Method for determining staggered distance between dual coal seam upper-lower simultaneous mining working faces in propelling direction

A technology for determining the method and working face, applied in underground mining, surface mining, earth-moving drilling and other directions, can solve the problems of lack of research on advancing direction and distance, tension in mine mining, low production efficiency, etc., so as to avoid concentrated tensile stress on the surface. Production, high-yield and high-efficiency production, to achieve the effect of uniform sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Taking a coal mine in northern Shaanxi as an example, the method for determining the staggering distance of the advancing direction of the upper and lower coal seam working faces of the double coal seam provided by the present invention will be further described through specific embodiments.

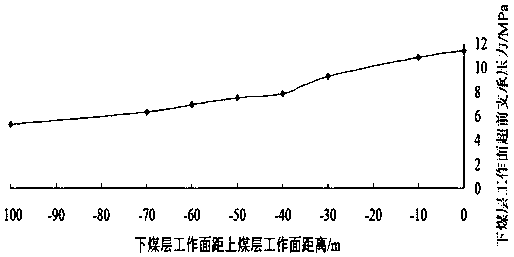

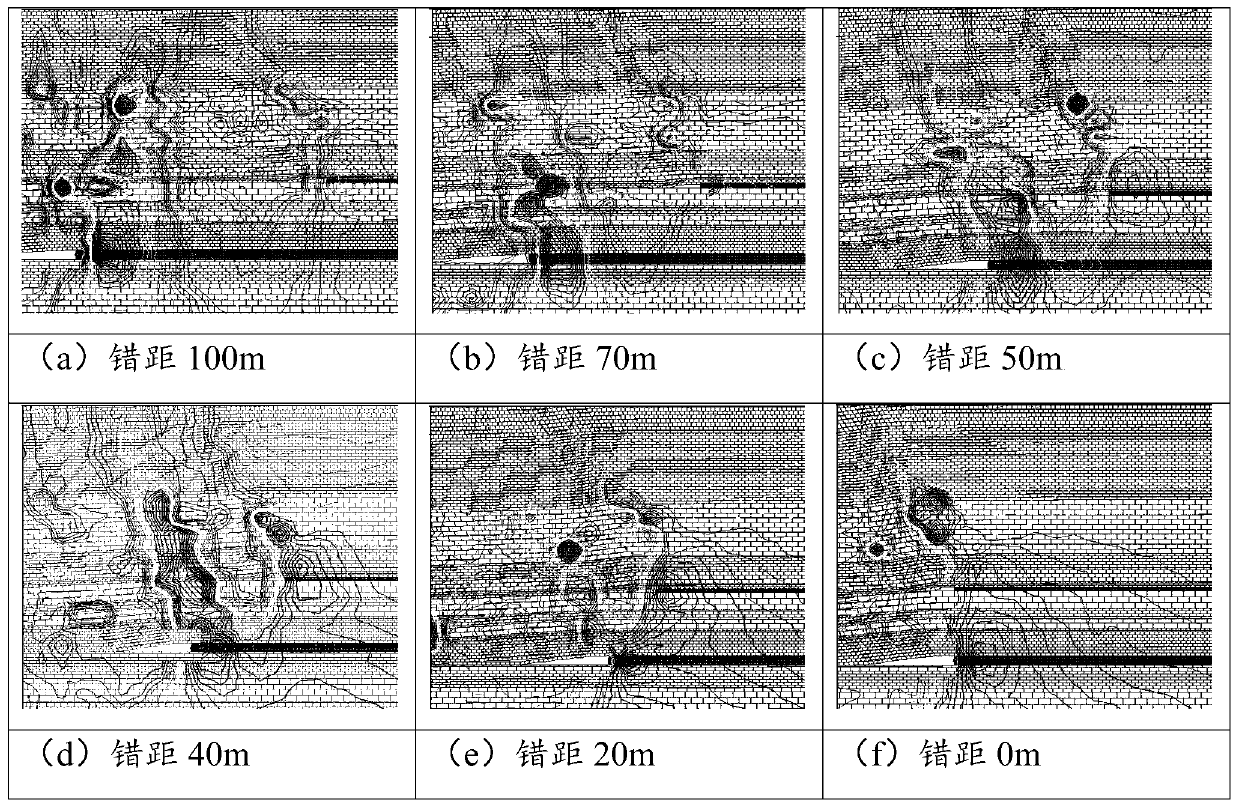

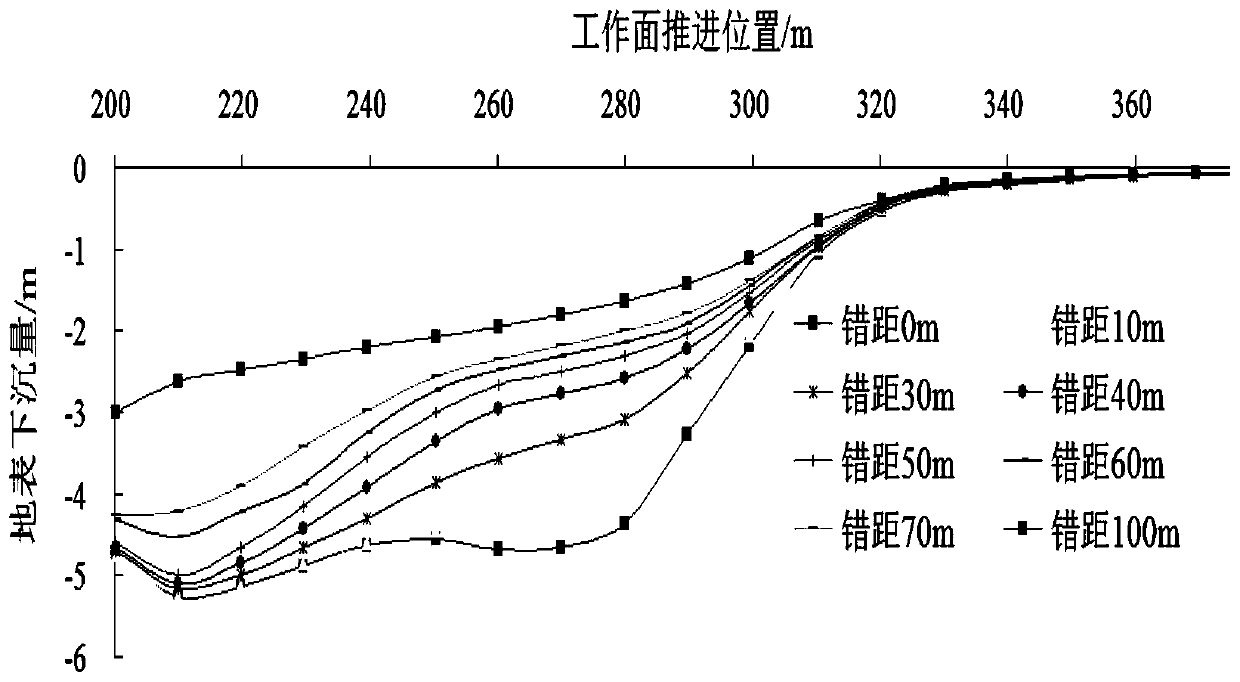

[0101] According to the mining conditions of typical shallow coal seams in northern Shaanxi, the application of this method is illustrated by taking the upper and lower simultaneous mining working faces of double coal seams in the east area of the north wing of a mine as an example. The mining area adopts inclined shaft development, one-time full-height long-arm comprehensive mechanized coal mining method, and full caving method to manage the roof. The dip angle of the coal seam is about 1°, which is a near-horizontal coal seam. Now the main mining 1 -2 Seam and 2 -2 coal seam. 1 -2 Seam and 2 -2 The internal friction angles of coal seams are 37.5° and 38.5°, and the cohesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com