Amorphous calcium aluminate and preparation method thereof

A calcium aluminate and amorphous technology, applied in the field of calcium aluminate, can solve the problems of slow melting speed, high energy consumption for refining, and inability to use at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

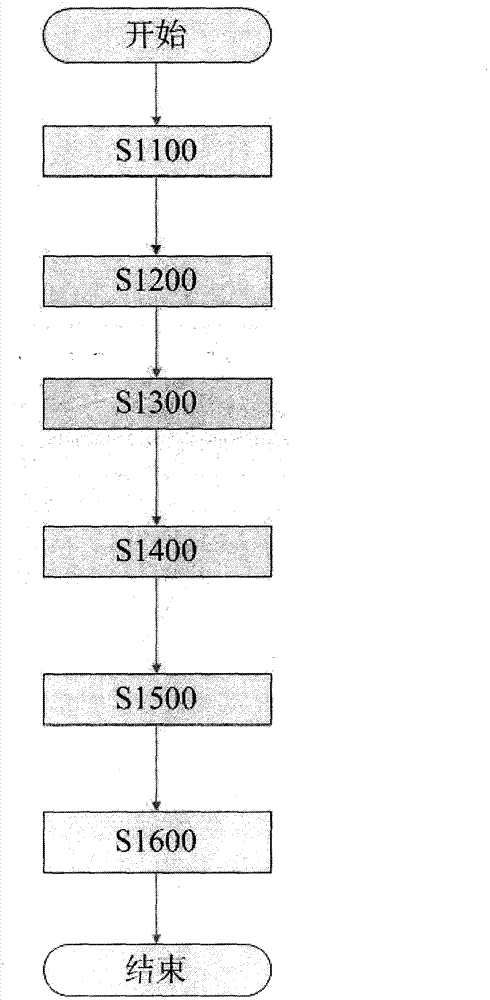

[0015] In this embodiment, first enter step S1100 to select the required raw materials; then enter the selected raw materials into step S1200. In this step, the proportion of raw materials can be adjusted according to the purpose and index. In this embodiment The following raw material ratio is selected: 40-60% CaO, 30-60% Al 2 o 3 , 0.01-1% S, 1-10% SiO 2 , 0.05-3% Fe 2 o 3 , 0.01-5% CaF 2 , 1-10% MgO, 0-3% TiO 2 and 0.01-1% P; then carry out the electric furnace smelting operation of step S1300 on the prepared raw materials, and the smelting temperature reaches 2000 degrees; then proceed to the step of S1400, during which the flow and velocity are adjusted; The key step of the present invention is S1500, starting from the temperature of 2000 degrees, cooling and forming, in this step, adjusting the time for cooling, the cooling process destroys the crystallization conditions of calcium aluminate, thereby forming non-crystalline calcium aluminate; finally The obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com