Patents

Literature

69results about How to "Temperature does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

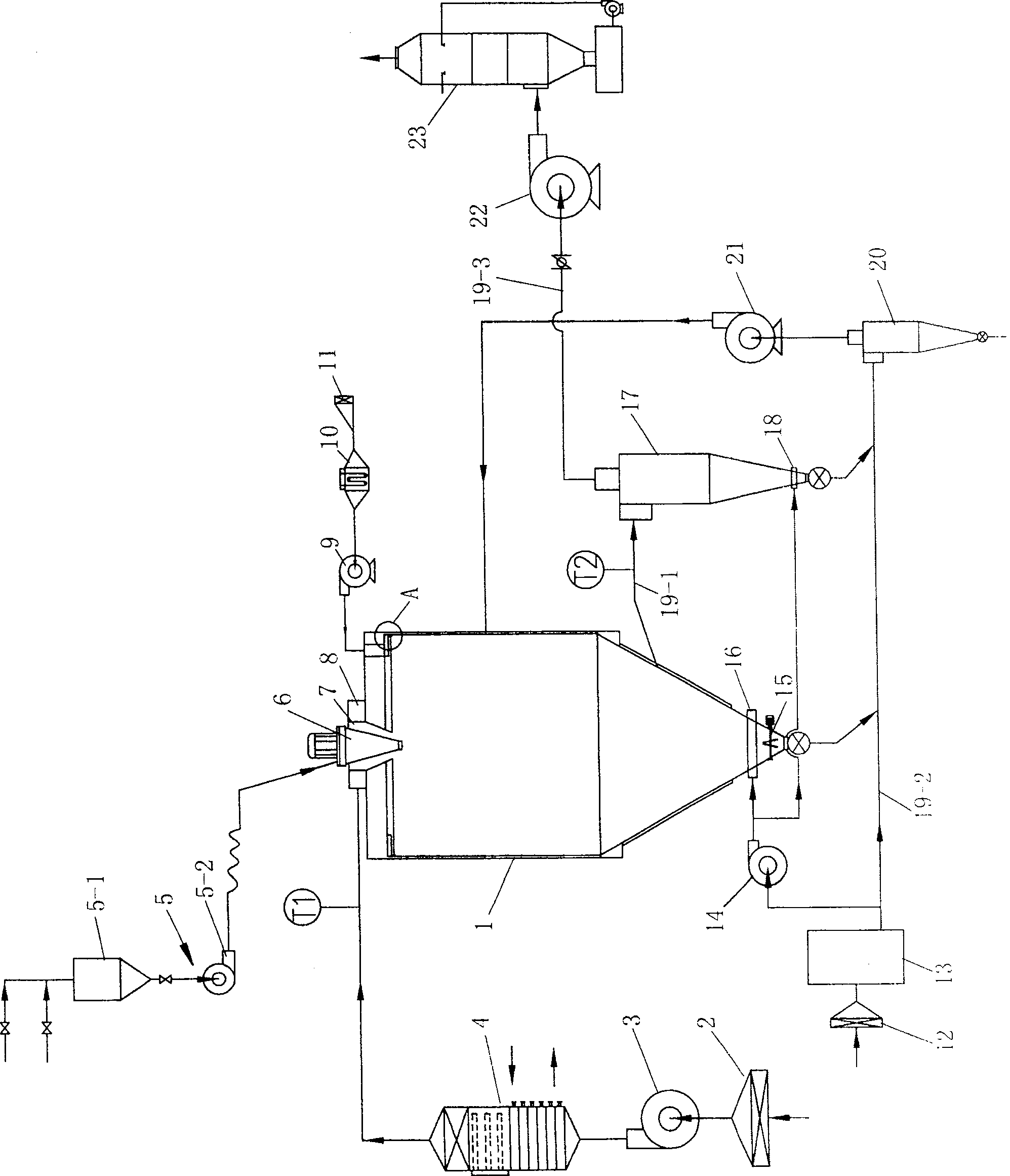

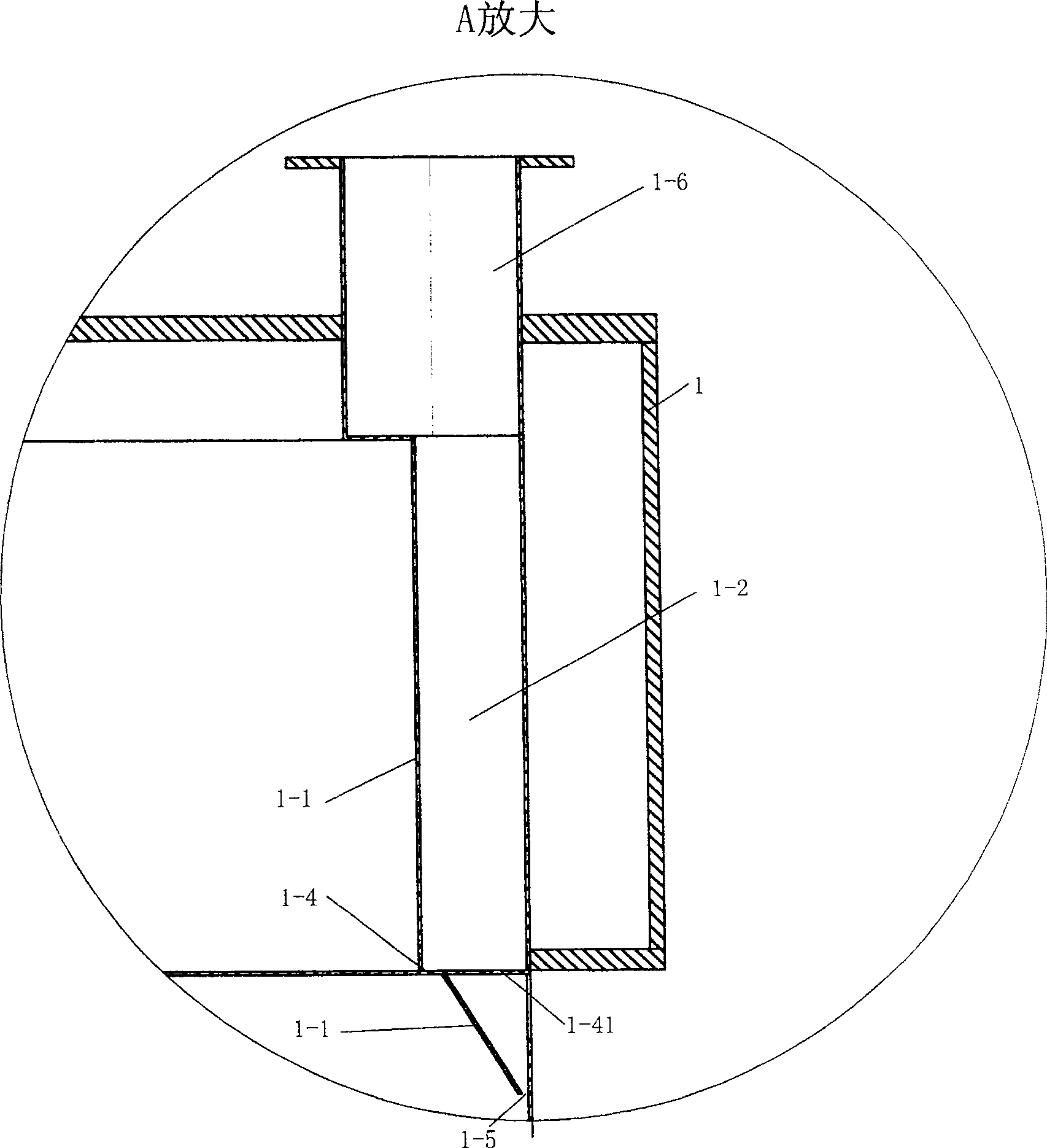

Seasoner sponging drying machine group

InactiveCN101178283AReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCycloneFeed technique

