Patents

Literature

69results about How to "Realize green mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt

InactiveCN103436720ASolve the problem of ammonia nitrogen pollutionRealize green miningProcess efficiency improvementAmmoniacal nitrogenCalcium hydroxide

The invention relates to a process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt. The process comprises the step of replacing ammonium salt by taking a mixture of calcium, magnesium and sodium salts as a leaching agent and taking non-ammonium salts, such as calcium hydroxide, magnesium hydrate or sodium hydroxide as a precipitator. According to the process disclosed by the invention, the ammonia nitrogen pollution problem in exploitation of ion-adsorption type rare earth is radically solved; environmental-friendly exploitation of the ion-adsorption type rare earth can be realized; the process disclosed by the invention has higher economic benefit and social benefit.

Owner:LONGNAN COUNTY NANYU RARE EARTH RESOURCES COMPREHENSIVE UTILIZATION CO LTD

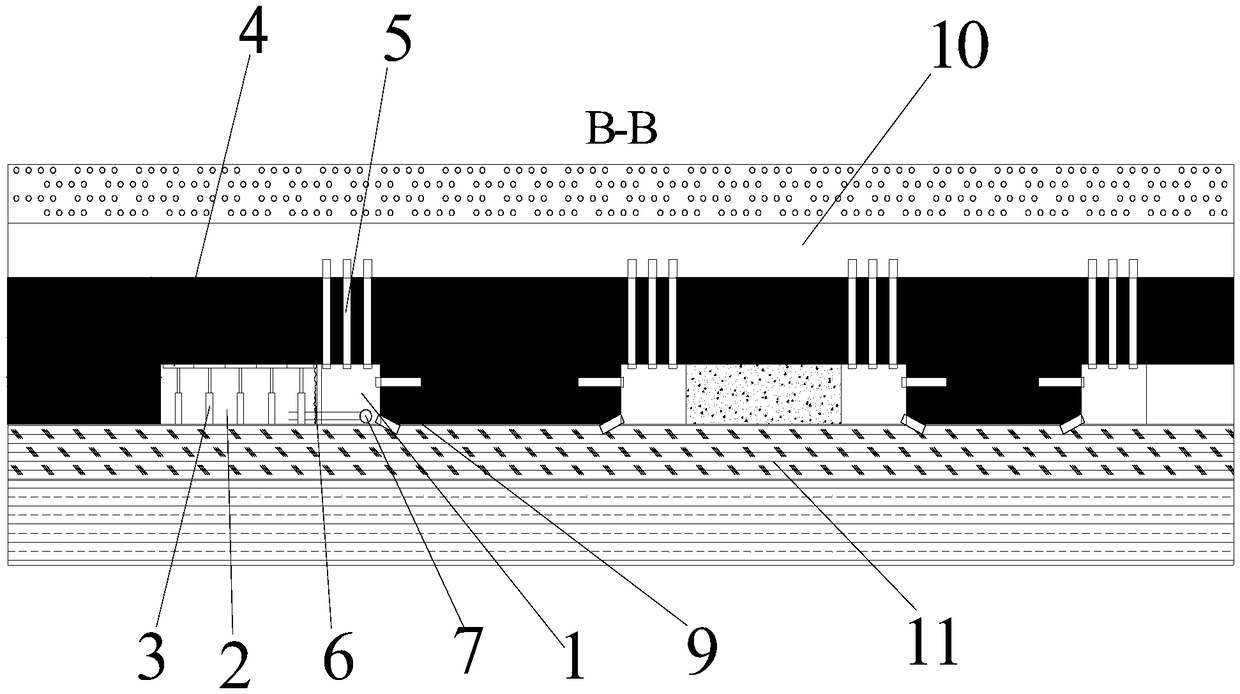

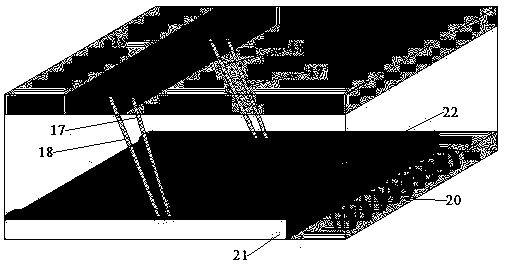

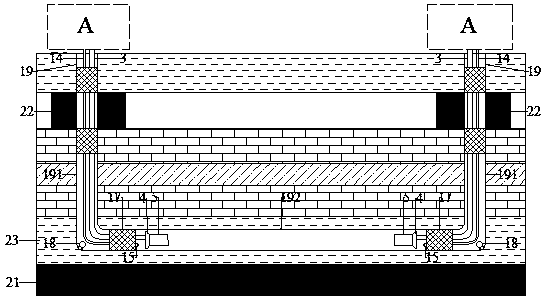

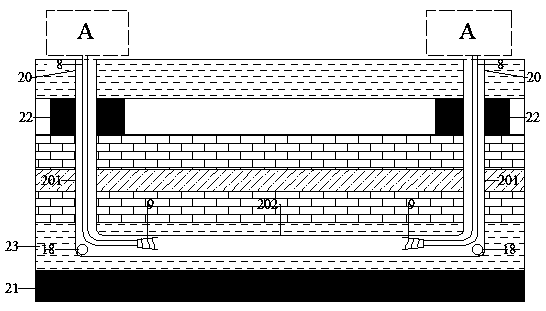

Filling wall body capable of protecting laneway through soft yielding in non-chain-pillar filling mining and construction method thereof

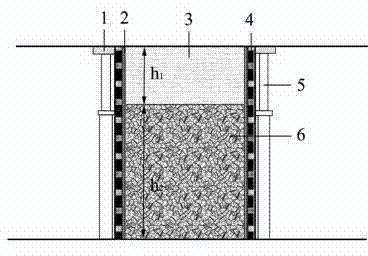

The invention provides a filling wall body capable of protecting a laneway through soft yielding in non-chain-pillar filling mining and a construction method of the filling wall body capable of protecting the laneway through soft yielding in non-chain-pillar filling mining, and belongs to the coal mine tunnel supporting and protecting technology. The filling wall body is composed of an upper portion and a lower portion, wherein the upper portion is an expansible organic foaming filling main wall body with large shrinkage, the foaming multiple ranges from 10 to 75, the uniaxial compressive strength is not more than 1.2Mpa when the volume compression amount is 80%, the lower portion is a paste-like filling main wall body, the paste-like filling main wall body is composed of the mixture of water, cement, coal ash, river sand and gangue according to the mass ratio of 1:0.3:1.2:1.7:2.8, the 1d uniaxial compressive strength is larger than 1.2Mpa, and the 28d strength is larger than 10Mpa. The filling height and the configuration proportion of the two filling main wall bodies are adjusted through calculation, therefore, the contractibility of the filling wall body can be kept within a reasonable range, the filling wall body capable of protecting the laneway through soft yielding in non-chain-pillar filling mining can better adapt to the motion law of the roof strata, and the stability of gob-side entry retaining is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH +1

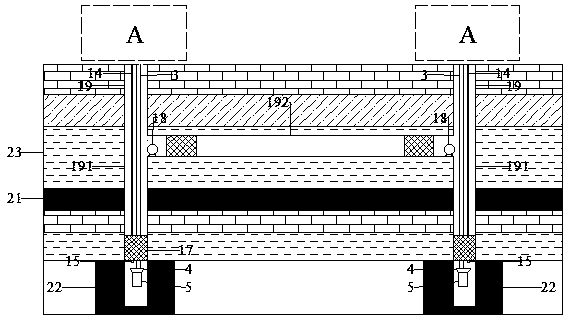

Underground mining, selecting and filling synergic mining method for close distance coal seam group

InactiveCN109162714ARelieve lifting pressureReduce high costUnderground miningTunnel/mines ventillationDynamic pressureCoal

The invention relates to an underground mining, selecting and filling synergic mining method for a close distance coal seam group and belongs to the field of mineral engineering. The method comprisesthe following steps: carrying out full-mechanized caving mining on the close distance coal seam group and designing an underground gangue sorting system and a filling working face according to a gangue output quantity in the production process; conveying the gangues produced in the mining process to an underground gangue sorting chamber, and conveying the sorted chambers to the filling working face for filling mining; and after underground washing of the gangues generated by the filling working face, conveying the gangues to the filling working face for backfilling. The method achieves zero emission of the gangues under an integrated mining condition of the gangues of the close distance coal seam group, eliminates adverse influence of ground gangues to the environment, increases the fine coal promoting rate, and liberates the primary lifting pressure. Meanwhile, the gangues are sorted nearby and fill in selected positions, so that damage and disturbance to underground rock bodies by aconventional mining method are alleviated greatly, and the strong dynamic pressure governing problem is pre-solved.

Owner:CHINA UNIV OF MINING & TECH

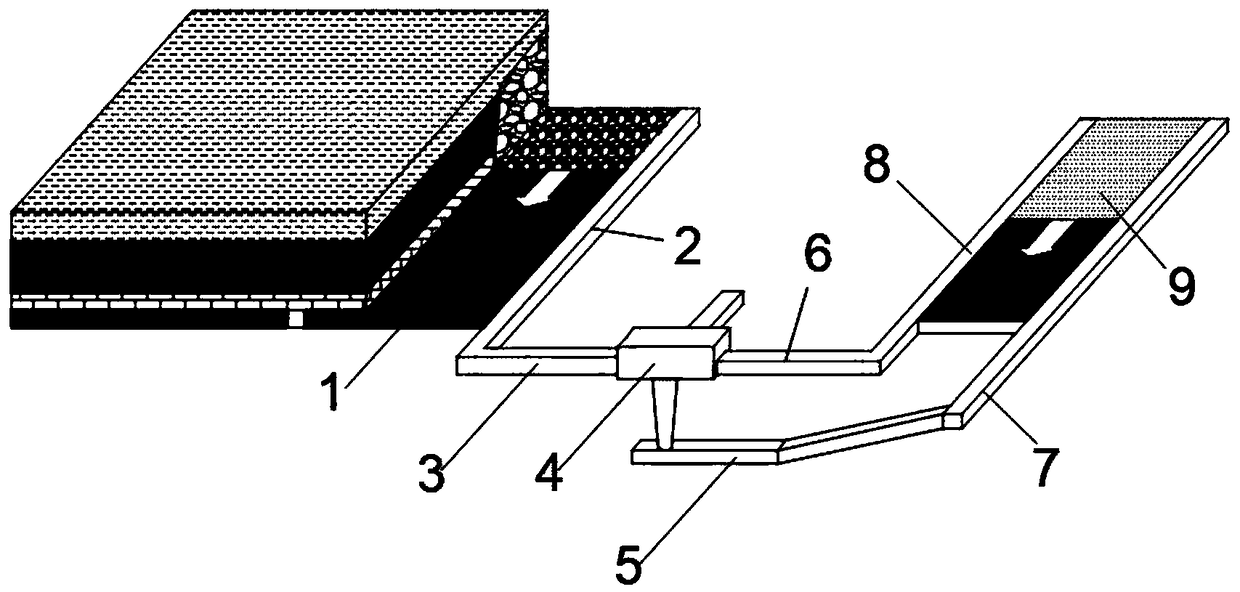

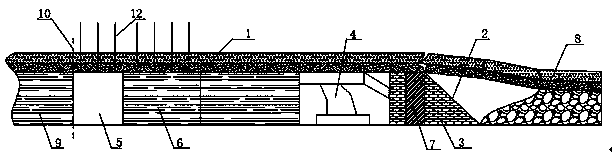

Thick coal seam wide-roadway tunneling and gangue paste body filling roadway forming method

ActiveCN108412542ARealize green miningTo achieve the effect of digging an alleyUnderground miningSurface miningMining engineeringCoal pillar

The invention discloses a thick coal seam wide-roadway tunneling and gangue paste body filling roadway forming method and belongs to the technical field of mining industry. The method comprises the steps that firstly, according to the coal seam geological condition, the widths of a filled belt and a newly-tunneled roadway are designed; secondly, according to the mine existing tunneling technological condition, the filling length, namely the circular filling step pitch, of each time is determined; when the newly-tunneled roadway is tunneled, through high strength anchor rods abd anchor net cables, top plates, bottom plates and roadway inner coal walls are supported; then, after the newly-tunneled roadway is tunneled by the circular filling step pitch, roadway-expanding tunneling begins to be conducted along the roadway outer coal wall; during roadway-expanding tunneling, hydraulic supporting columns are adopted to be matched with metal hinging top beams for temporary support of the filled belt and the junction of the filled belt and the newly-tunneled roadway; finally, after roadway-expanding tunneling is completed, the temporary support is removed, the filled belt is filled; and then the steps are sequentially and alternately implemented. According to the thick coal seam wide-roadway tunneling and gangue paste body filling roadway forming method, the coal loss caused by unexploited coal pillars can be effectively reduced, the influence of mine pressure in roadway tunneling is reduced, and the gangue treatment and roadway tunneling costs are reduced.

Owner:SHANDONG UNIV OF SCI & TECH

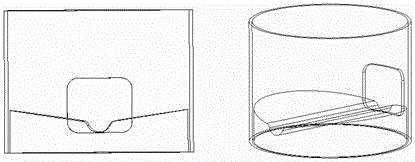

Roof contact method for stope filling

The invention relates to the technical field of combustion water heaters, and relates to a roof contact method for stope filling. The roof contact method for the stope filling comprises the followingstep that a stope empty area is filled with slag to a certain height to obtain a residual empty area, the height of the residual empty area is measured, the position of the highest point is determined, a hollow anchor rod is installed at the highest point, and a filling pipe is installed on the hollow anchor rod; a first dewatering pipe and a dewatering pipe are installed at the highest point, anda third dewatering pipe and a second dewatering pipe are installed from top to bottom according to the height difference; and the opening between the residual empty area and an inlet or a connectingchannel is blocked, and then filling slurry is conveyed into the filling pipe to realize roof-contacted filling of the residual empty area. The roof contact method for the stope filling has the characteristics of realizing effective roof-contacted filling of the stope empty area, and effectively ensuring the strength of the stope empty area.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

