Multifunctional intelligent distillation instrument

A distillation apparatus and multi-functional technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of bursting, short circuit, sample flushing and other problems of distillation bottles, and achieve smooth temperature rise and tracking performance. Good, prevent burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

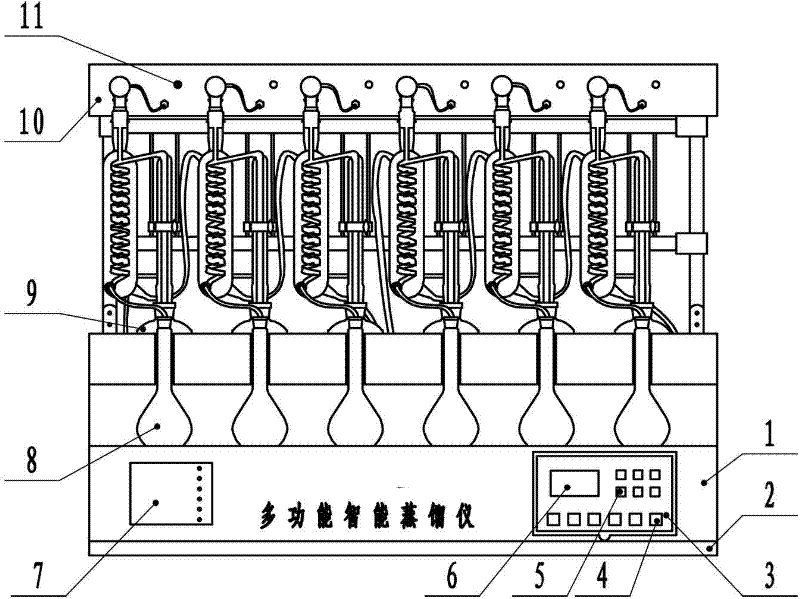

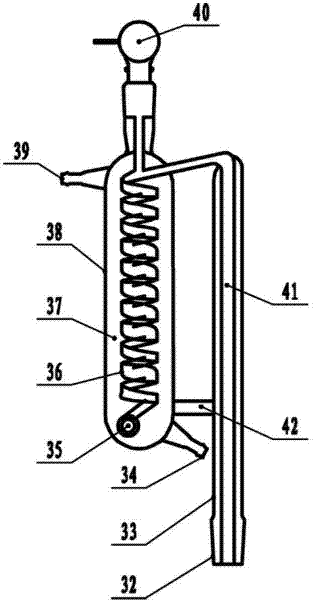

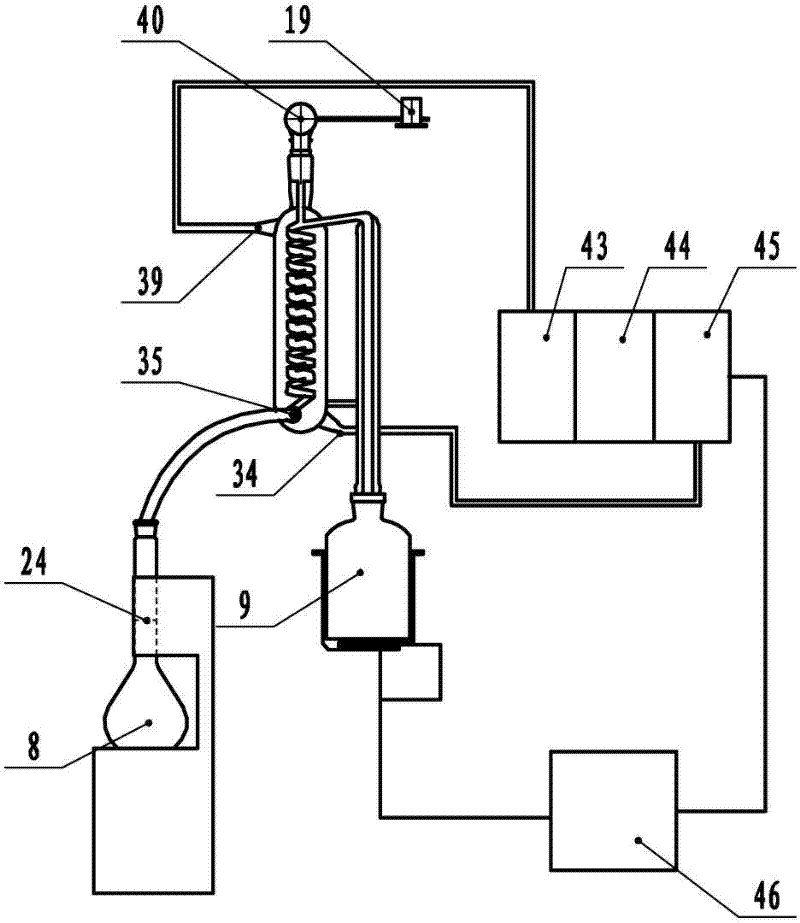

[0029] Such as figure 1 — Figure 5As shown, a multifunctional intelligent distillation apparatus includes a housing, a support, a heating device, a cooling device, and an automatic anti-suckback device. The heating device is a plurality of relatively independent heating units, and each heating unit includes a heating jacket 17, Heating rod 15, heating bowl 16, distillation bottle 9; heating bowl 16 is arranged in the heating box 18, the open end of the heating bowl top is the stove mouth, and the stove mouth is flush with the upper cover 25, and the distillation bottle 9 is placed in the stove mouth; heating Cover 17 is fixed on the periphery of heating bowl 16, and heating rod 15 is positioned at the bottom of heating bowl 16 and is fixed by baffle 21; The present invention also designs measurement and control device, and measurement and control device comprises temperature sensor 20, liquid level sensor 24, control circuit board 46. The control panel 3, the liquid crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com