Patents

Literature

65results about How to "Continuous transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

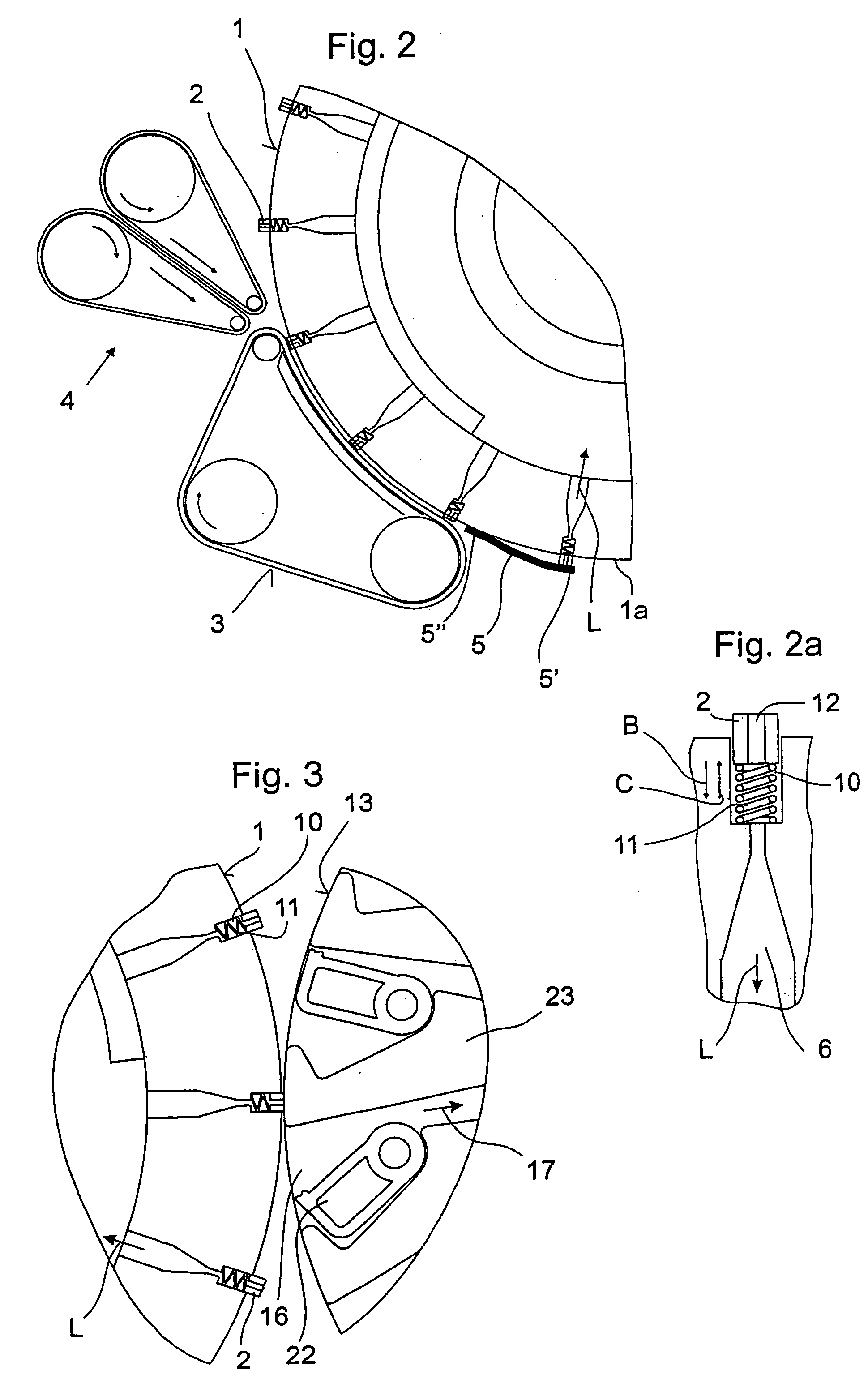

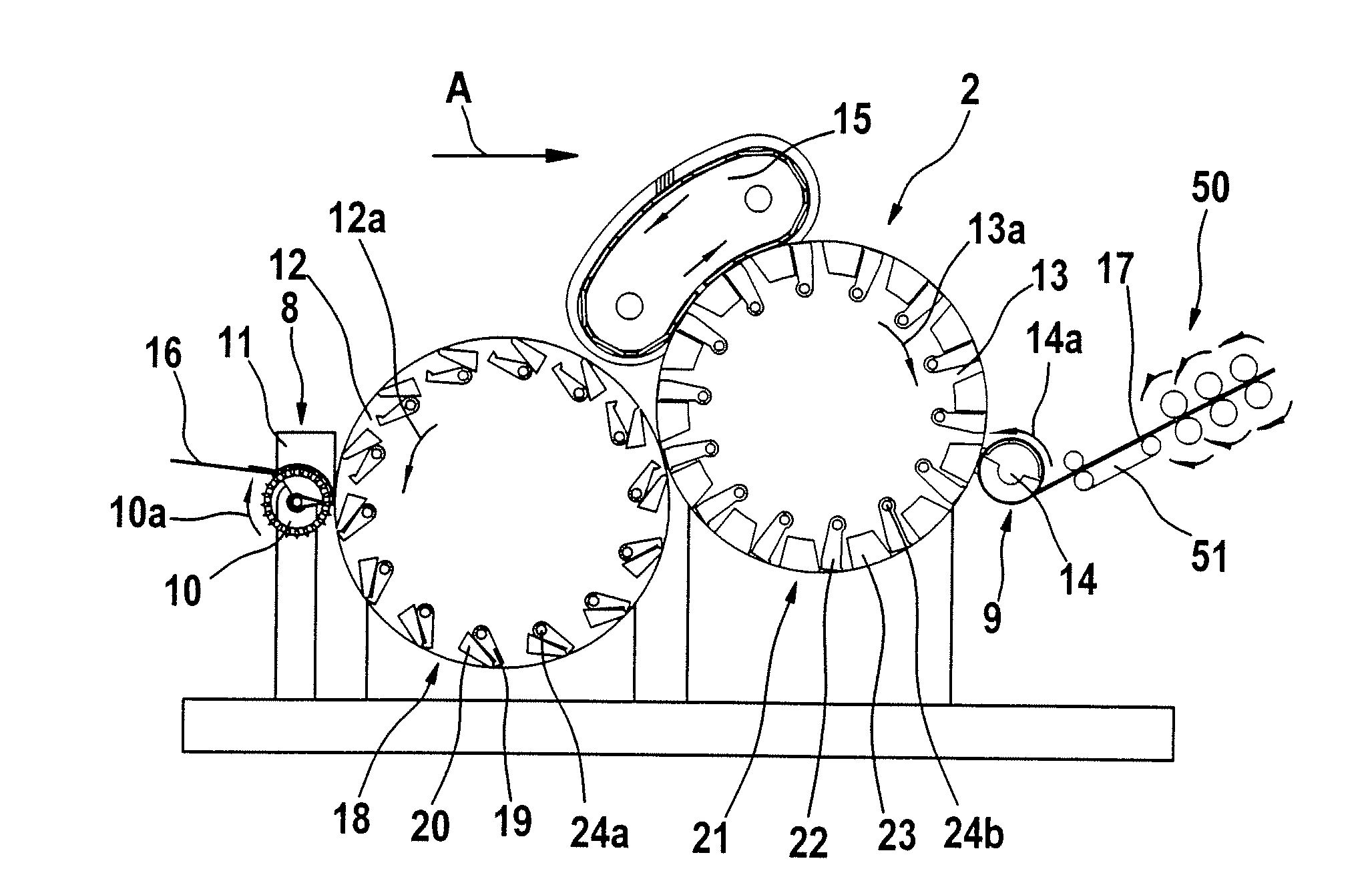

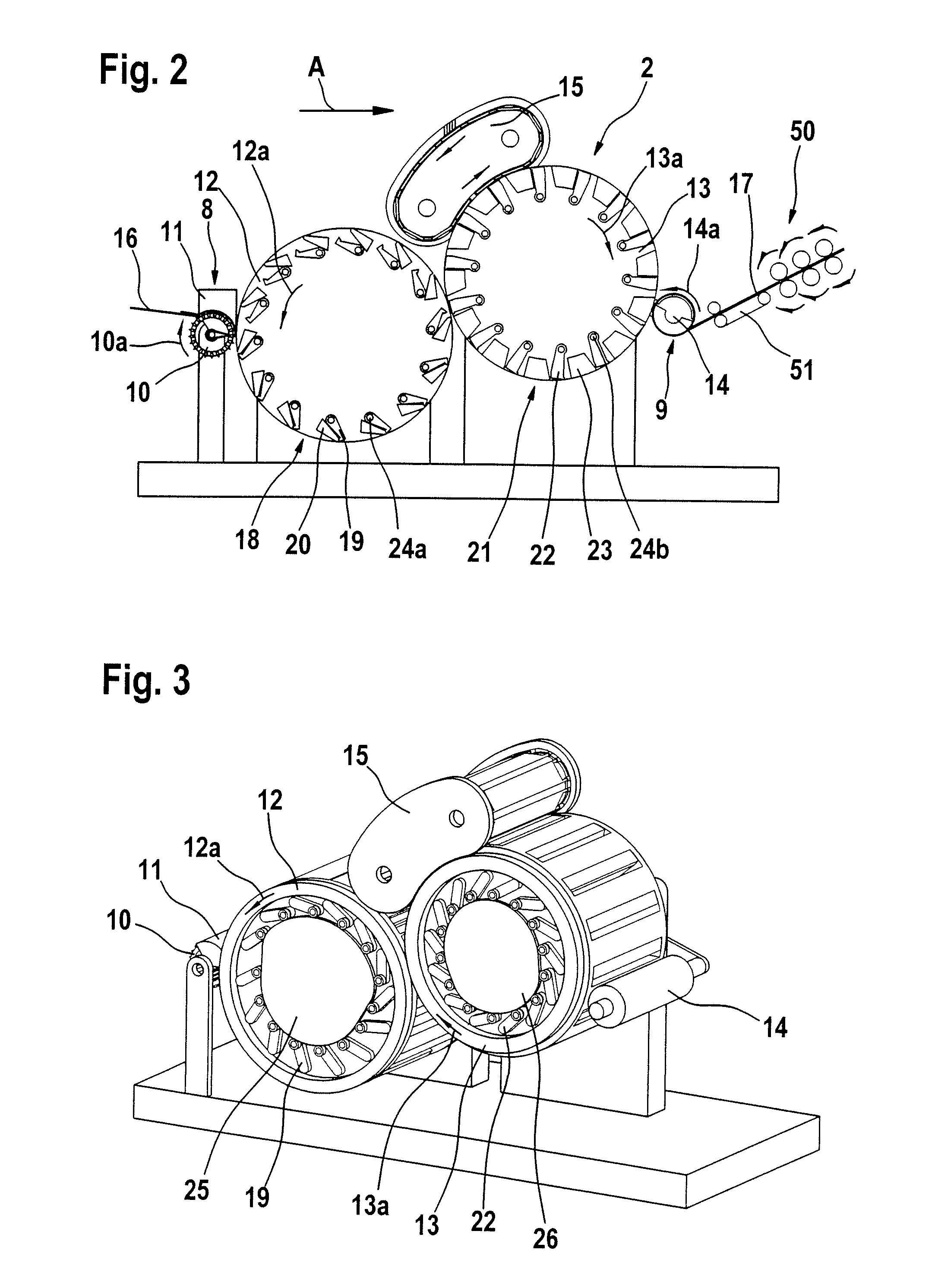

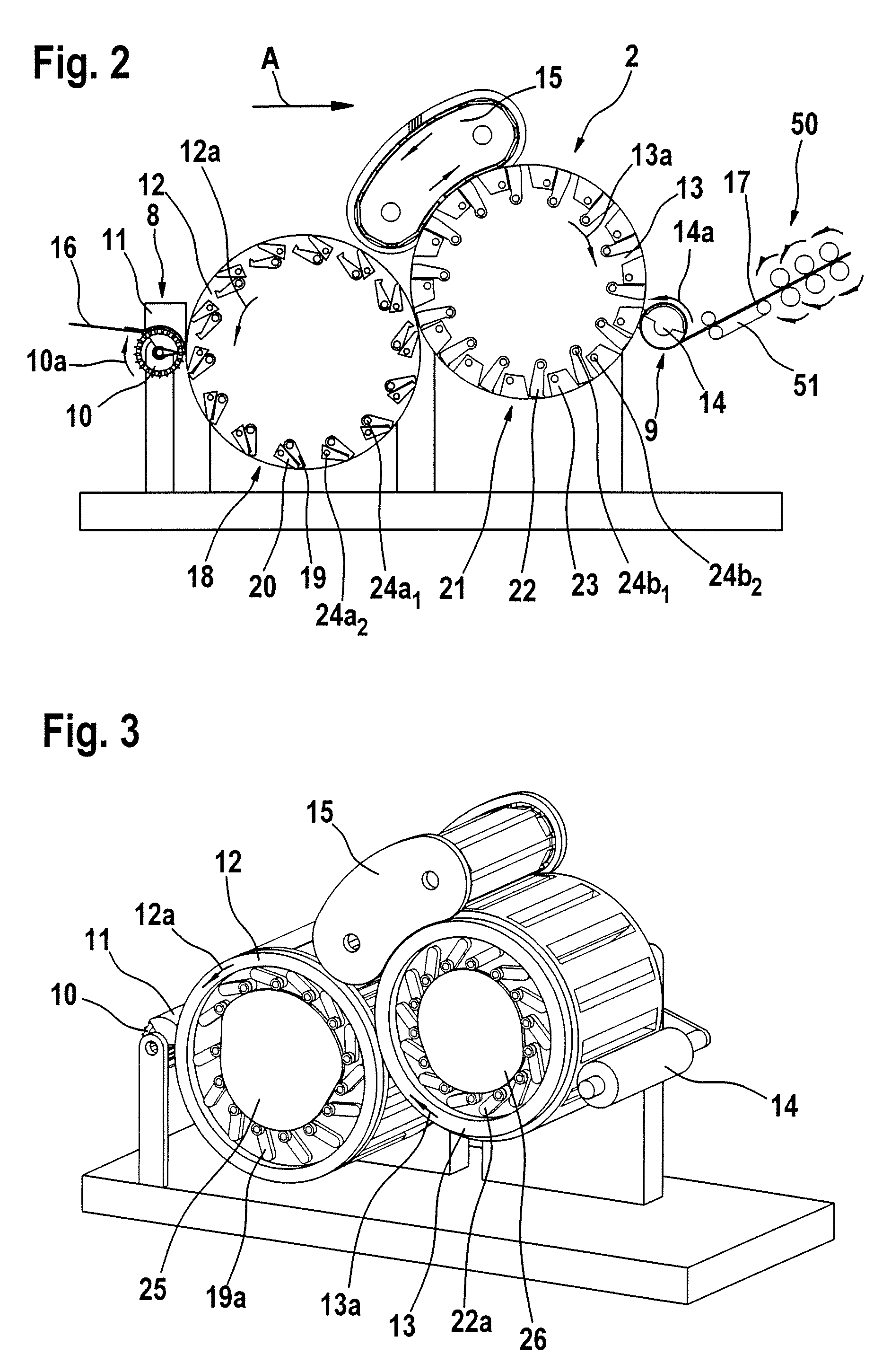

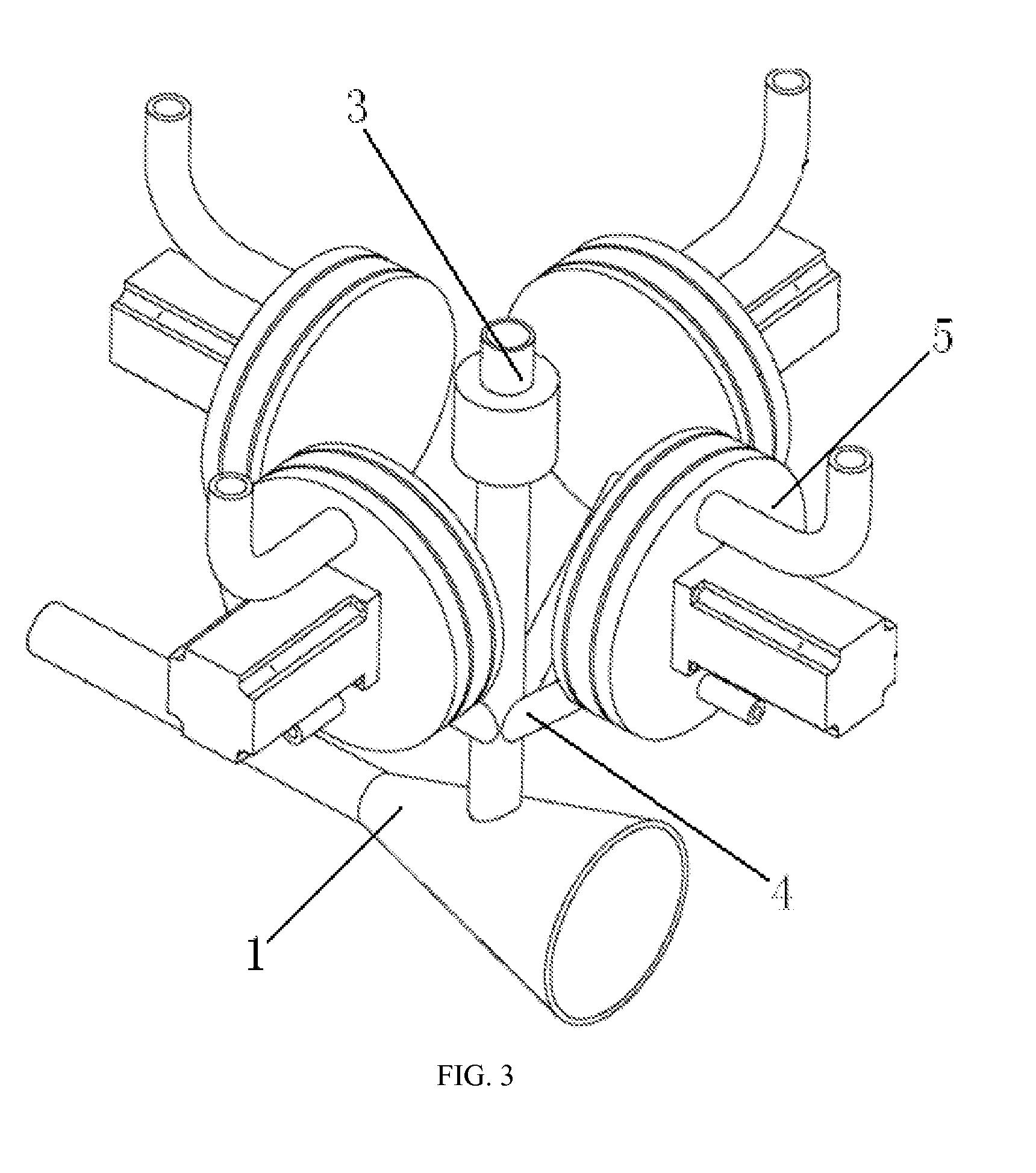

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000071A1Increase volumeImproved combed sliverCombing machinesTextile fiberFiber bundle