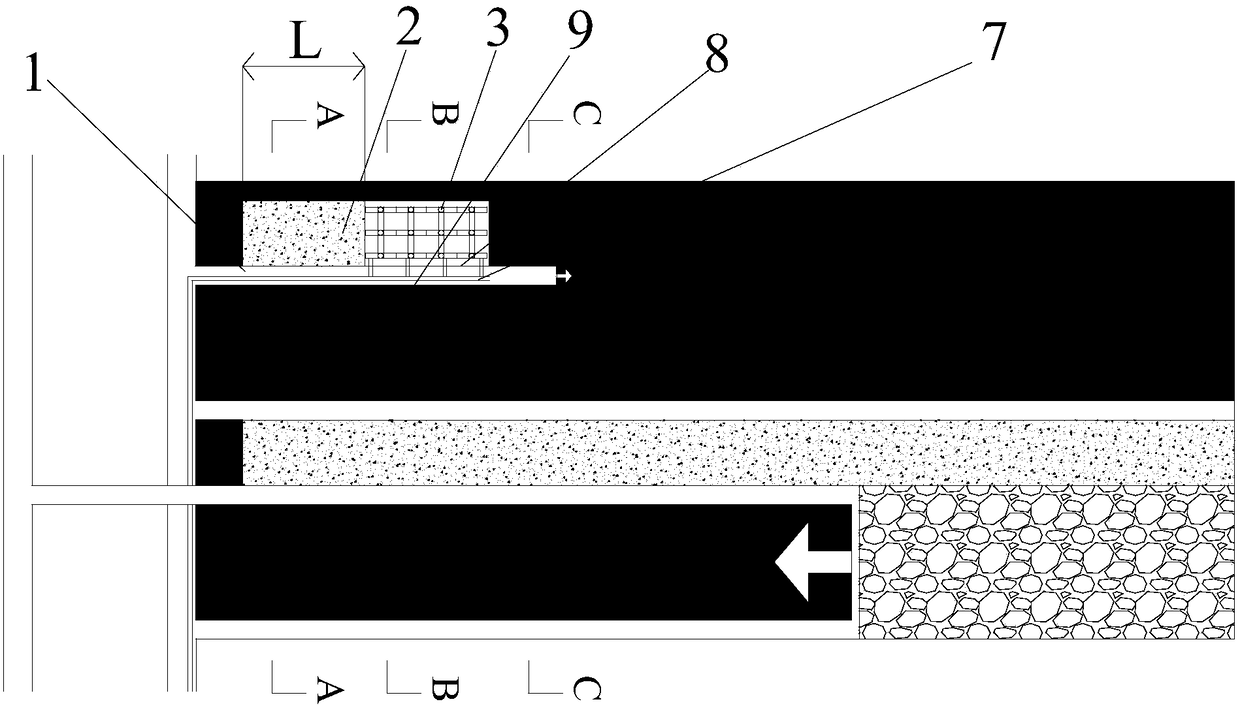

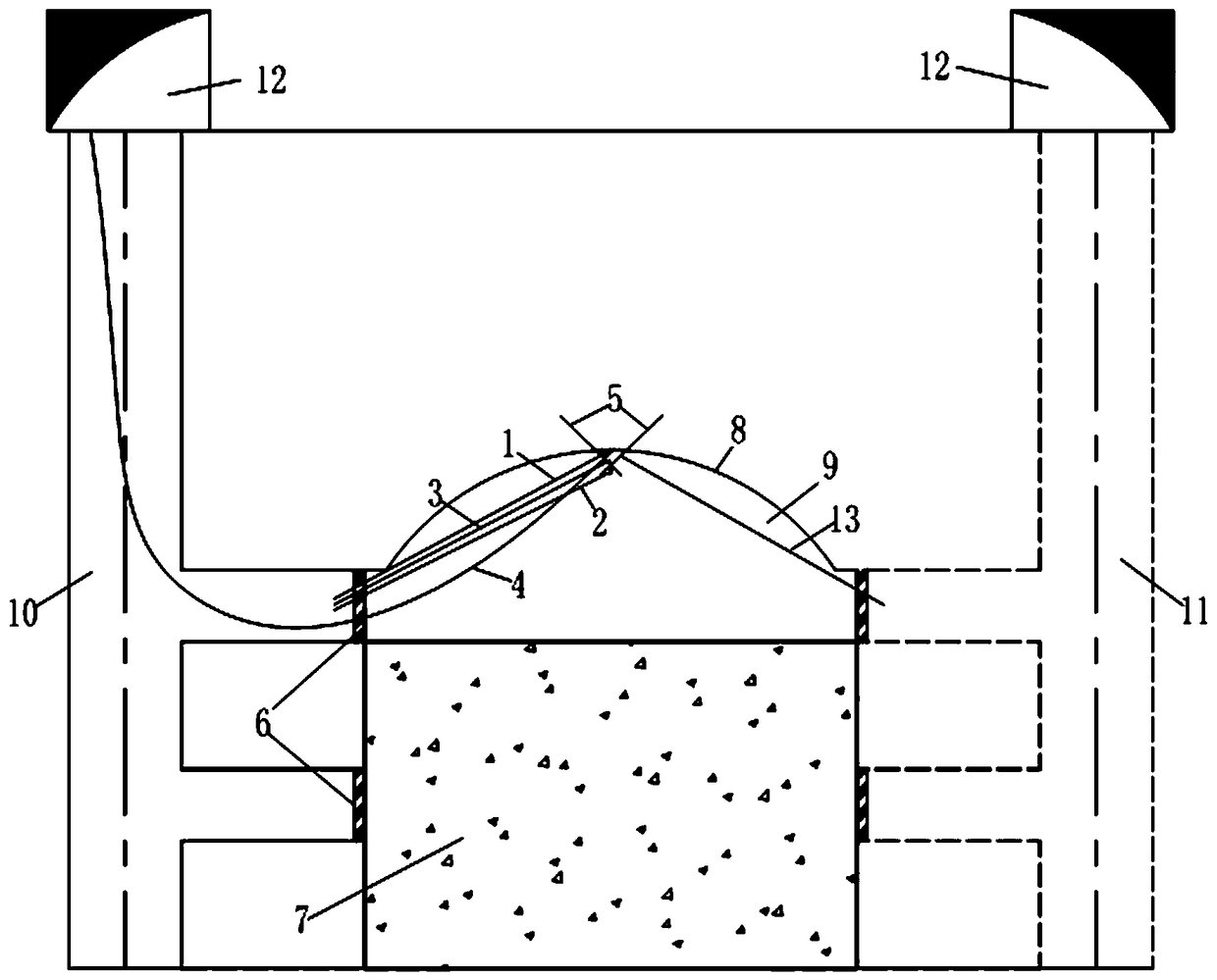

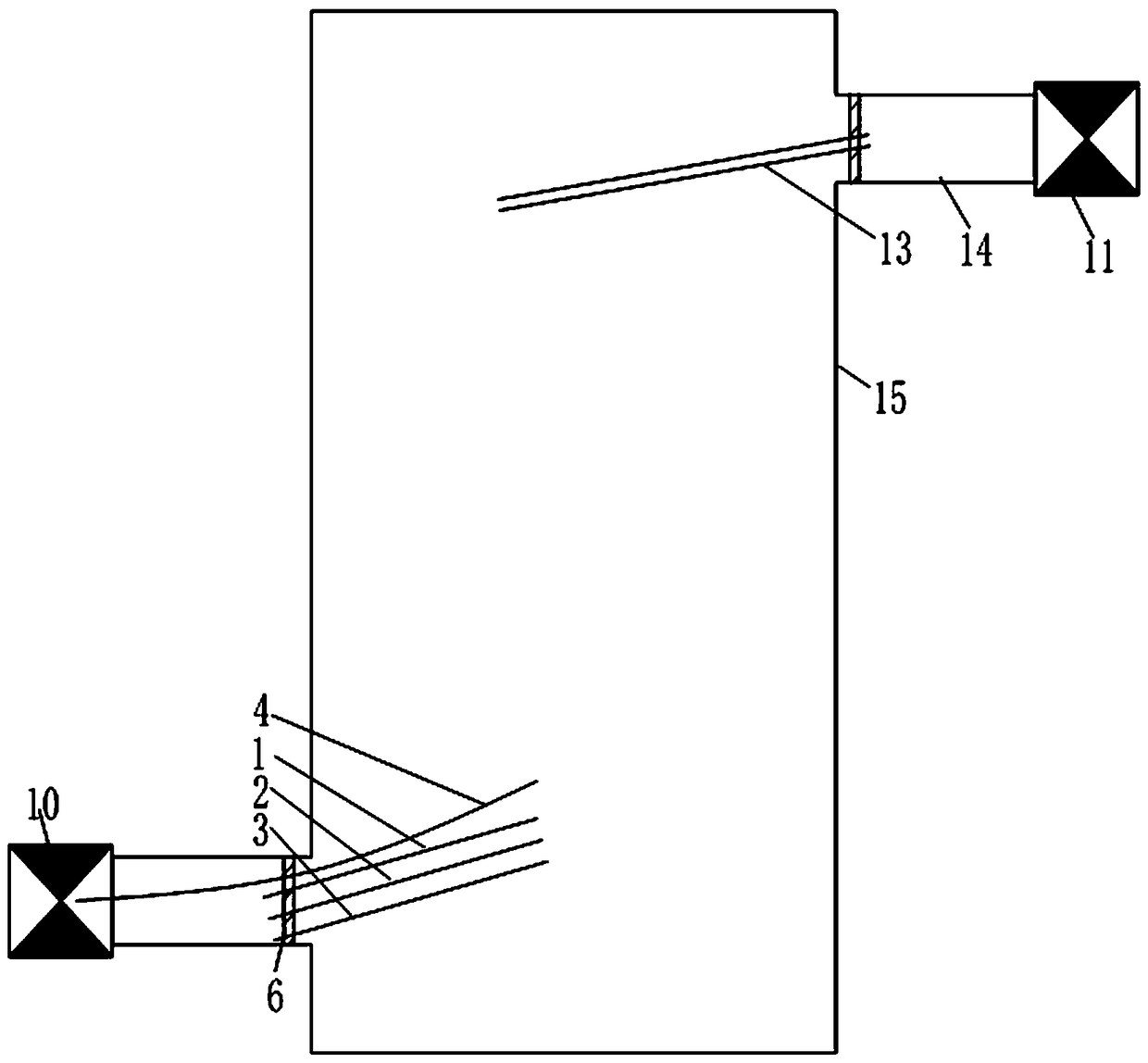

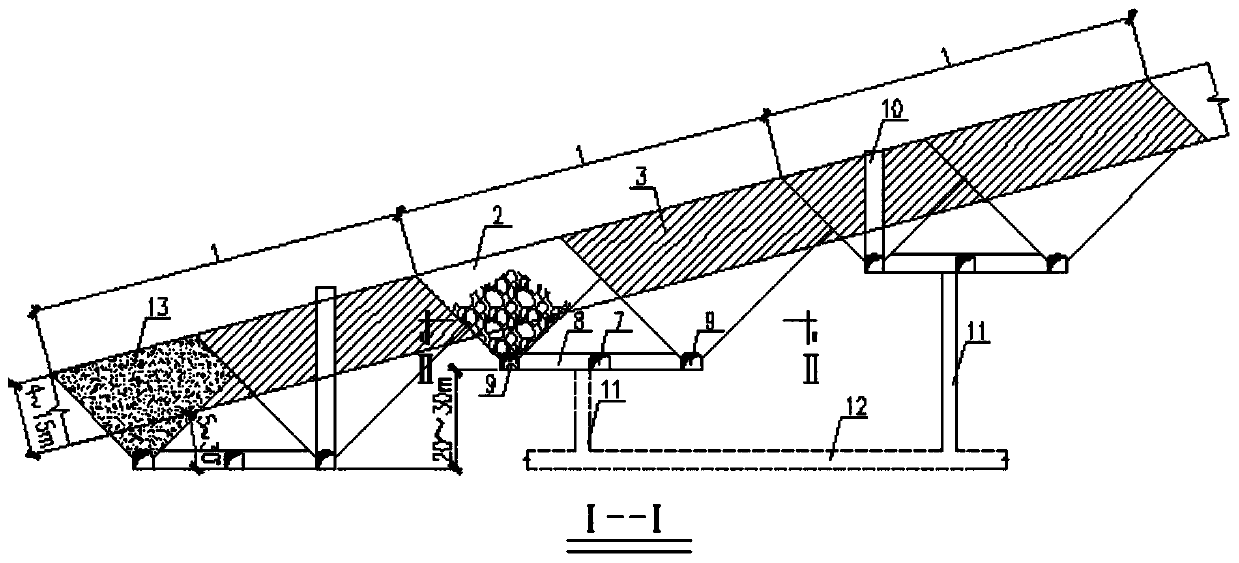

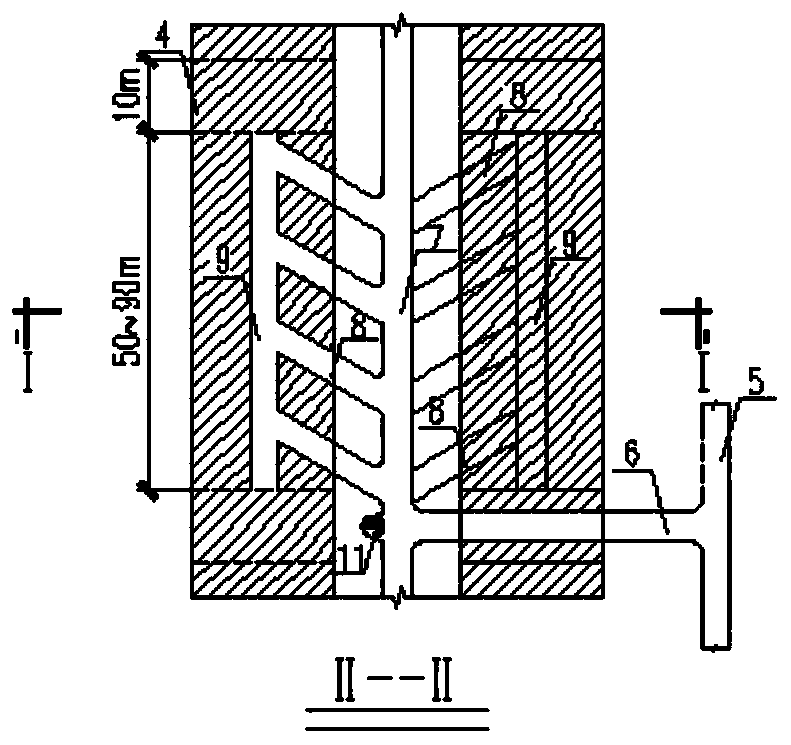

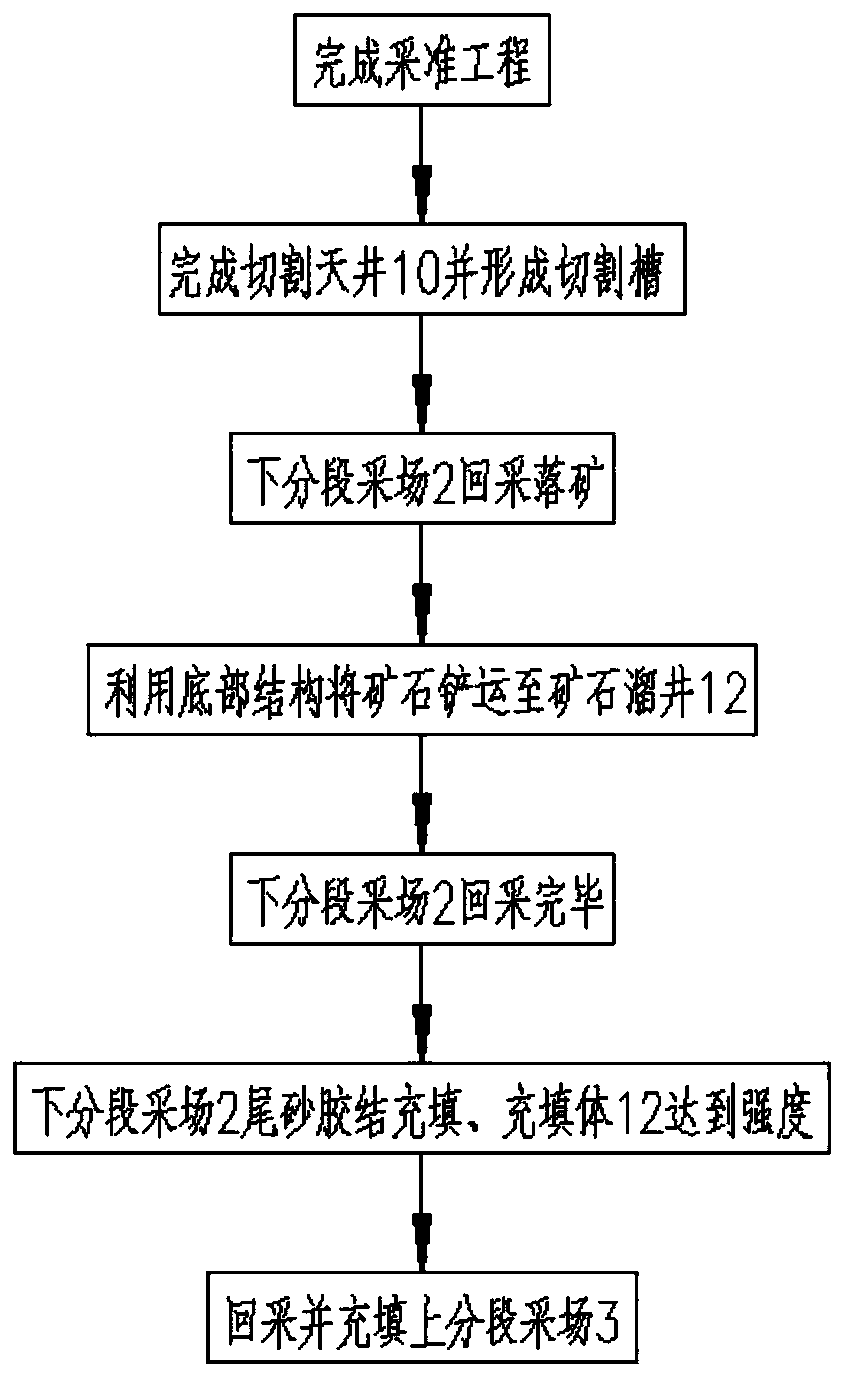

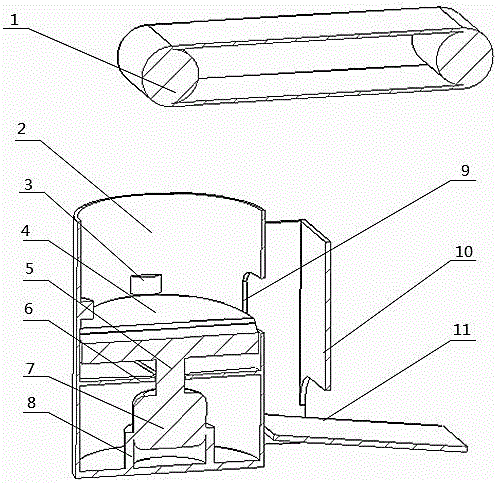

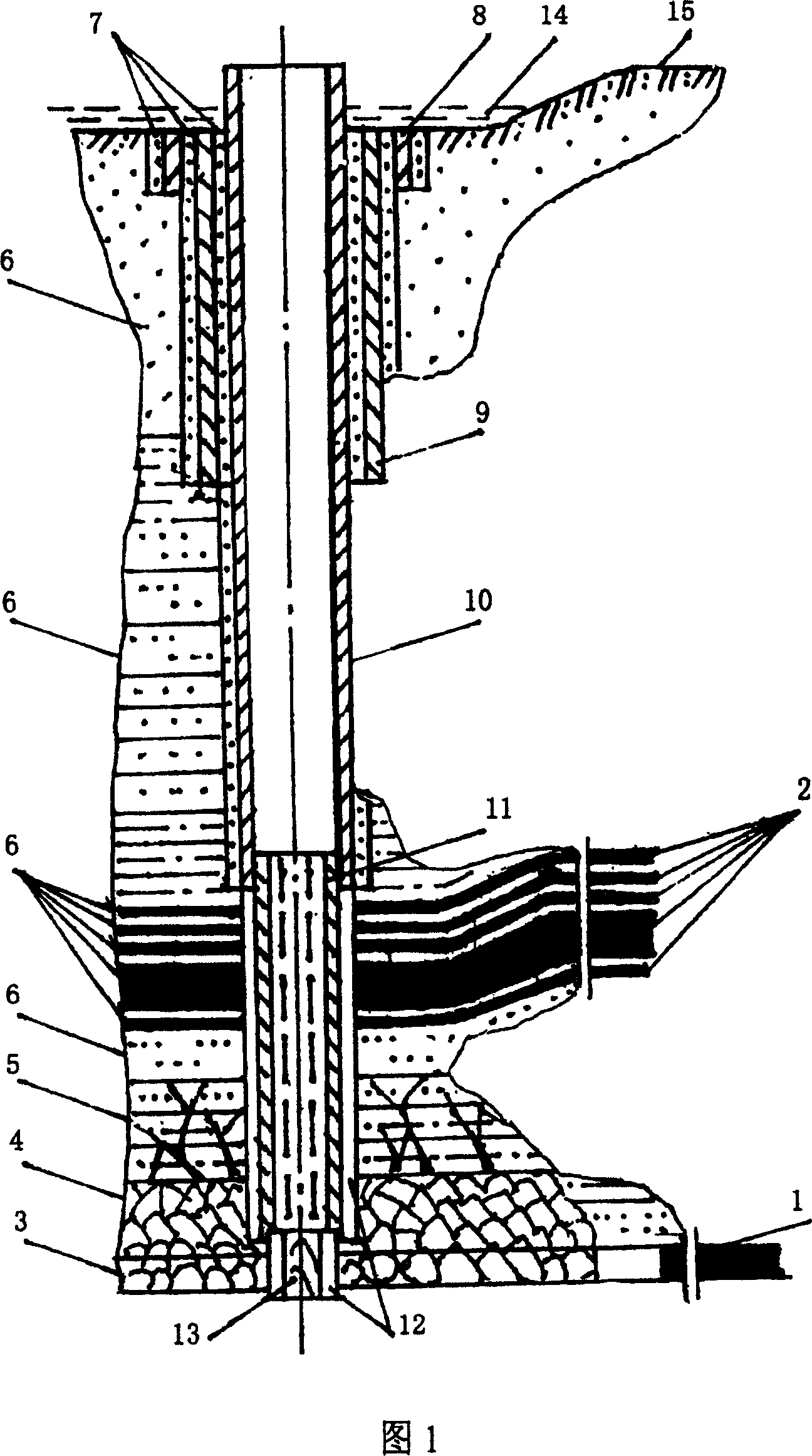

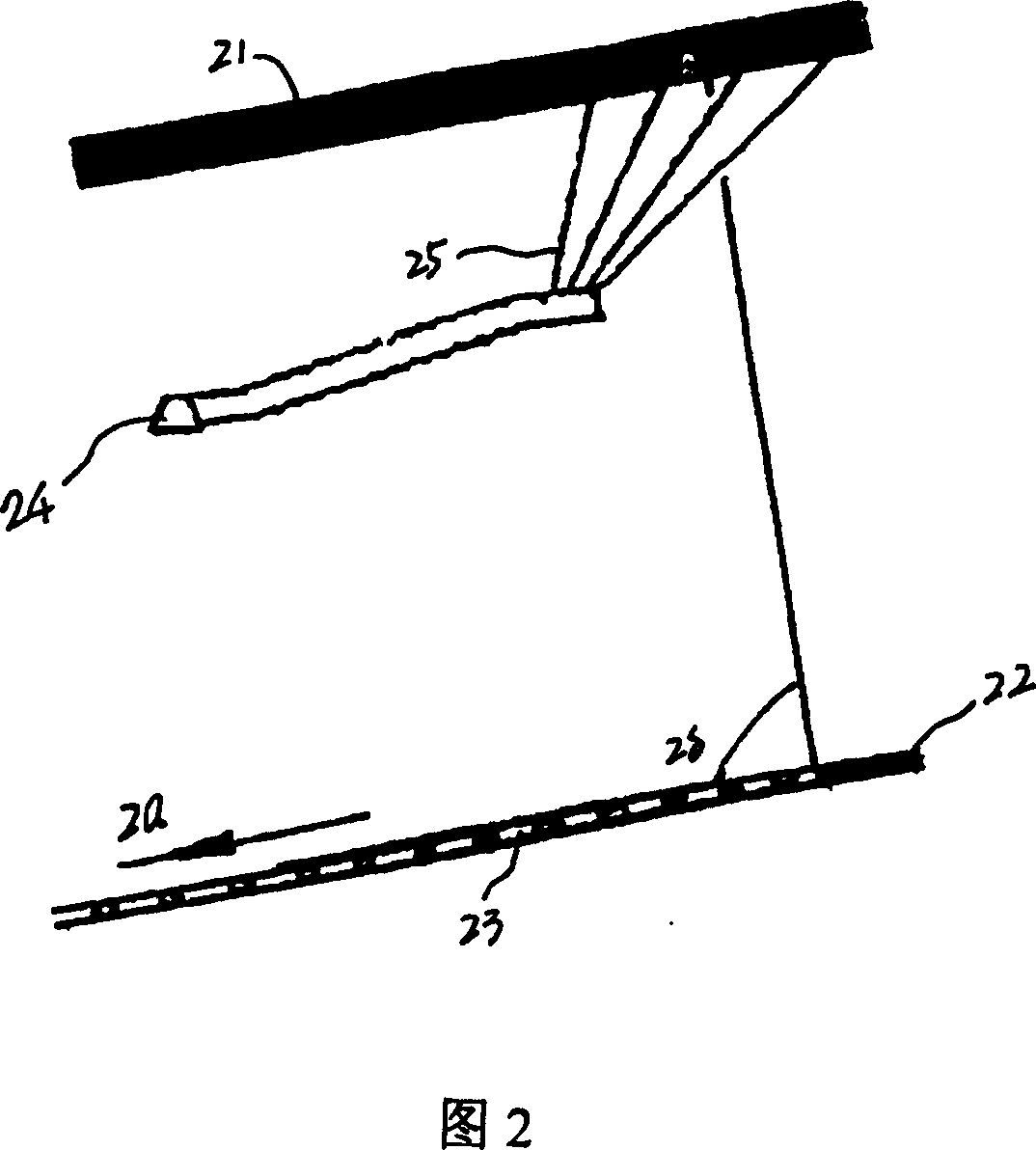

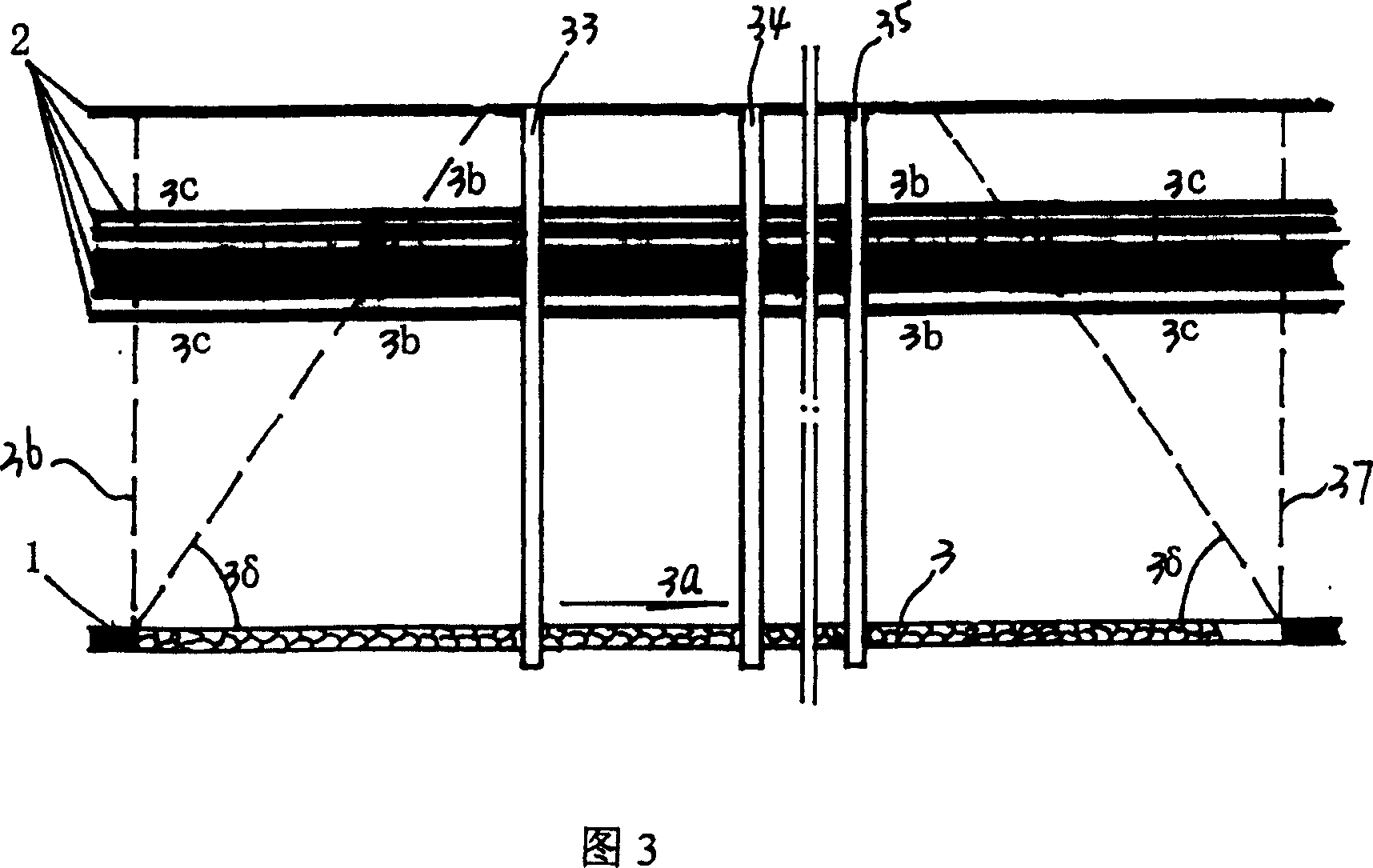

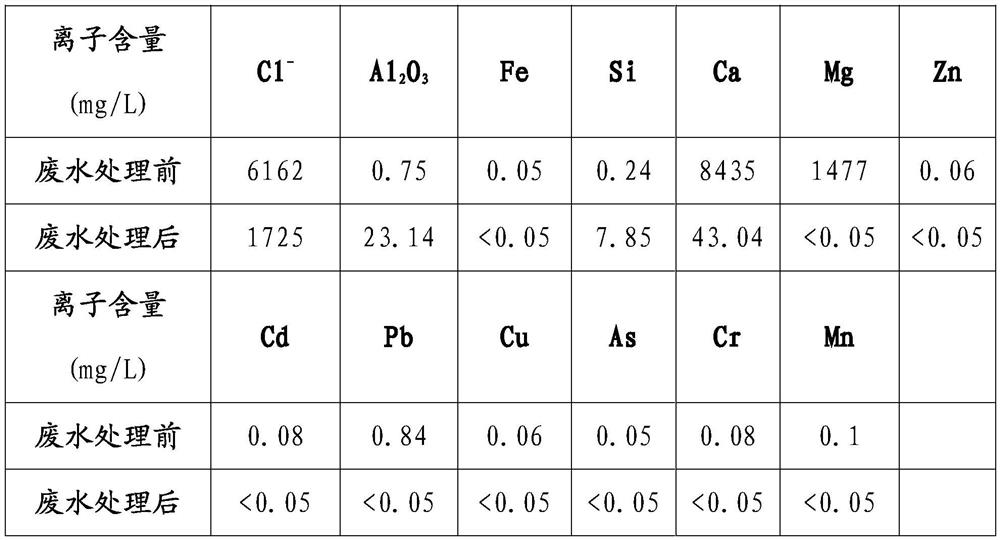

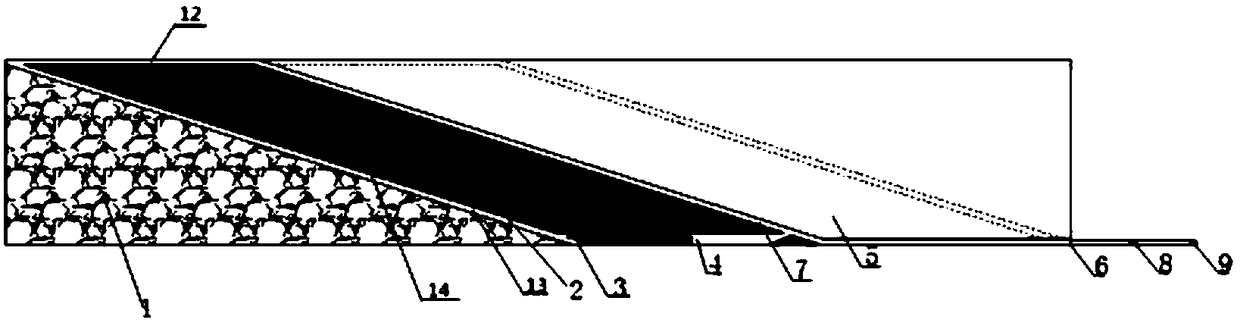

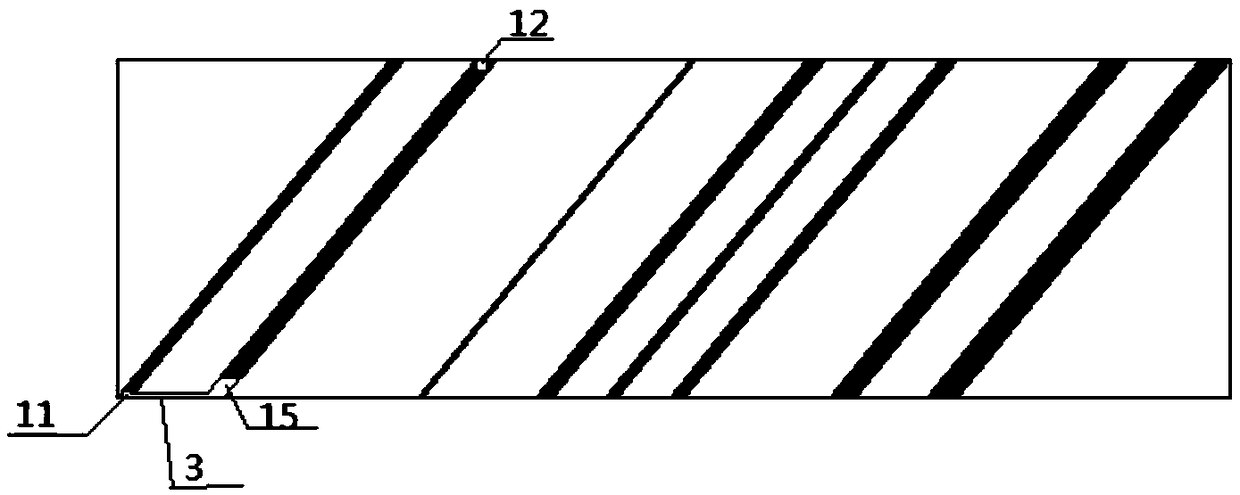

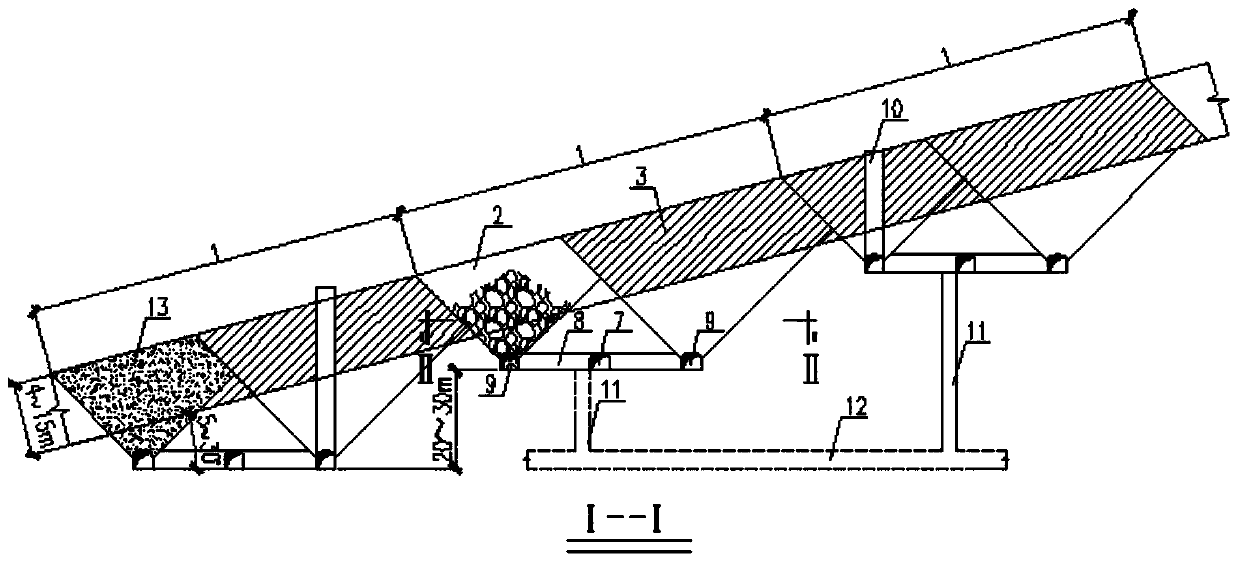

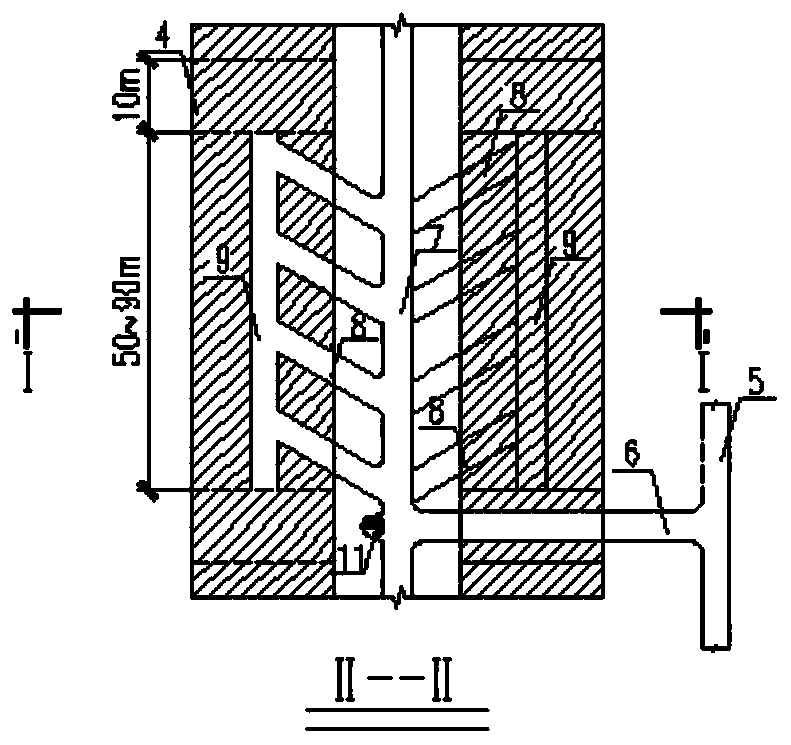

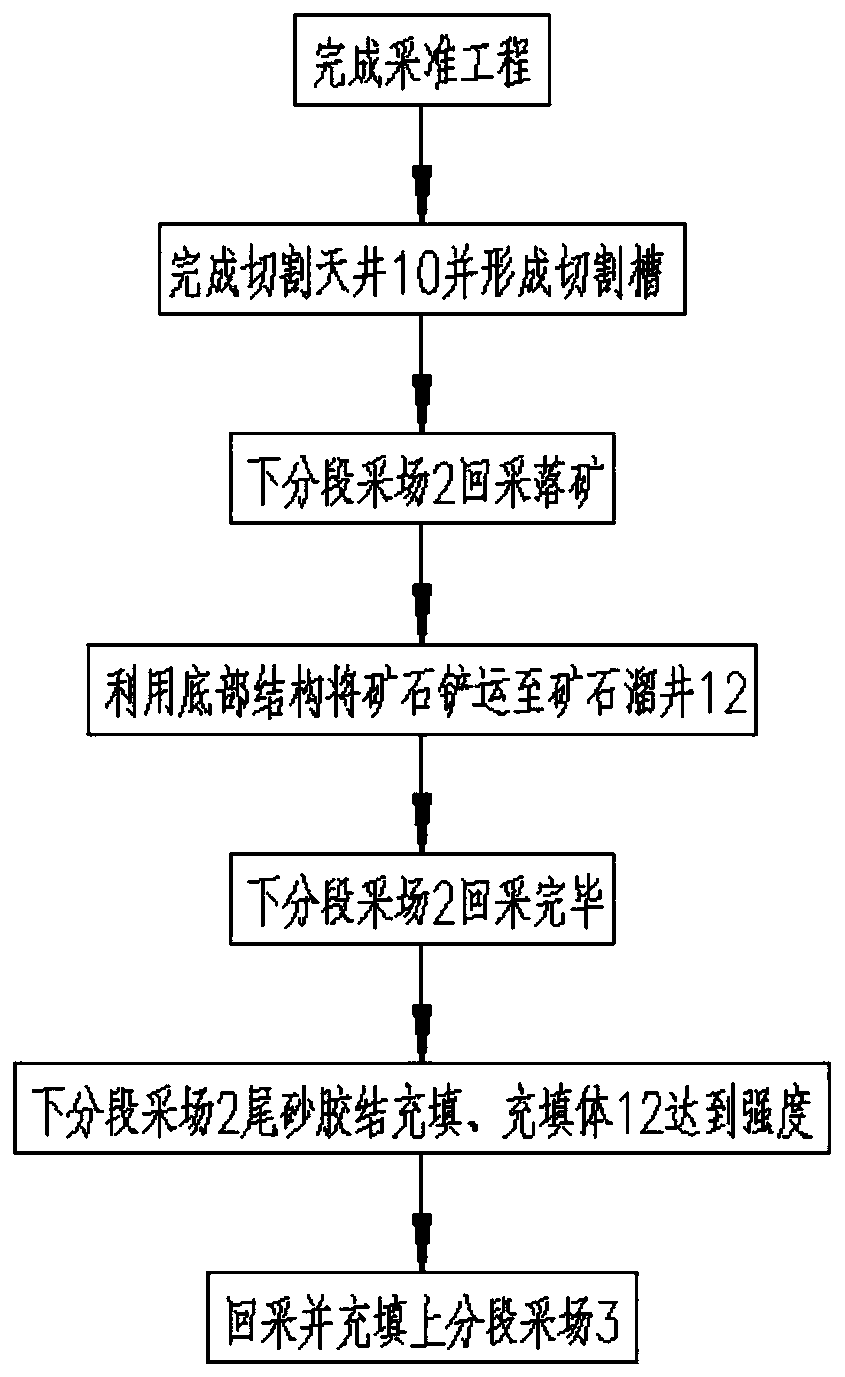

Gentle dip medium-thick ore body safety and low-cost combined segmented mining method

ActiveCN110359914AAvoid direct accessGuarantee job securityUnderground miningSurface miningEngineeringYard

The invention discloses a gentle dip medium-thick ore body safety and low-cost combined segmented mining method. Lower segmented stopes (2) and upper segmented stopes (3) are alternately arranged in the ore body vertical direction at each interval of 10-15 m, one recovery unit (1) is formed through combination of each lower segmented stope (2) and the corresponding upper segmented stope (3), and studs (4) are scratched at the end portions of the recovery units (1). In each lower segmented stope (2), a cutting groove is formed with a cutting open yard (10) as the free face, and ore falls into atrench (9). A shoveling and conveying machine is utilized for conducting ore loading in an ore loading access road (8), carries the ore into an ore drop shaft (11) through an ore discharging roadway(7) and then lowers the ore into a conveying roadway (12) for car loading and conveying-out. According to the gentle dip medium-thick ore body safety and low-cost combined segmented mining method, every two segmented stopes are gathered into one recovery unit for exploitation, the ore discharging roadway, the ore drop shaft, a slope ramp linking way and other projects are commonly used, the stopepreparation cost is reduced, the preparing time for the stope preparation work is saved, and the exploitation efficiency is improved. Exploited waste stone can be machined into building materials to be sold, and the stockpiling space is additionally arranged for tailing filling.

