Method for repairing and resetting road manhole cover

A reset method and manhole cover technology, applied in artificial islands, underwater structures, buildings, etc., can solve problems such as unsatisfactory repair quality of well circles, cracking and damage, etc., and achieve easy quality assurance, extended service life, and good durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by specific examples.

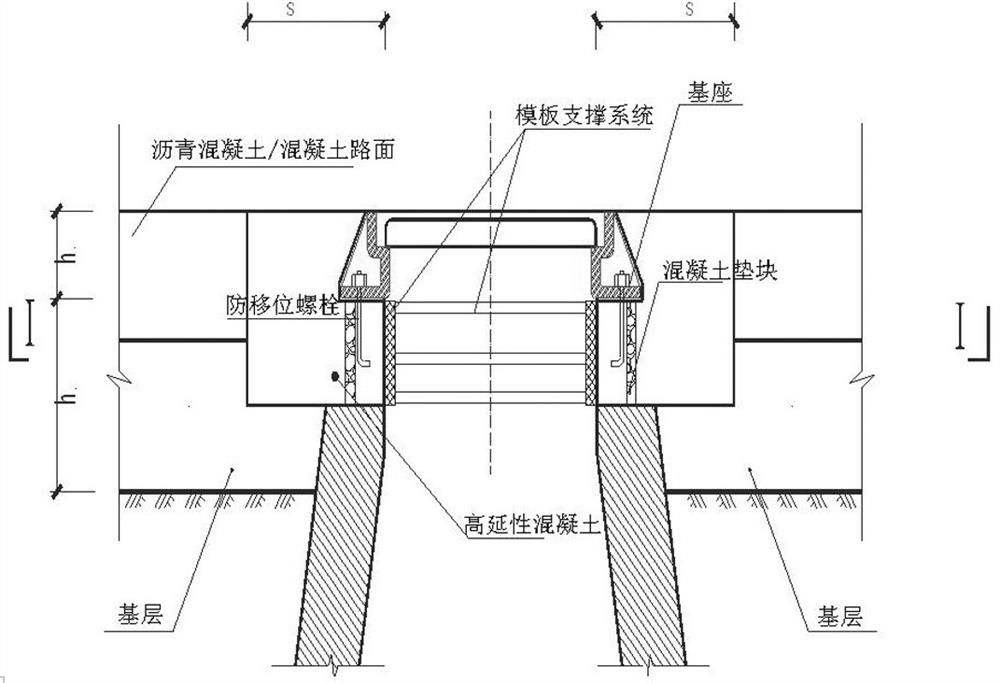

[0019] Such as figure 1 Shown, a kind of repair and reset method of road manhole cover, comprise

[0020] Step 1, preparing materials, including cement, slag powder, fly ash, steel slag aggregate, water reducer, biological glue, defoamer, expansion agent and polypropylene fiber, and measuring them separately;

[0021] Step 2. Put the ingredients prepared in step 1 into a blender and stir to obtain dry powder materials. The stirring time is not less than 5 minutes;

[0022] Step 3. Add water twice to the dry powder material obtained in step 2 and stir evenly. Add two-thirds of the water for the first time, and add the remaining water for the second time. The stirring time is not less than 7 minutes; Add polypropylene fibers in batches according to the set mix ratio, and stir evenly, and the stirring time is not less than 5 minutes to obtain a high-ductility concrete mixture;

[0023] Step 4. De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com