Patents

Literature

135results about How to "Does not affect temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

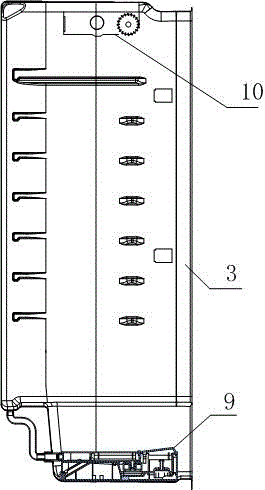

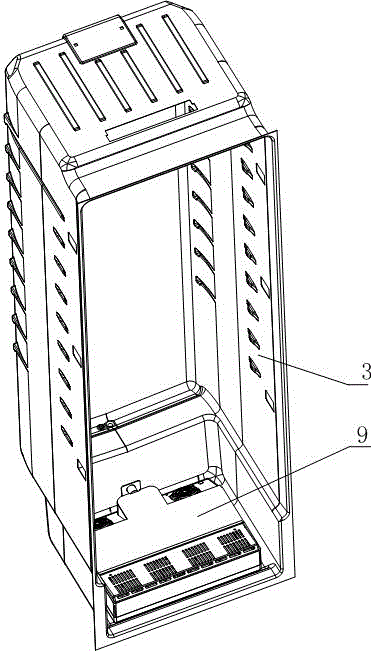

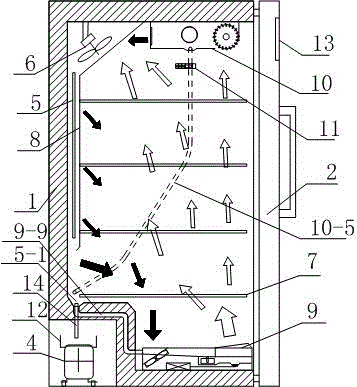

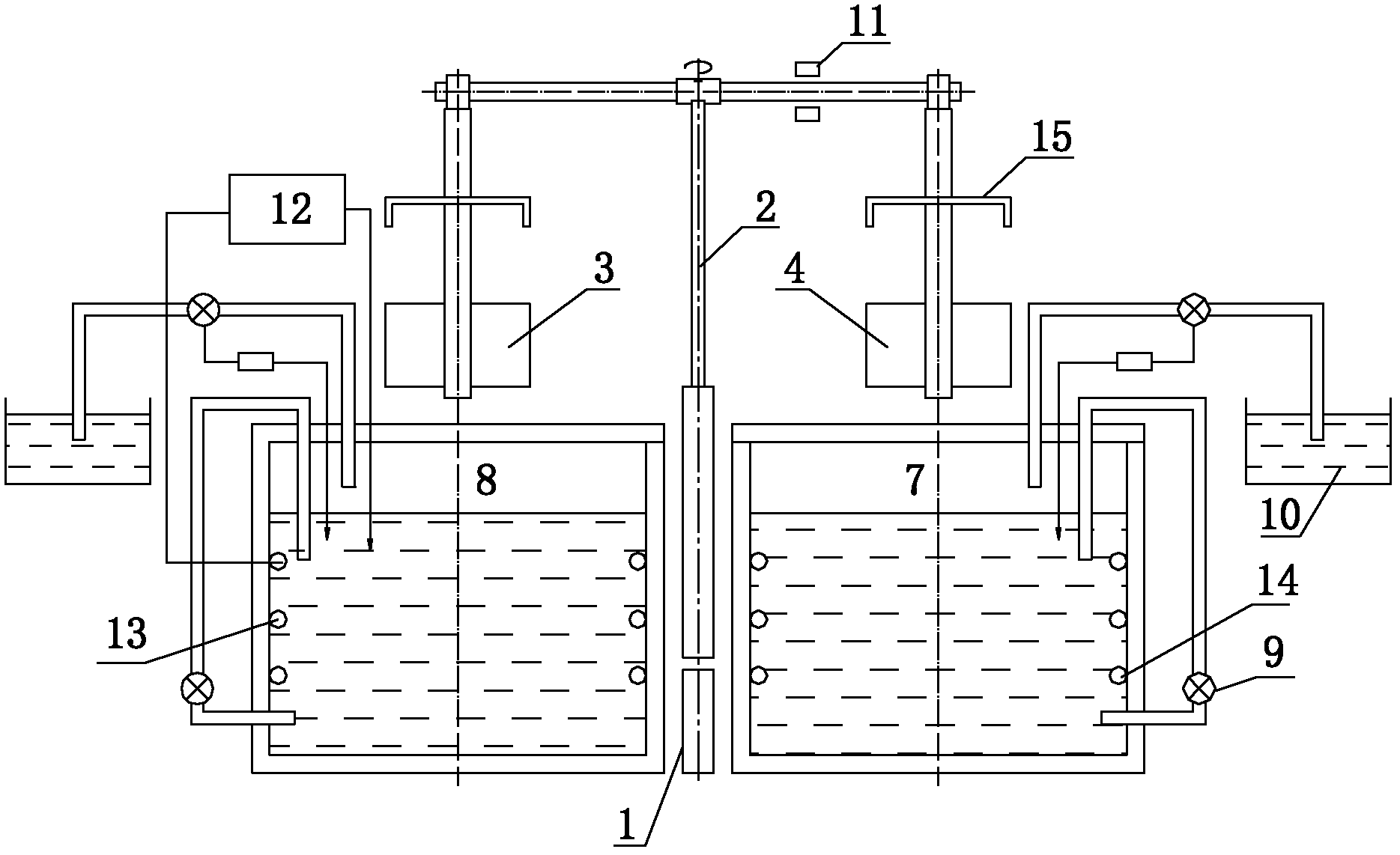

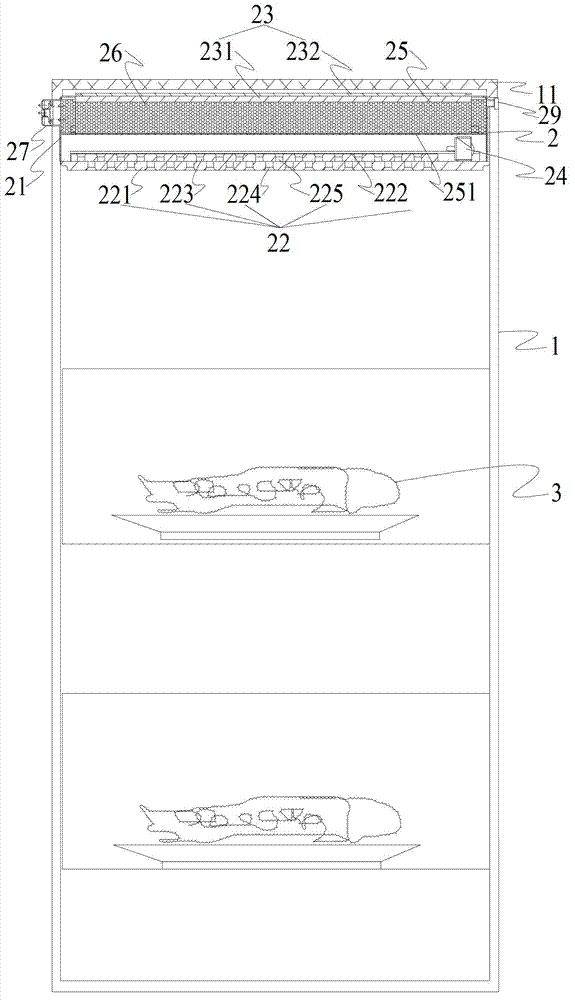

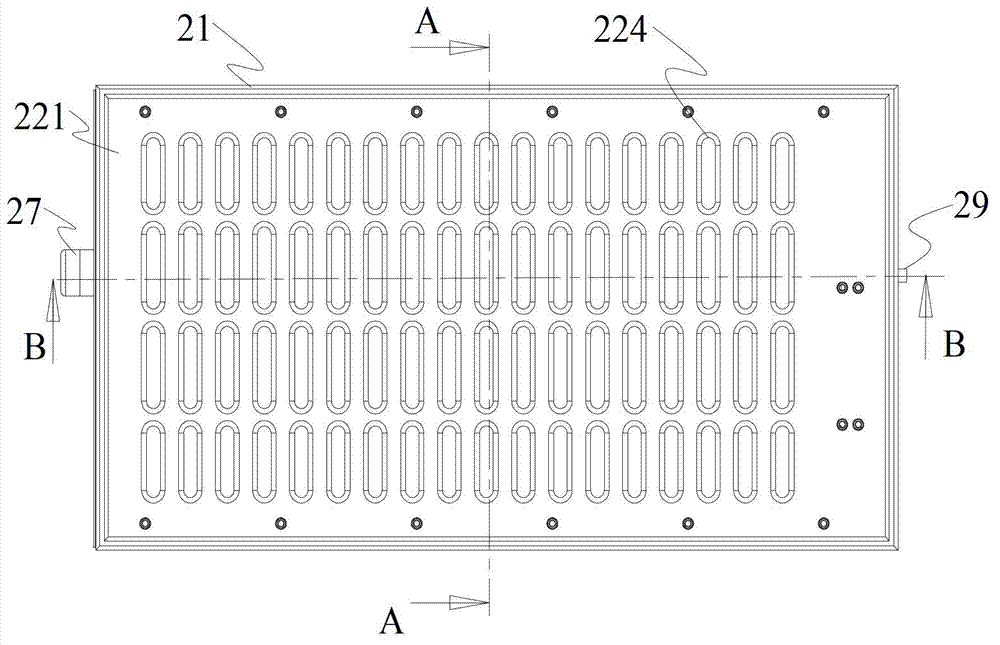

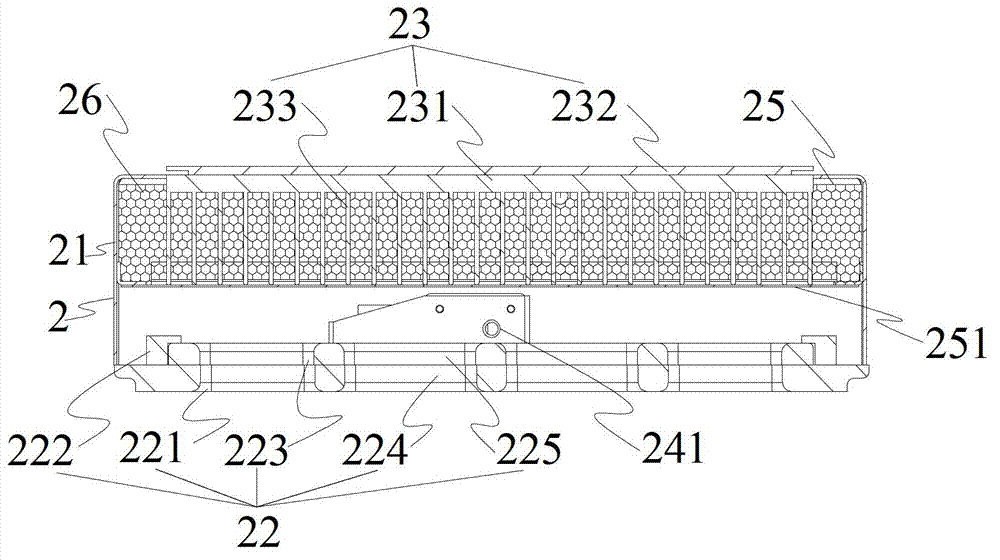

Precision humidity control system and wine cabinet

InactiveCN104374156AImprove securityHumidification evenly distributedDomestic cooling apparatusLighting and heating apparatusAutomatic controlControl system

The invention provides a precision humidity control system and a wine cabinet. The precision humidity control system comprises a humidifying module, a dehumidifying module and a controller; the humidifying module is used for ultrasonic humidifying and automatically controls a humidifying water level; the controller controls running of the humidifying module and the dehumidifying module. The invention further provides the wine cabinet with the precision humidity control system. The wine cabinet comprises a box, a door, a refrigerating system and the precision humidity control system; the refrigerating system comprises a compressor, an evaporator and a condenser; the precision humidity control system comprises the humidifying module, the dehumidifying module and the controller; the humidifying module is used for ultrasonic humidifying and automatically controls the humidifying water level; humidifying water for the humidifying module is mainly from condensation circulating water of the evaporator; the controller controls running of the humidifying module and the dehumidifying module. A humidifying unit is modularized, miniaturized and integrated to a liner, no space of the liner is wasted, and when the wine cabinet stops refrigerating, the humidity can still be adjusted to allow dehumidification and precision humidity control.

Owner:HAIER GRP CORP +1

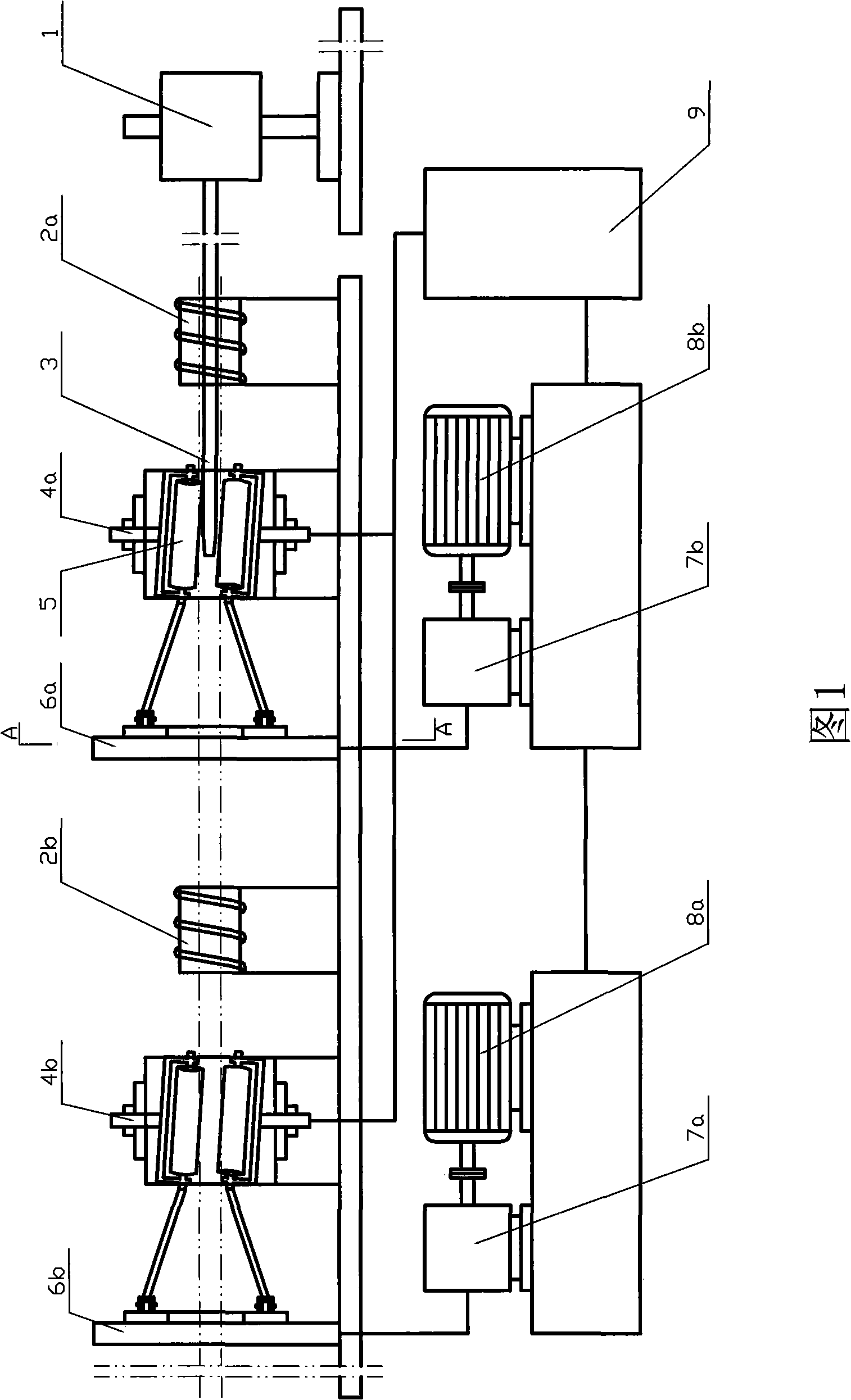

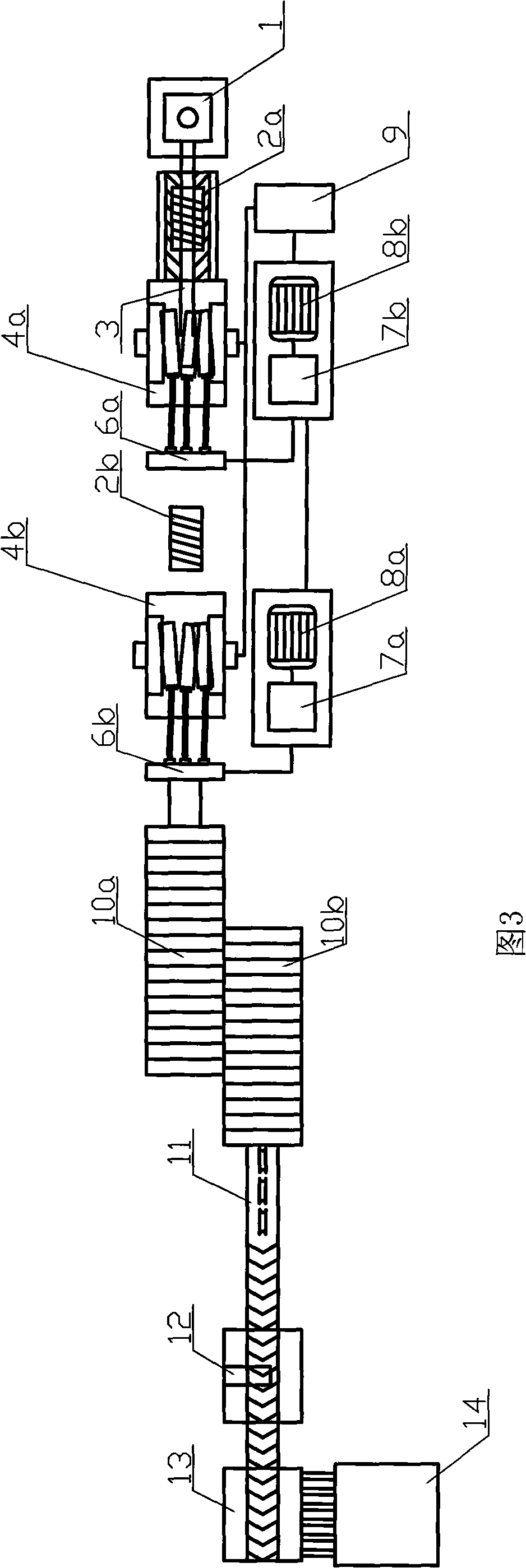

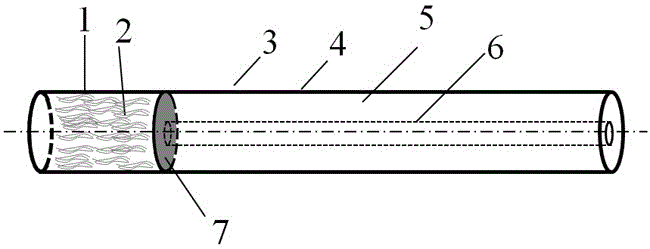

Two-stand angularly hot rolling minor diameter seamless steel tube rolling technique and equipment thereof

InactiveCN101259589AGuaranteed wall thicknessGuaranteed ovalityTemperature control deviceMandrelsIntermediate frequencyHeating furnace

The invention discloses the rolling technology of a double-stander oblique hot rolling small diameter seamless steel tube, and the rolling technology of the invention is that a mandrel trolley pushes a mandrel into a pierced billet and is pushed to move forward, the mandrel is heated to 950 DEG C to 1150 DEG C by an intermediate frequency induction heating electric furnace, the mandrel trolley continues to pushes the heating pierced billet into a rolling mill to carry out wall increasing and diameter reducing rolling, only the mandrel and a roller are cooled during rolling process; the pierced billet that breaks away from the mandrel is placed into a reheating electric furnace for heating to 950 DEG C to 1150 DEG C and is sent into a stretch reducing and wall increasing rolling mill to carries out the diameter reducing rolling, the heating while rolling can be realized, and only the roller is cooled during the rolling process; the invention is finished by cooling, straightening, cutting and online detecting after rolling. The invention realizes the technology of heating the mandrel and the roller while rolling and cooling by improving the heating method of a heating furnace, structure and the cooling method of the mandrel and the roller. The rolling technology of a double-stander oblique hot rolling small diameter seamless steel tub improves efficiency, simplifies the technology, reduces cost, saves energy and reduces pollution, thus the rolled steel tube is high in precision.