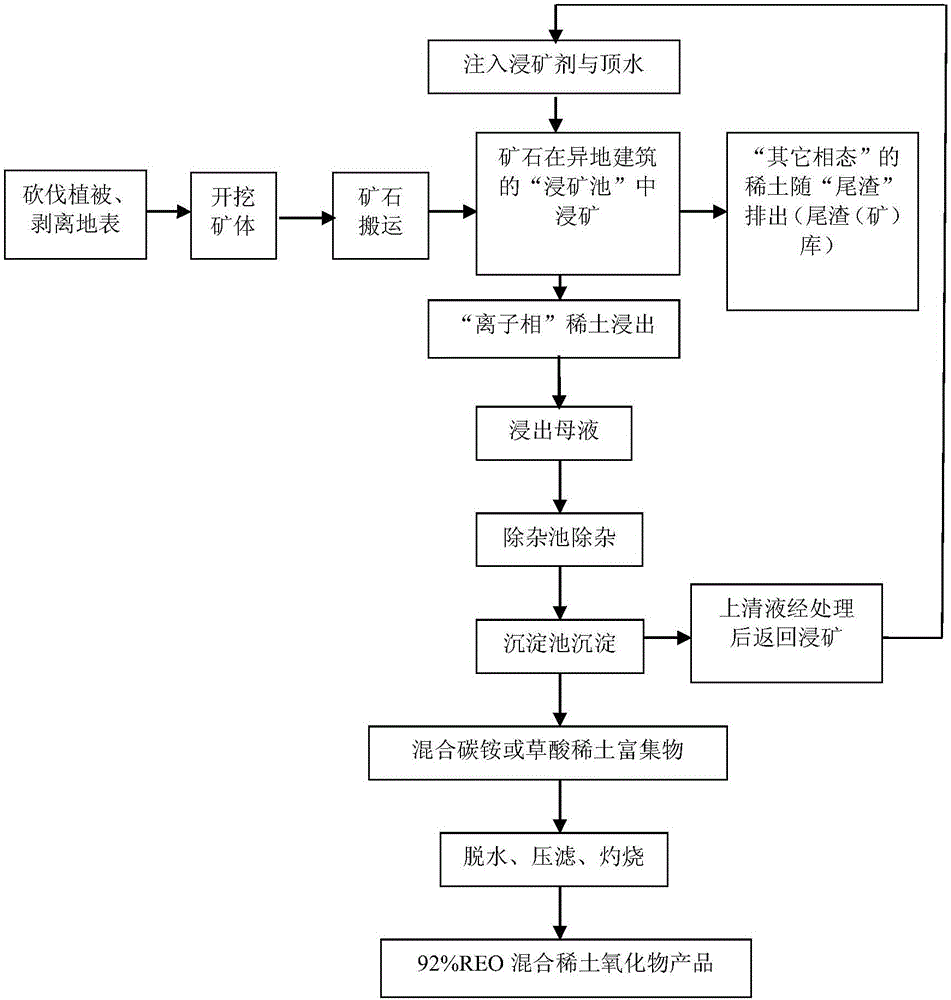

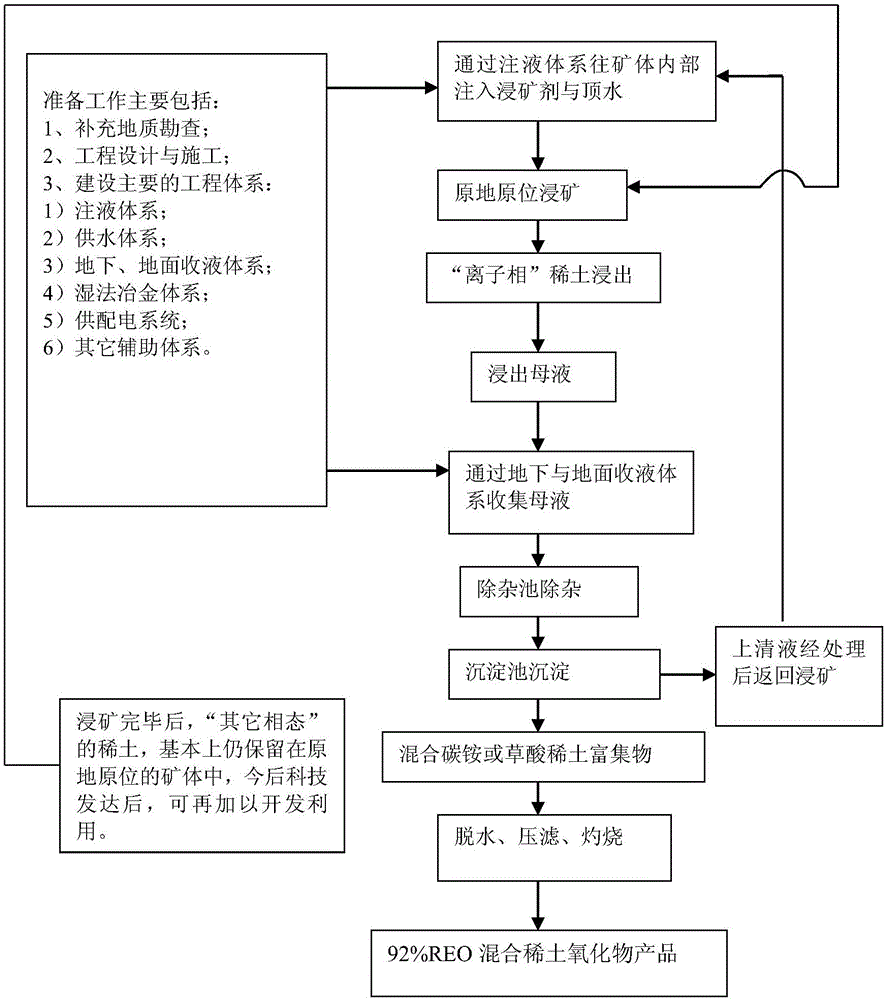

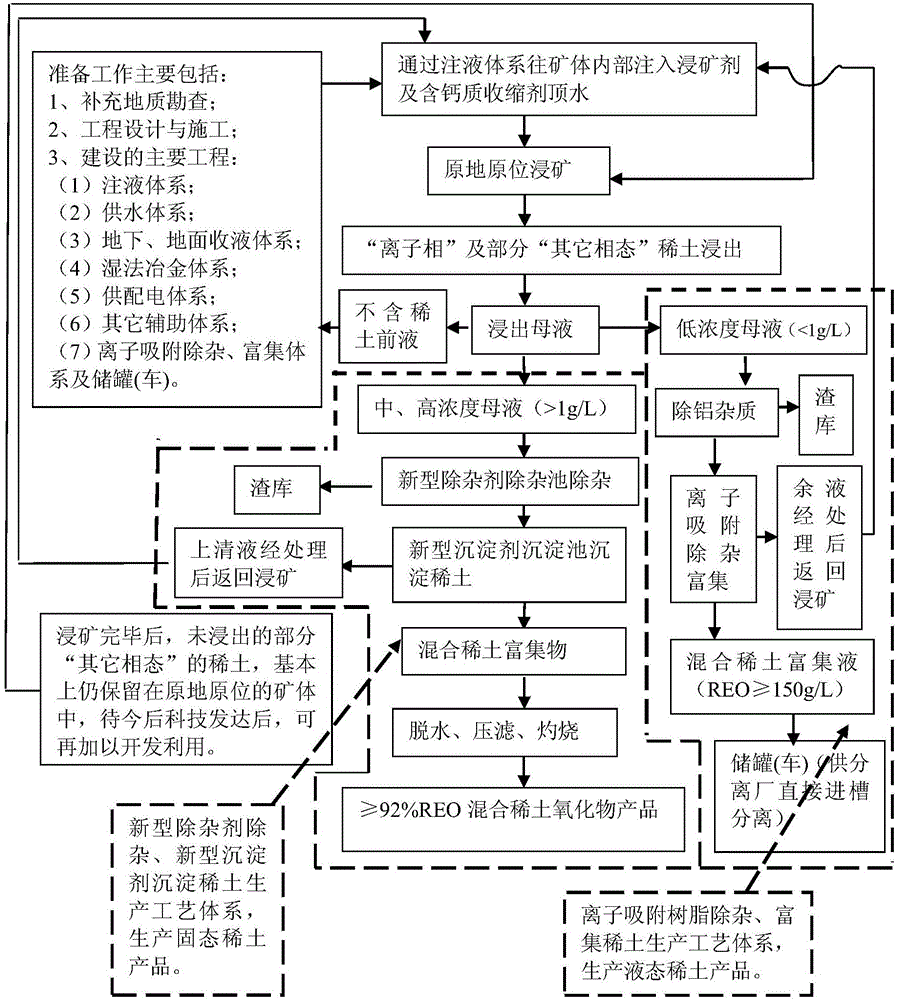

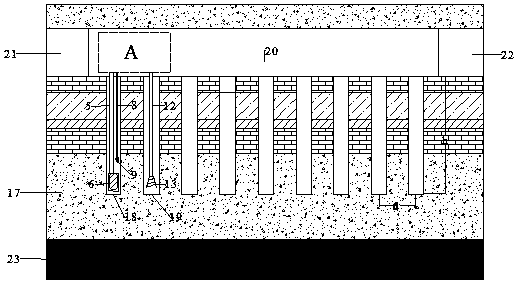

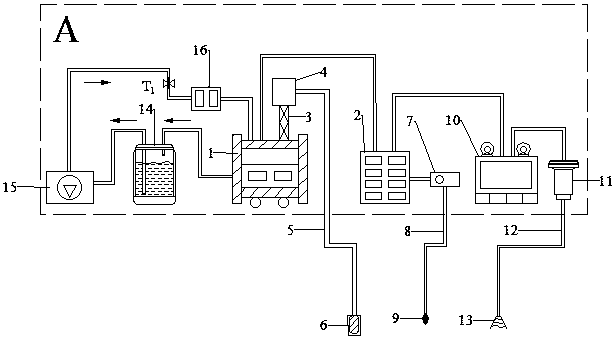

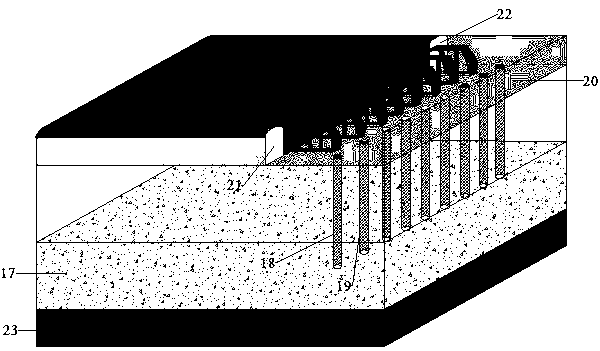

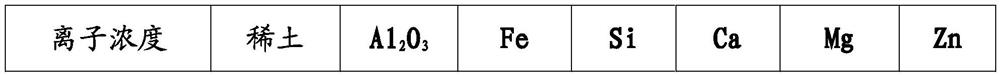

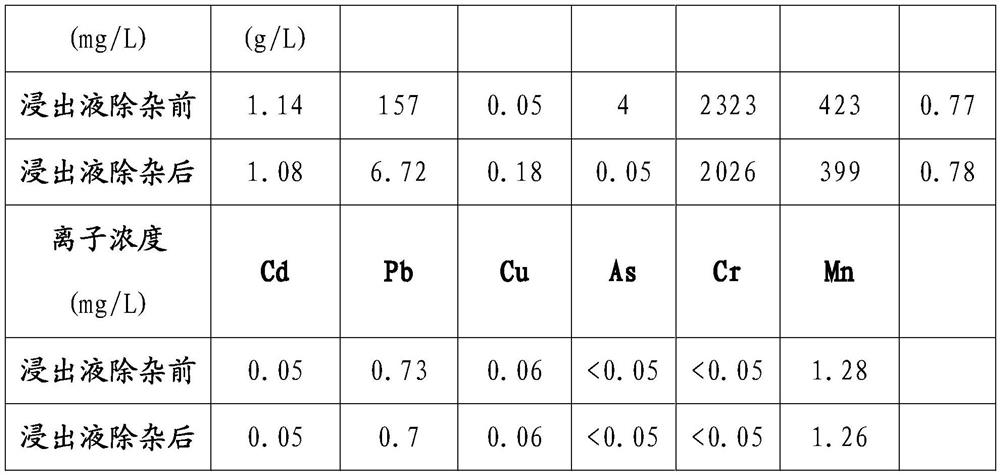

Rare earth in-situ leaching and enriching process for ionic rare earth ore

The invention discloses a rare earth in-situ leaching and enriching process for ionic rare earth ore. The rare earth in-situ leaching and enriching process comprises the following steps: step 1, injection an ore leaching agent and a shrinkage agent into ore body, and performing sited and in-situ ore leaching to enable 'ion-phase' and part of 'other-phase' rare earth to leach out to obtain a mother liquor; step 2, pumping an impurity removal agent I into the medium and high-concentration mother liquor for impurity removal, precipitating through a precipitator, washing with clear water, filtering, and firing to obtain a solid rare earth product, wherein the impurity removal agent I is a mixed solution of a sodium bicarbonate solution and a sodium carbonate solution, and the precipitator is a sodium bicarbonate solution; and pumping an impurity removal agent II into the low-concentration mother liquid for neutralization to remove aluminum impurities, pumping ion exchange columns into the mother liquor from which aluminum is removed for adsorptive enrichment of rare earth ions, and desorbing with acid to obtain a liquid rare earth product, wherein the impurity removal agent II is lime cream. The independently researched and developed brand-new agents are used together with the whole set of innovative technology to achieve the purposes of significant change of the ionic rare earth extraction process, comprehensive optimization of technical-economic indicators and friendly ecological environment.

Owner:赣州弘茂稀土工程有限公司

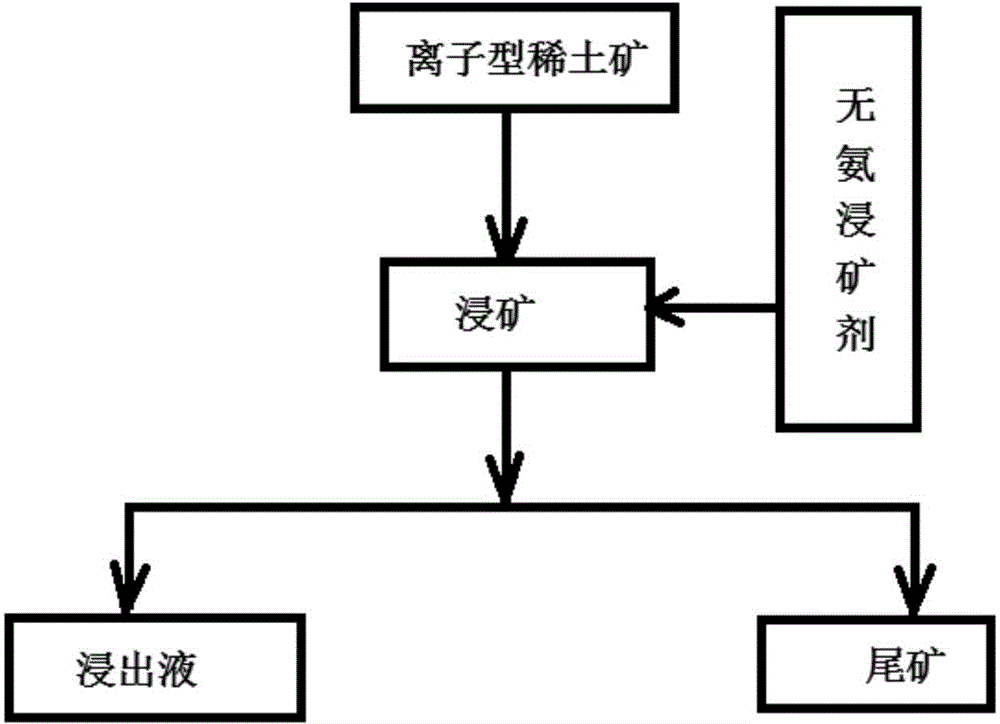

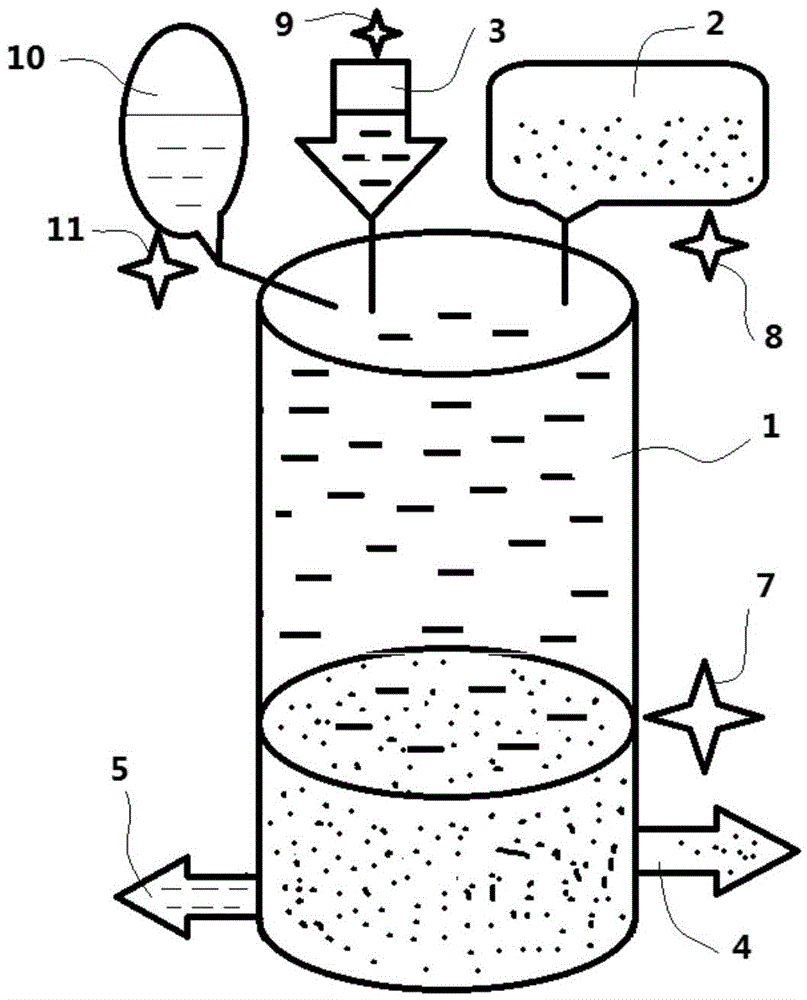

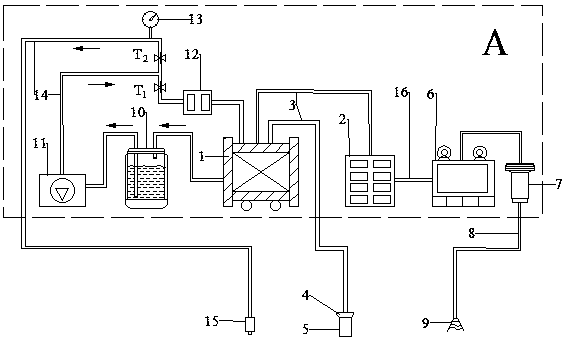

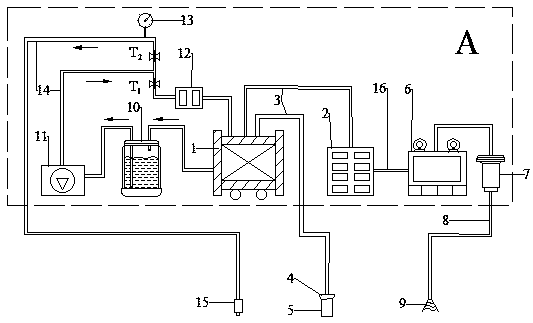

Mineral leaching method and mineral leaching system for ionic rare earth mine

InactiveCN103555939AImprove leaching effectImprove rare earth leaching rateProcess efficiency improvementRare earthMaceral

The invention relates to a mineral leaching method for an ionic rare earth mine. The mineral leaching method is characterized by comprising the following steps: carrying out percolation leaching on the mine by taking ammonia-free electrolyte as a mineral leaching agent, so that positive ions in the mineral leaching agent and ion-phase rare earth adsorbed on the surface of a carrier mine exchange to form a soluble rare earth compound entering the solution; loading the ionic rear earth mine in a mineral leaching exchange column, and adding the ammonia-free mineral leaching agent with the concentration of 2-5% according to the proportion of the mineral leaching agent (liters) to the mine (kilograms) being 0.6-0.8; after the surface of the mine is exposed out, adding top water according to the proportion of the top water (liters) to the mine (kilograms) being about 0.2; and draining away a residual solution in the mineral leaching exchange column fundamentally, namely ending mineral leaching work. The mineral leaching method is high in mineral leaching efficiency, and can prevent the pollution of ammonia nitrogen to the environment.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

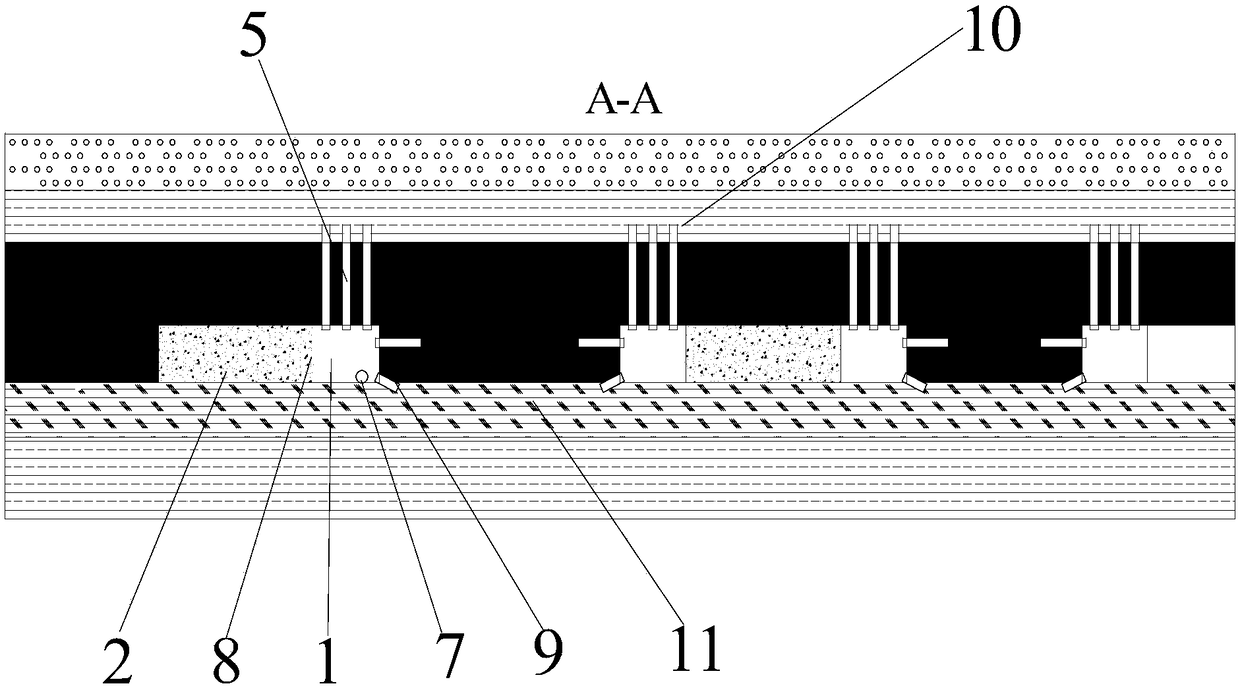

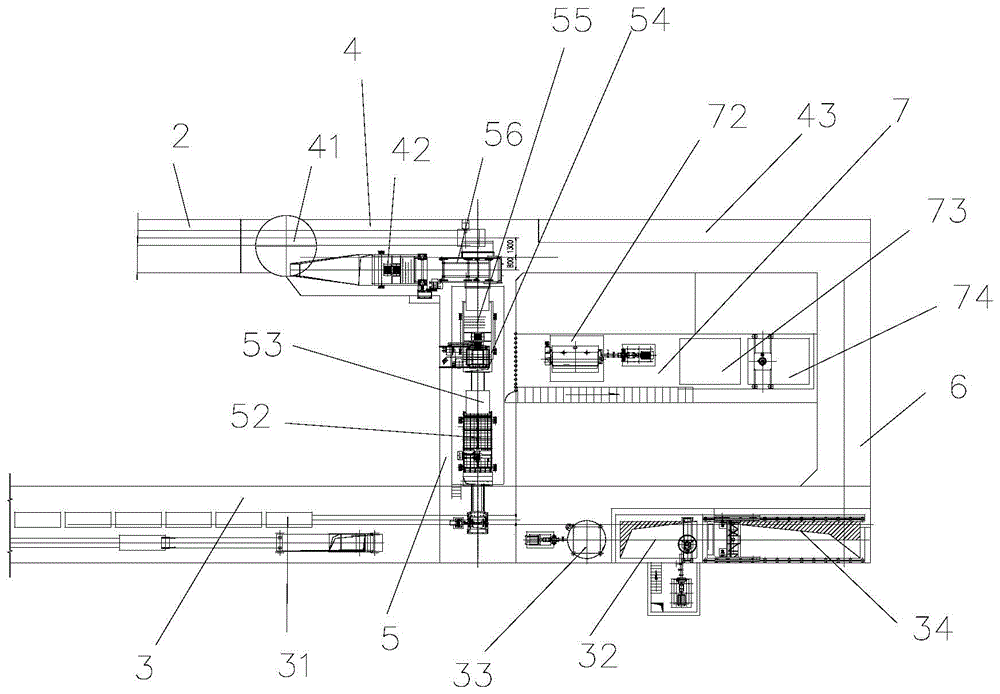

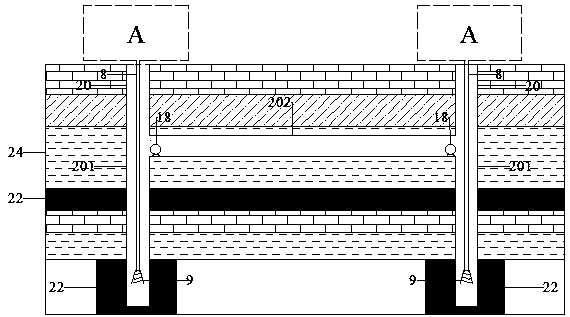

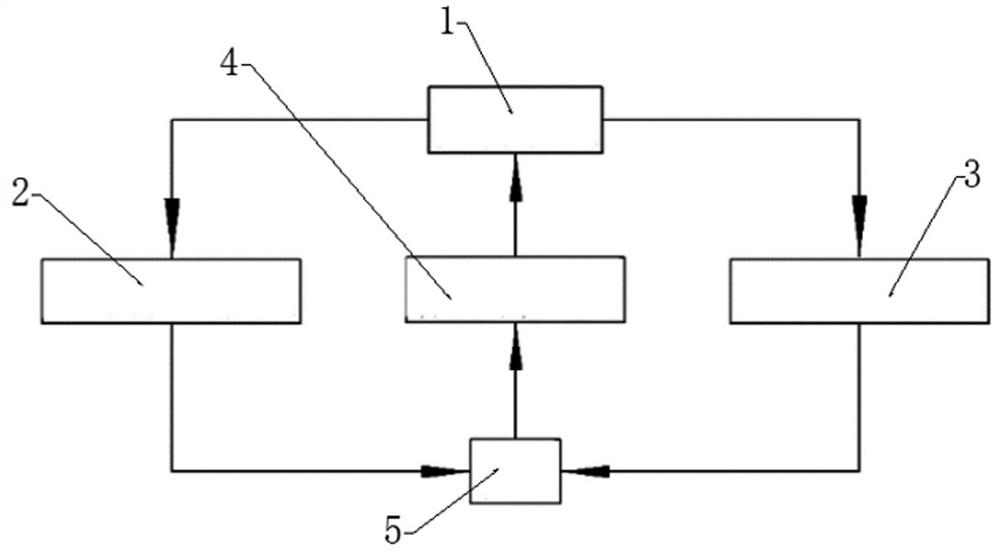

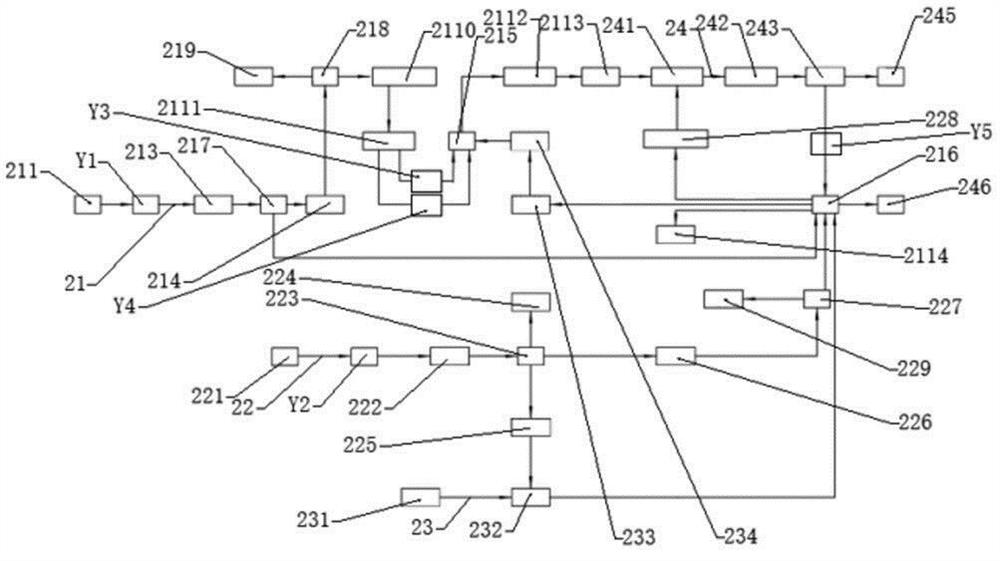

Underground coal and gangue separation system and coal and gangue separation method

InactiveCN105983478ARealize green miningSolve shipping problemsWet separationSeparation systemMineralogy

The invention provides an underground coal and gangue separation system and coal and gangue separation method, comprising a material conveying roadway, a downhole coal and gangue separation passage, a first roadway, a second roadway, a vertical roadway, a first connection and a second connection. The underground coal and gangue separation system and coal and gangue separation method is provided to allow underground separation and separate storage of a coal-gangue mixture, the fact that the original underground wash-dressing process is complex, equipment is too large and wash-dressing capacity is low is improved, the coal-gangue mixture conveying problem and gangue surface stacking problem are solved thoroughly, ineffective lifting and conveying of a mine are greatly reduced, and green mining is truly achieved.

