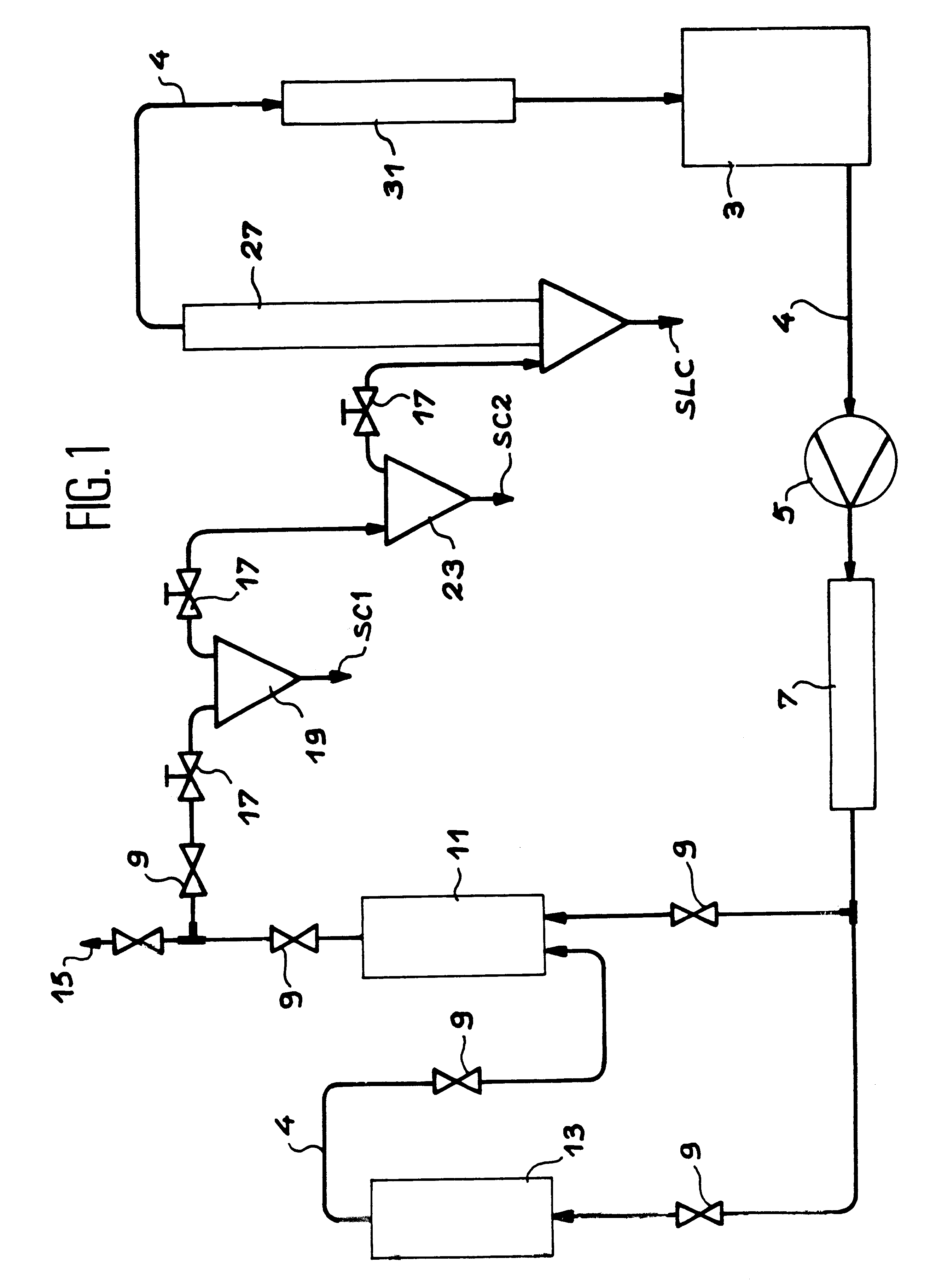

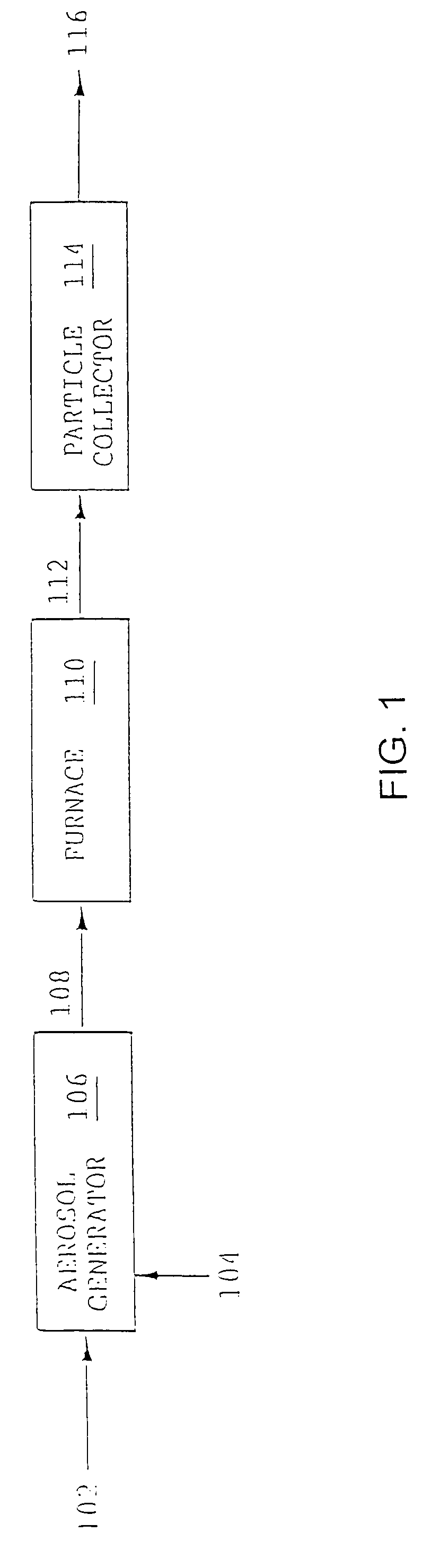

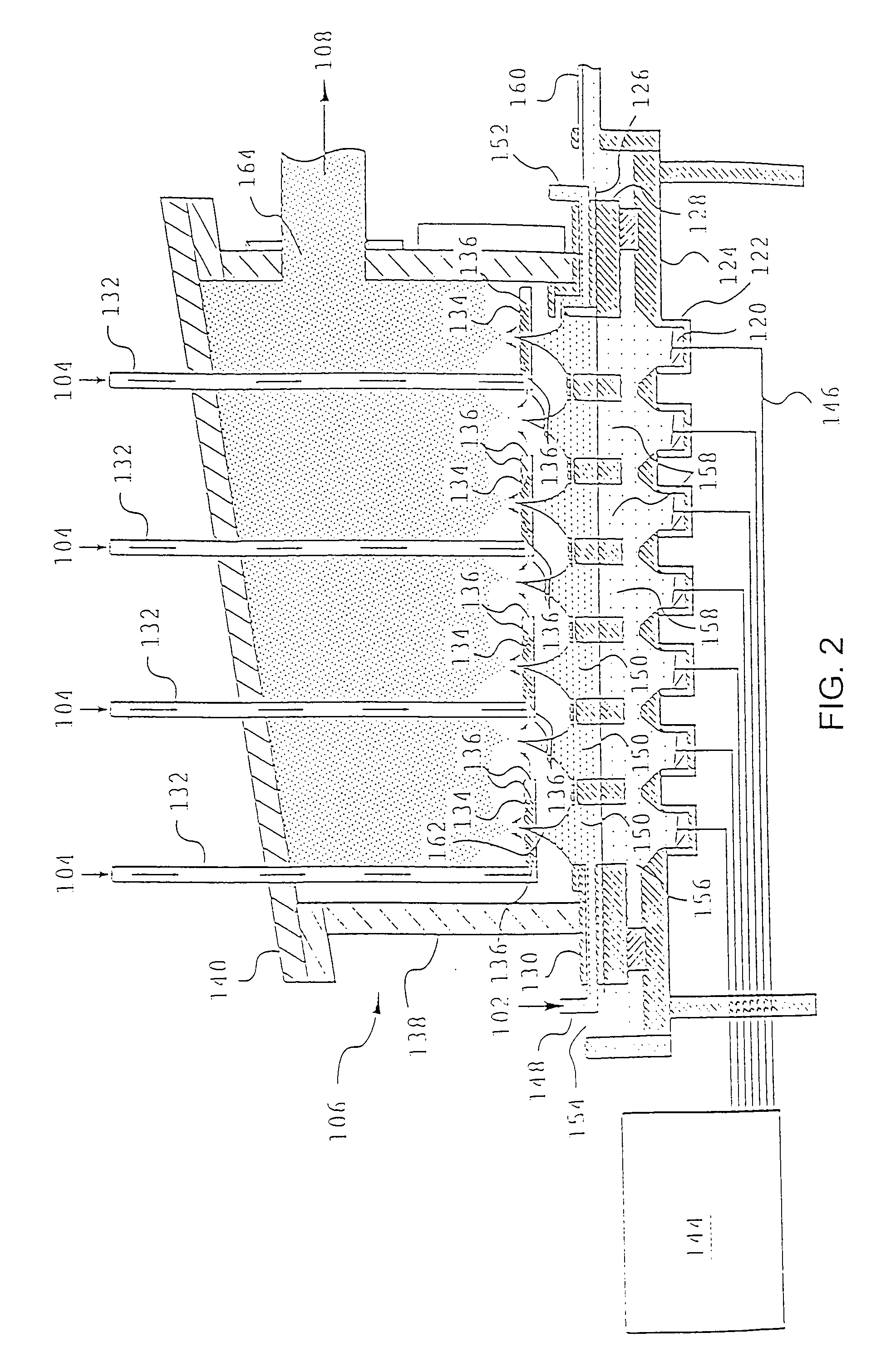

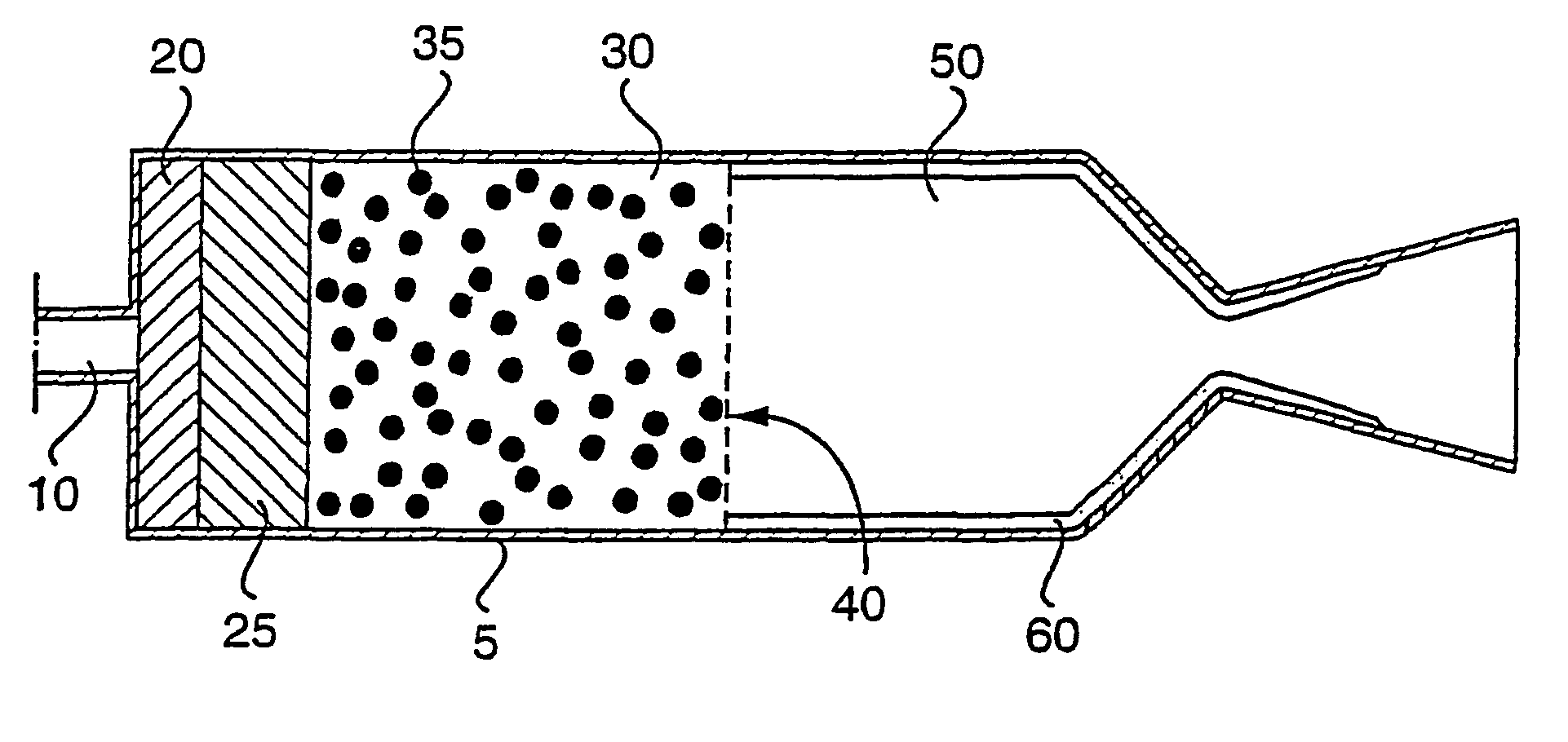

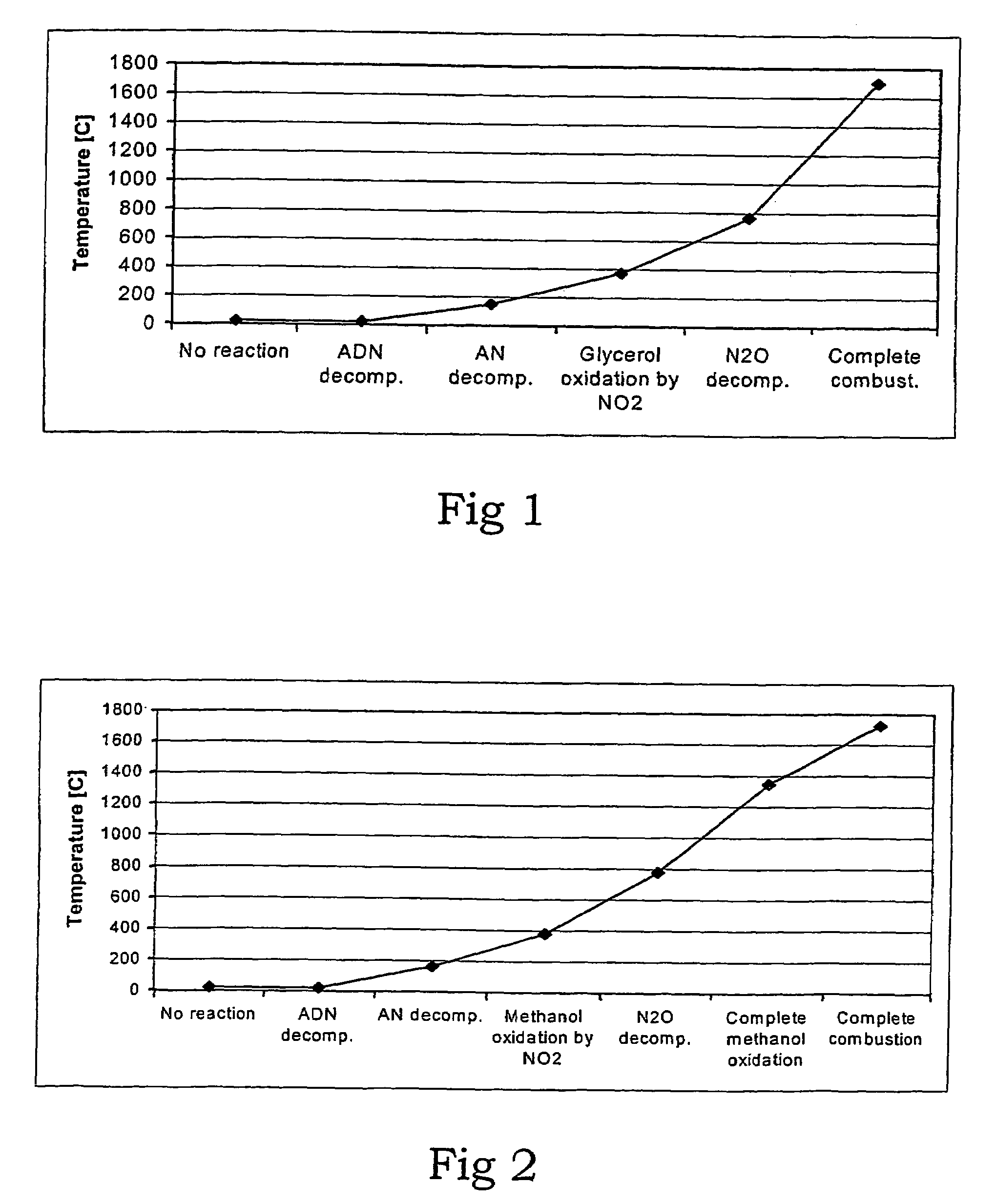

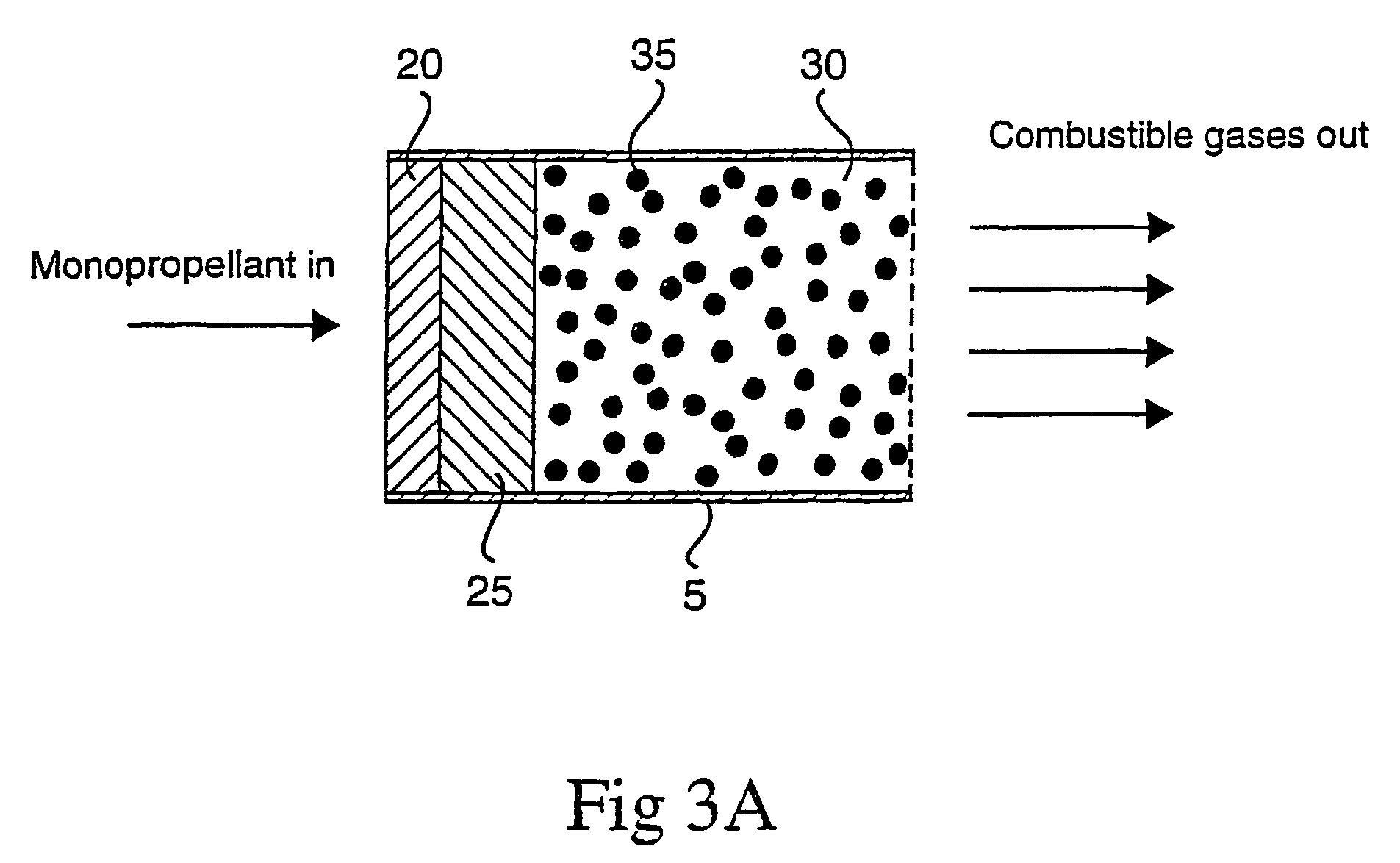

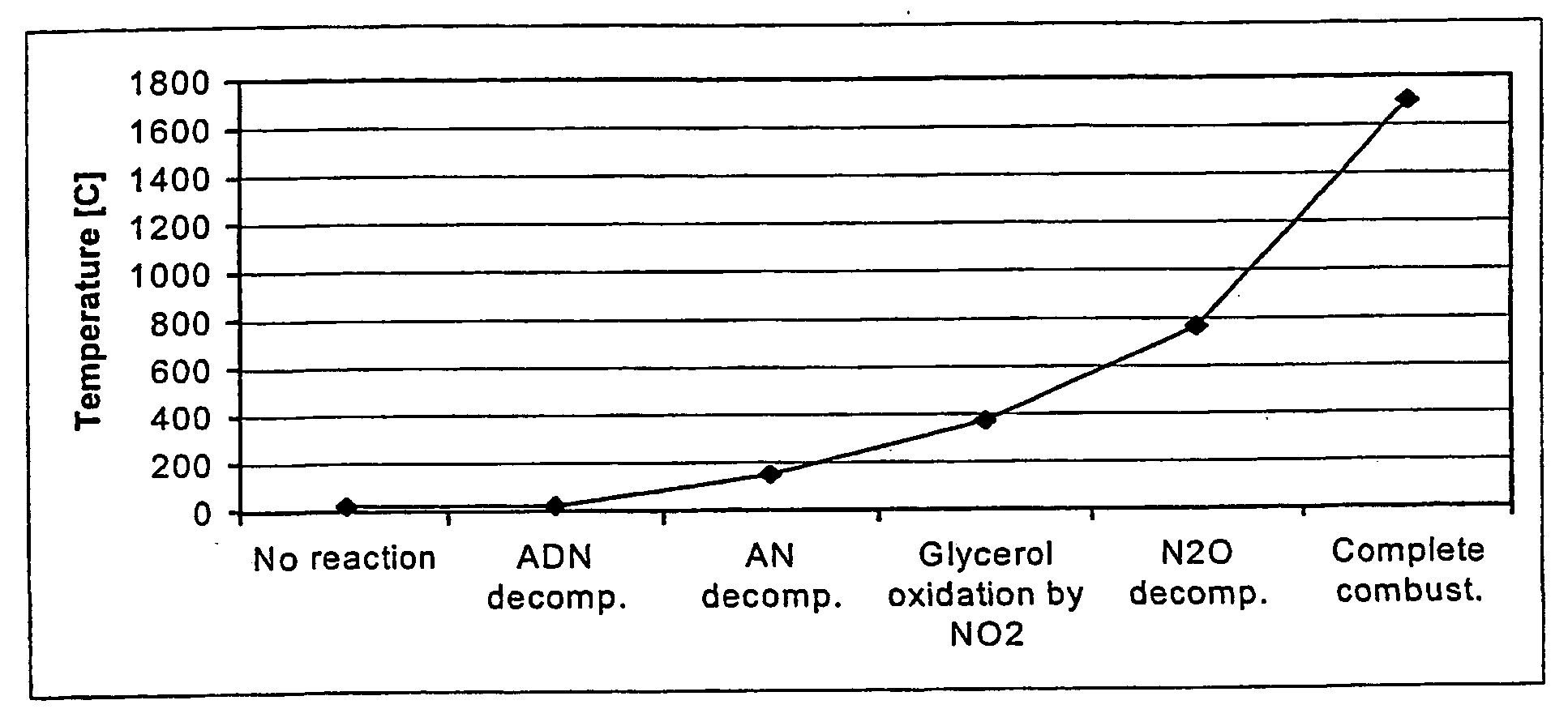

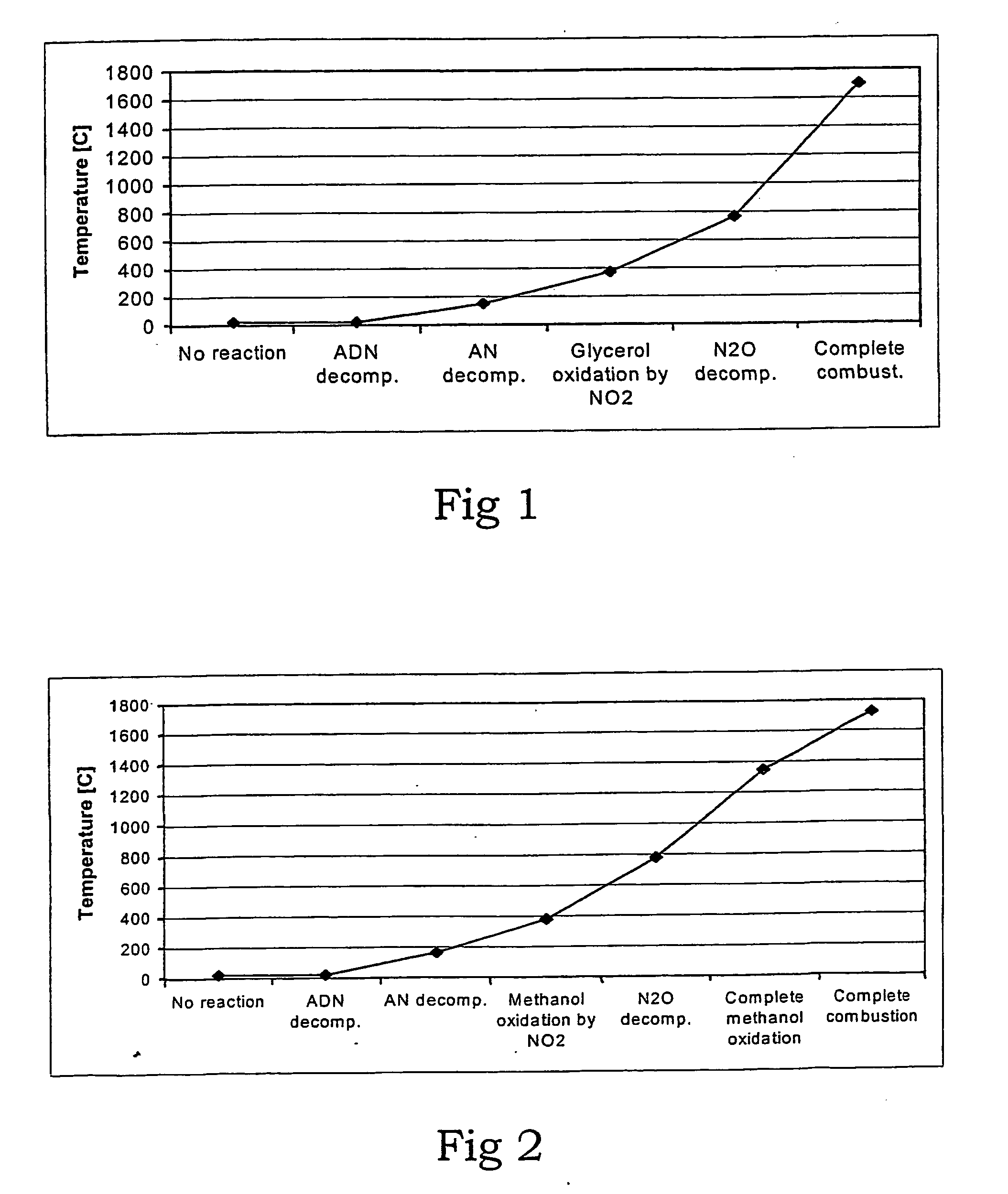

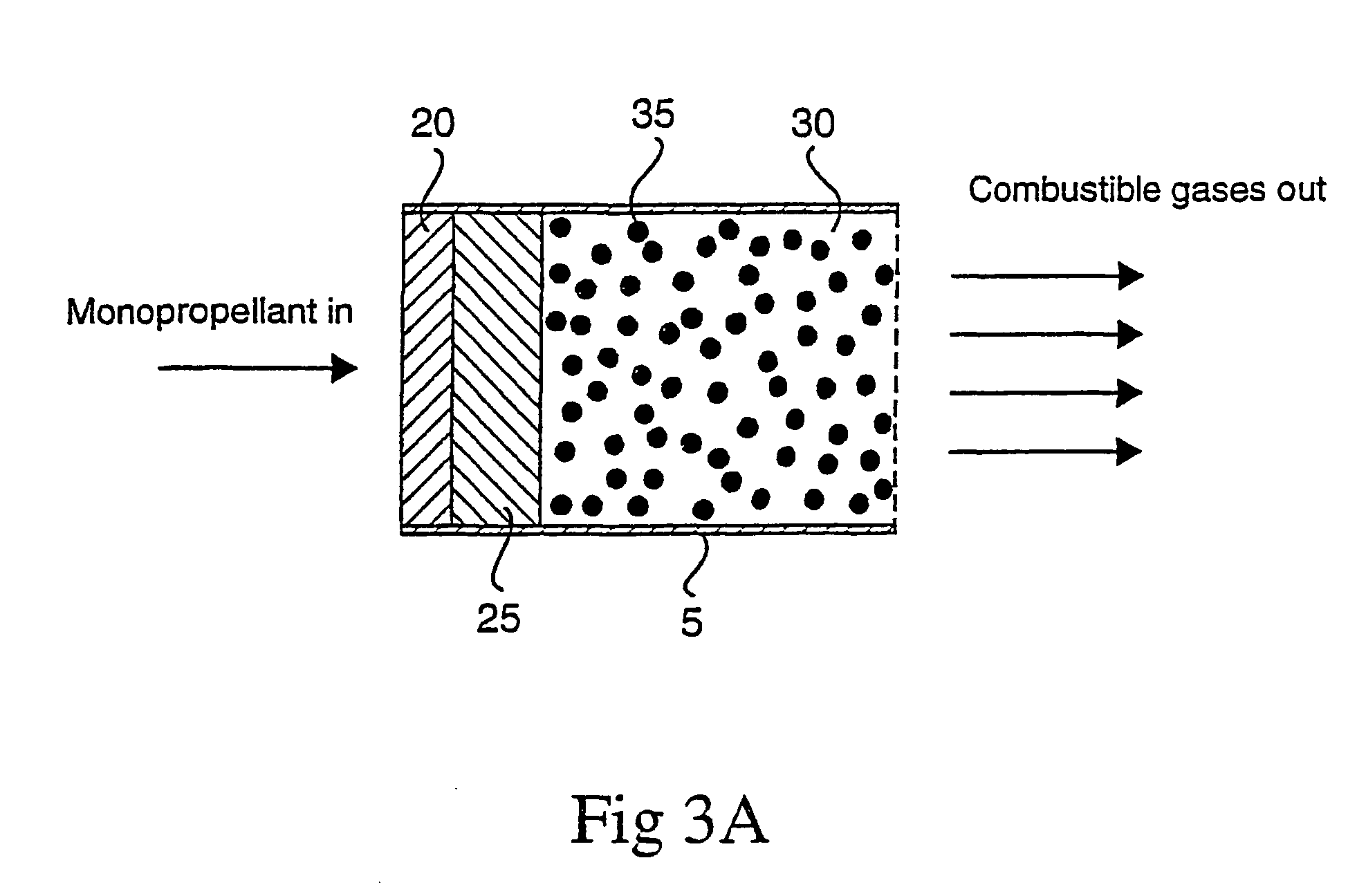

Reactor for decomposition of ammonium dinitramide-based liquid monopropellants and process for the decomposition

InactiveUS7137244B2Material nanotechnologyCatalyst activation/preparationCombustion chamberCombustible gas

The present invention relates to a reactor for the decomposition of ammonium dinitramide-based liquid monopropellants into hot, combustible gases for combustion in a combustion chamber, and more particularly a rocket engine or thruster comprising such reactor and a combustion chamber. The invention also relates to a process for the decompostion of ammonium dinitramide-based liquid monopropellants.

Owner:ECAPS

Method for preparing calcium-hexaluminate ceramic powder by calcium slag

InactiveCN101456575ASimple processWide applicabilityAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagRoom temperature

