Method for preparing magnesium hydroxide, magnesium and magnesium aluminate spinel by bischofite

A magnesia-aluminum spinel and bischofite technology, which is applied in the field of magnesium metallurgy and magnesium chemical industry, can solve the problems of high energy consumption, equipment corrosion, and high energy consumption in the dehydration process, and achieve good high-temperature performance and slag erosion resistance. Realize the effect of comprehensive utilization and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

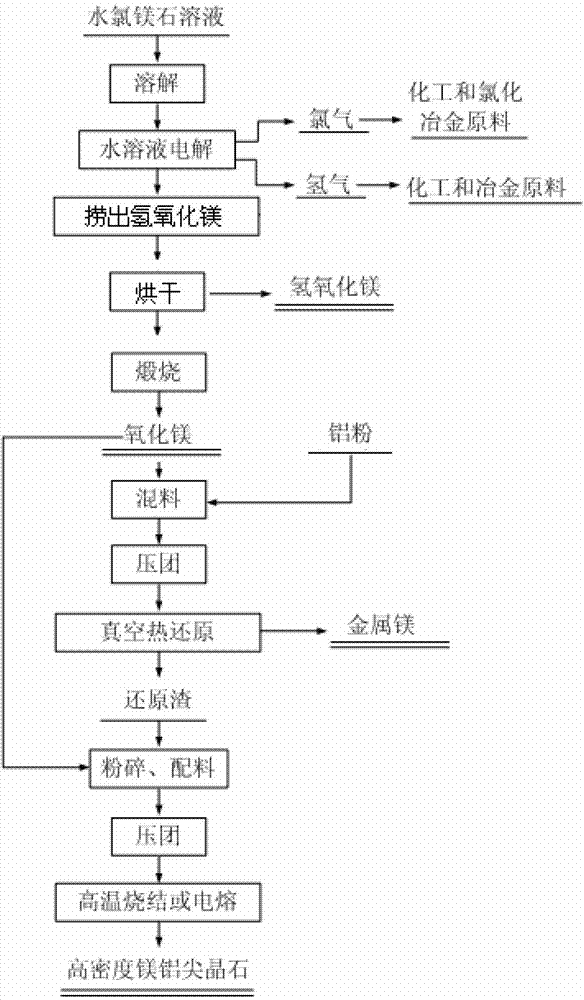

Method used

Image

Examples

preparation example Construction

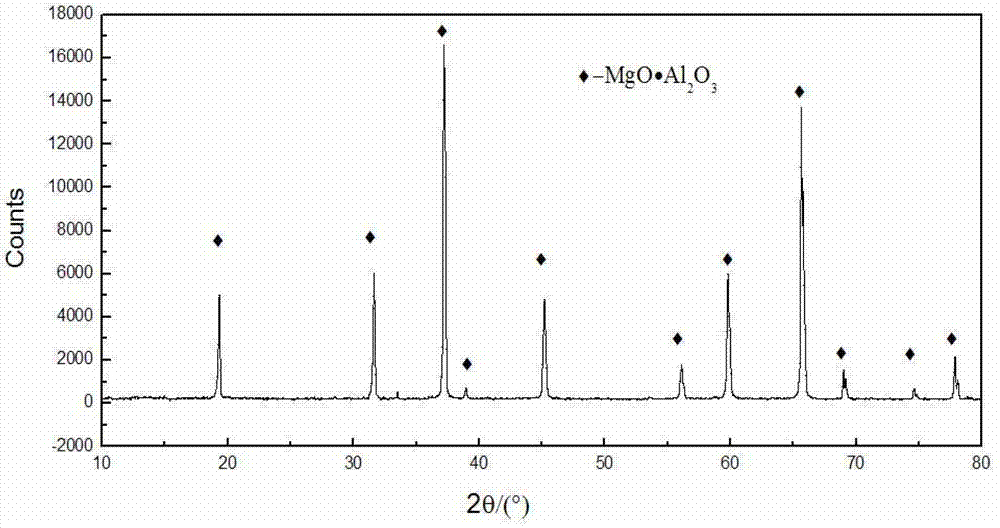

[0041] The equipment used to prepare the finished magnesium aluminum spinel is an industrial rotary kiln.

