Method of withdrawal passage combined with paste prefabricated blocks to assist working face withdrawal

A technology for withdrawing passages and assisting work, which is applied in tunnels, ground mining, tunnel linings, etc., and can solve problems such as strong dynamic pressure, strong bottom drum, and crushing accidents in the final mining stage, so as to achieve rapid withdrawal and reduce subsidence , The effect of reducing the final mining dynamic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a retraction channel combined with paste prefabricated blocks to assist the retraction method of the working face, including the following steps:

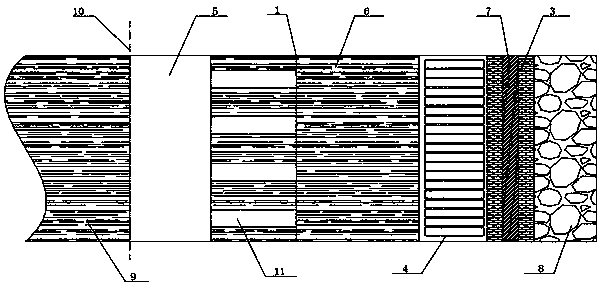

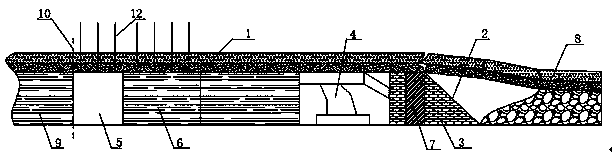

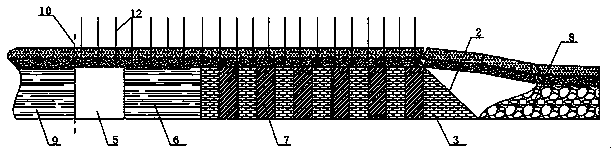

[0024] S100-Before the mining of the working face starts, numerical simulation is carried out to simulate the whole process of coal mining, and the range affected by the advanced bearing pressure is drawn. figure 1 Stop mining line 10 in the middle, close to the side of the working face, excavate a single retraction channel 5, and excavate multiple roadways at the same time, stop excavation at the boundary of the bearing pressure influence range, Figure 4 The middle retracement channel and the multiple lanes 11 form a retraction structure, and support the surrounding rock, so far the construction of the single retracement channel of the multiple lanes is completed.

[0025] Stirring test of paste filling material and pipeline transportation test of body filling material to ensure that it meets the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com