Method for preparing pure calcium aluminate powder for water treatment

A technology of calcium aluminate powder and calcium carbonate powder, which is applied in the preparation of alkaline earth metal aluminate/aluminum oxide/aluminum hydroxide, etc., can solve the problems of unsuitable polyaluminum chloride and uncontrollable heavy metal indicators of ore, and achieve reduction The use of raw material grinding, less insoluble matter, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

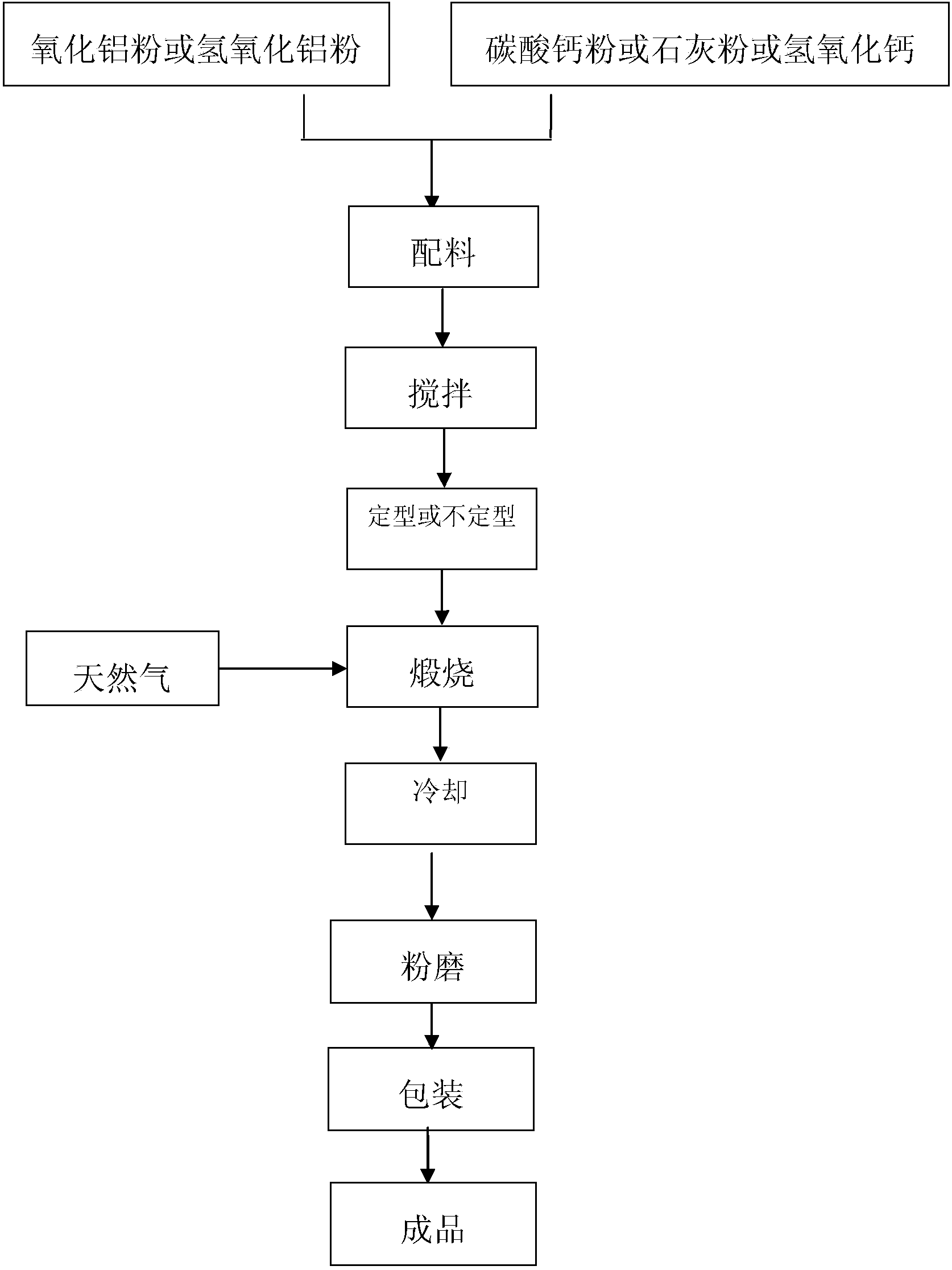

Method used

Image

Examples

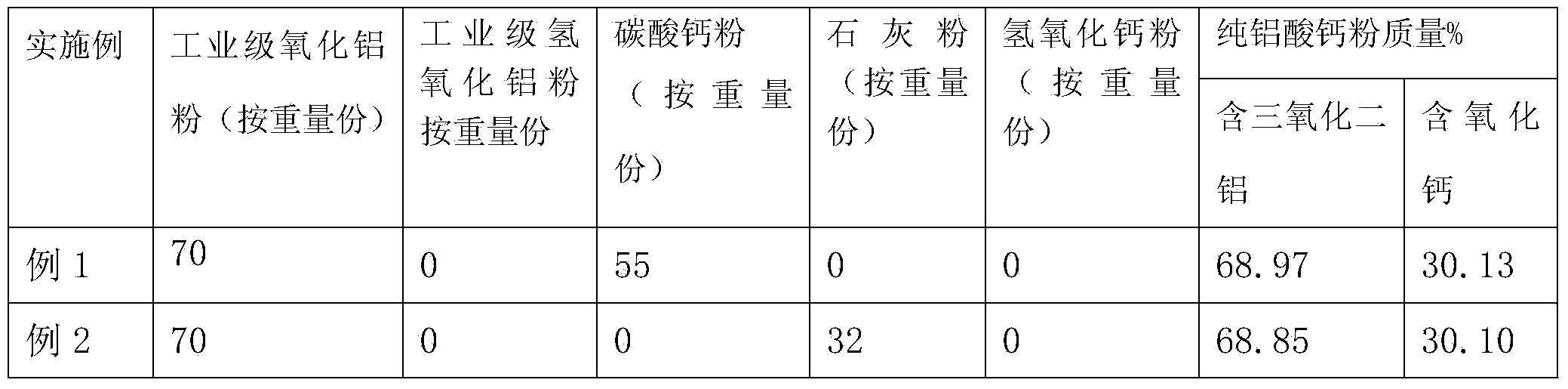

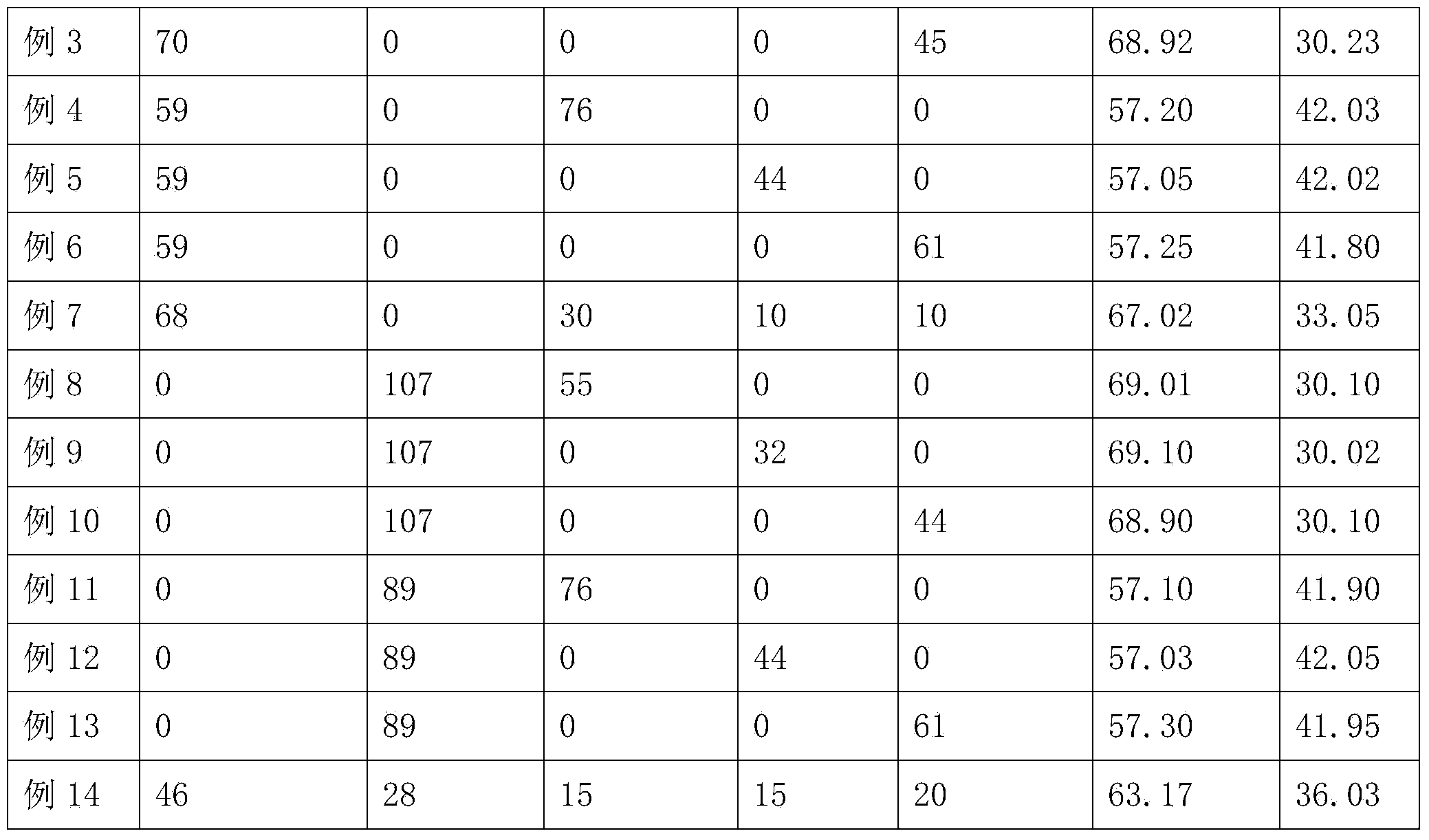

Embodiment 1

[0023] 1. Mix industrial-grade alumina powder containing 98-99% aluminum oxide with calcium carbonate powder containing 55-56% calcium oxide, lime powder containing 95-98% calcium oxide, and 90% calcium hydroxide. ~98% calcium hydroxide powder, calculated according to the production of 100 kilograms of pure calcium aluminate powder, the ratio of the raw materials by weight is industrial grade alumina powder: calcium carbonate powder: lime powder: calcium hydroxide powder=70: Mix at a ratio of 55:0:0 and stir evenly to obtain a mixture;