Owner:LUOYANG DINGRUI MATERIAL TECH

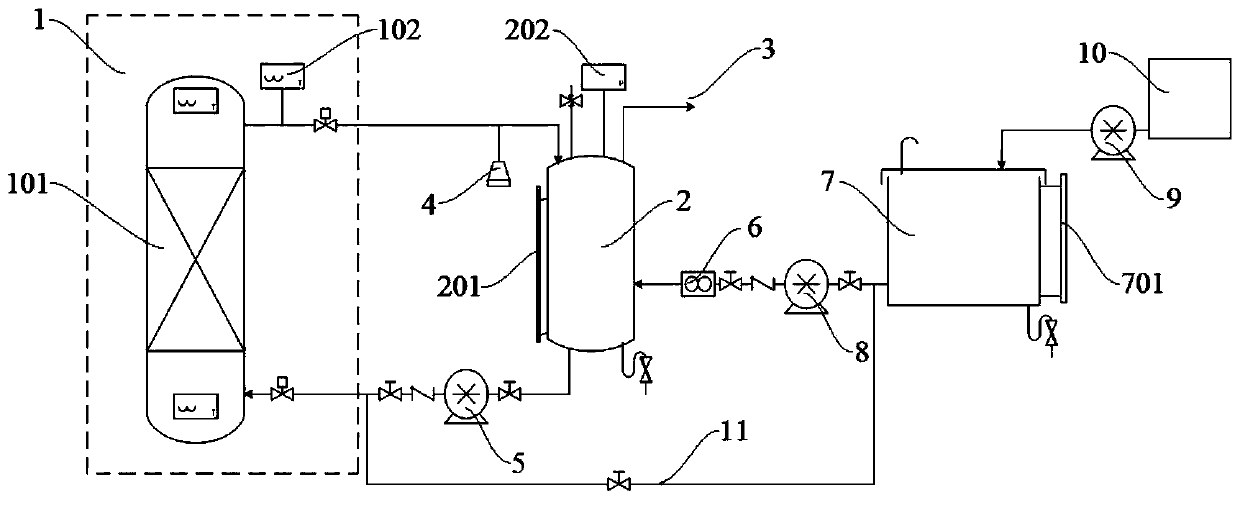

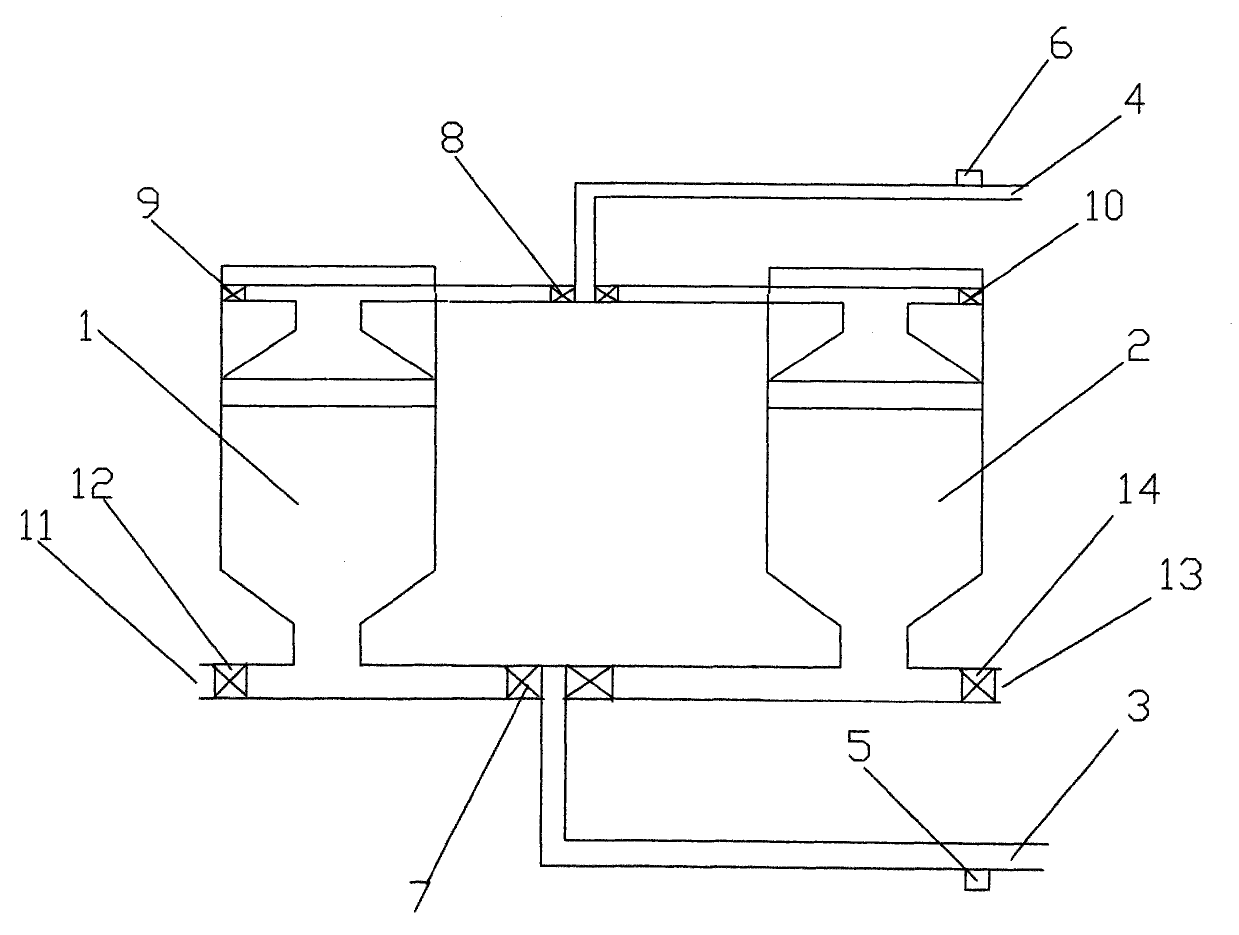

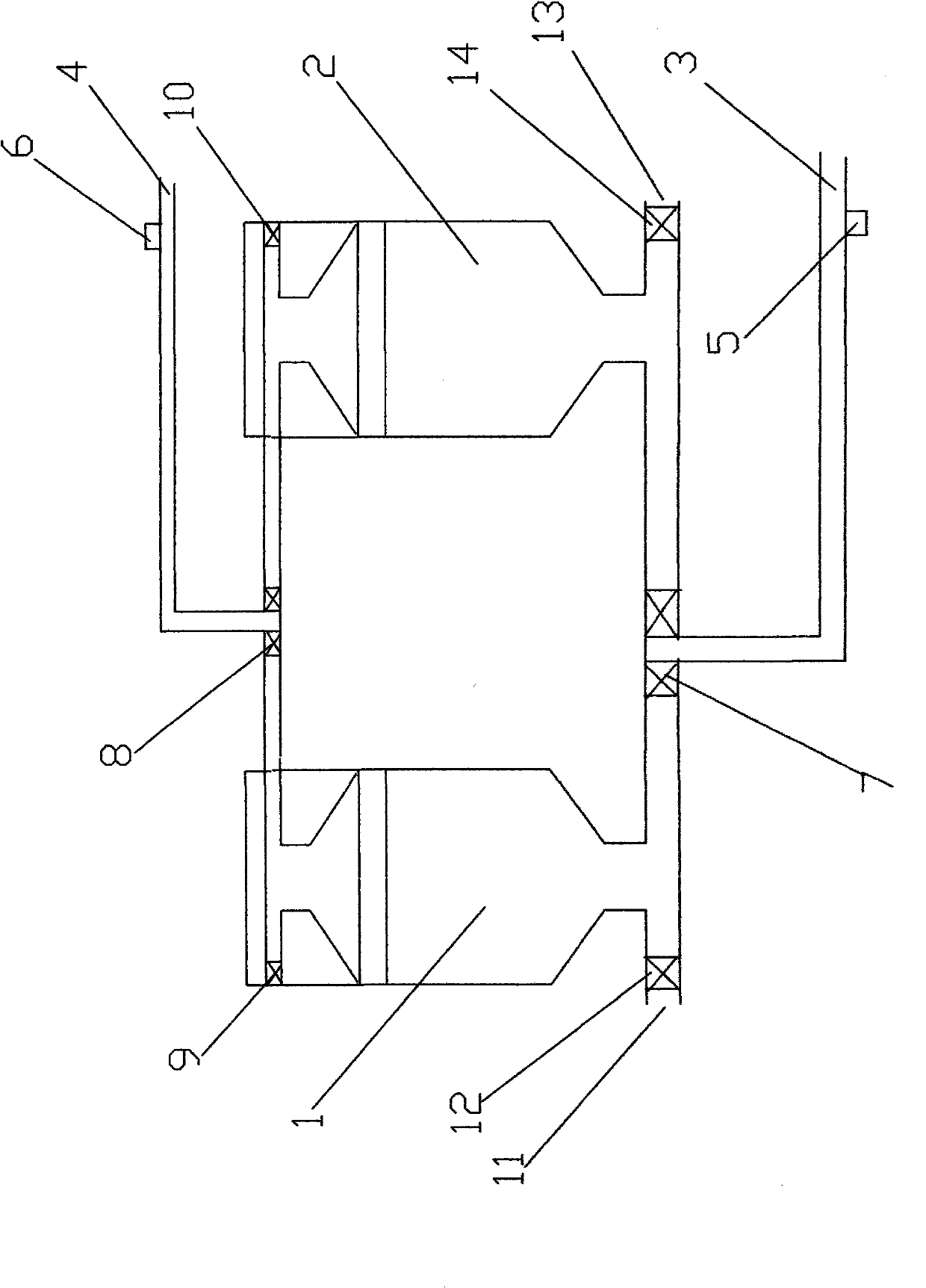

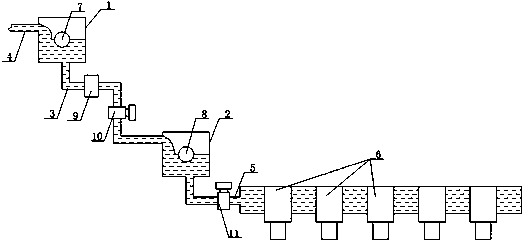

System for recycling raw gas afterheat of coke oven

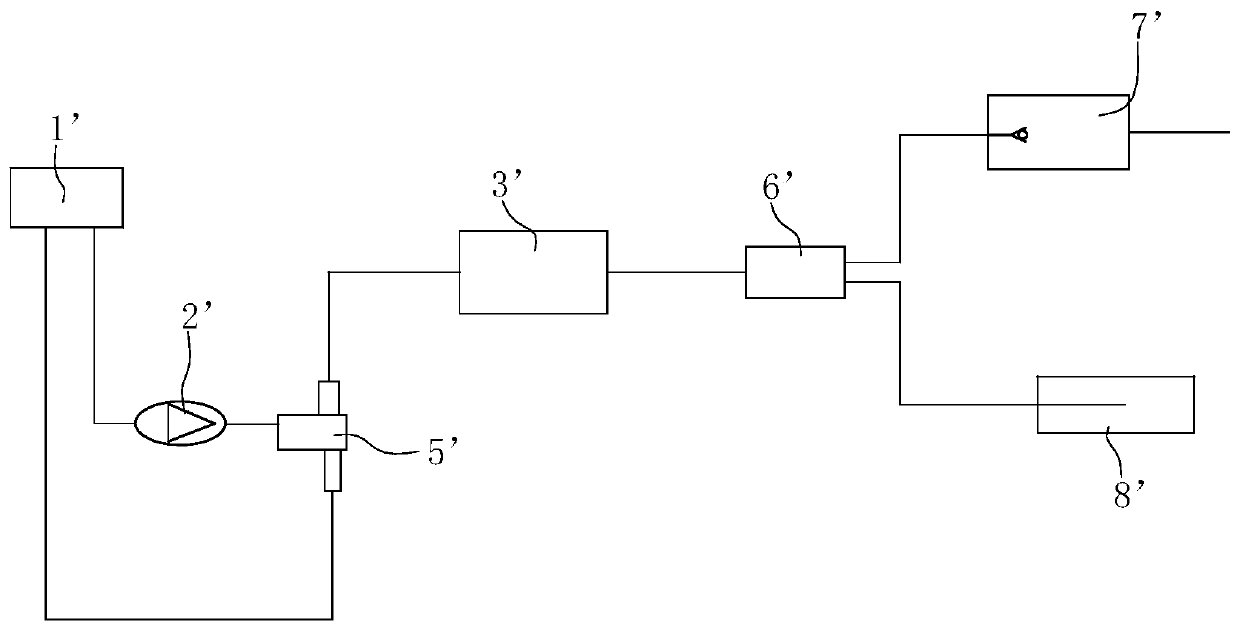

ActiveCN103436271ALong-term continuous productionSafe continuous productionSteam generation using hot heat carriersDistillation gas withdrawalCirculator pumpProcess engineering

The invention discloses a system for recycling the raw gas afterheat of a coke oven, and belongs to the technical field of the recycling utilization of raw gas afterheat. The system for recycling the raw gas afterheat of the coke oven comprises a heat exchange medium circulating system and a water charging system, wherein the heat exchange medium circulating system comprises a heat exchanger set, a steam pocket and a forced circulation pump, a water inlet of the heat exchanger set is connected to a water outlet of the steam pocket through the forced circulation pump, a water outlet of the heat exchanger set is connected to a water inlet of the steam pocket, and a steam outlet in the steam pocket is connected to an external steam pipe network; the water charging system comprises a buffer water tank, a make-up pump, a feed pump and a desalting oxygen removal water tank, the feed pump is arranged between the buffer water tank and the desalting oxygen removal water tank, and the buffer water tank is connected to the steam pocket through the make-up pump. The system can be used for effectively, safely and reliably recycling the raw gas afterheat and circularly converting a heat exchange medium into middle and low pressure steam; the system operation can be effectively detected and controlled, so that the safe and normal operation of the system is ensured, and the accident rate is reduced.

Owner:江苏龙冶节能科技有限公司

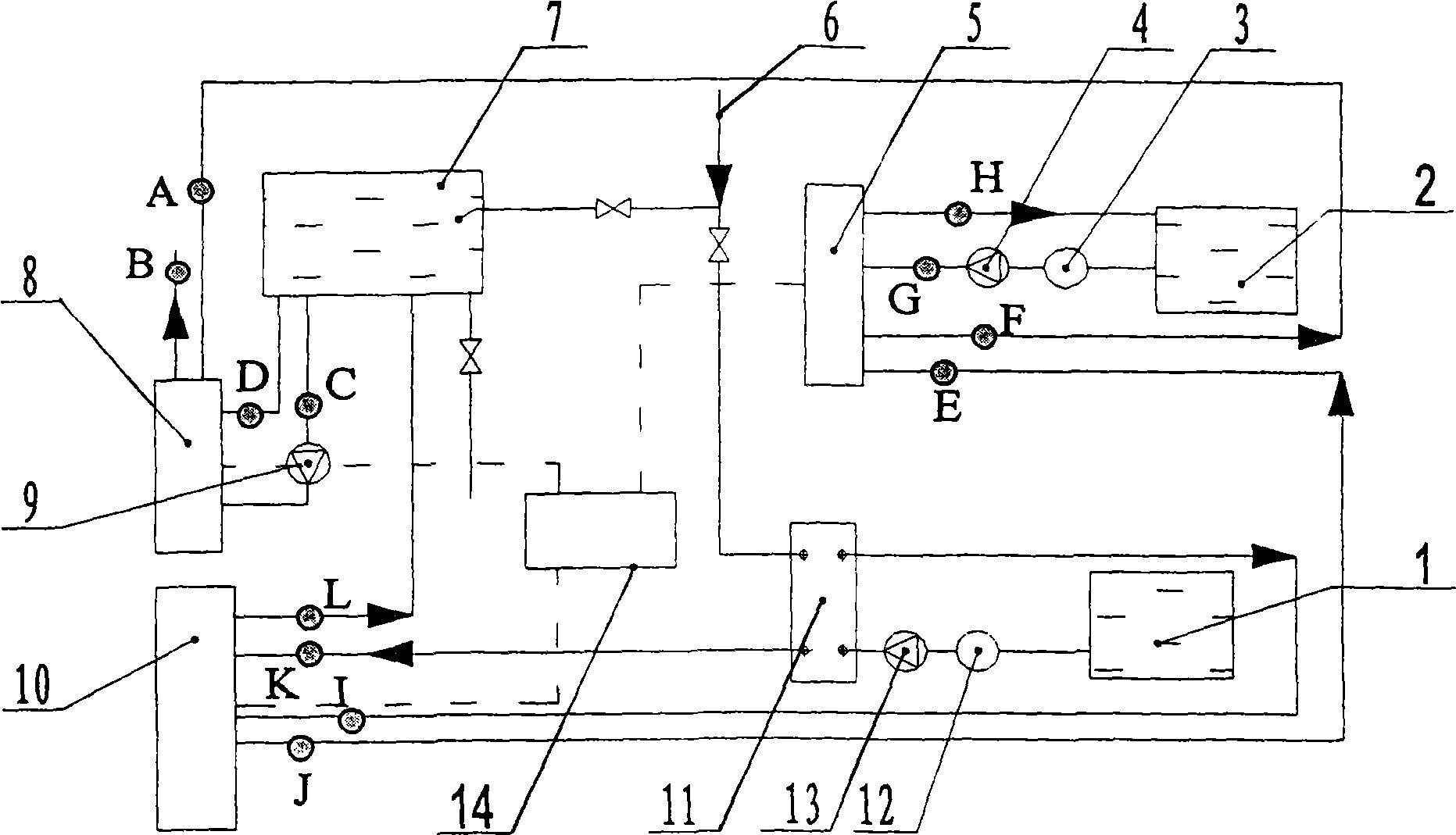

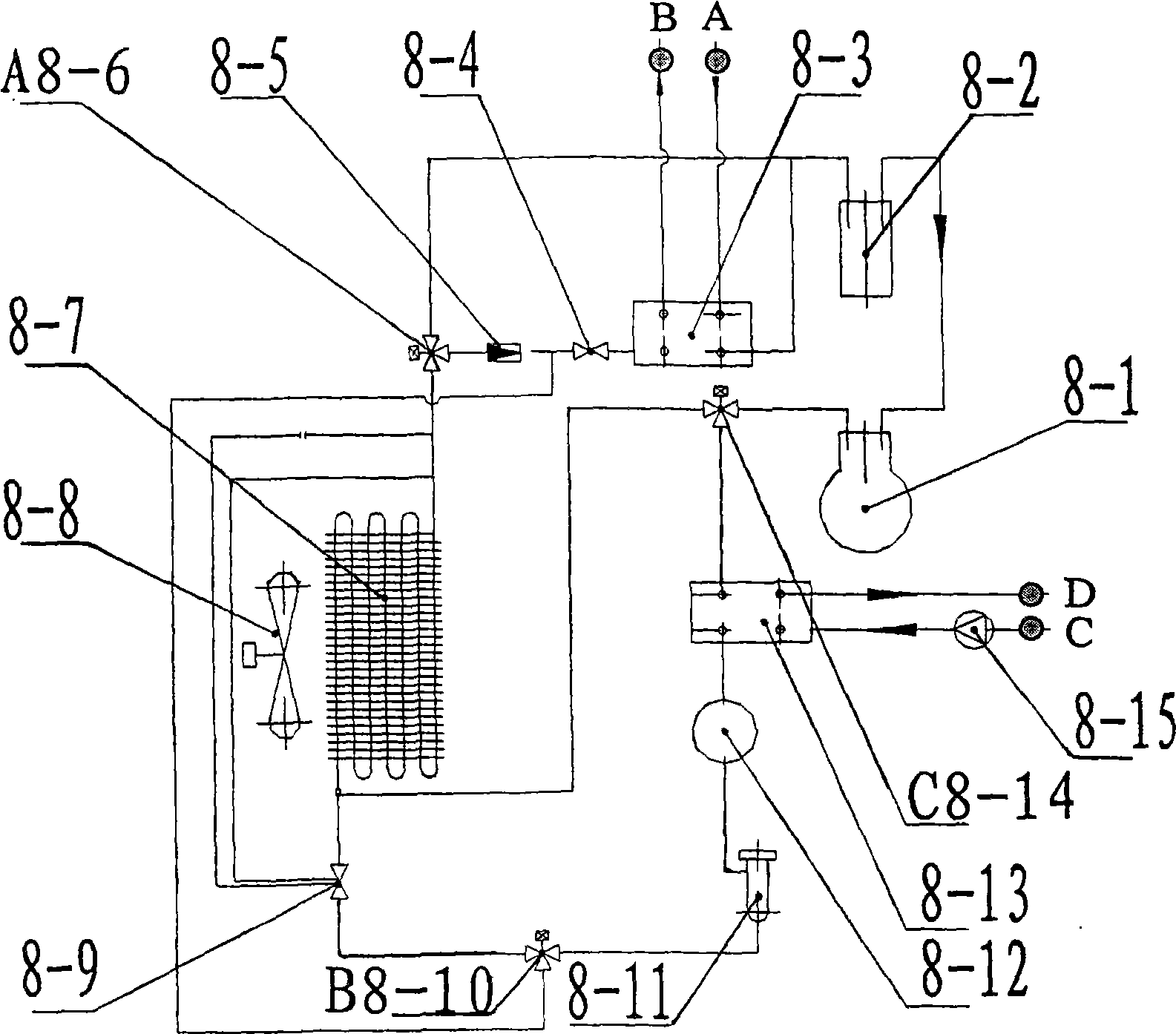

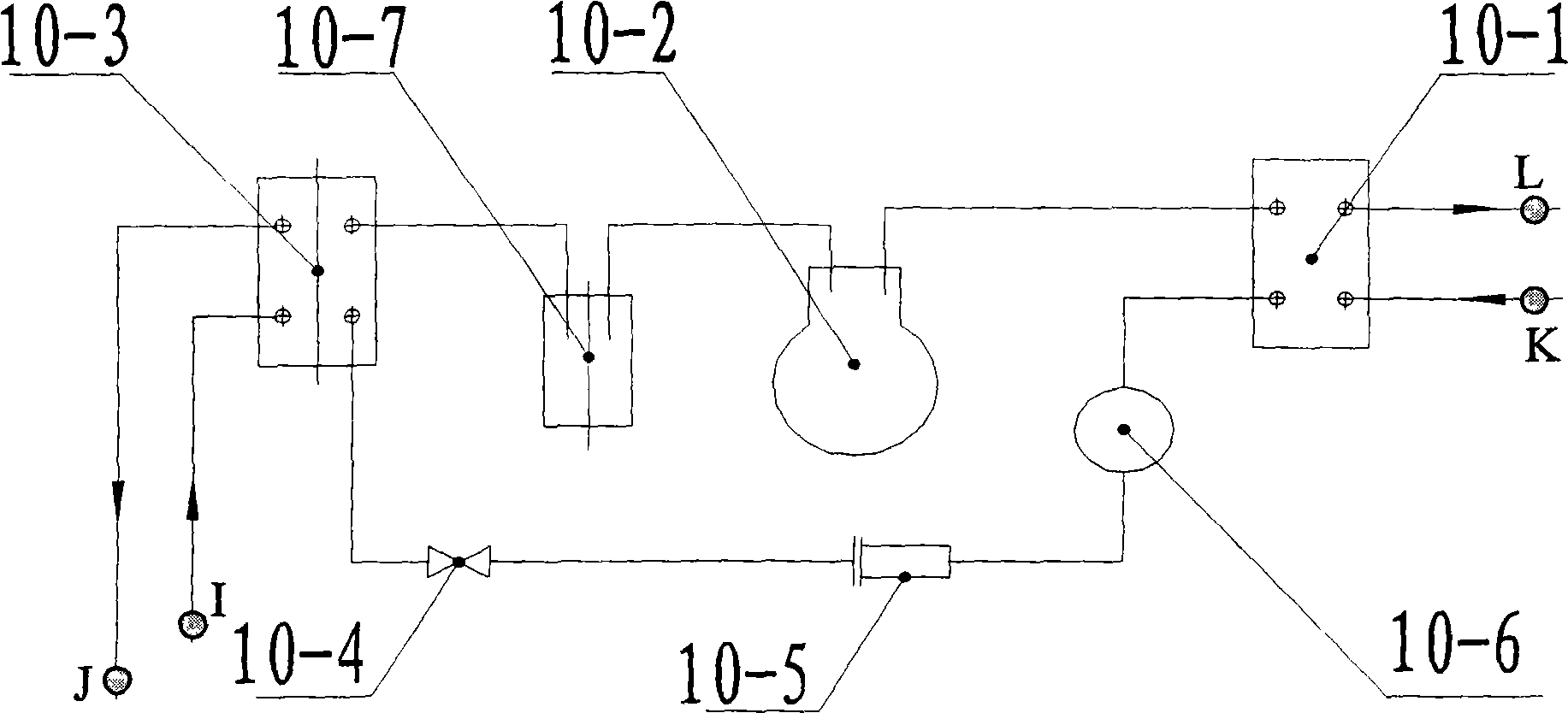

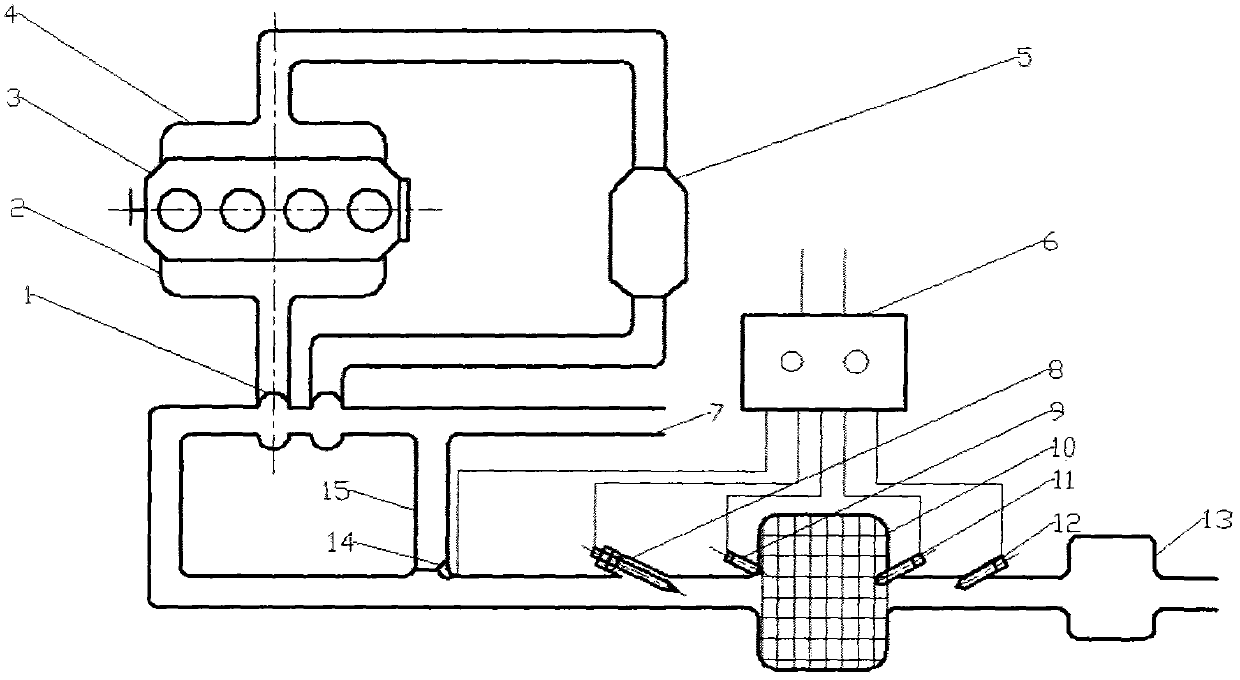

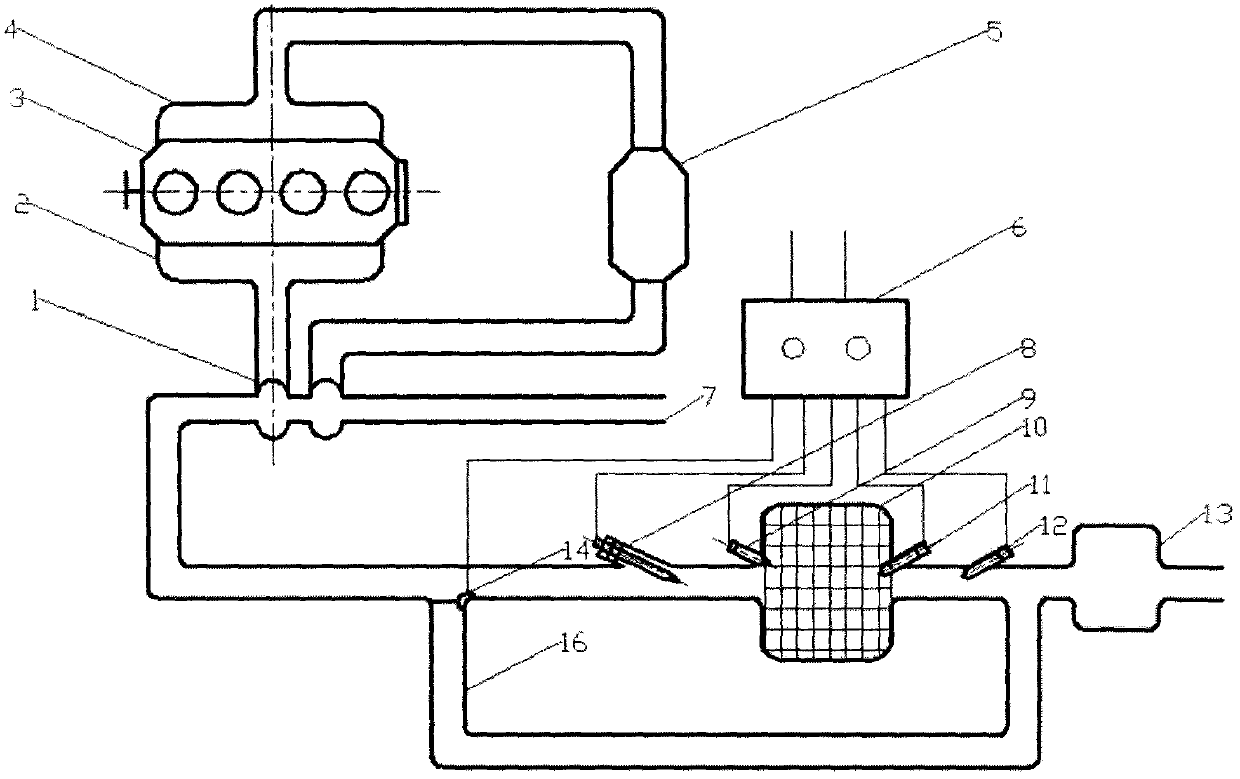

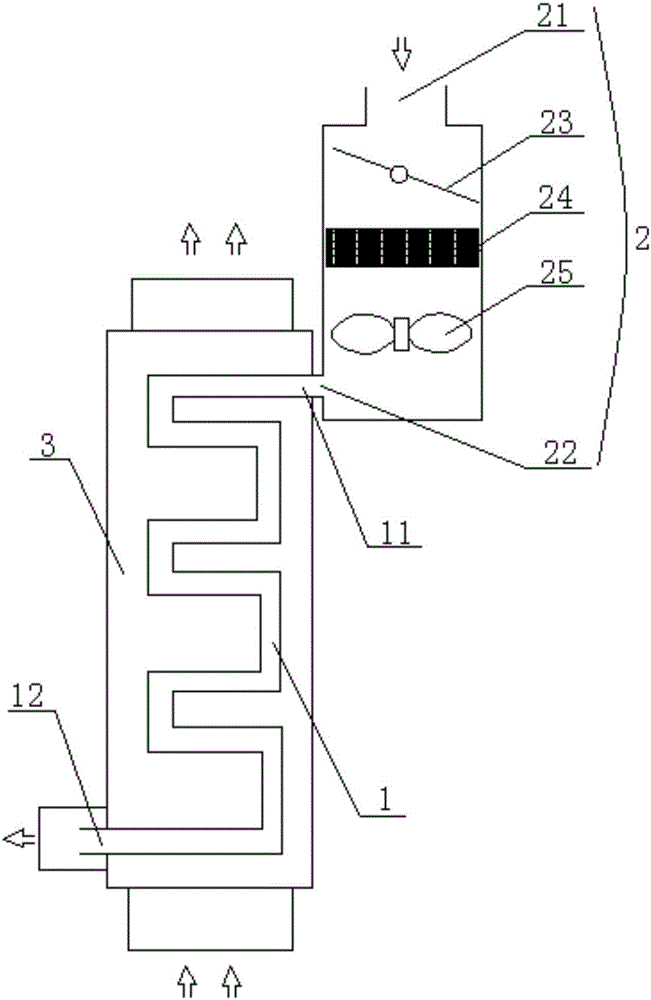

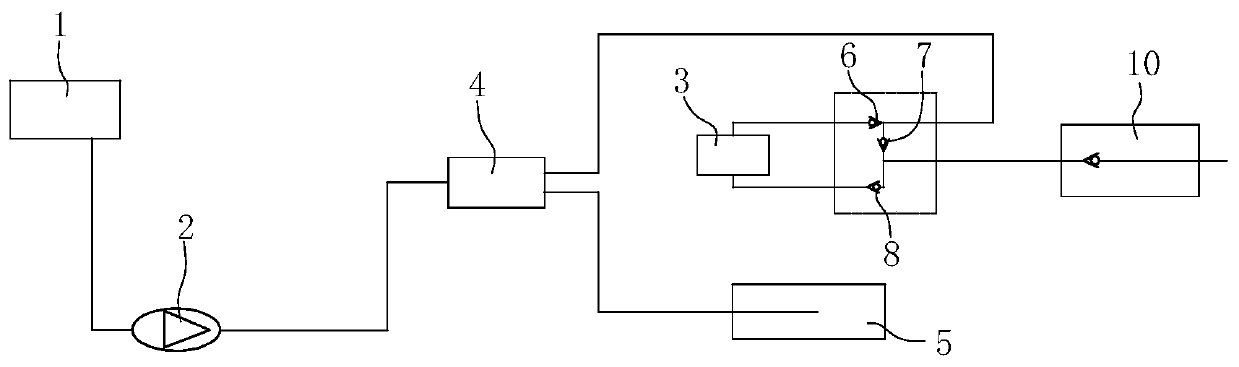

Waste hot water waste heat recovery type heat pump water heating system

InactiveCN101504190ADoes not affect temperatureImprove defrosting effectFluid heatersThermal energyWater source

The invention relates to a hot wastewater waste-heat recovery type heat pump hot-water system by utilizing waste heat of domestic and industrial hot wastewater, which comprises a wastewater recycle pool, a hot water tank, a filter, a water source circulating water pump, a water source heat pump, a make-up water pipe, a heat preservation water tank, a hybrid resource heat pump, a circulating water pump, a make-up water resource heat pump, a wastewater heat exchanger, and a hot wastewater circulating water pump, wherein three groups of modular units, namely the water source heat pump, the make-up water resource heat pump and the hybrid resource heat pump can be cooperated to run, also can be used independently and have flexible combination and convenient operation. An outdoor heat exchanger and a second heat exchanger of the hybrid resource heat pump can utilize thermal energy of air and the hot wastewater respectively; and when the defrosting is performed, the outdoor heat exchanger is taken as a condenser, and the second heat exchanger utilizes the hot wastewater as a heat source and is taken as an evaporator, the system has good defrosting effect and does not influence hot water temperature. The heat pump hot-water system utilizes the waste heat in a step way, fully recovers the waste heat, and has energy conservation and consumption reduction after the hot wastewater is collected.