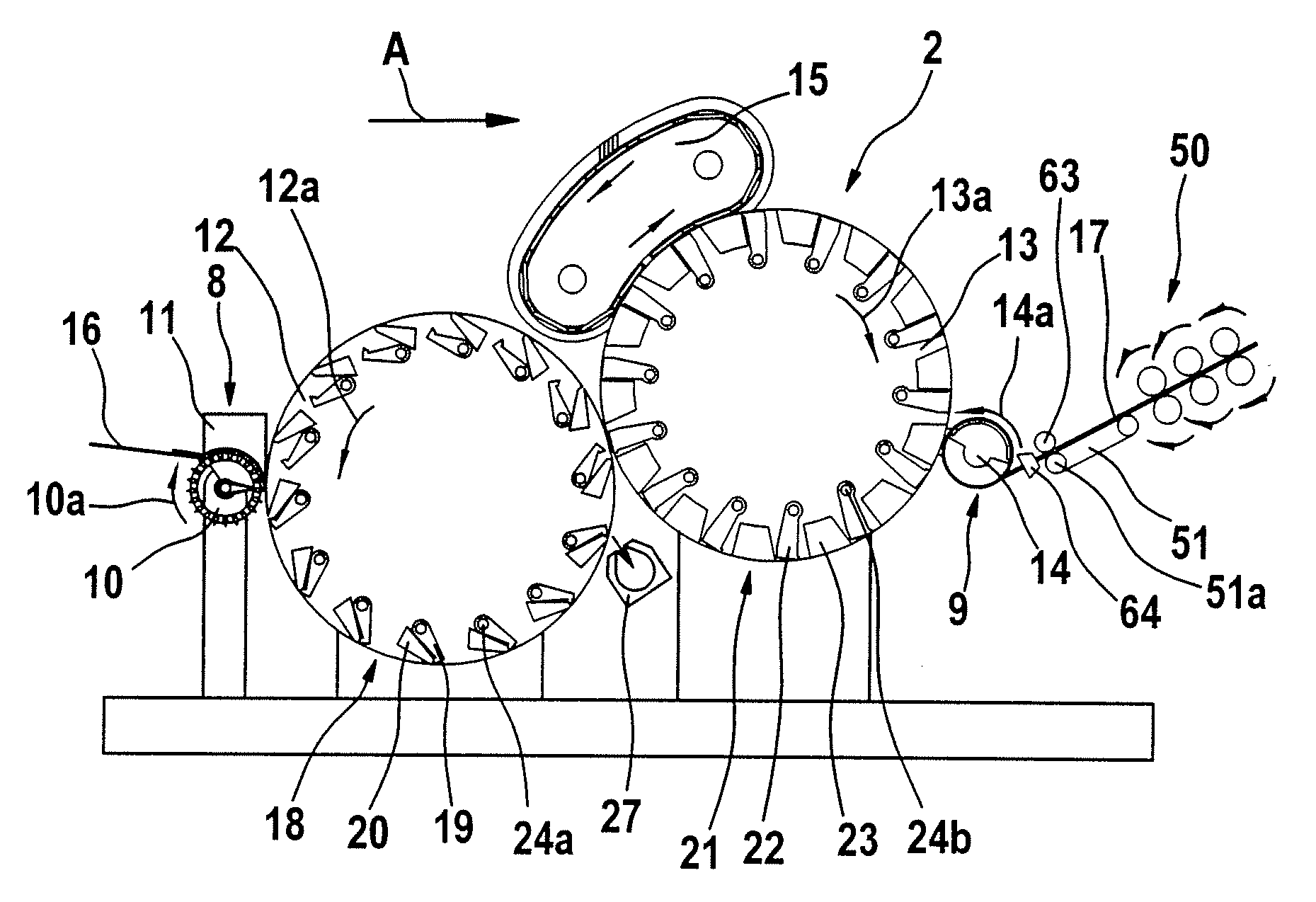

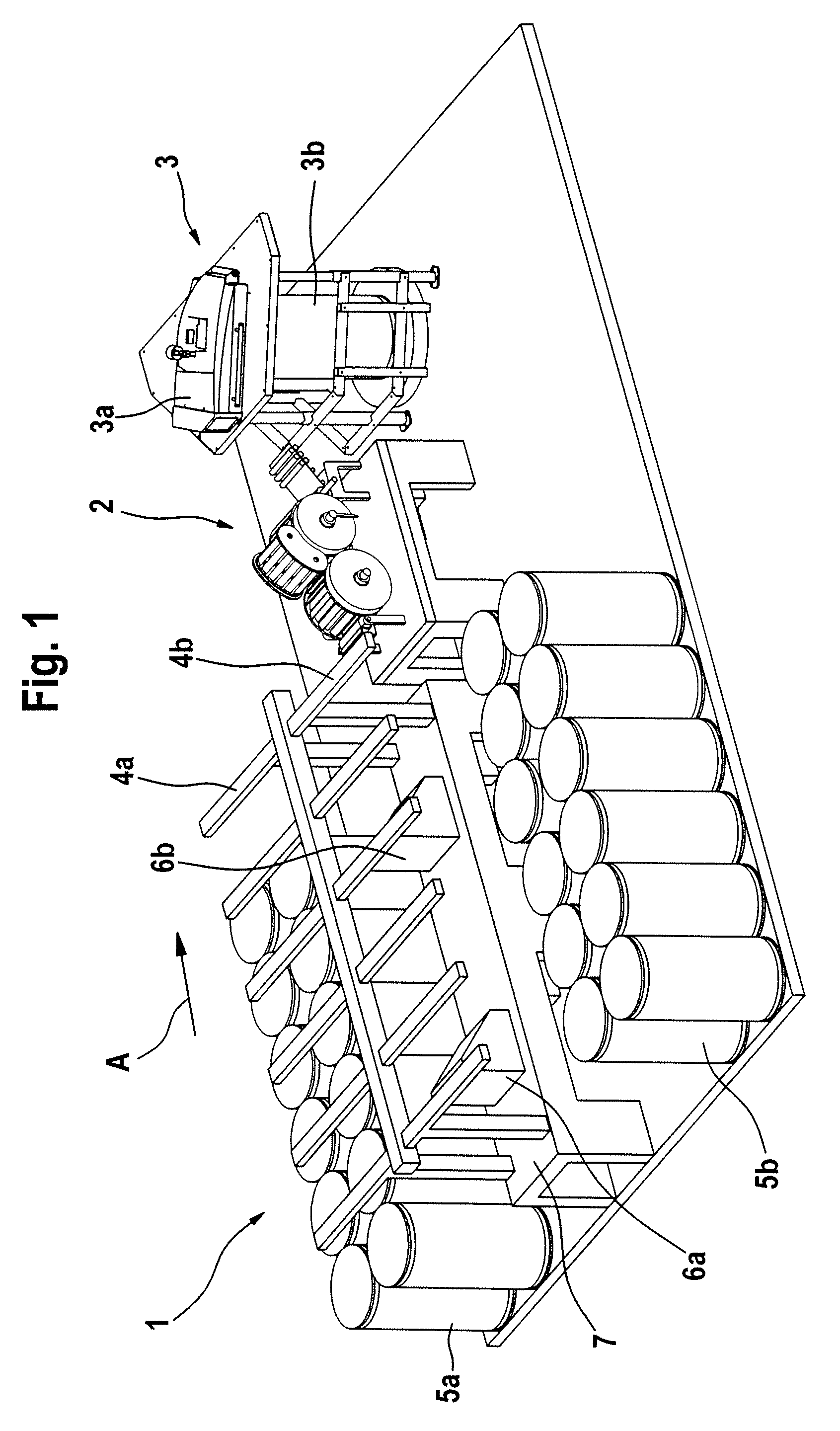

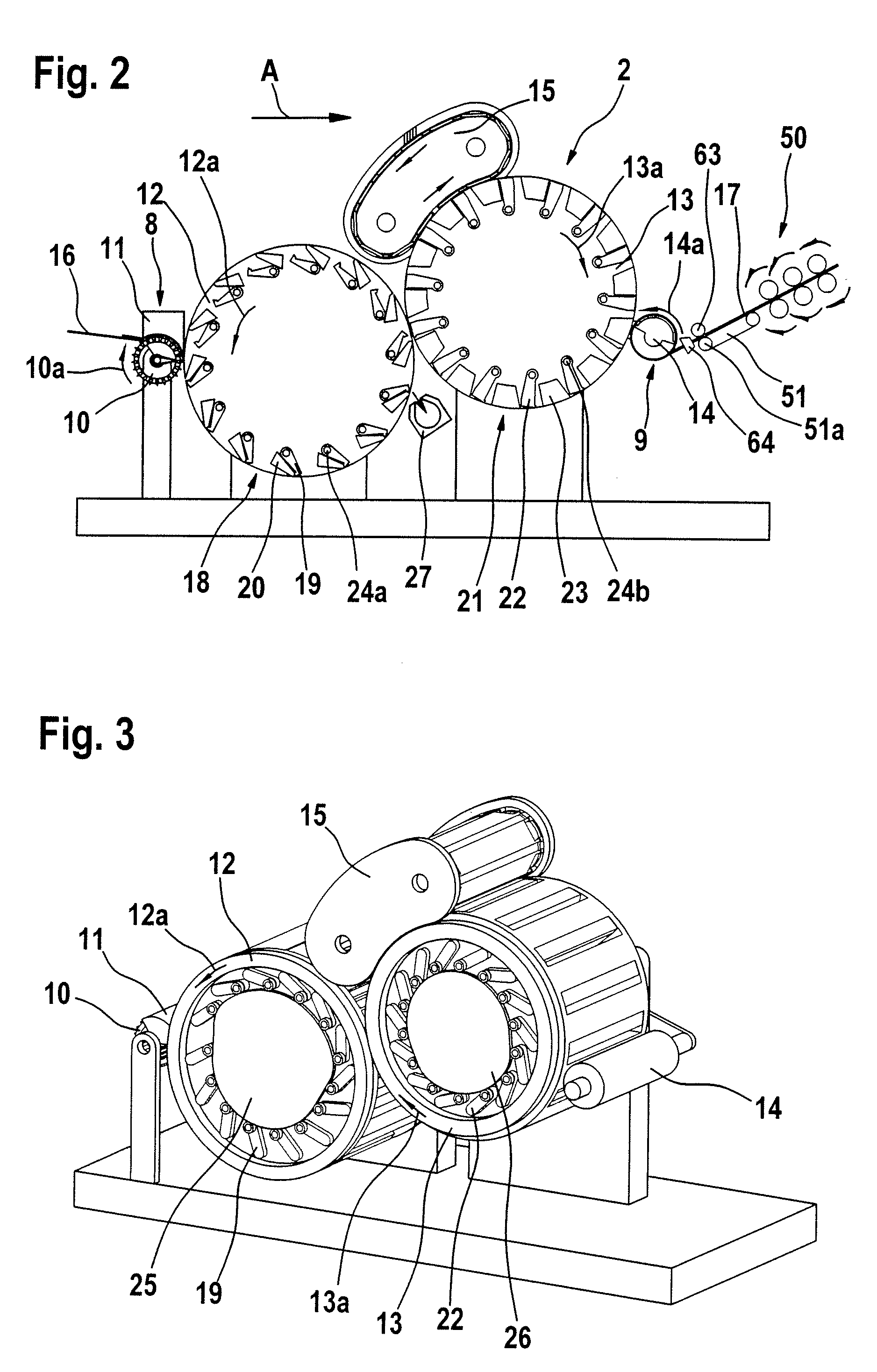

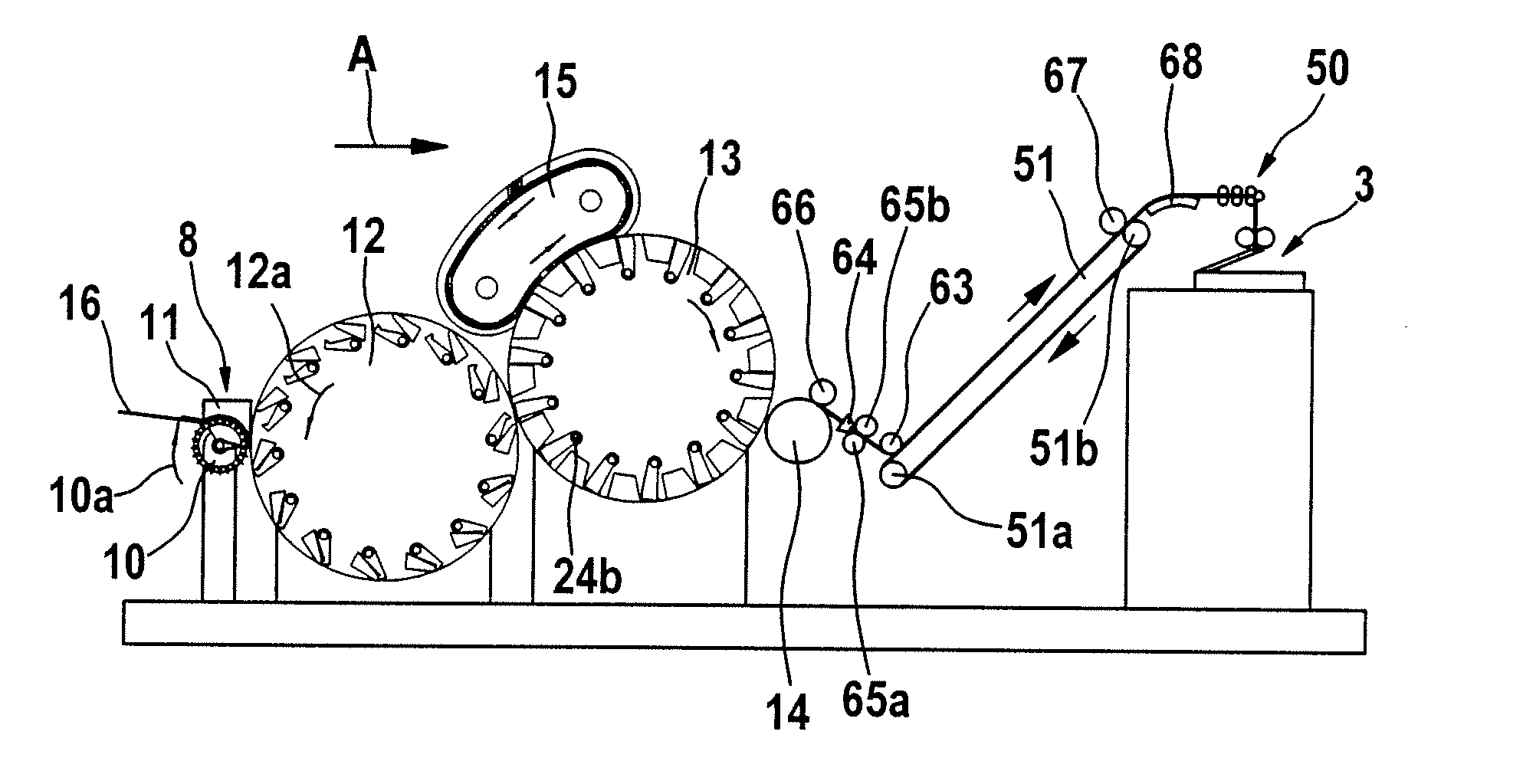

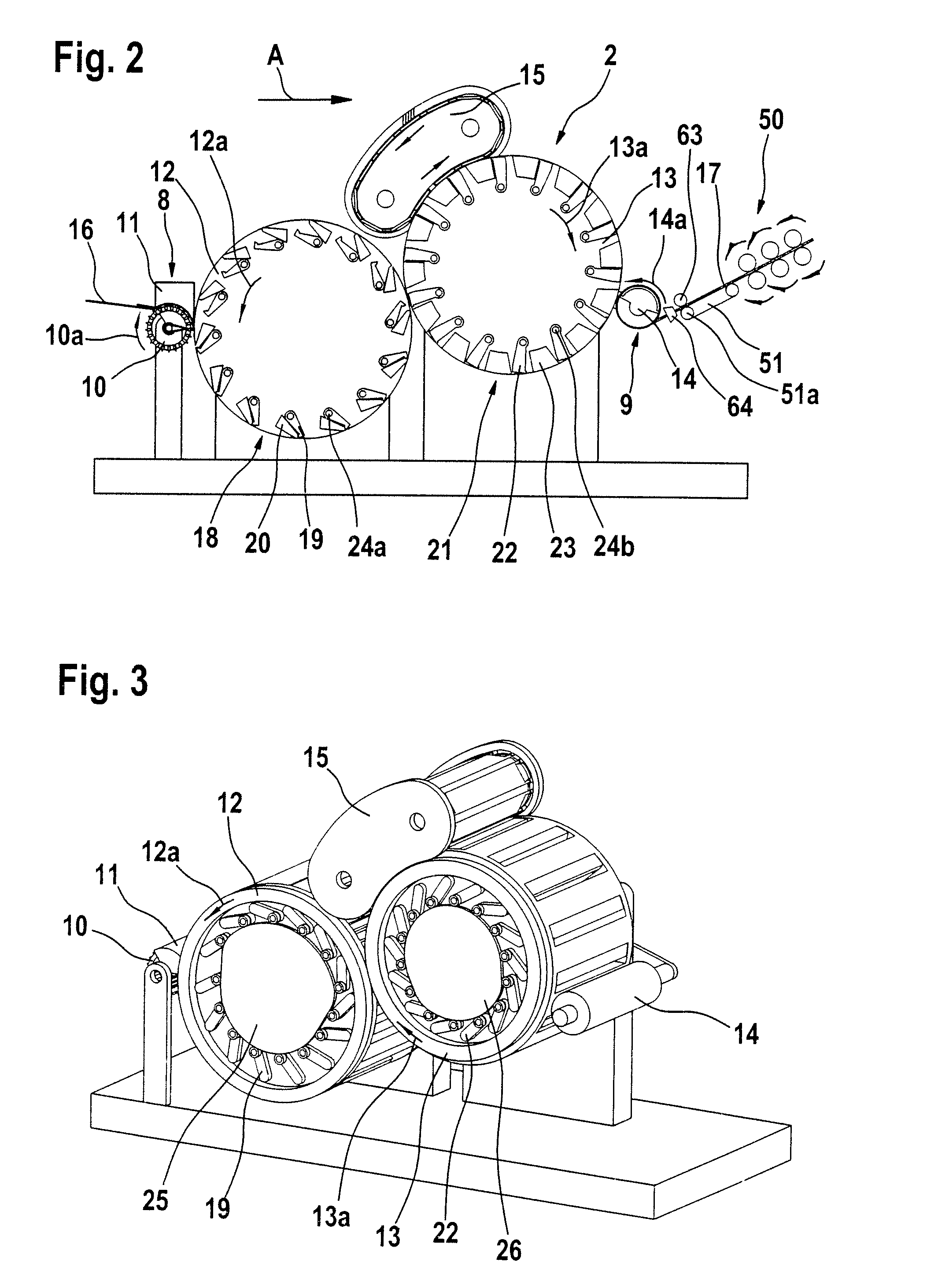

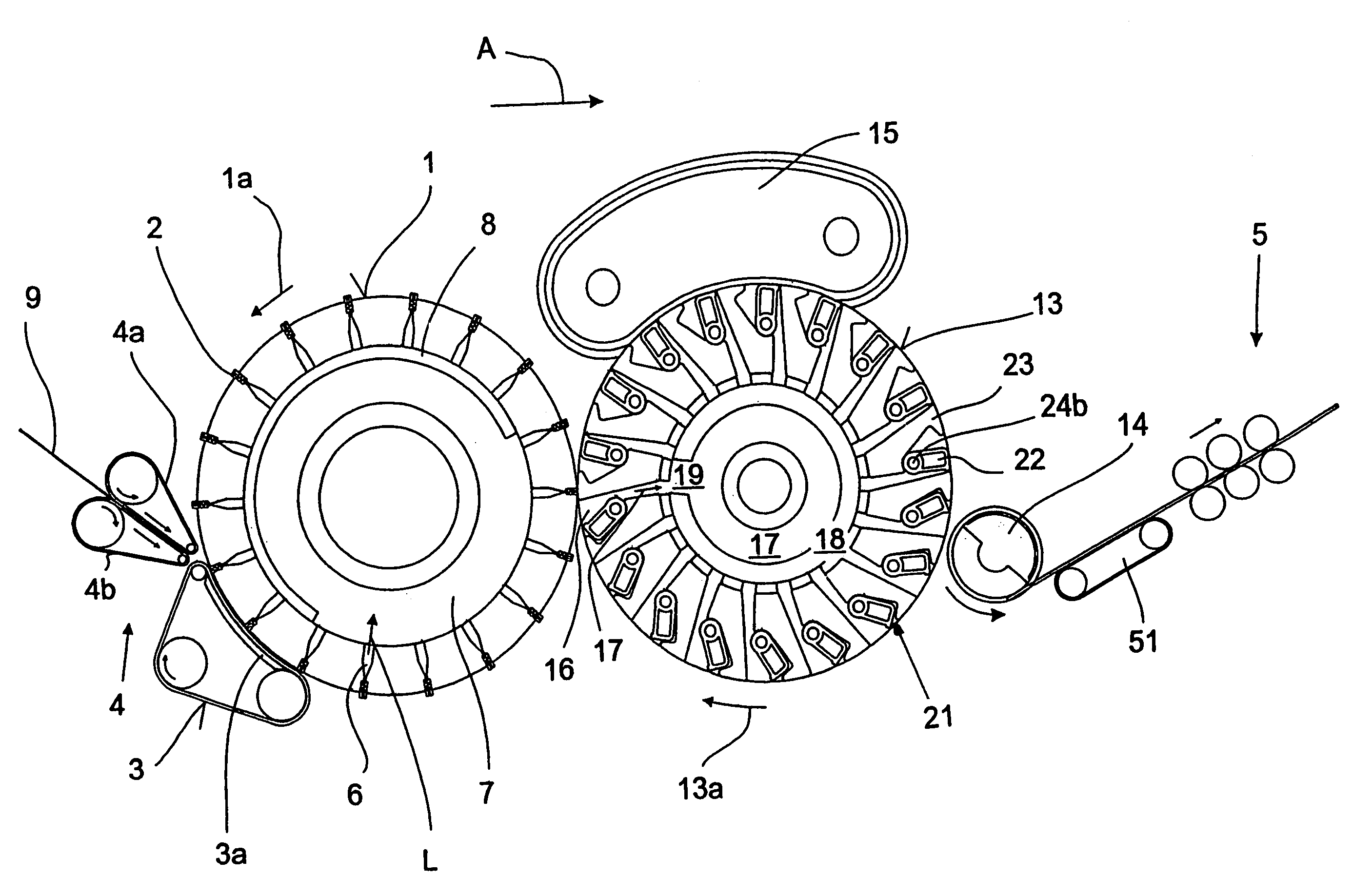

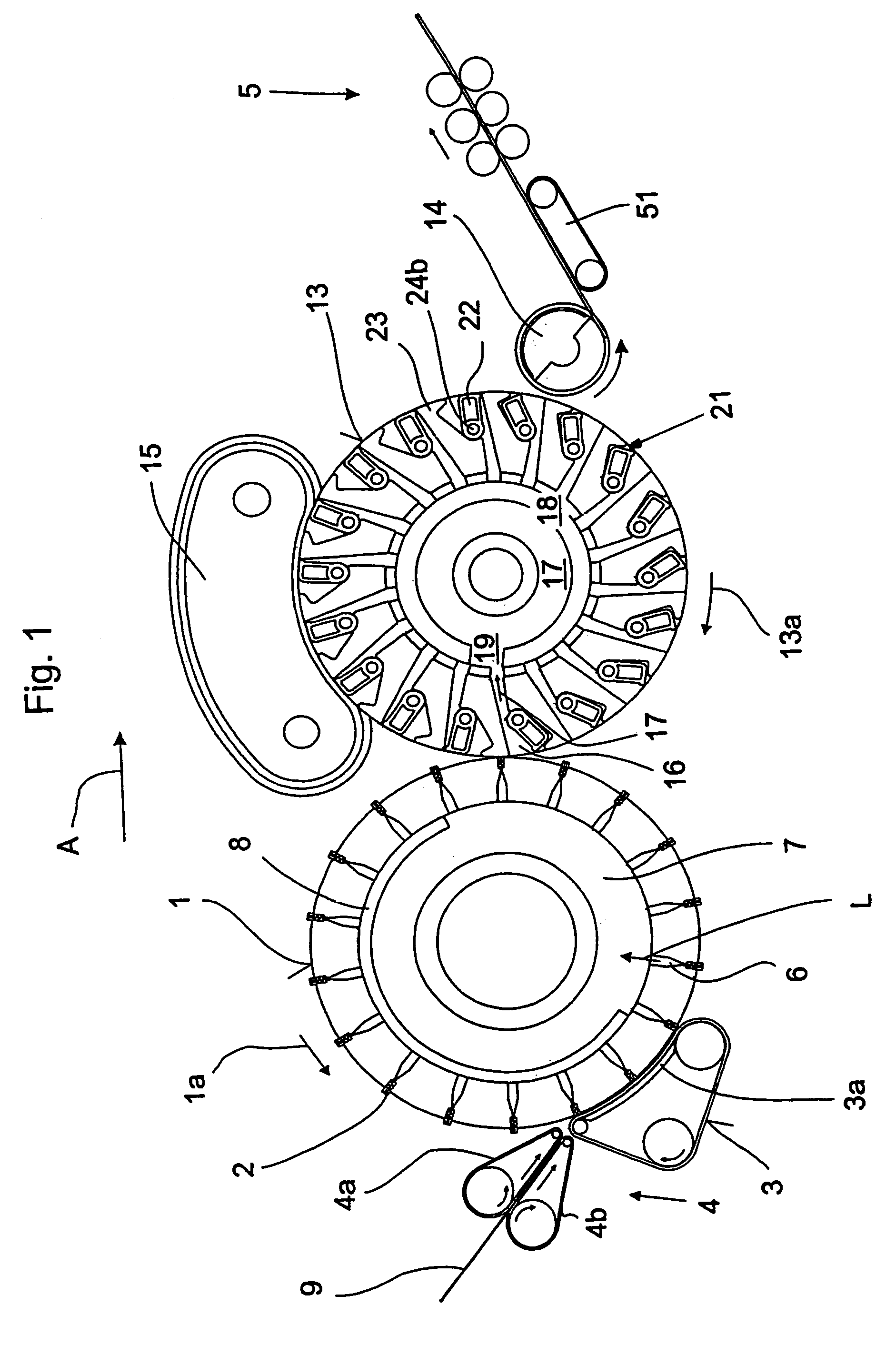

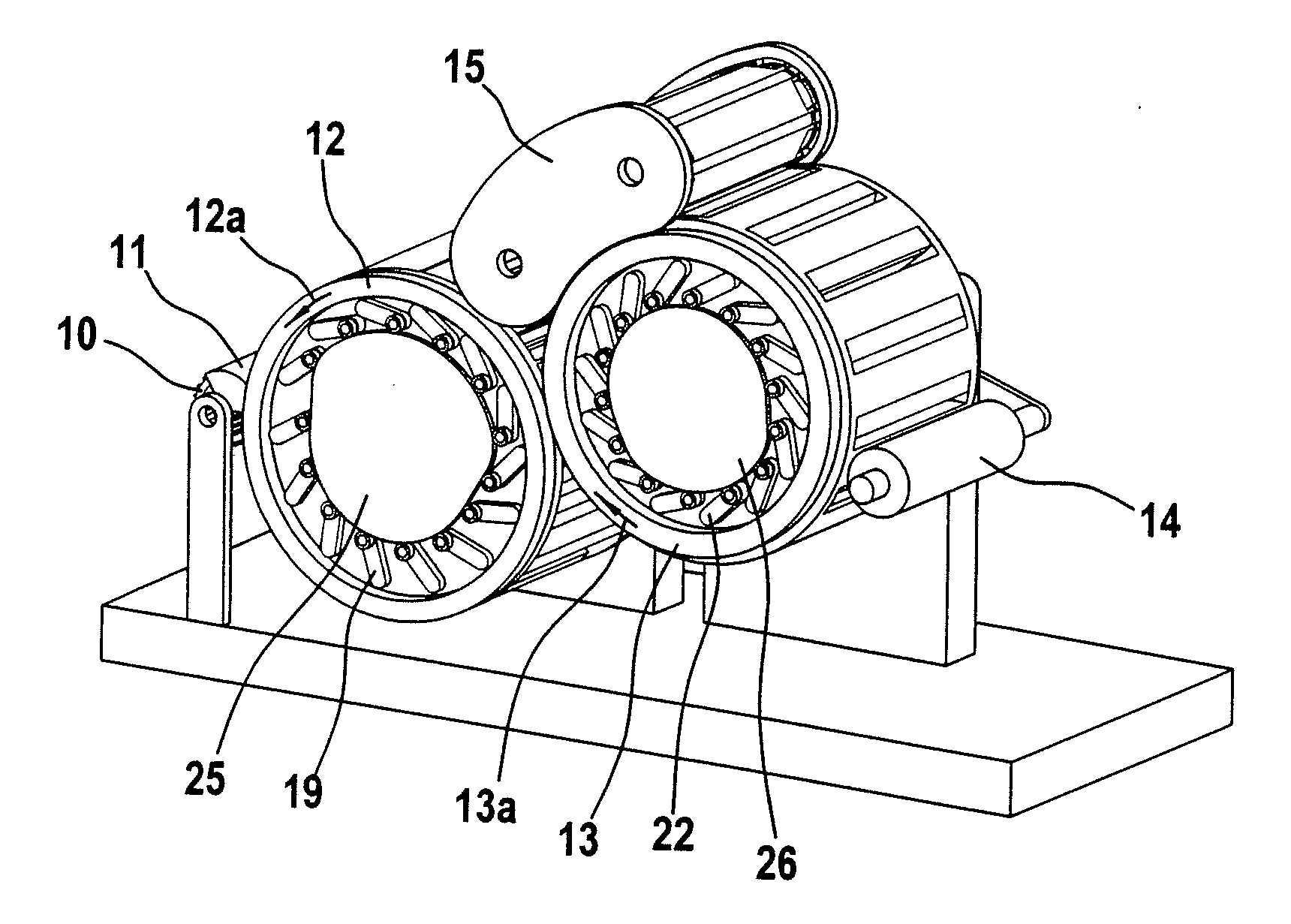

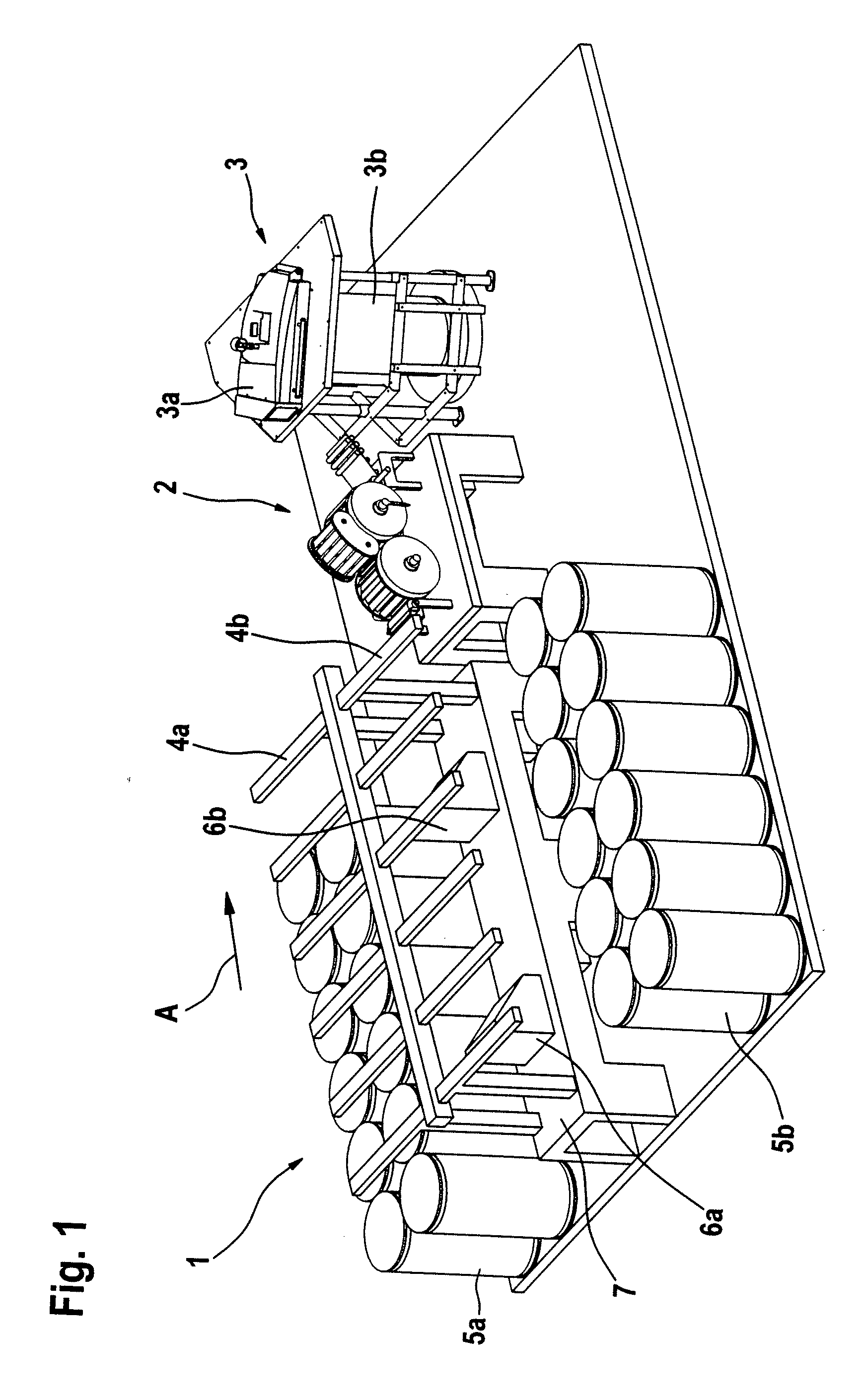

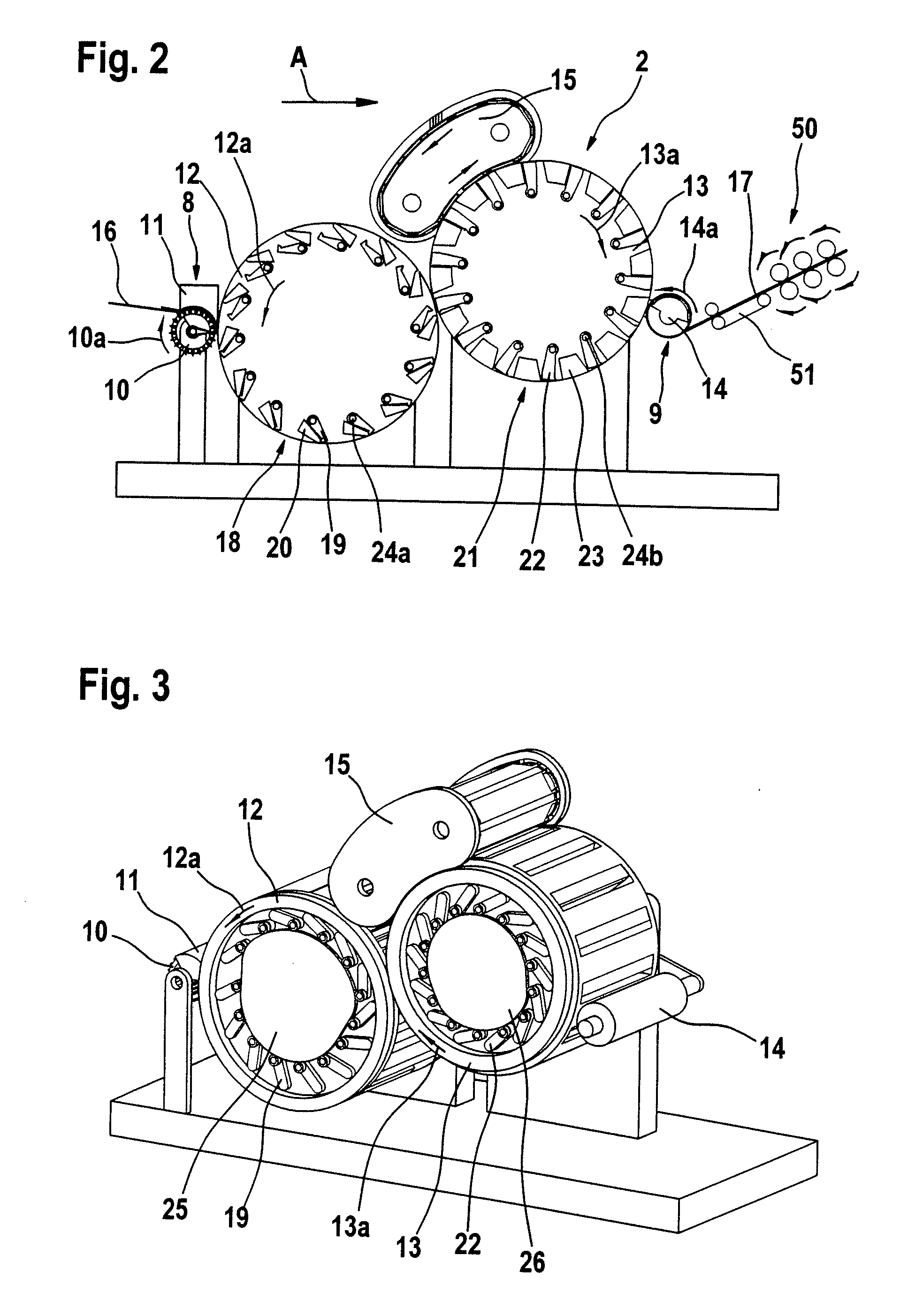

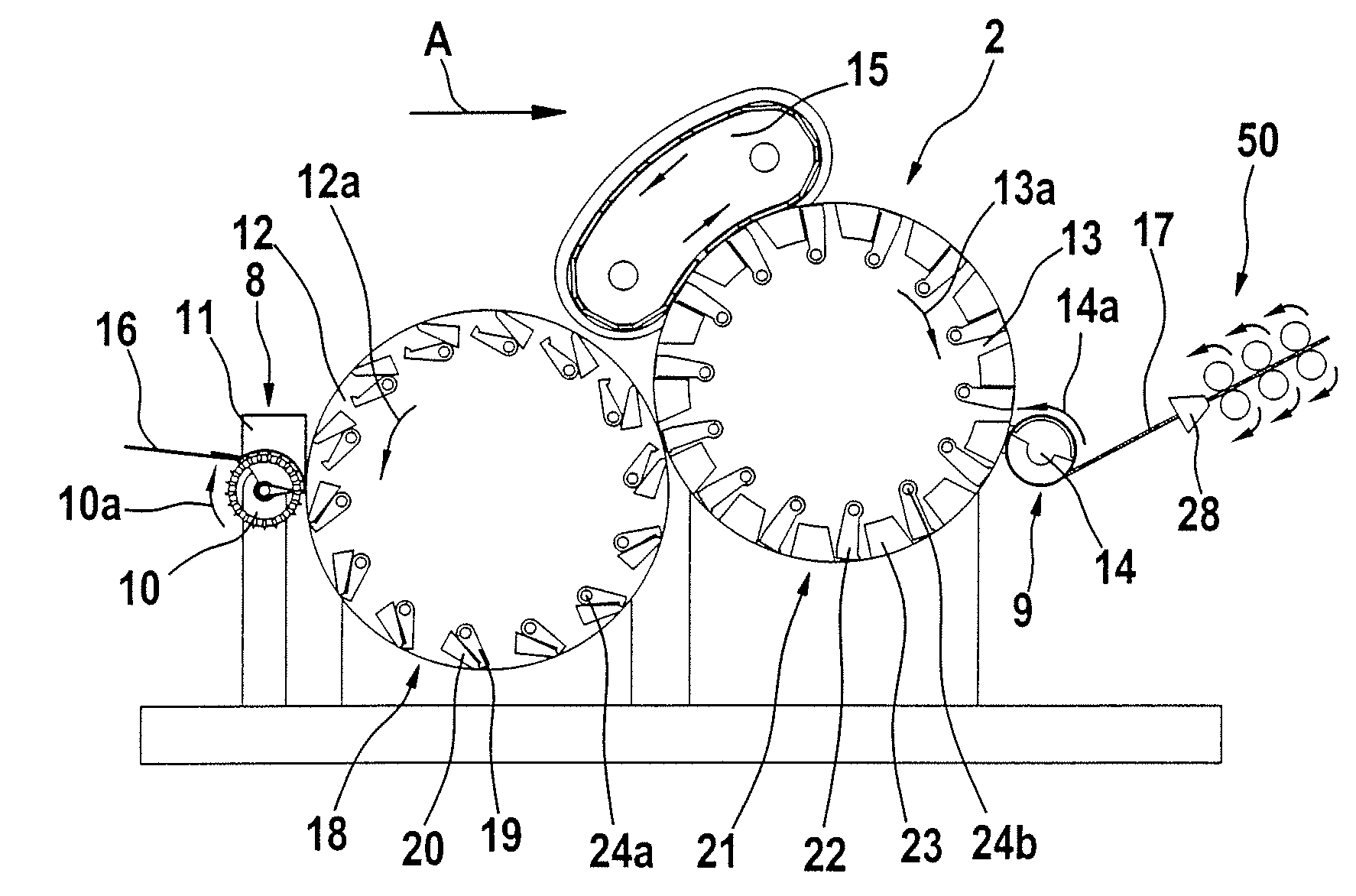

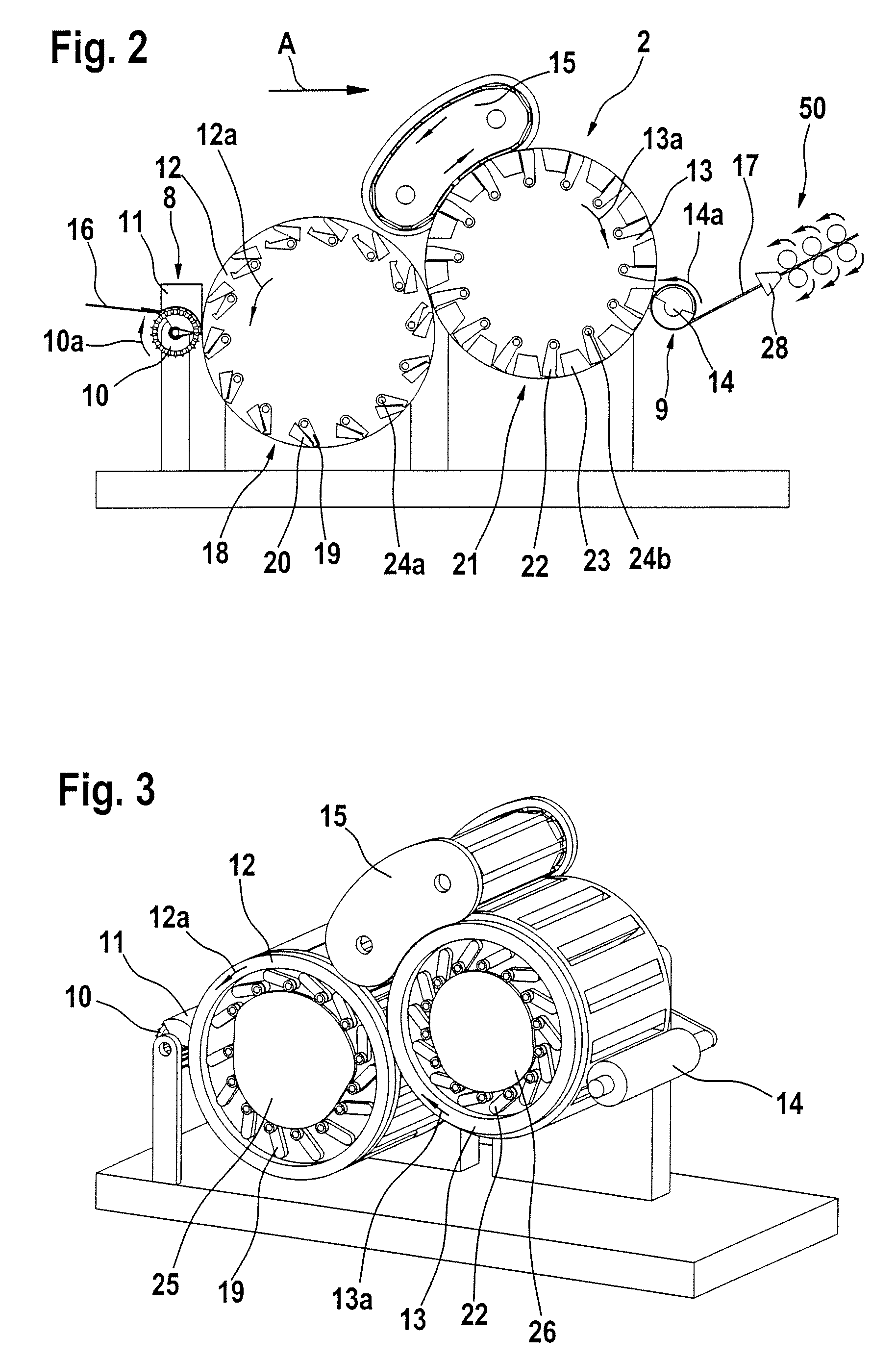

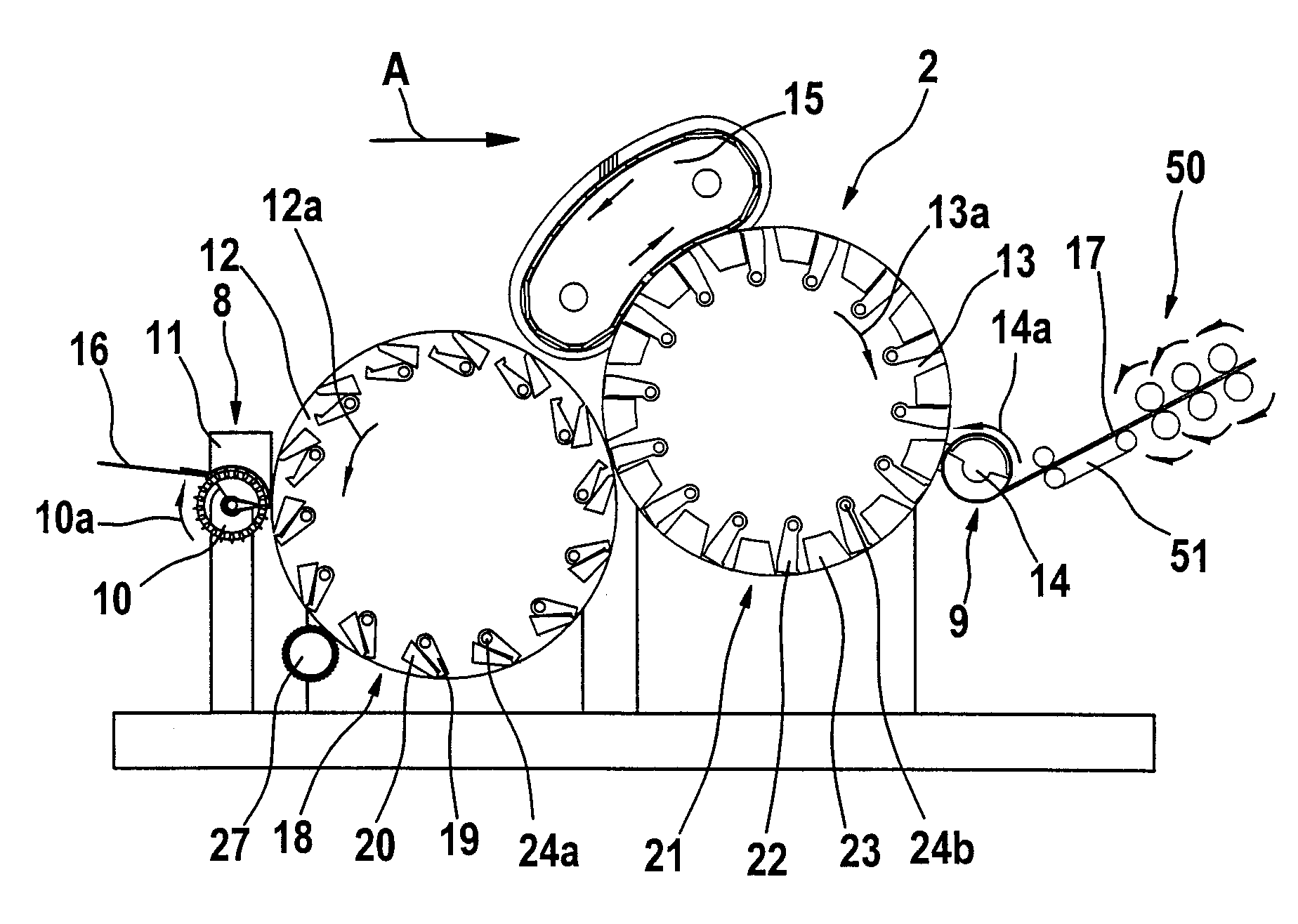

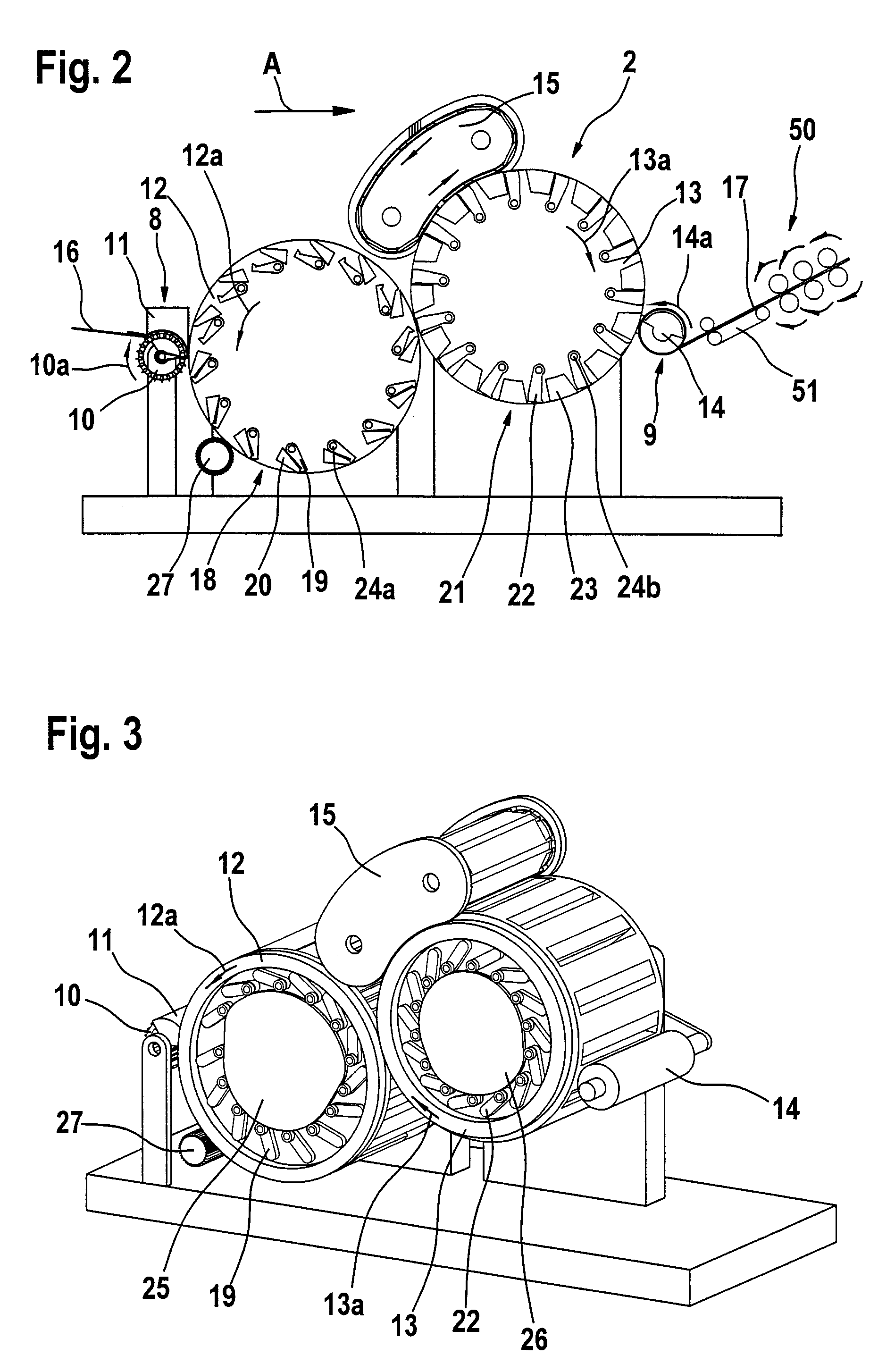

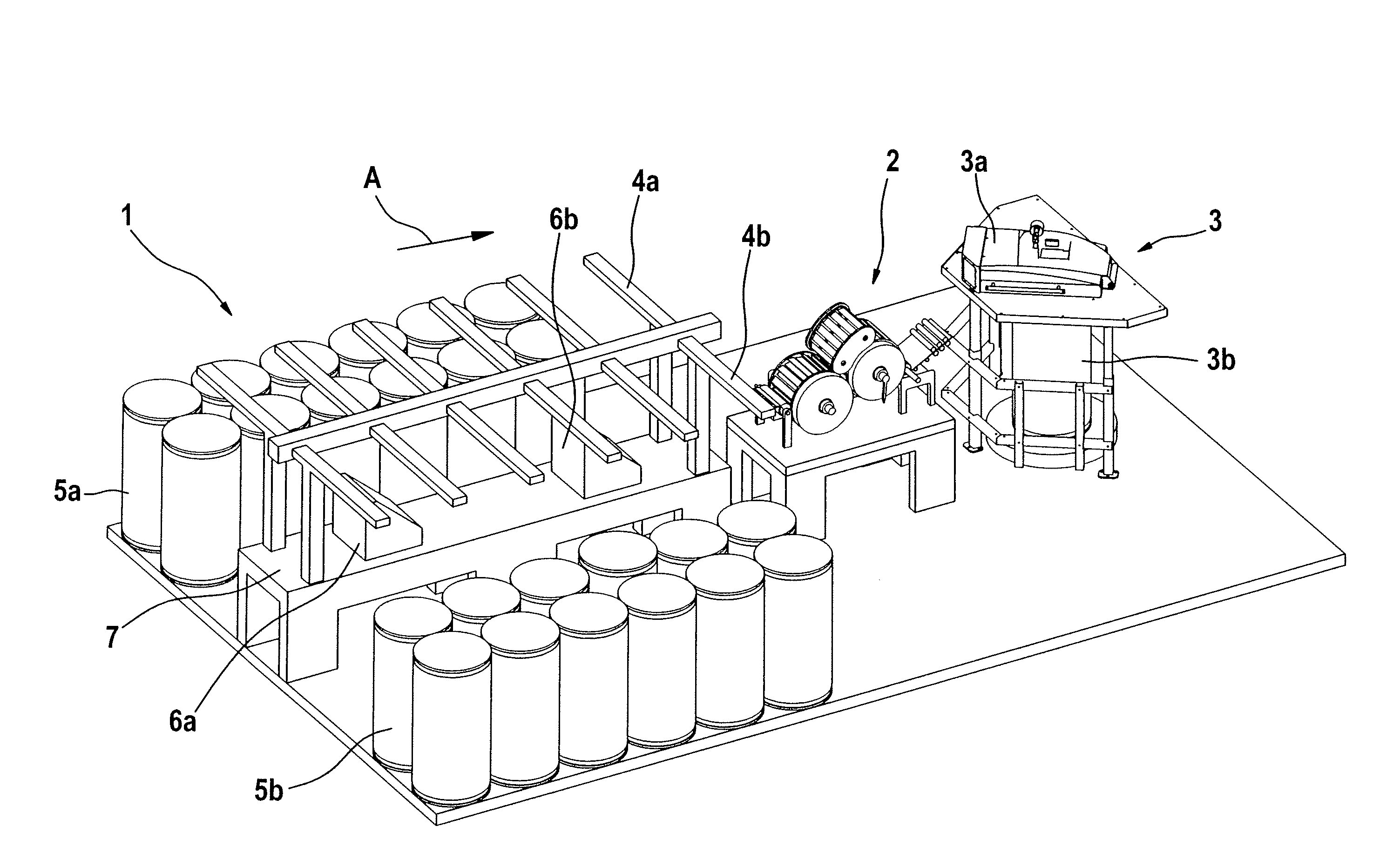

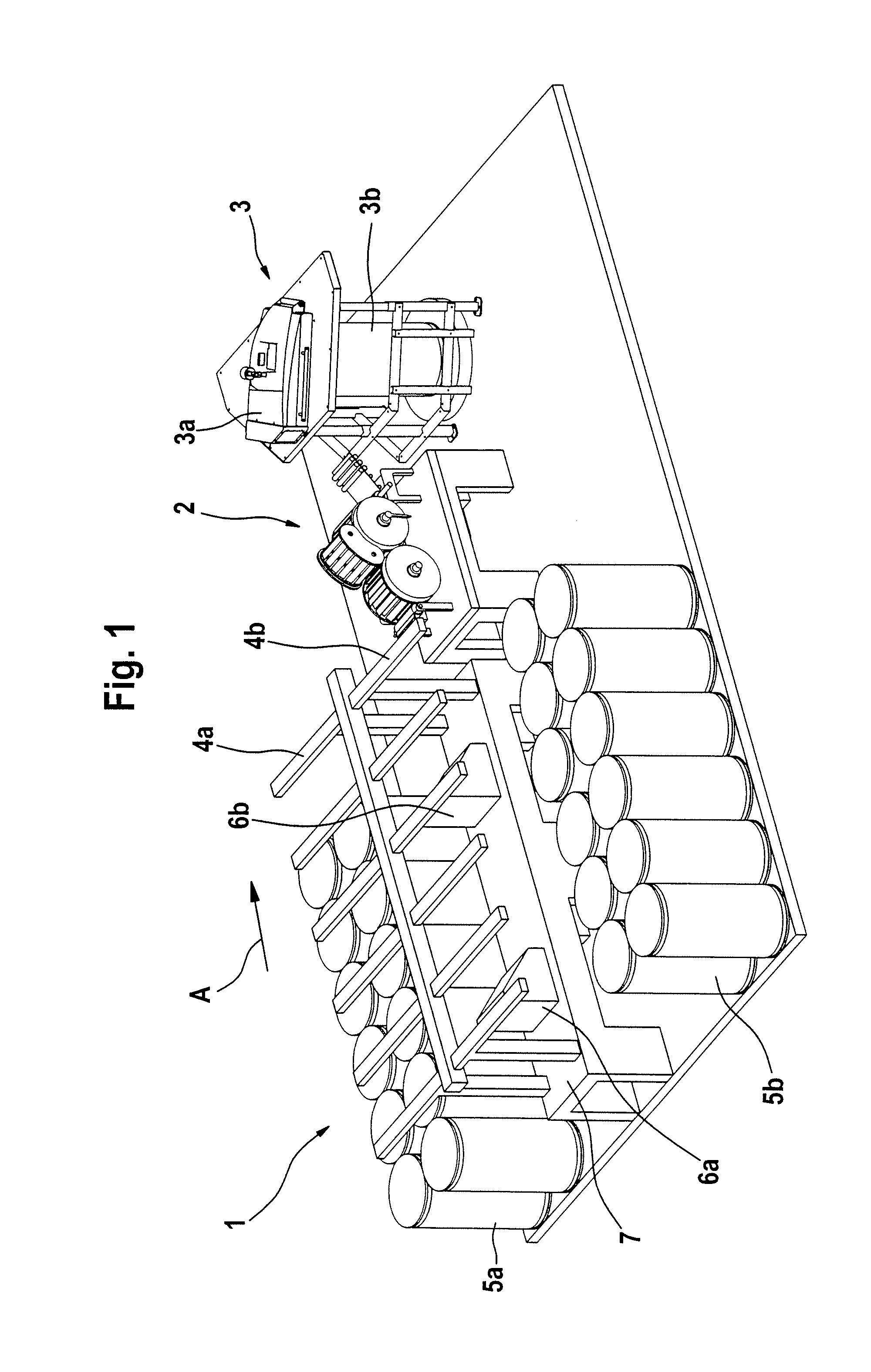

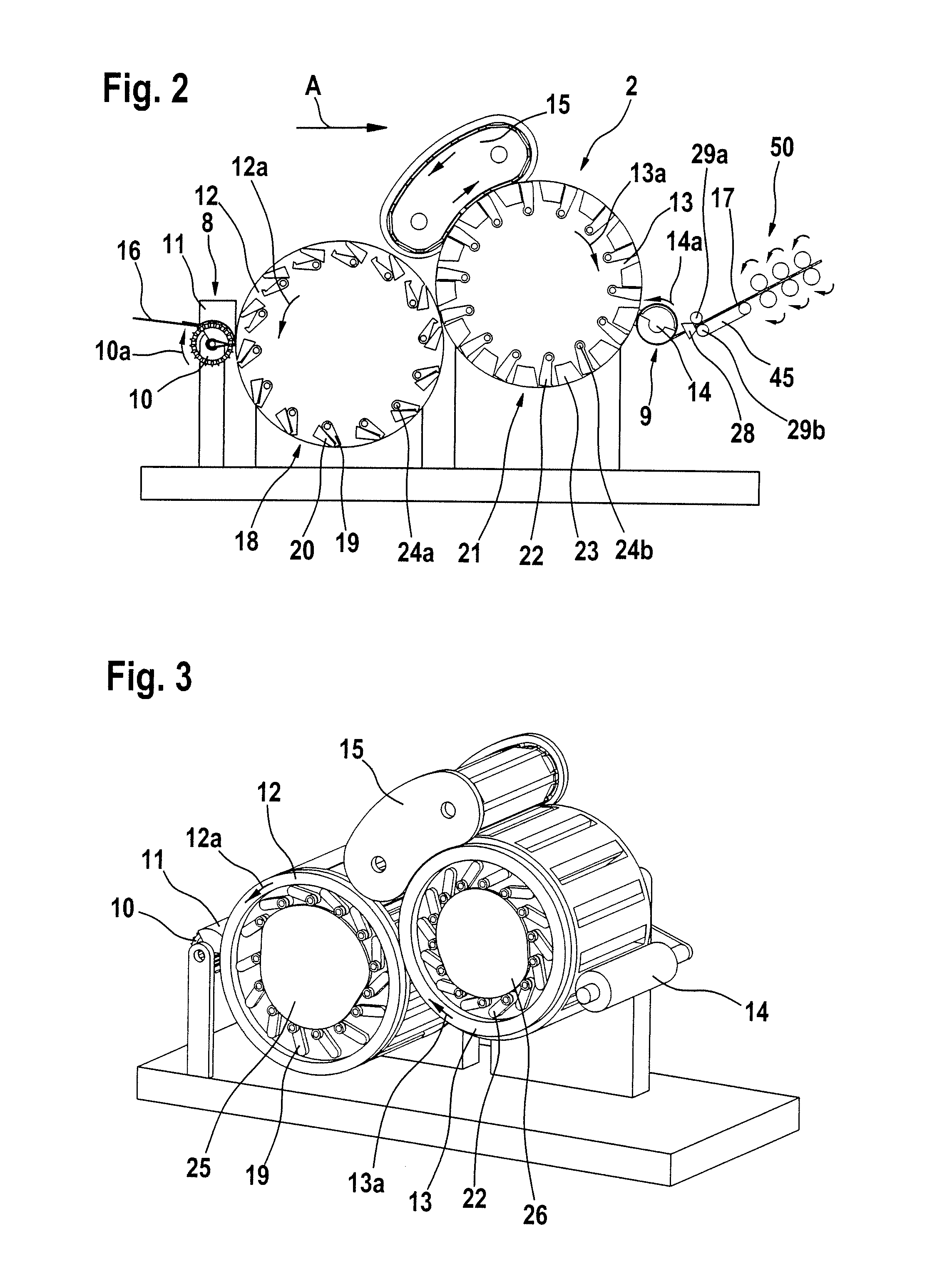

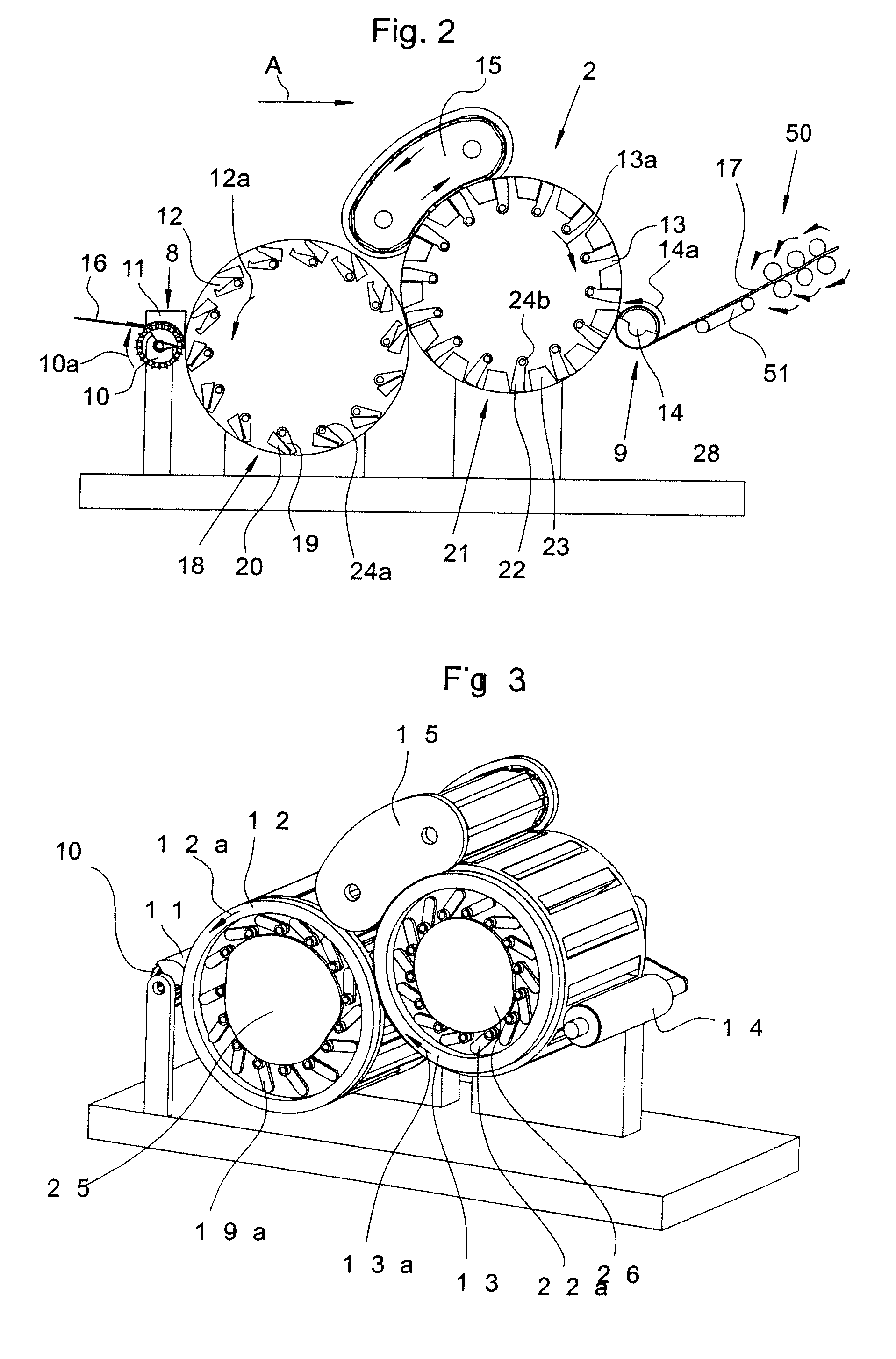

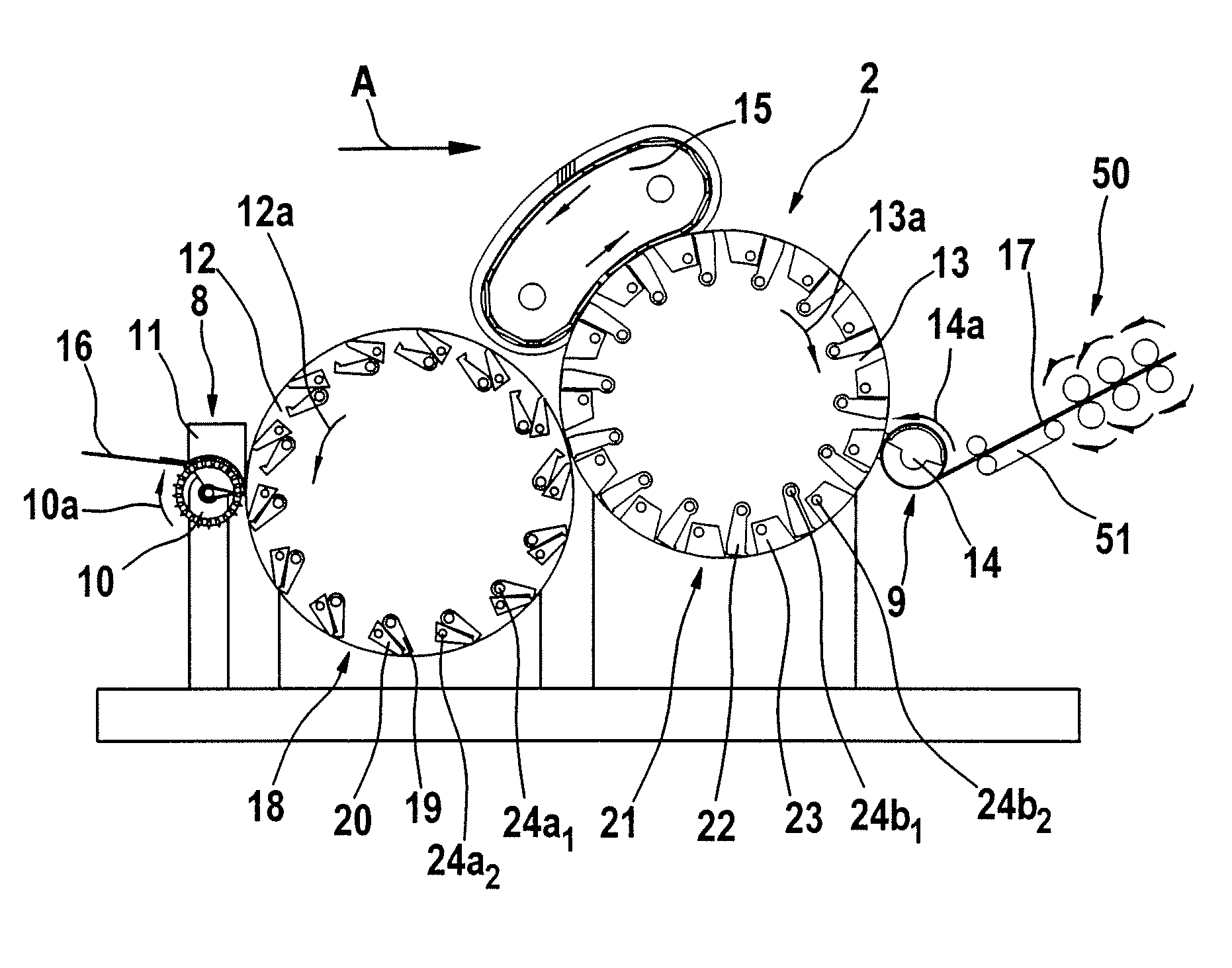

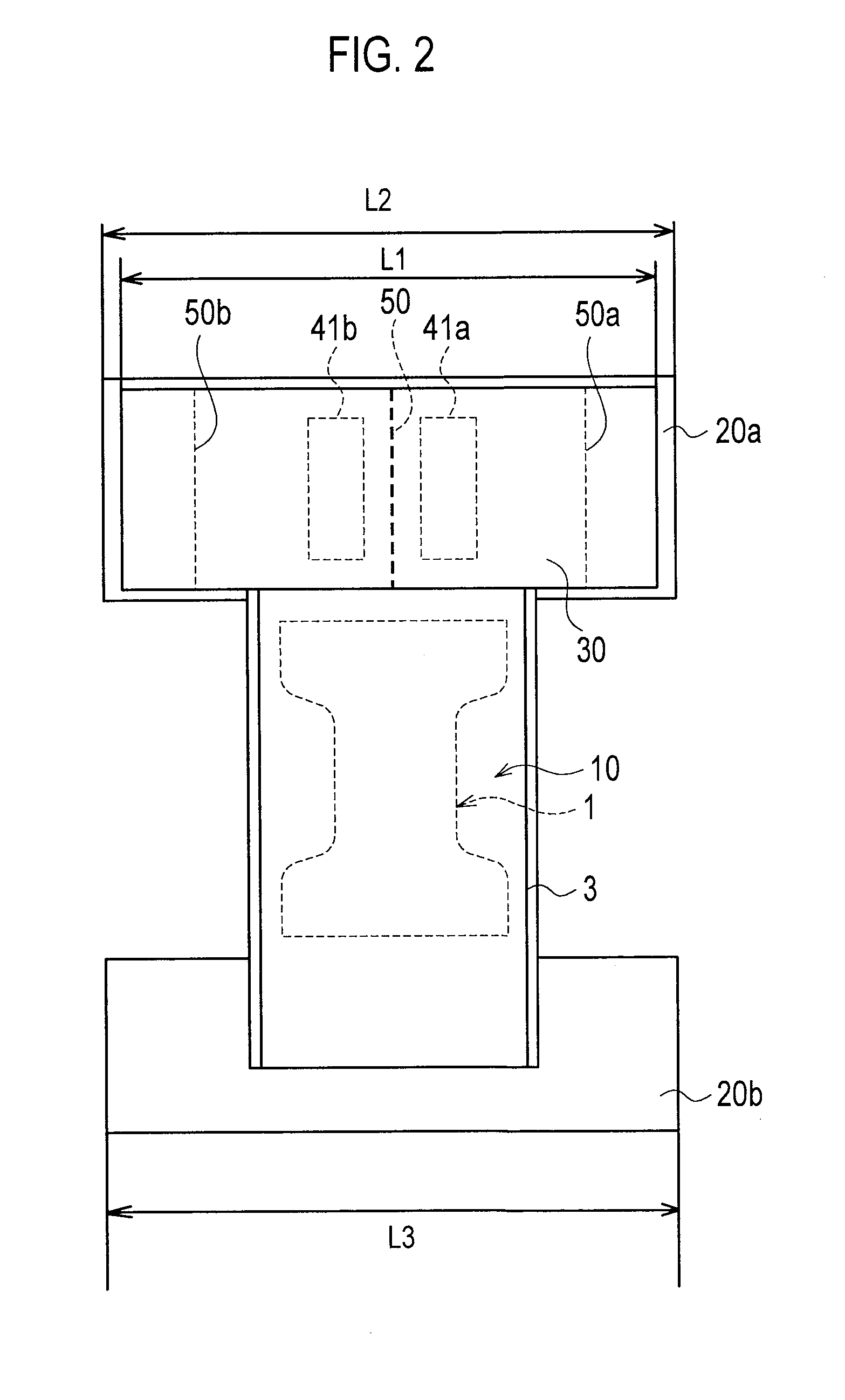

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action in order to loosen and remove non-clamped constituents from the fibre bundle, and a take-off device is present to remove the combed fibre material. To enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, which clamping devices are distributed around the periphery of the rollers, wherein in the region between the rollers, devices are present which provide an optimum feed of the fibre material and / or provide optimum positioning of the fibre material for transfer and take-up from the first roller to the second roller.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000067A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of a supply device to a fibre-sorting device, especially a combing device, for removal of the combed fibre material at least one take-off device with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices for the fibre bundle, and between the sliver-forming element and the drafting system at least one conveyor element for a formed combed sliver is present.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000079A1Improved sliverIncrease volumeCombing machinesFibre separationProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device, in which a mechanical device is present which generates a combing action to loosen and remove non-clamped constituents, and a clamping element is present for transfer of the supplied fibre material. To enable productivity to be increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged two rotatably mounted rollers, which are provided with clamping devices for the fibre material having clamping elements that are distributed spaced apart in the region of the roller periphery and co-operate with counter-elements, the counter-elements in the case of the first roller being arranged opposite the roller periphery and in the case of the second roller on or in the roller.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000066A1Improved sliverIncrease volumeCombing machinesCarding machinesFiber bundleEngineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action to remove non-clamped constituents such as short fibres. Downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, and the supply device comprises a feed unit, which feed unit comprises a feed roller and at least one feed tray defining a nip between said feed roller and said feed tray, and the retaining force in the nip optimally retains the short fibres completely or substantially completely in the nip during separation of a fibre bundle by said clamping devices.