Owner:DIZHEN COAL MINE SHANDONG TAISHAN ENERGY

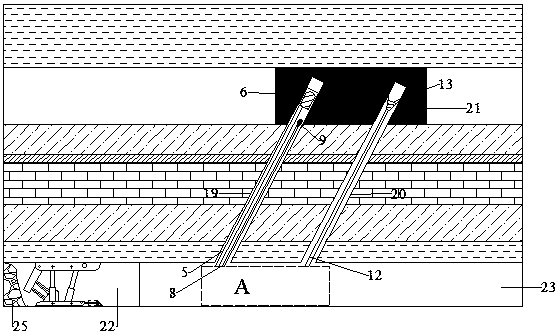

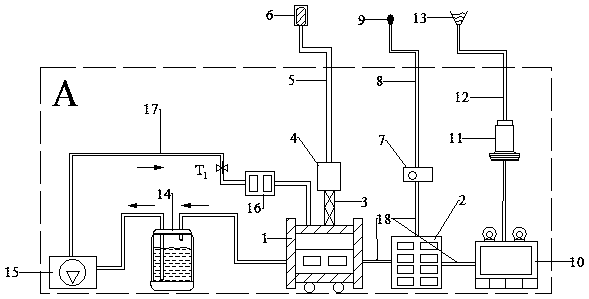

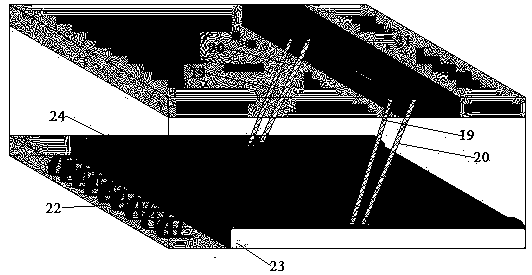

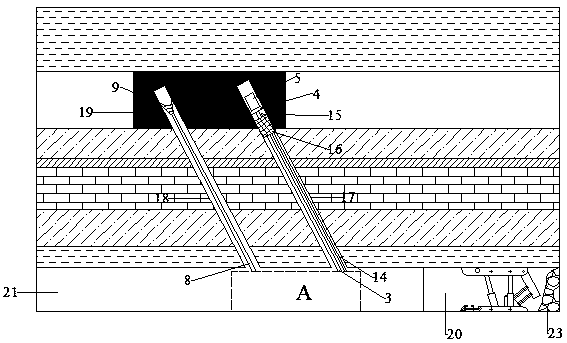

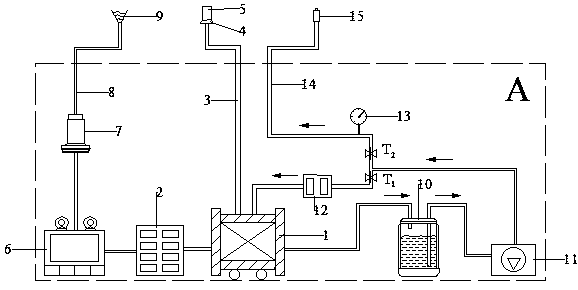

Method and device for weakening underlying coal seam mining thick-hard roof strong mine pressure through microwave heating

ActiveCN110374594AReduce or eliminate the hazardImprove securityDisloding machinesUnderground miningMicrowaveEngineering

The invention discloses a method and a device for weakening underlying coal seam mining thick-hard roof strong mine pressure through microwave heating. A row of holes are drilled from a bottom plate on a coal mining work face of an overlying coal seam to an underlying coal seam thick-hard roof, wherein the distance d between each two adjacent holes is 6-18m, the drilled holes are perpendicularly arranged in the advancing direction of the coal mining work face of the overlying coal seam, and when the overlying coal seam is mined, the strong mine pressure of the underlying coal seam mining thick-hard roof is weakened. The method and the device for weakening the underlying coal seam mining thick-hard roof strong mine pressure through the microwave heating fully utilize the characteristics ofbeing high in efficiency, large in energy density, wide in adaptability, strong in penetrability and the like of microwave heating rock breaking, perform presplitting on the underlying coal seam thick-hard roof when the overlying coal seam is mined, and achieve the purpose of weakening the underlying coal seam mining thick-hard roof strong mine pressure, thereby achieving green mining and safe production for coal mines.

Owner:TAIYUAN UNIV OF TECH

Method and device for upward cracking left coal pillars in residual mining area through microwave heating

ActiveCN110318755AEasy to controlGood effectMining devicesUnderground miningMicrowaveHeat transmission

The invention discloses a method and device for upward cracking left coal pillars in a residual mining area through microwave heating, and belongs to the field of coal mining. According to the methodand the device, in a stress relaxed area below the left coal pillars in the residual mining area, two drilling holes are drilled in each left coal pillar in the residual mining area in top rock of a haulage gate and an air return way 15-25 meters away from the working face end, and the left coal pillars in the residual mining area are cracked. The characteristics of microwave heating that the efficiency is high, energy density is high, no medium is needed for heat transmission, and penetrability is high are sufficiently utilized, and when a working face of an underlie coal seam is mined to theposition near the left coal pillars of the residual mining area, upward cracking is conducted on the left coal pillars in the residual mining areas from the underlie coal seam. According to the method for upward cracking the left coal pillars in the residual mining area through microwave heating, the efficiency is high, control is easy, the effect is good, the flexibility is high, the integrity of the coal pillars is reduced, the purposes of weakening strength, releasing stress and relieving strata behaviors are achieved, and the safety of roof control is greatly improved.

Owner:TAIYUAN UNIV OF TECH

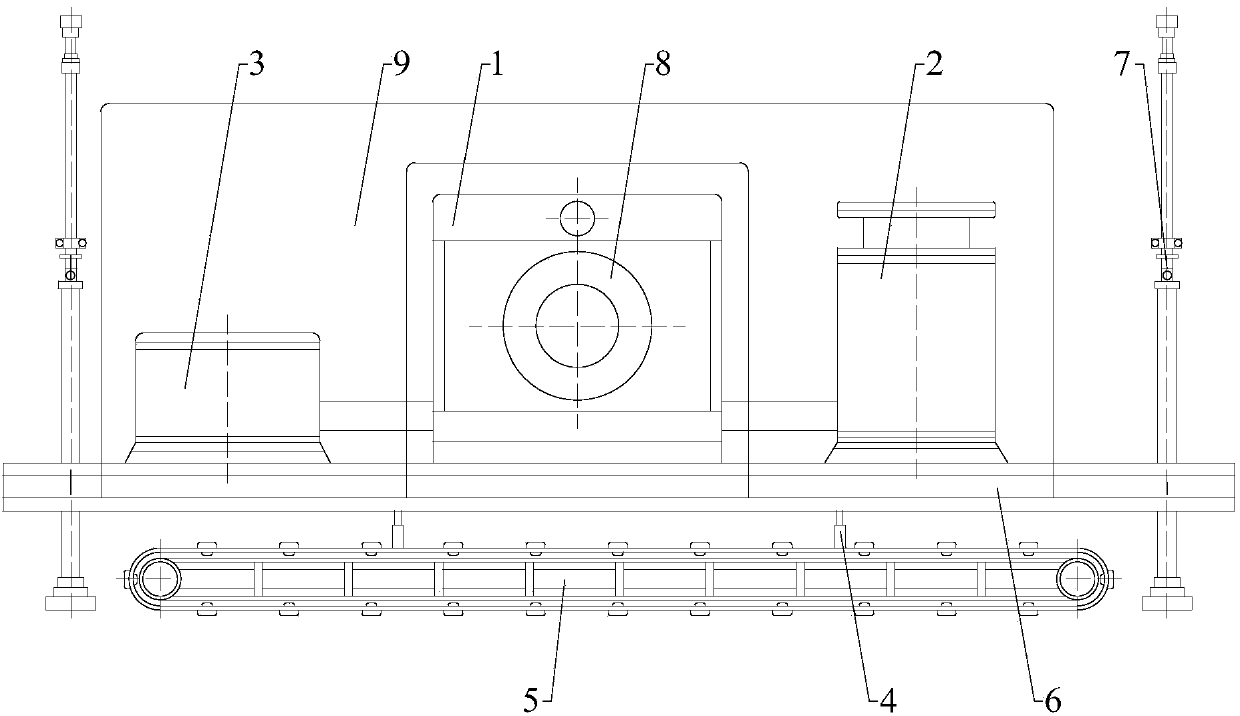

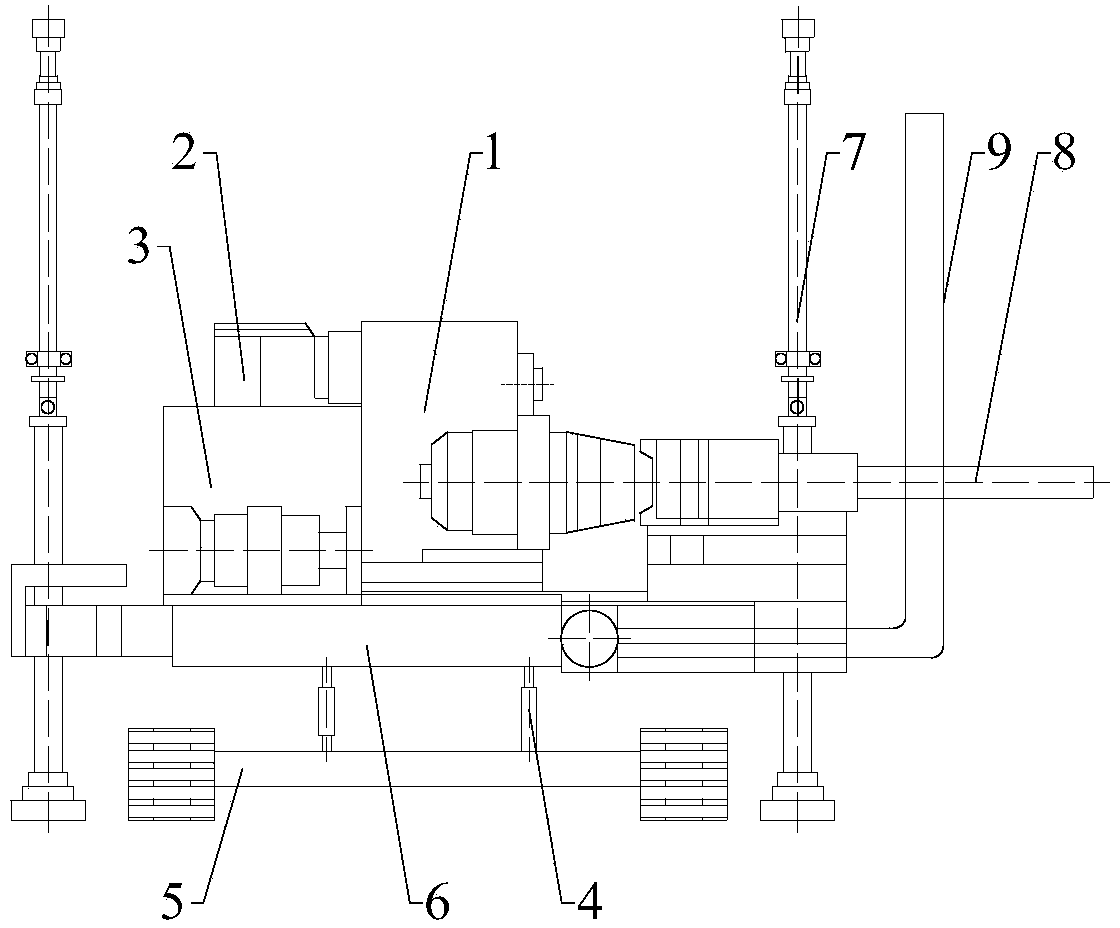

High-dipping low seam self-walking simple drill coal mining machine and mining method thereof

ActiveCN104405385AReduce volumeReduce weightSlitting machinesDrilling machines and methodsEconomic benefitsEngineering

The invention relates to a high-dipping low seam self-walking simple drill coal mining machine and a mining method thereof, which belongs to the drill coal mining machine and mining method. The simple drill coal mining machine comprises a host, a control board, a pumping station, a caterpillar base plate, a support hydraulic column, a pedestal, a stable hydraulic support, a drilling tool assembly and a coal baffle plate. A drilling rod and a drilling rod in the drilling tool assembly are connected through a planetary gear decelerator, the coal baffle plate employs a full transparent design; the invention provides a high-dipping low seam mining method, the height of the support hydraulic column is adjusted to determine the drilling direction, coal mined under gravity effect falls to a scraper plate conveyer along a drill pit, a goaf employs a nature caving method for treatment, and the ventilation mode of a drilling surface is a U type ventilation mode. According to the invention, jamming of a drilling tool can be effectively solved, drilling power and coal breaking effect of the drill coal mining machine can be ensured, and the drill coal mining machine has the advantages of simple production process, low equipment cost of working surface and high technical economic benefit, and the drill coal mining machine has important meaning for increasing coal mining rate and prolong the service time limit.

Owner:CHINA UNIV OF MINING & TECH

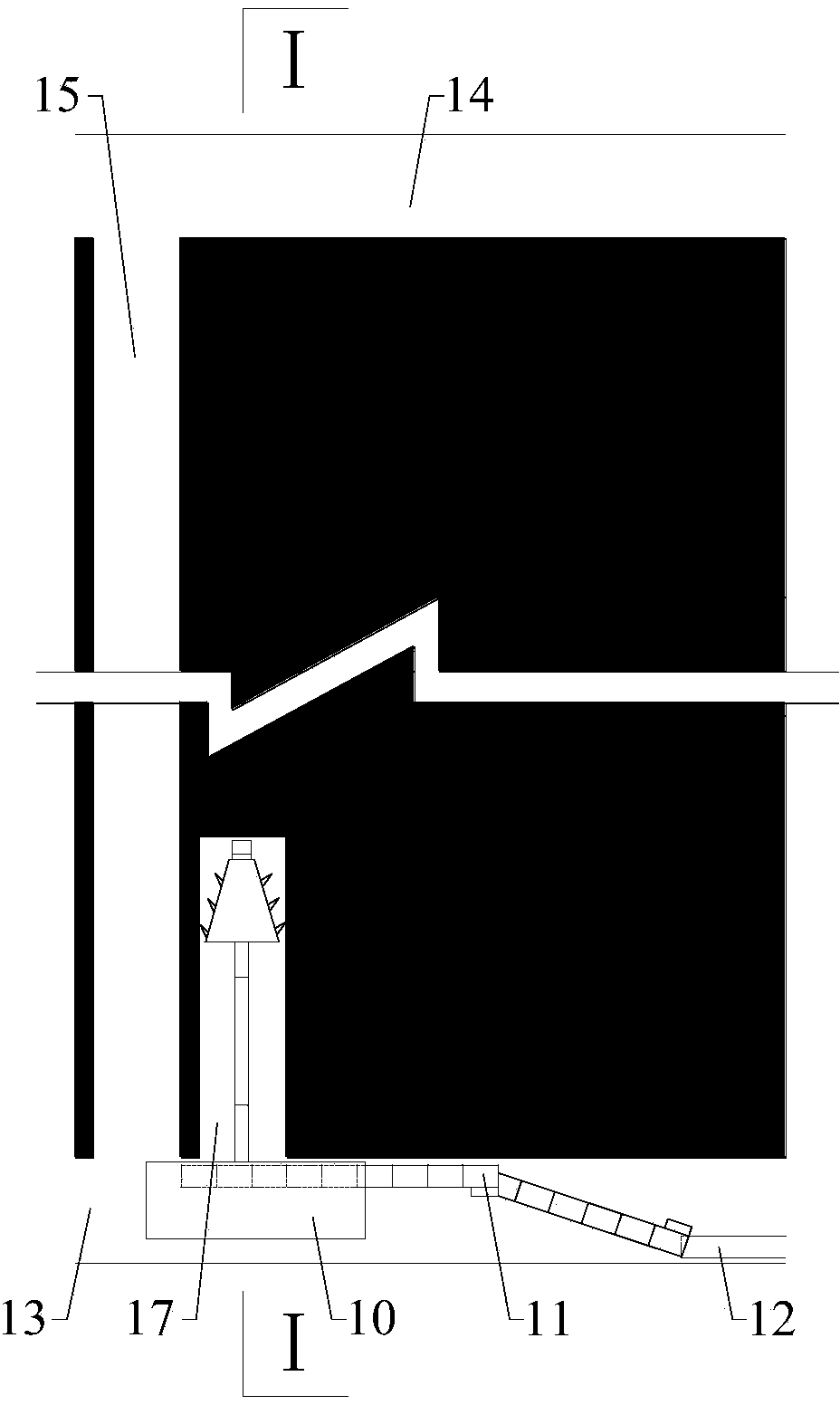

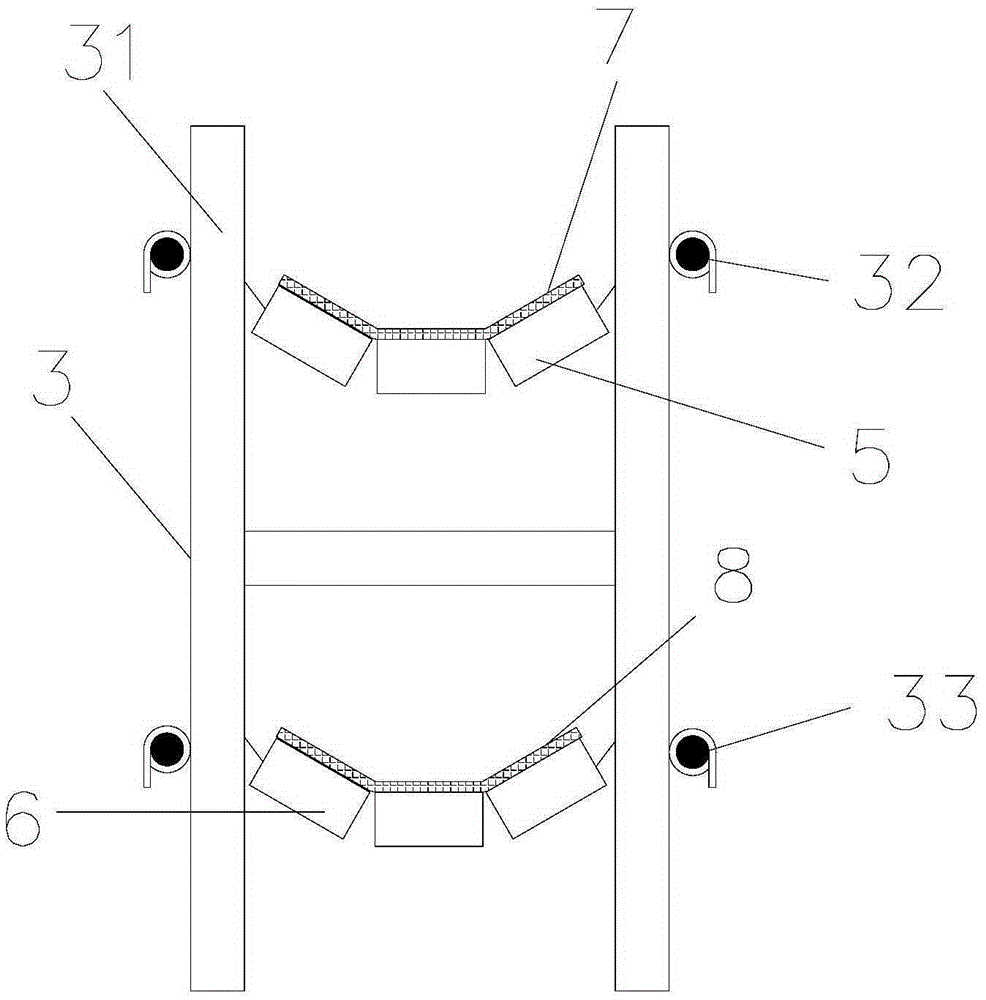

Reaction type gangue crushing and separating tester

A reaction type gangue crushing and separating tester comprises a belt conveying portion and a roller accelerated crushing portion; the belt conveying portion is a conventional belt conveyer portion; the roller accelerated crushing portion comprises a housing, an accelerating wheel is mounted in the housing, the wall of the housing is provided with three auxiliary crushing blocks, the right side of the housing is provided with a material casting outlet, the accelerating wheel is controlled by a motor fixed in the housing, a reaction plate is arranged in the material casting direction, gangue is crushed by the reaction plate and drops on a vibrating screening mechanism that is inclined, and the gangue and pulverized coal are separated by the vibrating screening mechanism. A speed sensor is mounted on a rotary shaft of the tester, such that the tester can meet the need of a gangue separator for material conveying, allows the material casting speed to be controlled and adjusted, and is of certain testing study significance.