Owner:黄邦兴 +1

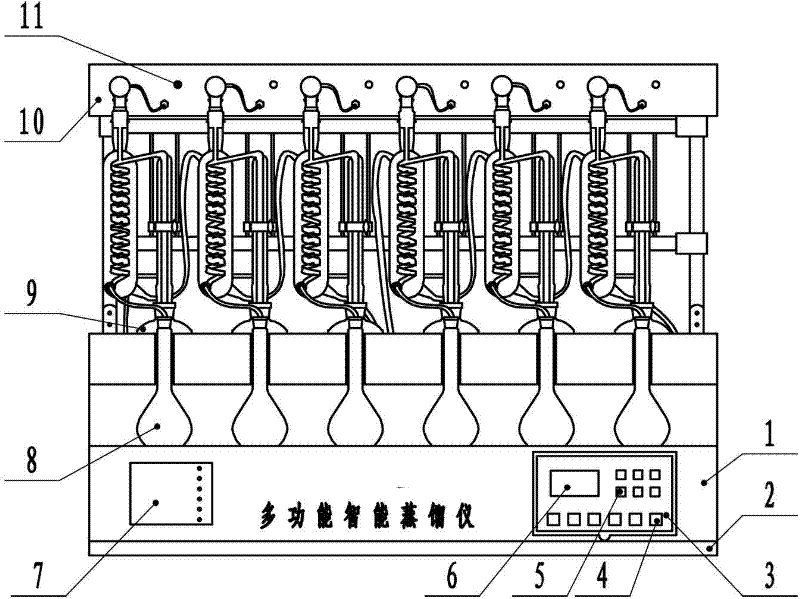

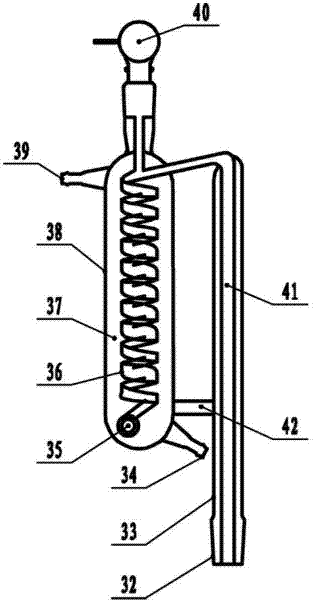

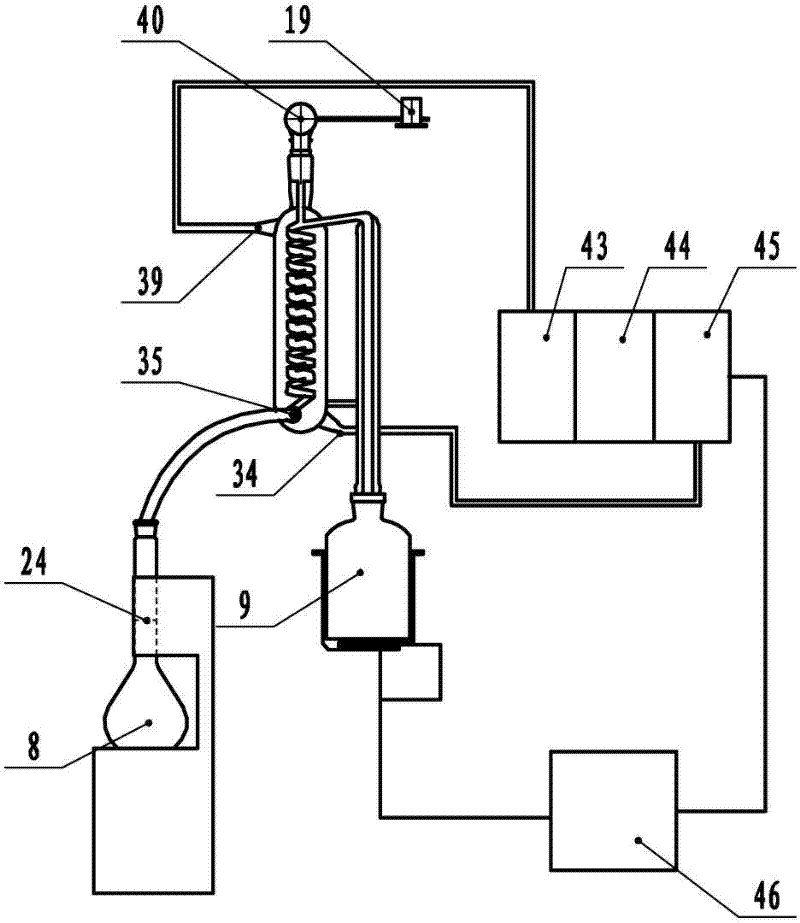

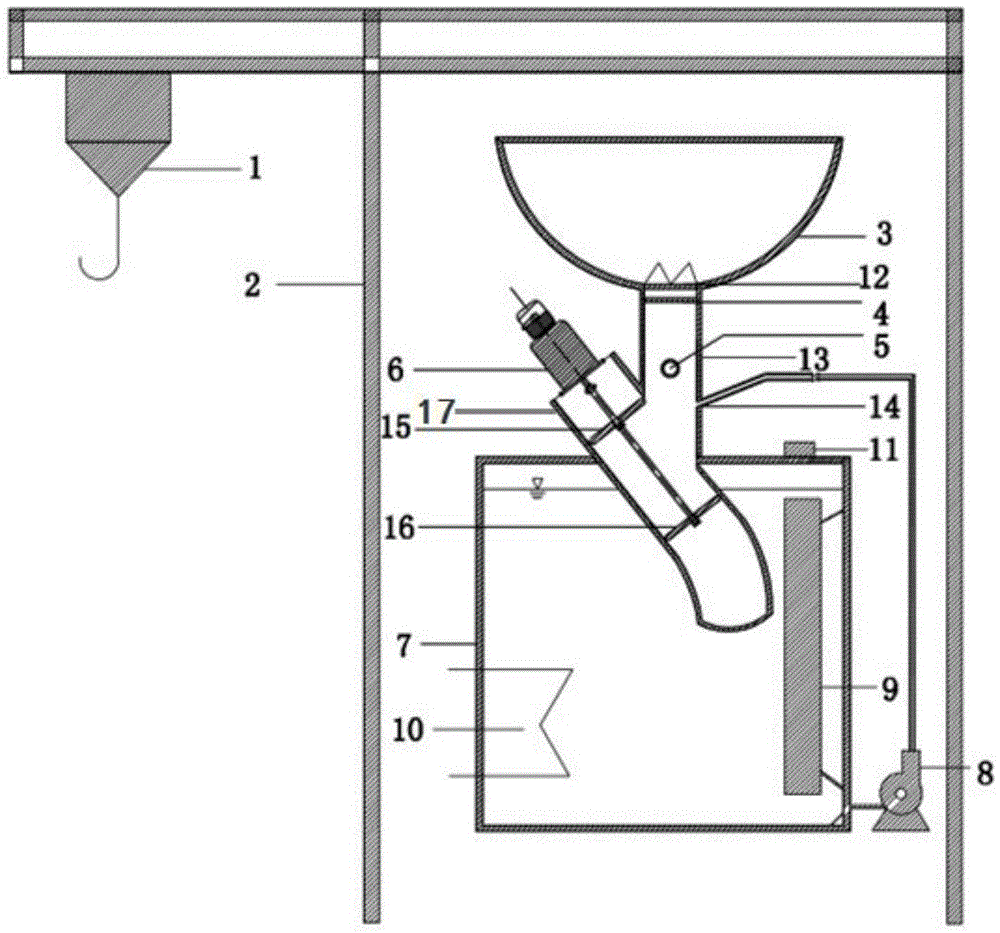

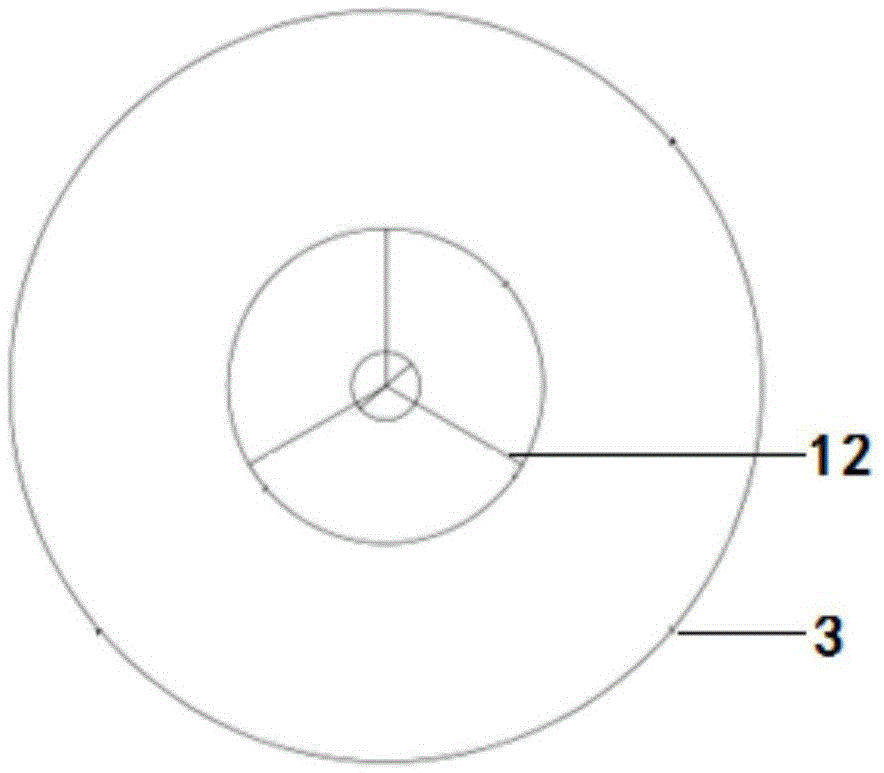

Multifunctional intelligent distillation instrument

InactiveCN102553666AGentle rise in temperatureAvoid burstingLaboratory glasswaresWater in oilDistillation

The invention discloses a multifunctional intelligent distillation instrument. The distillation instrument comprises a shell, a support, heating devices and a cooling device, wherein the heating devices are a plurality of relatively independent heating units, and each heating unit comprises a heating jacket, a heating bar, a heating bowl and a distillation bottle; the heating bowl is arranged in a heating box, the open end of the upper part of the heating bowl is provided with a stove port, and the distillation bottle is arranged in the stove port; the heating jacket is fixed on the periphery of the heating bowl; and the distillation instrument is also provided with a measurement and control device, a temperature sensor is fixed on the top of each heating bowl and connected with a control circuit board through a signal wire and transfers heating temperature to a control chip on the control circuit board, and a liquid level sensor is fixed on a console and senses the liquid level state in a volumetric flask through an optical fiber. The instrument can be widely applied to distillation treatment of projects of volatile phenol, cyanide, ammonia nitrogen, Kjeldahl nitrogen, water in oil and the like in various chemical laboratories requiring distillation treatment in environment friendliness, disease control, water supply and drainage, colleges, research institutions, industrial enterprises and the like.

Owner:山东益源环保科技有限公司

Protection material hot-cold pulse fatigue resistance test apparatus

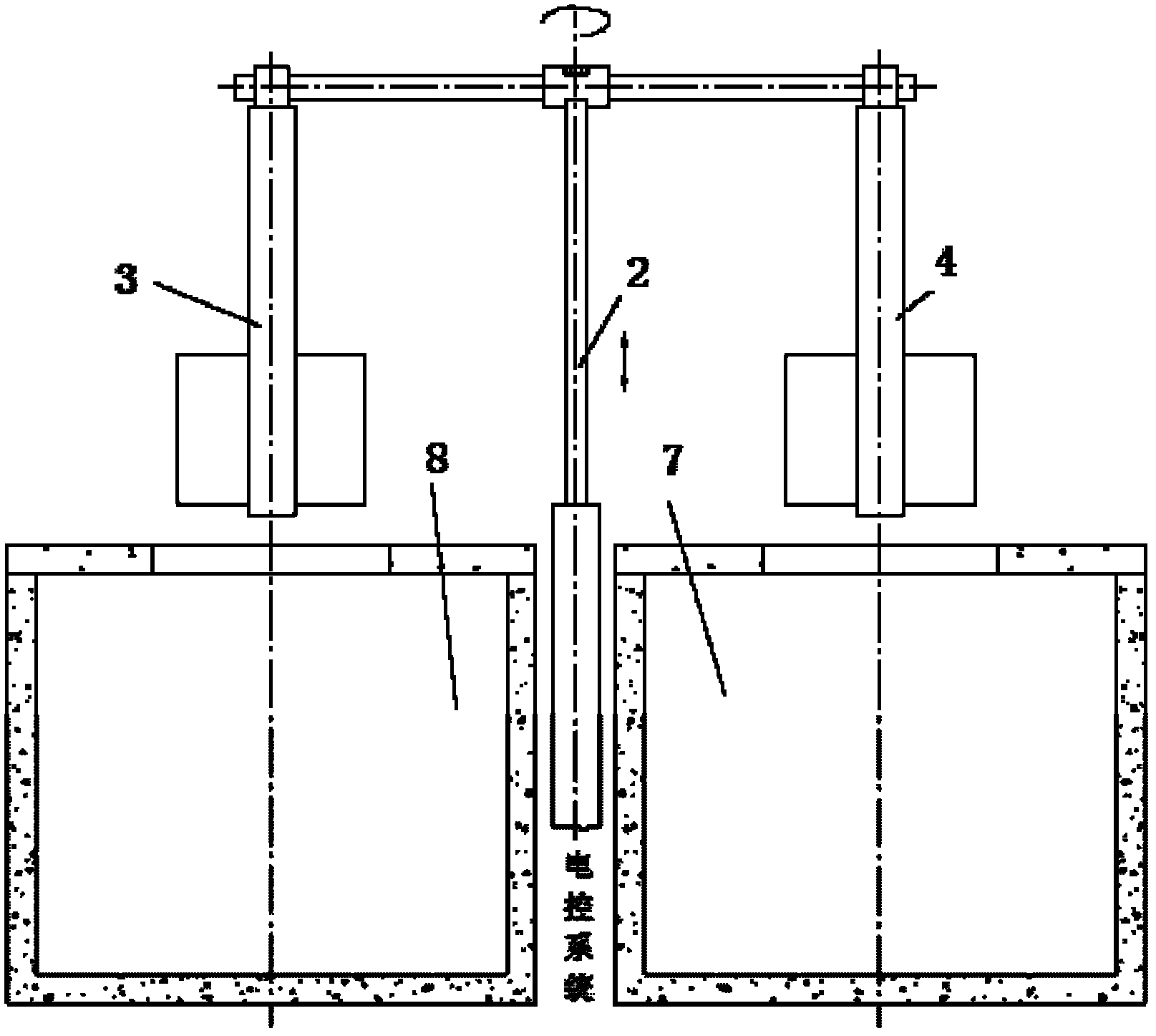

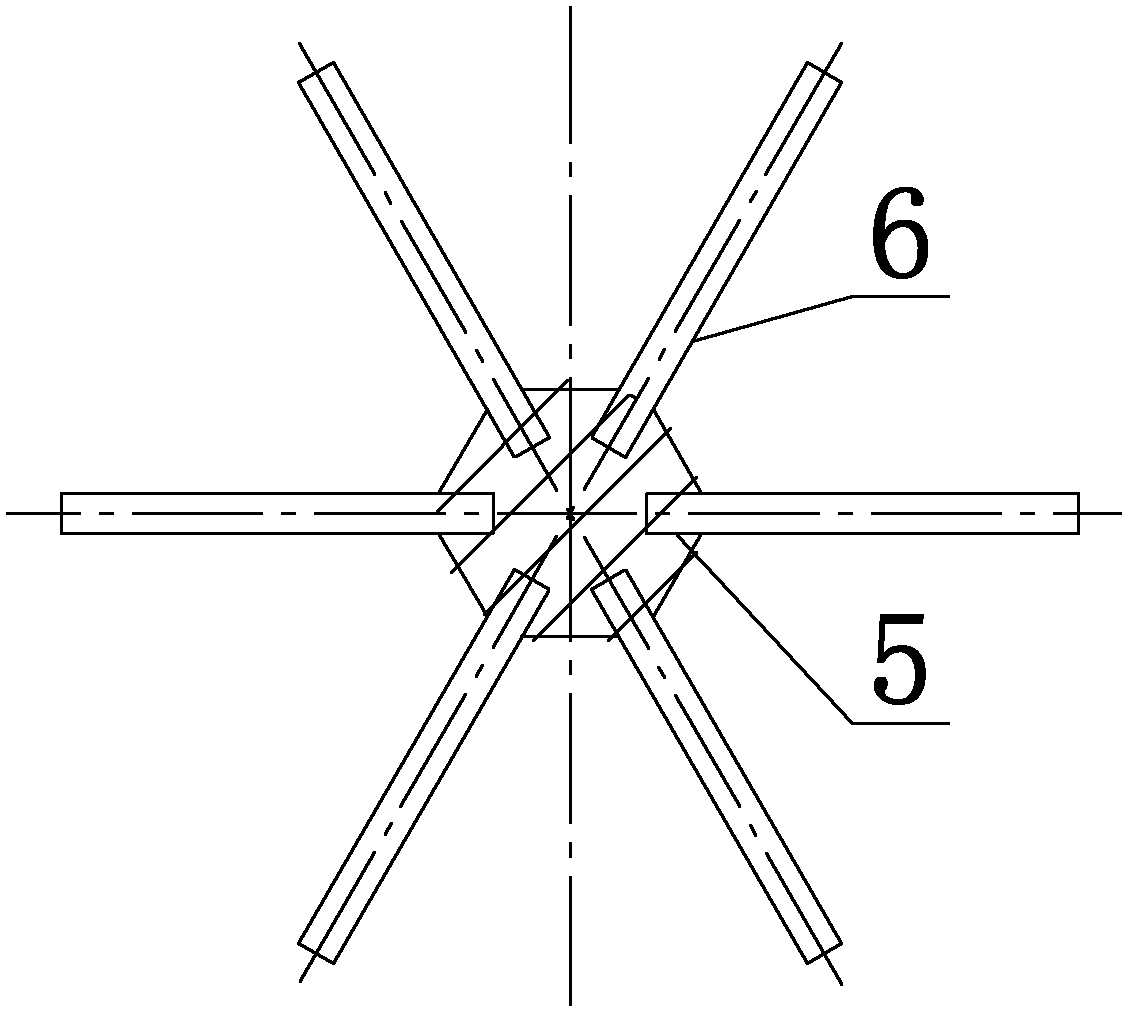

InactiveCN103257104APerformance pros and consHigh temperature control accuracyWeather/light/corrosion resistanceUsing mechanical meansEngineeringElectric control

A protection material hot-cold pulse fatigue resistance test apparatus includes an electric control system (1), an elevating rotation device (2), sample supports and test tanks wherein the electric control system (1) and the elevating rotation device (2) are connected into one; the sample supports are fixedly arranged on the elevating rotation device (2) having a rotary axis arranged in the vertical direction, and sample slots (5) used for disposing a sample (6) are fixedly arranged on the sample supports; and the test tanks used for disposing the sample (6) are arranged below the rotation paths of the sample supports outside the rotary axis of the elevating rotation device (2). The apparatus has the advantages of high automation degree, good temperature stability and excellent technological effects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

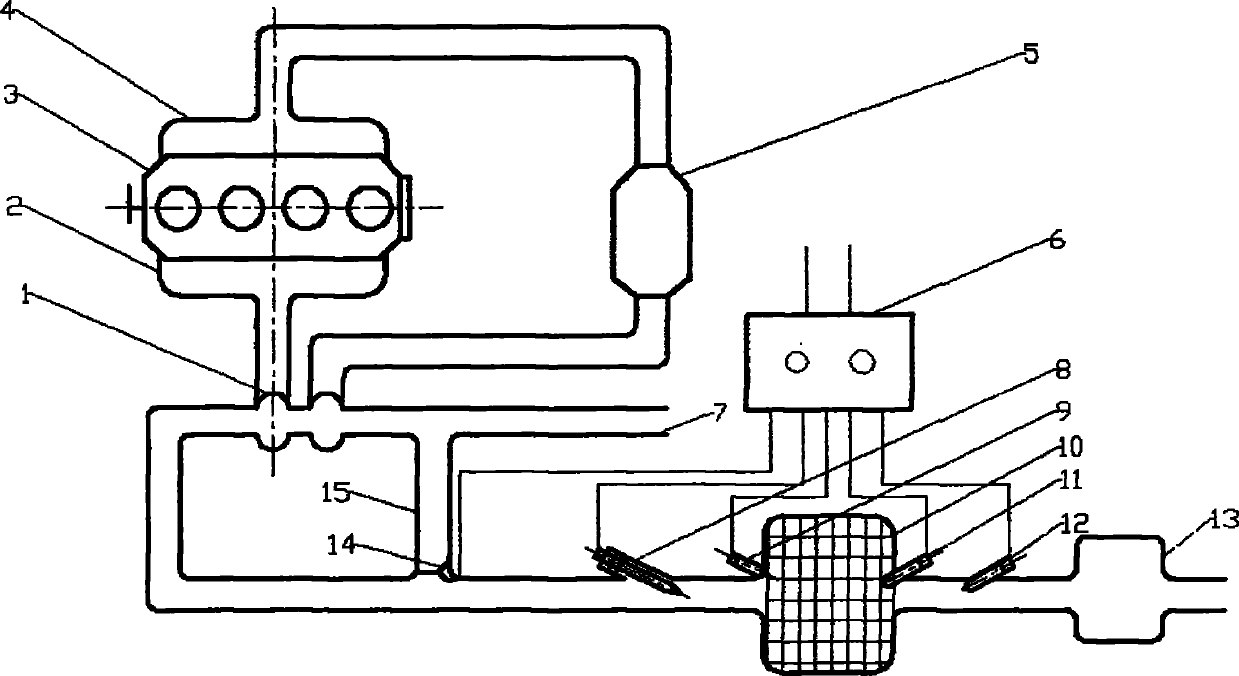

Engine waste gas aftertreatment system

InactiveCN102562233AStable jobEnvironmental protectionInternal combustion piston enginesExhaust apparatusAtmospheric airTurbocharger

The invention discloses an engine waste gas aftertreatment system, being used for purifying waste gas discharged from an exhaust pipe of the engine. The engine waste gas aftertreatment system comprises a catalytic converter, wherein the catalytic converter is connected with the exhaust pipe of the engine by virtue of a turbocharger, the turbocharger is connected with an air inlet pipe of the engine by virtue of an air inlet intercooler, the catalytic converter contains a catalyst which is used for an assisting reaction; when the engine is normally operated, an exhaust switching valve controls high temperature waste gas to enter into the catalytic converter, thus the high temperature waste gas enters into the air after being purified; and when the engine is in a reverse towing working condition, and the exhaust switching valve controls low temperature exhausted gas to enter into the engine to be circulated from a return line or is directly discharged into the air from a bypass pipeline, thus temperature of an aftertreatment device is not influenced by the low temperature exhausted gas. By adopting the engine waste gas aftertreatment system disclosed by the invention, the pipeline of the aftertreatment device is improved, the influence of exhaust to the temperature of the aftertreatment device is reduced, thus the aftertreatment device maintains high-efficiency purification exhaust when the engine is converted into the normal operation from the 'reverse towing' working condition, and hidden troubles that environment is polluted caused by the uncompleted waste gas purification can be effectively eliminated.