The invention relates to a method for preparing calcium hexaluminate ceramic powder from calcium slag in the technical field of ceramic materials, which comprises: firstly, adopting the calcium slag and industrial alumina as raw materials, and preparing the calcium hexaluminate ceramic powder by a reaction sintering method, wherein the weight percentage of the calcium slag and the industrial alumina is respectively 10 to20 percent and 80 to 90 percent, and the sum of the weight percentage of the calcium slag and the industrial alumina is 100 percent; secondly, performing uniform mixing and forming, and placing formed blanks into a high-temperature furnace for sintering; and thirdly, naturally cooling the formed blanks to the room temperature, crushing the formed blanks, and obtaining the calcium hexaluminate ceramic powder. The method has simple and convenient technology, has low requirements on the calcium slag raw material, does not need to treat the calcium slag, can prepare the calcium slag into the calcium hexaluminate ceramic powder, not only reduces the production cost of calcium hexaluminate but also realizes recycling of the calcium slag, and changes the waste into the valuable.

Owner:SHANGHAI JIAO TONG UNIV

Method for removing impurities and synchronously preparing calcium-aluminate-series steel-making desulfurization agent through aluminum ash sintering

ActiveCN109928414AInhibition of segregationAchieve volatilizationProcess efficiency improvementAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateAir atmosphere

The invention discloses a method for removing impurities and synchronously preparing a calcium-aluminate-series steel-making desulfurization agent through aluminum ash sintering. According to the method, aluminum ash and a calcium-containing raw material are evenly mixed and pressed into agglomerates; the obtained agglomerates are dried and then sequentially placed in an air atmosphere to be subjected to first-section low-temperature roasting, placed in a strong-oxidizing atmosphere to be subjected to second-section intermediate-temperate roasting and placed in an air atmosphere to be subjected to third-section high-temperature melting roasting, roasted products are cooled and crushed, and thus the pre-melted calcium-aluminate-series desulfurization agent taking 12CaO.7Al2O3 as the main phase is obtained. Through the method, industrial waste residue is utilized as a main raw material, the raw material source is wide, the cost is low, the high added value is achieved, operation is easy,the production cost is low, the environmental friendly effect is achieved, and industrial production requirements are met.

