Sterilization device for cans

A sterilizing device and canning technology, which is applied in the fields of application, food science, food preservation, etc., can solve the problems of canned food composition damage, sterilizing kettle bursting, pressure increase, etc., to ensure the taste and food safety, ensure the safety of use, prevent Burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

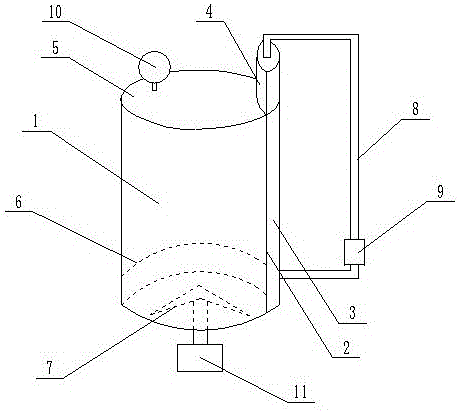

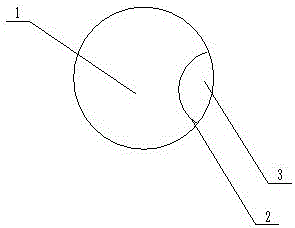

[0018] basically as figure 1 , figure 2 Shown:

[0019] The sterilizing device for canned food includes a sterilizer 1, a partition 2, and a cavity 3 surrounded by the partition 2 and the sterilizer 1. The sterilizer 1 is filled with water, and the partition 2 is a heat-conducting thin metal plate, which has the function of thermal expansion and contraction. characteristics, can quickly conduct temperature; the top of the cavity 3 is welded with a water storage tank 4, the bottom of the water storage tank 4 is provided with a number of through holes, the top of the sterilizer 1 is provided with a top cover 5, and the heating tube is coiled on the inner wall of the sterilizer 1 6. The heating pipe 6 can be used to heat the water in the sterilizer, so that the water body is heated evenly and the sterilizing effect is better. An inverted V-shaped pusher 7 is installed inside the sterilizer 1. The main shaft of the pusher 7 is connected to the output shaft of the motor 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com