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000068A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, fibre is supplied by a supply device to a fibre-sorting device, especially a combing device. Clamping devices clamp the fibre bundle at a distance from its free end, and a mechanical device combs the free end to loosen and remove non-clamped constituents, for example, short fibres, neps, dust and the like. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices, and measured value sensors for detecting values relating to the fibres or machine settings are connected to a control and regulation device, which is arranged to effect actions in dependence on the measured values.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000065A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device for removal of the combed fibre material at least one take-off means with a sliver-forming element is present, downstream of which is a drafting system to enable productivity to be substantially increased and an improved combed sliver to be obtained, downstream of the supply device there is arranged at least one rotatably mounted roller rotating rapidly without interruption, which is provided with clamping devices for the fibre bundle, which clamping devices are distributed spaced apart in the region of the periphery of the roller and the combed sliver formed is arranged to be supplied directly to the drafting system.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the Fibre-Sorting or Fibre-Selection of a Fibre Bundle Comprising Textile Fibres, Especially For Combing

InactiveUS20090000070A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateMechanical engineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of supply means to a fibre-sorting device, at least one mechanical device is present which generate a combing action to remove non-clamped constituents such as short fibres. To enable productivity to be substantially increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged at least first and second rotatably mounted rollers with clamping devices for the fibre bundles, and the apparatus further comprises at least two supply devices and / or at least one further high-speed roller and / or at least two take-off devices.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000075A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by a supply device to a fibre-sorting device, especially a combing device, having clamping devices, which clamp the fibre bundle at a distance from its free end, for combing to remove non-clamped constituents, at least one take-off device 14 with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and improve the combed sliver, the fibre-sorting device has at least two rotatably mounted rollers rotating rapidly without interruption, having the clamping devices and between the sliver-forming element and the drafting system the at least one fibre sliver is present in the form of a fibre structure having a width greater than its height, for example, following spreading by a web-spreader.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000064A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part which is at least partially resilient. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000069A1Increase volumeImproved combed sliverCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is suppled by a supply device to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and the clamping jaws of the each clamping device are arranged to be movable in relation to one another and separately drivable.

