Bolt point pressing machine

A technology of bolts and punching machines, applied in forming tools, feeding devices, positioning devices, etc., can solve problems such as burns and wasting time, achieve the effects of improving efficiency, reducing safety hazards, and realizing unmanned production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

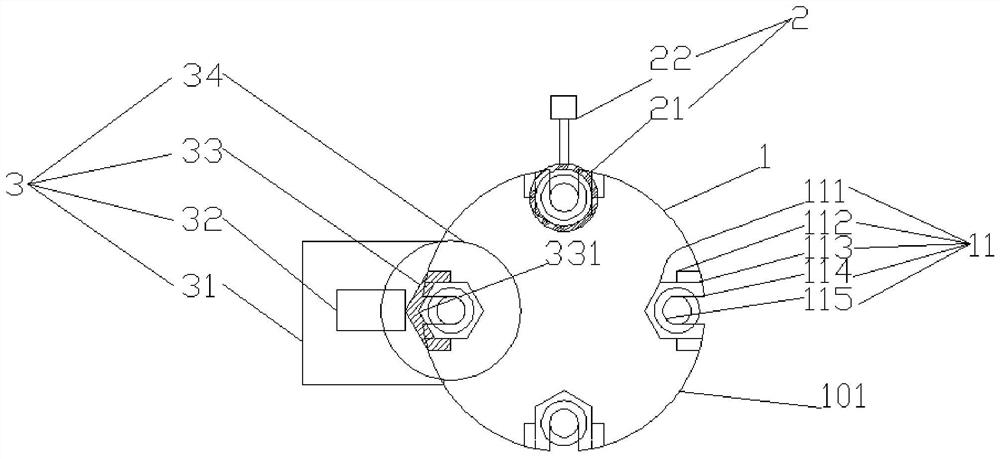

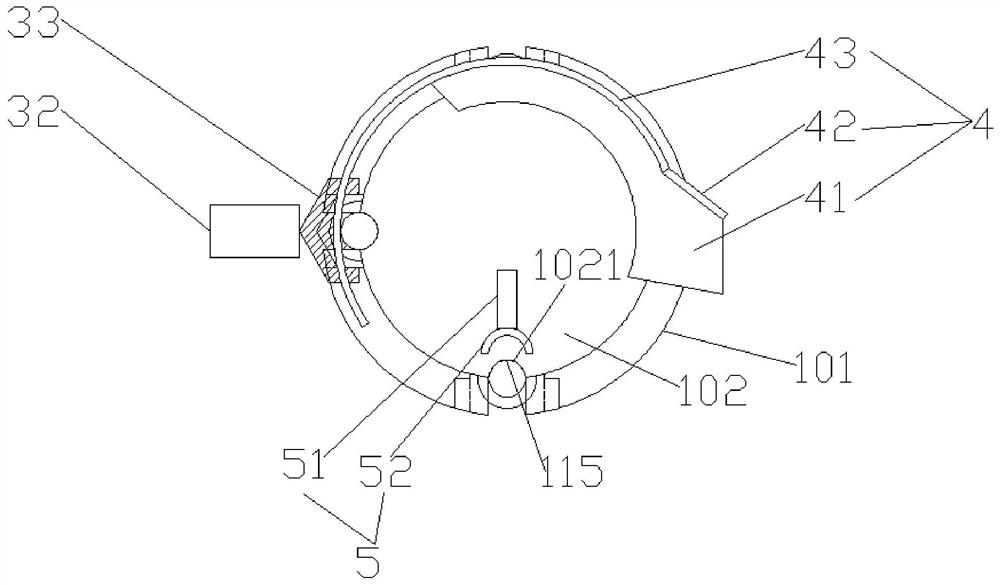

[0012] refer to figure 1 , figure 2 , a bolt pressure point machine of the present invention, comprising a turntable 1, an induction heating device 2, a stamping machine 3, a limit plate 4, the turntable 1 is composed of a first disc 101, a second disc 102, a first mold groove 11, a second Composed of half circular grooves 1021, the side wall of the first disc 101 is evenly provided with several first mold grooves 11, the first mold grooves 11 are composed of a first U-shaped groove 113, a first limiting groove 112, a first shaping groove 111, the second U-shaped groove 114, the second semicircular groove 115, the first U-shaped groove 113 extends vertically downward from the upper end surface of the first disc 101 to the middle of the first disc 101, the first U-shaped The groove 113 is adapted to the nut of the bolt, the groove bottom of the first U-shaped groove 113 is the first shaping groove 111, and the two symmetrical first limiting grooves 112 are respectively arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com