An intelligent speed regulation system and method for coal flow transportation in fully mechanized caving working face of coal mine

A fully-mechanized caving face and intelligent speed regulation technology, which is applied in underground transportation, transportation and packaging, mine roof supports, etc., can solve problems such as waste of power capacity, affecting the efficiency of underground coal flow transportation, and differences in worker experience, so as to ensure safety The effects of mining, increasing coal mine production efficiency, and reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

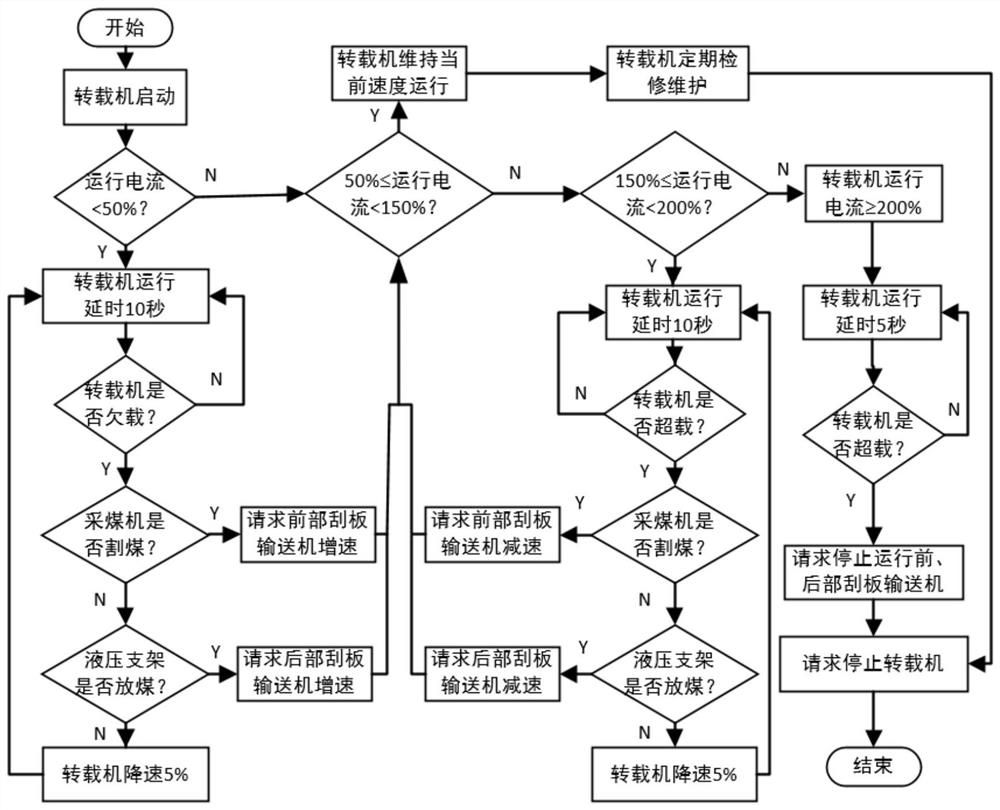

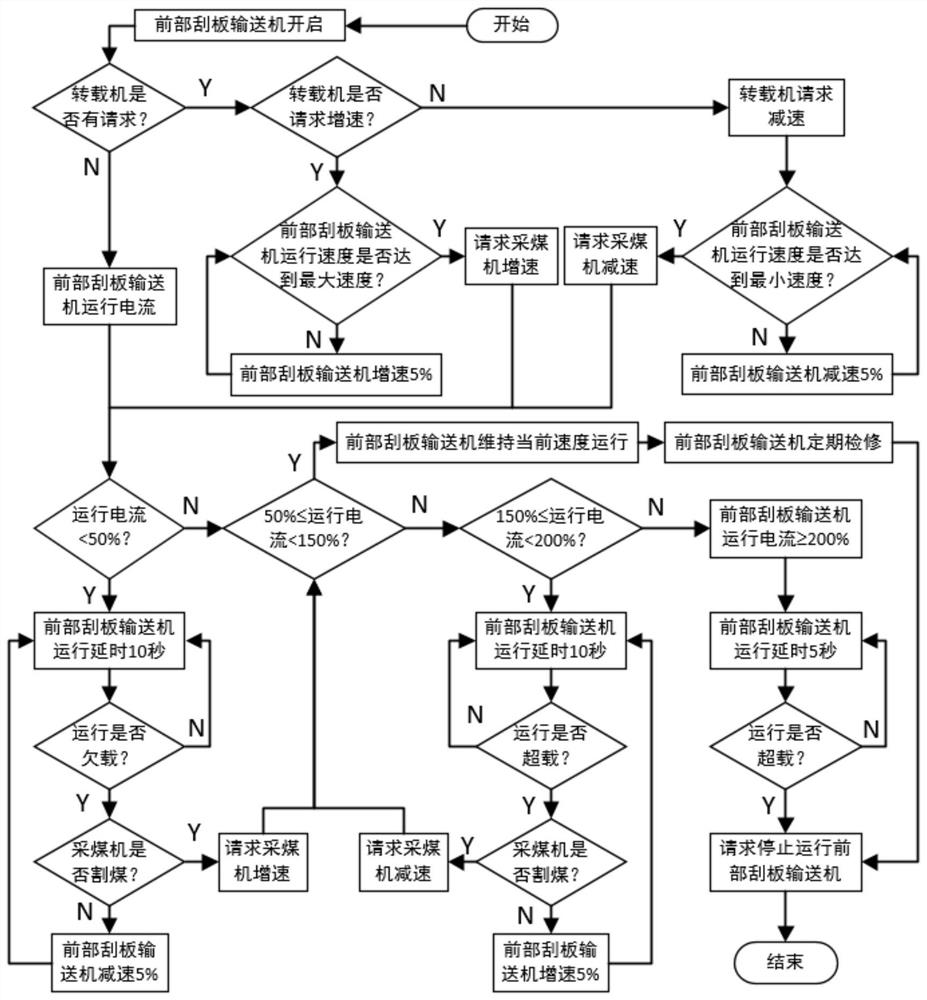

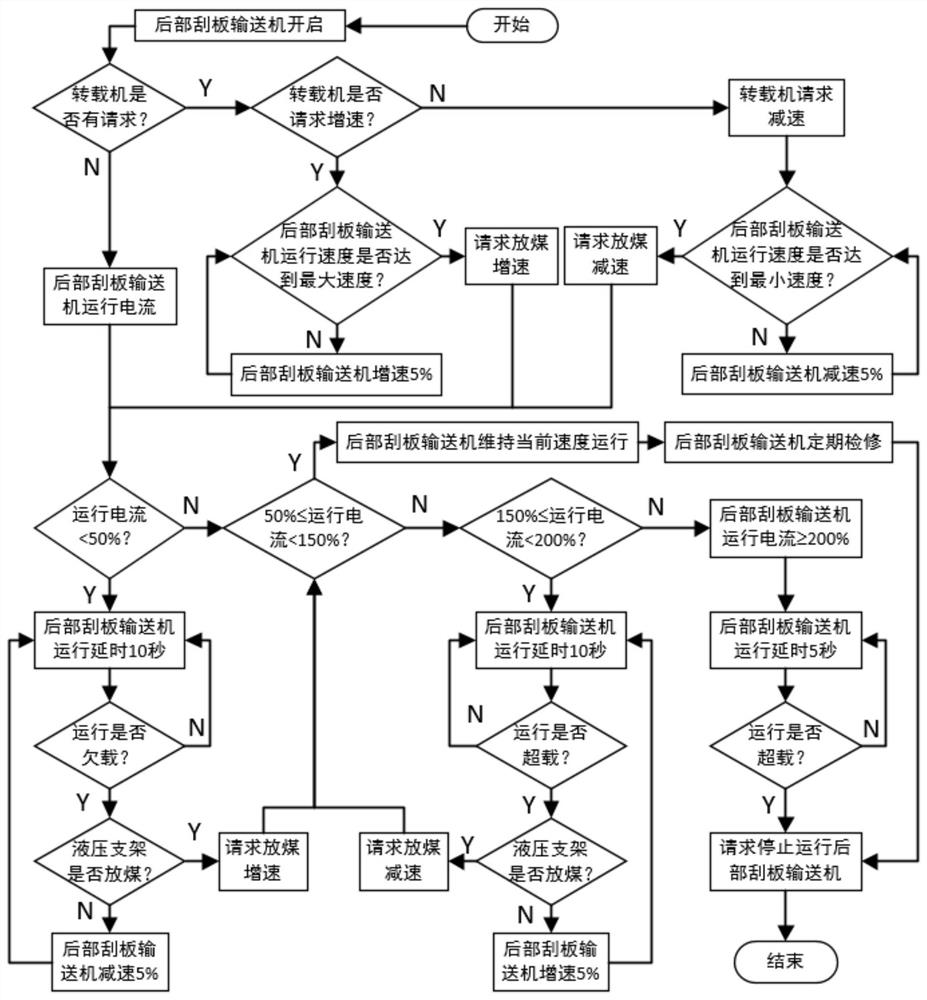

[0055] The working mode of the fully mechanized caving face transportation equipment (the front scraper conveyor 2, the rear scraper conveyor 4 and the reloading machine 5) in the present invention is the frequency conversion working mode, and the load current value is used as a reference to coordinately adjust the three The operating frequency of the transportation equipment enables each transportation equipment to operate at an appropriate operating frequency to match and balance their respective transportation loads, thereby realizing continuous work of the transportation equipment without stopping and improving the efficiency of coal flow transportation and coal production efficiency. Its transport load is reflected by the current of the respective running motors.

[0056] The specific expression that the current can reflect the load size of the transportation equipment is as follows:

[0057] P r = r·U·I·cosα (1)

[0058] In the formula, P r r is the number of stator p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com