Owner:TRUETZSCHLER GMBH & CO KG

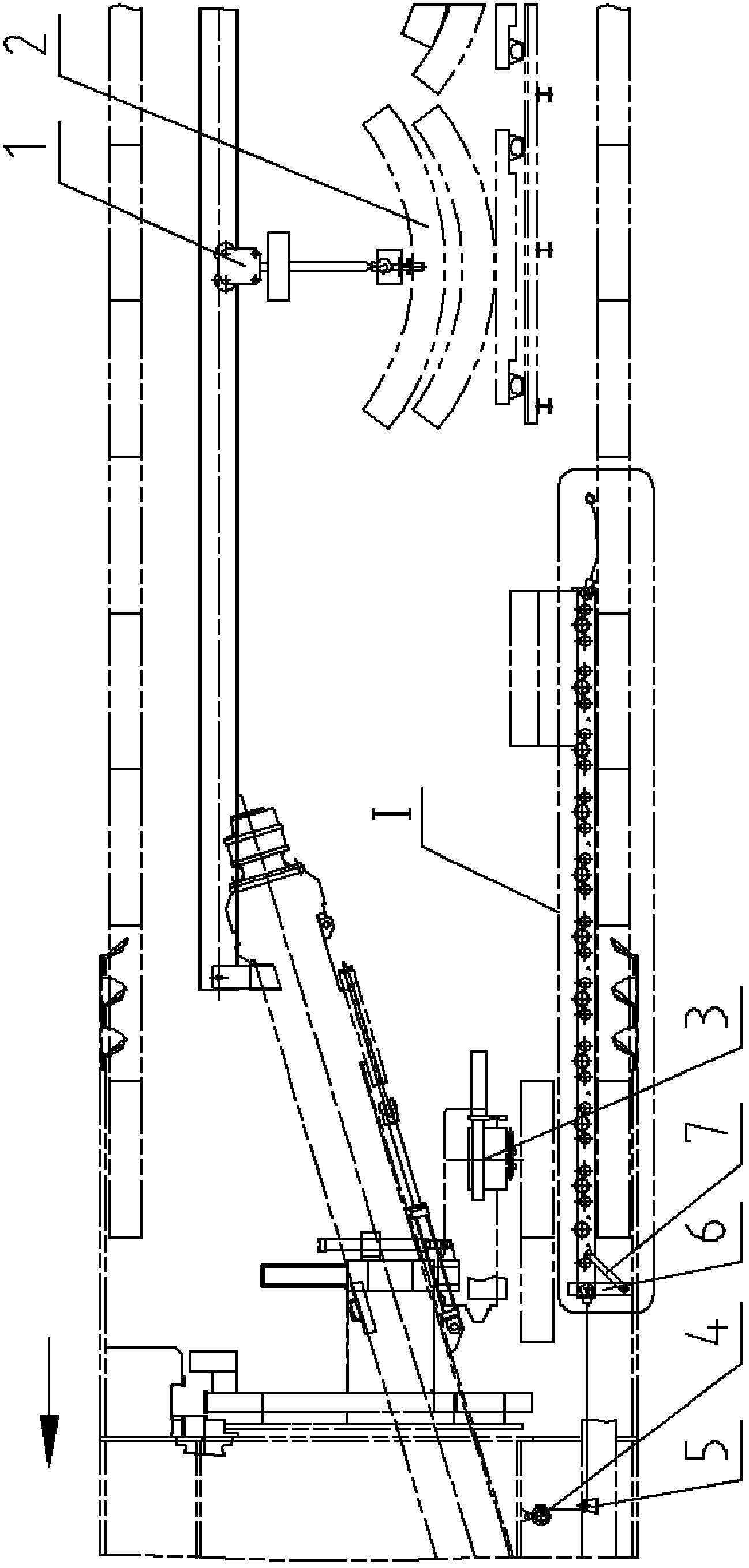

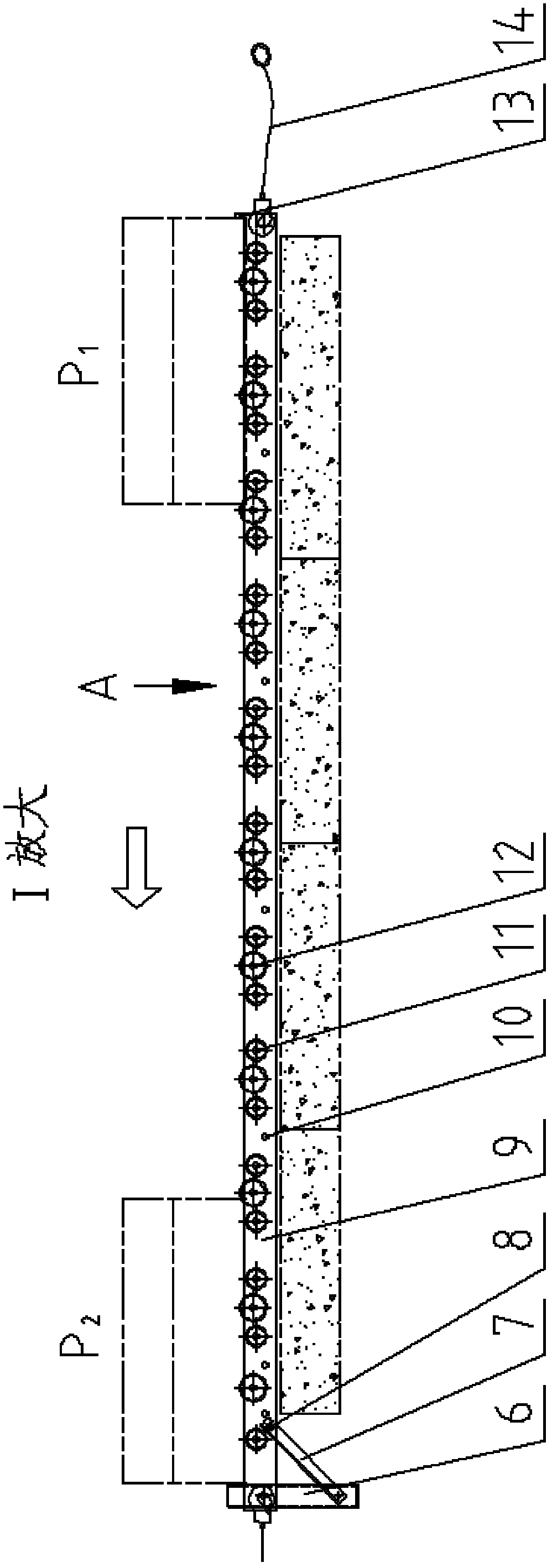

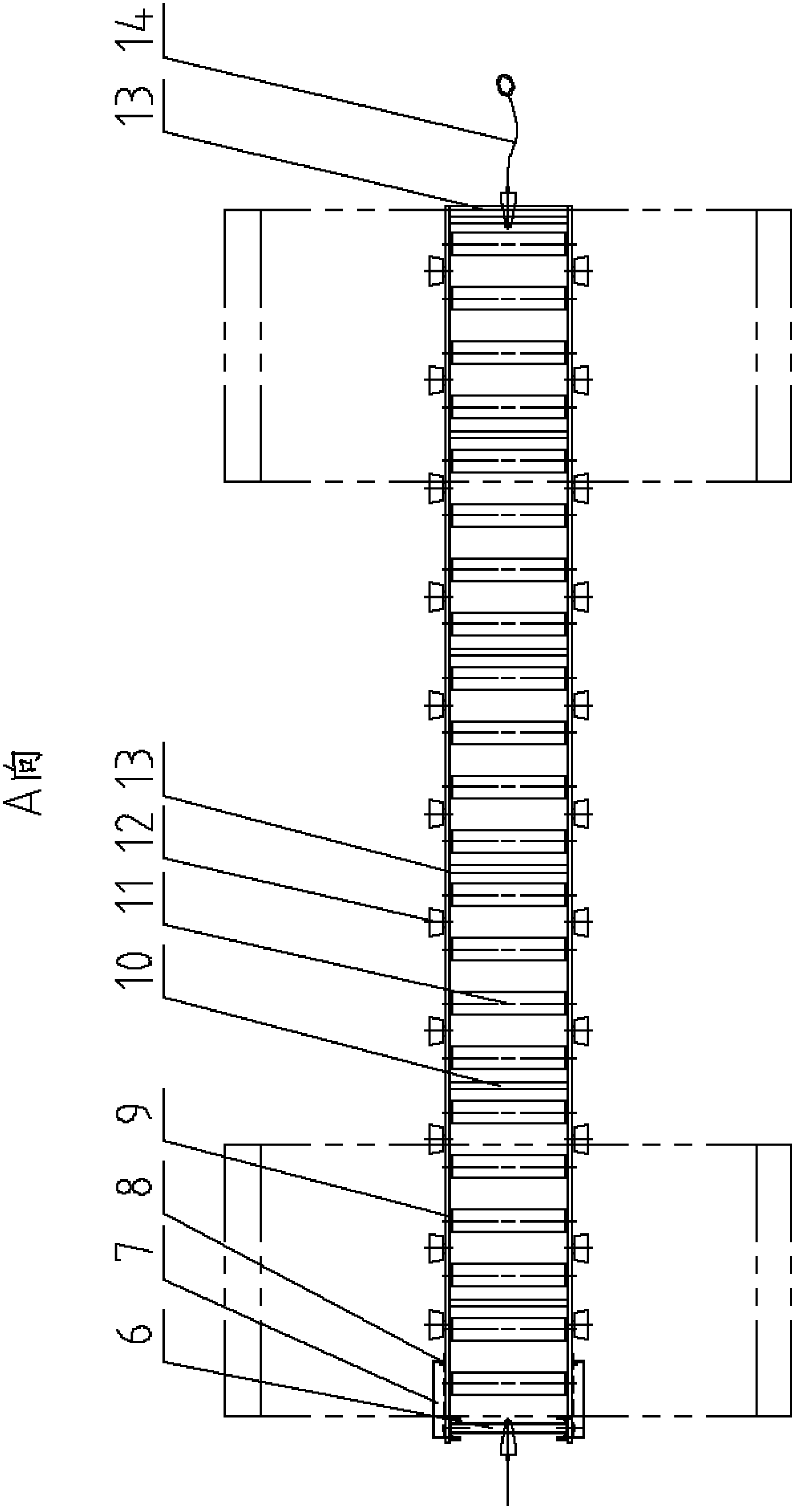

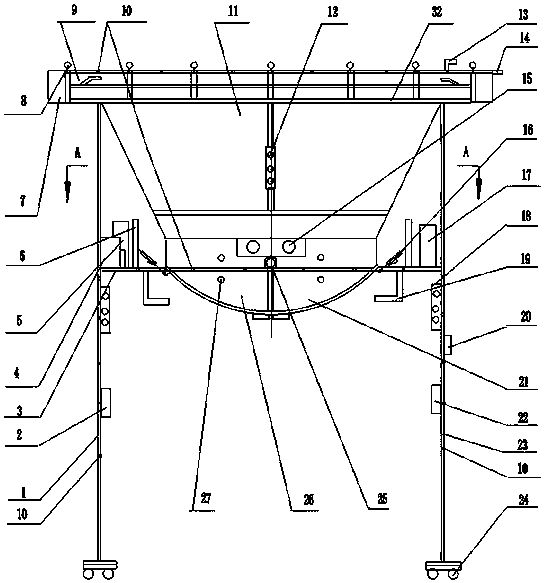

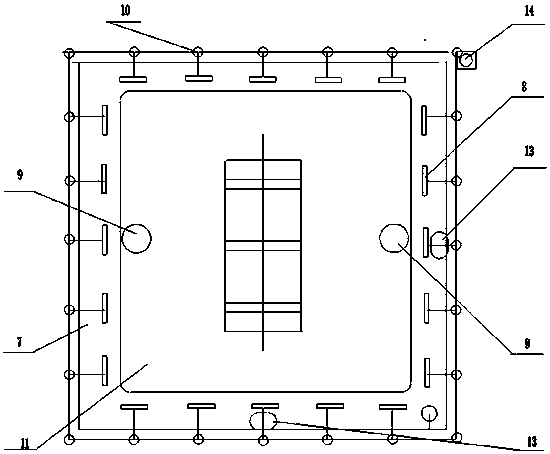

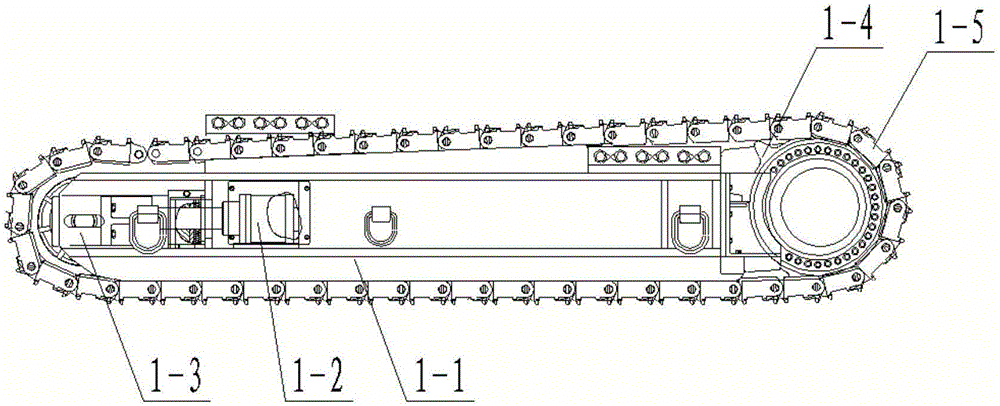

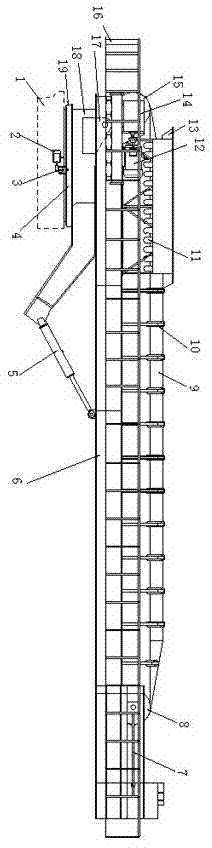

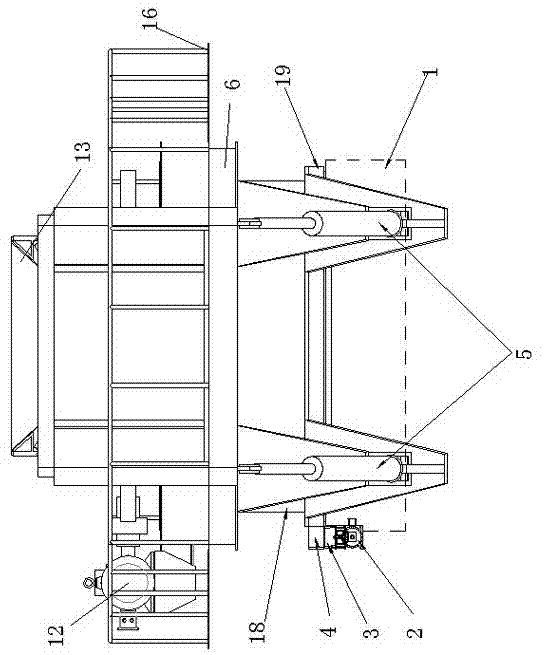

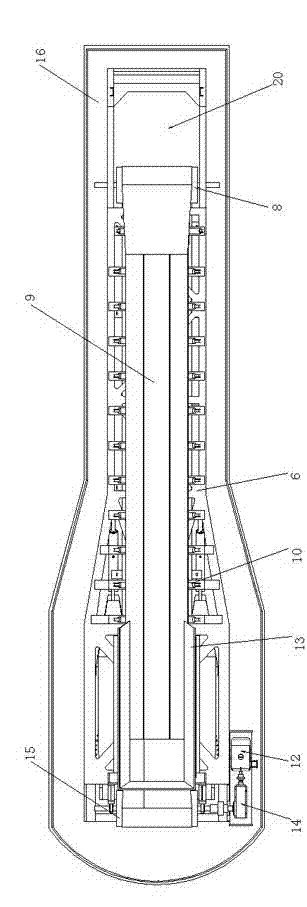

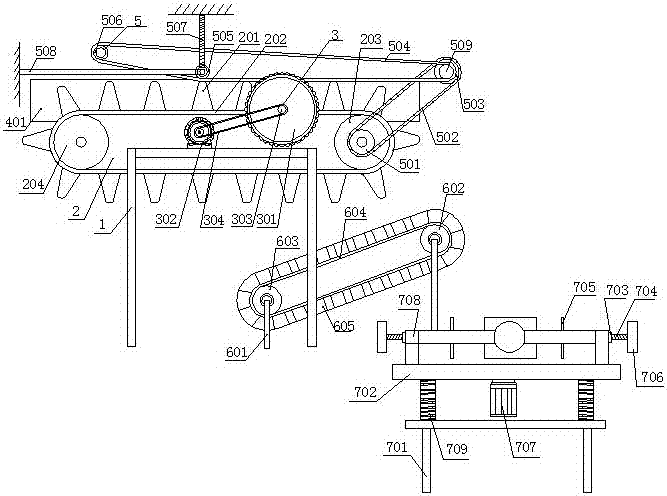

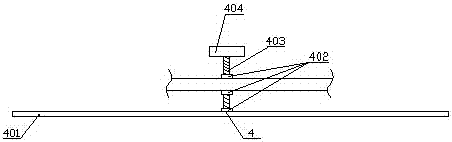

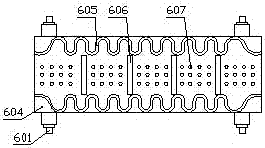

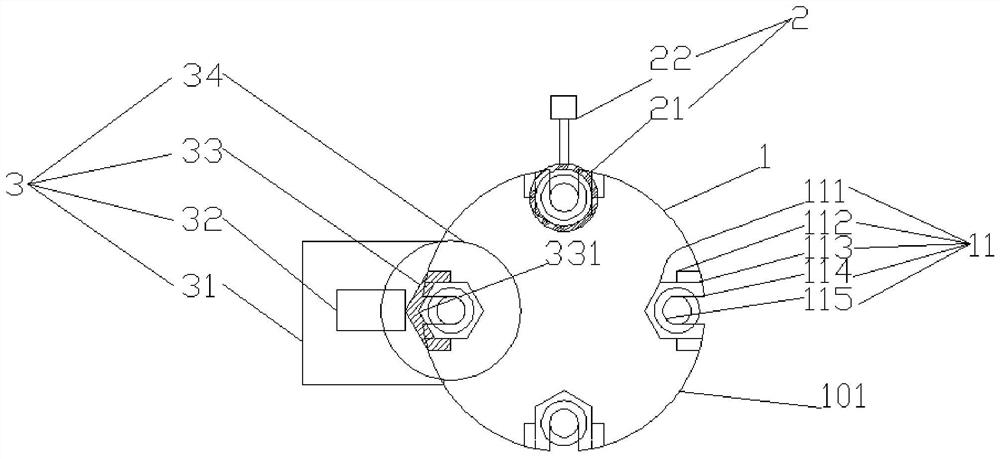

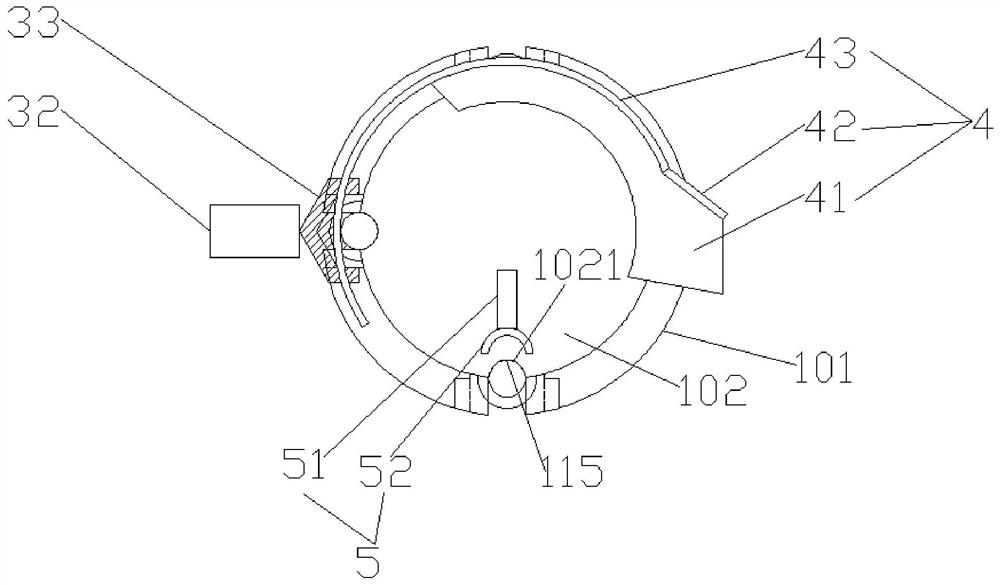

Segment transportation device and operation method for shield tunneling with tunnel diameter less than six meters

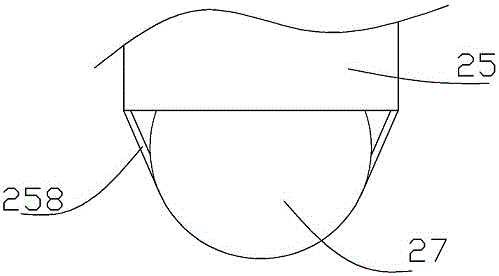

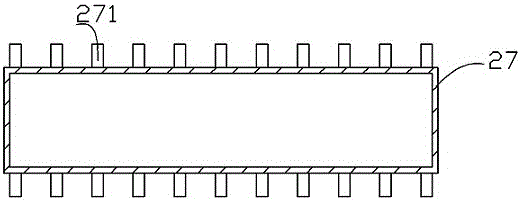

ActiveCN102278131ACompact structureSuitable for low space operationUnderground chambersTunnel liningEnergy conservationPulley

The invention belongs to shield excavating equipment, and relates to a duct piece conveying device for the shield construction of a tunnel with the diameter of less than 6 meters and an operation method. The duct piece conveying device is characterized in that: a duct piece conveyor consisting of a crane combination driving mechanism, a duct piece bearing roller platform and a support mechanism is arranged on the inner bottom surface of the tunnel; the crane combination driving mechanism consists of a front dragging machine consisting of a hoist crane and a fixed pulley and a rear pulling mechanism consisting of a duct piece crane and a hanging joint rigging; the duct piece bearing roller platform is driven by the crane combination driving mechanism, so that duct pieces are conveyed to a duct piece splicer to be spliced; and the duct piece bearing roller platform is a sliding bearing roller platform, a wheel set bearing roller platform or a rail bearing roller. The duct piece conveying device has reasonable design and a compact structure, is suitable for the conveying operation of the duct pieces in low space and adjusting the self-position, has the advantages of continuous conveying, smooth and stable running, safety, reliability, high efficiency, energy conservation, small investment, convenience for operation and use and the like.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

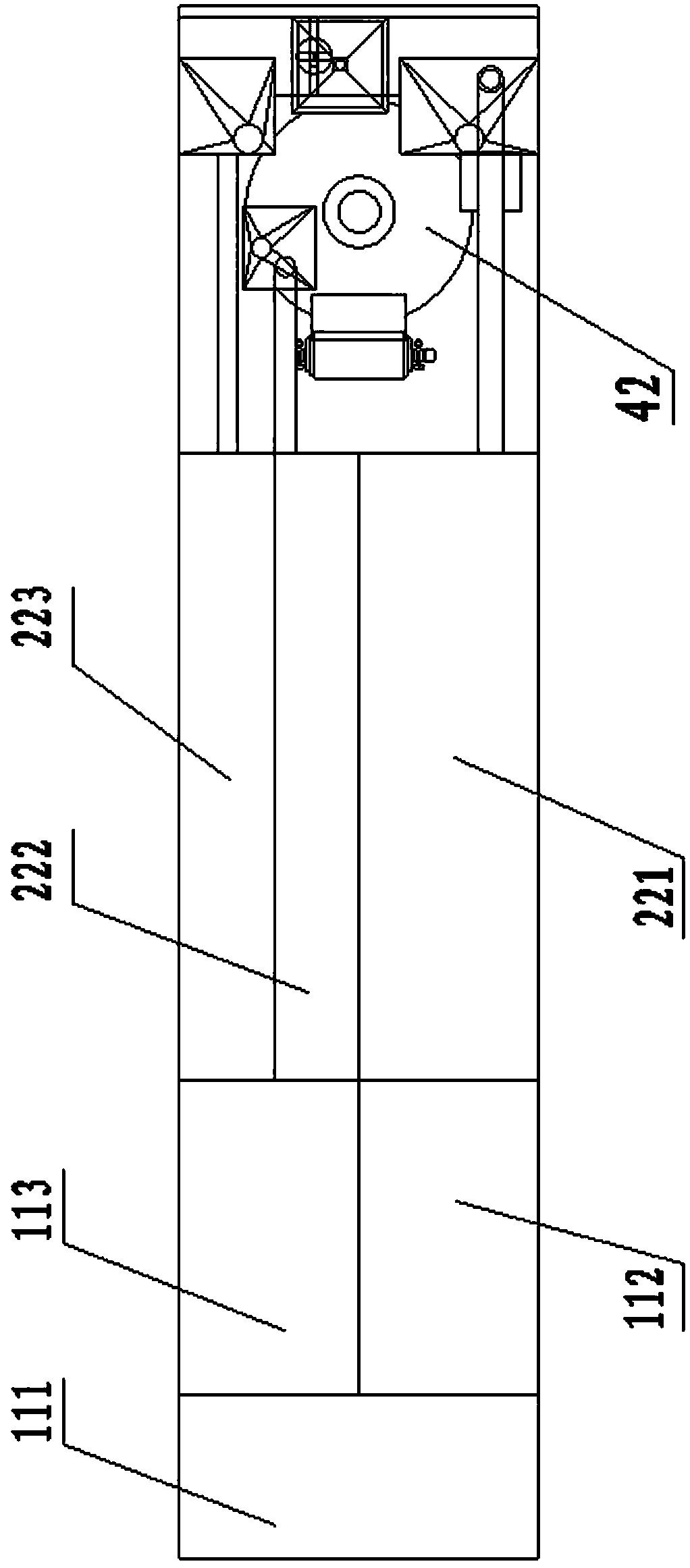

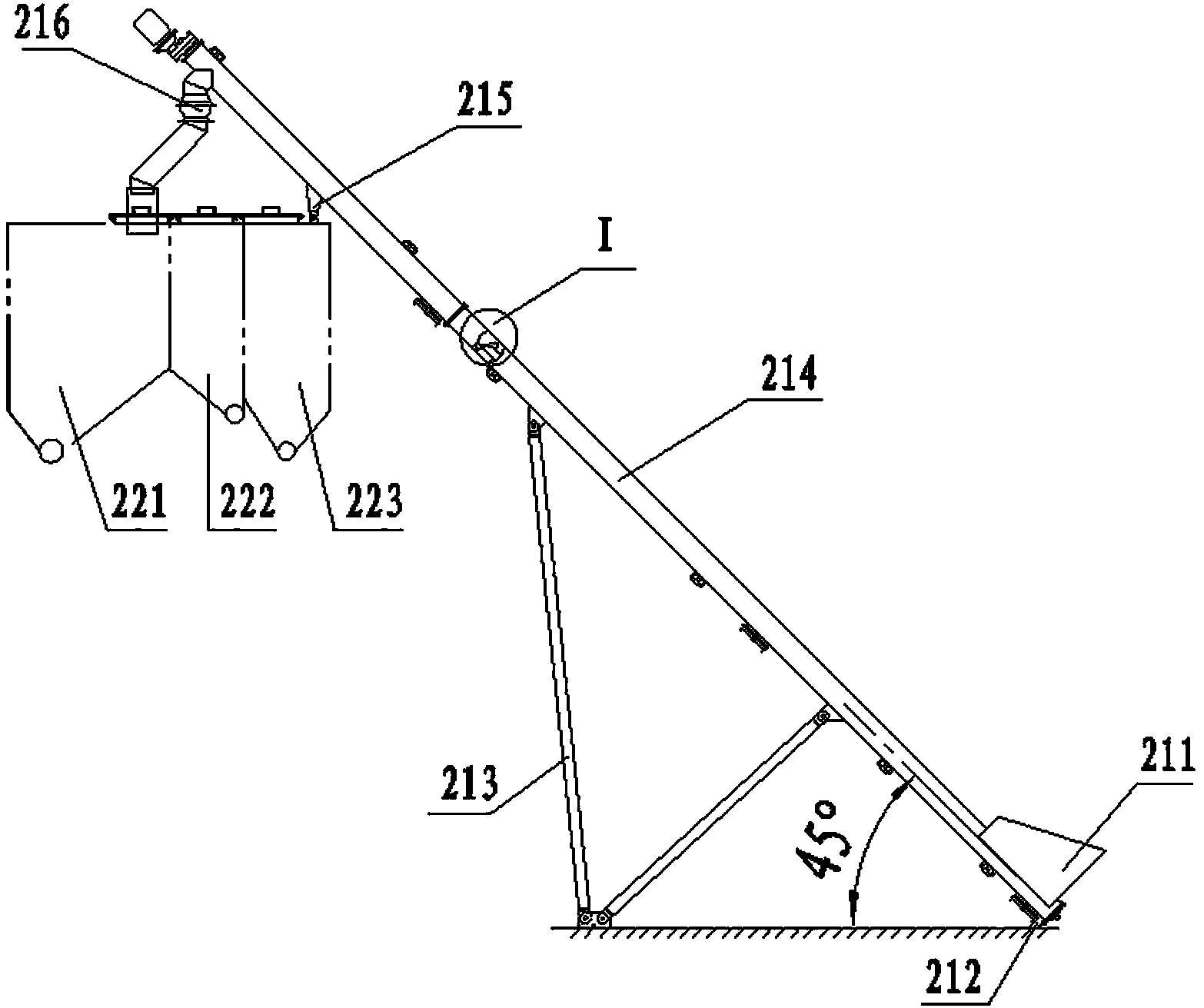

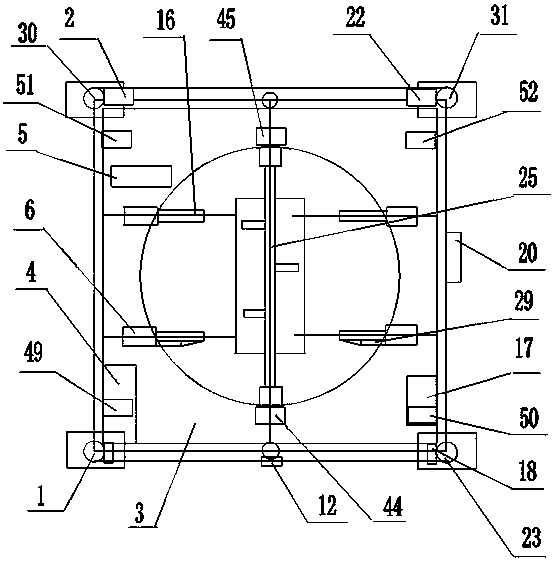

Quickly-moving type concrete mixing station

ActiveCN103660040AShorten the production periodIncrease productivityDischarging apparatusIngredients weighing apparatusMaterial supplyDelivery system

The invention discloses a quickly-moving type concrete mixing station, and relates to the technical field of concrete production equipment. The station comprises an aggregate supplying system, a powdered auxiliary material supplying system, a liquid auxiliary material supplying system, a stirring system, a control panel, a pump delivery system, and a transportation system; wherein the transportation system comprises traction equipment and a trailer plate, the aggregate supplying system, the powdered auxiliary material supplying system, the liquid auxiliary material supply system, the stirring system, the control panel, and the pump delivery system are all arranged on the trailer plate; the aggregate supplying system, the powdered auxiliary material supplying system, and the liquid auxiliary material supplying system all communicate with the stirring system, the stirring system comprises a frame and a stirrer, the stirrer is arranged on the frame; and the pump delivery system is arranged below the material unloading door of the stirrer. The quickly-moving type concrete station has the advantages of compact structure, user-friendliness, and rapid movement, can shorten the construction time and guarantee the concrete quality, satisfies the using requirement of small-batch concrete, improves the construction efficiency, and saves the construction cost.

Owner:SHIJIAZHUANG TIEDAO UNIV +2

Bulk material discharging, storage and transportation equipment and transportation method

PendingCN108328360ARealize human-computer interactionReduce misuseConveyorsLarge containersControl systemHouse building

The invention discloses bulk material discharging, storage and transportation equipment which comprises a transportation hopper installed on the upper portion of a frame. The lower end of the transportation hopper is provided with a discharge outlet, and the discharge outlet is provided with a bin door capable of being opened and closed. The equipment further comprises a bin door opening-closing and detection system, a vehicle positioning indication human-machine interaction system, a transportation hopper material level detection and indication system, an upper spraying device and a lower spraying device which are connected with a control system, wherein the upper spraying device is installed on the upper portion of the transportation hopper, and the lower spraying device is installed onthe lower portion of the transportation hopper. Transportation vehicle automatic monitoring and reminding are achieved, a boat discharging door machine can work without interruption, the storage capacity of the transportation hopper can be displayed in real time, the bin door is automatically opened and closed for discharging, the lower portion of the transportation hopper is provided with a material weighing system, an empty vehicle weight house, a heavy vehicle weight house and a discharging, storage and transportation device are integrated into a whole, loading and weighing are completed ina one-stop mode, the automobile weight house building cost is reduced, processes are reduced, and production efficiency is improved. The invention further provides a transportation method for transporting bulk materials through the bulk material discharging, storage and transportation equipment.

Owner:RIZHAO PORT +1

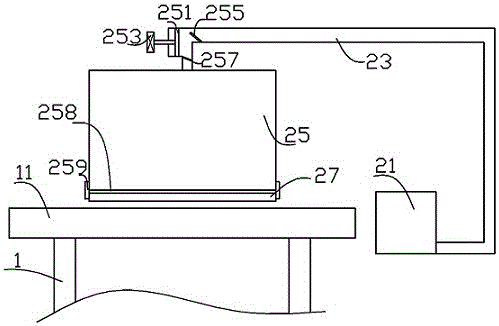

Wood gluing device

InactiveCN105922376AContinuous transportBrush glue continuouslyAdhesive application devicesMechanical engineeringStorage pool

The invention discloses a wood gluing device. The wood gluing device comprises a gluing mechanism and a glue outlet mechanism; the gluing mechanism includes a frame and a worktable; the worktable is connected to a worktable; the glue outlet mechanism includes a glue storage pool, a glue conveying pipe, a glue storage box and a glue brushing roller; the glue storage pool is connected with the glue storage box through the glue conveying pipe; a piston is arranged in the glue conveying pipe, and is connected with a cylinder; a first one-way valve is arranged on one side, near the glue storage pool, of the glue conveying pipe, and a second one-way valve is arranged on one side, near the glue storage box, of the glue conveying pipe; and the glue brushing roller is rotationally connected to the bottom end of the glue storage box, and is positioned above the worktable. The wood gluing device solves the problem of low efficiency caused by discontinuous operation of manual gluing in the prior art, and is continuous in gluing.

Owner:CHONGQING LUWAN WOOD CO LTD

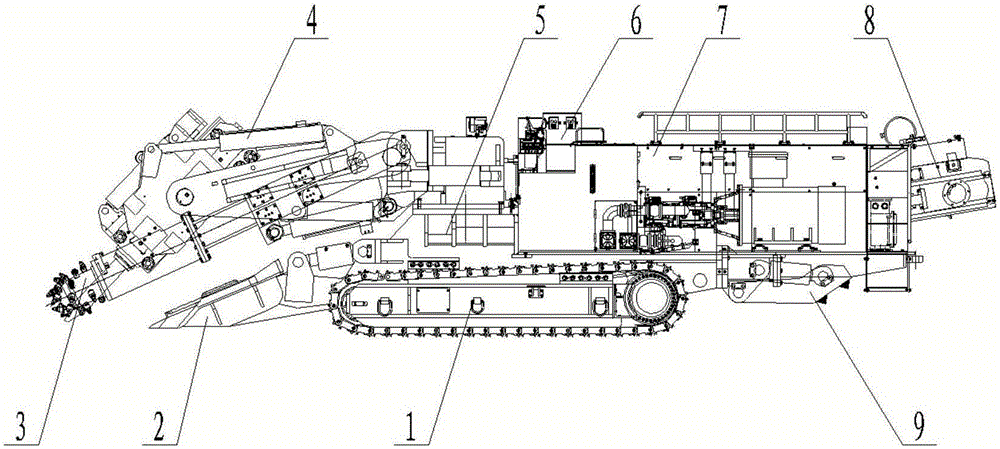

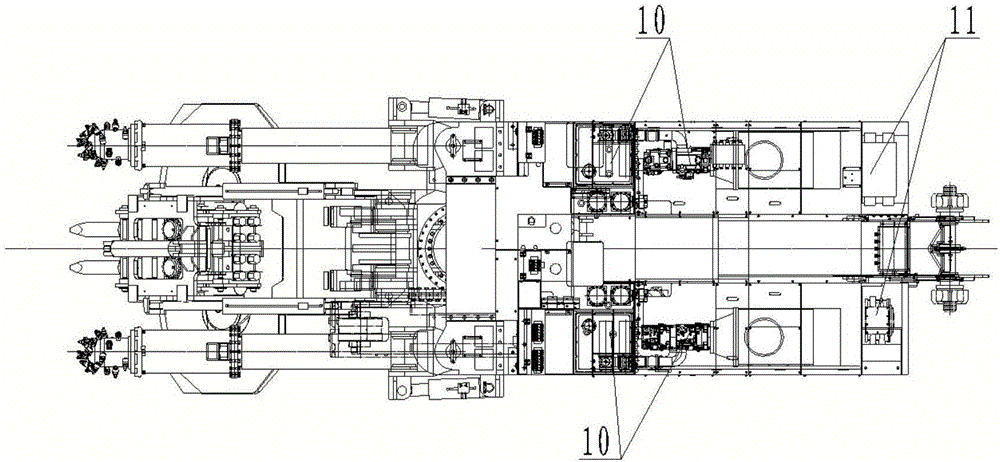

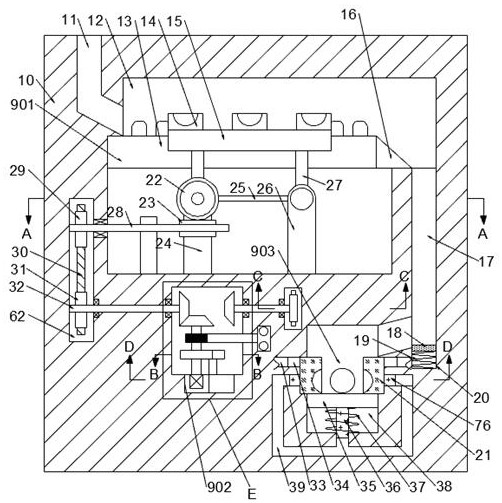

Efficient rapid rock drift tunneller

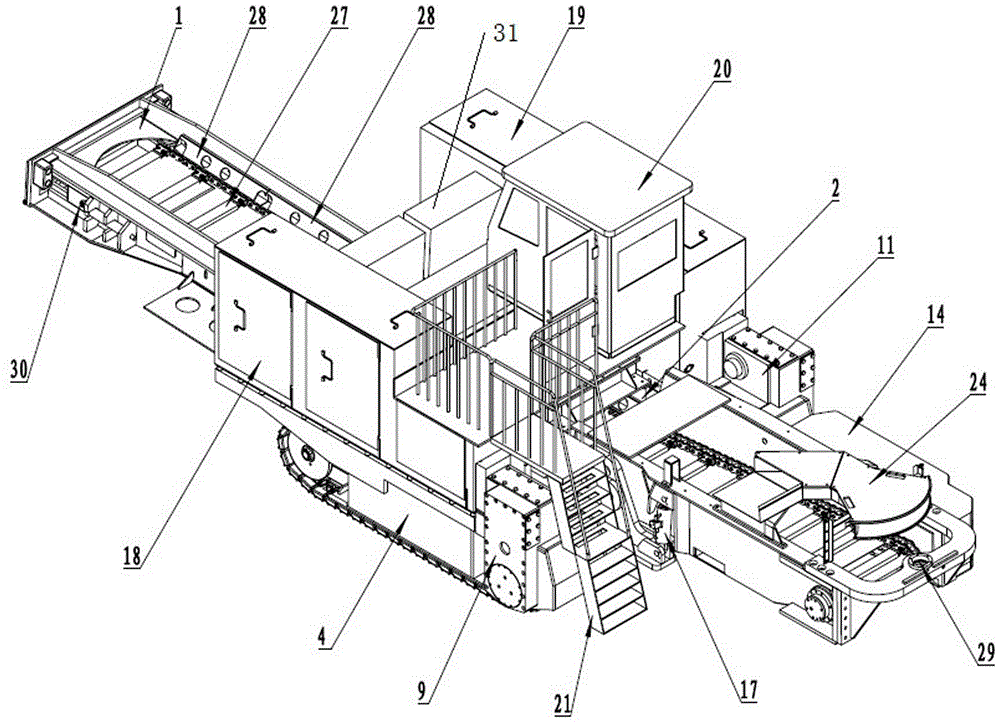

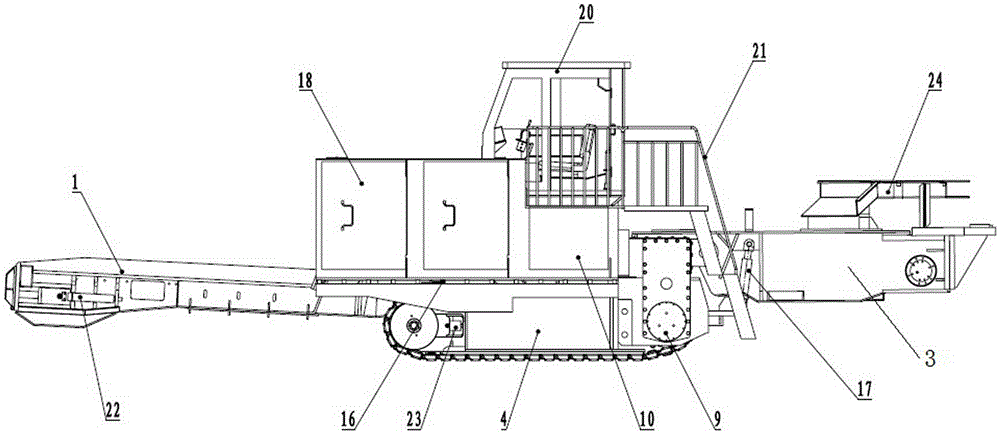

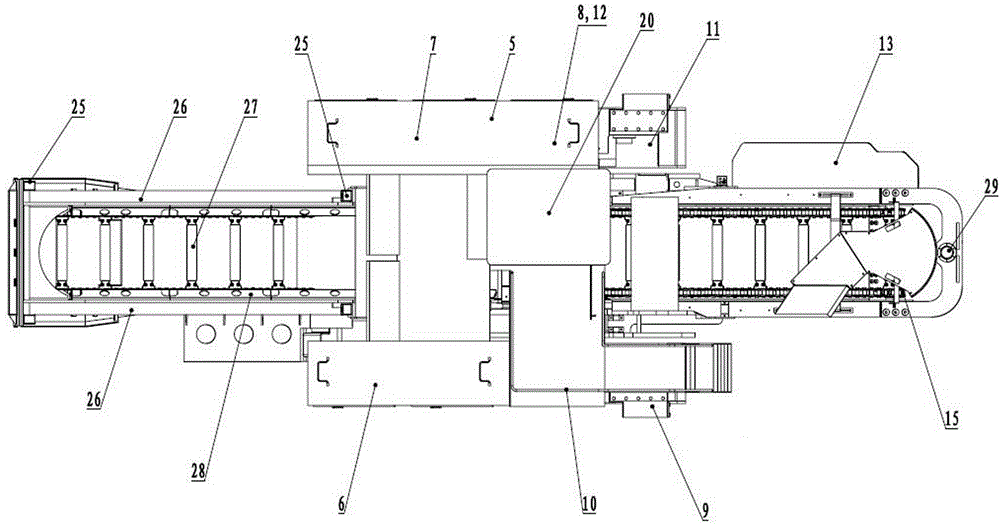

The invention belongs to the technical field of underground coal mine developing equipment, particular relates to an efficient rapid rock drift tunneller, and aims at solving the problems that rock drift tunnelling efficiency is low, rock drift forming is poor, the worker labor intensity is large, and many potential safety hazards exist. The efficient rapid rock drift tunneller comprises a walking part, an insertion board part, two cutting arms, a telescopic part, an engine body part, a control part, a guard board part, a conveying part, a rear support part, two hydraulic systems and electric systems; the walking part is arranged below the engine body part, the insertion board part is hinged to the front end of the engine body part, the telescopic part is arranged in the middle of the upper front portion of the engine body part, the cutting arms are symmetrically arranged on the left side and the right side of the upper front portion of the engine body, the conveying part is arranged in the middle of the engine body part, the rear support part is installed on the rear portion of the engine body, the hydraulic systems are symmetrically arranged on the left side and the right side of the middle of the engine body part, an operating part is installed above the engine body part, the guard board part is fixed on the two sides of the engine body part, and the electric systems are arranged on the two sides of the tail part of the engine body part.