Owner:GUANGXI YUCHAI MASCH CO LTD

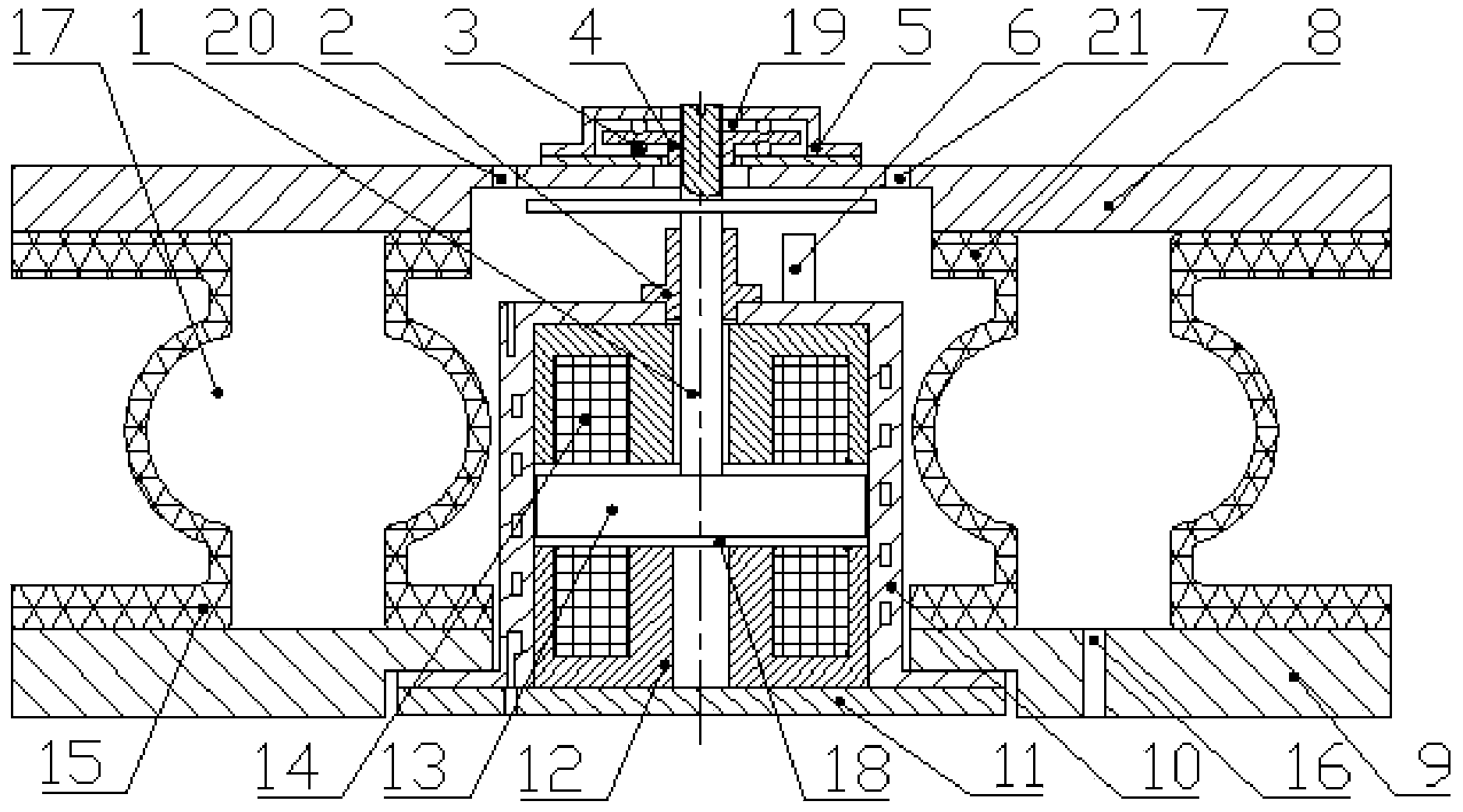

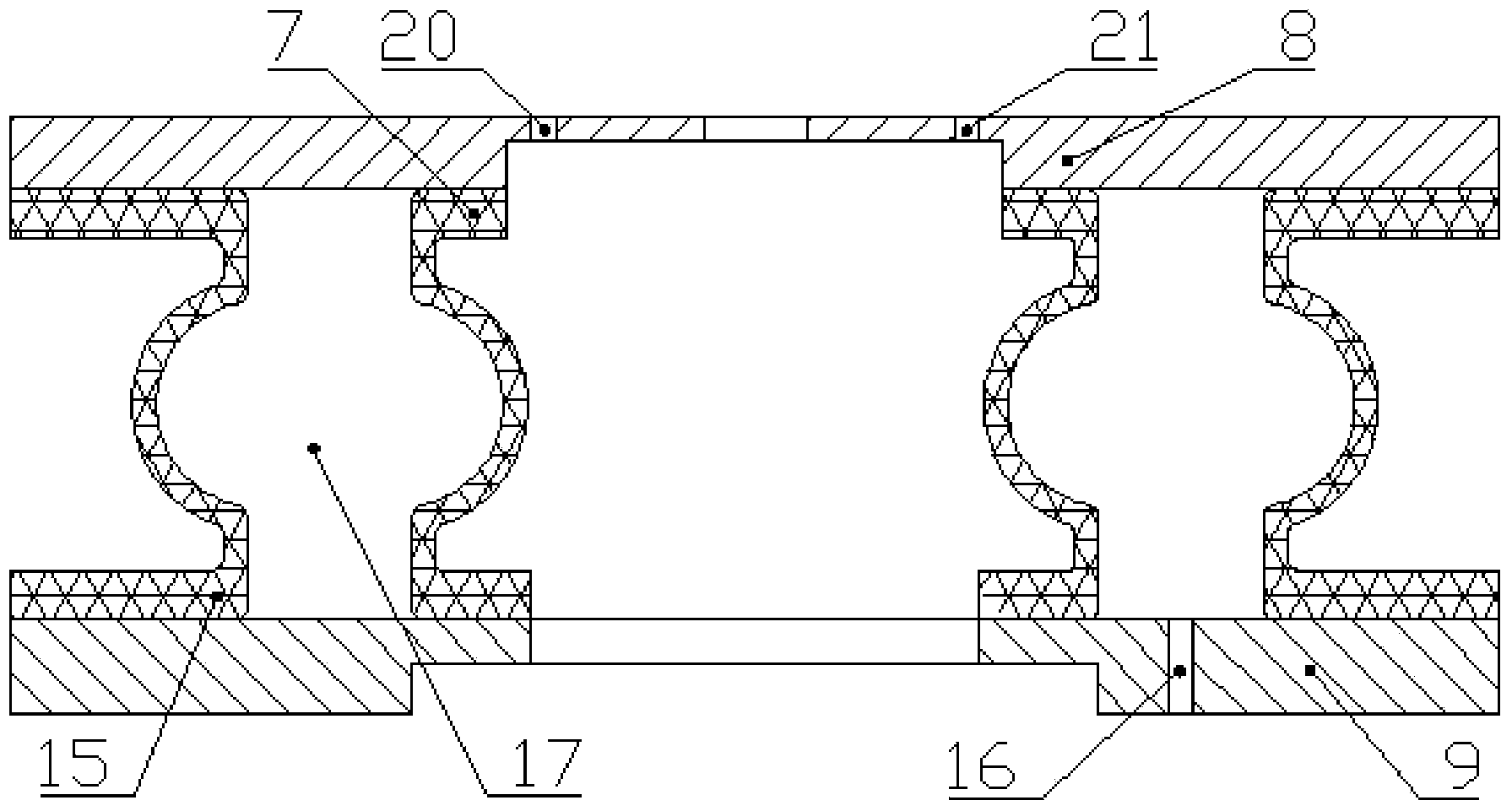

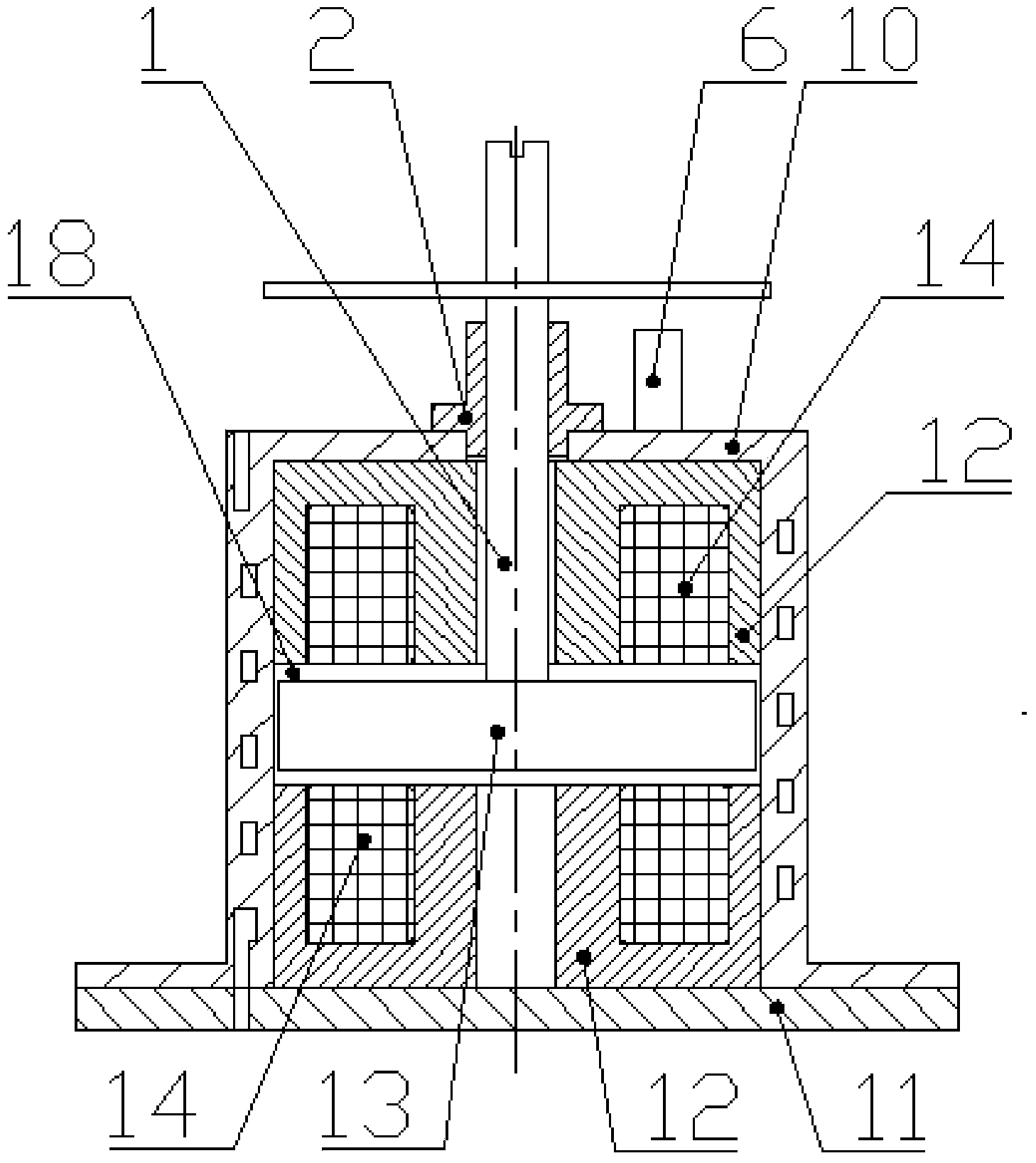

Air spring-magnetic suspension combined vibration isolator

InactiveCN104019179AImprove carrying capacityExcellent high-frequency vibration isolation performanceNon-rotating vibration suppressionAir springEngineering

The invention discloses an air spring-magnetic suspension combined vibration isolator. The combined vibration isolator comprises air springs (17), a magnetic suspension vibration isolator body (18) and a connecting component (19). The magnetic suspension vibration isolator body (18) is arranged between inner bag bodies (7) of the air springs (17). The connecting component (19) comprises a thrust disc (4), a pressing plate (5) and balls (3) with a holder, wherein the balls (3) with the holder are arranged on the thrust disc (4) in the vertical direction. The thrust disc (4) and the pressing plate (5) are connected with a connecting rod (1) of the magnetic suspension vibration isolator body (18) and an upper cover plate (8) of the air springs (17). The air spring-magnetic suspension combined vibration isolator has the advantages of being wide in working band, high in reliability, compact in structure, high in bearing capacity, convenient to maintain and the like and has great application prospects in the field of marine power plant vibration isolation.

Owner:WUHAN UNIV OF TECH

Cigarette with porous material

A cigarette with a porous material comprises a filter tip and a tobacco shred stick, and is characterized in that a hollow tube is axially arranged in the tobacco shred stick, and the porous material is arranged at a position where the hollow tube is connected with the filter tip. The structure of the cigarette is improved, and enough air is provided for combustion of tobacco shreds in a burning and smoking process of the cigarette to reduce CO gas generated by incomplete combustion of the tobacco shreds at high temperature. The original overall size of the cigarette is not changed, the CO release amount of the cigarette and smoking temperature of mainstream smoke can be reduced obviously on the premise of not changing the original smoking taste, and therefore, consumers can receive the cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

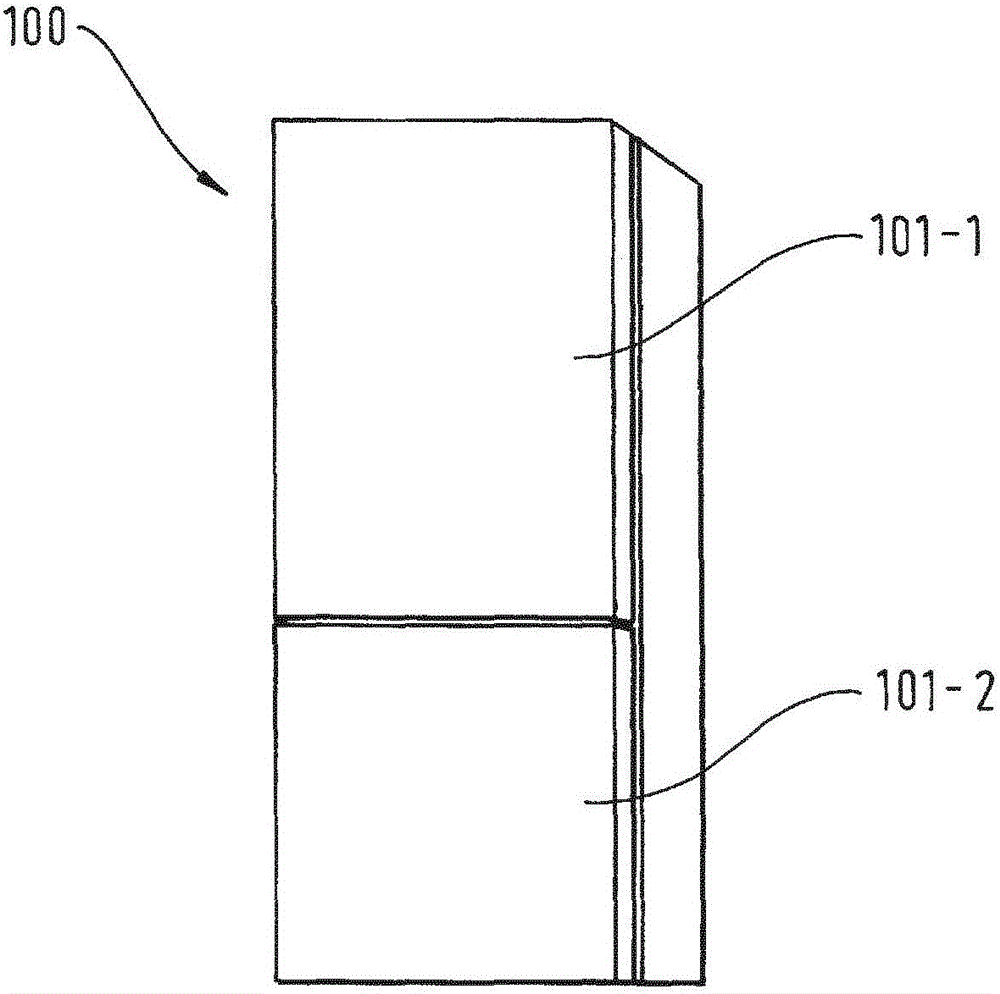

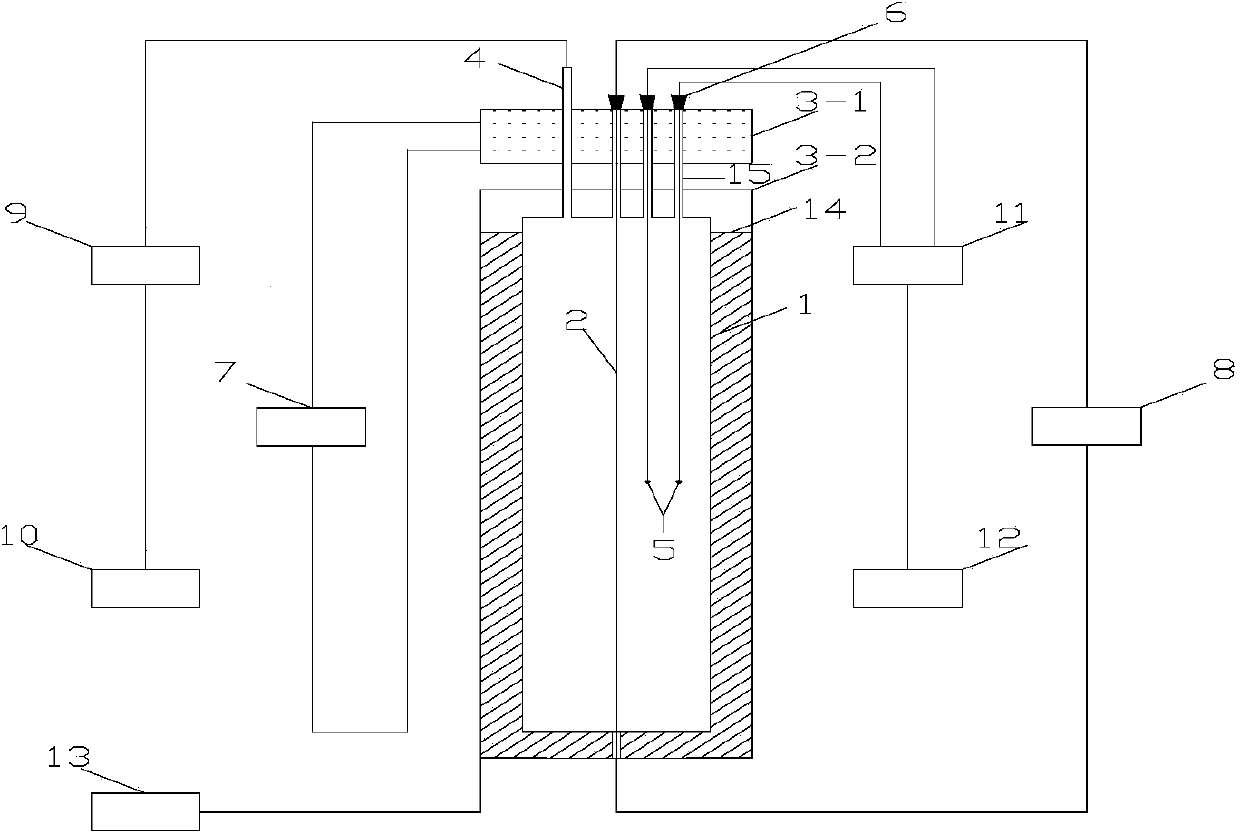

Refrigeration device having a plurality of refrigeration compartments

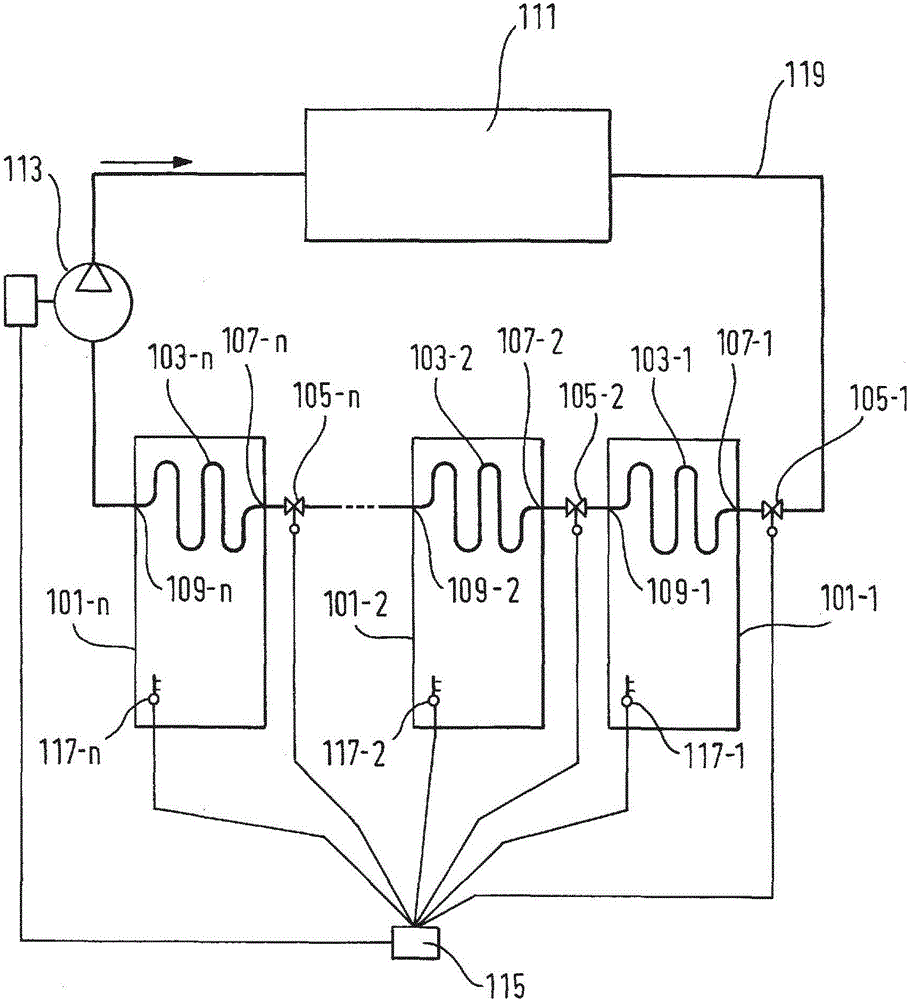

ActiveCN105829815ADoes not affect temperatureReduce flow rateMechanical apparatusDomestic refrigeratorsEngineeringRefrigerant

The invention discloses a refrigeration device having a plurality of refrigeration compartments. The present invention relates to a refrigeration device (100) having a first refrigeration compartment (101-1) for storing refrigerated goods at a first temperature, said first refrigeration compartment comprising a first evaporator (103-1) with a first controllable expansion valve (105-1) at the refrigerant inlet (107-1) of the first evaporator (103-1), and having a second refrigeration compartment (101-2) for storing refrigerated goods at a second temperature, said second refrigeration compartment comprising a second evaporator (103-2) with a second controllable expansion valve (105-2) at the refrigerant inlet (107-2) of the second evaporator (103-2), in which refrigeration device a refrigerant outlet (109-1) of the first evaporator (103-1) is connected to the second controllable expansion valve (105-2) at the refrigerant inlet (107-2) of the second evaporator (103-2).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