Owner:HENAN POLYTECHNIC UNIV

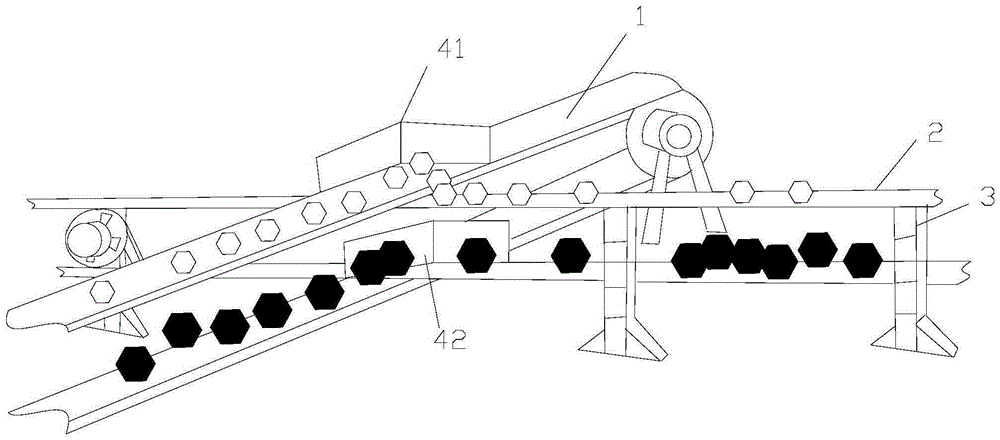

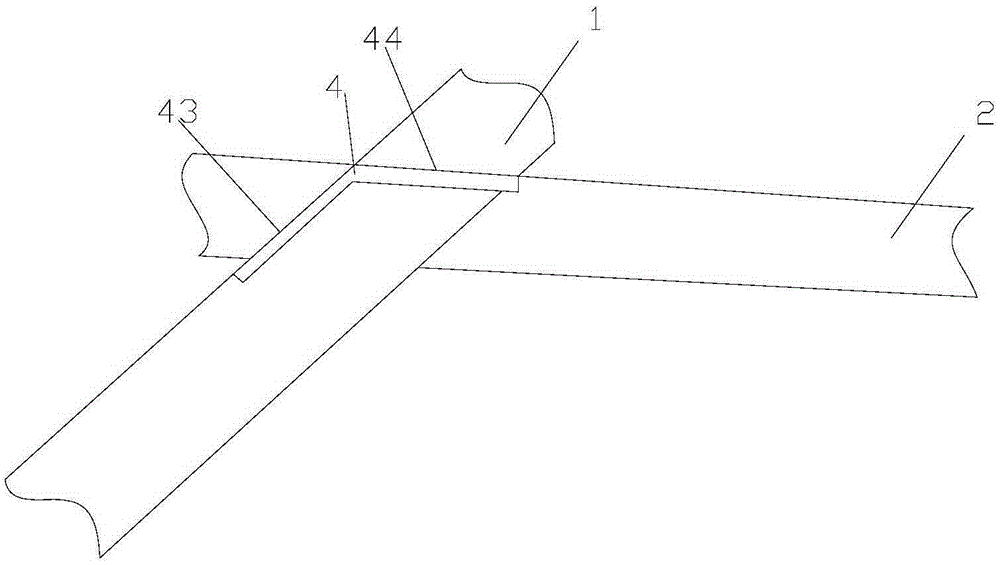

Two-way conveying equipment and application method thereof

ActiveCN106608510AReduce usageRealize one machine with multiple functionsConveyor partsMechanical conveyorsEngineeringBelt machine

The invention relates to two-way conveying equipment and an application method thereof. The two-way conveying equipment comprises belt conveyors and a bracket; the belt conveyors have annular conveying belts; multiple belt conveyors are provided, and include previous-stage belt conveyors and later-stage belt conveyors; the previous-stage belt conveyors and the later-stage belt conveyors form a relay conveying structure; and the annular conveying belts are divided into upper and lower two layers, and include upper conveying belts for forwards conveying and lower conveying belts for reversely conveying. The invention further proposes the application method of the two-way conveying equipment. The two-way conveying equipment has the following beneficial effects: the belt conveyors capable of conveying in two directions, multifunctional unloaders, transfer point intersection and three-dimensional joint are adopted to realize the purposes of synchronous transportation by the upper and lower layers of belts of the belt conveyors, two-way continuous transportation of raw coals and gangue and two-way unloading; the equipment utilization rate is increased; the use number of gangue transportation belt machines is reduced; and the operation efficiency of equipment with multiple purposes on one machine reaches 100%.

Owner:新汶矿业集团有限责任公司鄂庄煤矿

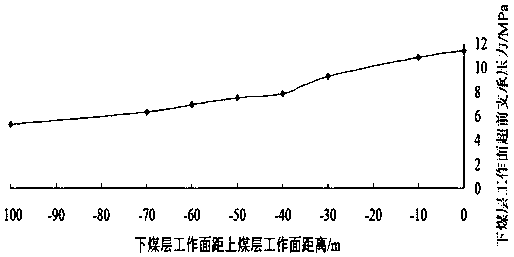

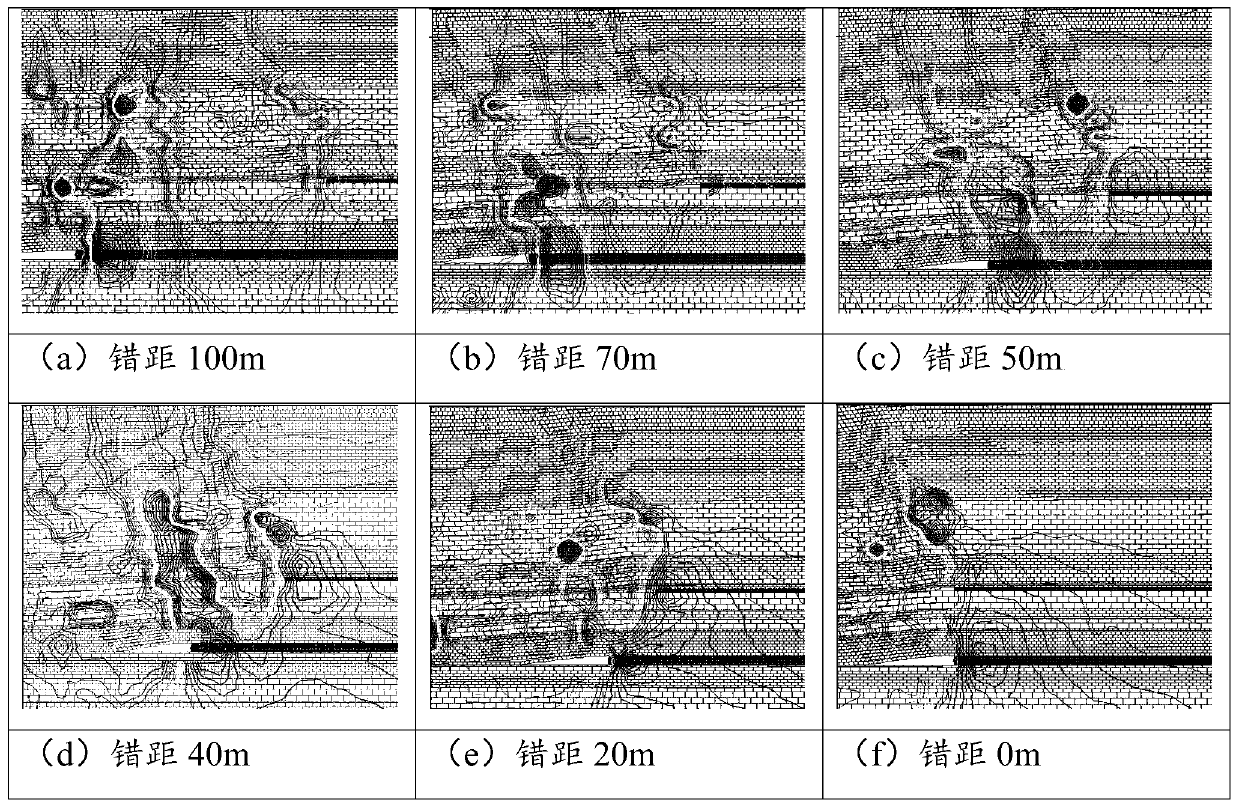

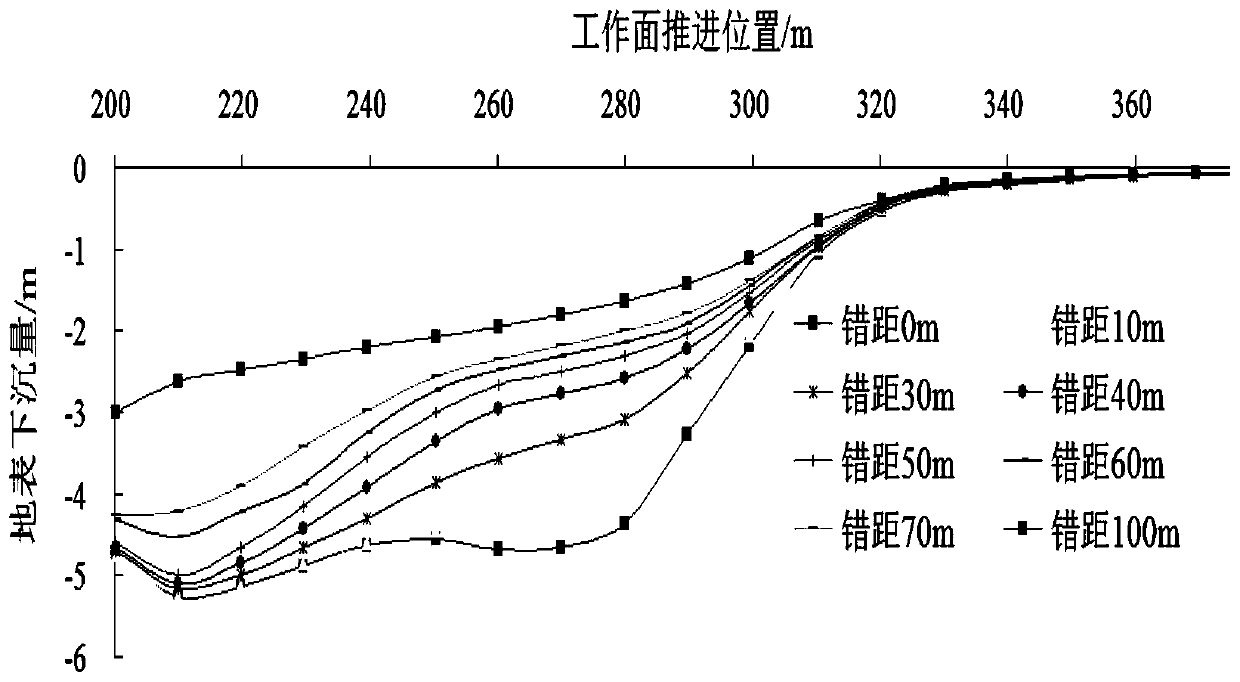

Method for determining staggered distance between dual coal seam upper-lower simultaneous mining working faces in propelling direction

InactiveCN110630268AEnsure safetyAchieving safe miningUnderground miningSurface miningMechanical modelsMaximum depth

The invention provides a method for determining the staggered distance between dual coal seam upper-lower simultaneous mining working faces in the propelling direction, and belongs to the technical field of coal mining. The method comprises the steps that the ideal staggered distance range is found out and obtained; according to the ideal staggered distance range, an ultimate bearing capacity computational formula during plastic slip of rock and soil is utilized to obtain a computational formula of the maximum depth H<max> of an upper coal seam bottom plate destruction region under the ultimate bearing pressure condition, and thus a computational formula of the maximum horizontal distance L<max> of an upper coal seam bottom plate broken rock stratum is obtained; a pressure-stabilizing mechanical model and a pressure-reducing mechanical model for the propelling direction of upper-lower coal seam working face simultaneous mining of dual coal seam mining are established, thus the maximumhorizontal distance of the upper coal seam bottom plate broken rock stratum, the bottom plate stress transfer angle and the spacing between an upper coal seam and a lower coal seam are obtained, and acomputational formula of the staggered distance in the pressure-stabilizing propelling direction and the pressure-reducing propelling direction is determined; and the computational result in the step3 is corrected. According to the method, the mine pressure strength of the lower coal seam working face and the earth surface damage degree during simultaneous mining of the dual coal seam superposition regions can be effectively lowered, and efficient and environment-friendly mining of the dual coal seams is achieved.

Owner:XIAN UNIV OF SCI & TECH

Method and device for performing plasma ascending cracking remaining coal pillar in residual mining area

ActiveCN110388206AGood effectReduced integrityDisloding machinesUnderground miningHigh pressureCoal pillar

The invention discloses a method and a device for performing plasma ascending cracking on remaining coal pillar in residual mining area and belongs to the technical field of coal mining. The remainingcoal pillar in the residual mining area is subjected to ascending cracking by a plasma device from an underlie coal seam, impact wave is formed by completely utilizing the characteristic that strongmovement along ions instantly generate high temperature and high pressure to enable the coal pillar to generate crack and expand, the integrity of the coal pillar is reduced and the aims of weakeningstrength, releasing stress and retarding strata behavior are fulfilled, so that green mining of coal is realized and safety production is realized.

Owner:TAIYUAN UNIV OF TECH

Gas pressure relief method of ground drilling extraction minery and goaf

InactiveCN1313702CLess gushAchieve destructive effectFluid removalGas removalMining engineeringWell drilling

This invention discloses a method for depressuring gas in ground drilled well and mining area. Before extracting coal a ground drilling well is drilled from ground to long distance, low breathing, high gas, projecting and soft covered seams, then extracting down seam. The gas from the up covered seam is exhausted from pipe.

Owner:HUAINAN MINING IND GRP

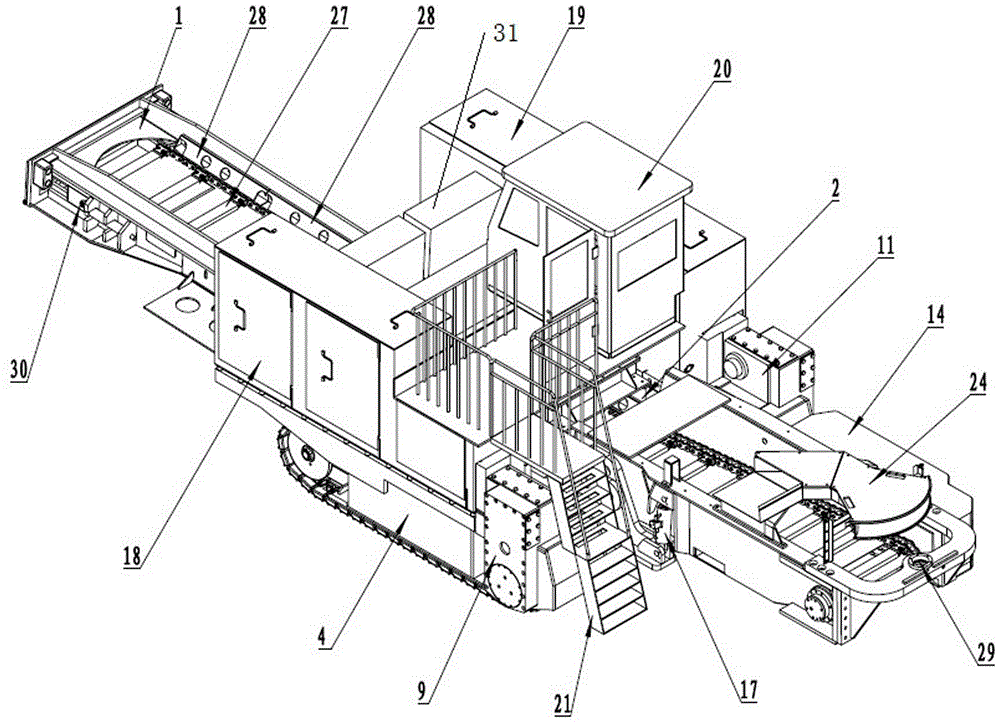

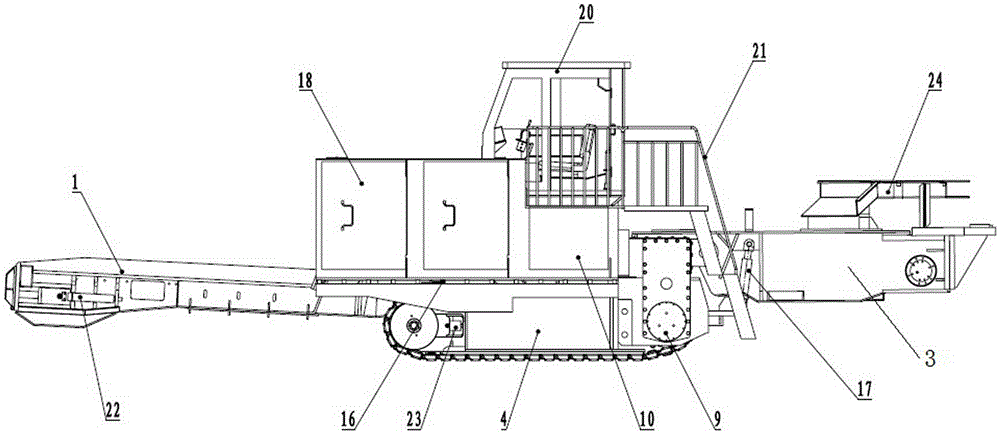

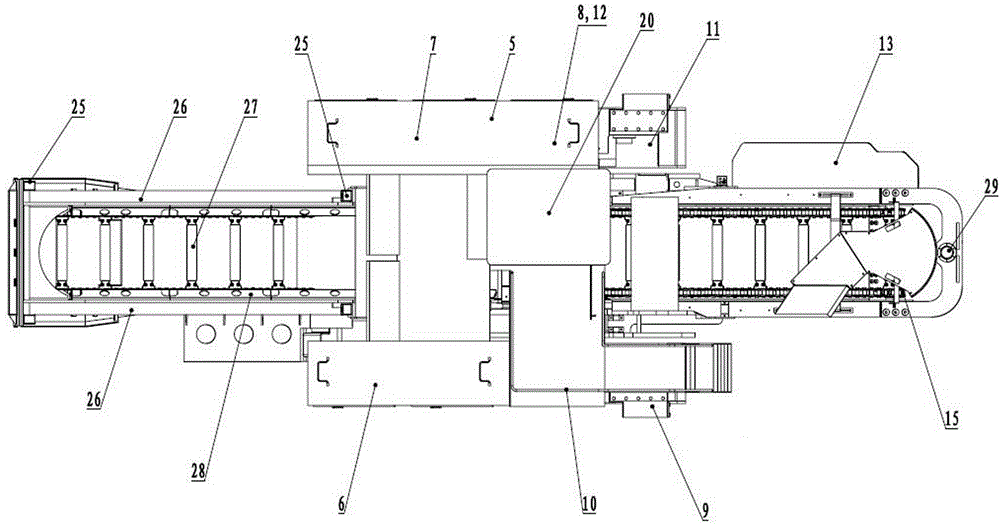

Continuous walking type transport loader of open pit coal mine

The invention belongs to the technical field of transport equipment of an open pit coal mine, and particularly relates to a continuous walking type transport loader of an open pit coal mine, which is used for solving the problem of a loader for existing open mining. A receiving part, a main rack and a discharging part main body are all of a welded groove-shaped structure, so that an upper chain channel and a lower chain channel are formed, and are hinged together by virtue of a pin roll to form a coal conveying chain channel of the whole equipment, a scraper chain is arranged in the coal conveying chain channel and penetrates through the whole coal conveying chain channel, the upper chain channel is provided with a chain pressing block, a transport driving chain wheel and a tail guide wheel are respectively arranged at two ends of the scraper chain and are meshed and linked with the scraper chain, the scraper chain drives a chain wheel shaft to be linked with transport driving parts which are arranged at the left side and the right side, and the transport driving parts are respectively provided with a transport driving part protecting cover. According to the continuous walking type transport loader, a truck transporting link is eliminated, the transport cost is lowered, the equipment investment is reduced, the production capability and the production efficiency are improved, the cost of per ton coal is lowered, and the environmental-friendly mining of coal is realized.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