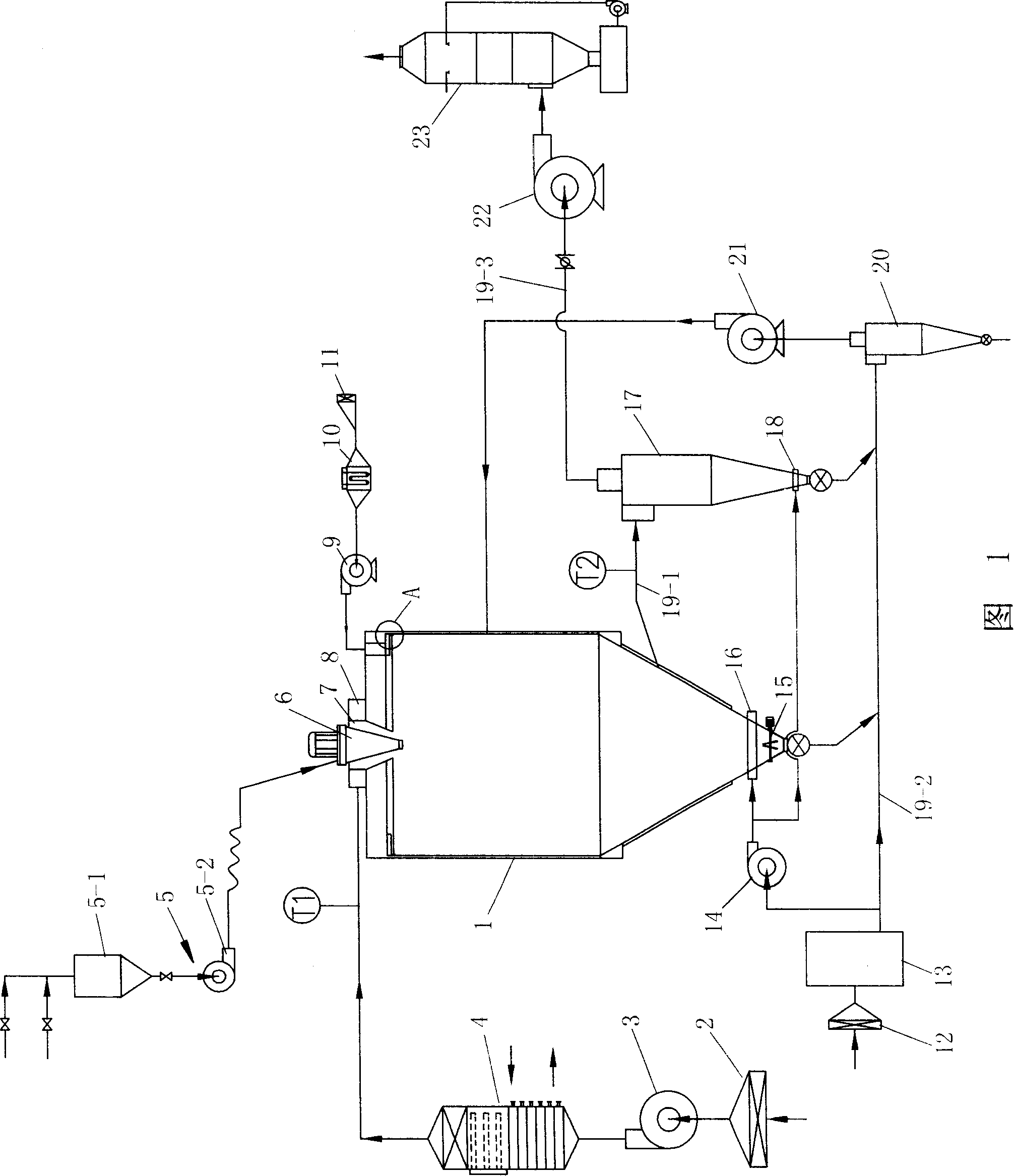

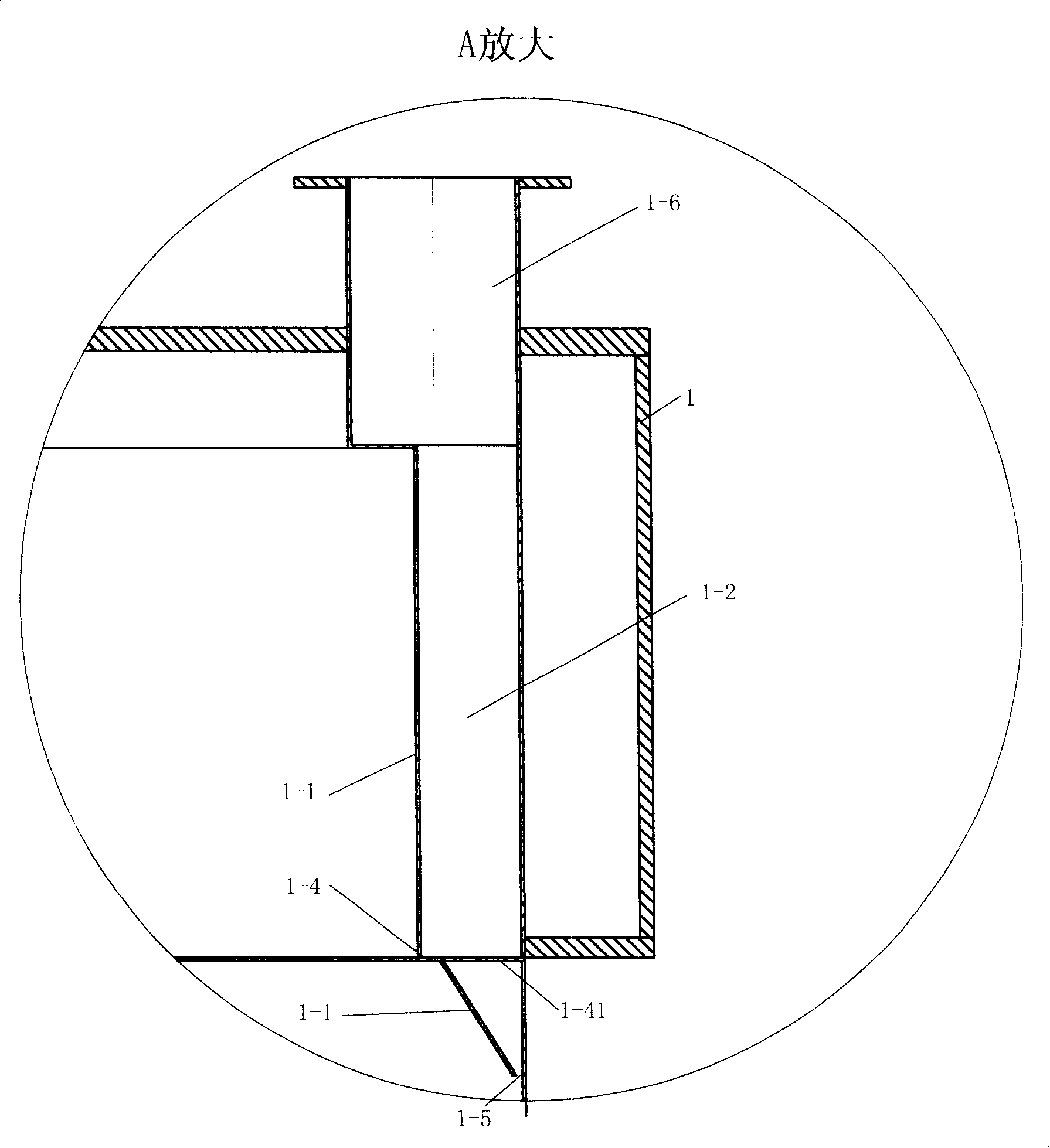

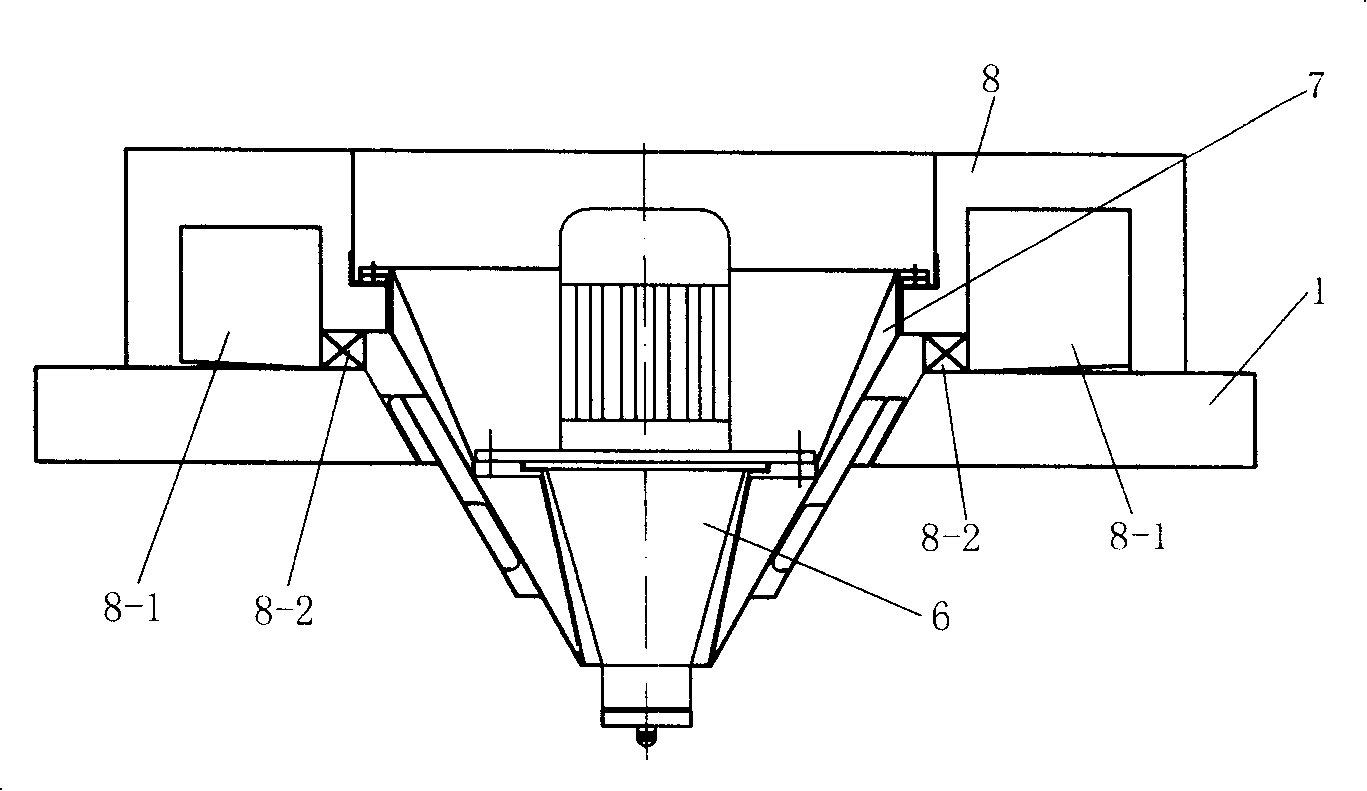

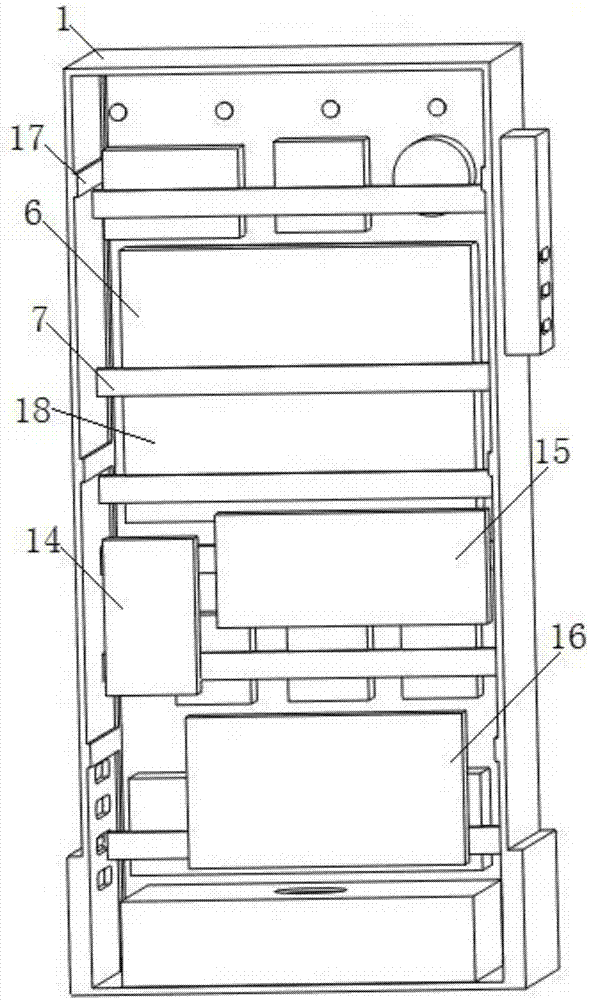

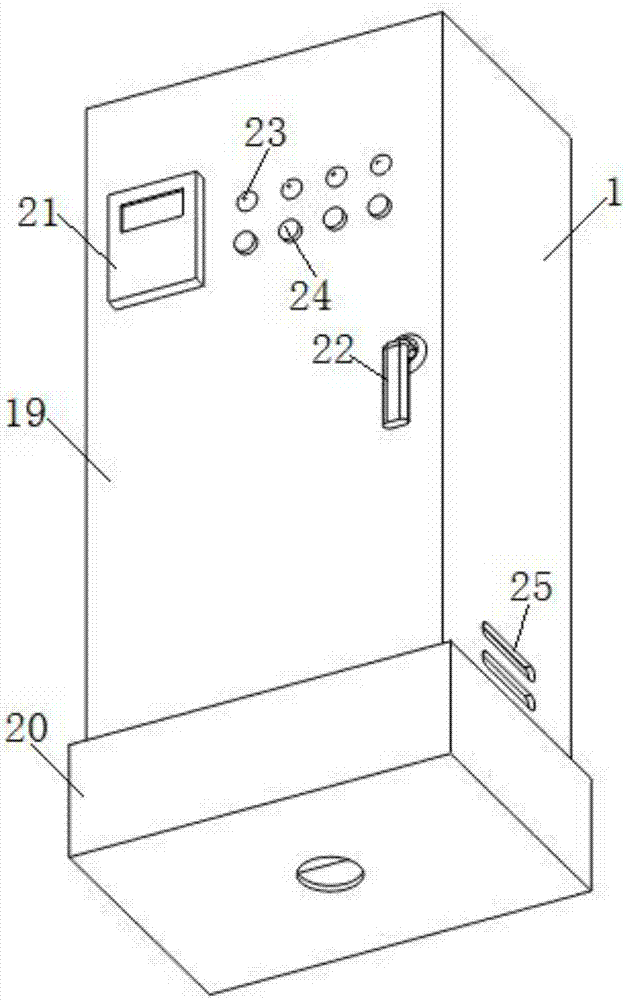

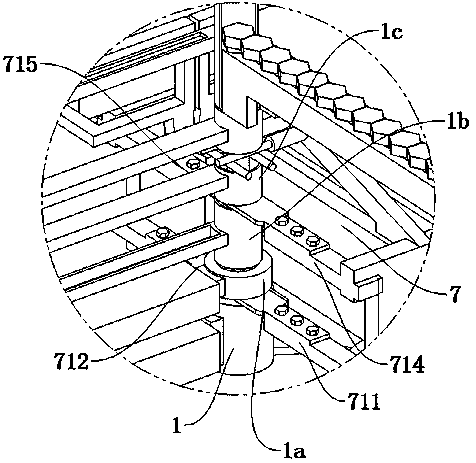

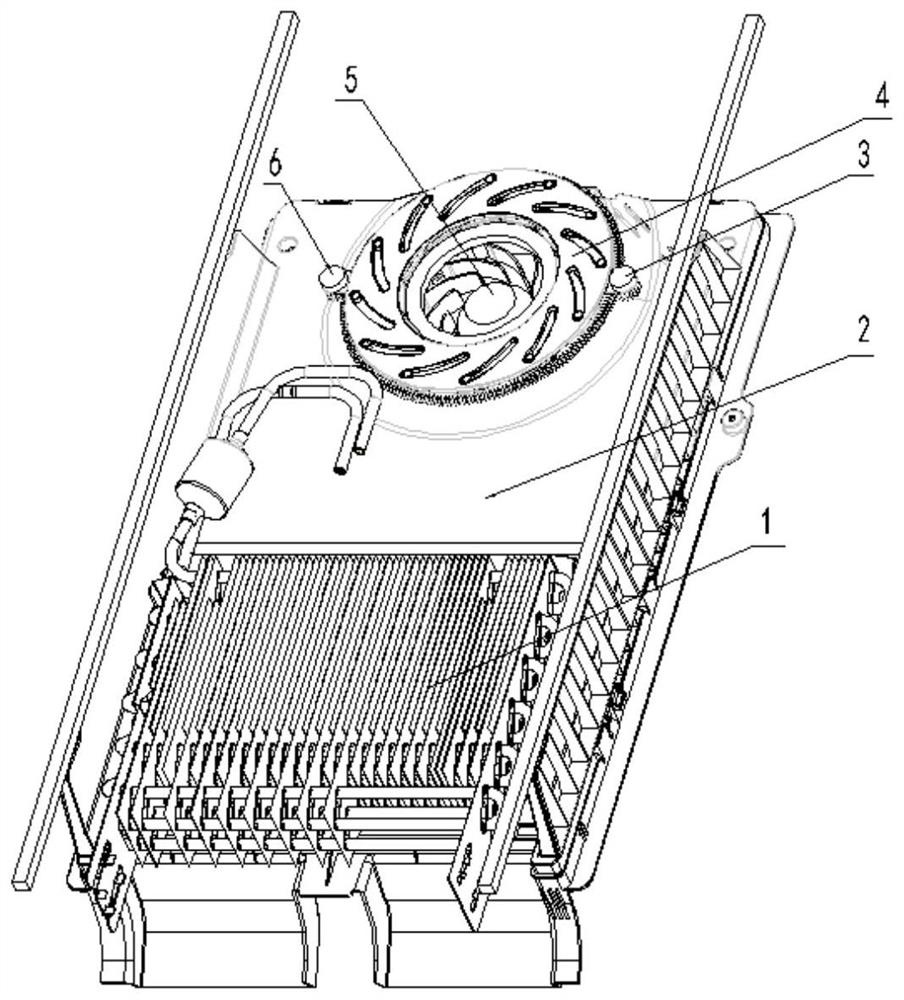

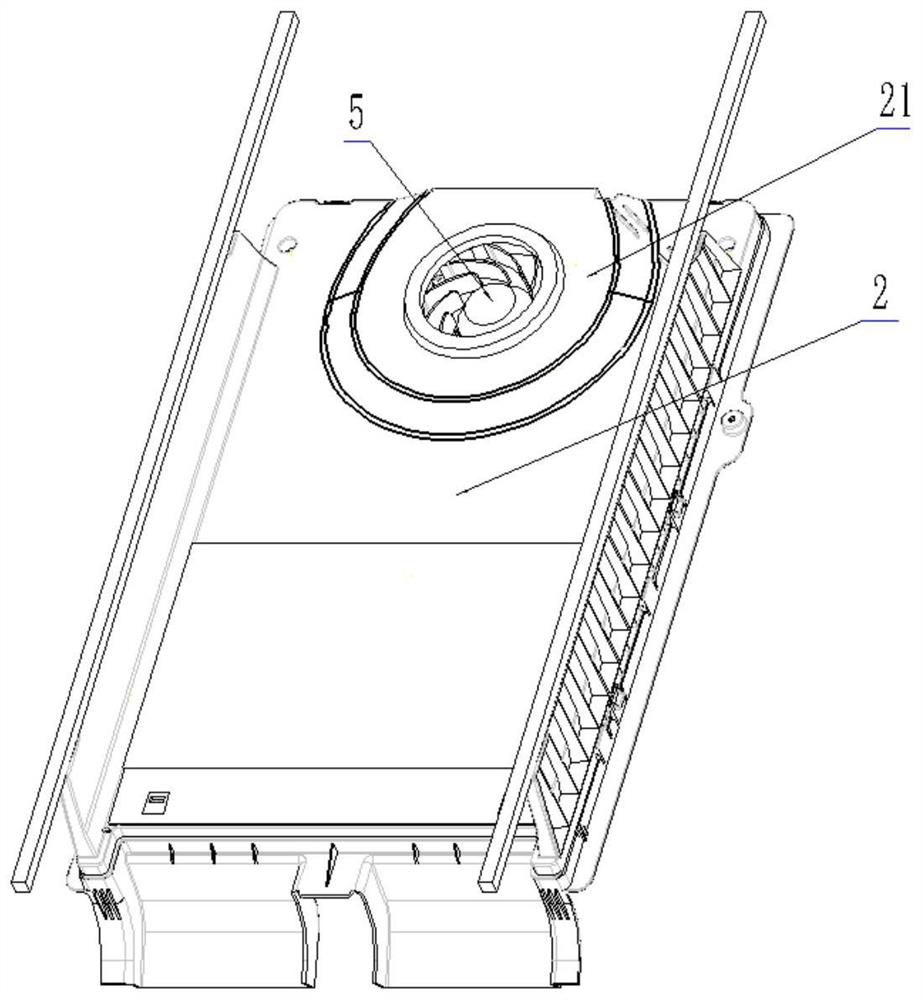

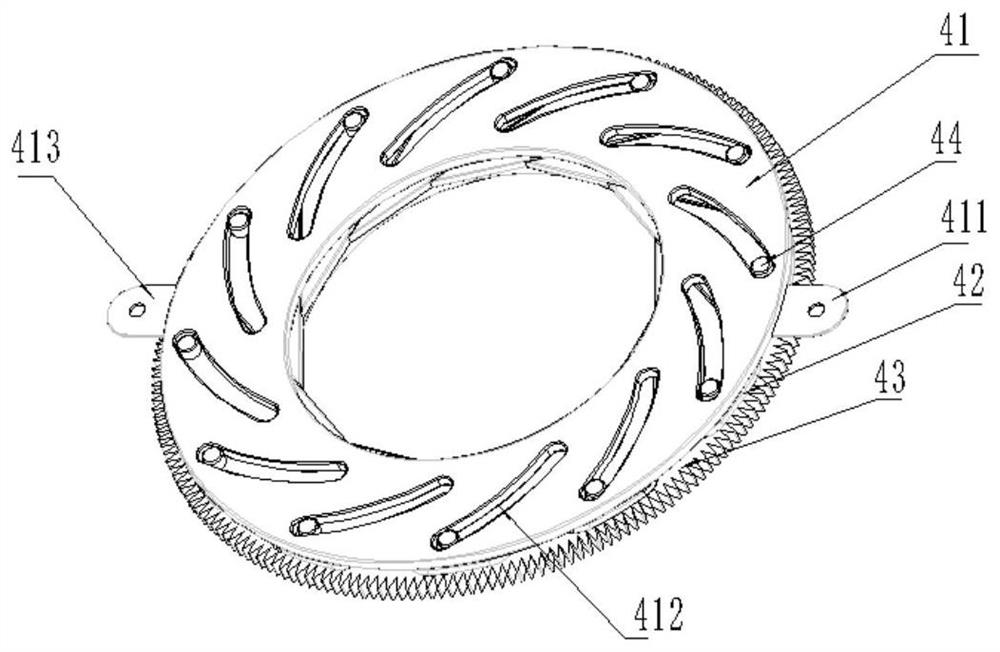

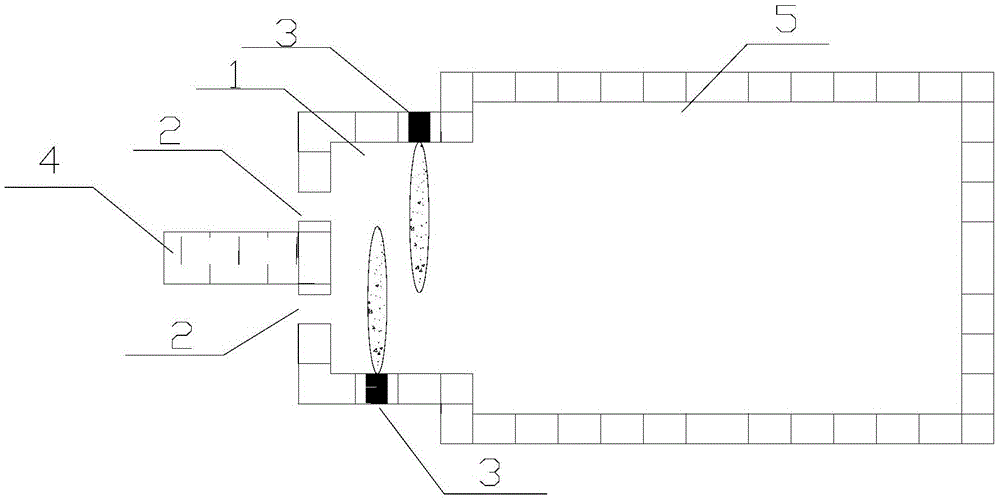

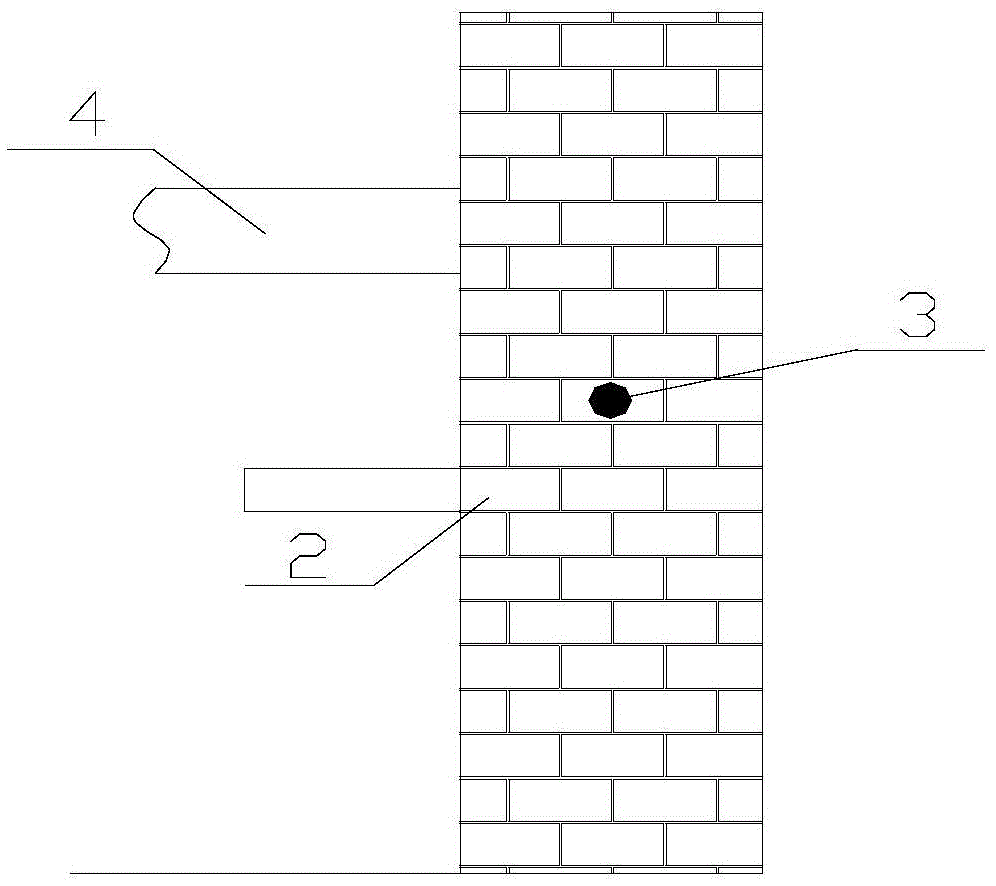

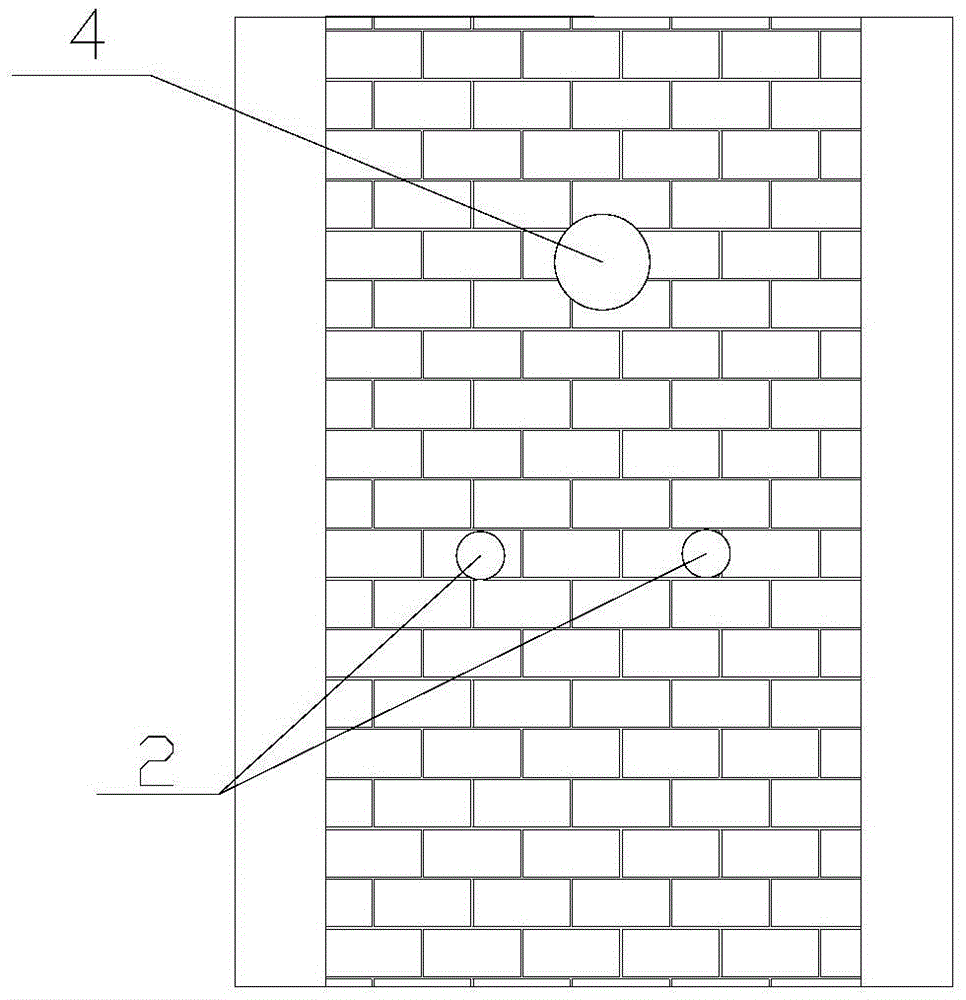

The invention comprises a material feeding device, a drying tower, a No 1 fan, a No 1 heater, a first-level cyclone separator and water-membrane dust remover. A hot air distributor and an atomizer which is arranged at the center of the hot air distributor and is connected with the material feeding device are arranged on the top of the drying tower. An air channel disk with a spiral-case shaped air channel is arranged on the top of the drying tower. The inlet of the air channel disk is connected with the output pipeline of the No1 heater, and the outlet of the spiral-case shaped air channel is connected with the inlet of the hot air distributor. A clamp sleeve is arranged in the internal tower body and near the top of the drying tower. A wall-blowing air channel is a space between the clamp sleeve and the inner side wall of the tower body. An annular clearance between the clamp bottom and the inner wall of the tower body is an air vent, and the air forms the wall-blowing air through the annular clearance. The invention adopts the air channel disk spiral air-feeding and wall-blowing feeding technique of the spiral-case shaped air channel, which not only can enhance drying efficiency but also can provide the wall-blowing air to form an air membrane in the drying tower. The air membrane can isolate powder materials from the tower wall so as to avoid a wall-sticking phenomenon.