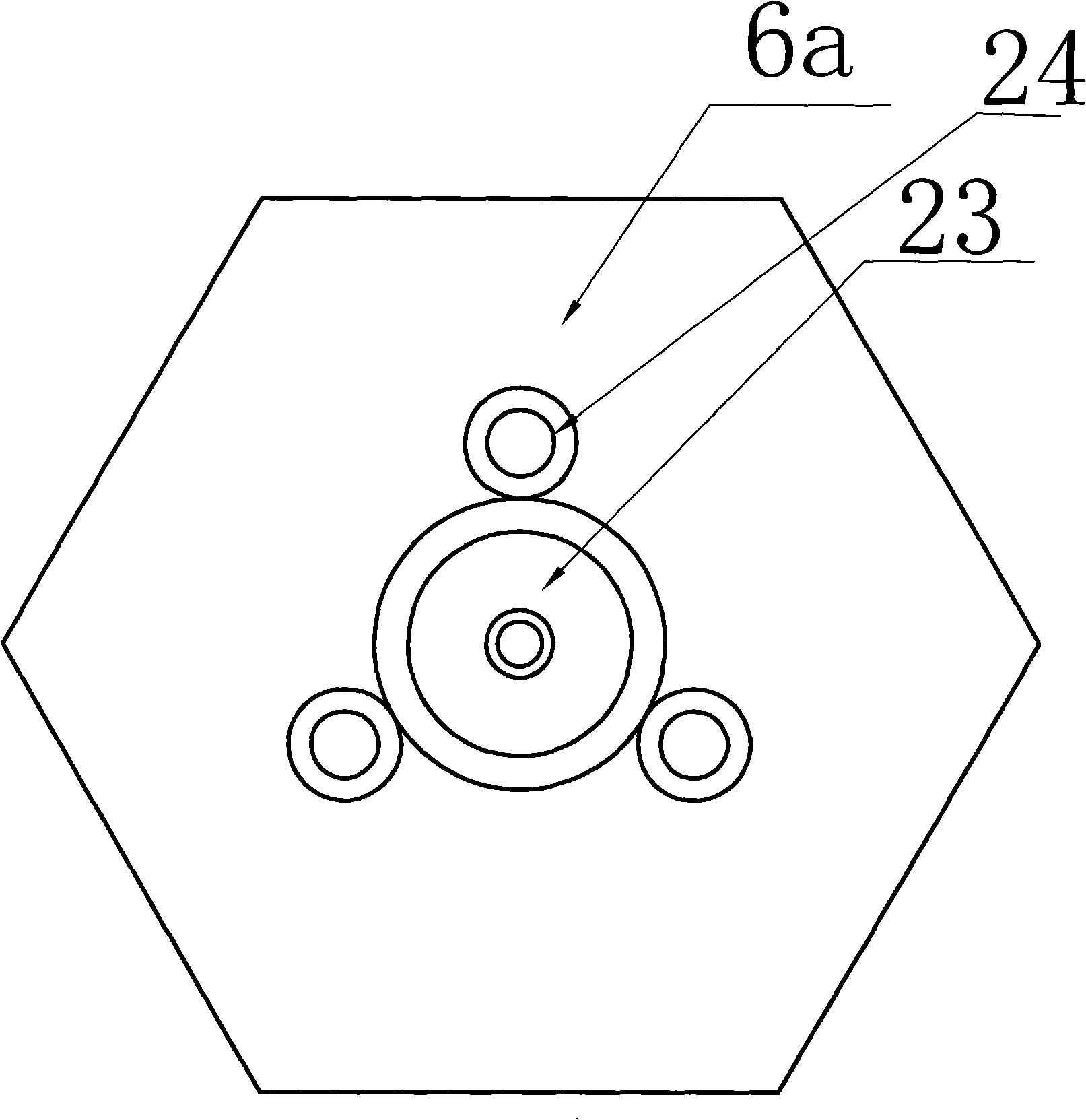

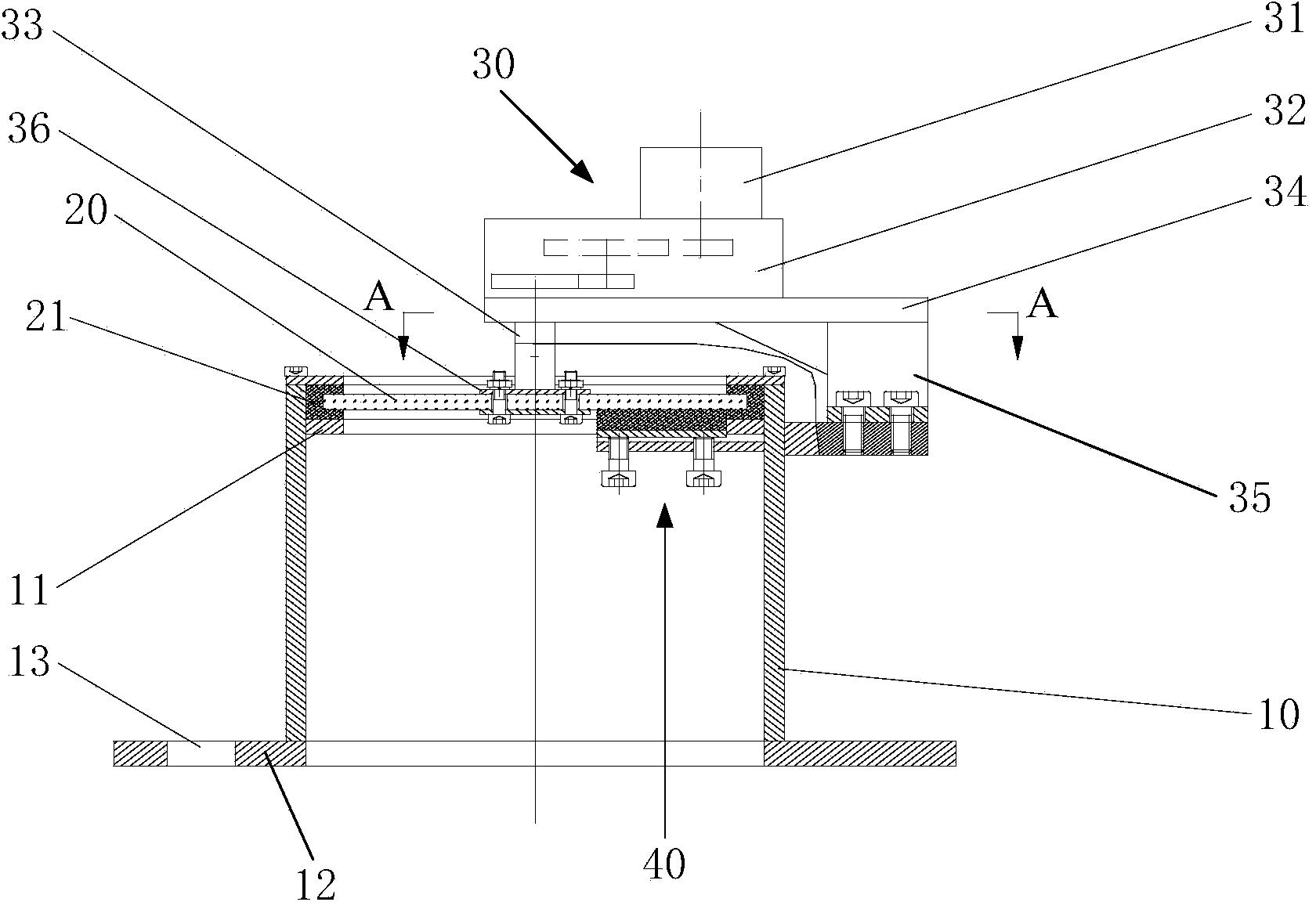

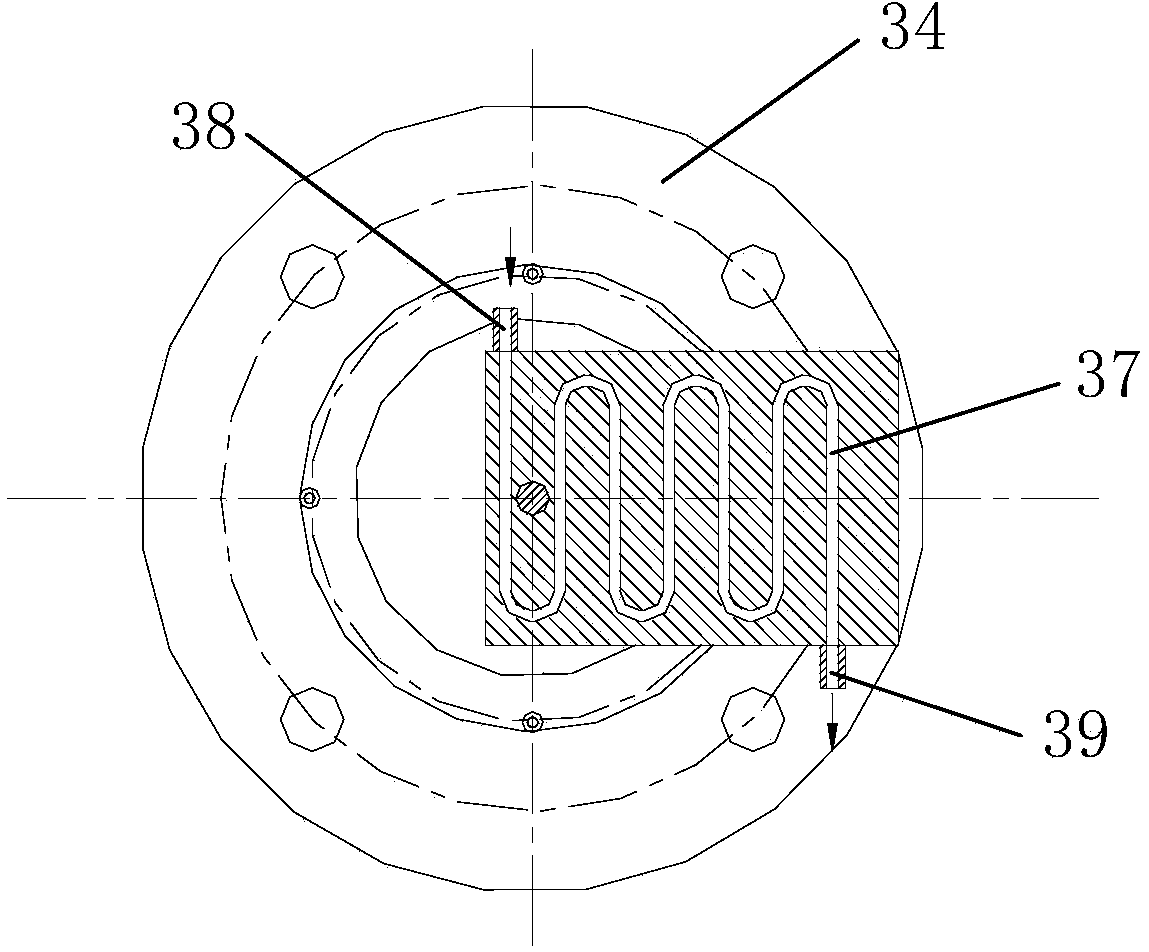

Self-cleaning observation window device

ActiveCN103913072AGuaranteed observation effectWill not affect the line of sightFurnace componentsCleaning using toolsEngineeringElectrical and Electronics engineering

The invention relates to a self-cleaning observation window device comprising a housing with two end openings, observation window glass, a rotary drive mechanism, and a cleaning brush mechanism. One end opening of the housing is fixed to an article to be observed. The observation window glass is mounted at the other end opening of the housing. The fixed end of the rotary drive mechanism is fixed outside the housing; the moving end of the rotary drive mechanism is fixedly connected with the observation window glass; the rotary drive mechanism drives the observation window glass to rotary around a center shaft in the housing. The cleaning brush mechanism is fixed inside the housing and contacts with the inner surface of the observation window glass. The self-cleaning observation window device has the advantages that the rotary drive mechanism drives the observation window glass to rotate just after the housing is mounted on an opening of the article to be observed, the observation window glass is cleaned by the cleaning brush mechanism meanwhile, cleanliness of the observation window glass is ensured, no influence is generated upon interior temperature and vacuum degree of the article to be observed, and the self-cleaning observation window device is more widely applicable.

Owner:BAOSTEEL ENG & TECH GRP

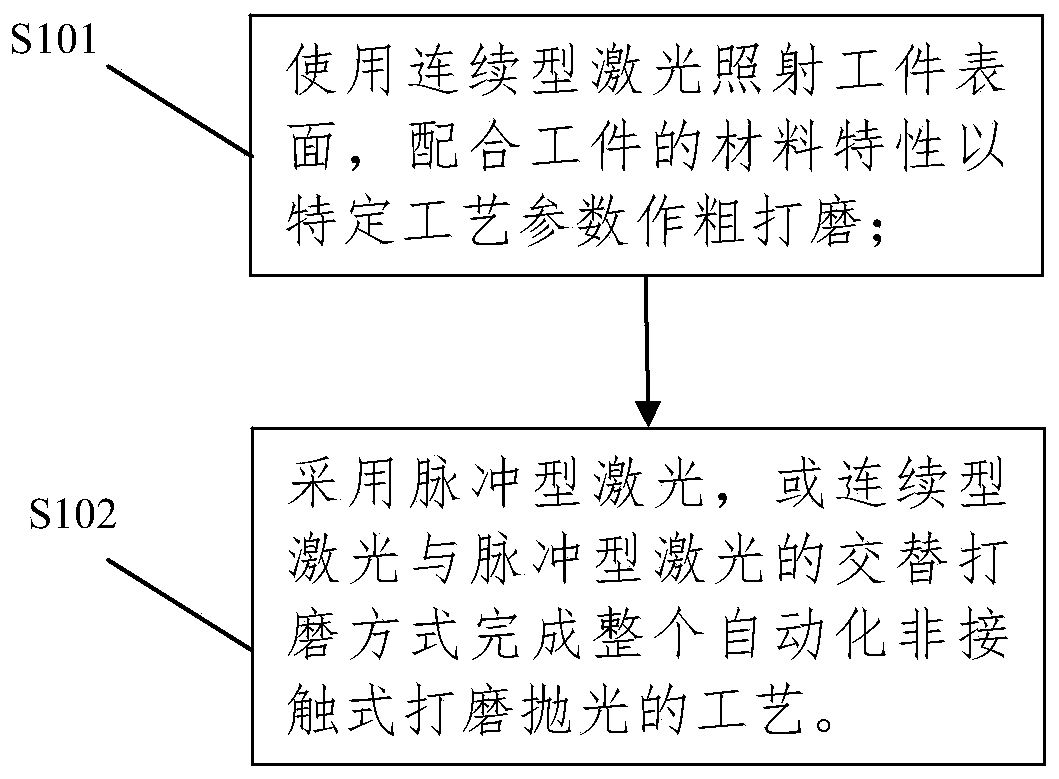

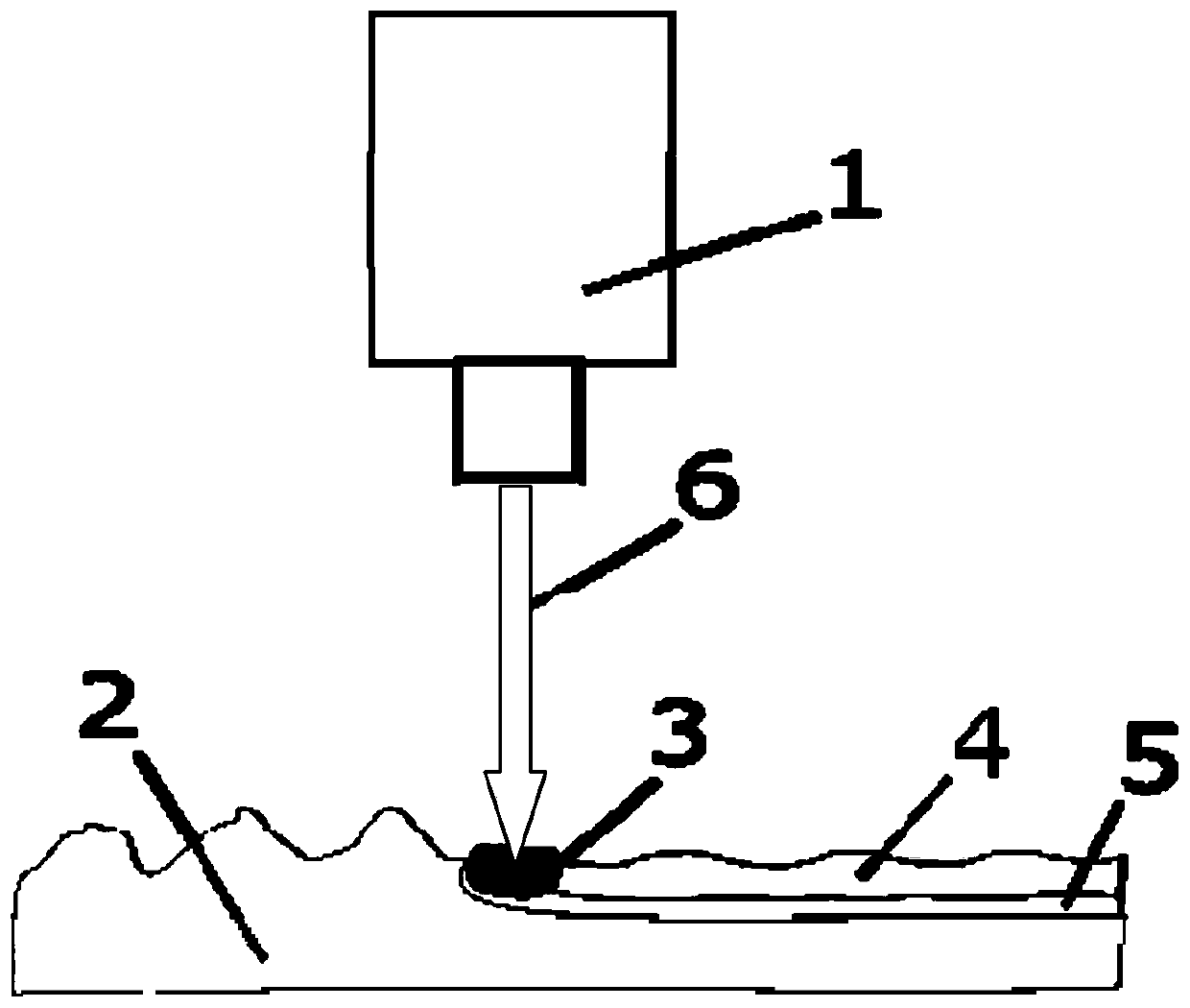

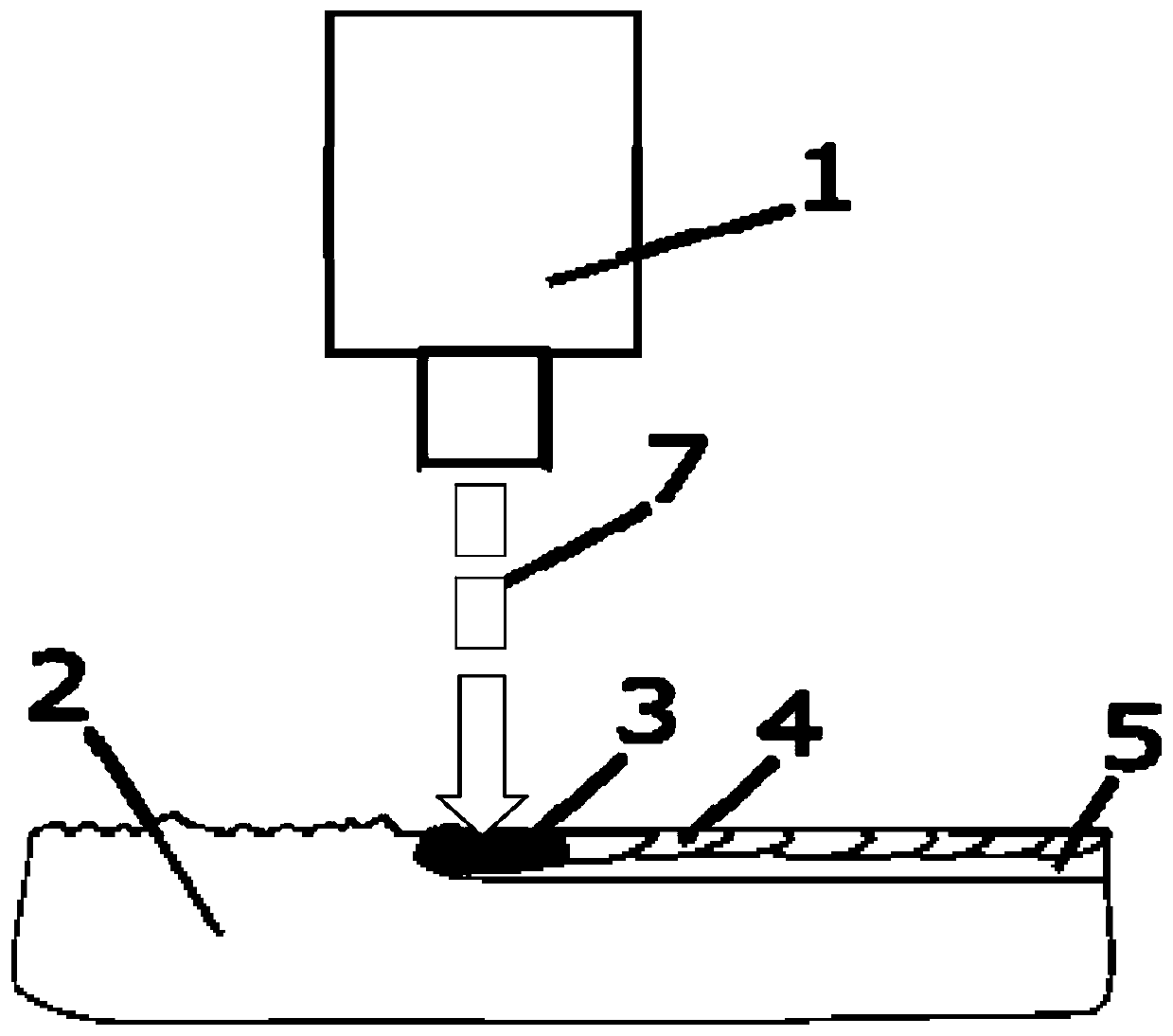

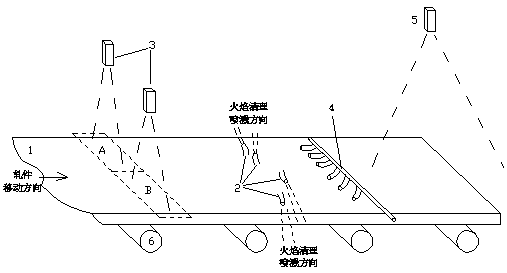

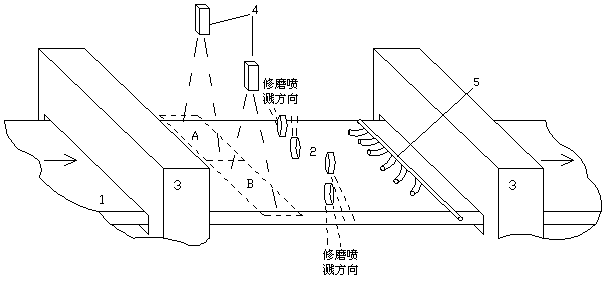

Method and device for grinding and polishing parts and molds by mixing laser

ActiveCN109848566AHighlight substantiveSignificant progressLaser beam welding apparatusContact typeMachining process

The invention discloses a method and a device for grinding and polishing parts and molds by mixing laser. The method comprises the following steps that firstly, a workpiece surface is irradiated by using a continuous laser, and a material characteristic of the workpiece is matched to carry out coarse grinding according to specific technological parameters; then, a pulse laser, or a continuous laser and pulsed laser alternate grinding mode is adopted to complete a whole automatic non-contact type grinding and polishing process. The method and the device have the advantages that the implementation is simple, the temperature of a part body cannot be influenced in the machining process, and the influence on the precision of the part is avoided, and certain complex geometrical surfaces which cannot be machined by a traditional method can be machined.