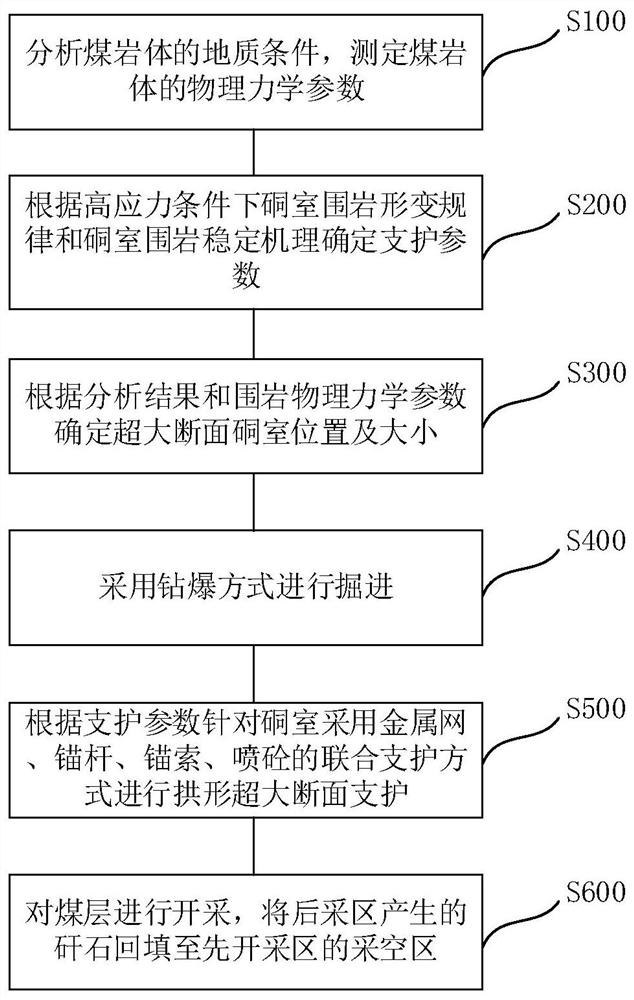

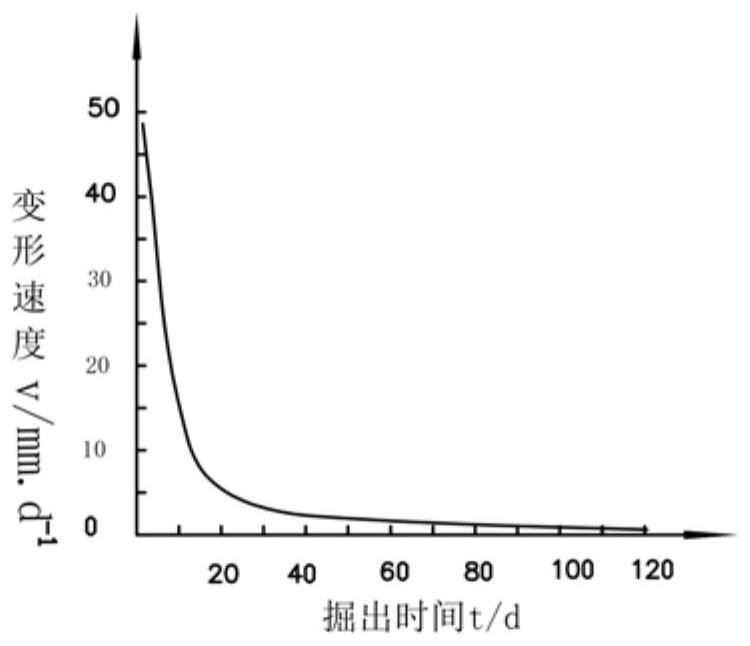

Surrounding rock stability control method for deep ultra-large section dense chamber group

PendingCN112343627APerfect construction technologyImprove support strengthUnderground chambersTunnel liningMetal meshCoal

The invention relates to a surrounding rock stability control method for a deep ultra-large section dense chamber group. The technical problem that existing deep ultra-large section chamber surrounding rock is unstable is solved. The method comprises the following steps that geological conditions of coal and rock masses are analyzed, and physical and mechanical parameters of the coal and rock masses are measured; support parameters are determined according to the chamber surrounding rock deformation rule and the chamber surrounding rock stability mechanism under the high stress condition; theposition and the size of an ultra-large section chamber are determined according to the analysis result and the surrounding rock physical and mechanical parameters; tunneling is performed in a drilling and blasting mode; according to the support parameters, a combined supporting mode of a metal net, anchor rods, anchor cables and sprayed concrete is adopted for supporting the arch-shaped ultra-large section of the chamber; and the coal seam is mined, and gangue generated in the post-mining area is used for backfilling into the goaf of the pre-mining area. According to the method, the construction process of the deep ultra-large section chamber is perfected, the supporting strength is improved, the deformation of the surrounding rock of the chamber is controlled to be stabilized within an allowable range for a long time, later maintenance of the chamber is reduced, secondary supporting is avoided, and meanwhile green mining is achieved.

Owner:中国平煤神马控股集团有限公司

Method for microwave heating reducing of composite strong mine pressure of thick and hard top plate and left coal pillar

ActiveCN110388207AReduced integrityDoes not affect coal mining workDisloding machinesUnderground miningMicrowaveWell drilling

The invention discloses a method for microwave heating reducing of the composite strong mine pressure of a thick and hard top plate and a left coal pillar. A microwave heating device is adopted, a T-shaped drill well is drilled on the ground over the residual mining area, the T-shaped drill well is divided into two parts including a T-shaped drill well vertical section and a T-shaped drill well horizontal section, the T-shaped drill well vertical section penetrates through the overlying coal bed thick and hard top plate and an overlying coal bed to arrive at the interior of the underlying residual mining area left coal pillar, the T-shaped drill well horizontal section in the overlying coal bed thick and hard top plate is parallel to the work plane pushing direction, one well has dual purposes, pre-splitting is conducted on the overlying coal bed thick and hard top plate and the overlying residual mining area left coal pillar, and the purpose of reducing the composite strong mine pressure of the thick and hard top plate and the residual mining area left coal pillar is achieved. According to the method, the characteristics that microwave heating rock breaking efficiency is high, theenergy density is large, adaptability is wide, and penetrability is high are sufficiently utilized, coal mine green mining is achieved, and safety production is achieved.

Owner:TAIYUAN UNIV OF TECH

Green extraction method of ionic rare earth ore calcium salt system

PendingCN112176209AReduce the impactSmooth processProcess efficiency improvementAluminium chlorideMagnesium salt

The invention discloses a green extraction method of an ionic rare earth ore calcium salt system. Calcium salt is taken as an ore leaching agent, calcium oxide is taken as a purification impurity removal agent, and calcium oxide is taken as a precipitant; the ore leaching agent, chlorine removal and heavy metal elements are recovered in a form of Friedel's salt; no ammonia nitrogen and high-salt wastewater is discharged in the whole process, the process is smooth, the product impurity content is low, and after ore closing, the mining area environment influence is small, and green and environment-friendly mining of ionic rare earth can be implemented. In addition, the method takes calcium chloride as a main component, a small amount of acid regulators such as aluminum chloride, ferric chloride and ammonium chloride are added, the formed composite salt ore leaching agent is a main component of ore soil, and compared with an ore leaching system with ammonium salt, magnesium salt, sodium salt and potassium salt as main components, the composite salt ore leaching agent has almost no influence on the environment, the leaching rate and the leaching peak concentration of rare earth can beeffectively improved, the tailing phenomenon of the ore leaching agent is reduced, the ore leaching time is shortened, and the ore leaching efficiency is improved.

Owner:RISING NONFERROUS METALS SHARE CO LTD +2

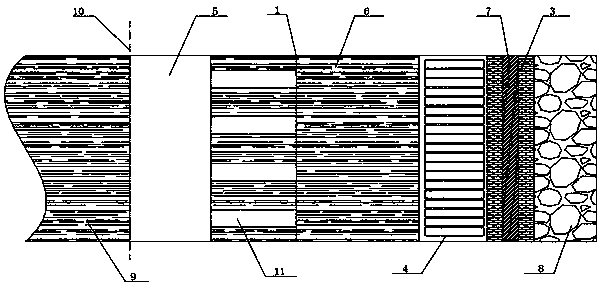

Sharp inclined coal seam paste filling mining technology

InactiveCN108894783ASafe and Efficient MiningPrevent collapseUnderground miningSurface miningEngineeringEarth surface

The invention discloses a sharp inclined coal seam paste filling mining method. According to the method disclosed by the invention, medium-thickness coal seam having the coal bed pitch of 40-90 degrees can be safely and effectively mined. The method can achieve effects of effectively preventing surface subsidence, protecting groundwater resources and surface environment from being damaged and realizing green mining. According to the method, the coal seam roof and floor can be effectively controlled, equipment on the coal face is less, the management is simple, non-pillar mining can be realized, the recovery ratio is high, the stope face is in a two-wing arrangement manner for alternate mining in the mining process, namely when the left-wing stope face is filled, right-wing stope face is recovered. According to the mining method, the mining efficiency can be improved, and the mine production can be increased.

Owner:鄂托克旗乌仁都西煤焦有限责任公司

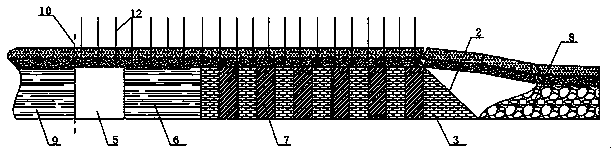

Stope structure arrangement method applicable to gently inclined medium and thick ore body combination sectioned mining

ActiveCN110388210AReduce preparation timeReduce the amount of quasi-engineeringUnderground miningSurface miningEngineeringTailings

The invention discloses a stope structure arrangement method applicable to gently inclined medium and thick ore body combination sectioned mining. Lower sectional stopes (2) and upper sectional stopes(3) are alternately arranged in the vertical direction of an ore body every 10-15 m, each lower sectional stopes (2) and upper sectional stopes (3) are combined into a mining unit (1); studdings (4)are formed at the ends of the mining unit (1); cutting troughs are formed in the stopes with slot raises (10) as a free surface; ore falls into ditches (9); and ore is loaded in an ore loading approach road (8) through a carry-scraper, carried to an ore draw shaft (11) through an ore removal roadway (7), and then dropped to a haulage roadway (12) to be loaded and conveyed out. Every two sectionalstopes are divided into a mining unit for mining, projects such as the ore removal roadway, the ore draw shaft and a slope road linking taxiway are shared, the accurate mining cost is reduced, the preparation time for accurate mining work is saved, the mining efficiency is improved, mined waste rock can be processed into building materials for sale, and new storage space for tailings filling is additionally formed.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

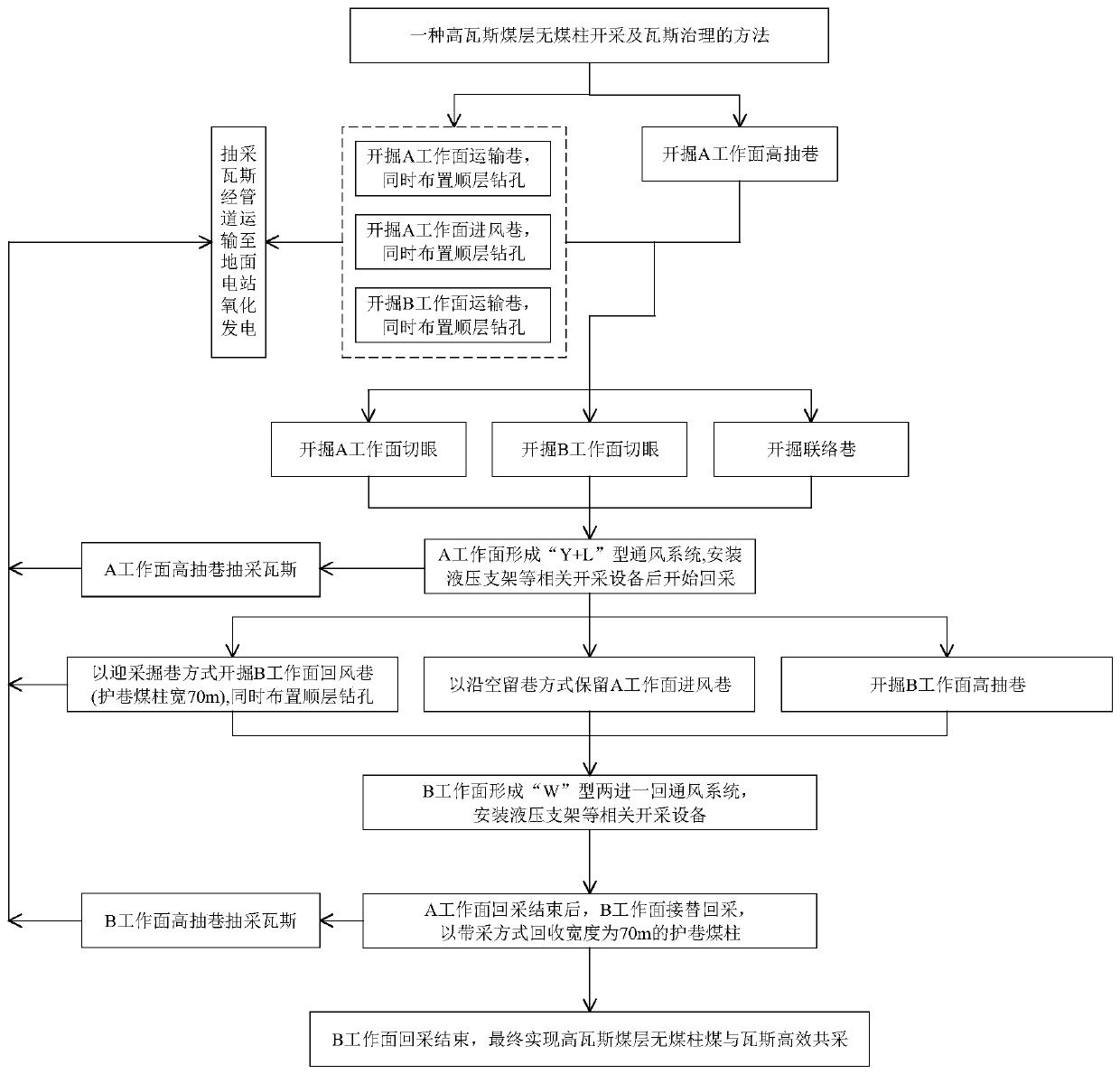

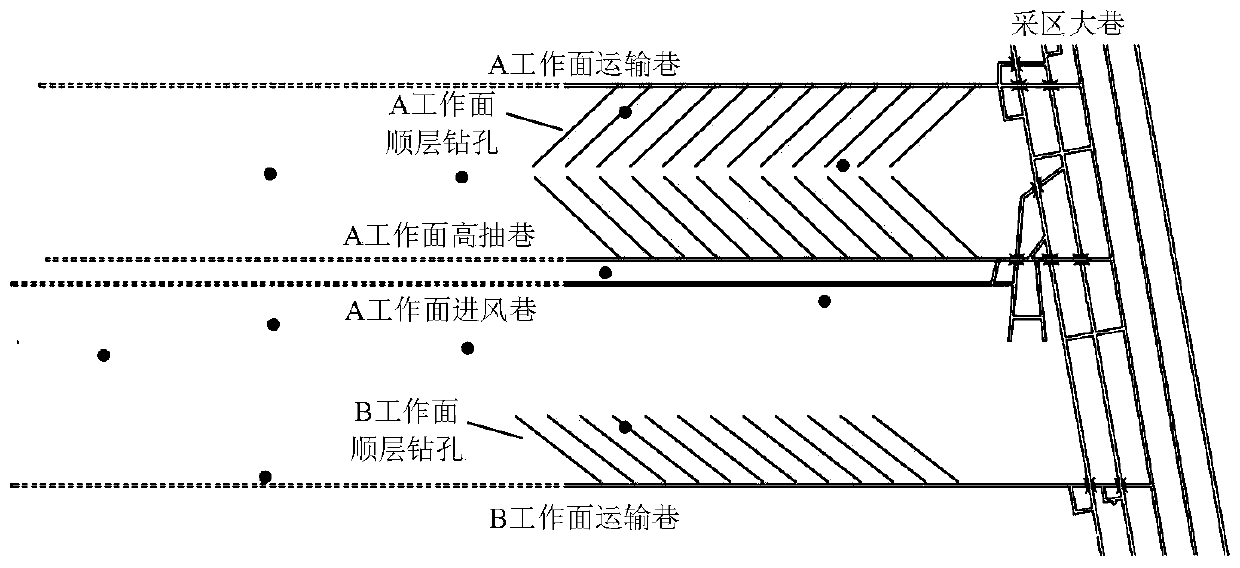

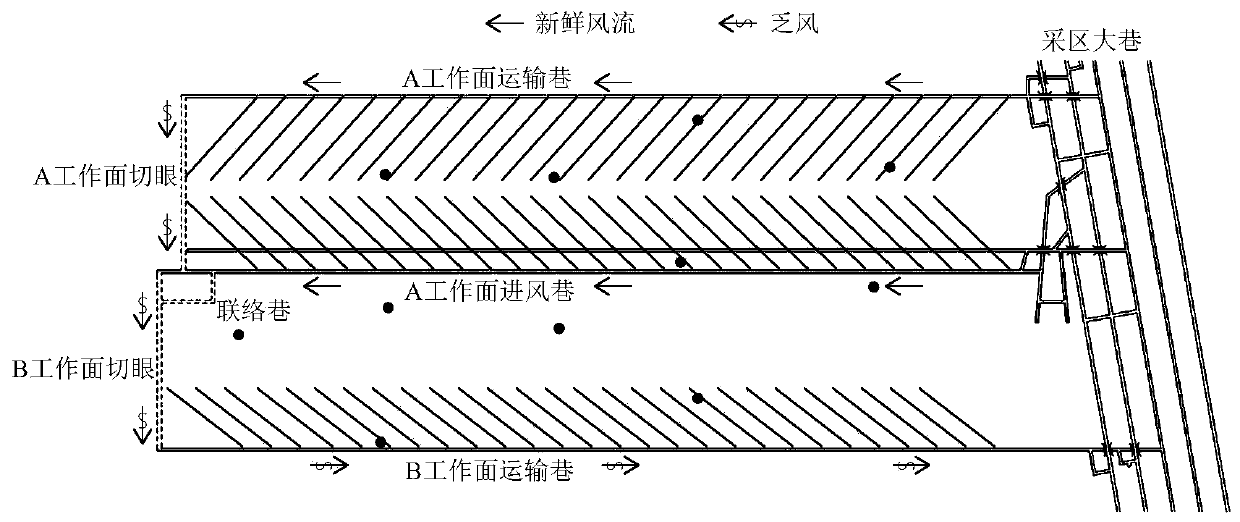

Coal-pillar-free mining and gas treatment method for high-gas coal seam

ActiveCN111577281AEnsuring Green MiningLong prepumping timeUnderground miningSurface miningCoal pillarStoping

The invention discloses a coal-pillar-free mining and gas treatment method for a high-gas coal seam. The method is suitable for being used in an underground coal mine. Firstly, mining roadways on thetwo sides of a working face A and a transportation roadway of a working face B are excavated, bedding drill holes are formed in the side portions of the roadways in the excavation period to pre-extract coal seam gas, and open-off cuts of the two working faces are continuously excavated and communicate. At the moment, the working face A belongs to a Y + L type ventilation system, the ventilation amount of the working face is large, gas at the upper corner can be diluted and discharged easily, and the problem of gas accumulation at the upper corner is solved. During stoping of the working face A, an air inlet roadway of the working face A is reserved in a gob-side entry retaining mode, an air return roadway of the working face B is arranged in a head-on entry driving mode, stoping of the working face B is performed after stoping of the working face A, and a W type fully mechanized caving face sequentially replaces a Y + L type fully mechanized caving face. Roadway protection coal pillarsbetween the two working faces are recovered through strip mining during the stoping of the working face B, coal-pillar-free mining is achieved, the mining rate of the mine is effectively increased, and the problem of upper-corner gas treatment in the high-gas working face is solved.

Owner:CHINA UNIV OF MINING & TECH

Plasma H-type method for reducing thick and hard roof and residual coal pillar composite strong ore pressure

ActiveCN110374596AReduced integrityDoes not affect coal mining workDisloding machinesUnderground miningWell drillingDual purpose

The invention discloses a plasma H-type method for reducing thick and hard roof and residual coal pillar composite strong ore pressure and belongs to the field of coal mining. According to the method,the characteristic that high temperature and high pressure are generated instantly due to strong movement between plasmas is fully utilized, an H type borehole is drilled in the ground over a residual mining area residual coal pillar, and is divided into an H type borehole left vertical segment, an H type borehole horizontal segment and an H type borehole right vertical segment; the H type borehole left and right vertical segments penetrate through an overlying coal layer thick and hard roof and an overlying coal layer to reach into an underlying residual mining area residual coal pillar; theH type borehole horizontal segment is parallel with the work face propelling direction in the overlying coal layer thick and hard roof; one well achieves dual purposes, and two-way operation is achieved; and pre-cracking is performed on the overlying coal layer thick and hard roof and the underlying residual mining area residual coal pillar, the purpose of reducing the thick and hard roof and residual mining area residual coal pillar composite strong ore pressure is achieved, and therefore green mining of the coal mine is achieved, and safe production is achieved.

Owner:TAIYUAN UNIV OF TECH

Plasma U type method for reducing composite high mine pressure of thick-hard roof and abandoned coal pillars

ActiveCN110273684AReduced integrityDoes not affect coal mining workDisloding machinesUnderground miningShock waveMining engineering

The invention discloses a plasma U type method for reducing composite high mine pressure of a thick-hard roof and abandoned coal pillars. Strong movements between ions are fully utilized for instantly producing high temperature and high pressure characteristics, U type boreholes are drilled in the ground, the number of the U type boreholes is L / d, L is the length of a working face of an underlying coal seam, and d is the borehole space. Each U type borehole is divided into a U type borehole left vertical section, a U type borehole horizontal section and a U type borehole right vertical section, wherein the left and right vertical sections correspondingly penetrate through two residual mining area abandoned coal pillars to reach the thick-hard roof of the underlying coal seam, and the horizontal section is parallel to the advancing direction of the working face in the thick-hard roof of the underlying coal seam. A one-borehole dual-purpose effect and bidirectional operation are achieved, presplitting is conducted on the thick-hard roof of the underlying coal seam and the residual mining area abandoned coal pillars, shock waves are formed, cracks are formed and extend in the thick-hard roof and the residual mining area abandoned coal pillars, the purpose of reduction of the composite high mine pressure of the thick-hard roof and the residual mining area abandoned coal pillars is achieved, thus green mining of a coal mine is achieved, and production is safe.