Owner:SHANXI TIAN JU HEAVY IND

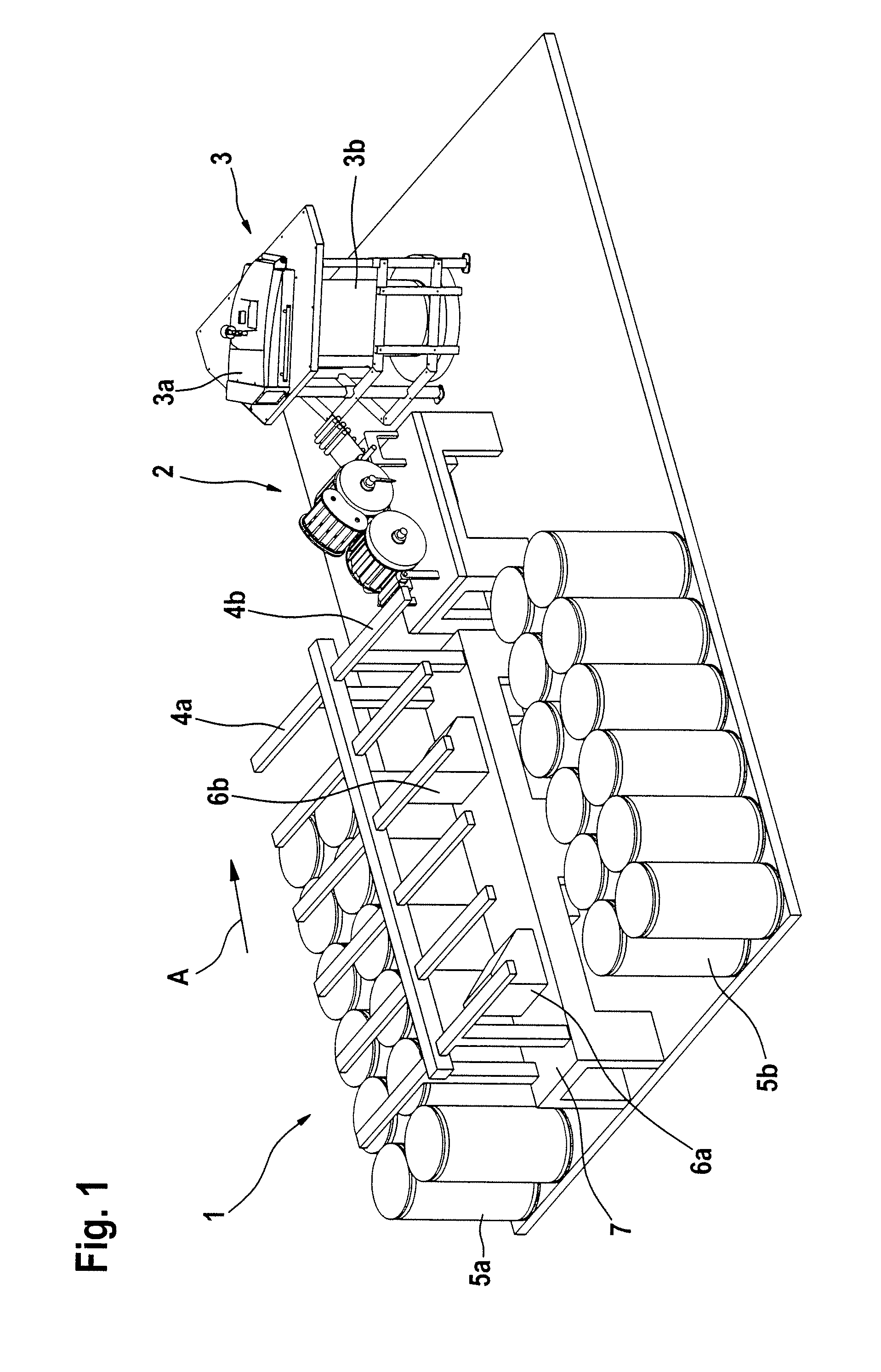

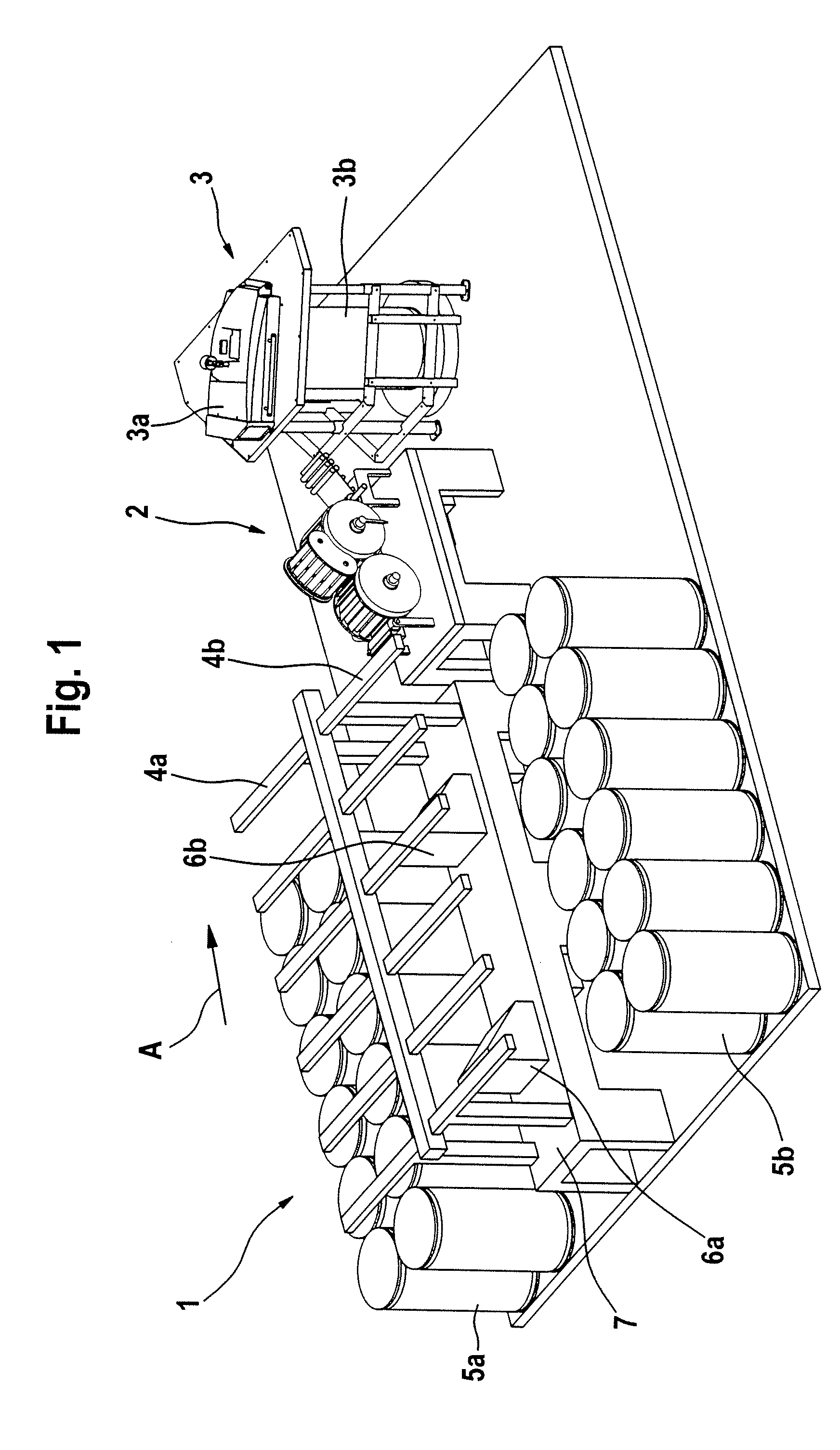

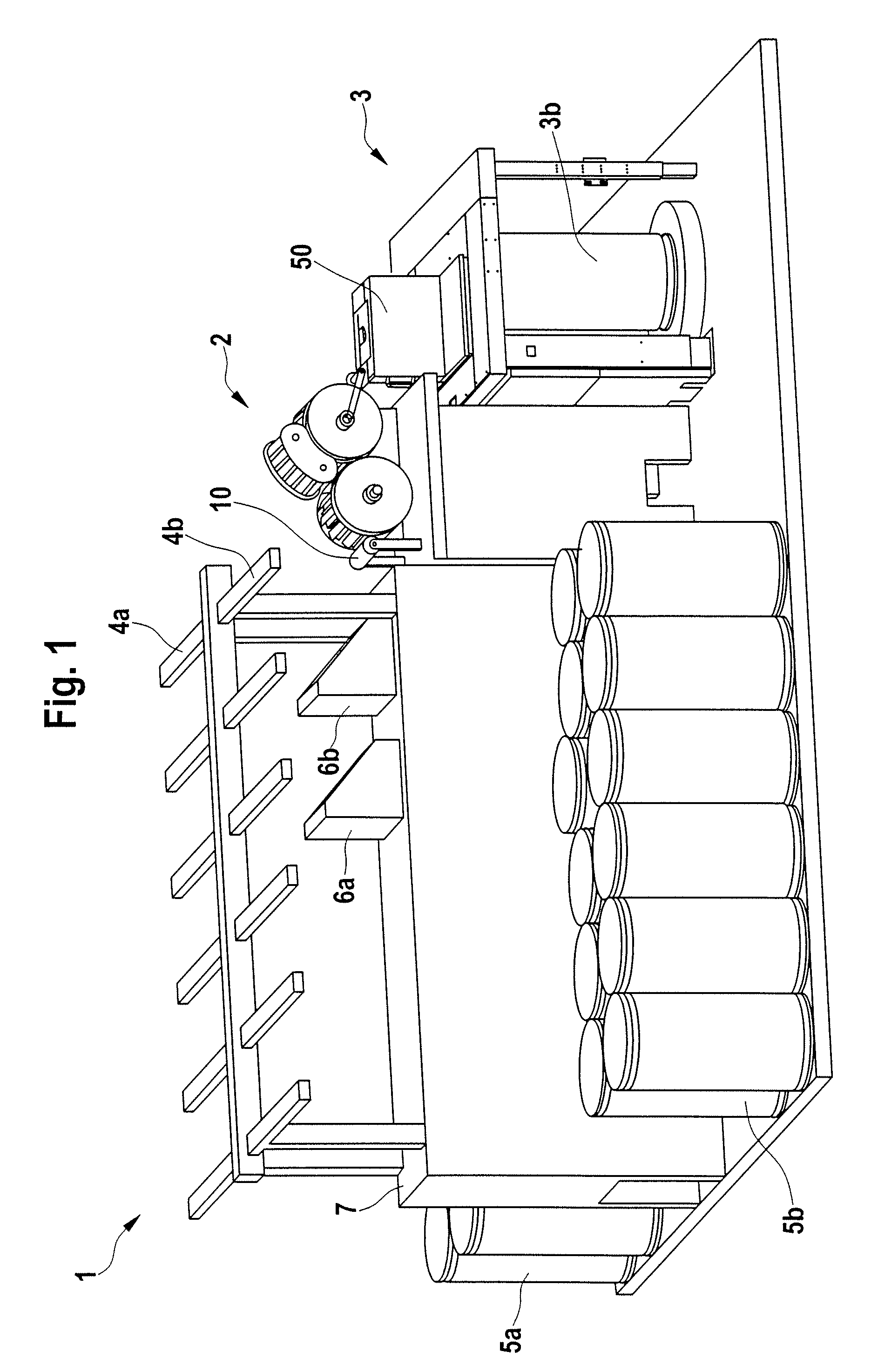

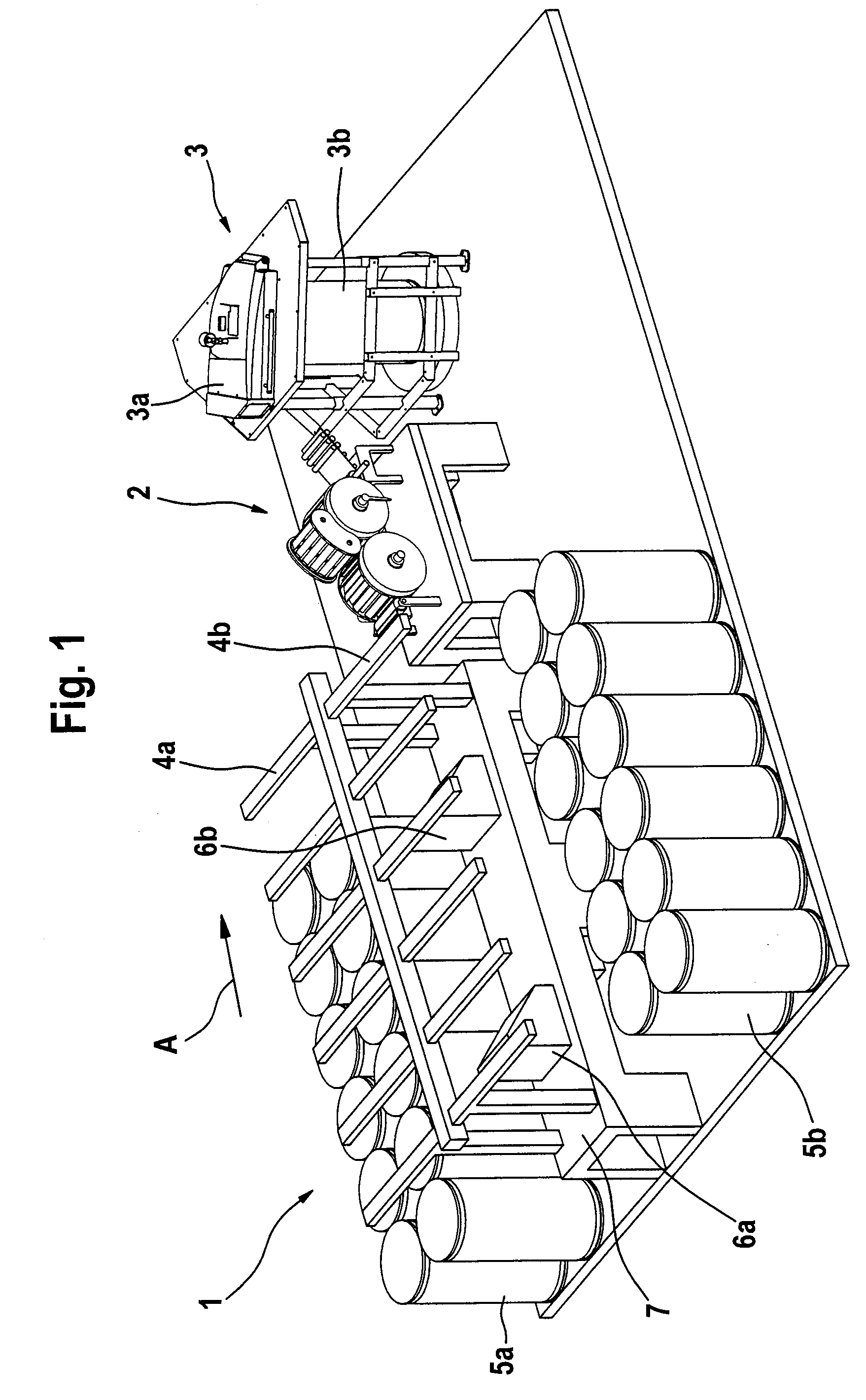

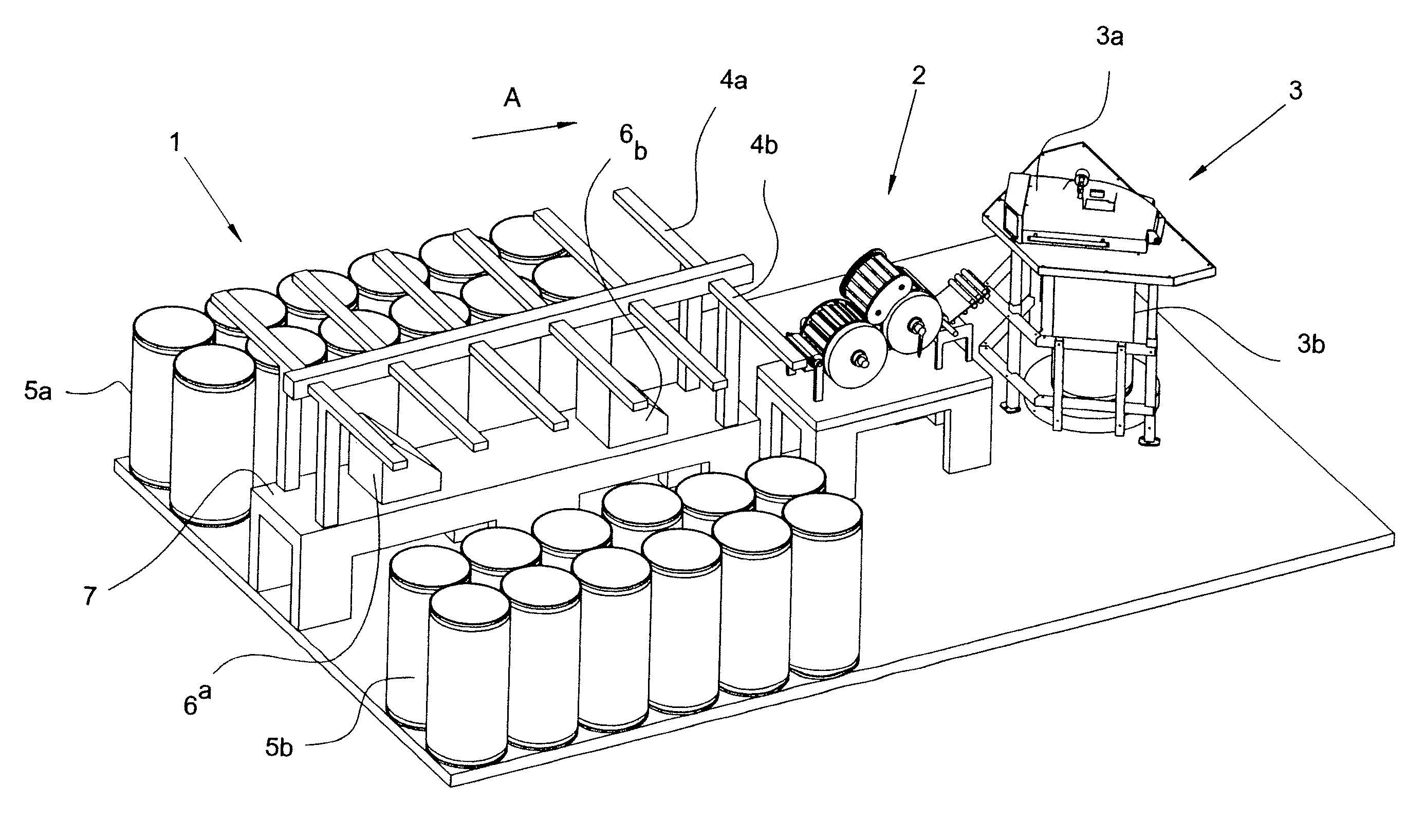

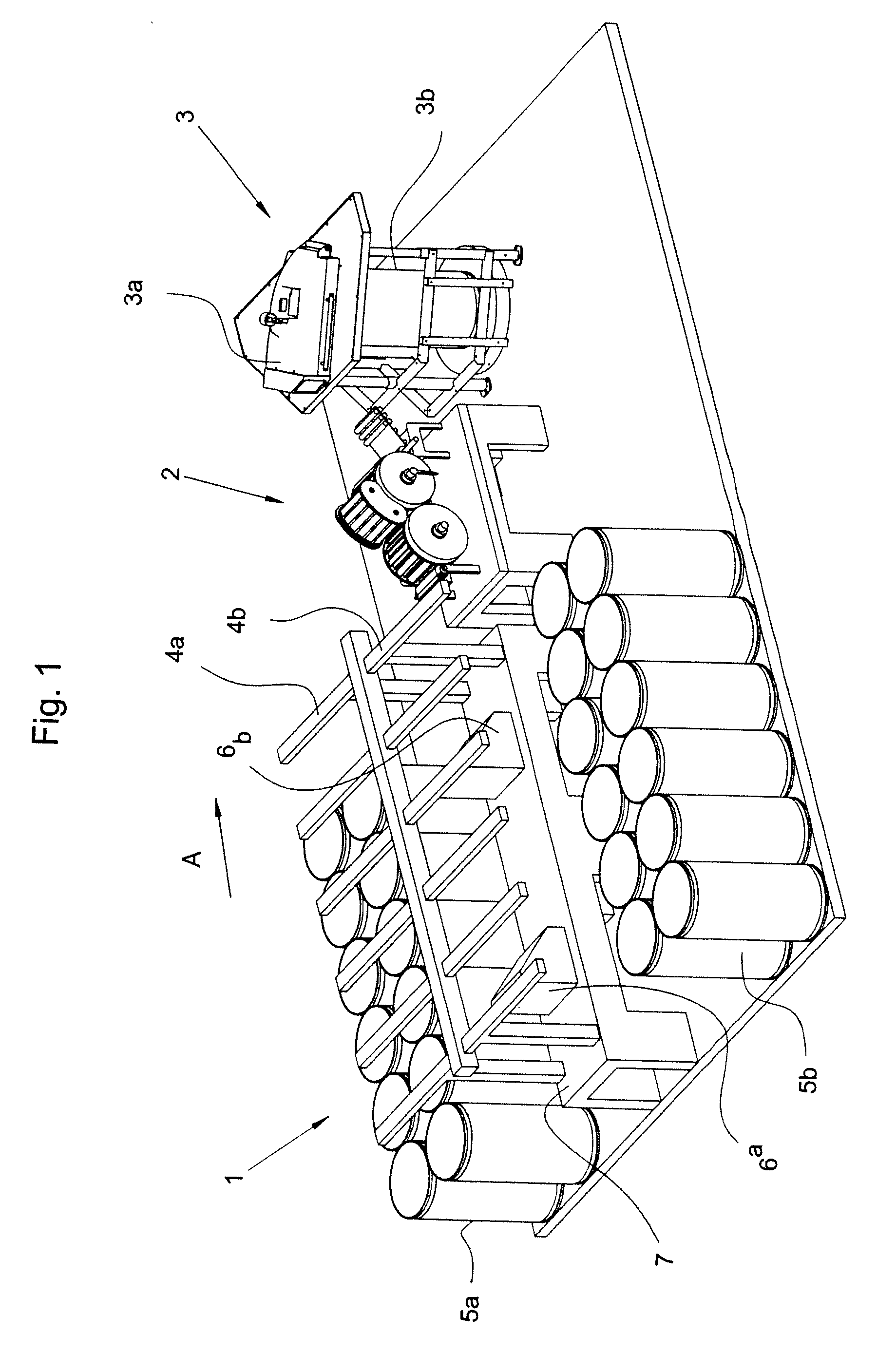

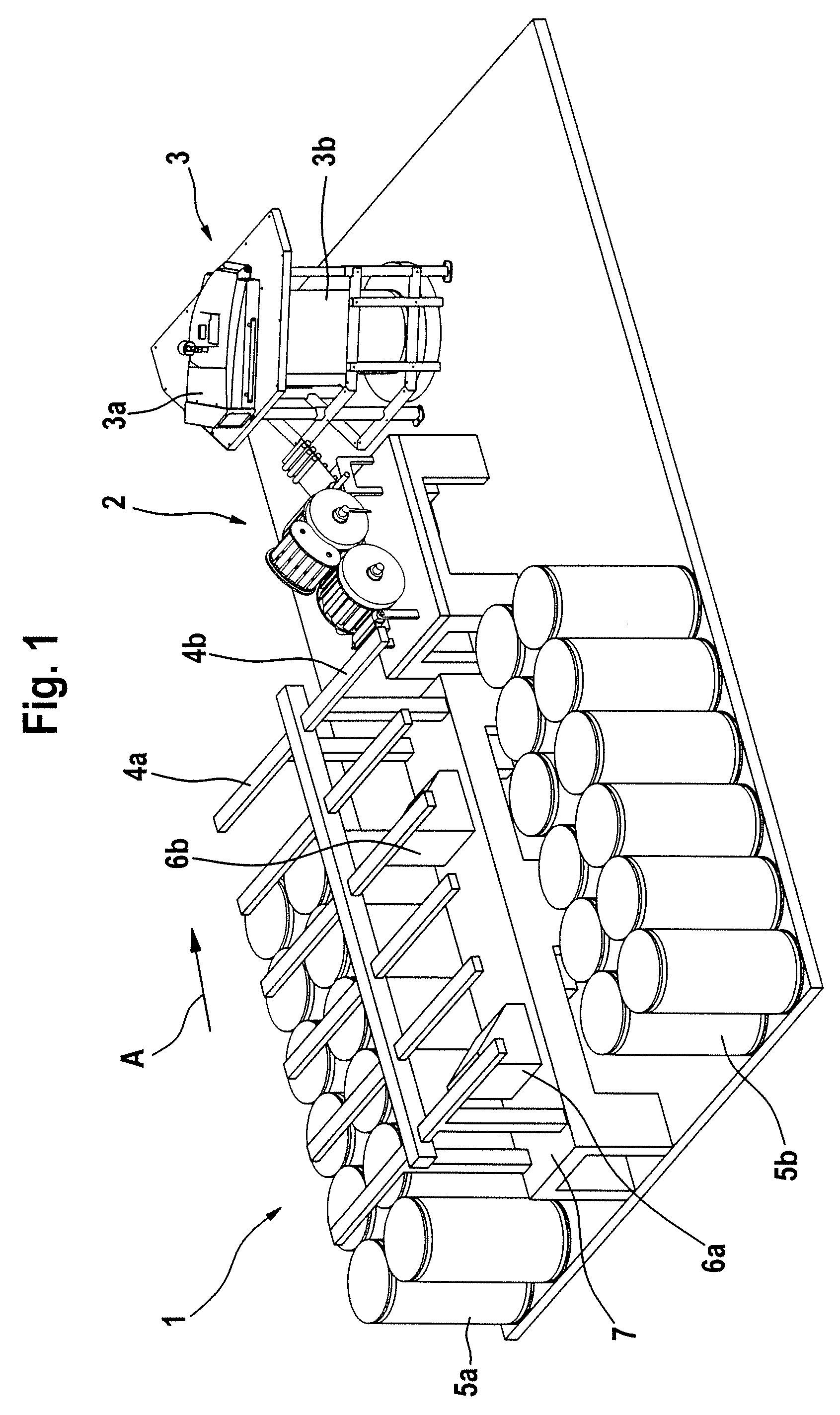

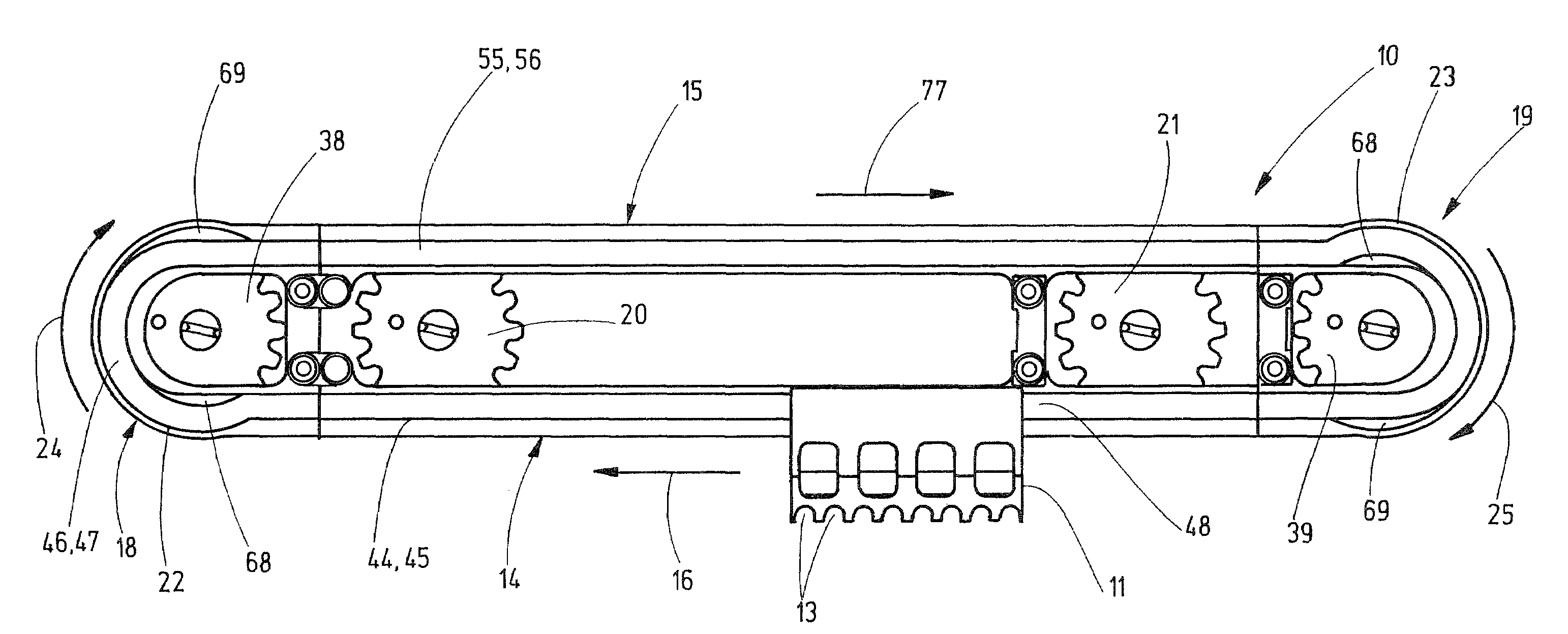

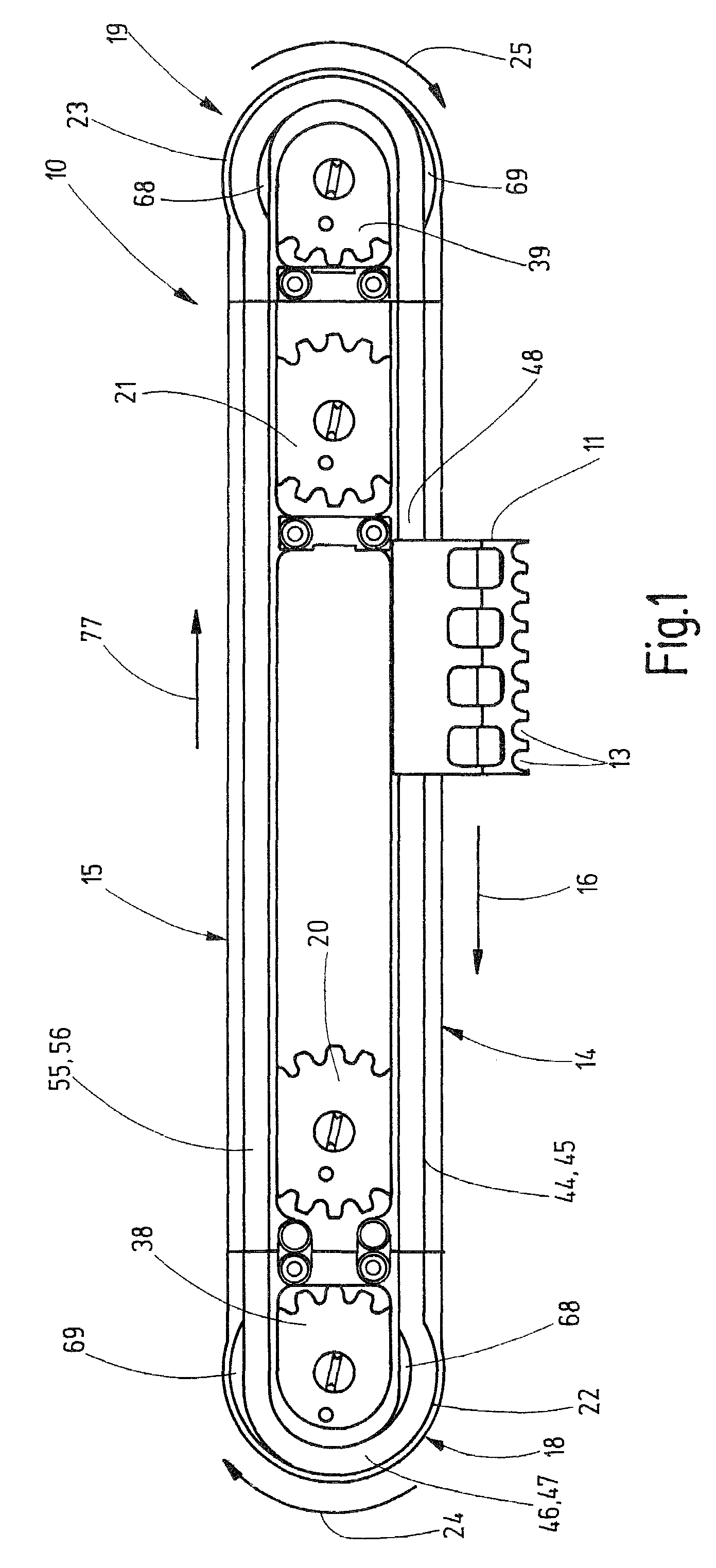

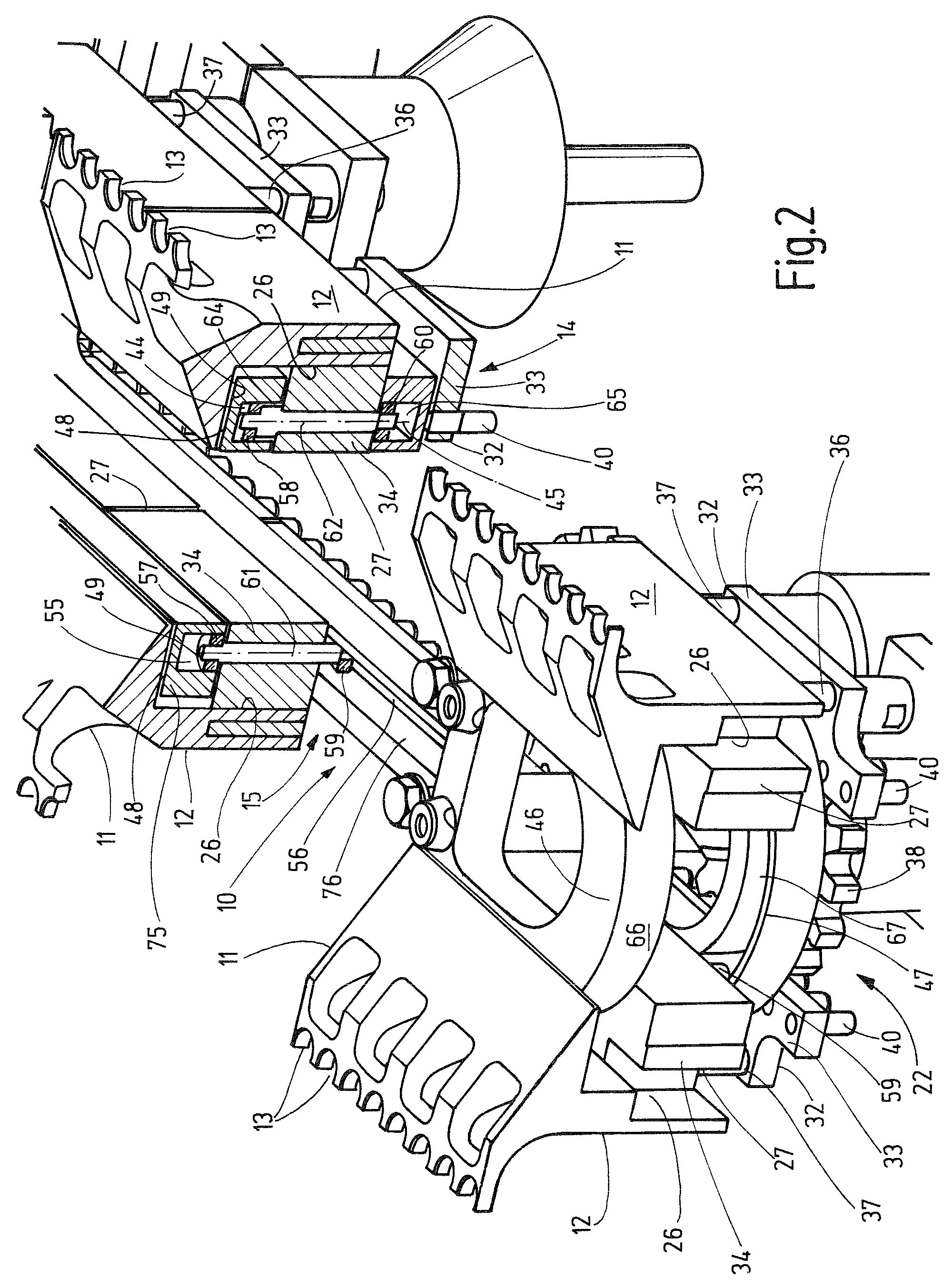

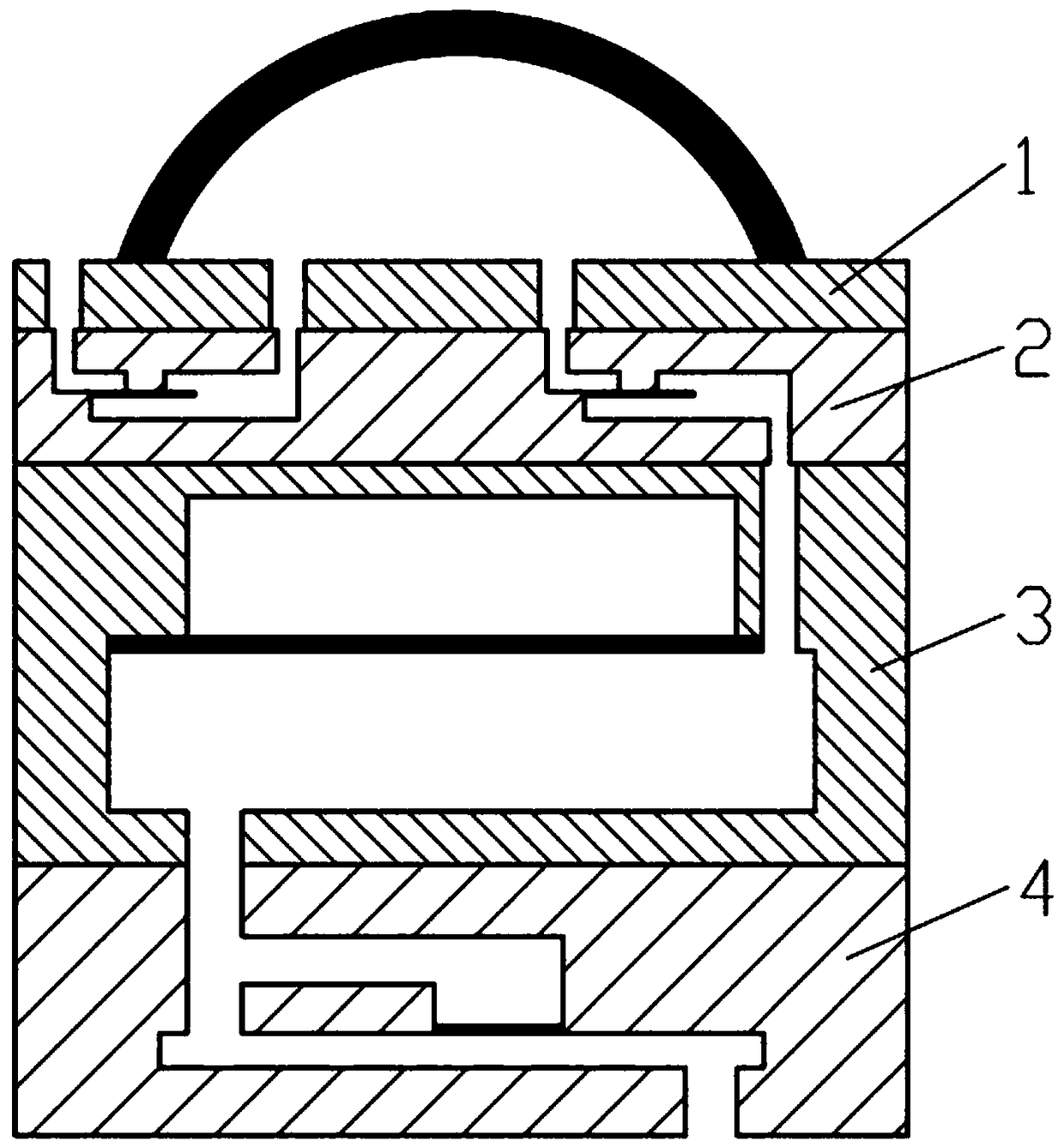

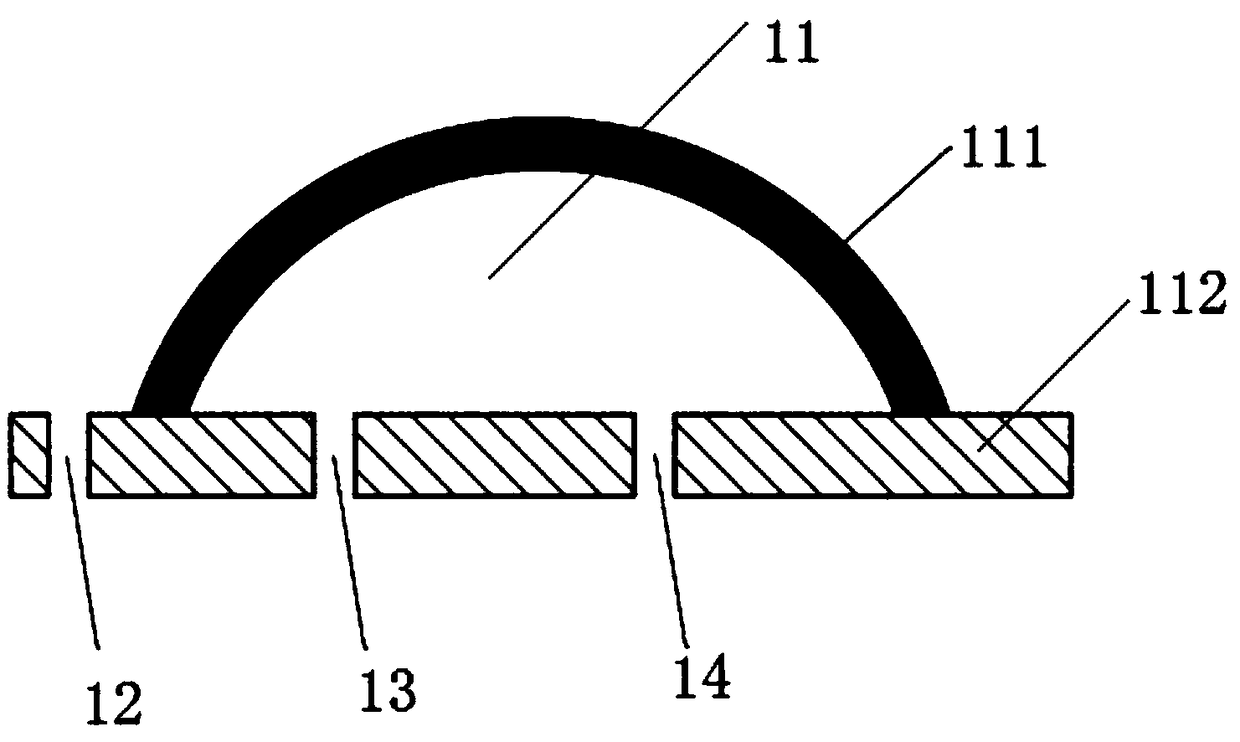

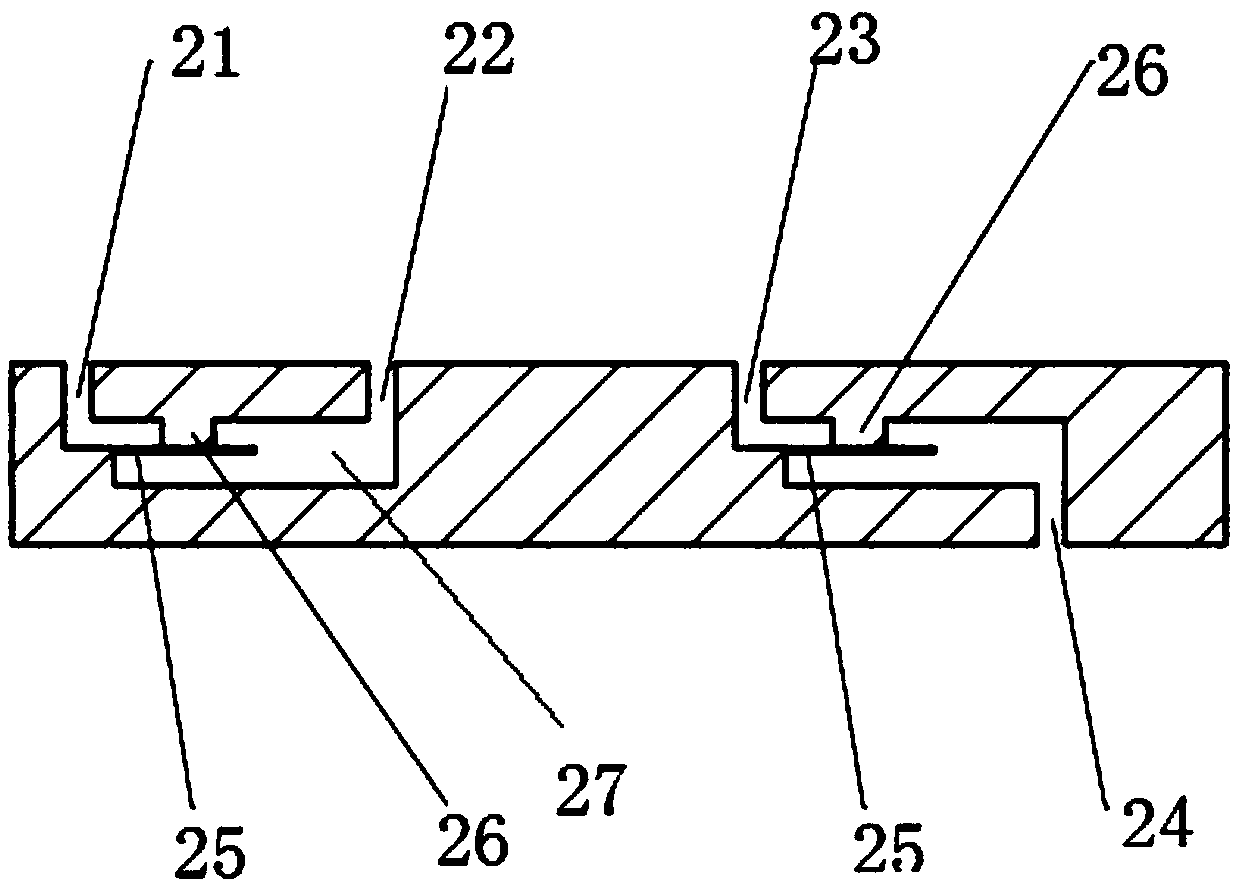

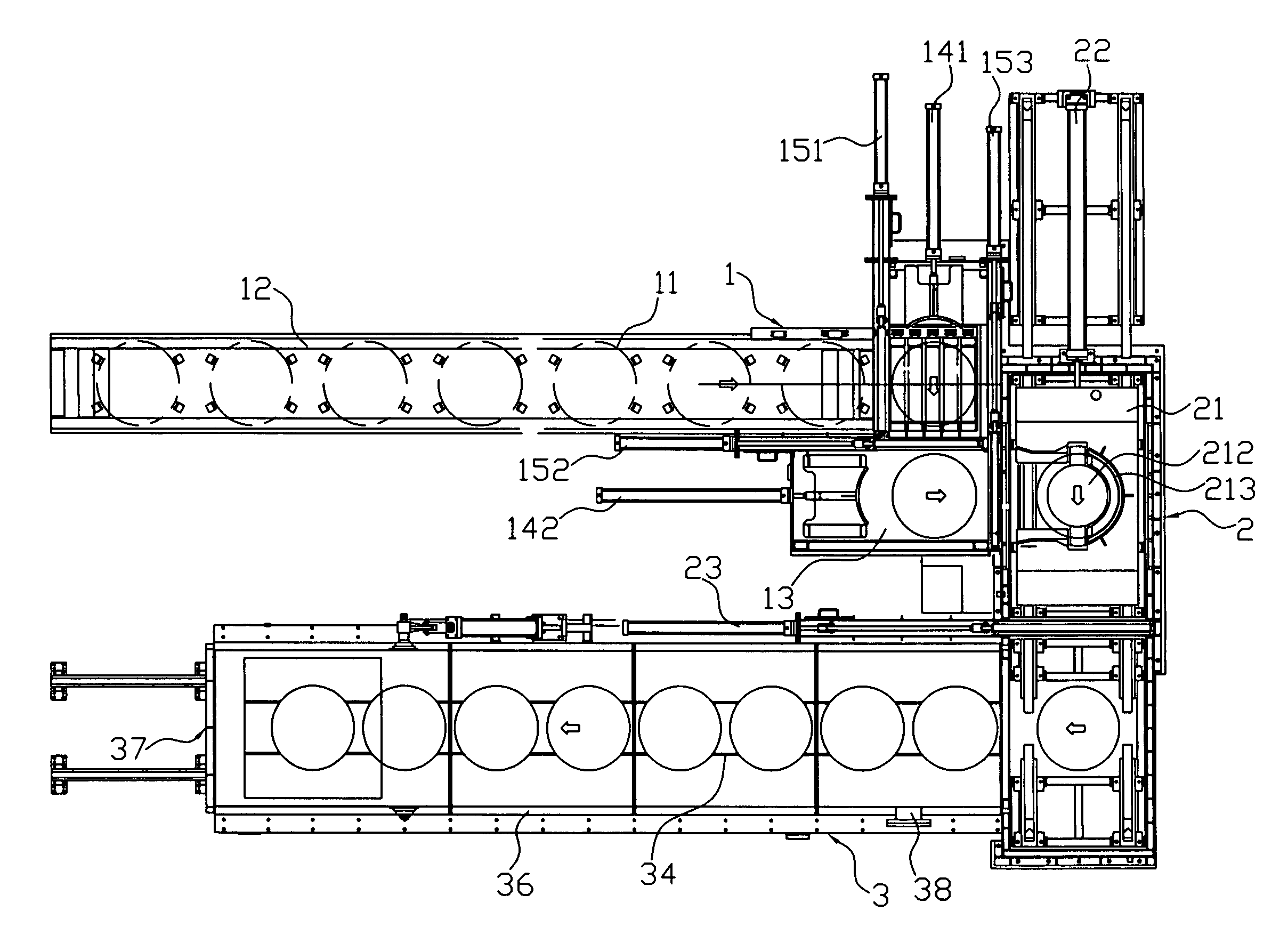

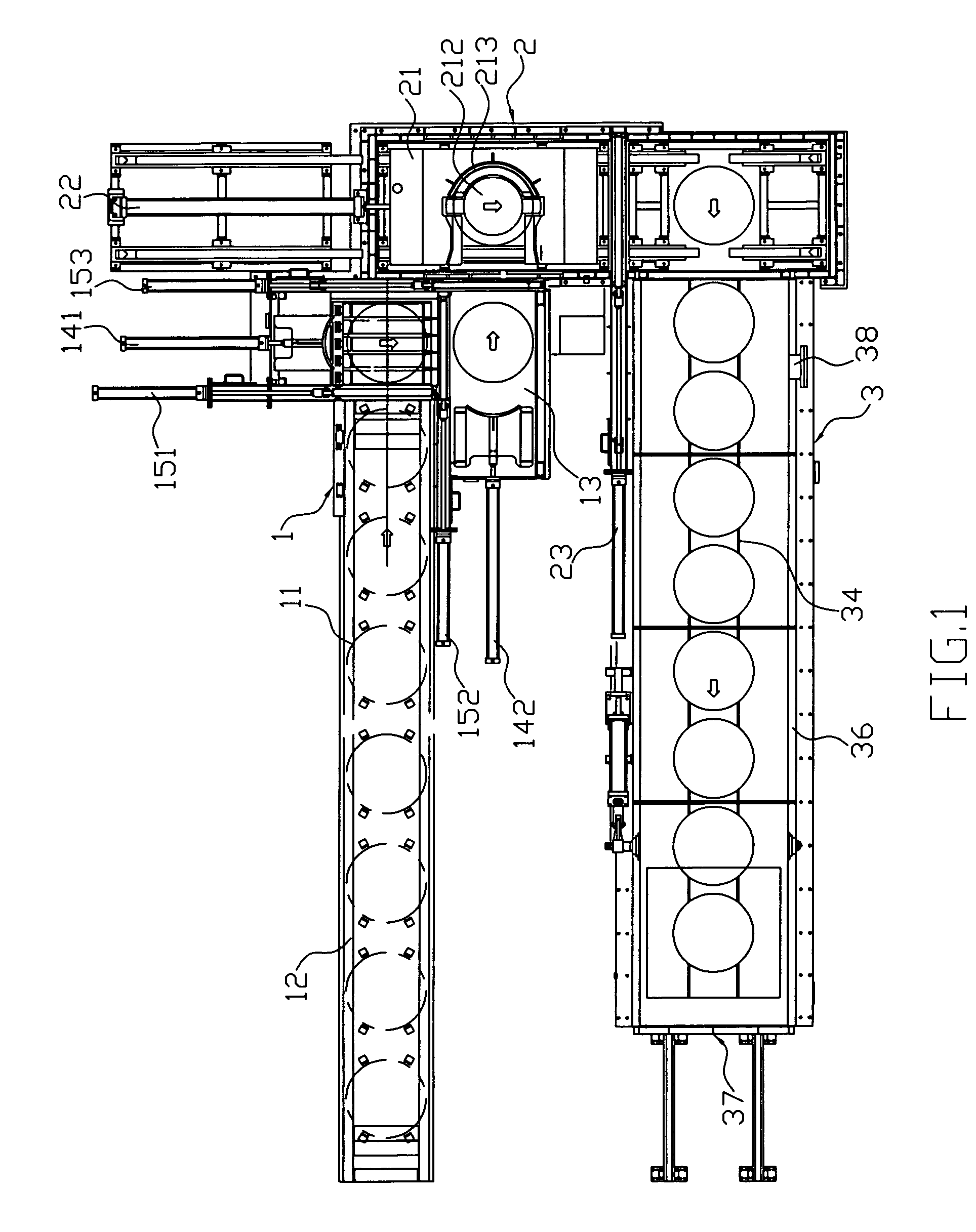

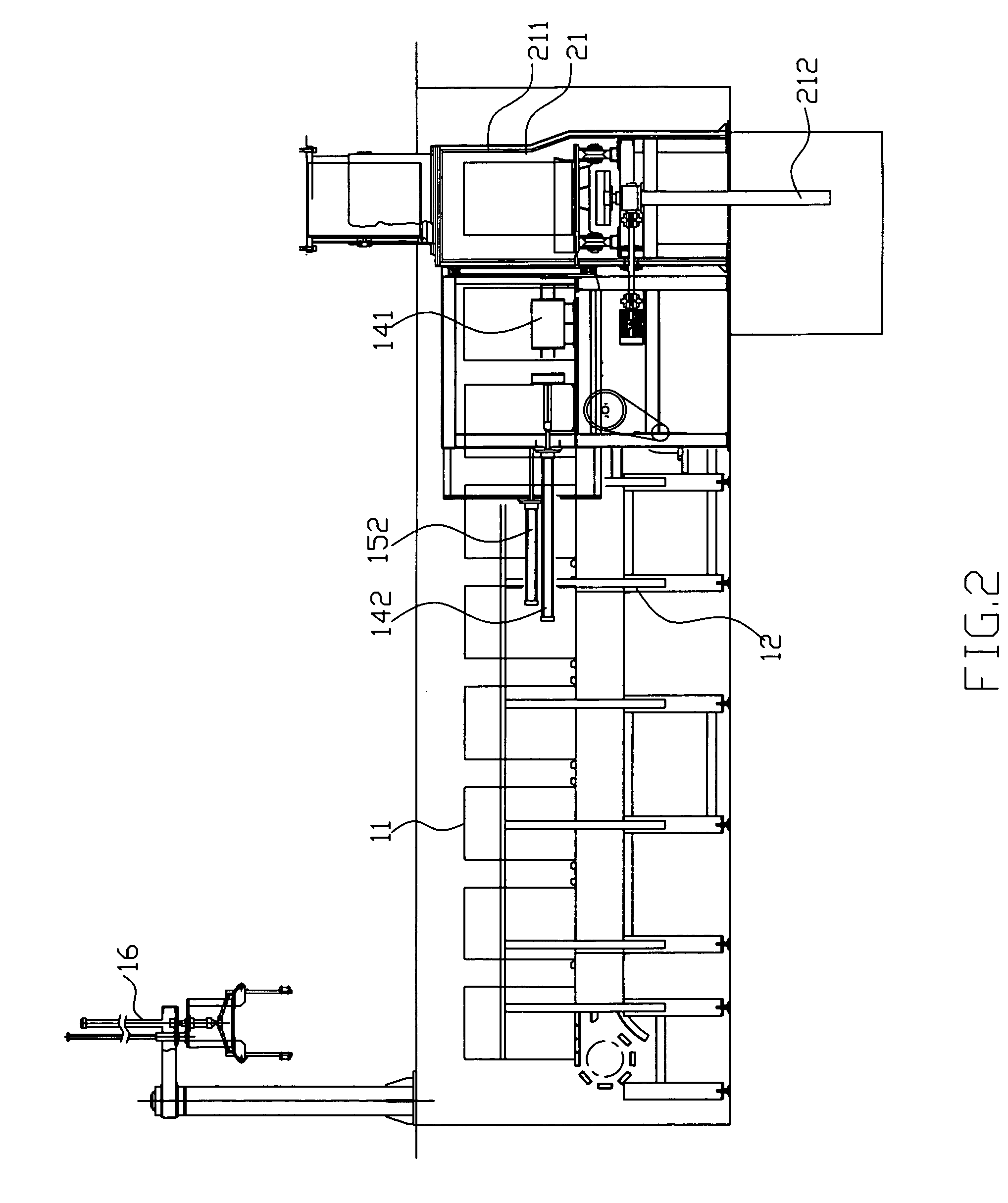

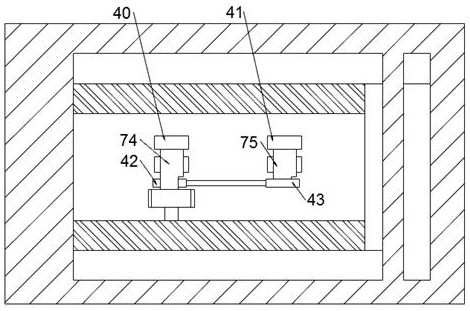

Apparatus for transporting containers to at least one processing station

An apparatus for transporting containers to at least one processing station, in particular a filling and / or sealing station, having a number of container carriers that accommodate the containers and having two parallel guides spaced apart from each other and extending in the transverse direction, which are used for the advance and return of the container carriers and have turnaround devices at their ends that perform the function of switching the container carriers from one guide into the other guide; pinions are also provided for transporting the container carriers and are situated between the guides and engage the container carriers. The turnaround devices each have arc guides that adjoin the ends of the two guides and are connected to them and that also transition in the arc from one guide to the other guide.

Owner:GRONINGER

Pneumatic precision micropump

ActiveCN109351367ADrive precisionEasy to controlLaboratory glasswaresFluid controllersAtmospheric airEngineering

The invention relates to a pneumatic precision micropump, which comprises a pneumatic module, a check valve group, a liquid storage module and a flow regulation module. The pneumatic module comprisesan air bag; the check valve group comprises a first check valve and a second check valve, an inlet of the first check valve is communicated with the external atmosphere while an outlet is communicatedwith the air bag, and an inlet of the second check valve is communicated with the air bag while an outlet is communicated with the liquid storage module; the liquid storage module comprises a cavityand a liquid storage pool, the cavity and the liquid storage pool are spaced through a first elastic diaphragm, the