Owner:HONG KONG PRODUCTIVITY COUNCIL

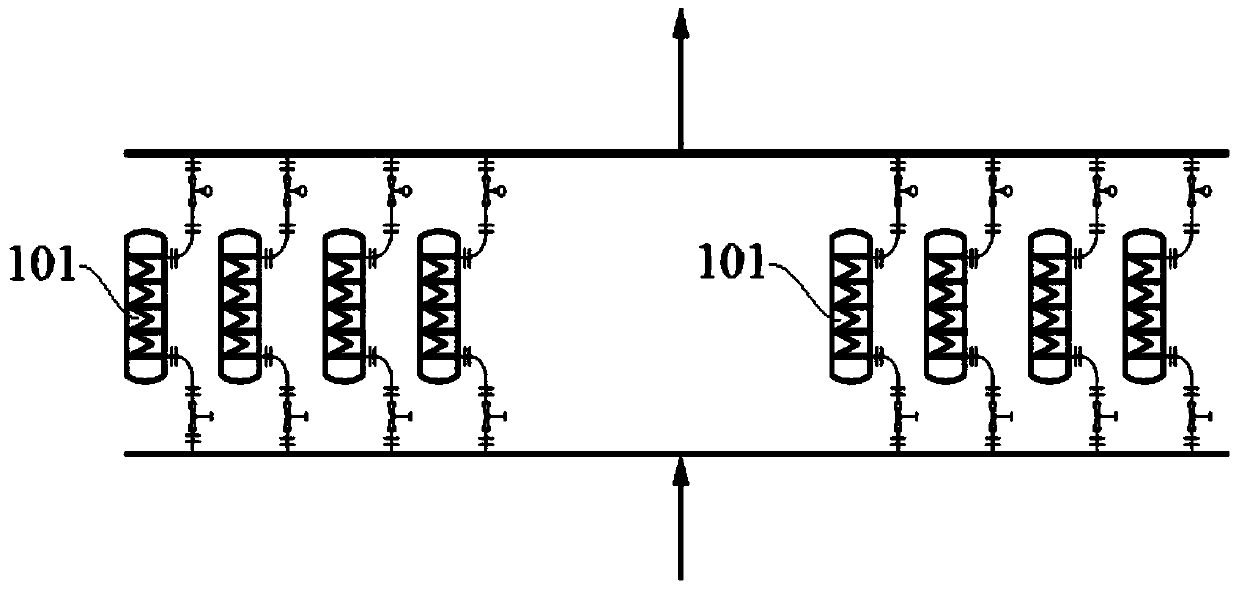

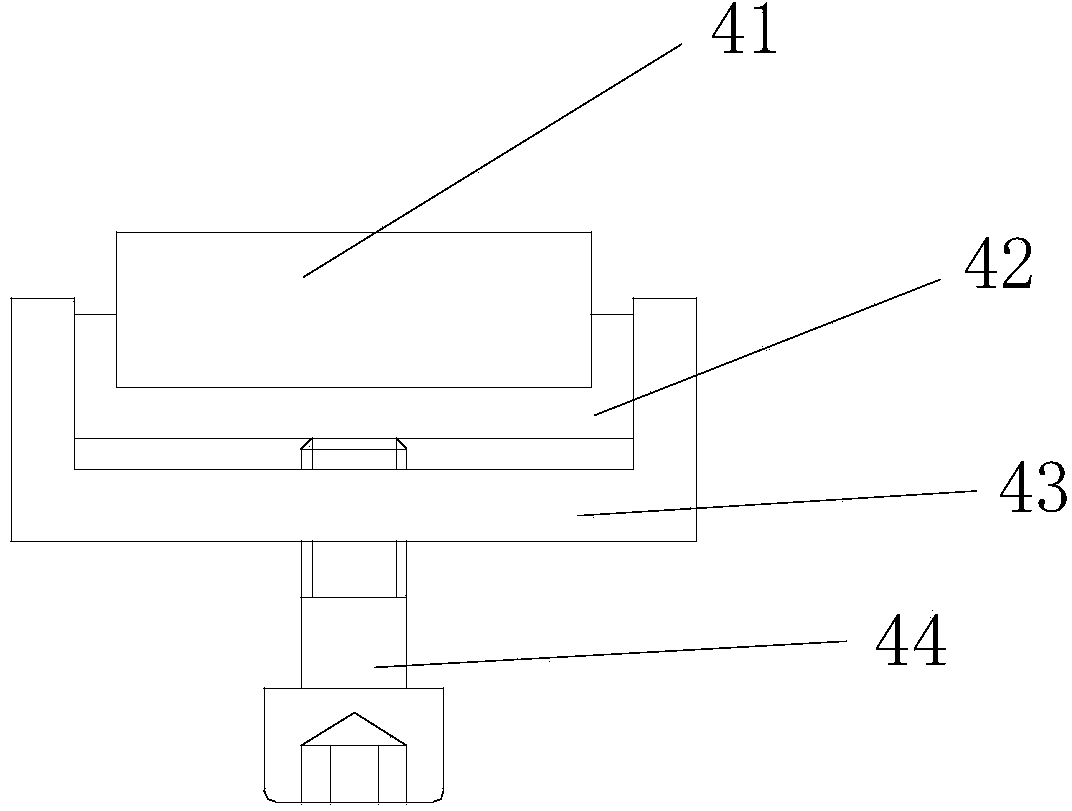

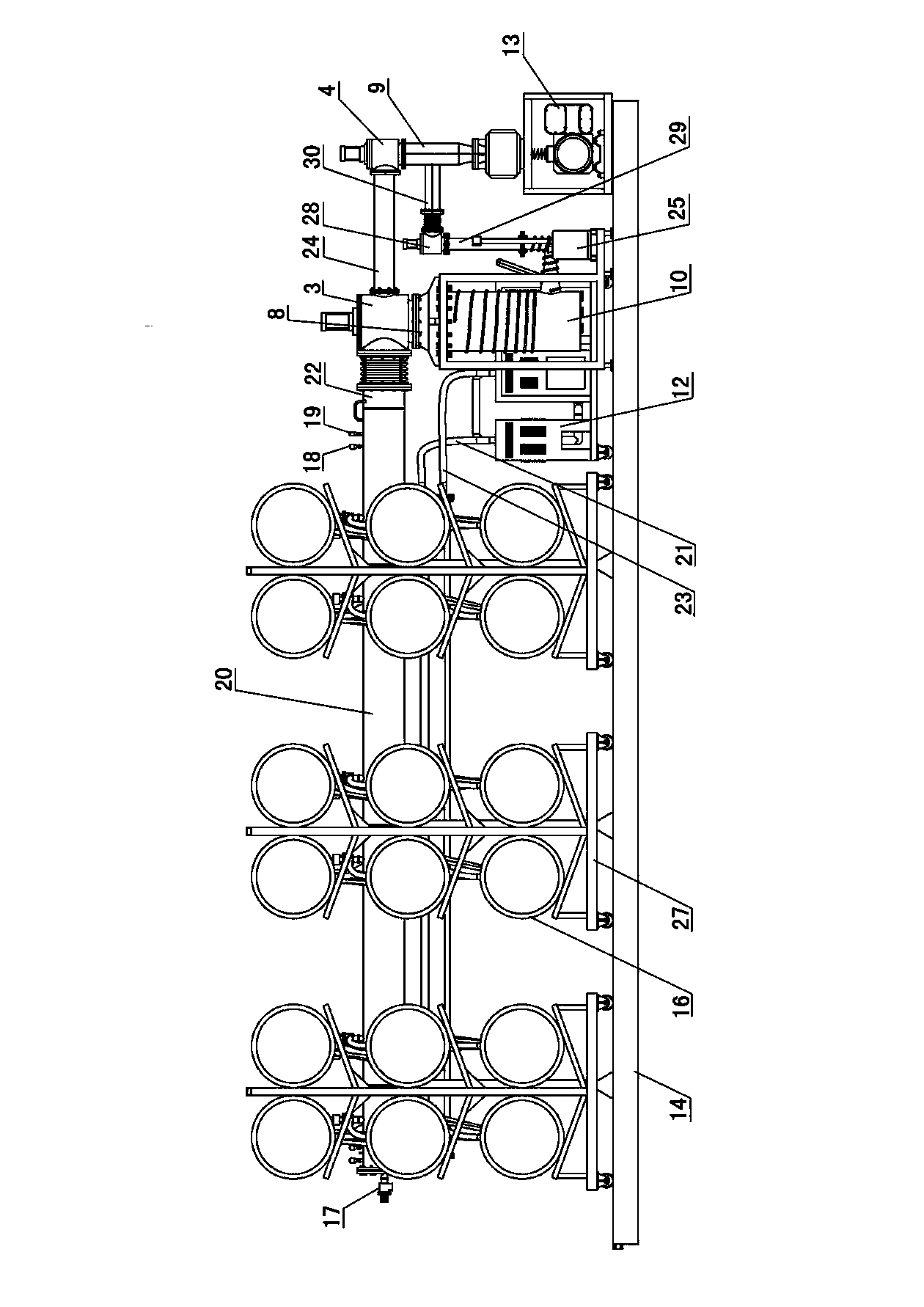

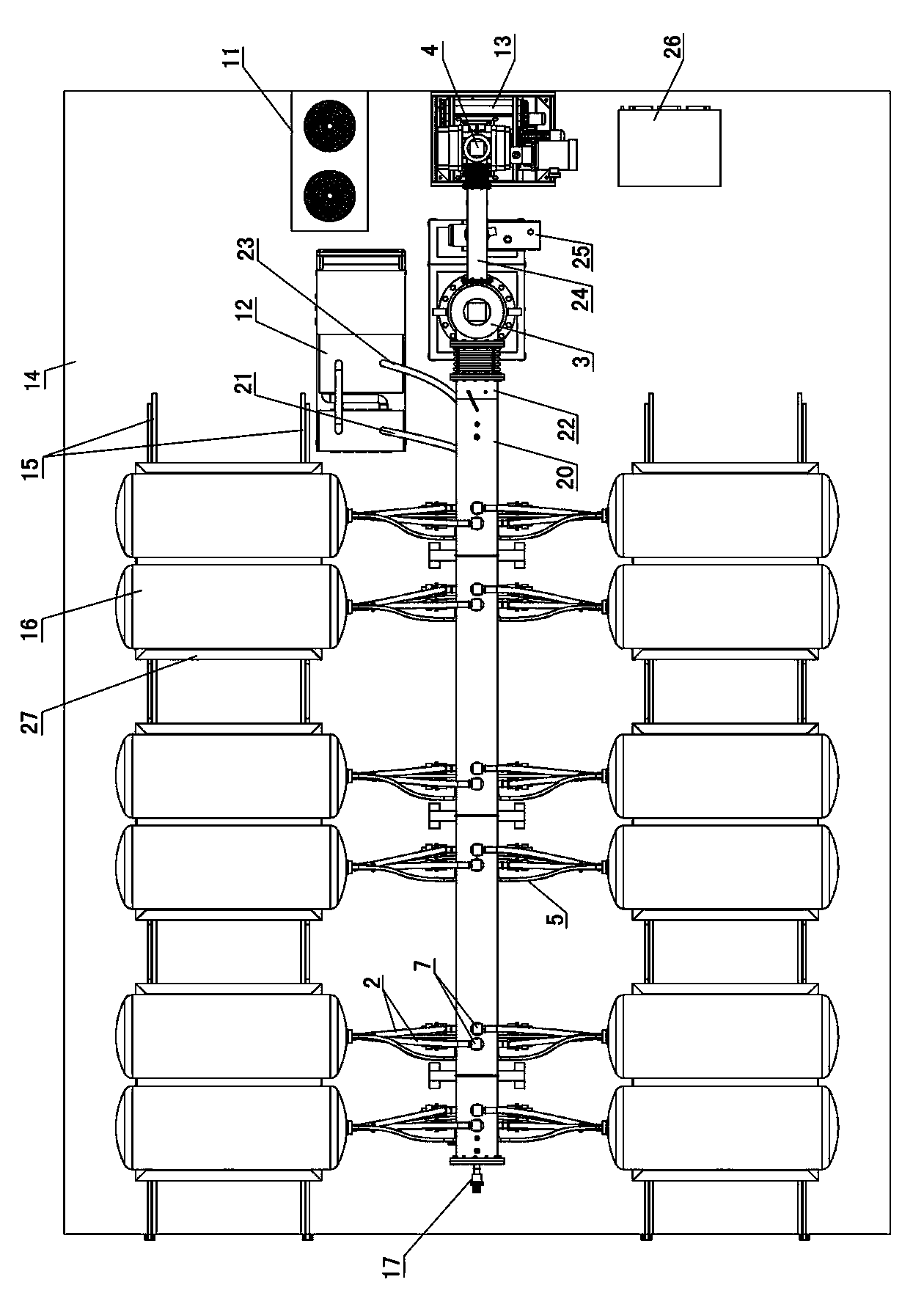

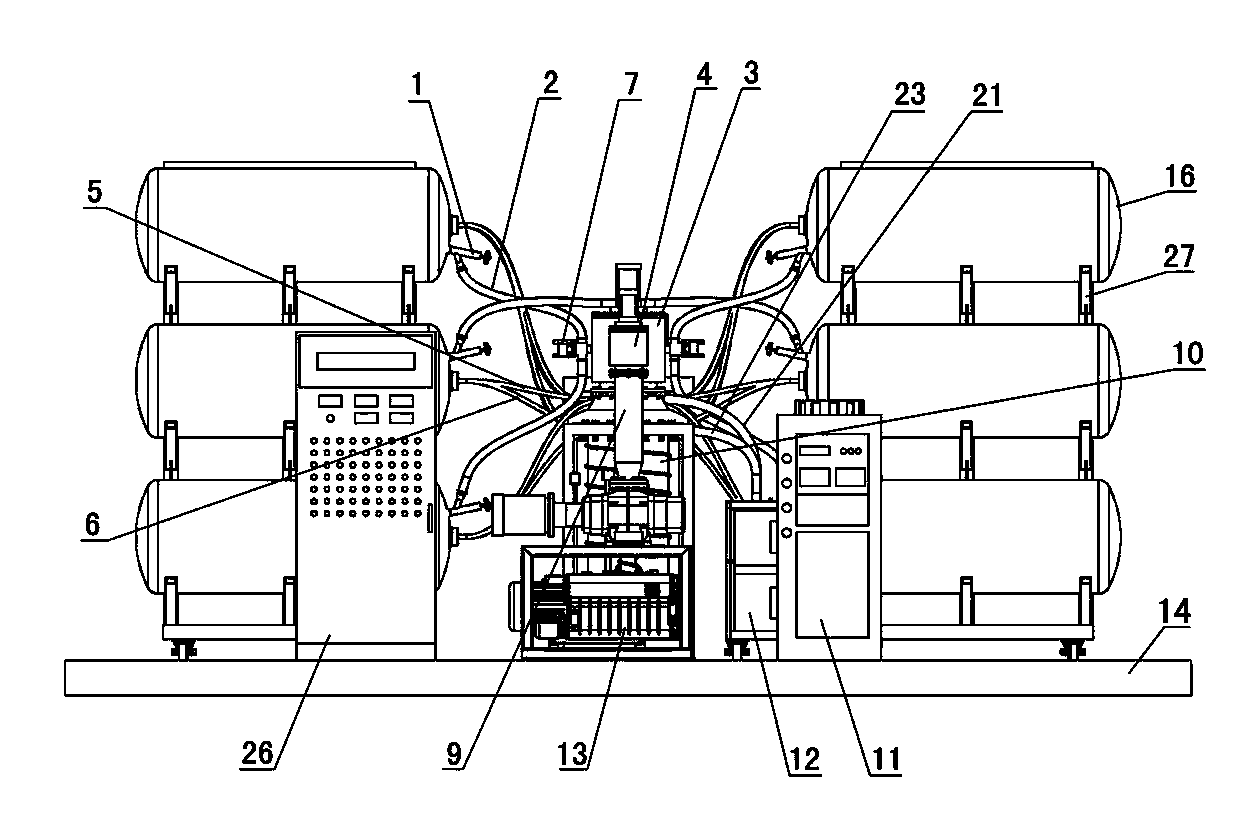

Liquefied natural gas bottle sandwiching vacuum-pumping system and method with function of circularly heating inner container

InactiveCN103822085AGuaranteed vacuuming effectGuaranteed production efficiencyPressure vesselsVacuum pumpingProcess engineering

The invention discloses a liquefied natural gas bottle sandwiching vacuum-pumping system with a function of circularly heating an inner container. The system comprises a vacuum-pumping device, a liquefied natural gas bottle placing device and a liquefied natural gas bottle inner heating device, wherein the liquefied natural gas bottle inner heating device comprises a dry oil-free inner heating circulating fan, a heat inlet main pipe, a heat discharging main pipe, a heat inlet branch pipe and a heat discharging branch pipe; an air outlet of the dry oil-free inner heating circulating fan is communicated with the heat inlet main pipe, the heat inlet main pipe is communicated with the heat inlet branch pipe, and the heat inlet branch pipe is communicated with an air inlet of a to-be-heated liquefied natural gas bottle; an air outlet of the liquefied natural gas bottle is communicated with the heat discharging branch pipe, the heat discharging branch pipe is communicated with the heat discharging main pipe, and the heat discharging main pipe is communicated with an air inlet of the dry oil-free inner heating circulating fan. The system and method disclosed by the invention have the advantages that the vacuum-pumping does not need, meanwhile, a drying room is not utilized to persistently externally heat; the vacuum-pumping effect and production efficiency are guaranteed, and meanwhile, the manufacturing cost and using cost are also saved.

Owner:北京华诚浩达真空空压设备有限公司

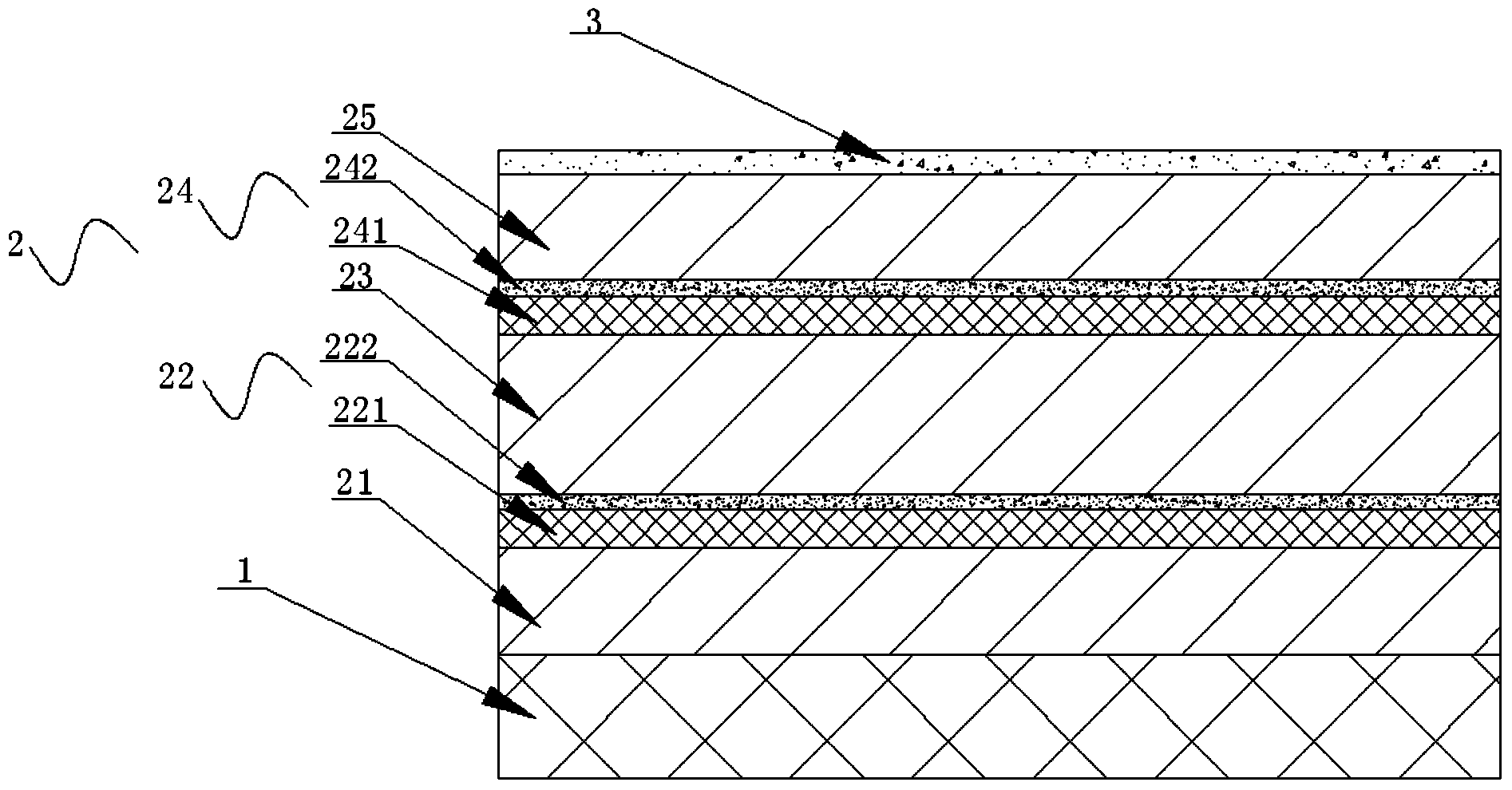

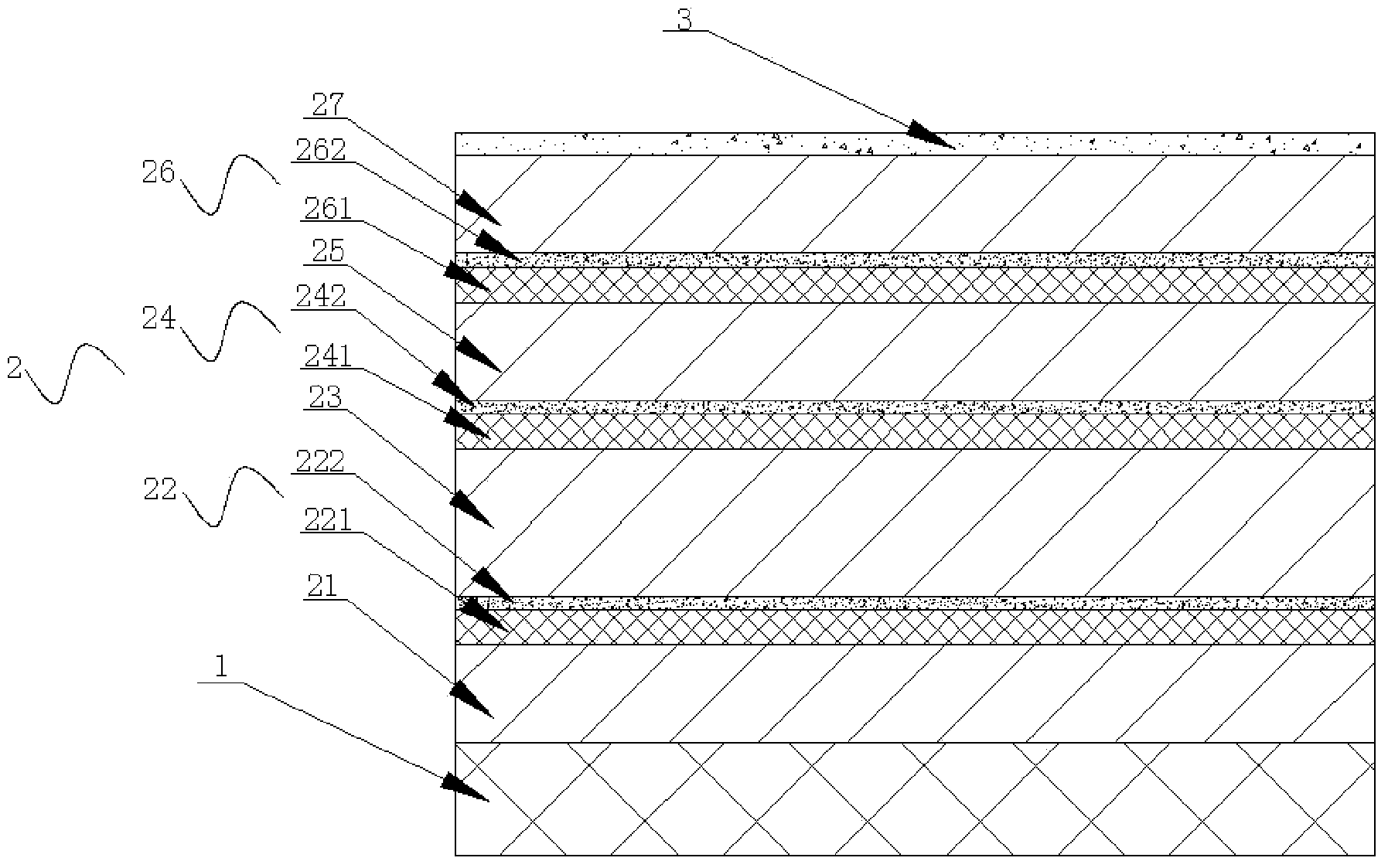

Window film core functional layer and preparation method thereof

InactiveCN104325760AImprove reflectivityReduce reflectivitySynthetic resin layered productsVacuum evaporation coatingCore functionPet substrate

The invention discloses a window film core functional layer and a preparation method thereof. The window film core functional layer comprises a PET substrate thin film, and a first transparent oxide layer, a first composite metal layer, a second transparent oxide layer, a second composite metal layer, a third transparent oxide layer and an outer side seal layer which are sequentially deposited from bottom to top by magnetron sputtering. The preparation method of the window film core functional layer comprises the step of sequentially performing coating in six chambers of a six-chamber coiling type magnetron sputtering coating machine or a double-roller and three-chamber coiling type magnetron sputtering coating machine to form the magnetron sputtering layers. The window film core functional layer has the beneficial effects that an Au layer with the thickness of 3-10nm is deposited at the outer side of the third transparent oxide by magnetron sputtering, so that the infrared reflectivity is increased to 90% from 80%; the reflectivity of visible light is reduced while the infrared reflectivity is increased, so that the temperature in a chamber using the window film core functional layer is maintained to be constant while lighting is not influenced.

Owner:邹申秀

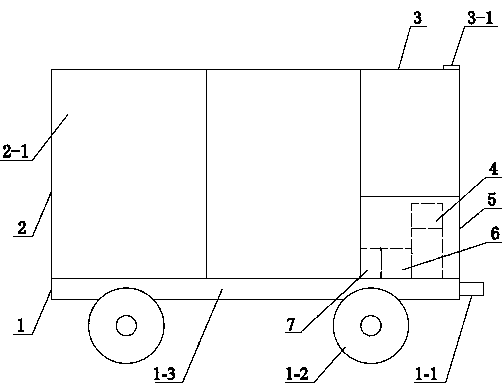

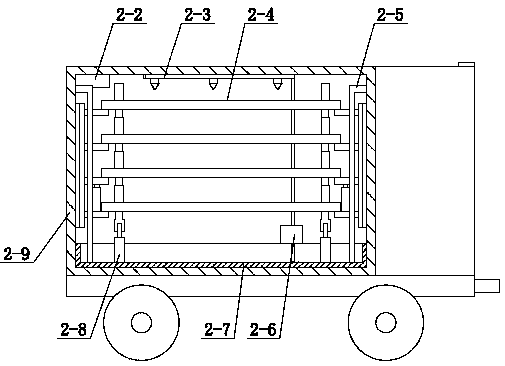

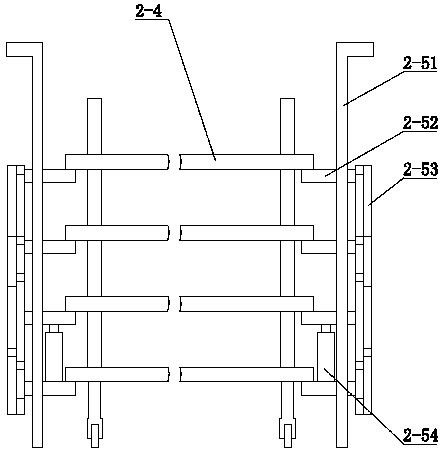

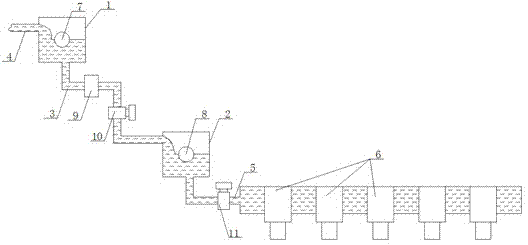

Road engineering material maintenance vehicle

PendingCN109702876ATemperature does not affectDoes not affect temperaturePreparing sample for investigationCeramic shaping apparatusAuto regulationWater channel

The invention discloses a road engineering material maintenance vehicle. The road engineering material maintenance vehicle comprises a trailer chassis, a maintenance tank and a water tank; the maintenance tank and the water tank are arranged on the trailer chassis parallelly, the maintenance tank is a sealed heat preservation tank body, and the water tank is closed; a water injection opening witha water injection plug is formed in the top of the water tank, and an air conditioner, a humidifier, a test-piece support, a water channel, a temperature sensor and a humidity sensor are arranged in the maintenance tank; a PLC and a power supply are arranged outside the maintenance tank, and the water channel and the water tank are connected through a water injection pump; the water channel supplies water to the humidifier, and the water injection pump, the air conditioner, the humidifier, the temperature sensor and the humidity sensor are all connected with the PLC through signal lines; and power lines of the water injection pump, the air conditioner, the humidifier and the PLC are connected with the power supply. The road engineering material maintenance vehicle is provided with the trailer chassis, and thus is convenient to drag by other power devices and easy to move, the temperature and humidity in the maintenance tank can be automatically adjusted according to the setting, the water channel is formed in the maintenance tank, the appropriate amount of water is injected into the water channel before maintenance each time, and the temperature in the maintenance tank is not influenced during humidity adjustment of the humidifier; and the road engineering material maintenance vehicle is provided with the power supply and thus is suitable for fields.