Owner:TAIYUAN UNIV OF TECH

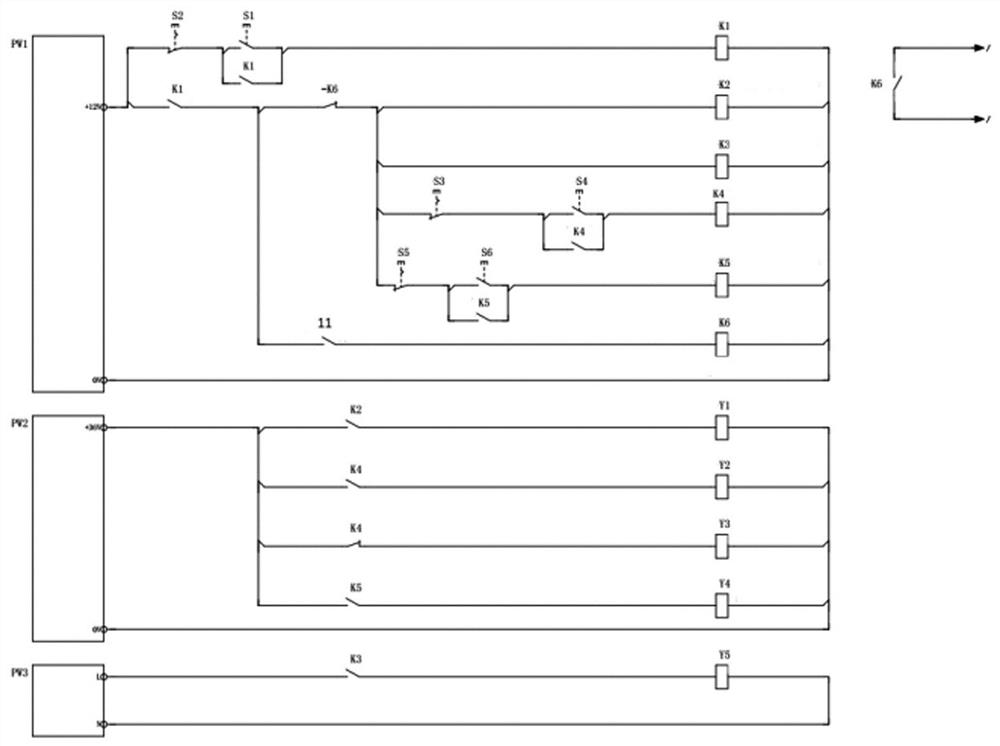

Efficient and intelligent dust removal system for mine

PendingCN111720159AImprove dust removal efficiencyOptimal consumption and utilization of energyMining devicesDust removalAutomotive engineeringFlour dust

The invention belongs to the technical field of dust removal, and particularly relates to an efficient and intelligent dust removal system for a mine. The system comprises a control device, a foam dust-removal device, a fan dust-removal device and a dust sensor; the control device is connected with the foam dust-removal device, the fan dust-removal device and the dust sensor; and the control device comprises a first intrinsically-safe power supply, a first alternating-current power supply, a second alternating-current power supply, a second intrinsically-safe power supply, a dust concentrationsensor, a dust sensor switch, a power switch, a toggle button and an auxiliary solenoid valve button. According to the system, intelligent dust removal can be realized, manual control is not required, the intelligent dust removal system starts equipment intelligently according to the dust concentration of the working surface, the dust removal efficiency is high, energy consumption and utilizationare optimized, a safe and comfortable production environment is provided, the driving working surface of the system is dust-free, noiseless and pollution-free, and green mining is realized. The system is applied to dust removal.

Owner:阳泉煤业(集团)有限责任公司煤机装备研究院

Method of withdrawal passage combined with paste prefabricated blocks to assist working face withdrawal

ActiveCN109209484AReduce sinkingRealize green miningMining devicesUnderground chambersEngineeringDynamic pressure

The invention belongs to the field of mining safety and particularly relates to a method of a withdrawal passage combined with paste prefabricated blocks to assist working face withdrawal. The methodcomprises steps that S100, the range of influence of the advanced support pressure is drawn, on the side of a stop line close to a working face, a single-withdrawal channel is excavated through construction, multi-linkage lanes are further excavated, and surrounding rocks are further supported; S200, filling paste is prepared, and filling prefabricated blocks are prepared; S300, preparation of thepaste prefabricated structure is completed; S400, the paste filling prefabricated block support structure is completed; S500, at the end mining stage of the working face, when the withdrawal channelis maintained, net support is carried out to maintain of top plates and coal sides at the end mining stage; S600, a belt conveyor is utilized to send the prefabricated blocks to the rear of a workingface bracket, after transfer, the prefabricated blocks are piled up, the paste is filled, and the paste prefabricated block filling structure is formed; and S700, the steps S500 and S600 are repeatedto complete withdrawal of comprehensive mining equipment. The method is advantaged in that safety, dynamic pressure and rapid withdrawal of the comprehensive mining equipment are achieved.

Owner:TAIYUAN UNIV OF TECH

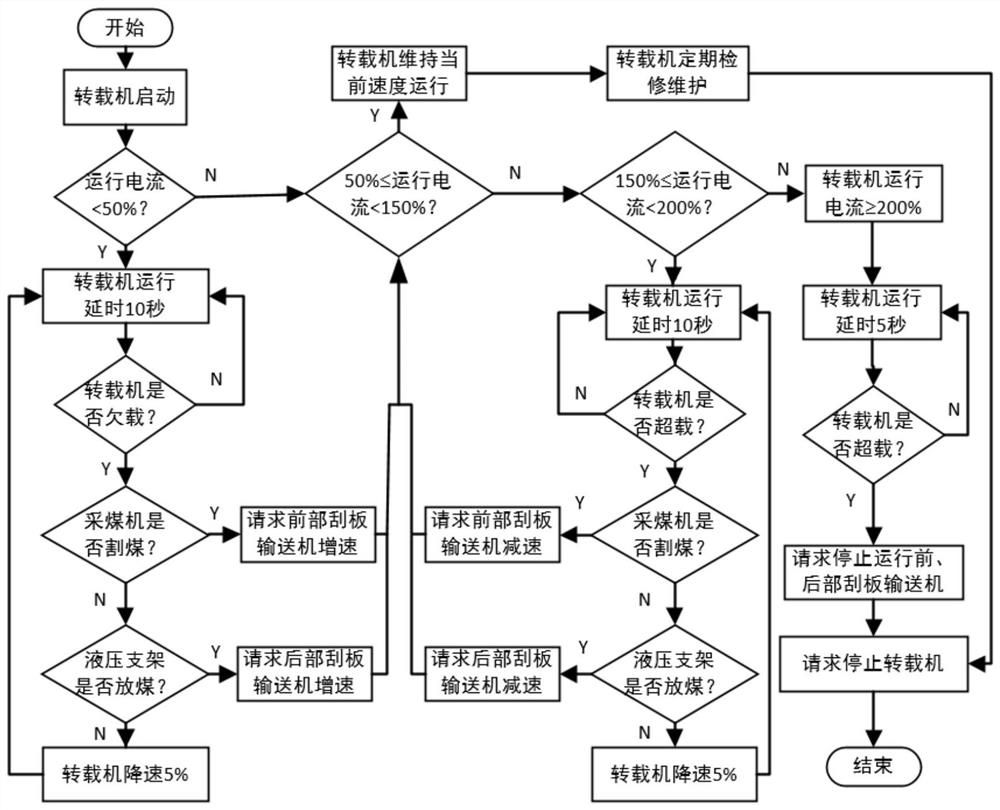

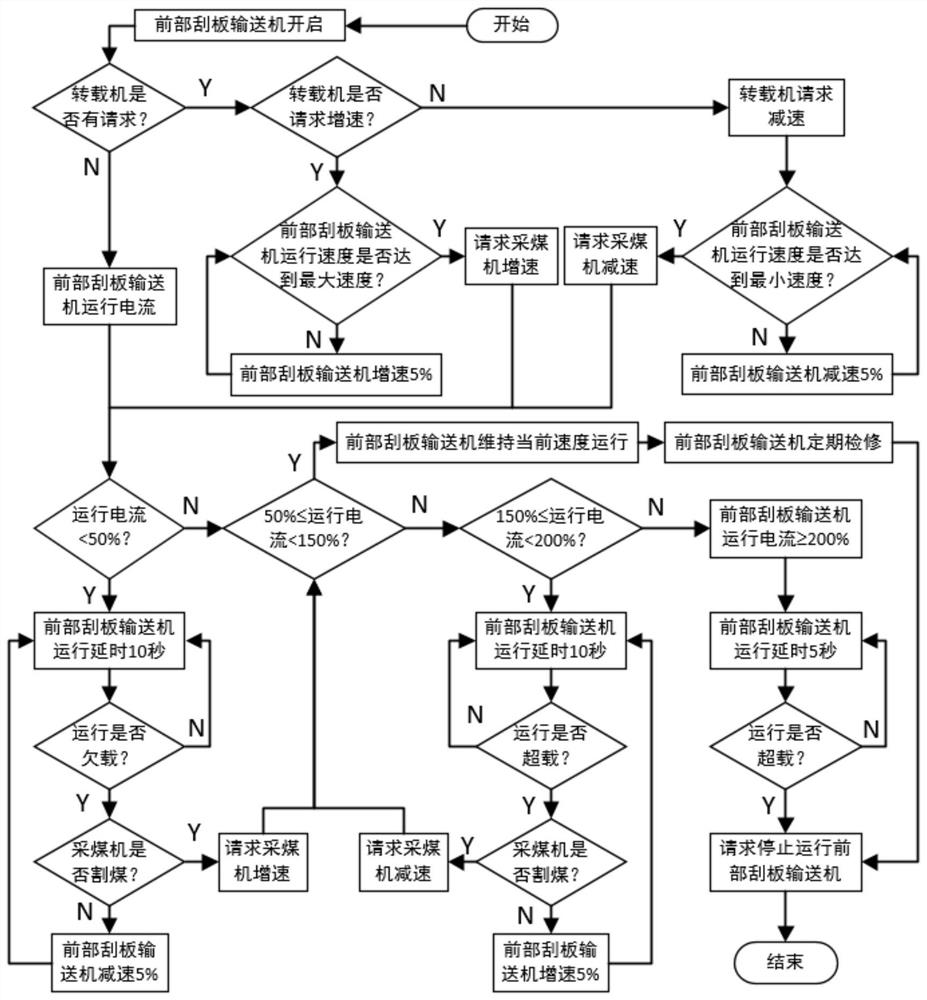

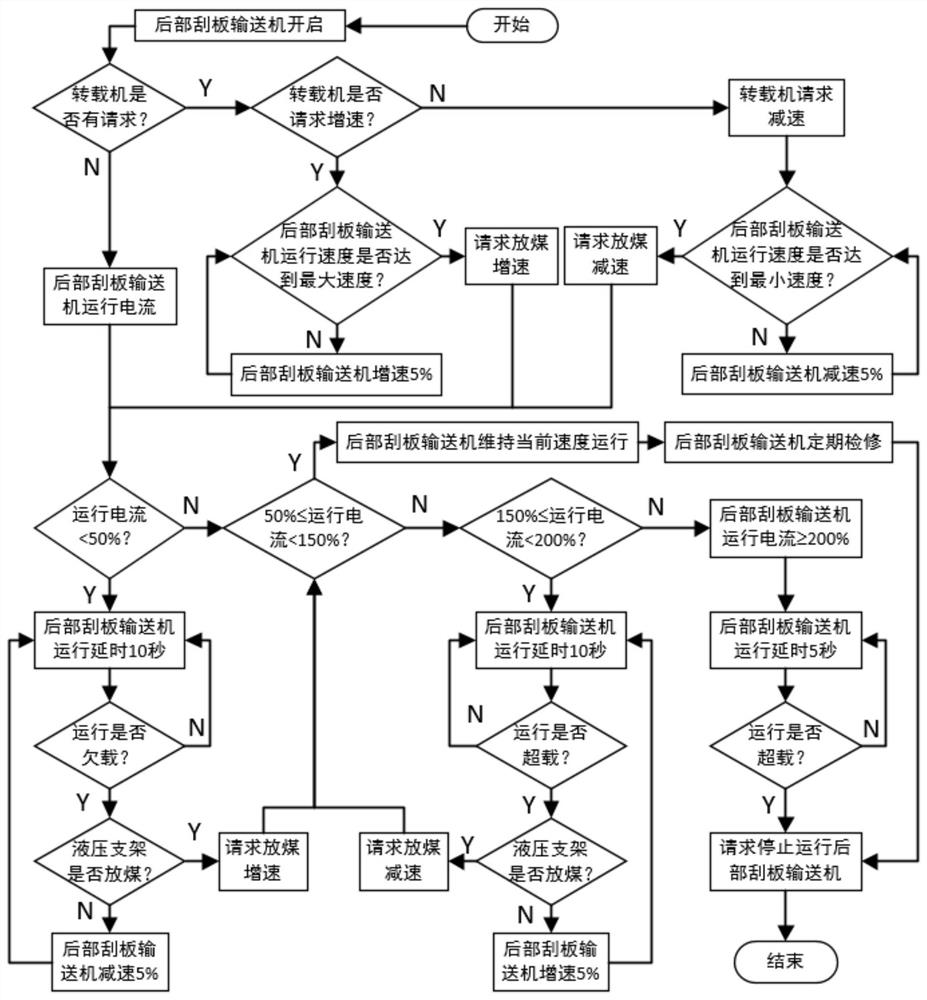

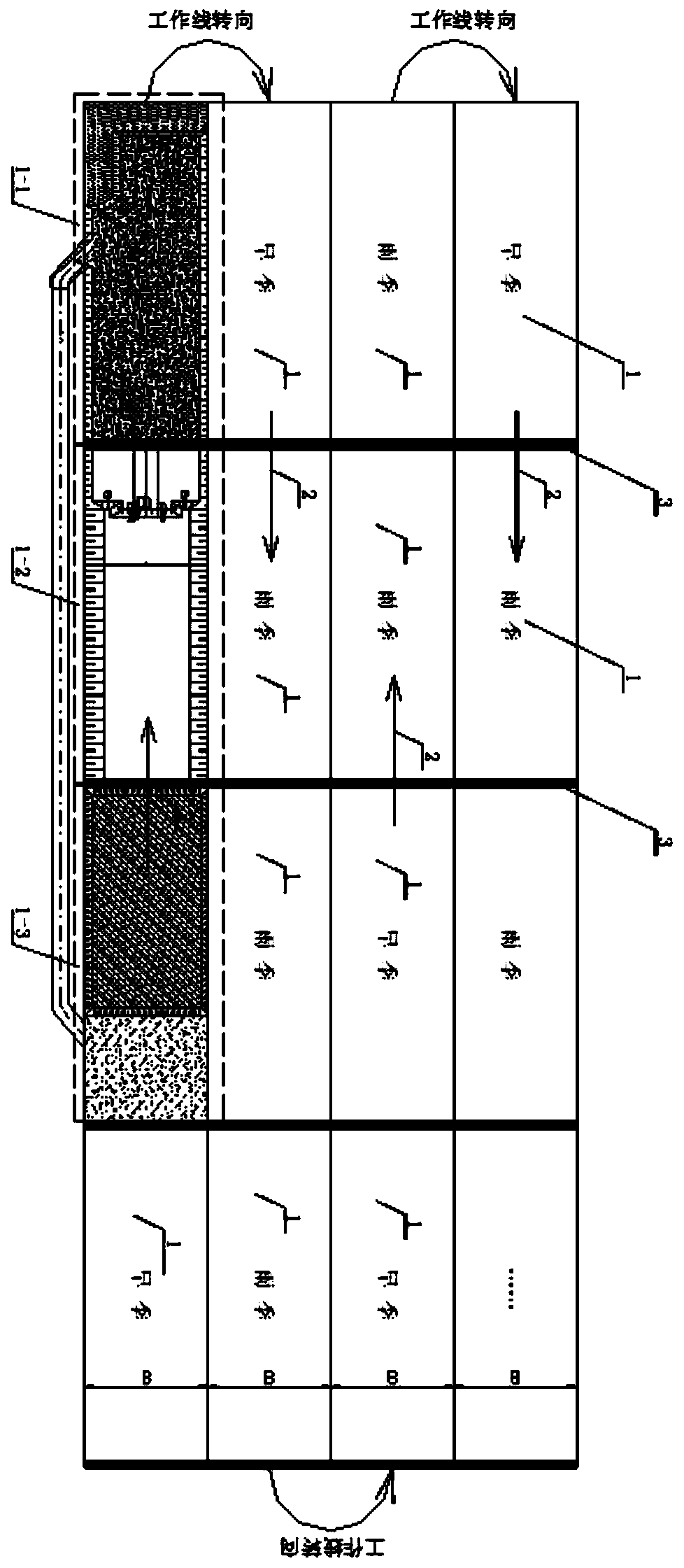

An intelligent speed regulation system and method for coal flow transportation in fully mechanized caving working face of coal mine

ActiveCN111663959BHigh degree of automationGuaranteed safe miningMining devicesSlitting machinesThermodynamicsProcess engineering

The invention discloses an intelligent speed regulation system and method for coal flow transportation in fully mechanized caving working faces of coal mines, which are used to control the front scraper conveyor, rear scraper conveyor and For the operating frequency of the reloader, the present invention uses the load current values of the three transport equipment as a reference to coordinately adjust the operating frequency of the three transport equipment, so that each transport equipment operates at an appropriate operating frequency to match and balance the respective transport loads, thereby realizing transportation The equipment works continuously without stopping, improving the efficiency of coal flow transportation and coal production efficiency.

Owner:CHINA UNIV OF MINING & TECH

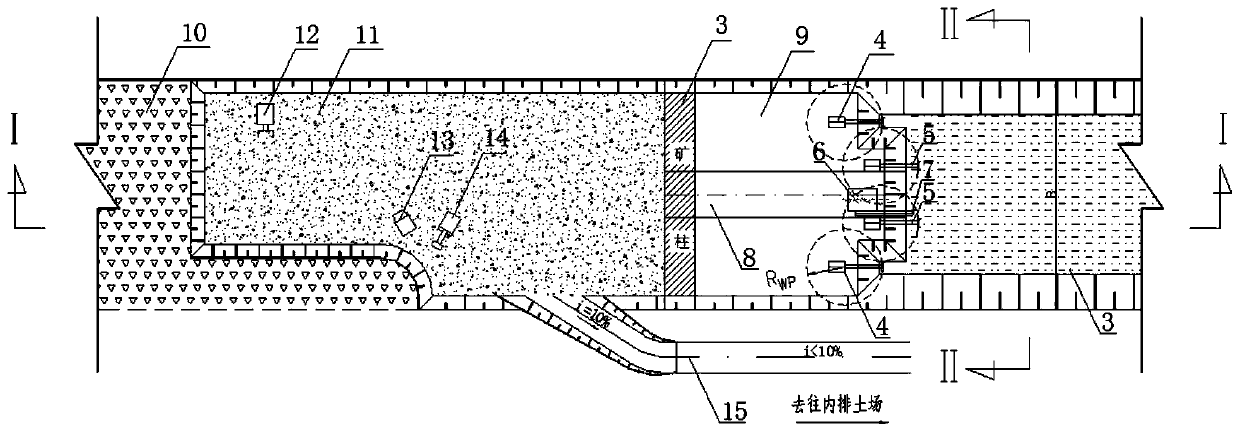

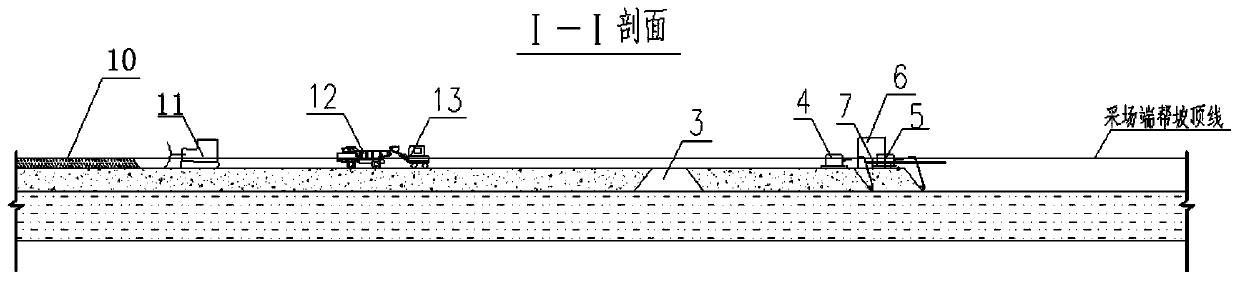

A grid-type mining method in an open-pit mine

ActiveCN108716403BShort distanceReduce transport volumeOpen-pit miningLand resourcesPipeline transport

The invention discloses an open pit mine grid mining method. The method comprises the following steps: a stope is divided in a grid format along the strike, a plurality of mining grids are obtained, pillars are left between each of the mining grids; stripping, mining and abandonment operations are carried out in sequence on the mining grids by adopting a stoping sequence of layered mining; movabletype preliminary screening equipment is arranged in a mining area, materials below a sieve are used for slurrying, slurry is transported to a beneficiation workshop, and the materials on the sieve isdirectly discharged to gobs of the current mining grids; mine wastes are transported by trucks to a disposal area, and mill tailings produced from the beneficiation workshop are transported to the disposal area through pipelines; by adopting the open pit mine grid mining method provided by the invention, the material transportation volume can be effectively reduced; the gobs of the stope are utilized for storing tailings, thereby saving land resources; the mining, slurrying, pumping and returning of water are carried out inside the stope, thereby ensuring a process to be more compact, and improving the operating efficiency of a whole system; and the mill tailings disposal is integrated with the inner discharge of the mine wastes, thereby achieving the green mining of mines.

Owner:CINF ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com