cavity is a closed cavity, and the liquid storage pool is connected with the air bagthrough the second check valve; the flow regulation module comprises a first flow passage and a second flow passage, the first flow passage and the second flow passage are both communicated with theliquid storage pool, an outlet of the first flow passage is closed, an outlet of the second flow passage is communicated with the outside of the flow regulation module, and the first flow passage andthe second flow passage are spaced through a second elastic diaphragm. The pneumatic precision micropump has advantages of low starting pressure, stability in fluid delivery, small size, easiness in integration and the like, and microfluid stable driving and control demands are met.

Owner:HOHAI UNIV CHANGZHOU

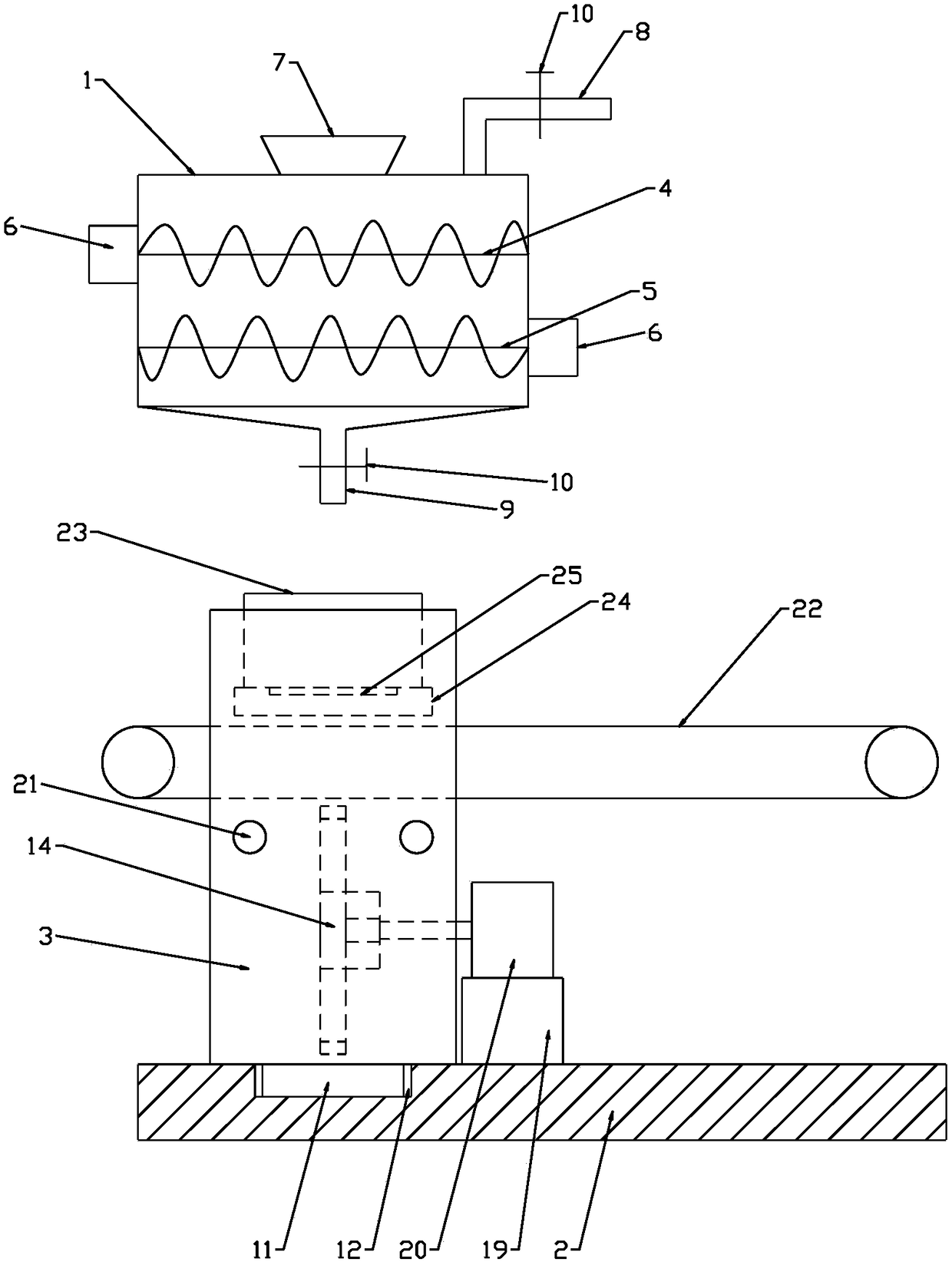

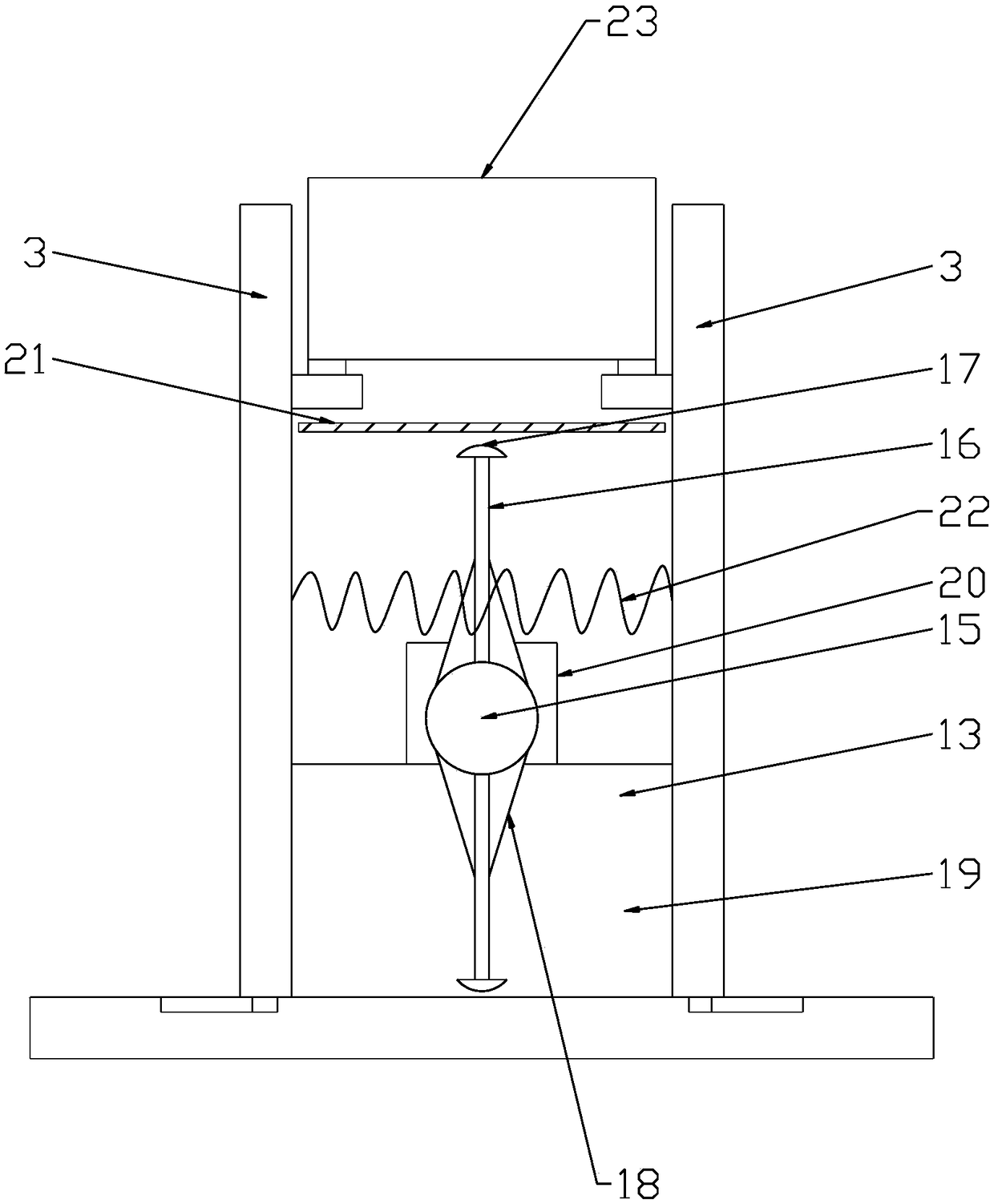

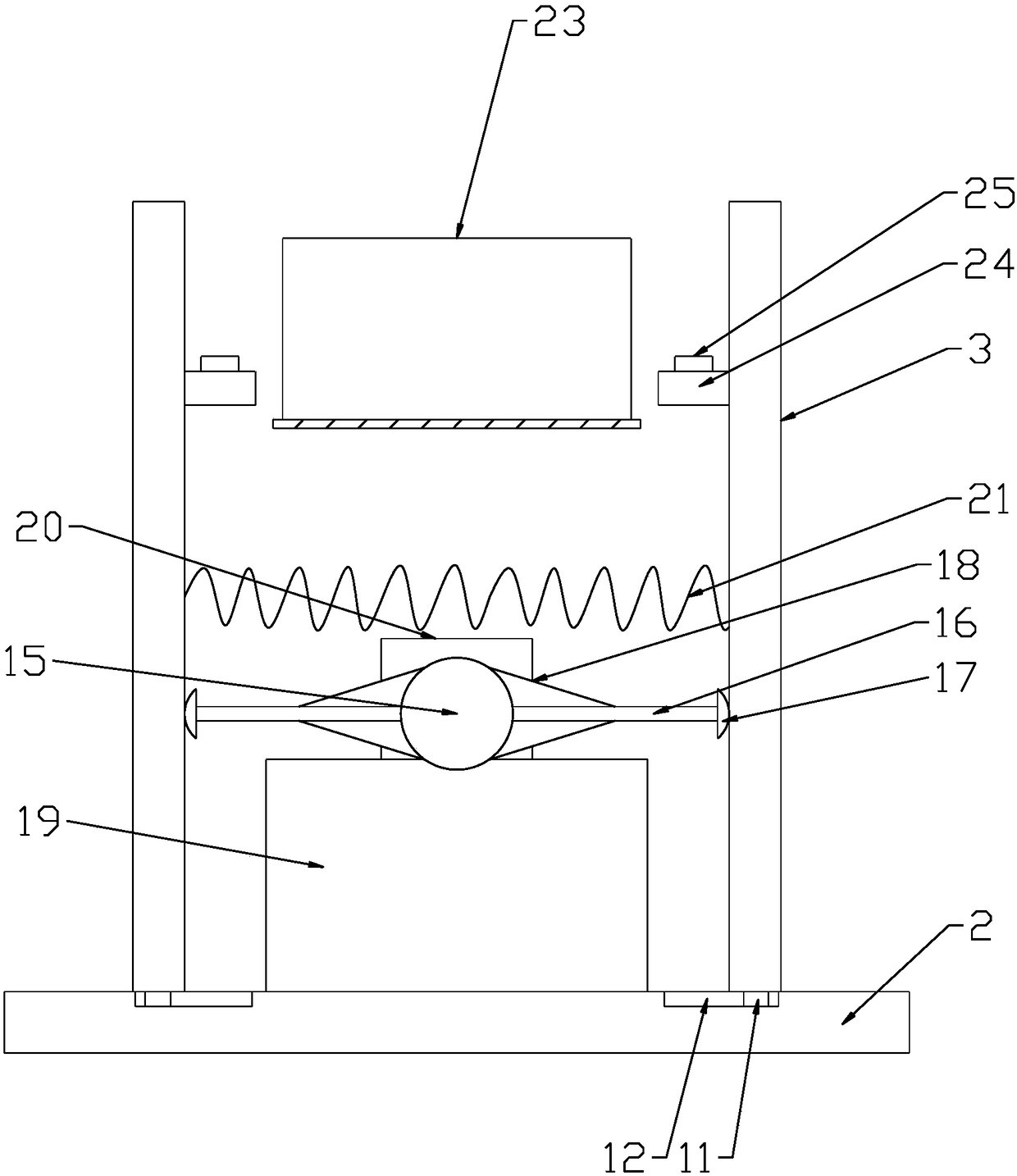

Quantative conveying equipment for fertilizer production

PendingCN108945657AImprove Quantitative Output EfficiencyStir wellSolid materialBiochemical engineeringElectric machinery

The invention relates to the technical field of fertilizer production, in particular to quantative conveying equipment for fertilizer production. The quantative conveying equipment for fertilizer production comprises a stirring box, a base, two supporting plates and a transmitting device. The quantative conveying equipment for fertilizer production is characterized in that a spiral stirring rod Iand a spiral stirring rod II are horizontally arranged in the stirring box, the spiral stirring rod I is arranged above the spiral stirring rod II, both the spiral stirring rod I and the spiral stirring rod II are connected to a motor I, the motor I is arranged on the stirring box, a main material port and an adding pipe are arranged at the upper end of the stirring box, the main material port isfunnel-shaped, and a discharge pipe is arranged on the lower part of the stirring box; the base is located below the stirring box, and the two supporting plates are symmetrically arranged in the widthdirection of the base. The quantative conveying equipment for fertilizer production adopting the technical scheme provided by the invention can solve the problem that a stirred and mixed fertilizer finished product is output in a quantative manner and is conveyed to the next working procedure by way of a conveyor belt and is high in degree of automation, and the production efficiency of the fertilizer is improved.