Owner:JIANGSU XIANFENG DRYING ENG

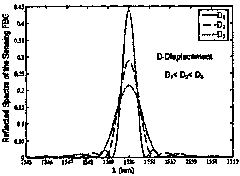

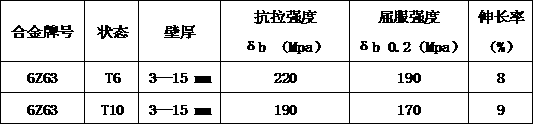

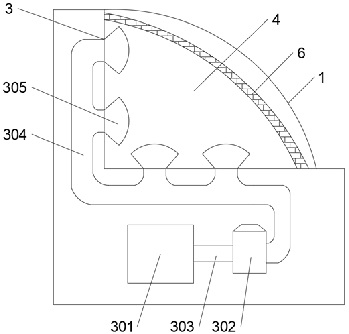

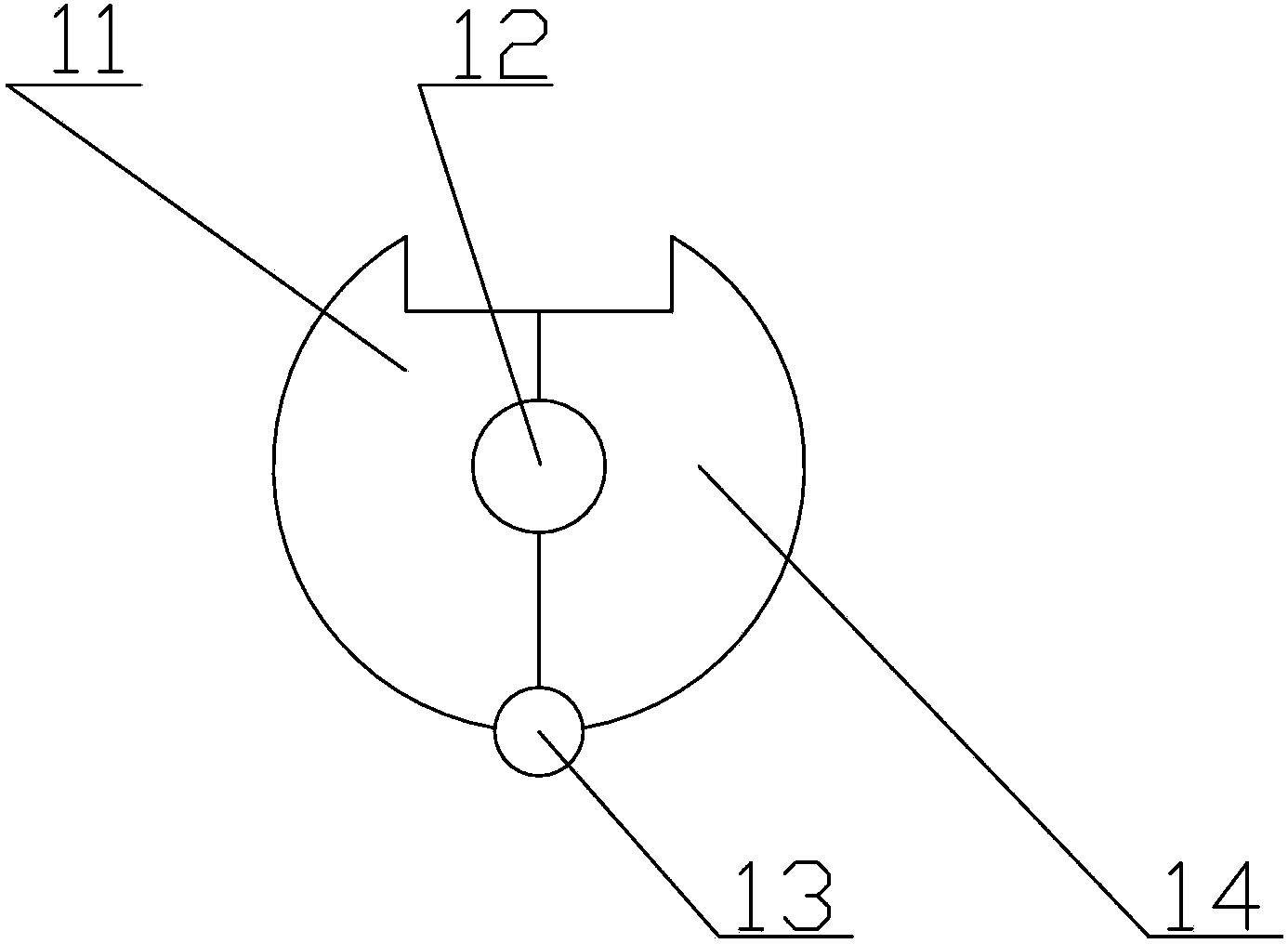

Blazed fiber bragg grating demodulation-based micro-displacement sensor and detection method

InactiveCN101825434ASimple instrument structureInnovative designUsing optical meansMitigation of undesired influencesBeam angleLight source

The invention relates to a blazed fiber bragg gating demodulation-based micro-displacement sensor and a detection method and belongs to the technical field of photoelectric detection. The sensor consists of a wideband light source 1, an optical circulator 2, optical fiber links (31, 32, 33), fiber bragg gating 4 used for sensing, a double-arched beam 5, a base 6, a helix millesimal screw 7, a blazed fiber bragg gating 8 used for demodulation, a refractive index matching liquid groove 9, a columnar lens 10, an optical fiber array 11, a CCD photoelectricity prober 12, a signal processing unit 13 and a computer 14. The sensor is characterized in that a reflective spectrum signal of the fiber bragg gating 4 used for sensing is broadened under the action of the detected micro-displacement; the signal is sent to the optical fiber array 11 by the blazed fiber bragg gating 8 used for demodulation with a certain beam angle and is transmitted to the CCD photoelectricity prober 12; the error of the measurement caused by light intensity wave, optical fiber transmission loss and the like is avoided on the basis of a gauss fitting algorithm and by identifying the detected displacement corresponding to the facula size received by the CCD photoelectricity prober 12.