Owner:SHANDONG JIAOTONG UNIV

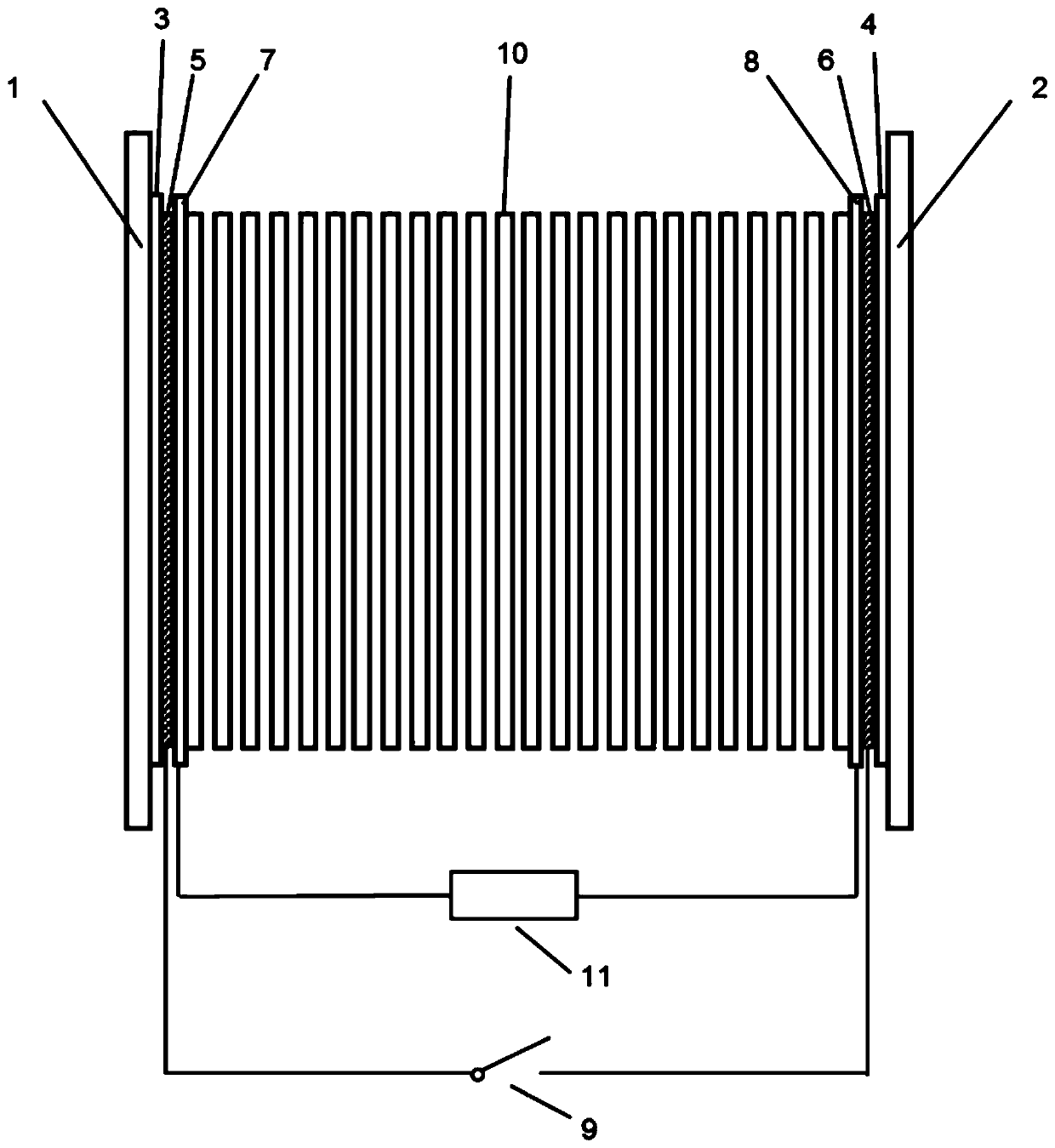

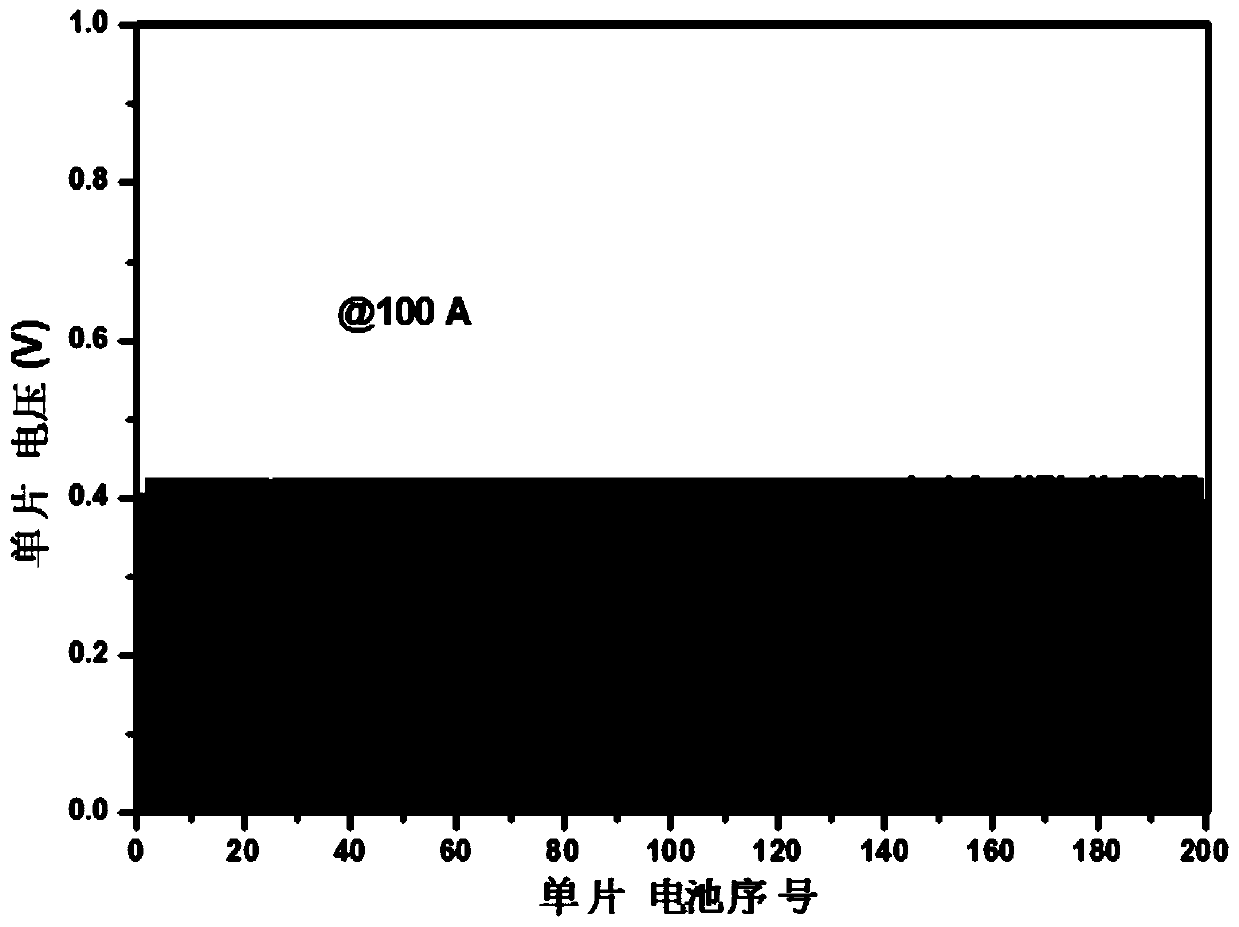

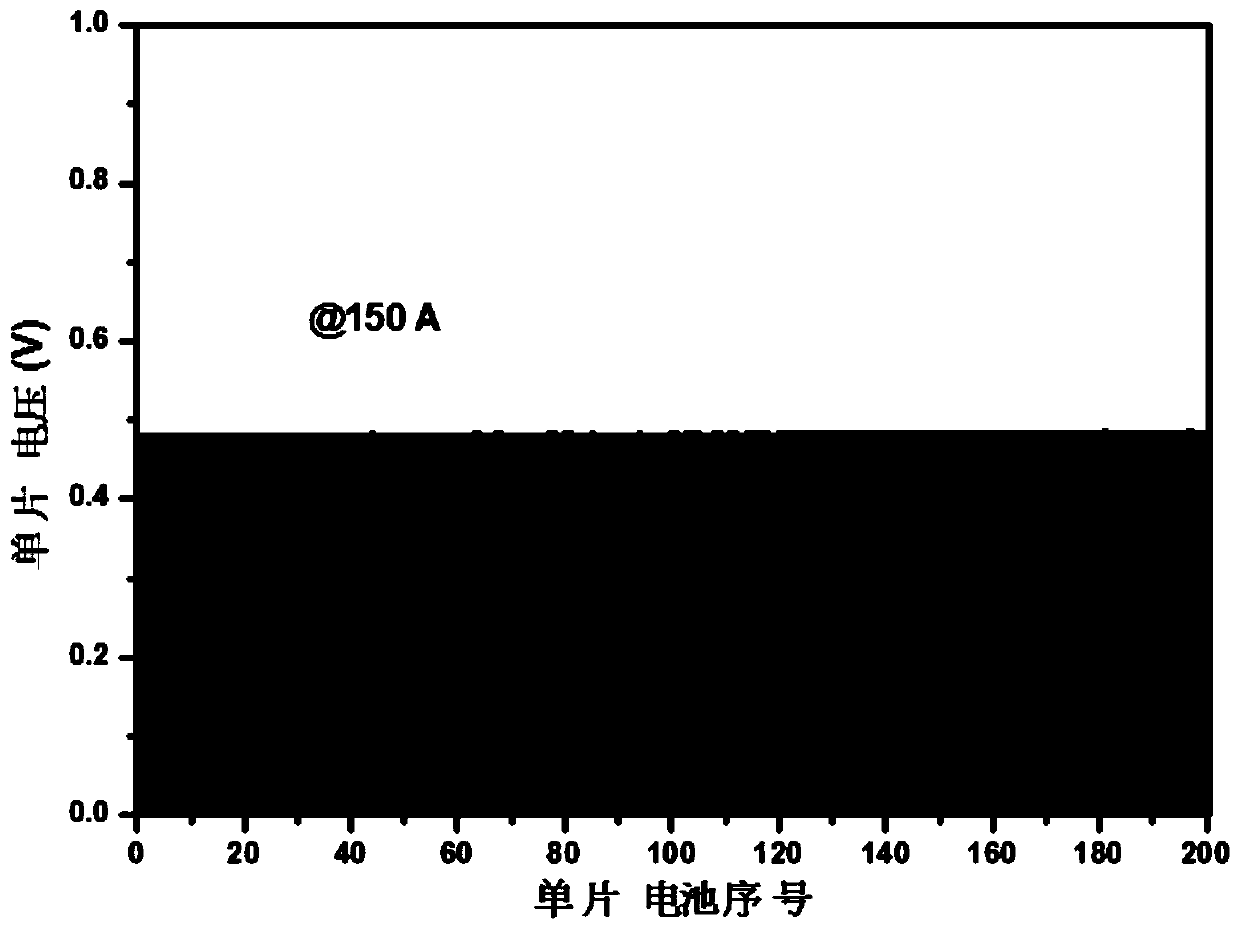

Low-temperature starting device and method for fuel cell system

ActiveCN111180758ASimple structureEasy to operateFuel cell heat exchangeElectrical batteryElectronic switch

The invention relates to a low-temperature starting device and method for a fuel cell system. The device comprises a fuel cell stack, an electronic switch, a DCDC controller, an anode heating resistorand a cathode heating resistor, wherein the fuel cell stack and the DCDC controller are electrically connected to form a control loop; and the electronic switch, the anode heating resistor, the fuelcell stack and the cathode heating resistor are electrically connected to form a heating loop. The method comprises the following steps: closing the electronic switch to connect the heating loop, so that the heating resistor generates heat under the current action of the fuel cell stack to heat the single cells on the cathode and anode sides of the fuel cell stack. Compared with the prior art, thedevice is simple in structure and convenient to operate, the two ends of the fuel cell can be heated only by controlling the heating loop and the control loop, the improvement process has little influence on the fuel cell stack, the heating resistor can stop working by cutting off the heating loop, the temperature of single pieces at the two ends is not affected, high voltage is avoided, and theefficiency and service life of the fuel cell are not affected.

Owner:SHANGHAI SHENLI TECH CO LTD

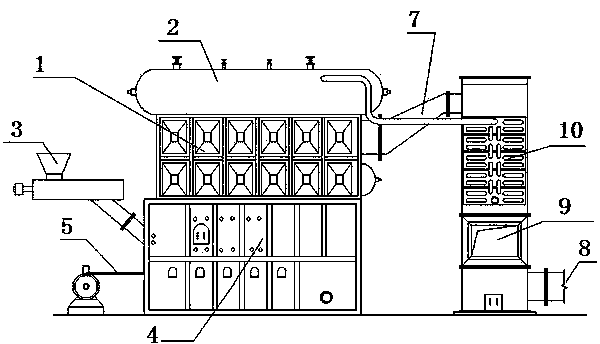

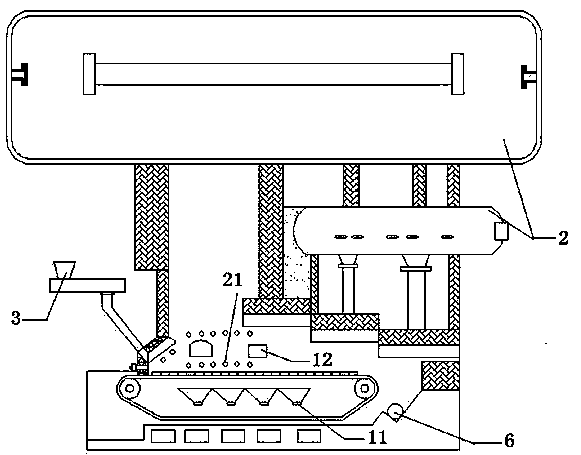

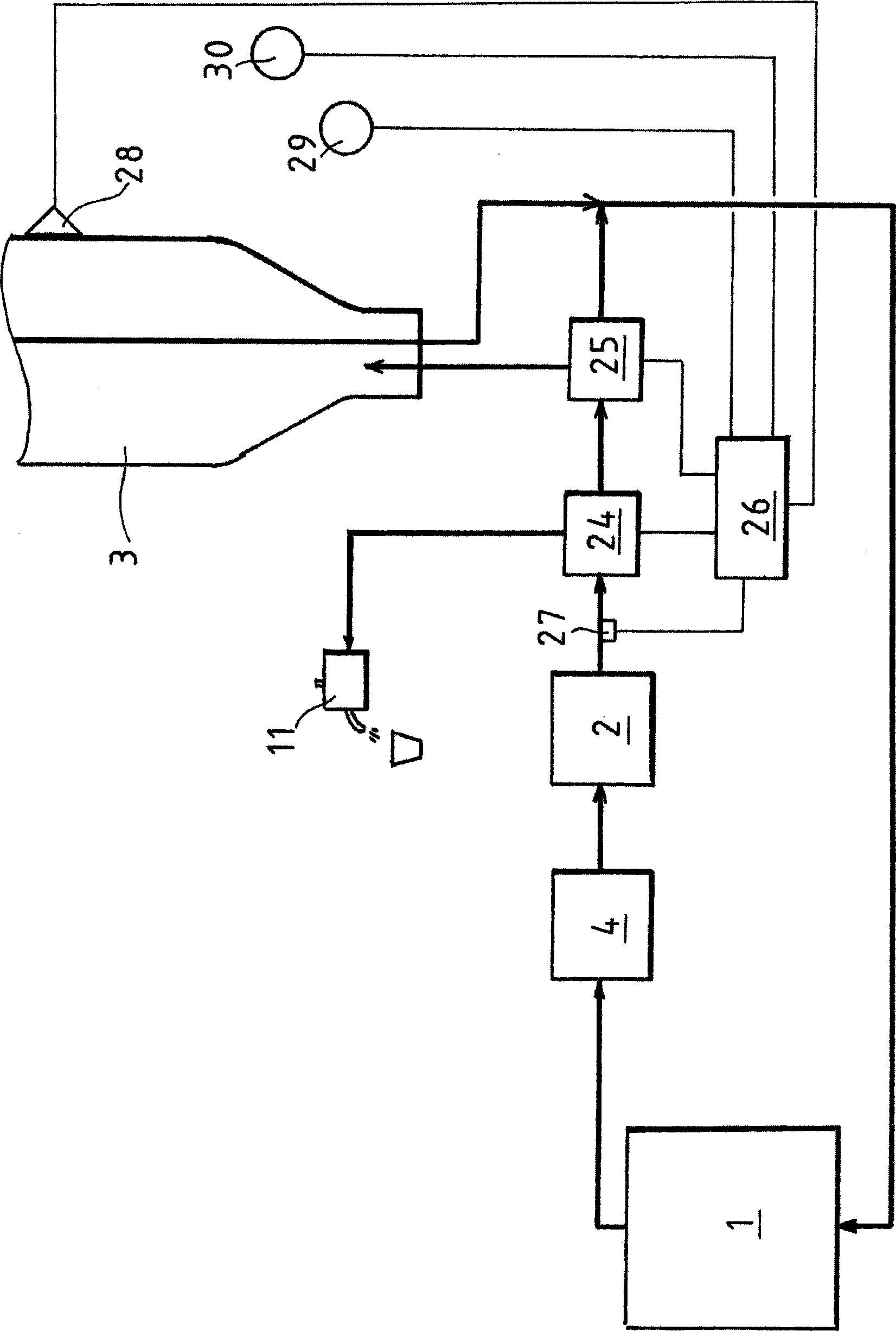

High-efficiency energy-saving biomass boiler system

ActiveCN103644561AIncrease profitDoes not affect temperatureBoiler controlSolid fuel combustionAir preheaterAutomatic control

The invention provides a high-efficiency energy-saving biomass boiler system which comprises a boiler body, a feeding system, a fire grate, a discharging device, a smoke discharging opening, a primary air inlet chamber, a secondary air inlet pipe and an air inlet chamber. A combustion chamber and a water vapor system placed above the combustion chamber are arranged in the boiler body. The feeding system is connected with the boiler body, so that biomass forming fuel is sent into the combustion chamber. The fire grate and the discharging device are placed at the bottom of the combustion chamber. The smoke discharging opening is communicated with the combustion chamber and penetrates through the water vapor system. The primary air inlet chamber is arranged below the fire grate. The secondary air inlet pipe and the air inlet chamber are arranged above the fire grate. Hot smoke discharged from the smoke discharging opening is recycled through a smoke discharging pipe and then passes through a water preheater and a secondary air preheater, wherein an outlet of the secondary air preheater is connected with a secondary air inlet chamber of the combustion chamber, inlet air is heated, and the water preheater is connected with a water inlet of a boiler, so that inlet water has certain temperature. According to the high-efficiency energy-saving biomass boiler system, burning is complete, boiler operation cost is low, feeding is convenient, heat using rate after biomass forming material burning releasing is improved, and steam production amount can be guaranteed by achieving automatic control over parameters.

Owner:浙江中吉新能源有限公司

System and method for measuring equivalent heat conductivity coefficient

ActiveCN104198524ANo gas emissionsRealize determinationMaterial heat developmentThermal insulationCollection system

The invention relates to a system and a method for measuring an equivalent heat conductivity coefficient. The system comprises a sample cylinder, a heating system, a gas collection system and a data acquisition processing system, wherein the sample cylinder comprises a sample cylinder body and a sample cylinder cover; the heating system comprises a heating device, a direct current stabilized voltage supply and an alternating current power supply; the gas collection system comprises a gas collection pipe and a gas collection device; the data acquisition processing system comprises a detection device, a data acquisition device and a data processing device; the cylinder wall of the sample cylinder body comprises a heating element, a thermal insulation layer and a shell from interior to exterior; the sample cylinder cover comprises an upper cylinder cover and a lower cylinder cover; the upper cylinder cover and the lower cylinder cover are connected through the gas collection pipe and a sealing pipe; a graphite washer is arranged between the sample cylinder cover and the sample cylinder body; the heating device is arranged at an axis position of the sample cylinder; the gas collection device collects gas from interior of the sample cylinder through the gas collection pipe; and the detection device is arranged at a position, which deviates from the axis of the sample cylinder, inside the sample cylinder.

Owner:SHENWU TECH GRP CO LTD

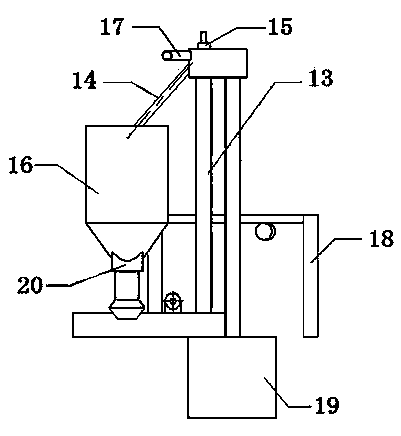

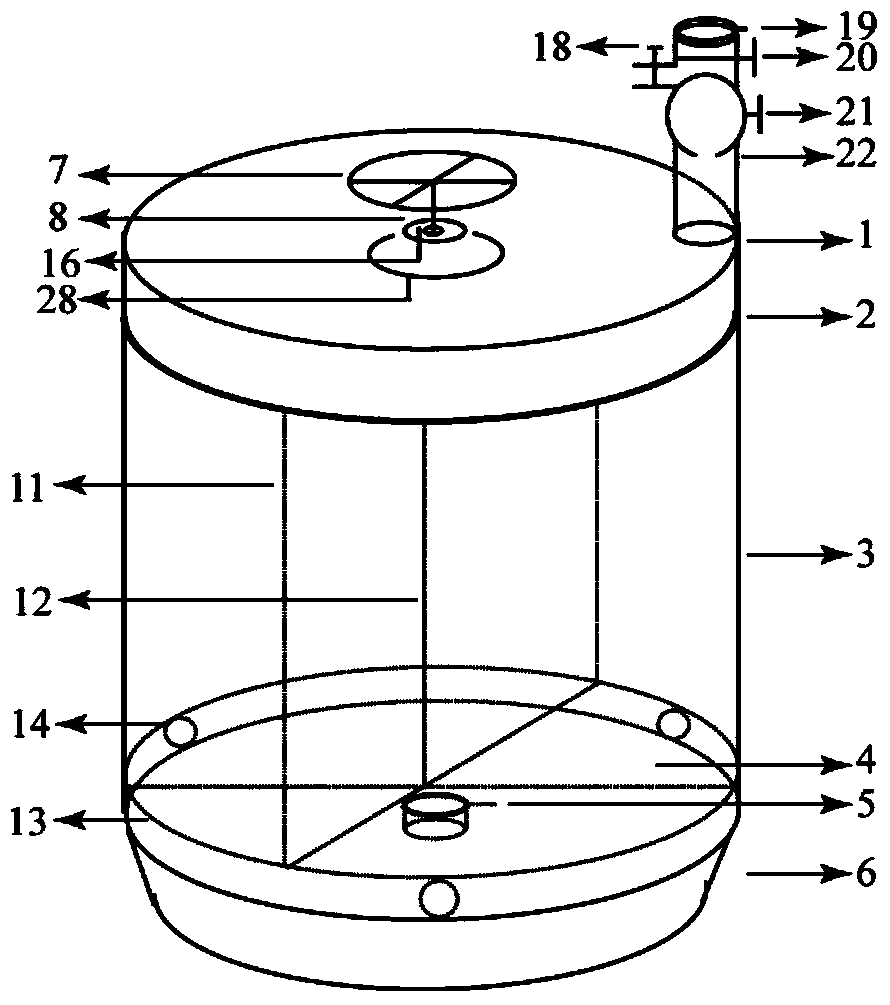

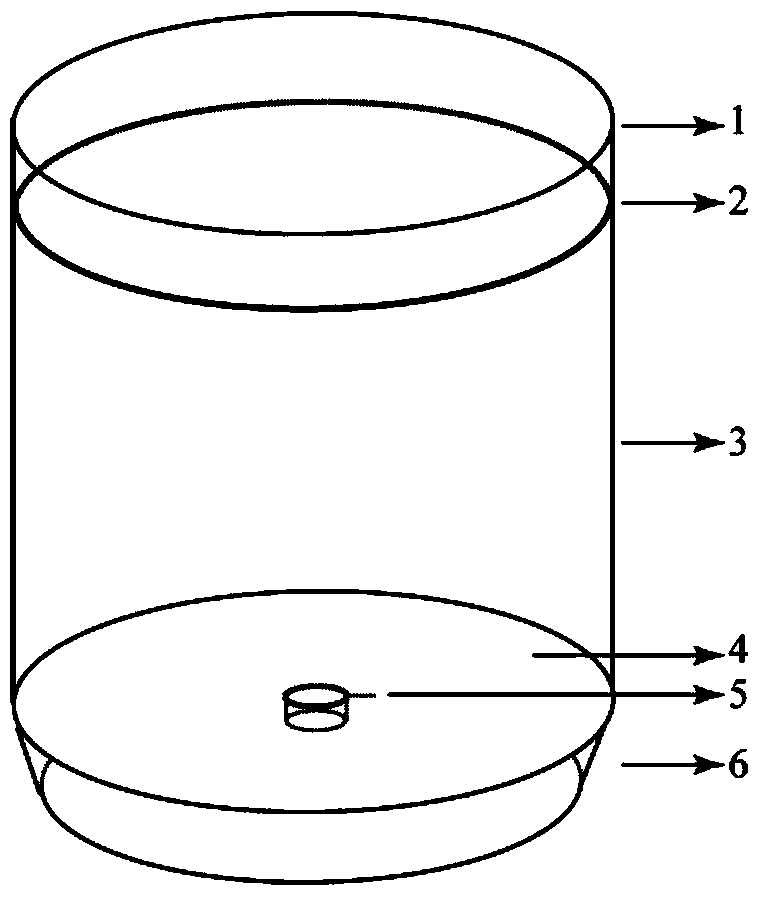

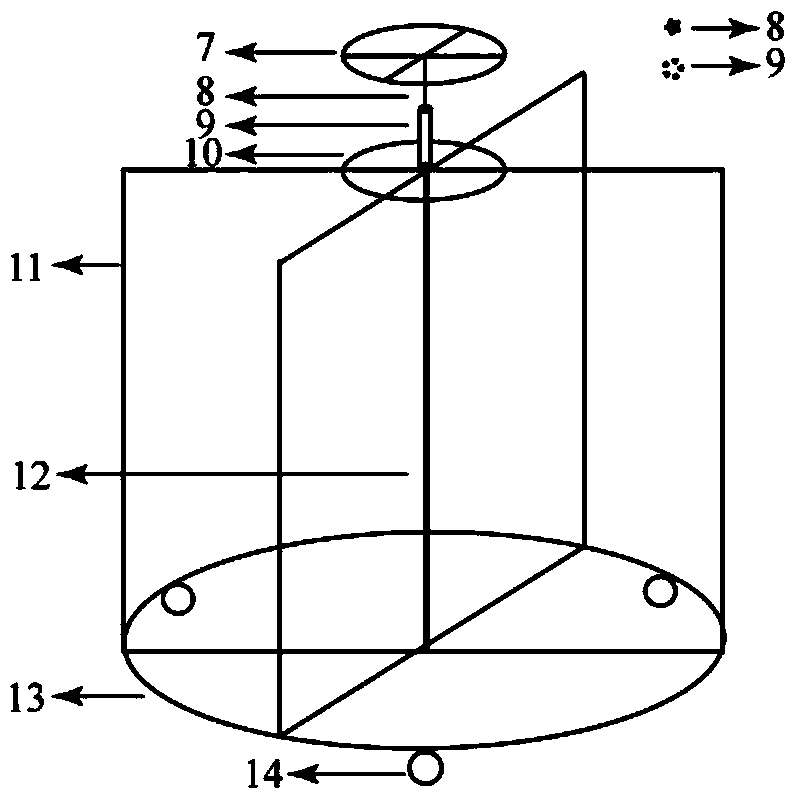

Powder unloading and quick dissolution integrated device for ton bag

ActiveCN105521737AAvoid accumulationAvoid corrosionTransportation and packagingMixer accessoriesEngineeringDissolution

The invention provides a powder unloading and quick dissolution integrated device for a ton bag. The device comprises an electric hoist, a support, a stirrer and a dissolution tank, wherein the dissolution tank is welded and fixed with the support. The device is characterized by further comprising a material bearing bowl, a gate valve and a circulating pump; the bottom of the material bearing bowl is connected with the top of the dissolution tank through a discharging pipeline; the gate valve is mounted on the discharging pipeline at the bottom of the material bearing bowl; a dissolution water inlet and a circulating solution inlet are formed below the gate valve on the discharging pipeline; the stirrer is obliquely mounted in an oblique pipeline of the dissolution tank; an angle between a central line of the stirrer and a central line of the discharging pipeline is 30 to 60 degrees. The powder unloading and quick dissolution integrated device for the ton bag has the advantages of safety, reliability, high dissolution efficiency and the like.

Owner:深圳清新环境技术有限公司

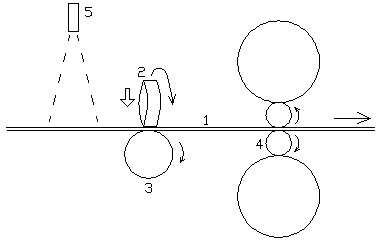

Rolling mill and online robot finishing platform on extension cord

PendingCN110293566AImprove the qualified rate of rolled productsImprove product qualification rateMilling cuttersPlaning/slotting toolsMaterials scienceRolling mill

The invention discloses a rolling mill and an online robot finishing platform an extension cord. According to the platform, a robot finishing tool is applied to a rolling line, when the rolling mill rolls a material to be rolled to be thin, emerging defects on the surface of the material to be rolled can be found in real time, and corresponding defects are finished in real time. The online robot finishing platform has the advantages of finding and processing internal defects of casting blanks in real time. The method can increase the yield of the material to be rolled. Particularly, in the iron and steel industry, the yield of the material to be rolled of continuous casting and rolling can be increased.