[0024] 2. Shape the mixture obtained in step 1 or use the mixture directly. If you use the mixture directly, you need to put it on a tray. The following examples are the same;

[0025] 3. Push the shaped material obtained in step 2 or directly use the mixed material into a natural gas kiln, and sinter for 2 hours at a sintering temperature of 1350 ° C. After sintering the clinker, cool it and grind it into pure calcium aluminate powder.

[00...

Embodiment 2

[0029] 1. Mix industrial-grade alumina powder containing 98-99% aluminum oxide with calcium carbonate powder containing 55-56% calcium oxide, lime powder containing 95-98% calcium oxide, and 90% calcium hydroxide. ~98% calcium hydroxide powder, calculated according to the production of 100 kilograms of pure calcium aluminate powder, the ratio of the raw materials by weight is industrial grade alumina powder: calcium carbonate powder: lime powder: calcium hydroxide powder=70: Mix at a ratio of 0:32:0 and stir evenly to obtain a mixture;

[0030] 2. Shape the mixture obtained in step 1 or directly use the mixture;

[0031] 3. Push the shaped material obtained in step 2 or directly use the mixed material into a natural gas kiln, and sinter for 1 hour at a sintering temperature of 1400°C. After sintering the clinker, cool it and grind it into pure calcium aluminate powder.

[0032] The obtained pure calcium aluminate powder has a mass percentage of aluminum oxide of 68.85% and a ...

Embodiment 3

[0035] 1. Mix industrial-grade alumina powder containing 98-99% aluminum oxide with calcium carbonate powder containing 55-56% calcium oxide, lime powder containing 95-98% calcium oxide, and 90% calcium hydroxide. ~98% calcium hydroxide powder, calculated according to the production of 100 kilograms of pure calcium aluminate powder, the ratio of the raw materials by weight is industrial grade alumina powder: calcium carbonate powder: lime powder: calcium hydroxide powder=70: Mix at a ratio of 0:0:45 and stir evenly to obtain a mixture;

[0036] 2. Shape the mixture obtained in step 1 or directly use the mixture;

[0037] 3. Push the shaped material obtained in step 2 or directly use the mixed material into a natural gas kiln, and sinter for 2 hours at a sintering temperature of 1350 ° C. After sintering the clinker, cool it and grind it into pure calcium aluminate powder.

[0038] The obtained pure calcium aluminate powder has a mass percentage of aluminum oxide of 68.92% and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com