Owner:CENT SOUTH UNIV

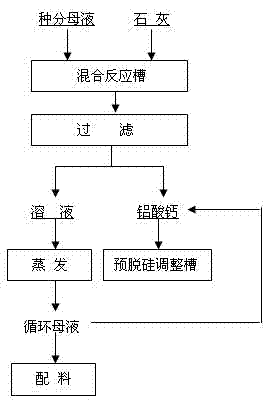

Method for improving caustic ratio of Barer process seeded precipitation mother solution

InactiveCN102730725AIncrease the caustic ratioLow alumina contentAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesAluminateSodium aluminate

The invention which discloses a method for improving the caustic ratio of a Barer process seeded precipitation mother solution relates to an improvement of a technology for producing alumina through a Barer process. The method is characterized in that lime is added to the Barer process seeded precipitation mother solution and subjected to a reaction, filter separation is carried out, the resulting separated filtrate is evaporated through an evaporation procedure, the evaporated filtrate is used to dissolve out a next batch of bauxite as a cycle mother solution, and a solid phase is separated through flushing with the cycle mother solution to a pre-desilicication adjustment tank to adjust the solid content in a desilicication slurry. The method of the invention, which allows calcium aluminate to be generated through adding lime to the Barer process seeded precipitation mother solution and reacting with a sodium aluminate solution, enables the concentration of alumina in the seeded precipitation mother solution to be reduced, so the caustic ratio of the seeded precipitation mother solution is improved, and a Barer process cycle efficiency improvement purpose is reached. Calcium aluminate generated in the reaction is settled and filtered, returns to the Barer process production flow, and is added to the pre-desilicication adjustment tank to substitute parts of lime. Energy consumed by evaporating the low-alumina-concentration seeded precipitation mother solution can be reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Reactor for decomposition of ammonium dinitramide-baed liquid monopropellants and process for the decomposition

InactiveUS20050014641A1Material nanotechnologyCatalyst activation/preparationCombustion chamberCombustible gas

The present invention relates to a reactor for the decomposition of ammonium dinitramide-based liquid monopropellants into hot, combustible gases for combustion in a combustion chamber, and more particularly a rocket engine or thruster comprising such reactor and a combustion chamber. The invention also relates to a process for the decompostion of ammonium dinitramide-based liquid monopropellants.