Owner:NORTHEASTERN UNIV

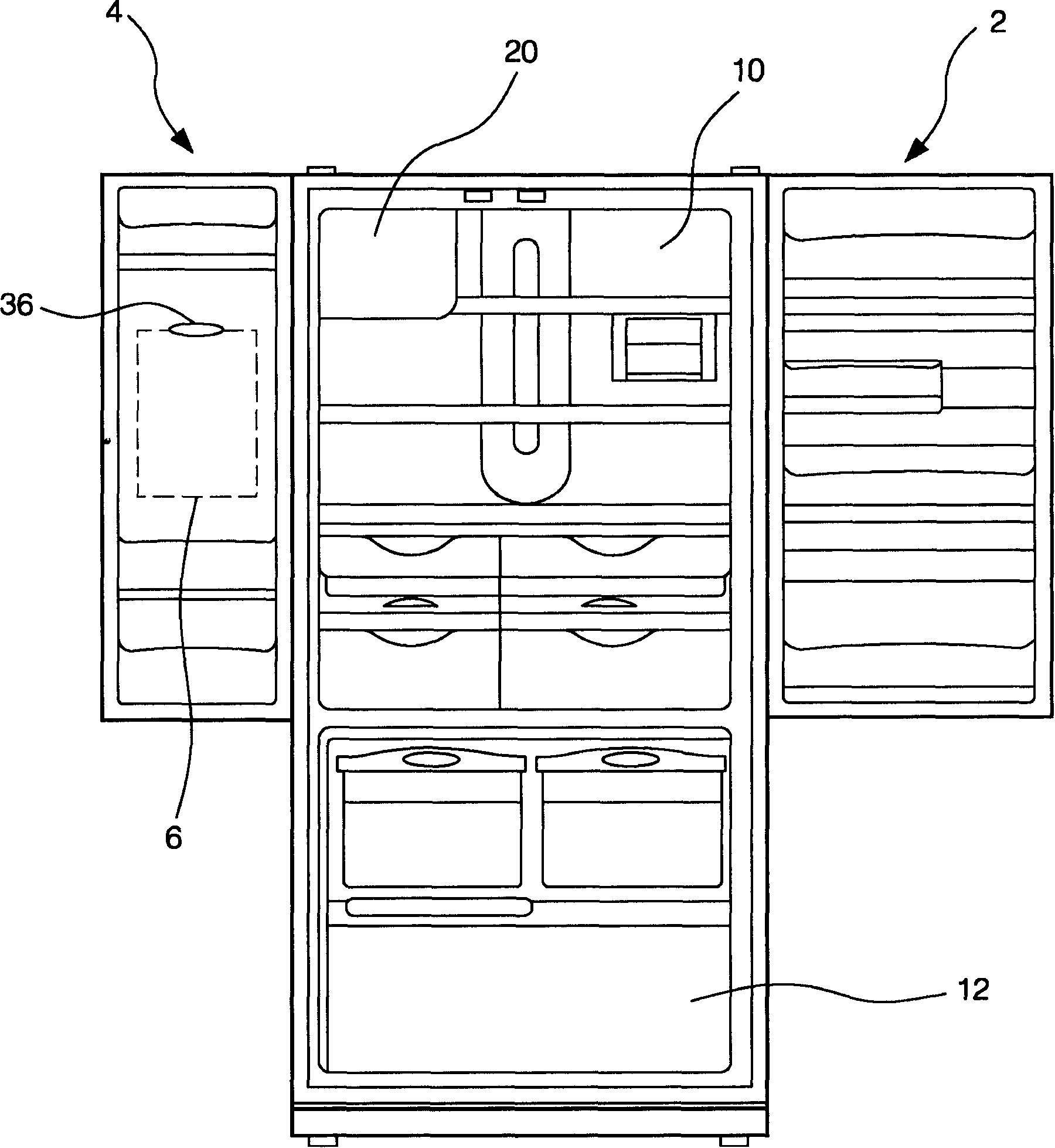

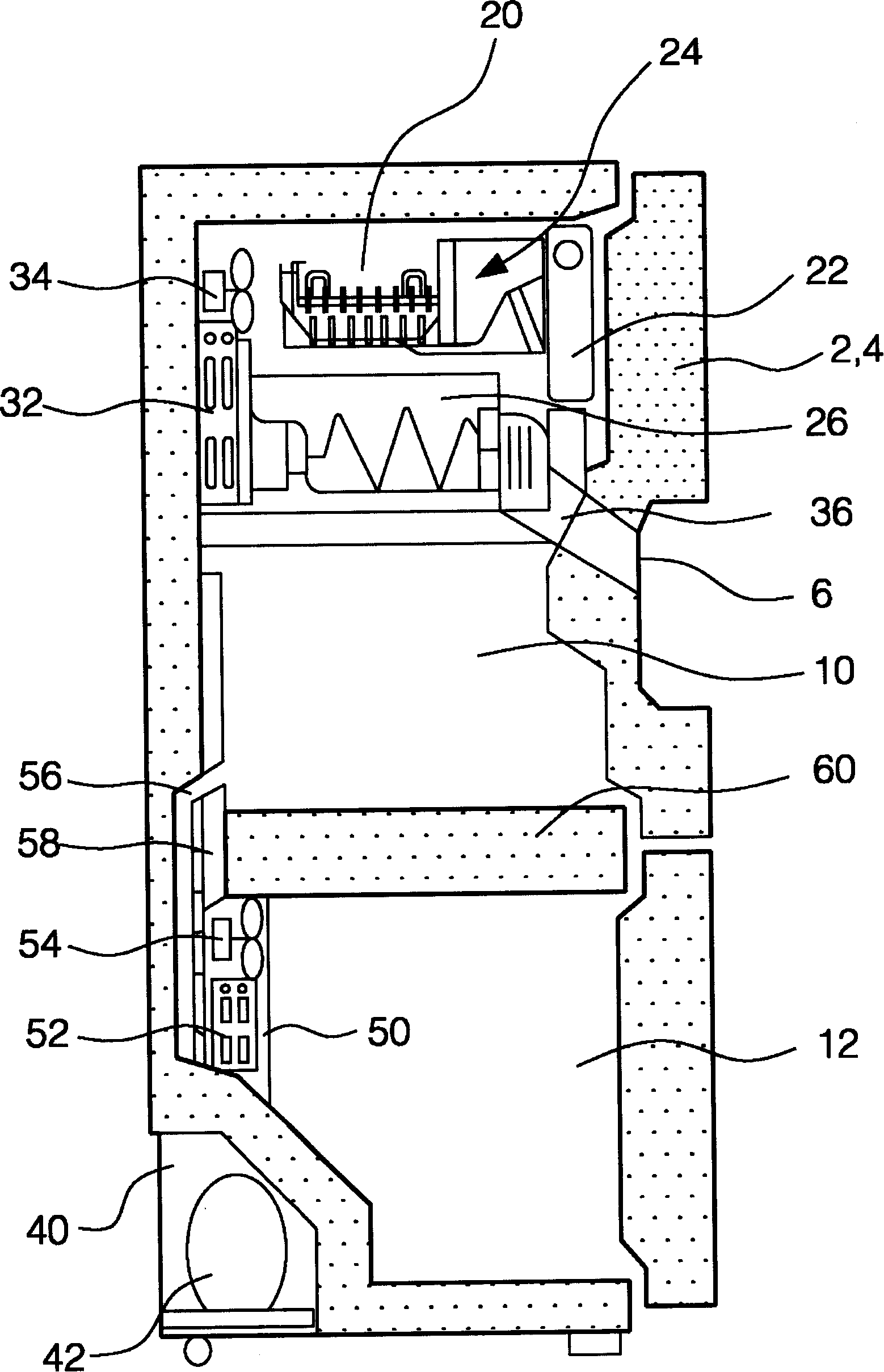

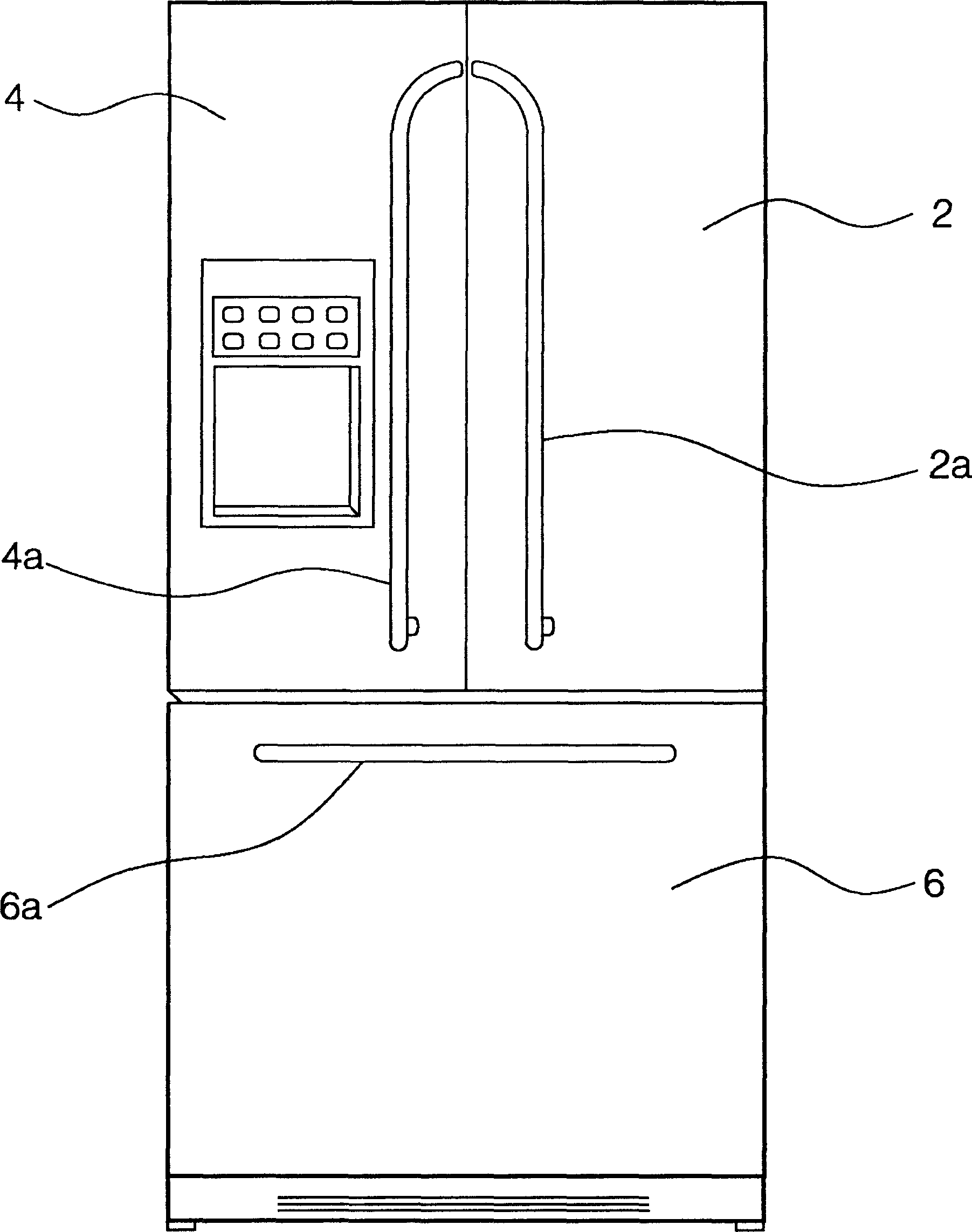

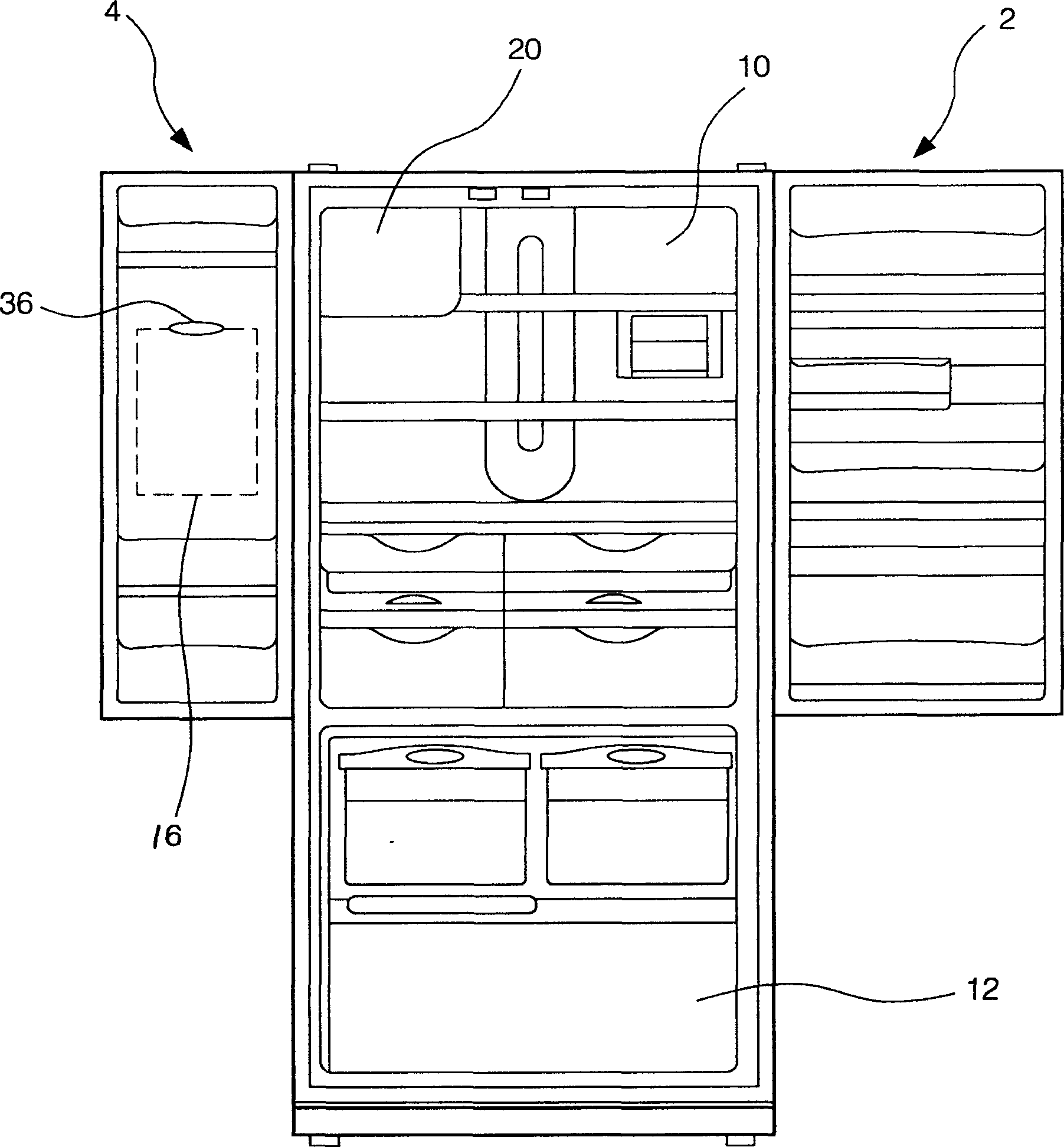

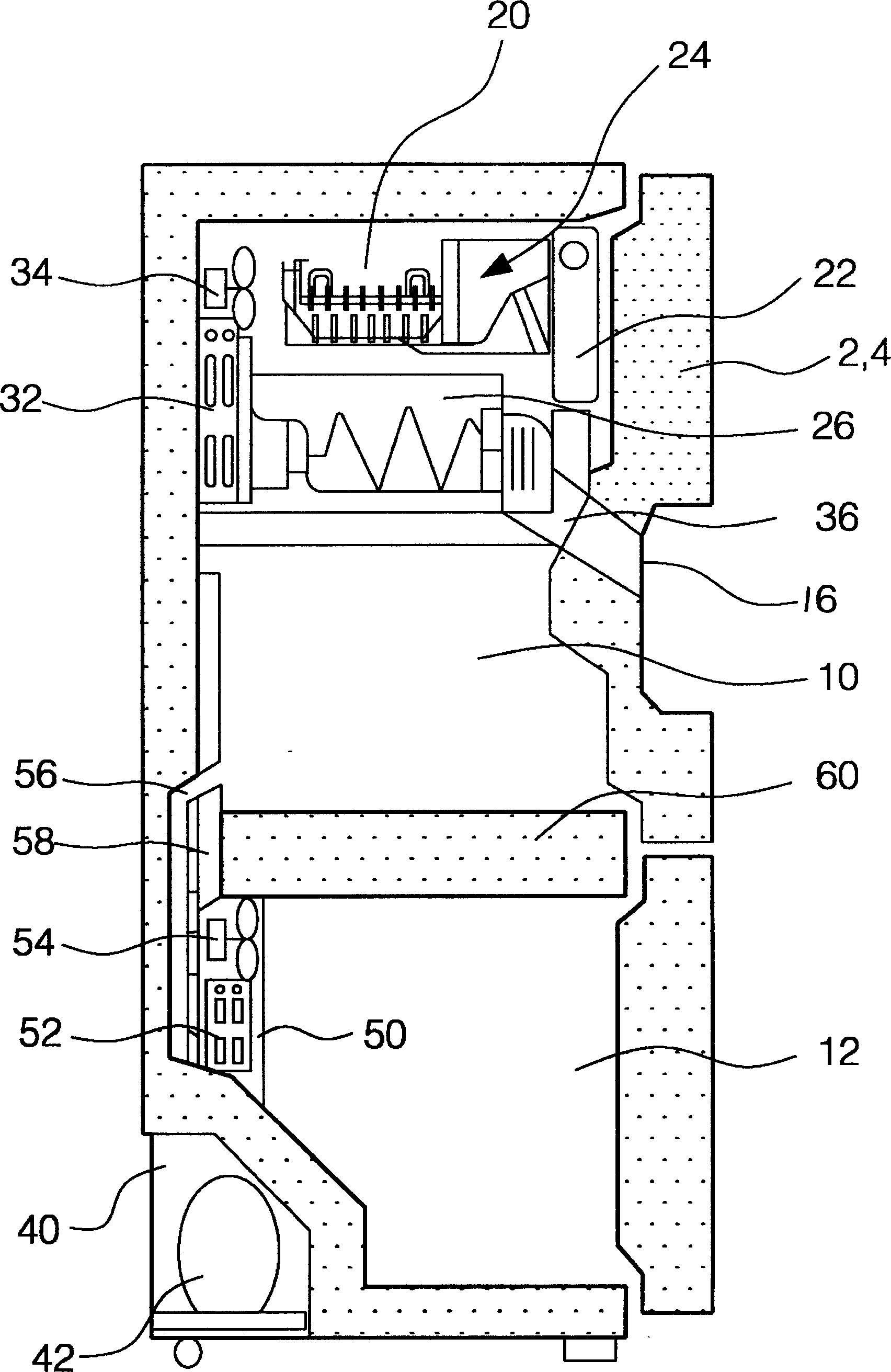

Refrigerator with ice maker in cold storage room

InactiveCN1683862ATemperature does not affectNormal working temperatureLighting and heating apparatusDomestic refrigeratorsCold airIce storage