Owner:四川施邦威生物科技发展有限公司

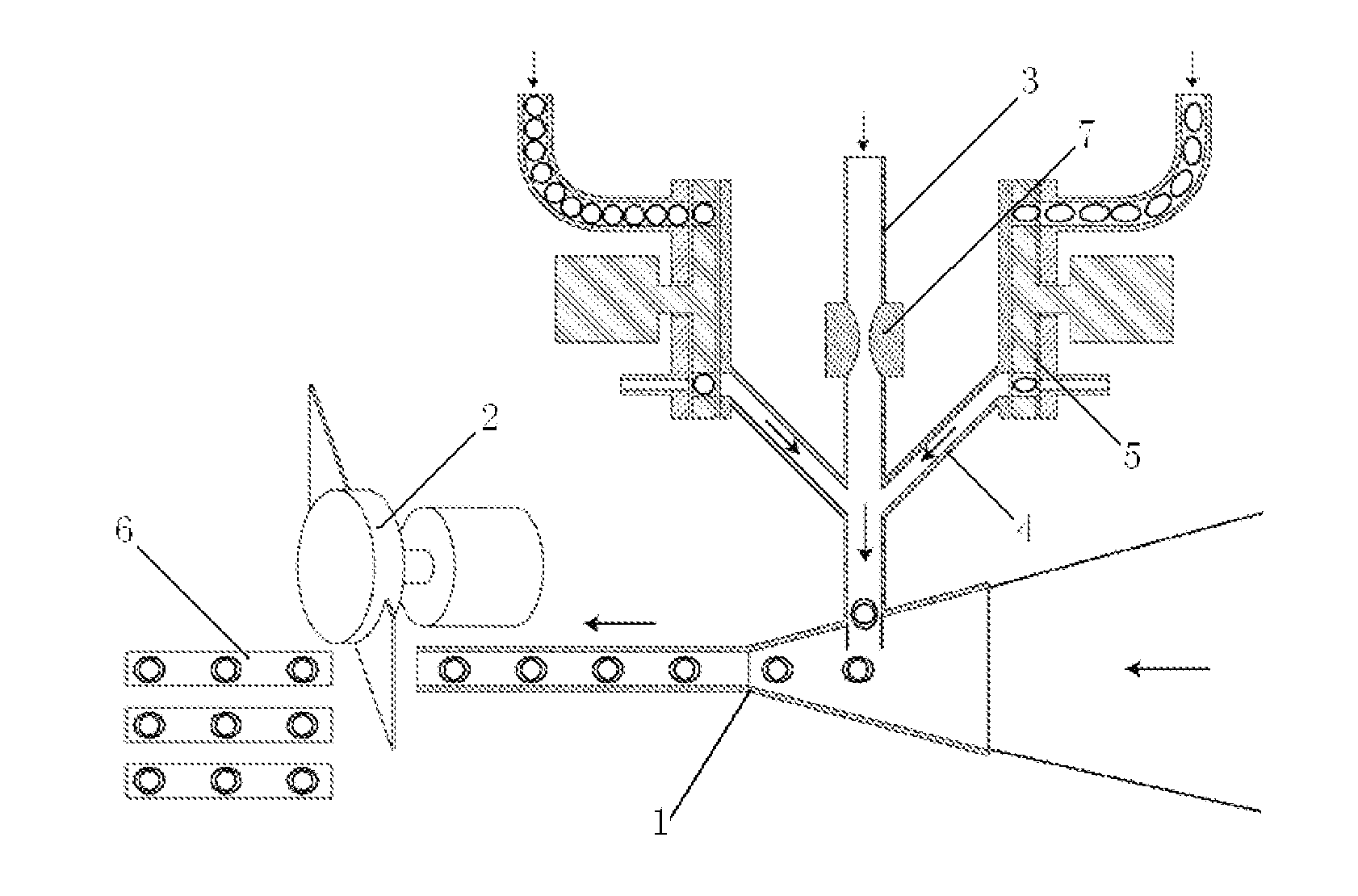

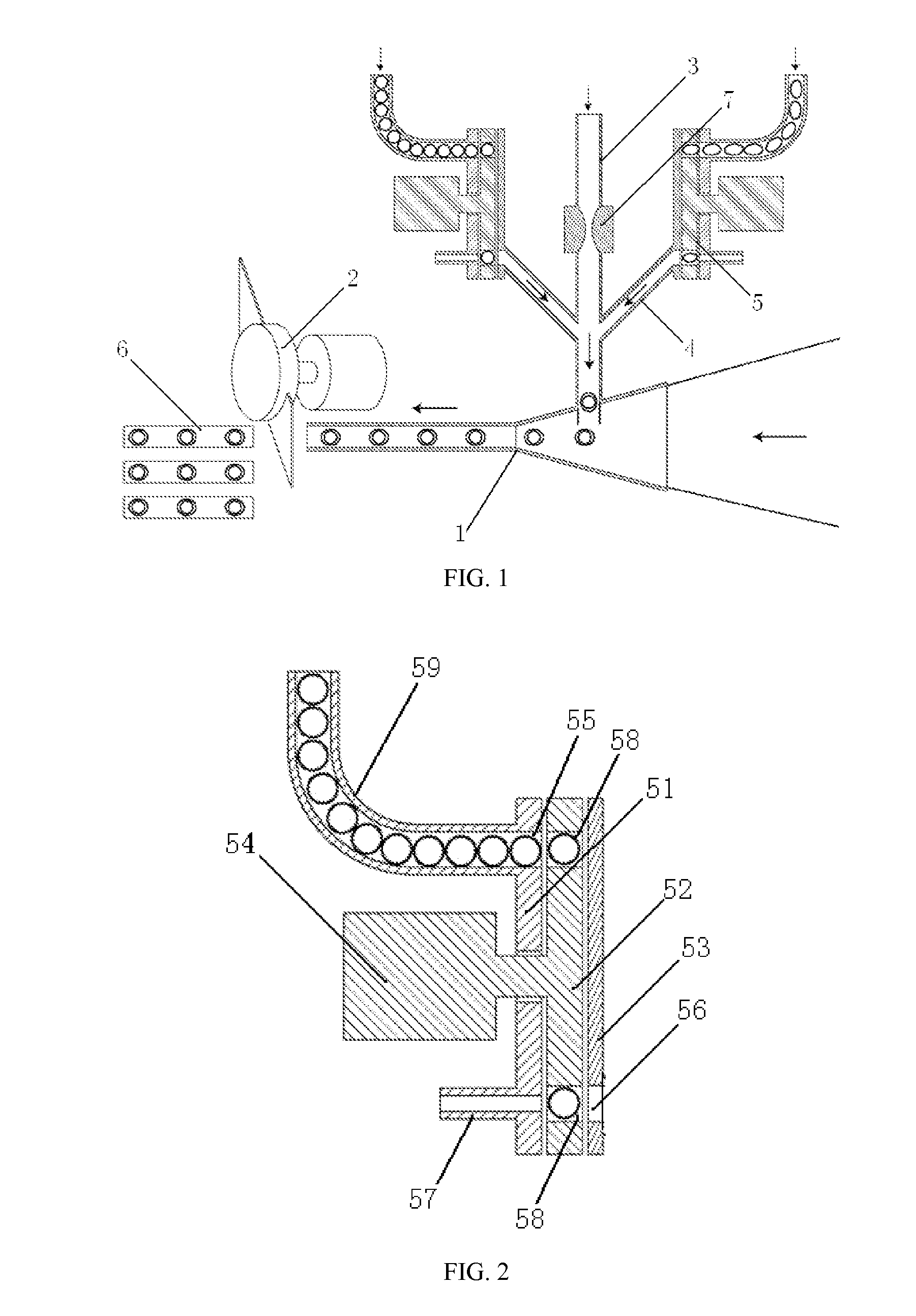

Mehod and device for forming cigarette filter rod

ActiveUS20150148207A1Increase speedImprove accuracy and uniformityPaper/cardboard wound articlesCigarette manufactureProcess engineeringCigarette filter

A method and device for forming a cigarette filter rod. The method is as follows: in a process of continuously conveying forward cigarette filter materials that tend to converge to have a rod shape, multiple granular additives are continuously output in accordance with a certain time interval, and are sprayed into the cigarette filter materials that converge forwards under the action of continuous transporting flows, so that after the cigarette filter materials converge to form a continuous filter rod, multiple groups of additive unit combinations formed of different granular additive units are embedded in an axial direction of the filter rod. With the method and device for forming a cigarette filter rod, a filter rod containing multiple granular additives can be formed in one step; multiple granular additives can be combined and arranged in any way along an axial direction of the filter rod; dosage positions and intervals of various granular additives can be adjusted and changed randomly; a production process is simplified and the production cost is reduced.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

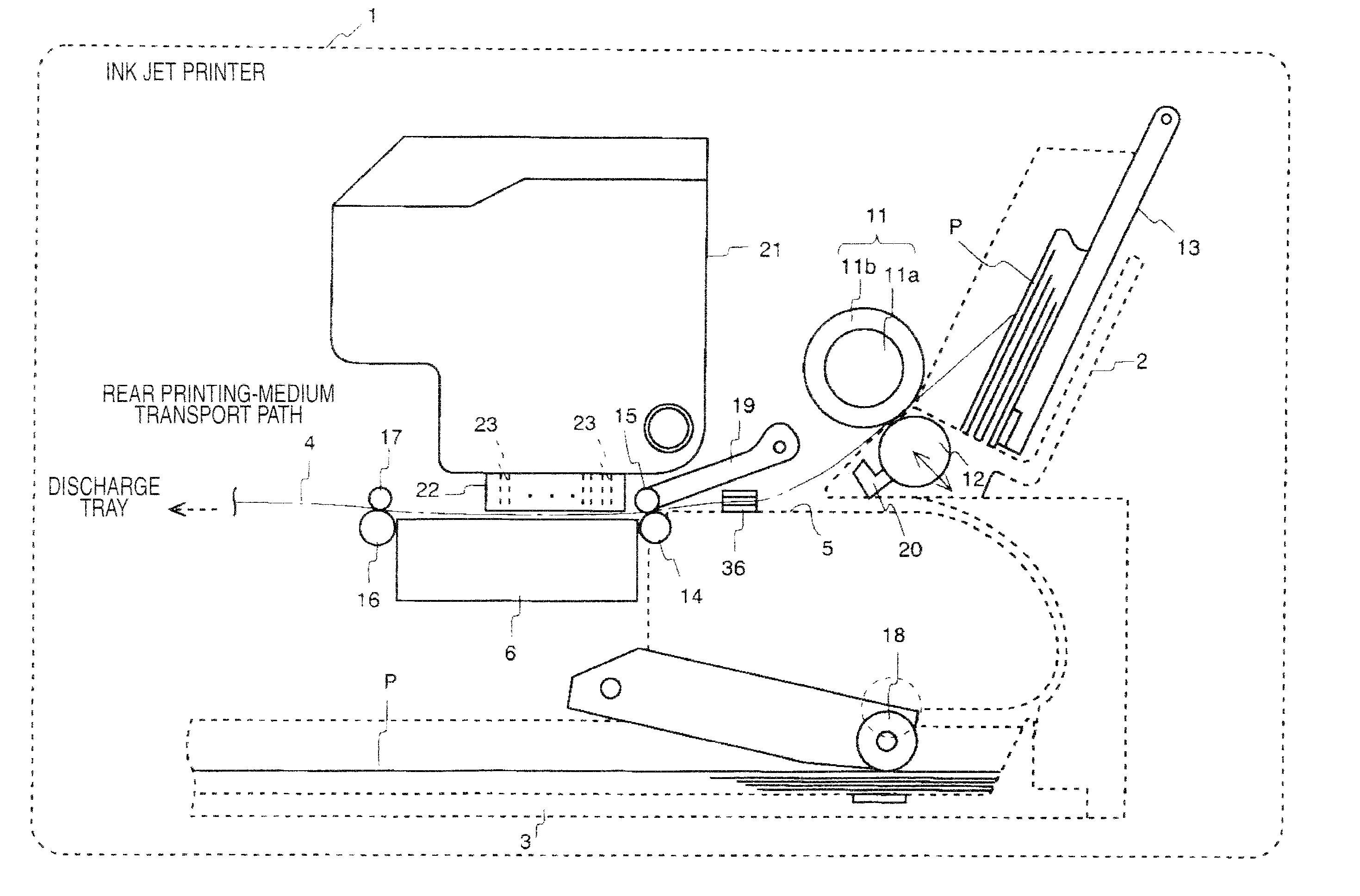

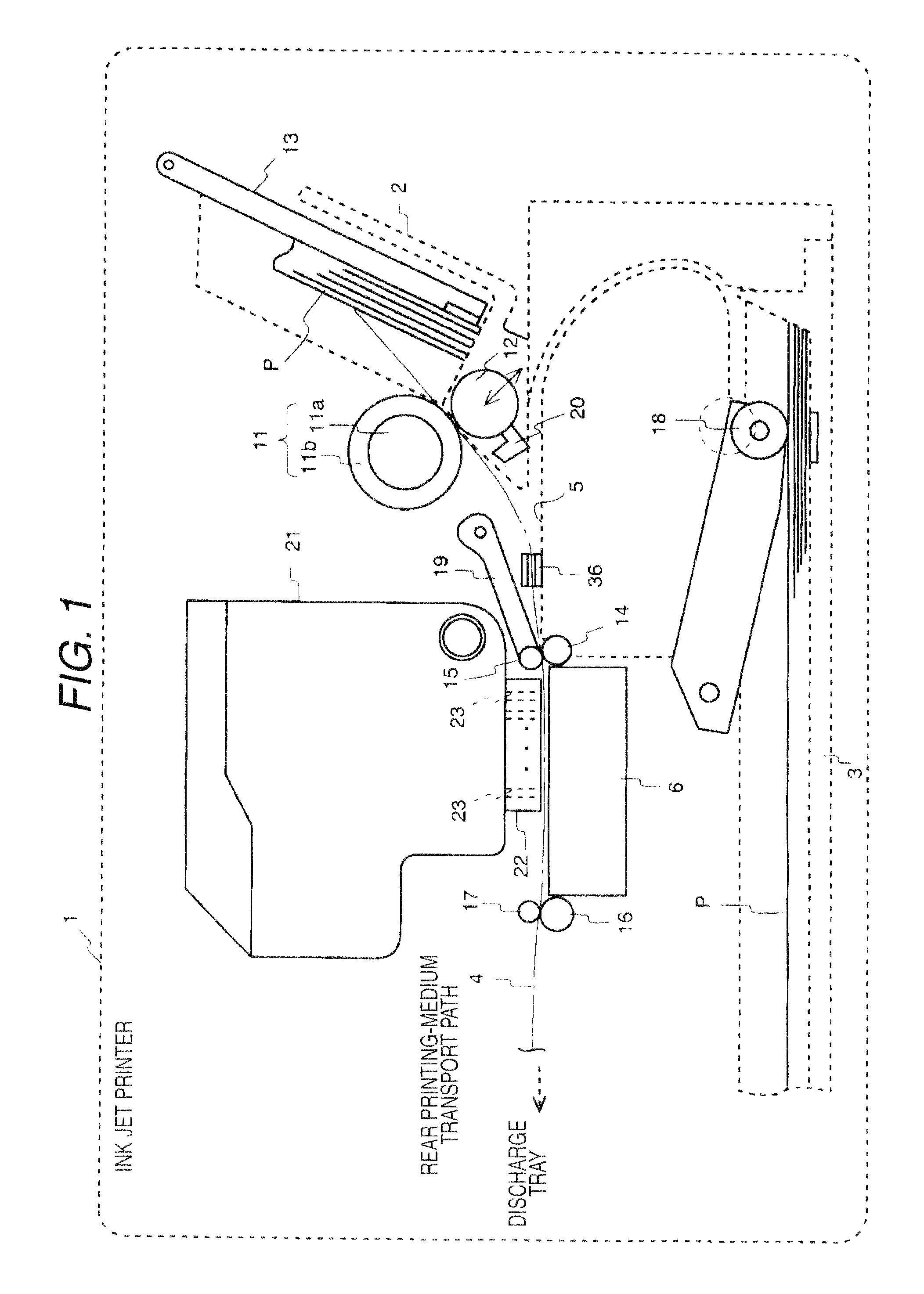

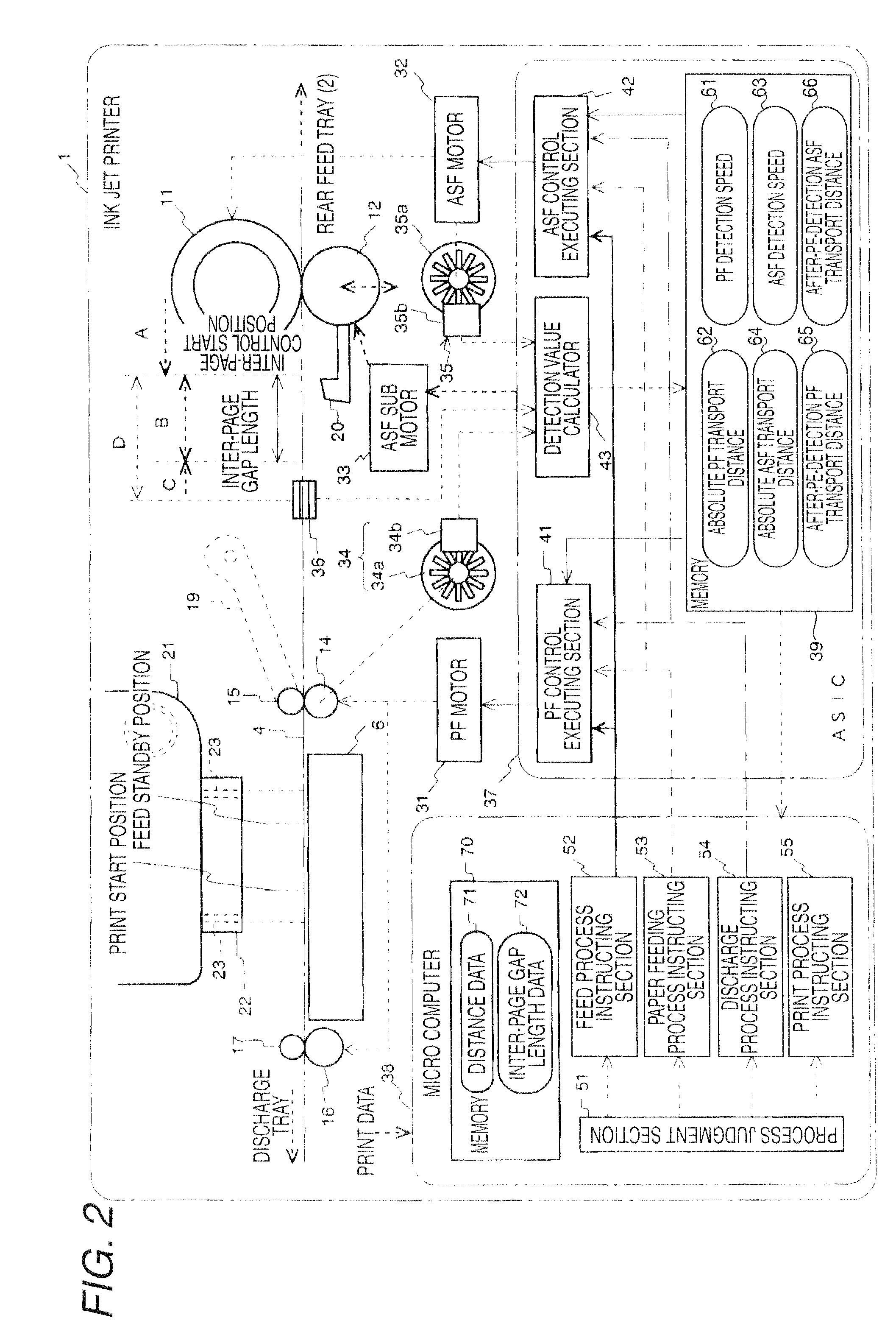

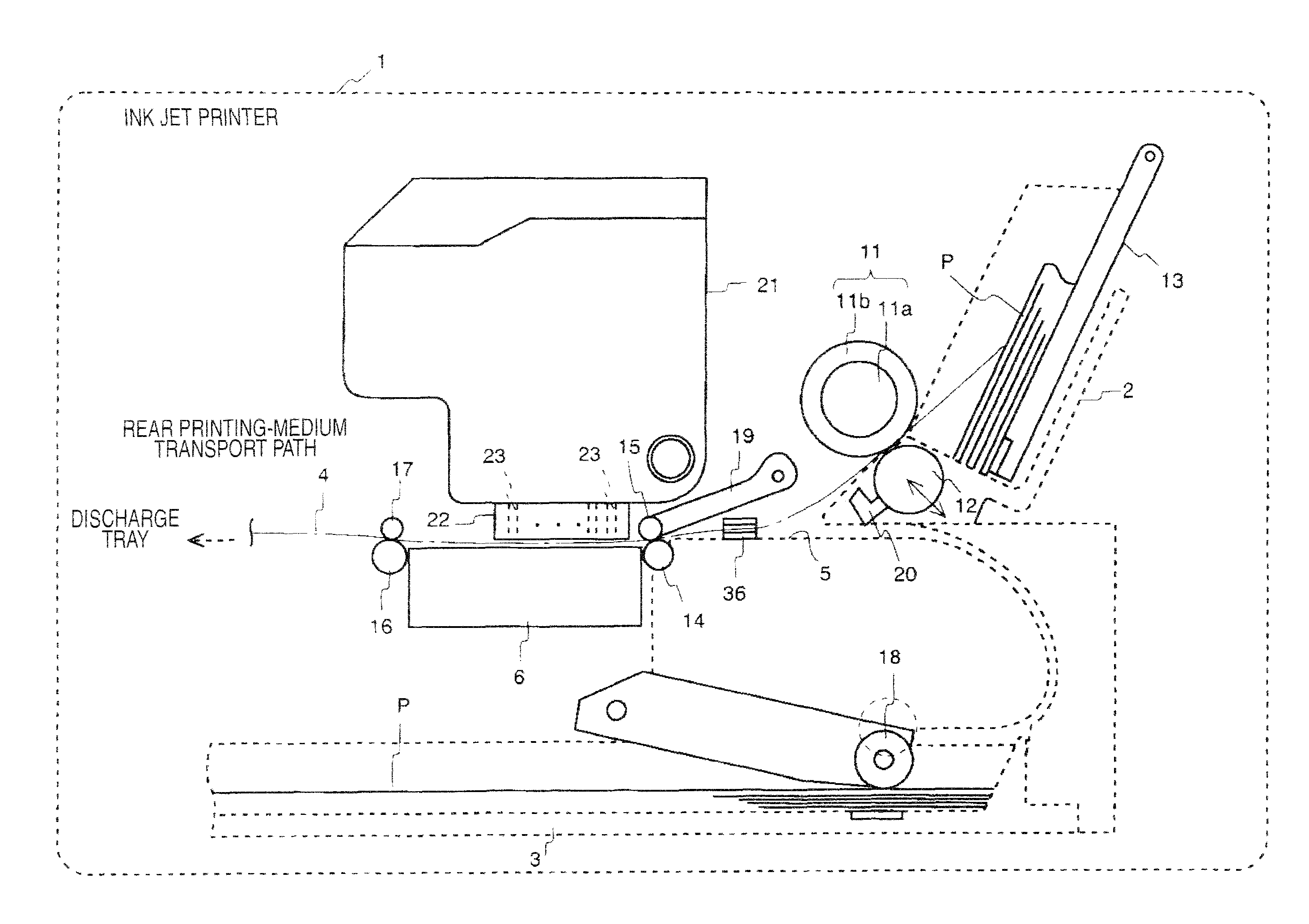

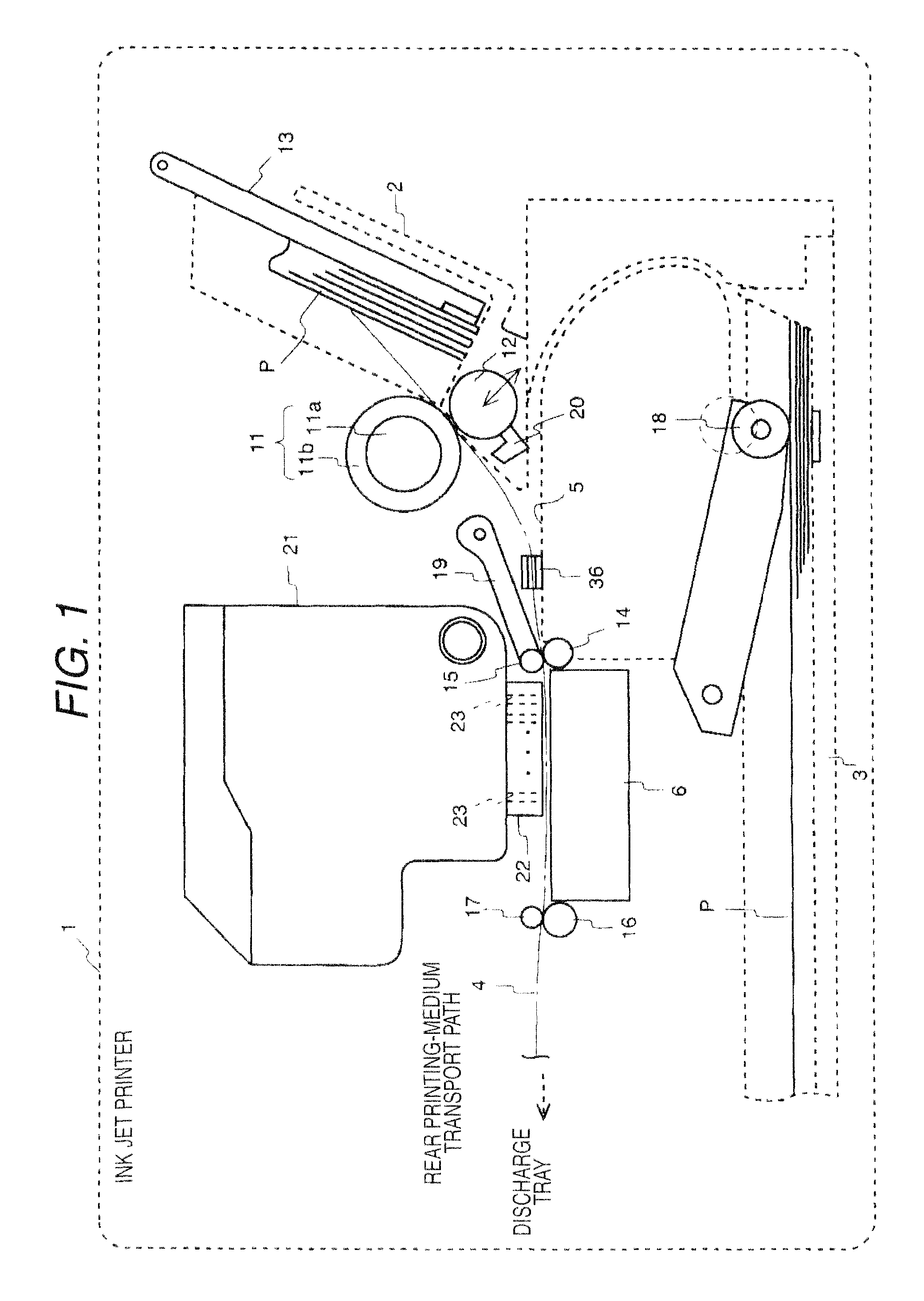

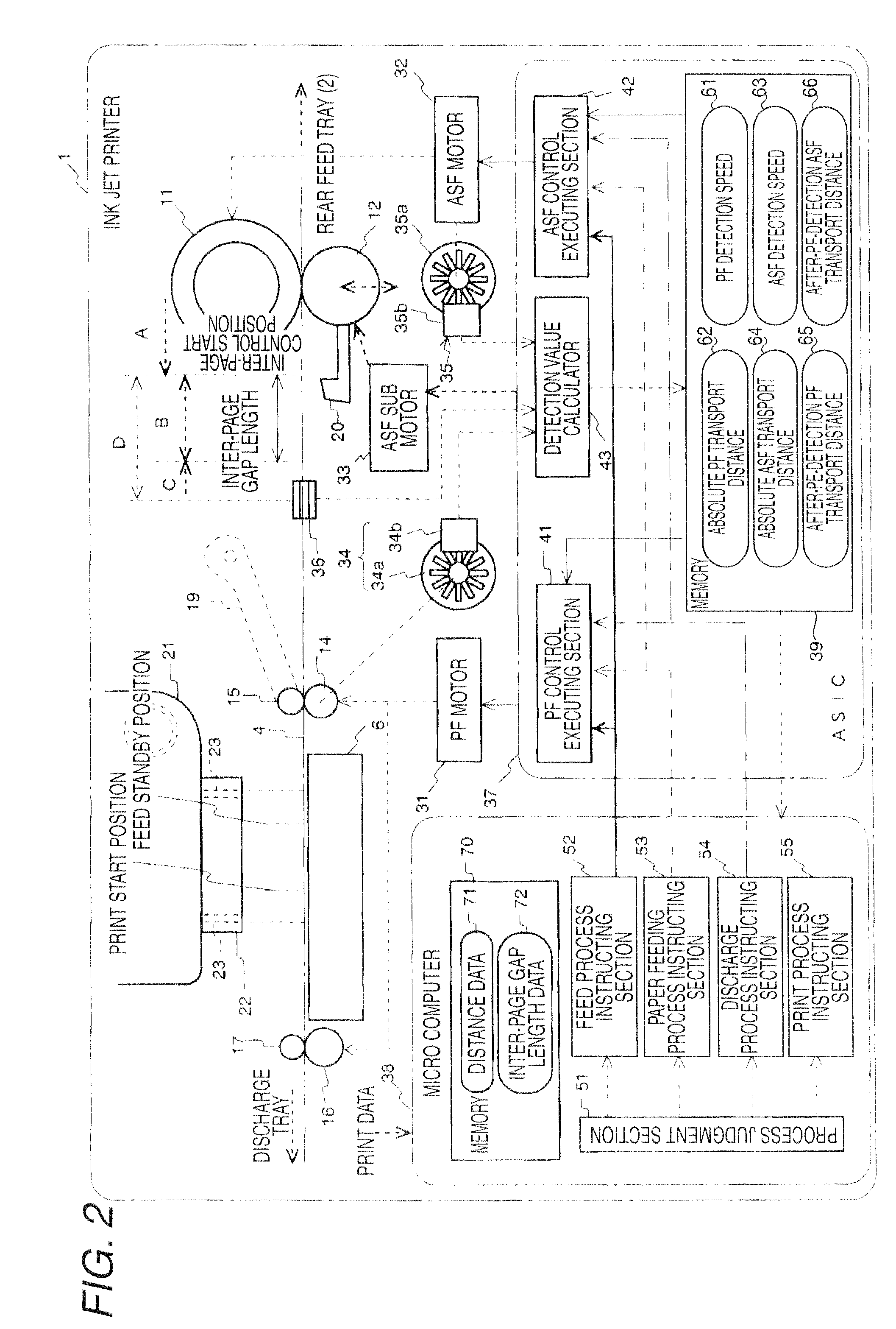

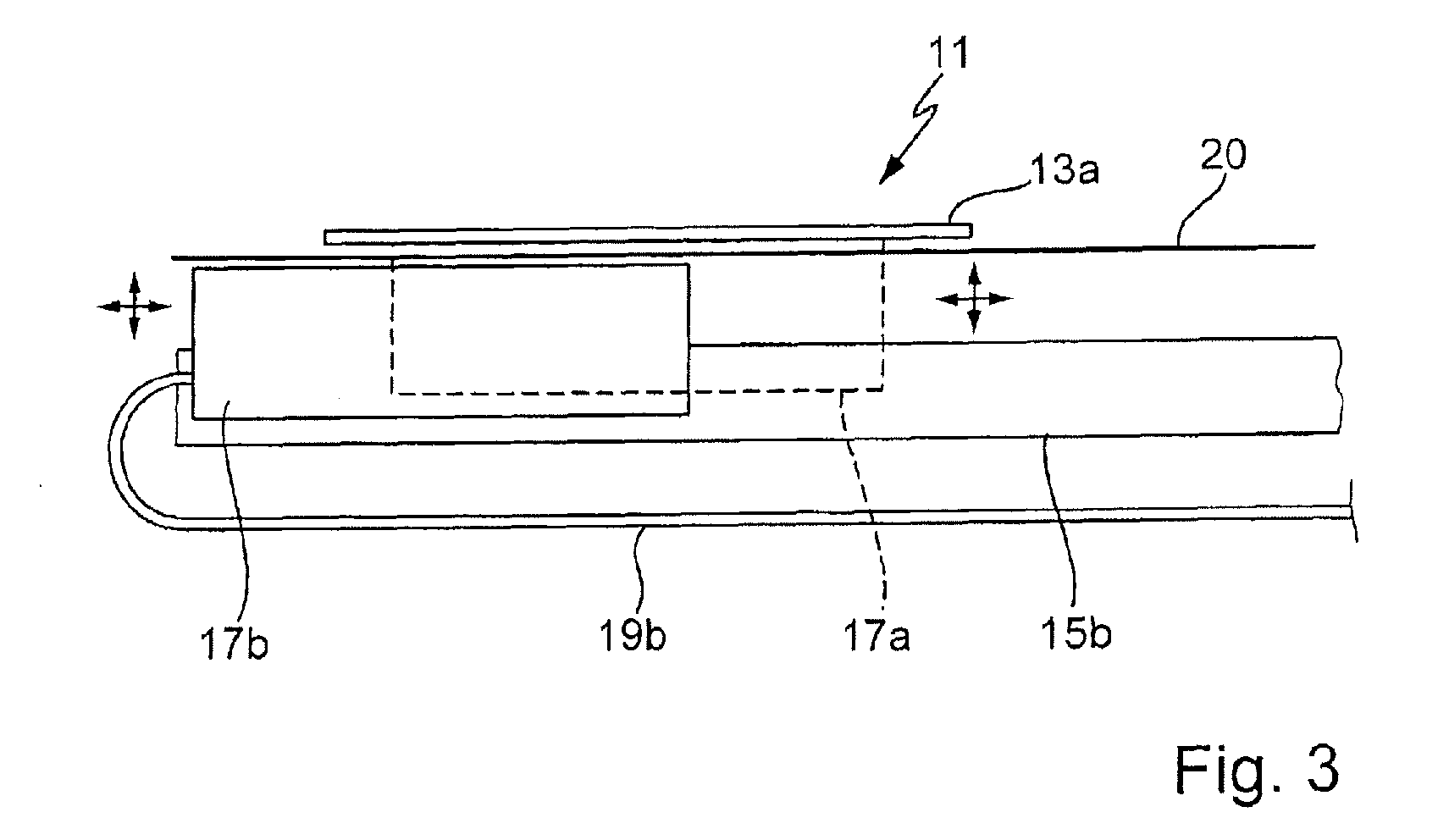

Printer and method of interrupting printing operation in continuous transport process

InactiveUS20080080923A1Continuous transportOperation is interruptedOther printing apparatusArticle feedersEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Discharging belt system with rotating and pitching movements

InactiveCN103482326AContinuous transportPrecise transportationSupporting framesHydraulic cylinderSteel structures

The invention relates to bulk material conveying equipment, in particular to a discharging belt system with rotating and pitching movements. The discharging belt system comprises a rotary base, a rotary supporting device, a pitching dual hydraulic cylinder and a rotary driving mechanism. The body of the discharging belt system is a steel structural rack. One end of the steel structural rack is hinged to the rotary base, and the other end is hinged to the pitching dual hydraulic cylinder. A belt steel structure rack of a supporting belt is placed above the rotary base, and the belt is arranged on the belt steel structure rack. One end of the belt is a feeding end, and the other end is a discharging end. The system has independent pitching and active rotating functions, has the advantages of simplicity of operation, compact structural arrangement and high reliability, and is capable of adapting to complicated on-site conditions. When the discharging belt system is fitted on the bulk material conveying equipment, in the process of conveying the bulk material or mining minerals, materials can be conveyed to a designated discharging position or equipment continuously, accurately and rapidly.