Owner:ECAPS

Preliminary melting type calcium aluminate for ultra-clean steel and method of manufacturing the same

ActiveCN101244835AImprove deoxygenatioImprove purification effectProcess efficiency improvementAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagCalcium aluminates

The invention relates to a premelt calcium aluminate for super clean steels and the preparation method, the weight percentages of the chemical components in the calcium aluminate are as follows: CaO is 48 to 56%, Al2O3 is 40 to 50%, SiO2 is 0.5 to 3%, MgO is 0.5 to 1.5%, Fe2O3 is no more than 0.5%, TiO2 is no more than 0.02%, C is no more than 0.02%, S is no more than 0.02% and P is no more than 0.02%. The preparation method comprises the following steps: pressing calcium carbonate and alumina of certain amount into block, the weight percentage of the components: calcium carbonate 47 to 55.5% and alumina 36 to 50%; adding the calcium carbonate and the alumina in a melting furnace in batches for melting; obtaining the premelt calcium aluminate for super clean steels with the composition. The preparation method has the advantages of continuous feeding and slag tapping, simple process, stable components and low cost of products.

Owner:上海彭浦冶金辅料有限公司

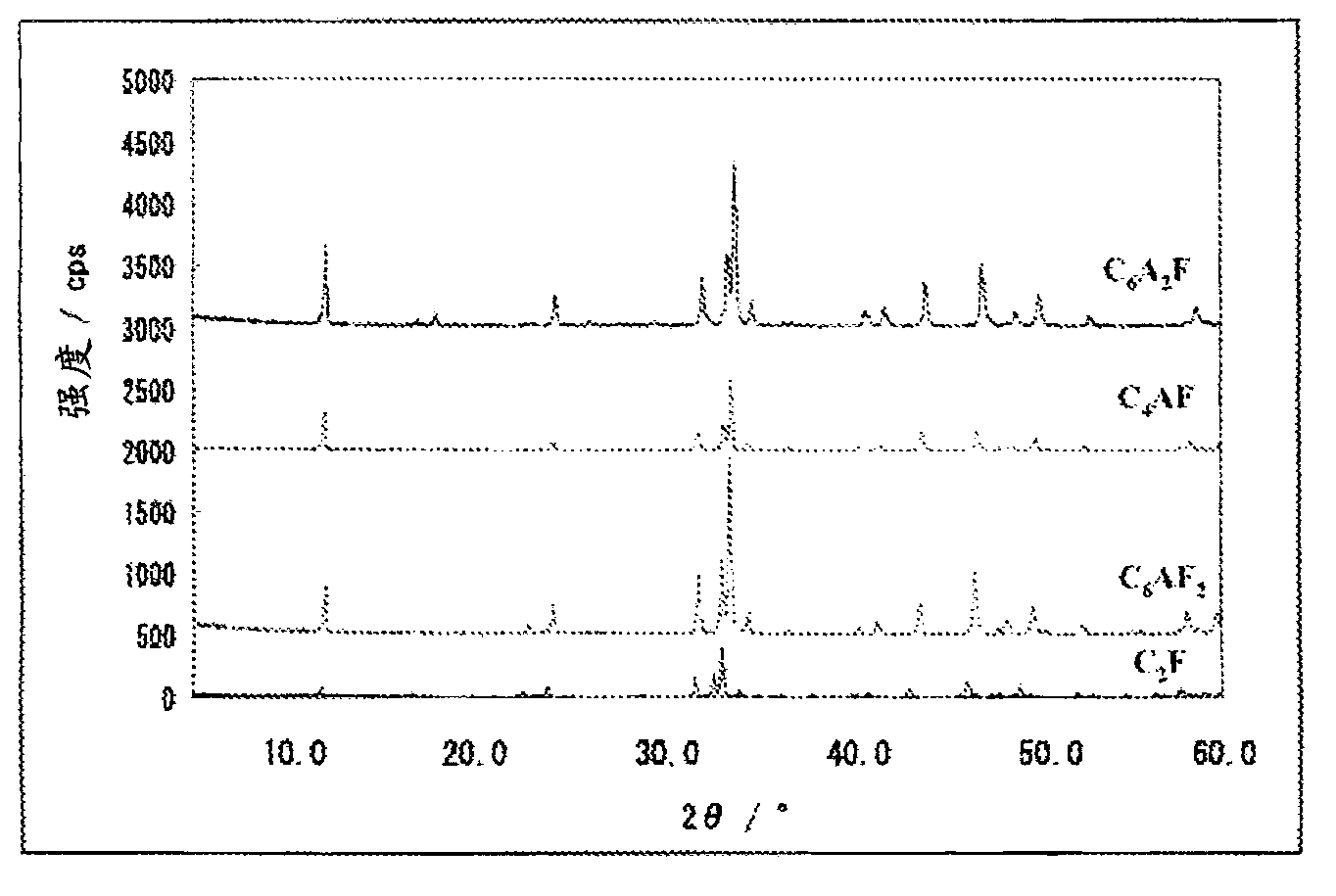

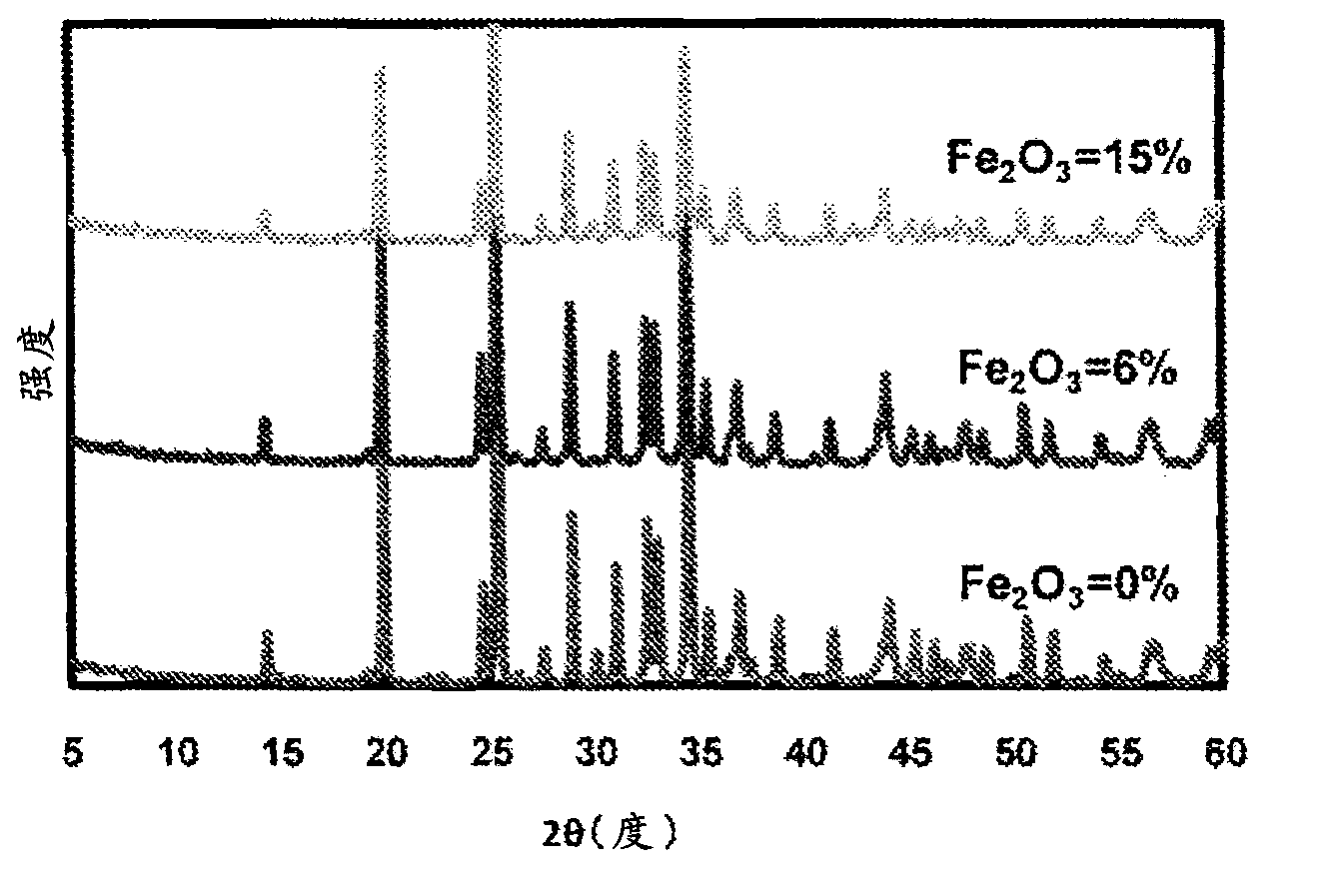

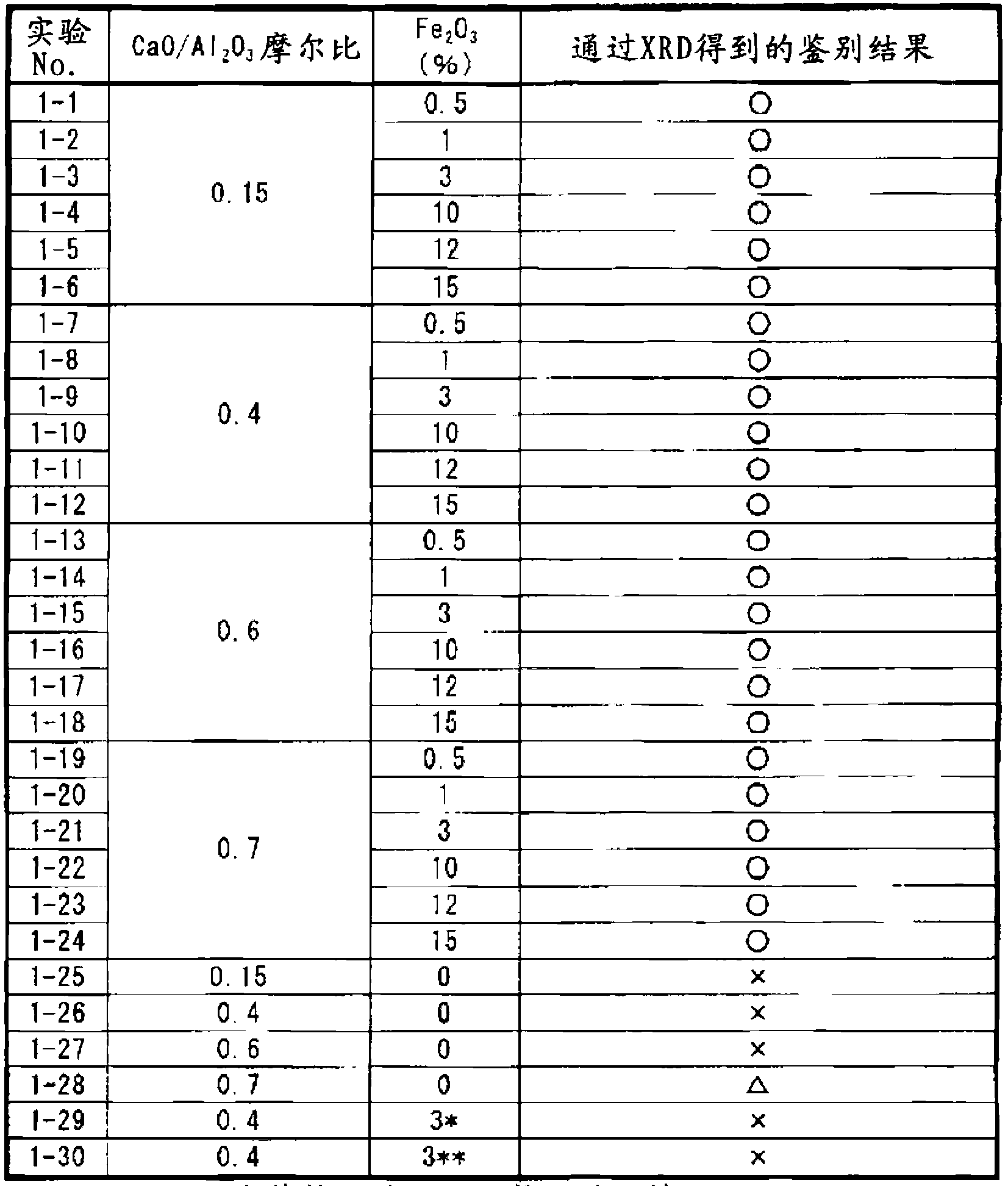

Calcium ferroaluminate compound, cement admixture and process for producing same, and cement composition