Owner:北京鼎新时代科技有限公司

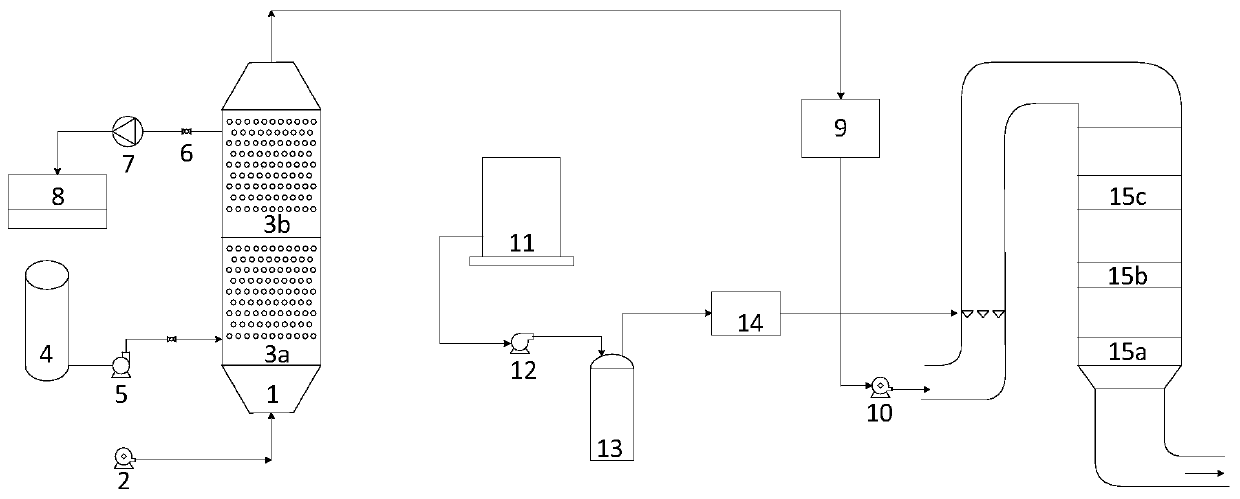

Industrial boiler flue gas dehumidifying desulphurization denitration system and method

PendingCN110394056ASimple processReduce energy consumptionGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses an industrial boiler flue gas dehumidifying desulphurization denitration system and a method. The industrial boiler flue gas dehumidifying desulphurization denitration system comprises a dehumidifying desulphurization system, a flue gas heater, and a low temperature denitration system which are connected successively; the dehumidifying desulphurization system comprises a dehumidifying desulphurization tower, a supercharging blower fan, and a hollow fiber film absorber; the bottom of the dehumidifying desulphurization tower is provided with a flue gas inlet connected with the supercharging blower fan, the top is provided with a flue gas outlet, and the middle part is provided with the hollow fiber film absorber used for absorbing sulfur dioxide and water vapour; an input end of the hollow fiber film absorber is connected with an adsorption liquid supply unit, and an output end is connected with an adsorption liquid regeneration unit; an inlet of the flue gas heater is connected with a flue gas outlet on the top of the dehumidifying desulphurization tower; the low temperature denitration system comprises a denitration tower, an ammonium hydroxide supply unit,and a plurality of low temperature SCR catalyst units; a flue gas inlet on the bottom of the denitration tower is connected with an outlet of the flue gas heater through a blower fan; the ammonium hydroxide supply unit is connected with an ammonia spray grating arranged in the denitration tower; and the plurality of low temperature SCR catalyst units are arranged in the denitration tower successively.

Owner:HUANENG POWER INTERNATIONAL +1

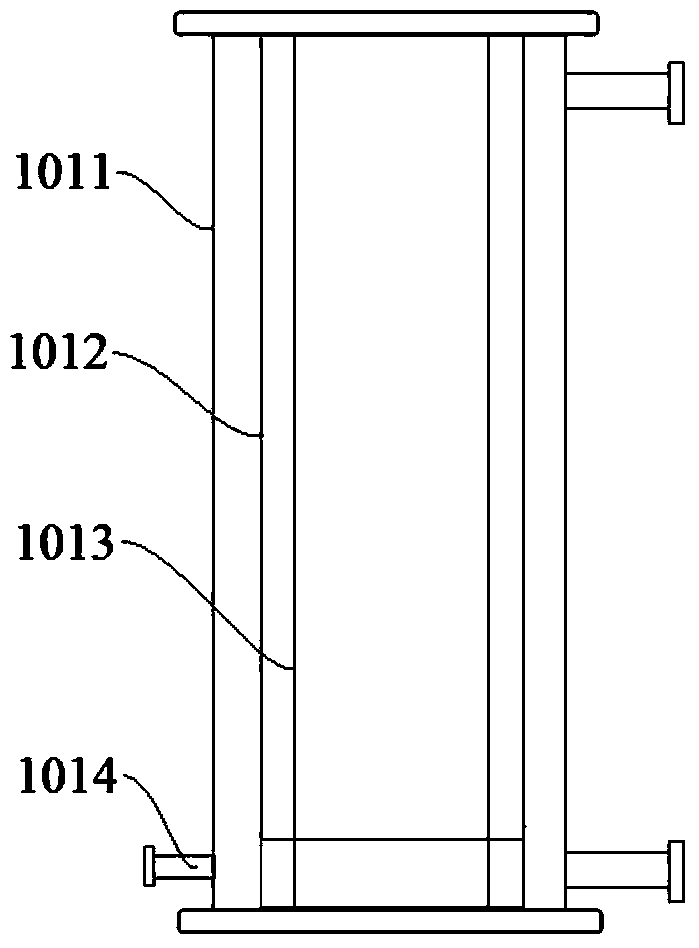

Automatic double-barrel-switching melt filter

InactiveCN101906669ADoes not affect temperatureQuality assuranceFilament-forming treatmentYarnBiochemical engineering

The invention discloses an automatic double-barrel-switching melt filter which comprises a melt feeding hole, a melt discharging hole, a first filter barrel and a second filter barrel. The feeding hole of the first filter barrel and the feeding hole of the second filter barrel are respectively connected with the melt feeding hole through feeding valves, the discharging hole of the first filter barrel and the discharging hole of the second filter barrel are respectively connected with the melt discharging hole through discharging valves, the melt feeding hole is provided with a pre-filtration pressure sensor, the melt discharging hole is provided with a post-filtration pressure sensor, the first filter barrel is provided with a first drain valve, the second filter barrel is provided with a second drain valve, and the feeding valves, the discharging valves, the first drain valve, second drain valve, the pre-filtration pressure sensor and the post-filtration pressure sensor are connected with a controller. The automatic double-barrel-switching melt filter alternately uses two filter barrels, not only can ensure the continuous operation of melt filtration and surely avoid broken yarn in spinning, but also ensure the spinning quality without influencing the temperature of the melt.

Owner:曹华

Energy-saving and environment-friendly fresh air supplying device for kitchen

InactiveCN106813348AImprove cleanlinessSmall temperature differenceEnergy recovery in ventilation and heatingMechanical apparatusFresh airSmoke

The invention discloses an energy-saving and environment-friendly fresh air supplying device for a kitchen. The device is cooperated with a kitchen lampblack machine or an exhaust fan in use and comprises a heat exchange pipe and a fresh air purification device connected with the heat exchange pipe; the heat exchange pipe is arranged in an exhaust duct connected with an outlet of the kitchen lampblack machine or the exhaust fan, and a heat exchange pipe inlet and a heat exchange pipe outlet in the two ends of the heat exchange pipe are exposed out of the exhaust duct; the fresh air purification device is provided with an air inlet communicated with the outdoor, and an air outlet communicated with the heat exchange pipe inlet, and an air valve and a dust filter net are arranged between the air inlet and the air outlet in sequence. The energy-saving and environment-friendly fresh air supplying device for the kitchen is reasonable in structure, and can automatically supply fresh air to the enclosed kitchen so as to improve the smoke exhaust or air exhaust efficiency of the kitchen lampblack machine or the exhaust fan.

Owner:SHENYANG NORMAL UNIV

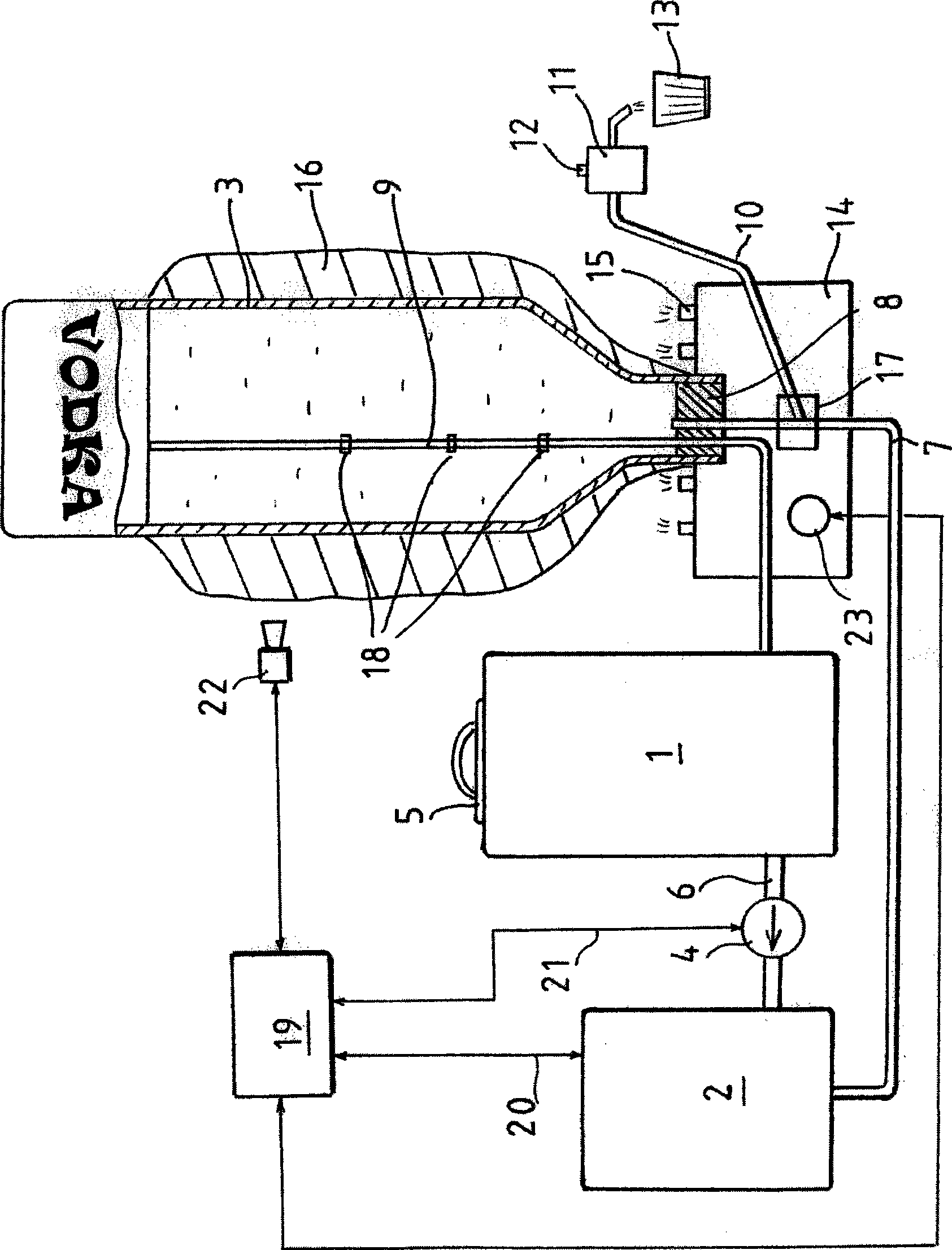

Dispenser

InactiveCN101479184AWon't breakDoes not affect temperatureLighting and heating apparatusLiquid dispensingBiomedical engineeringAlcoholic spirits

Owner:BARFIX

Drying machine based on mineral drying agent form

InactiveCN103115485ASave spaceDoes not affect temperatureDrying solid materials without heatDrying chambers/containersWater vapor absorptionDrying Agents

The invention discloses a drying machine based on a mineral drying agent form. The drying machine based on the mineral drying agent form is used for containing dried objects and is provided with a container with a container door, a container humidity sensor which is arranged inside the container, a container door state sensor used for sensing opening or closing of the container door, a micro control unit (MCU) and a drying device which is arranged on top of the container. According to the drying machine based on the mineral drying agent form, the structure is adopted, and the drying device is installed on the upper portion of a dried container. According to a principle that water vapor is lighter than air, the installation mode is optimal in water vapor absorption, and the container using space can be further and effectively saved. The drying machine based on the mineral drying agent form is small in occupied space size and convenient to install, and drying agent heating reduction does not affect the temperature of the dried objects.

Owner:东莞市誉能五金制品有限公司

Sensitive seed storage device and application thereof

ActiveCN103950644AExtended shelf lifeDoes not affect temperatureClosure with auxillary devicesContainers preventing decayEngineeringLiquid nitrogen

The invention relates to a sensitive seed storage device and application thereof. The barrel body of the storage device is divided into an upper part and a lower part through an interlayer, a seal hole is formed in the interlayer, the lower part of the barrel body is filled with liquid nitrogen through the seal hole,a hollow cavity which can be used for the placement of a drying agent is arranged on a barrel cover, a semi-circular plate which can be opened and closed is arranged at the bottom end of the barrel cover, the semi-circular plate is used for realizing the opening or closing of the hollow cavity, a sampling pipe running through the barrel cover is further arranged on the barrel cover, a ball valve, an air valve and a valve are arranged on the sampling pipe, ,a pipe orifice plug for blocking an opening is arranged at the top end of the sampling pipe, and seeds are taken out through the sampling pipe. According to the device, low-temperature, dry, dark and low-oxygen storage conditions can be effectively kept, so that the storage life of seeds is prolonged; meanwhile, the device is convenient in operation of an application method and convenient to carry; moreover, the storage efficiency is high, several seeds can be stored at the same time, and the space is effectively saved.

Owner:SHANDONG CROP GERMPLASM CENT

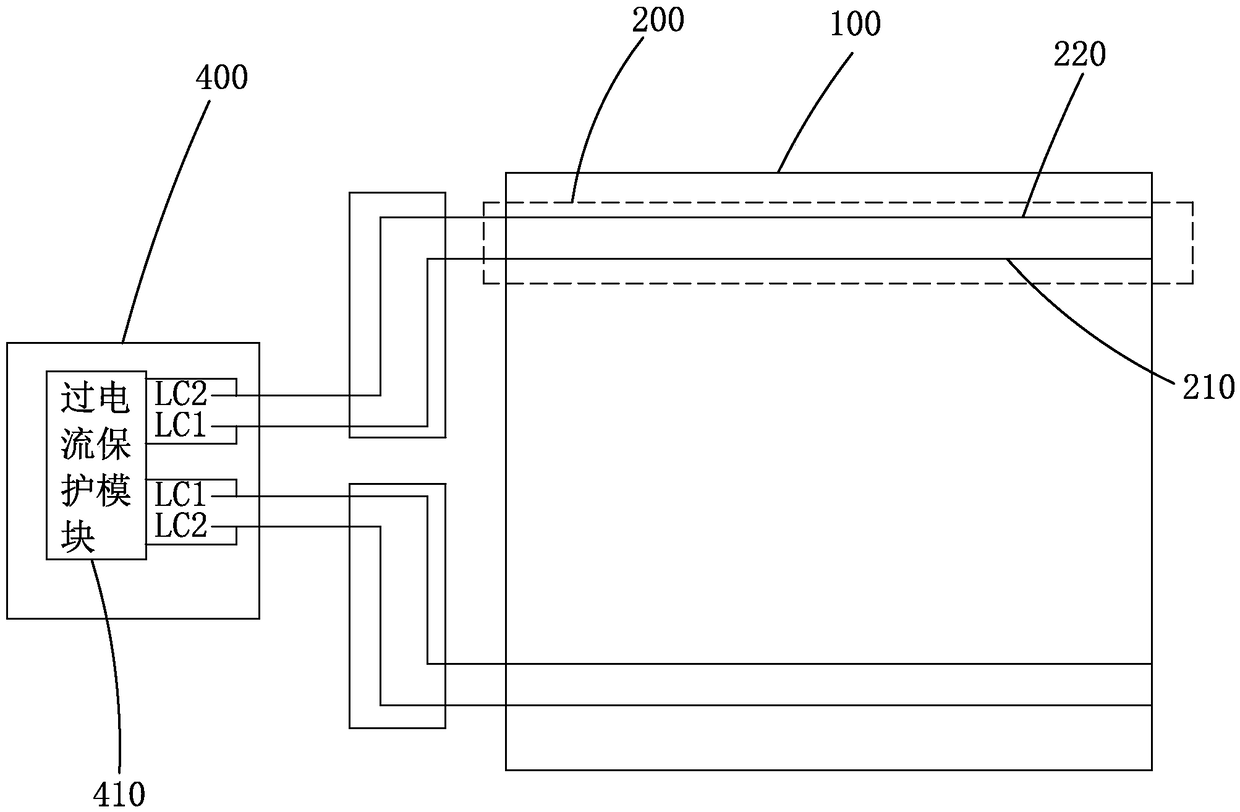

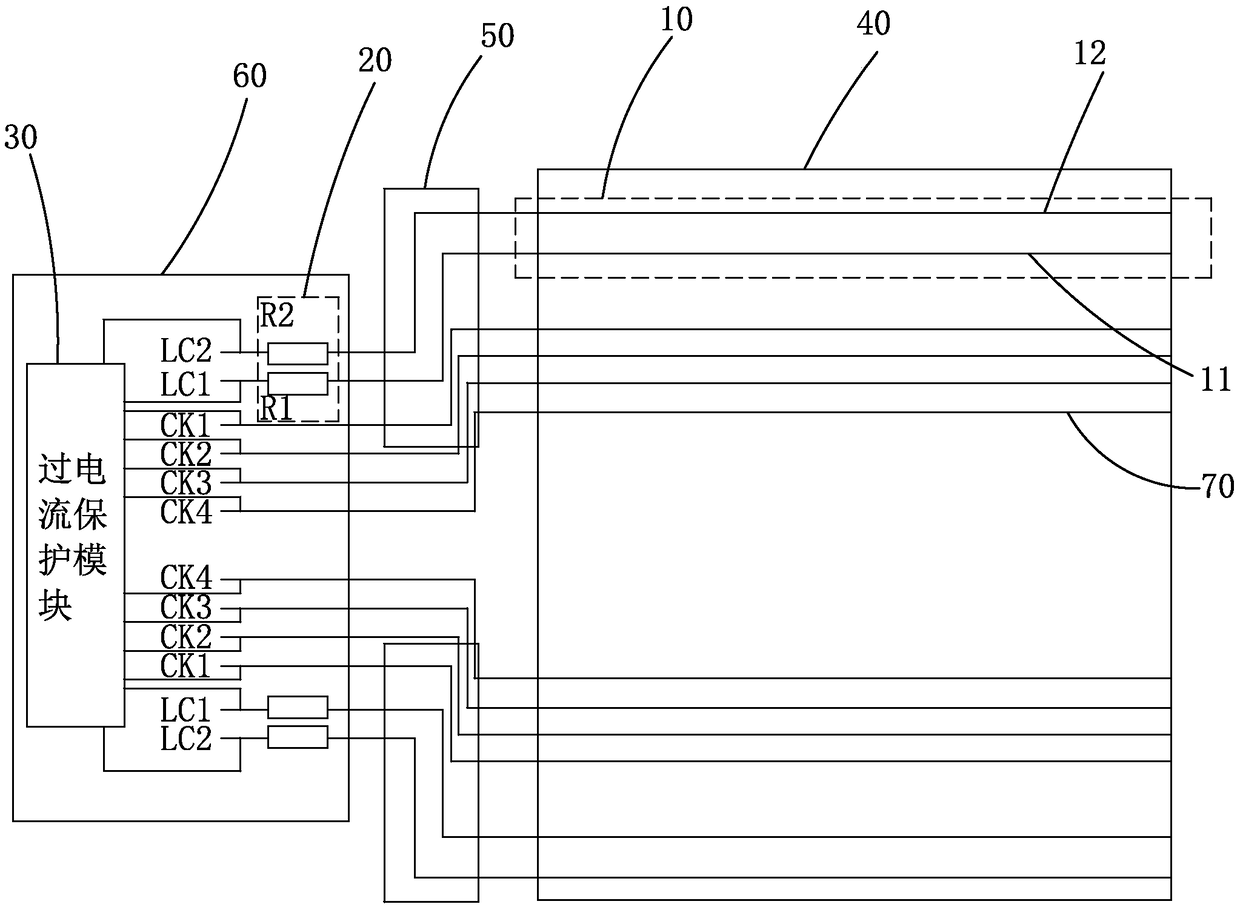

Display device

The invention provides a display device. The display device comprises a bus group, a resistor unit and an over-current protection module, wherein one end of a first resistor of the resistor unit is connected to a first low-frequency control signal, and the other end of the first resistor is electrically connected with one end of a corresponding first low-frequency control signal bus, one end of asecond resistor is connected with a second low-frequency control signal, and the other end of the second resistor is electrically connected with one end of a corresponding second low-frequency controlsignal bus, and the sum of the resistances of the first resistor and the second resistor of each resistor unit is larger than the ratio of the difference between the high potential and the low potential of the first low-frequency control signal to the preset protection current. In this way, no matter at which position the first low-frequency control signal bus and the second low-frequency controlsignal bus are short-circuited, the current of the first low-frequency control signal bus and the current of the second low-frequency control signal bus are both smaller than the protection current,so that the protection current value is set to be higher on the premise that the temperature of the display device is not influenced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Drinking water system for livestock farm

InactiveCN104206312AWill not affect healthDoes not affect humidityAvicultureWater storage tankEngineering

The invention discloses a drinking water system for a livestock farm. The drinking water system comprises a water storage tank and at least one water drinking tank, wherein the height of the water drinking tank is less than that of the water storage tank, the bottom of the water storage tank is connected with the water drinking tank by virtue of a water conveying pipe, the top of the water storage tank is provided with a water inlet pipe, the bottom of the water drinking tank is provided with a water guide pipe communicated with the water drinking tank, the water drinking pipe is provided with waterers for chicken at intervals. The water storage tank is internally provided with a water storage tank floating valve. The water drinking tank is internally provided with a water drinking tank floating valve, the water conveying pipe is provided with a filter, and the water conveying pipe is provided with a water conveying pipe ball valve; one end, which is close to the water drinking tank, of the water guide pipe is provided with a water guide pipe ball valve. The drinking water system has the advantages of being simple in structure, convenient to use, high in intensity, capable of uninterruptedly conveying water to a water drinking point of chicken, free from influence on the humidity and temperature of a henhouse and free from influence on the health of the chicken.

Owner:QINGDAO LANYING POULTRY IND

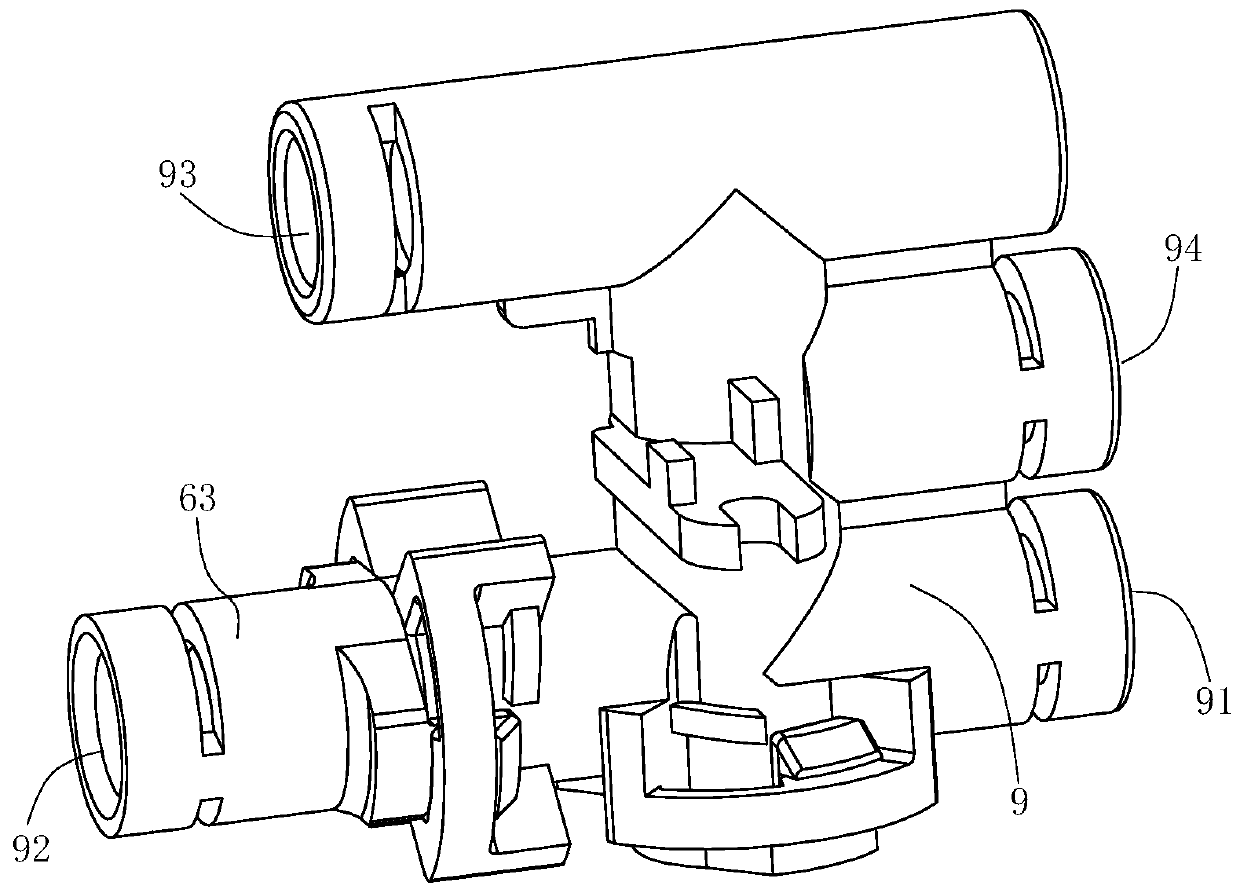

Water path system of beverage extraction equipment and diverter valve applicable to water path system

PendingCN110063652ASatisfy the function of exhausting airDoes not affect temperatureBeverage vesselsWater flowEngineering

The invention relates to a water path system of beverage extraction equipment. The system comprises a water tank, a water pump, a boiler, a pressure relief valve and a waste water box; a water outletof the water tank is connected with a water inlet end of the water pump. The system is characterized in that a water outlet end of the water pump is connected with one port of the pressure relief valve; another port of the pressure relief valve is connected with the waste water box, another port of the pressure relief valve is divided into two paths, one path is connected with a cold water inlet end of the boiler through a first one-way valve, and the other path is connected with a water inlet end of an extraction group through a second one-way valve; the first one-way valve only allows waterflow to flow from the pressure relief valve to the boiler, and the second one-way valve only allows the water flow to flow from the water inlet end of the extraction group to the pressure relief valvewhen the pressure is relieved; a hot water outlet end of the boiler is connected with the water inlet end of the extraction group through a third one-way valve, and the third one-way valve only allows hot water to flow to the water inlet end of the extraction group. The hot water in a pipeline cannot be discharged during pressure relief of the water path system, and the route of the hot water entering the extraction group is short. The invention also relates to a diverter valve.

Owner:NINGBO AAA GROUP ELECTRIC APPLIANCE

Poultry farm drinking water system using method

InactiveCN104255578AEasy to adjust water pressureEasy to control drinking waterAvicultureWater storage tankEngineering

The invention discloses a poultry farm drinking water system using method. The system comprises a water storage tank and at least one drinking tank, the bottom of the water storage tank is connected to the drinking tanks through water pipes, the top of the water storage tank is provided with a water incoming pipe, the bottoms of the drinking tanks are provided with water guide pipes for communication, and poultry drinking devices are arranged on the water guide pipes at intervals; a water storage tank floating ball valve is arranged in the water storage tank, and drinking tank floating ball valves are arranged in the drinking tanks; a filter and a water pipe ball valve are arranged on the water pipe; water guide pipe ball valves are arranged at one ends of the water guide pipes adjacent to the drinking tanks. The using method has the advantages that the using method is simple, the used product is simple in structure, strength is high, water can be delivered to poultry drinking points continuously, humidity and temperature in a poultry house is not influenced, and the poultry health is not influenced.

Owner:QINGDAO LANYING POULTRY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com