The refrigerator with ice making machine in the cold storage chamber includes cold storage chamber in the upper part of the refrigerator; the freezing chamber in the upper part of the refrigerator; ice making chamber enclosed with heat isolating boards inside the cold storage chamber and with ice making machine and ice storage; the first evaporator inside the ice making chamber to lower the temperature inside the ice making chamber; and the second evaporator set inside the freezing chamber to provide cold air to both the freezing chamber and the cold storage chamber. The ice making chamber is inside the cold storage chamber, and has no influence on the normal temperature of the cold storage chamber. In addition, the separate control of evaporators in both the ice making chamber and the freezing chamber makes the refrigerator has high ice making capacity and low power consumption.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Refrigerator with ice maker in cold storage room

InactiveCN1683859ATemperature does not affectEasy to open and closeLighting and heating apparatusDomestic refrigeratorsCold airIce storage

The refrigerator with ice making machine in the cold storage chamber includes cold storage chamber in the upper part of the refrigerator, freezing chamber in the lower part of the refrigerator, and ice making machine. There are ice making chamber enclosed with heat insulating partitions inside the cold storage chamber, the first evaporator to lower the temperature of the ice making chamber inside the ice making chamber, the second evaporator inside the freezing chamber to provide cold air to both the freezing chamber and the cold storage chamber, ice making machine and ice storage inside the ice making chamber, freezing chamber door and double door for the cold storage chamber. The refrigerator of the present invention has separated doors for both freezing chamber and cold storage chamber, and has less heat loss and low power consumption.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