ActiveCN102869633AExcellent penetration resistancePlenty of time to operateSolid waste managementIron compoundsSelf-healingSludge

Provided is a cement admixture which gives cured cement concrete that imparts excellent non-corrodible properties to the reinforcing bars present therein, has resistance to external infiltration of chloride ions, and can be inhibited from becoming porous because Ca-ion eluviation occurs little and that has self-healing ability. Also provided is a cement composition. The cement admixture is characterized by comprising a calcium ferroaluminate compound which is based on CaO, Al2O3, and Fe2O3, has a Fe2O3 content of 0.5-15 mass%, and has a CaO2Al2O3 structure, the CaO / Al2O3 ratio being in the range of 0.15-0.7 by mole. It is preferred that the admixture have a degree of fineness of 2,000-7,000 cm2 / g in terms of Blaine specific surface area and that a latent hydraulic substance and / or a pozzolanic substance (pozzolanic substance and the like) be used in combination with the calcium ferroaluminate compound. The pozzolanic substance and the like preferably comprise one or more substances selected from a group consisting of ground granulated blast furnace slag, fly ash, silica fume, metakaolin, incineration ash of pulp sludge, incineration ash of sewage sludge, and waste glass powder. It is preferred that the ratio of the calcium ferroaluminate compound to the pozzolanic substance and the like be from 10 / 1 to 1 / 10 by mass. The cement composition comprises cement and the cement admixture.