Owner:TIANDI TANGSHAN MINING TECH

Printer and method of interrupting printing operation in continuous transport process

InactiveUS7914216B2Continuous transportOperation is interruptedOther printing apparatusArticle feedersTransfer procedureEngineering

Owner:SEIKO EPSON CORP

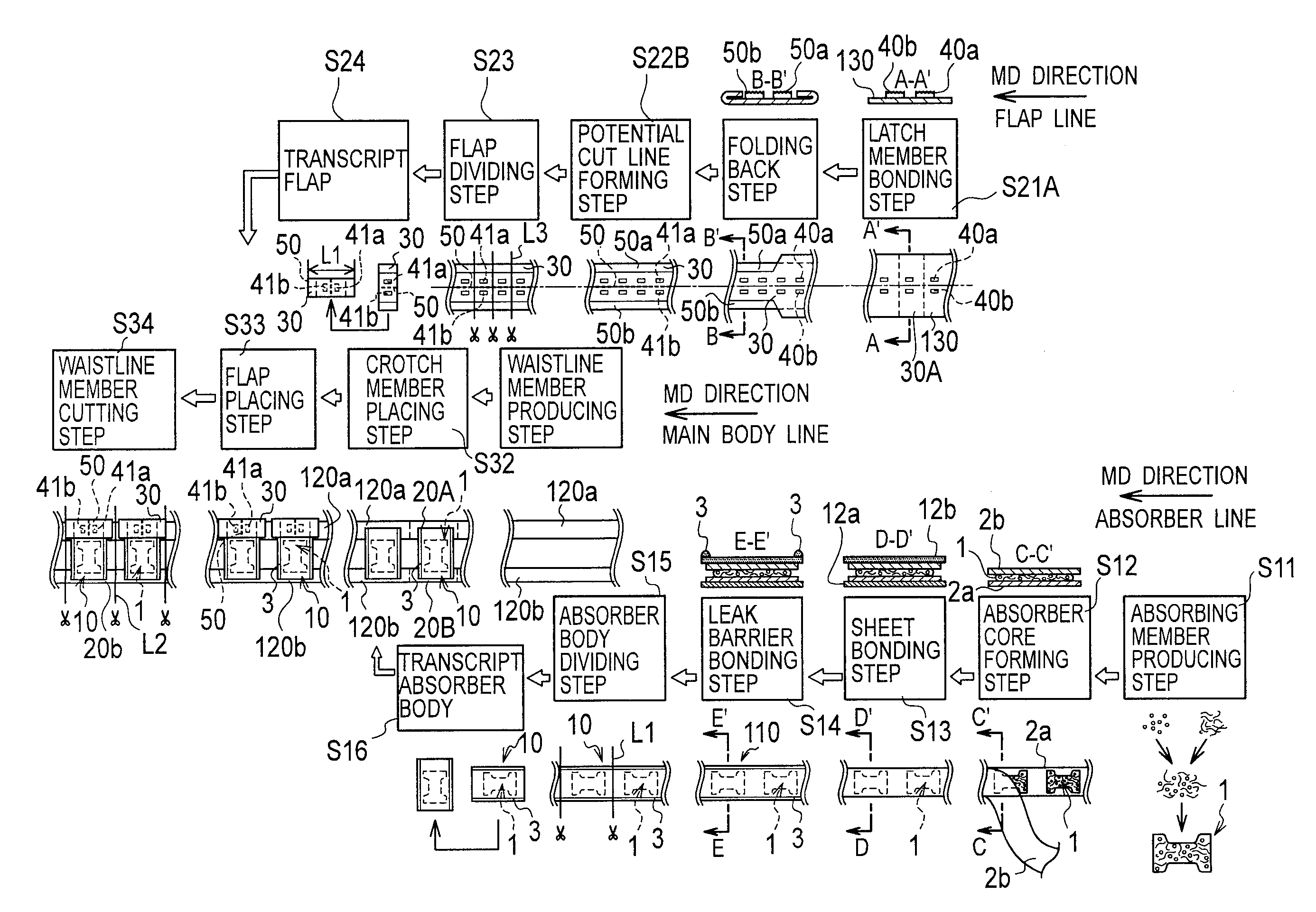

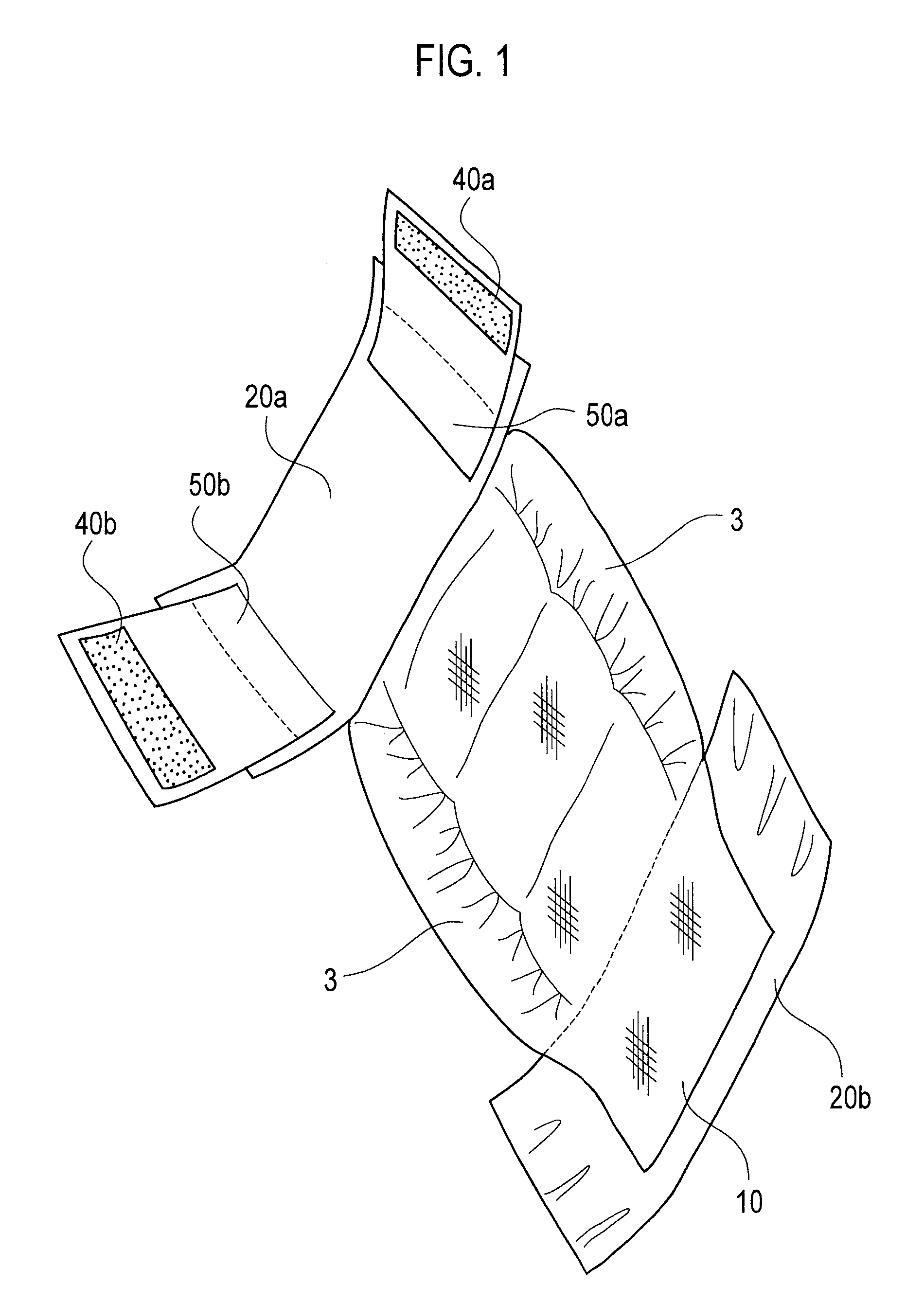

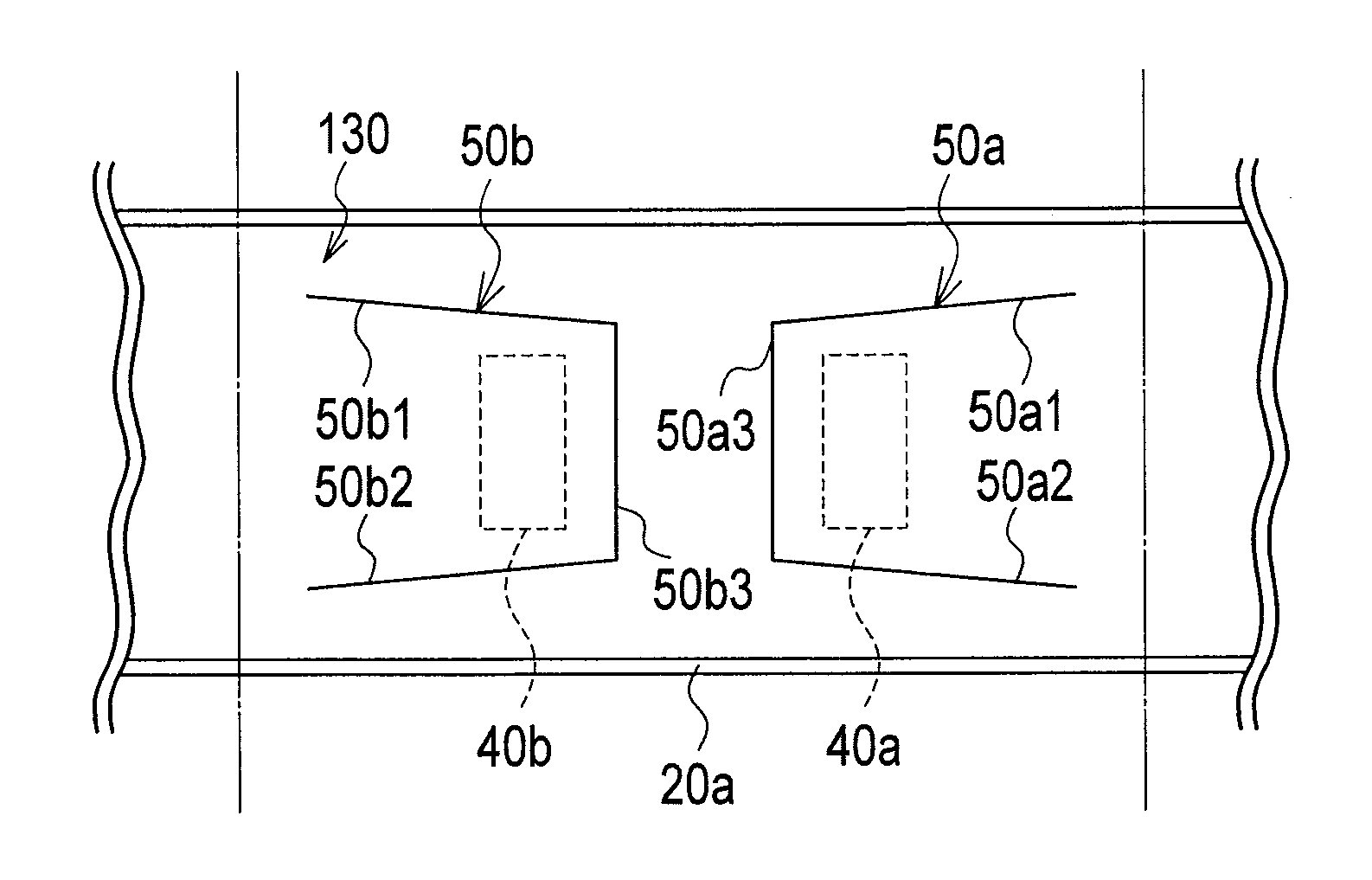

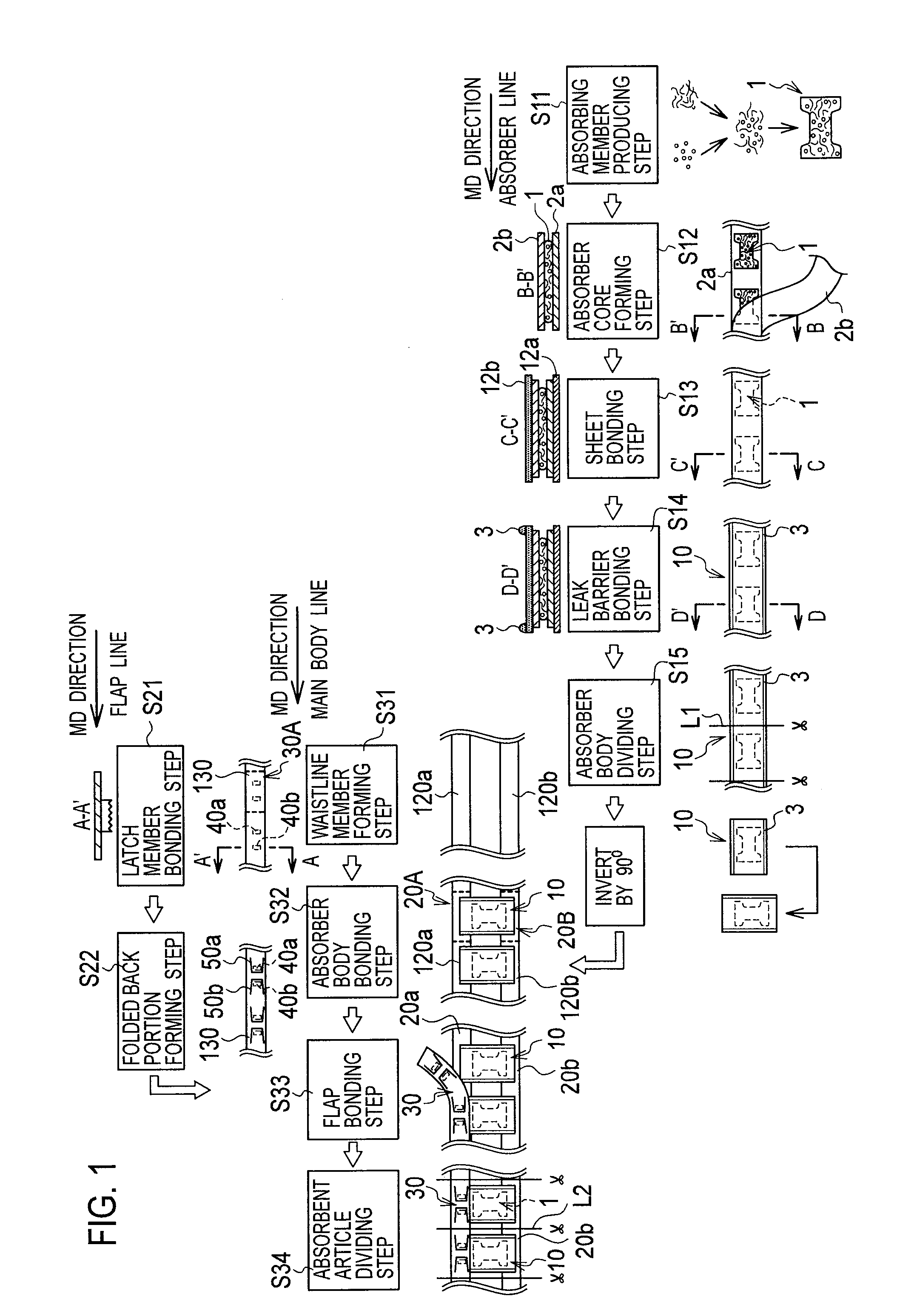

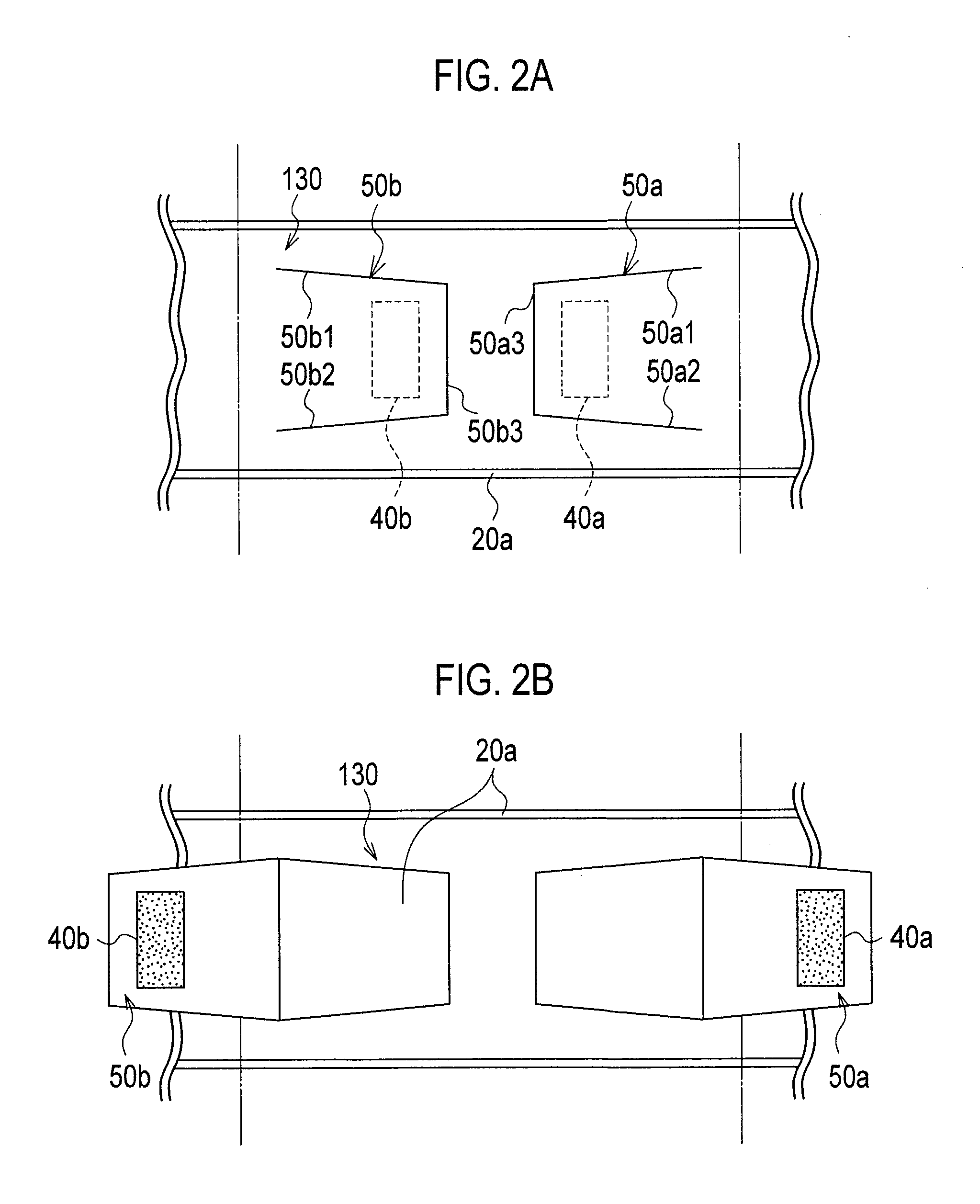

Manufacturing method for absorbent products and manufacturing device for absorbent products

InactiveUS20110173794A1Easily tearEnhance bonding strengthAssembly machinesAbsorbent padsBody linesEngineering

Provided is a manufacturing method for absorbent products that has a process for placing on connected rectangular flaps that are continuously conveyed on a flap line fastening members that are fastenable on both sides to prescribed areas near center line that is parallel to the MD-direction, a process for forming a cutable line along the center line that can divide the connected flaps in two, a process for forming flaps by cutting the connected flaps along the CD-direction on the flap line, and a process for placing the flaps on connected front torso-surrounding member or back torso-surrounding member or on the main body line so that center line is orthogonal to the MD-direction of the main body line.

Owner:UNI CHARM CORP

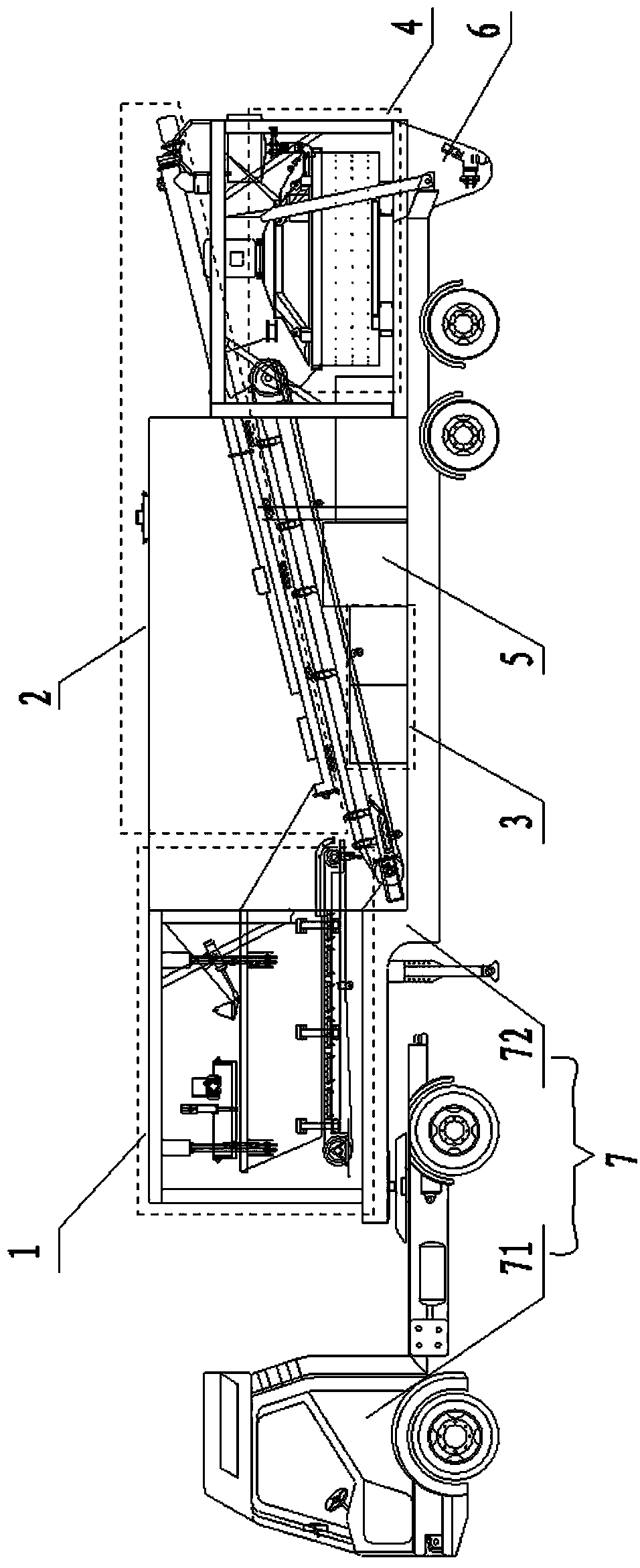

Continuous walking type transport loader of open pit coal mine

The invention belongs to the technical field of transport equipment of an open pit coal mine, and particularly relates to a continuous walking type transport loader of an open pit coal mine, which is used for solving the problem of a loader for existing open mining. A receiving part, a main rack and a discharging part main body are all of a welded groove-shaped structure, so that an upper chain channel and a lower chain channel are formed, and are hinged together by virtue of a pin roll to form a coal conveying chain channel of the whole equipment, a scraper chain is arranged in the coal conveying chain channel and penetrates through the whole coal conveying chain channel, the upper chain channel is provided with a chain pressing block, a transport driving chain wheel and a tail guide wheel are respectively arranged at two ends of the scraper chain and are meshed and linked with the scraper chain, the scraper chain drives a chain wheel shaft to be linked with transport driving parts which are arranged at the left side and the right side, and the transport driving parts are respectively provided with a transport driving part protecting cover. According to the continuous walking type transport loader, a truck transporting link is eliminated, the transport cost is lowered, the equipment investment is reduced, the production capability and the production efficiency are improved, the cost of per ton coal is lowered, and the environmental-friendly mining of coal is realized.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Transporting and cooling device for plasma lava

InactiveUS20070039487A1No pollution to the environmentContinuous transportFood preservationRadioactive decontaminationGas explosionPollutant

The present invention continuously transports and cools down plasma lava with no gas explosion under an indirect cooling; comprises fewer rotating parts for transportation; prevents radioactive pollutants from escaping out under an air-locked environment; and, avoids motor of transport caravan operating under high temperature, where the present invention can be applied to a plasma melting process for radioactive material.

Owner:INST NUCLEAR ENERGY RES ROCAEC

A kind of asparagus root cutting processing and packaging equipment

InactiveCN105129317BImprove processing efficiencyRegular shapeConveyorsPackagingHigh volume manufacturingEngineering

The invention relates to asparagus root cutting and packing equipment. The equipment comprises a root cutter, a lifting conveyer and a vibrator, wherein the lifting conveyer is arranged rightly below a discharge end of the root cutter; and the vibrator is arranged rightly below a discharge end of the lifting conveyer. In the asparagus root cutting and packing equipment, cutting lines of asparaguses after root cutting are straight, cut roots of the asparaguses are not omitted, and the remainder lengths of the asparaguses after root cutting can be accurately adjusted, so that the asparagus processing efficiency is greatly improved, and the large-batch production is adapted to; the asparaguses after root cutting are tidy in shape and beautiful; the product quality is high; the cost is saved; the transportation efficiency is high; and the potential safety hazards are effectively eliminated.

Owner:HENAN CHUANGJIA FOOD CO LTD

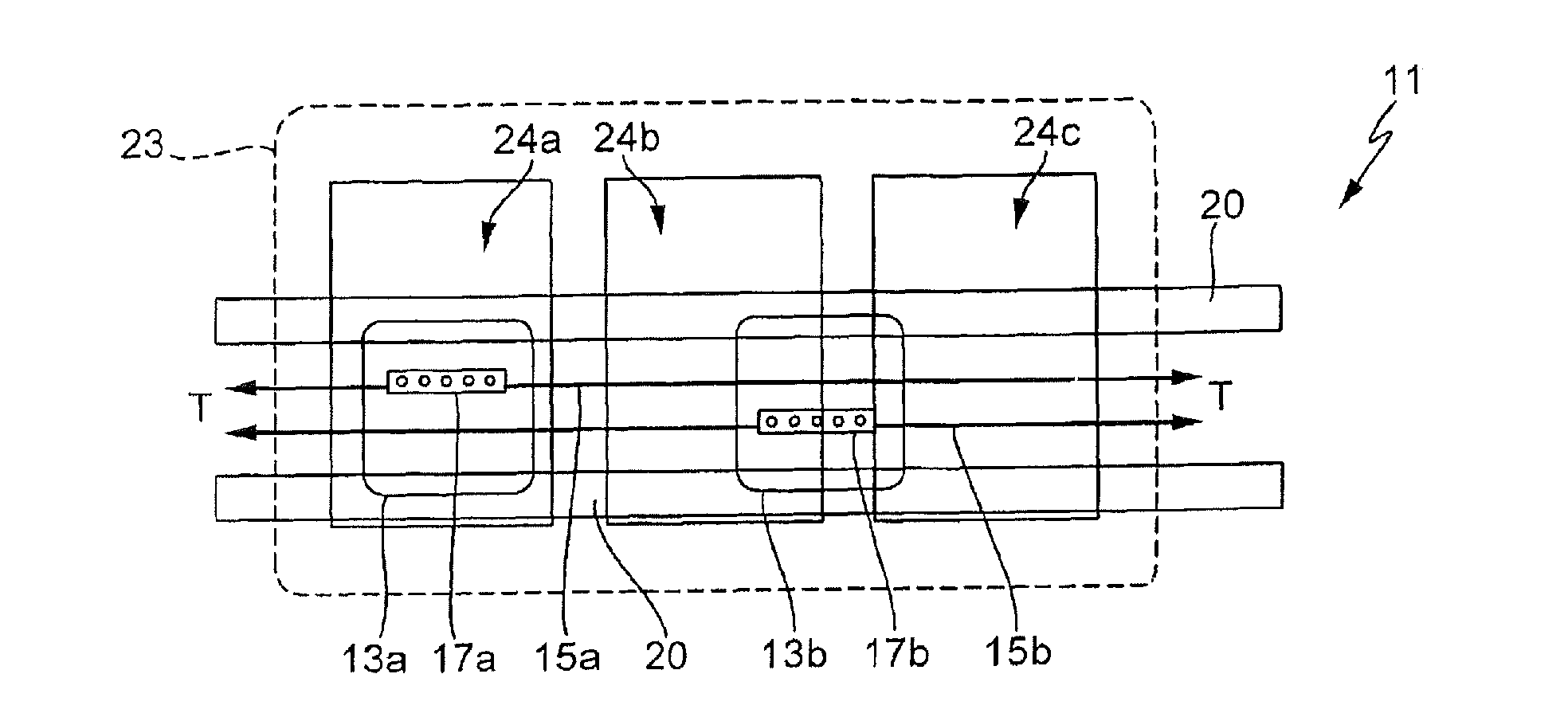

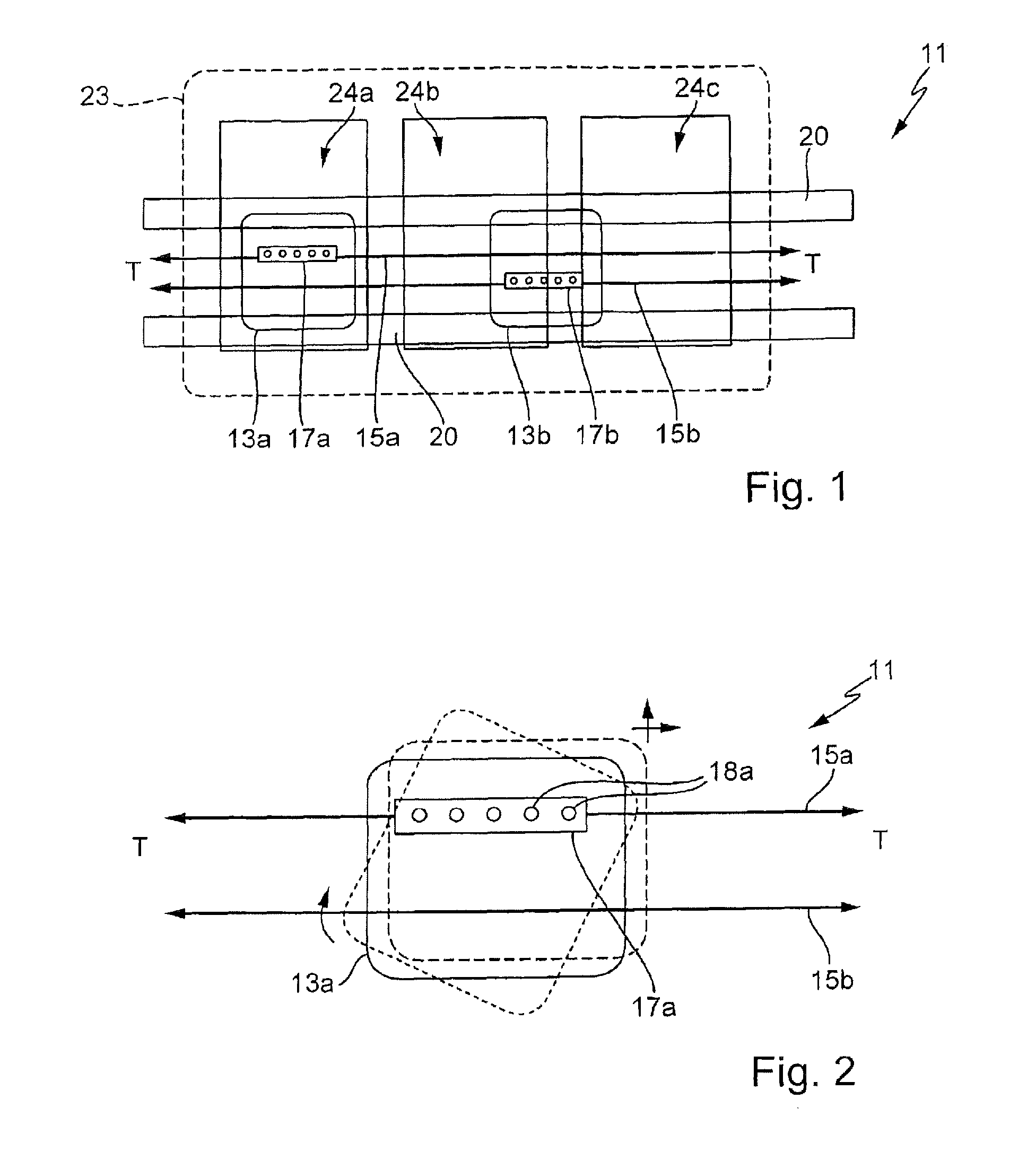

Apparatus and Method for Transporting Substrates

InactiveUS20130101738A1Easy to adaptImprove overall utilizationSemiconductor/solid-state device manufacturingAxle-box lubricationEngineeringMechanical engineering

An apparatus for transporting silicon wafers in a horizontal transporting direction into a printing device has two transporting units, which each have a traversing device and a holding means thereon. At least two transporting units each with a holding means are provided, wherein the traversing devices of said units run next to each other along the transporting direction. The holding means are each formed and arranged in such a way that an unloaded holding means has space to pass by a holding means loaded with a silicon wafer. The traversing devices are rails and the holding means are carriages mounted thereon.

Owner:SCHMID TECH

Manufacturing method for absorbent products and manufacturing device for absorbent products

InactiveUS20110139336A1Easily unfoldedEasy to unfoldSlide fastenersAbsorbent padsEngineeringMechanical engineering

Provided is a manufacturing method for absorbent products that has a process for forming a pair of fold-over portions, which can be folded over in the direction of conveyance of a flap line and in the direction opposite said conveyance direction, on portions of regions that constitute a single flap in flap continuum that are continuously conveyed on the flap line, a process wherein fastening members, which are fastenable to prescribed areas, are placed on the pair of fold-over portions, and a process wherein the flap continuum are connected with connected front torso-surrounding members or back torso-surrounding members or so that each region that constitutes a single flap, corresponds to areas, that constitute a single absorbent product in connected front torso-surrounding members or back torso-surrounding members.

Owner:UNI CHARM CORP

Bolt point pressing machine

InactiveCN113414271ADoes not affect temperatureRealize continuous unmanned productionShaping toolsMetal-working feeding devicesCircular discPunching

The invention discloses a bolt point pressing machine. The bolt point pressing machine comprises a rotating disc, induction heating equipment, a punching machine and a limiting plate, the rotating disc is composed of a first disc, a second disc, first mold grooves and first semicircular grooves, the multiple first mold grooves are evenly formed in the side wall of the first disc, each first mold groove is composed of a first U-shaped groove, a first limiting groove, a first shaping groove, a second U-shaped groove and a second semicircular groove, and the first U-shaped groove vertically extends downwards from the upper end face of the first disc to the middle of the first disc. According to the bolt point pressing machine, the rotating rotating disc is used as a picking and processing fixing device for bolt raw materials, so that continuous feeding can be realized, and the induction heating equipment not only can quickly heat a nut of a bolt, but also hardly affects the temperature of a working space and does not interfere with other equipment; and the induction heating equipment, the punching machine and the rotating disc are matched with one another to guarantee continuous transportation, heating and machining of bolt raw materials, continuous unmanned production of bolt finished products is achieved, efficiency is improved, and potential safety hazards are reduced.

Owner:HAIYAN HUASHENG AUTO PARTS

Laser cutting equipment for transporting, cutting and collecting metal pipes

InactiveCN111618449AContinuous cuttingContinuous transportWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention discloses a laser cutting equipment for transporting, cutting and collecting metal pipes. The laser cutting equipment comprises a machine body, a feeding cavity used for transporting themetal pipes is formed in the machine body, an inlet cavity communicating with the feeding cavity is formed in an upper side wall body of the machine body, a feeding device used for transporting the metal pipes one by one is arranged in the feeding cavity, and the feeding device comprises a slope fixedly arranged on a protruding platform wall body of the right side of the feeding cavity. The lasercutting equipment is provided with the feeding device, a first rotating shaft and a second rotating shaft can be driven to rotate by a driving worm gear, so that a conveying table is driven to feed the metal pipes one by one, the working efficiency is effectively improved, and cutting and transportation of the metal pipes can be continuously carried out; and the laser cutting equipment is provided with a clamping device, a pressing table can be pressed down through the metal pipes, and therefore a clamping block is driven to clamp the metal pipes.

Owner:PUJIANG SULI MASCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com