[0042] The equipment used to prepare the finished fused magnesia-aluminum spinel is an industrial electric arc furnace.

Embodiment 1

[0044] Preparation of magnesium hydroxide, magnesium oxide, magnesium and magnesium aluminum spinel by electrolysis of schoffite:

[0045] (1) Dissolve and prepare the bischofite into MgCl 2 An aqueous solution with a mass percentage of 20%;

[0046] (2) Electrolysis, electrolyze the magnesium chloride aqueous solution, the electrolysis temperature is 20℃, the direct current, the current density is 1.0A / cm 2 , Add bischofite and water every 30 minutes to maintain MgCl 2 The mass percentage is 10~30%, and the magnesium hydroxide is taken out every 30 minutes;

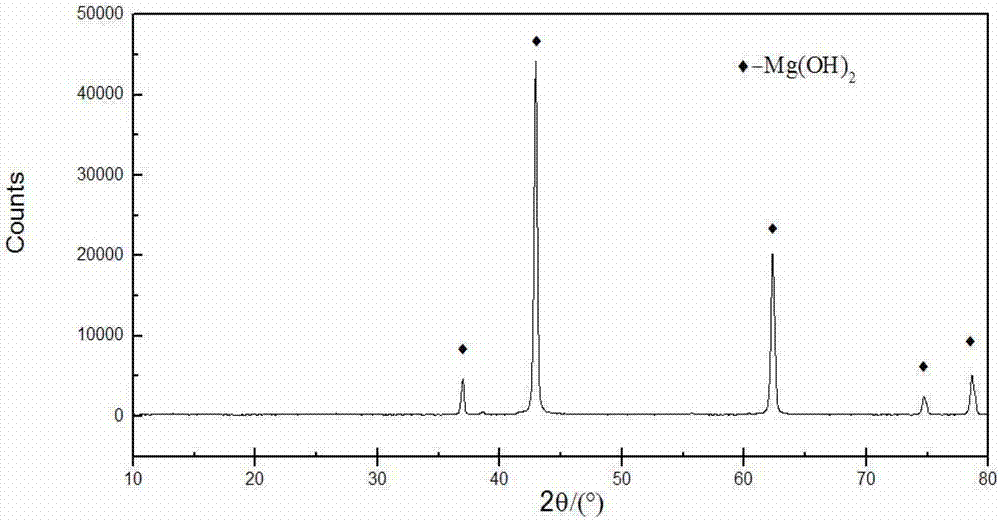

[0047] (3) Drying, drying the magnesium hydroxide at 250°C for 1.0 hour;

[0048] (4) Calcining, calcining the dried magnesium hydroxide at 500°C for 10 hours, after cooling, grinding, and screening magnesium oxide powder with a particle size of less than 120 mesh;

[0049] (5) To make magnesium, mix magnesium oxide powder with aluminum powder with a particle size of 120 mesh, the mass ratio of magnesium oxide powder to aluminum p...

Embodiment 2

[0053] Preparation of magnesium hydroxide, magnesium oxide, magnesium and magnesium aluminum spinel by electrolysis of schoffite:

[0054] (1) Dissolve and prepare the bischofite into MgCl 2 An aqueous solution with a mass percentage of 30%, then the magnesium chloride solution is added to the electrolytic cell, and 1% sodium chloride is added to the solution;

[0055] (2) Electrolysis, electrolysis of magnesium chloride aqueous solution, electrolysis temperature 80℃, direct current, current density 0.8A / cm 2 , Add bischofite and water every 60 minutes to maintain MgCl 2 The mass percentage is 3-20%, and the magnesium hydroxide is taken out every 60 minutes;

[0056] (3) Drying, drying the magnesium hydroxide at 225°C for 1.5 hours;

[0057] (4) Calcining, calcining the dried magnesium hydroxide at 500°C for 10 hours, after cooling, grinding, and screening magnesium oxide powder with a particle size of less than 120 mesh;

[0058] (5) To make magnesium, mix magnesium oxide powder and al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com