Owner:DENKA CO LTD

Process for producing SrAl2O4:Eu,Dy long afterglow luminescent material

InactiveCN101428835AReduce energy consumptionLow equipment requirementsAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationLuminescent compositionsOxalateCombustion

The invention relates to the field of luminescent materials, in particular to a preparation method of SrAl2O4:Eu<2+> and Dy<3+> long afterglow luminescent materials. The preparation method comprises the following steps: taking Al(NO3)3.9H2O, Sr(NO3)2, Eu2O3 and Dy2O3 as raw materials, H3BO3 as a fluxing agent, CO(NH2)2 as fuel, and oxalic acid as a precipitator, adjusting the pH value of mixed liquor by ammonia water; then placing the mixed liquor into a burning reaction furnace; lighting at the temperature of 500 to 800 DEG C to carry out combustion reaction; and finally obtaining the SrAl2O4:Eu<2+> and Dy<3+> long afterglow luminescent materials. The preparation method has the advantages of quick reaction, simple process, saved time and energy; the illuminant performance of the combined product is excellent; the initial illuminant brightness can achieve 19150 mcd / m<2>; and the afterglow time can achieve 216 h simultaneously.

Owner:GUANGXI NORMAL UNIV

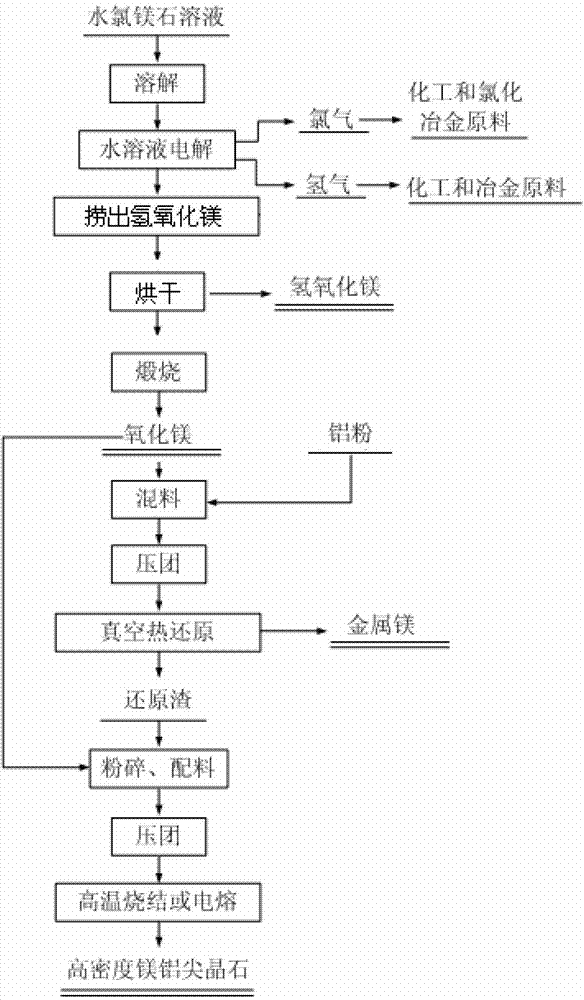

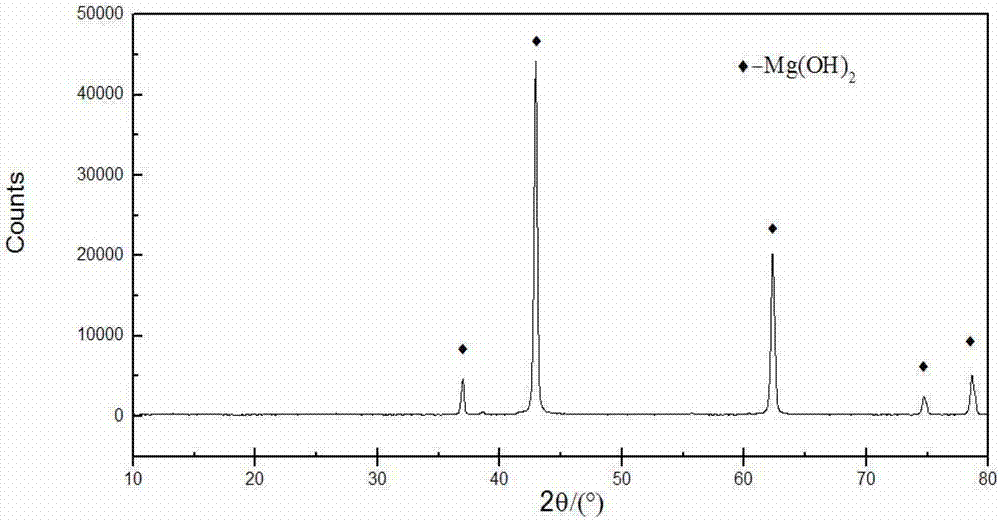

Method for preparing magnesium hydroxide, magnesium and magnesium aluminate spinel by bischofite

InactiveCN102817041AHigh priceLow impurity contentElectrolysis componentsProcess efficiency improvementChemical industryElectrolysis

The invention discloses a method for preparing magnesium hydroxide, magnesium and magnesium aluminate spinel by bischofite and belongs to the field of magnesium metallurgy and chemical industry. The method comprises the steps of: taking bischofite as a raw material to produce magnesium hydroxide, hydrogen gas and chlorine gas through electrolysis, and then taking magnesium oxide, which is obtained by calcining magnesium hydroxide, as a raw material to produce magnesium metal and magnesium aluminate spinel through vacuum thermal reduction. The by-product, i.e., bischofite, during extraction of potassium salt and lithium salt in west salt lakes and in the salt manufacturing industry of the eastern coastal regions, is utilized for producing the magnesium hydroxide, magnesium oxide and magnesium aluminate spinel, therefore, the purpose of changing waste into valuable is realized. Compared with the traditional electrolysis technology of fused magnesium chloride, the method has the characteristics of low energy consumption, low cost, small environment pollution and the like.

Owner:NORTHEASTERN UNIV

Alumina production process by using monohydrate bauxite lime Bayer process

InactiveCN1380253ARaise the reaction temperatureExtended reaction timeAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCalcium silicateFoxtail

The production process of alumina by using monohydrate bauxite ore and adopting Bayer process is characterized by that when preparing ore pulp, the lime is added according to the demand for that the CaO content being in lime and TiO2 content being in bauxite are reacted to produce perovskite and the CaO in the lime and SiO2 being in bauxite are reacted to form hydrated calcium silicate, in which the molecular ratio of CaO added for balancing TiO2 is C / T=1-1.5 and the molecular ratio of CaO added for balancing SiO2 is C / S=1.5-3.0 and then the ore pulp is undergone the process of desilication pretreatment at 90-110 deg.c for 2-12 hr. and then undergone the conventional Bayer process. Its desilicated product mainly is hydrated calcium silicate.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Popular searches

Nanostructure manufacture Tantalum compounds Wood layered products Natural mineral layered products Phosphorus compounds Metal layered products Peroxides/peroxyhydrates/peroxyacids/superoxides/ozonides Gallium/indium/thallium compounds Calcium/strontium/barium sulfates Synthetic resin layered products

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com