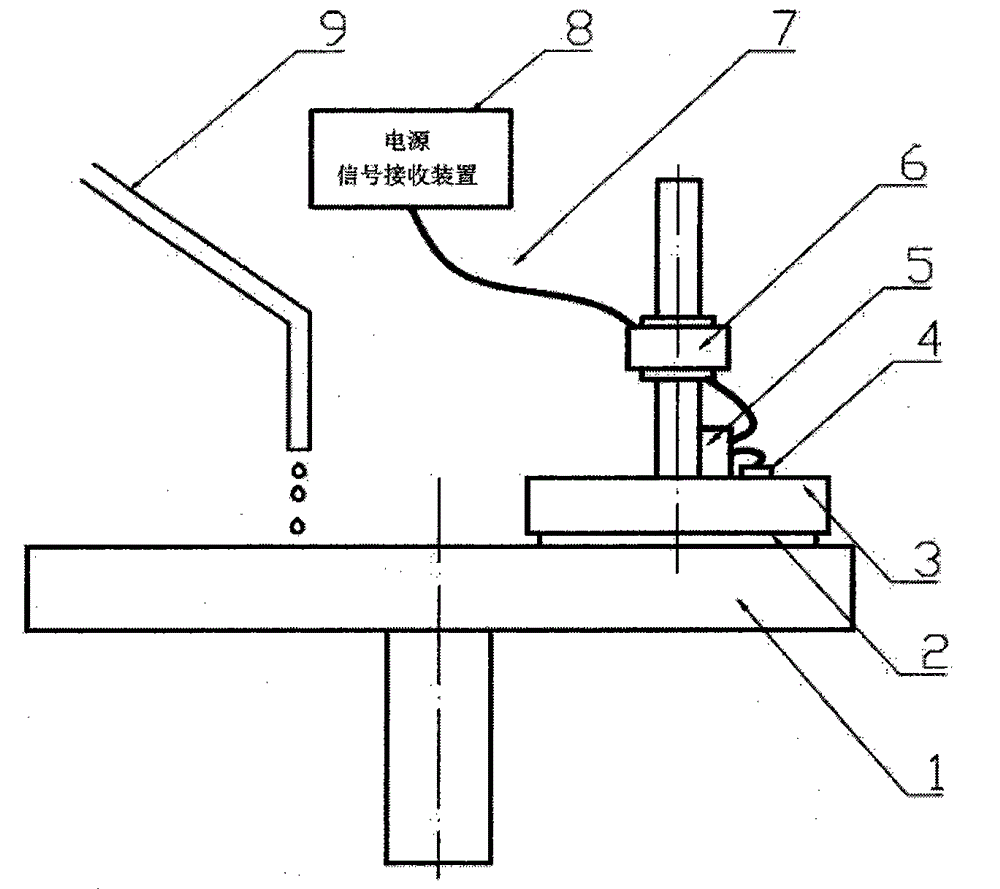

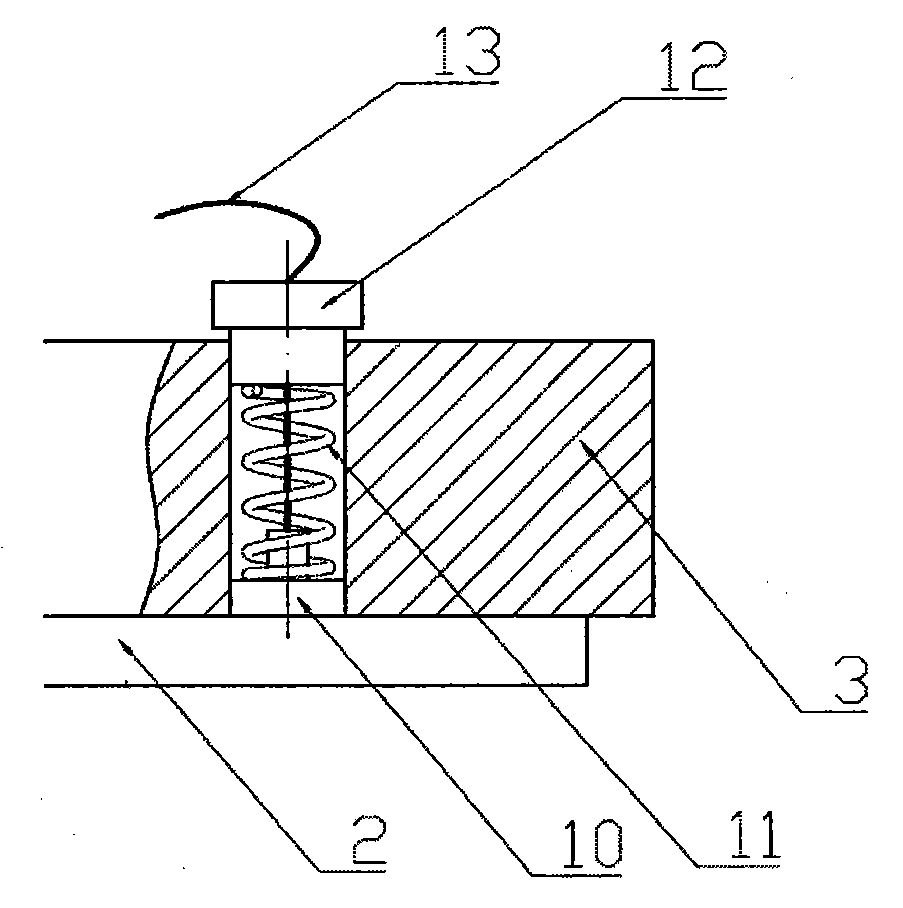

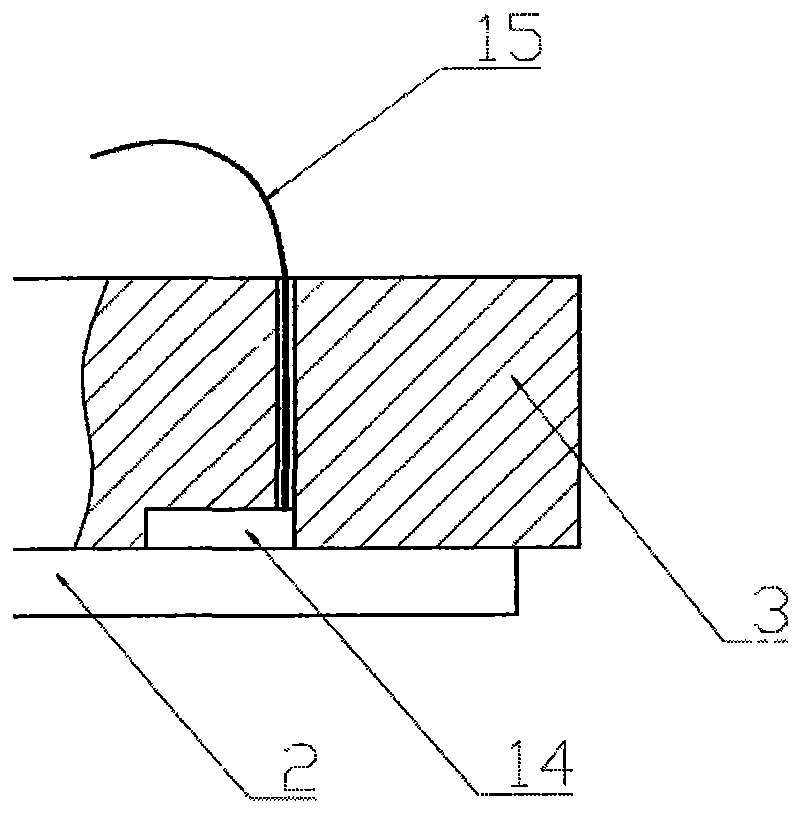

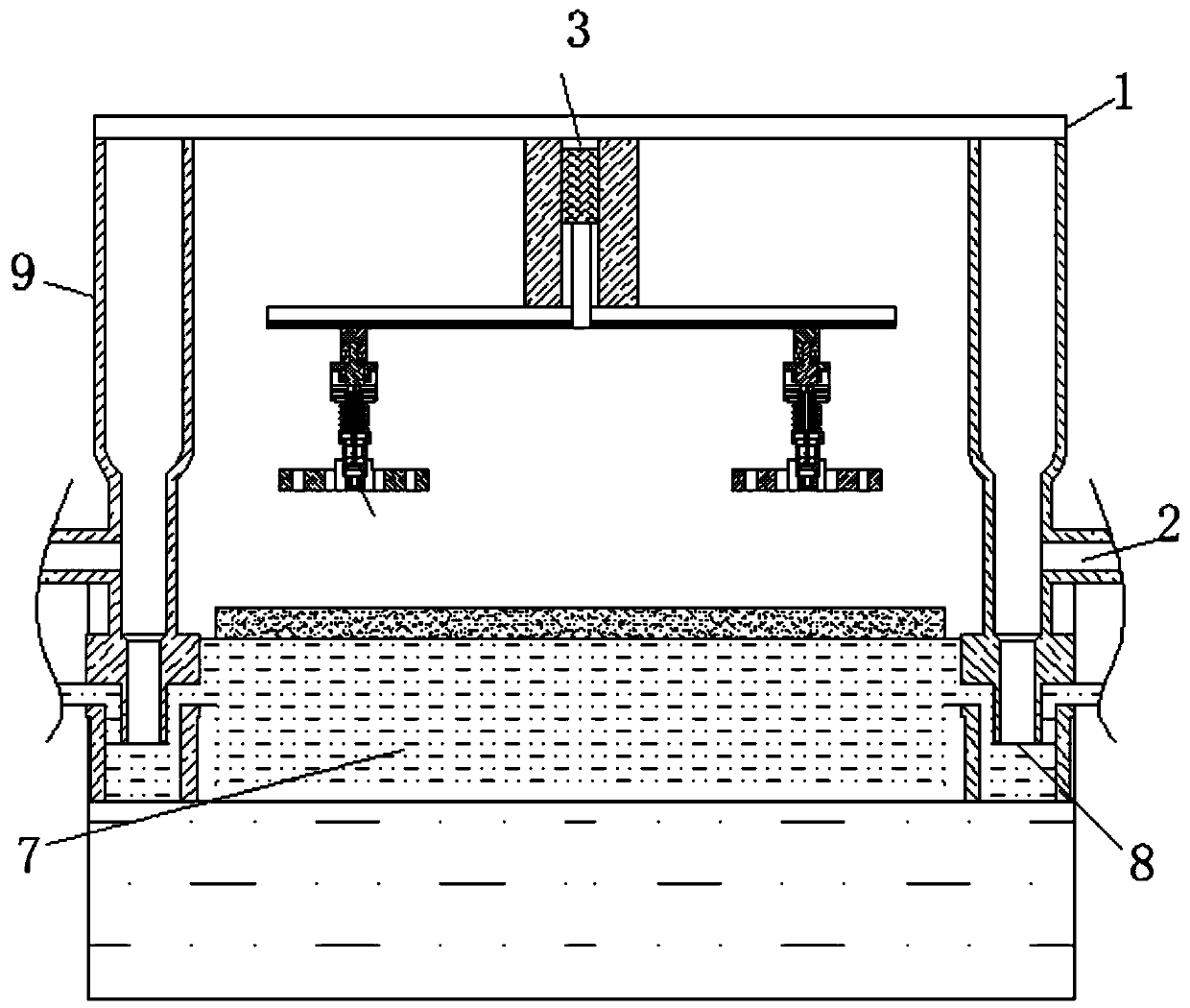

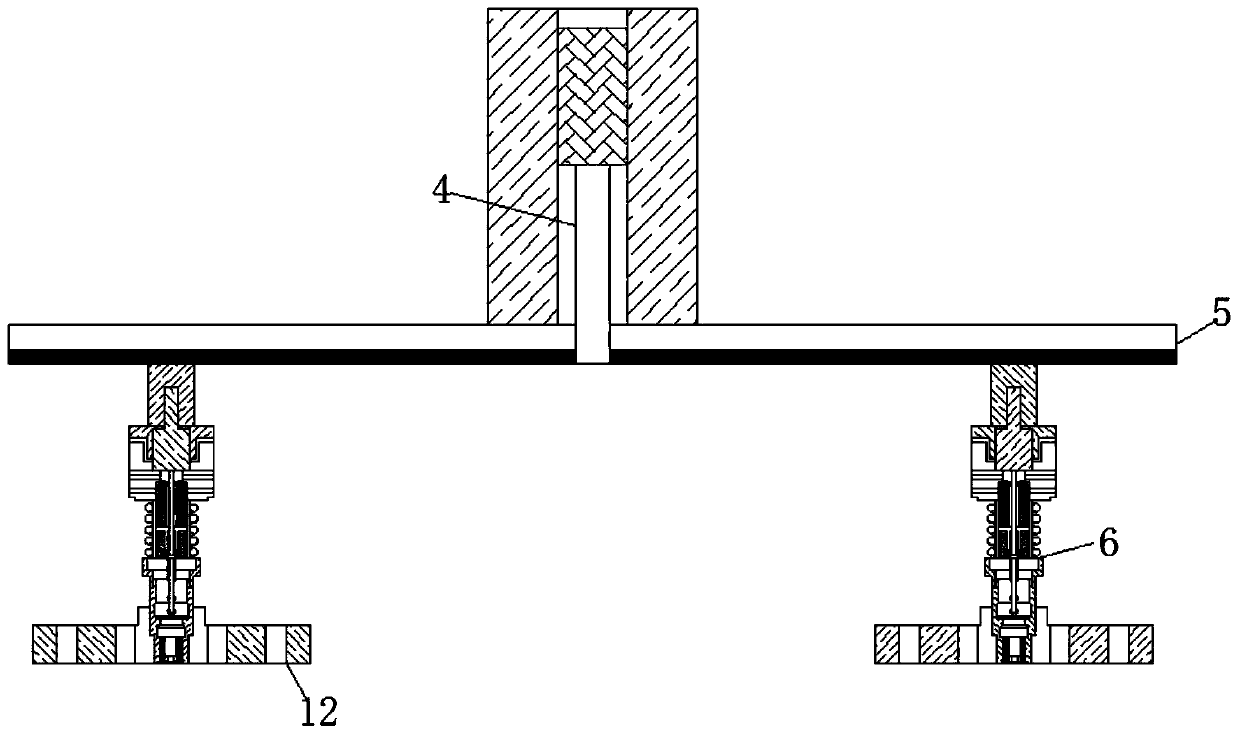

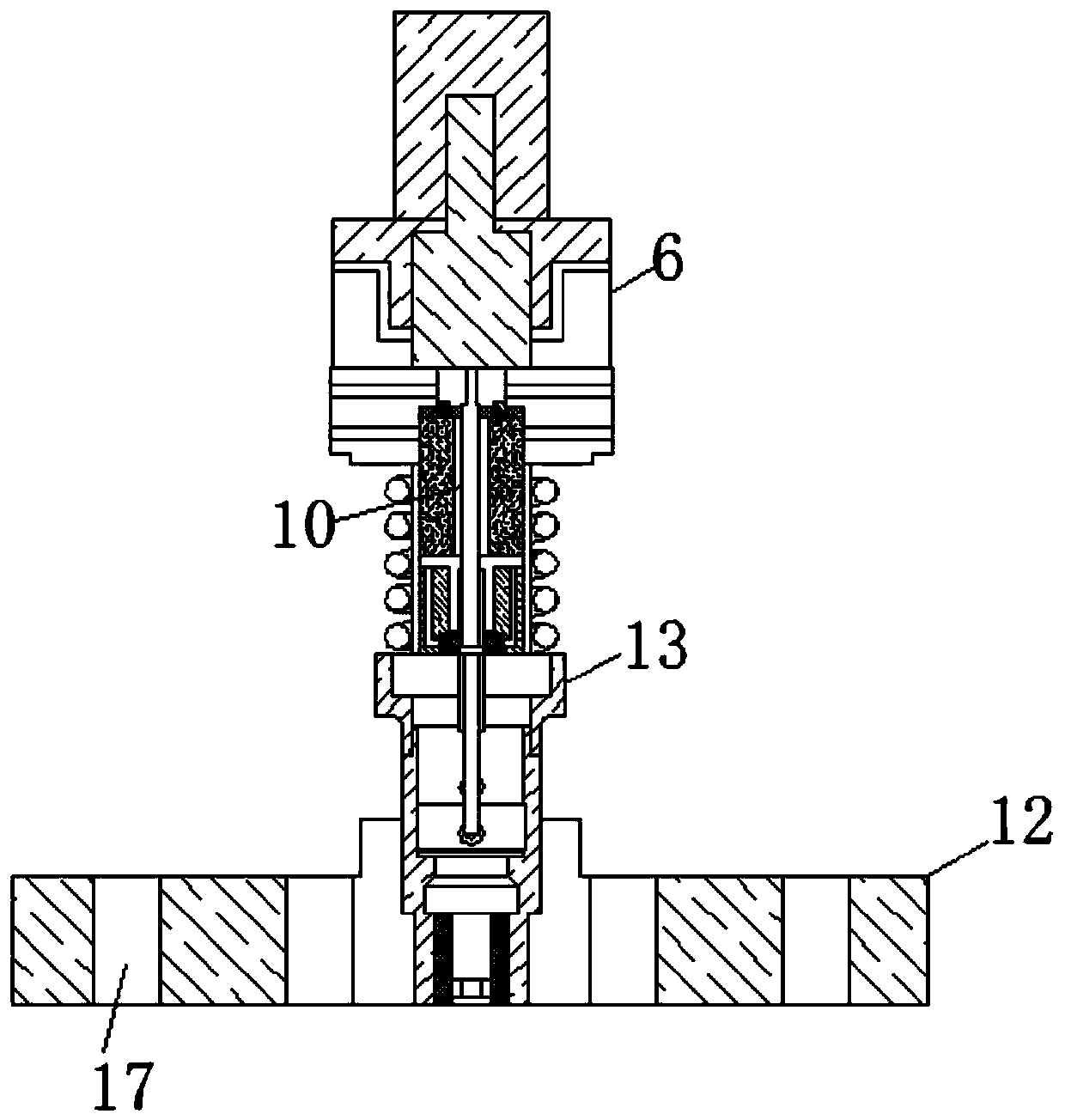

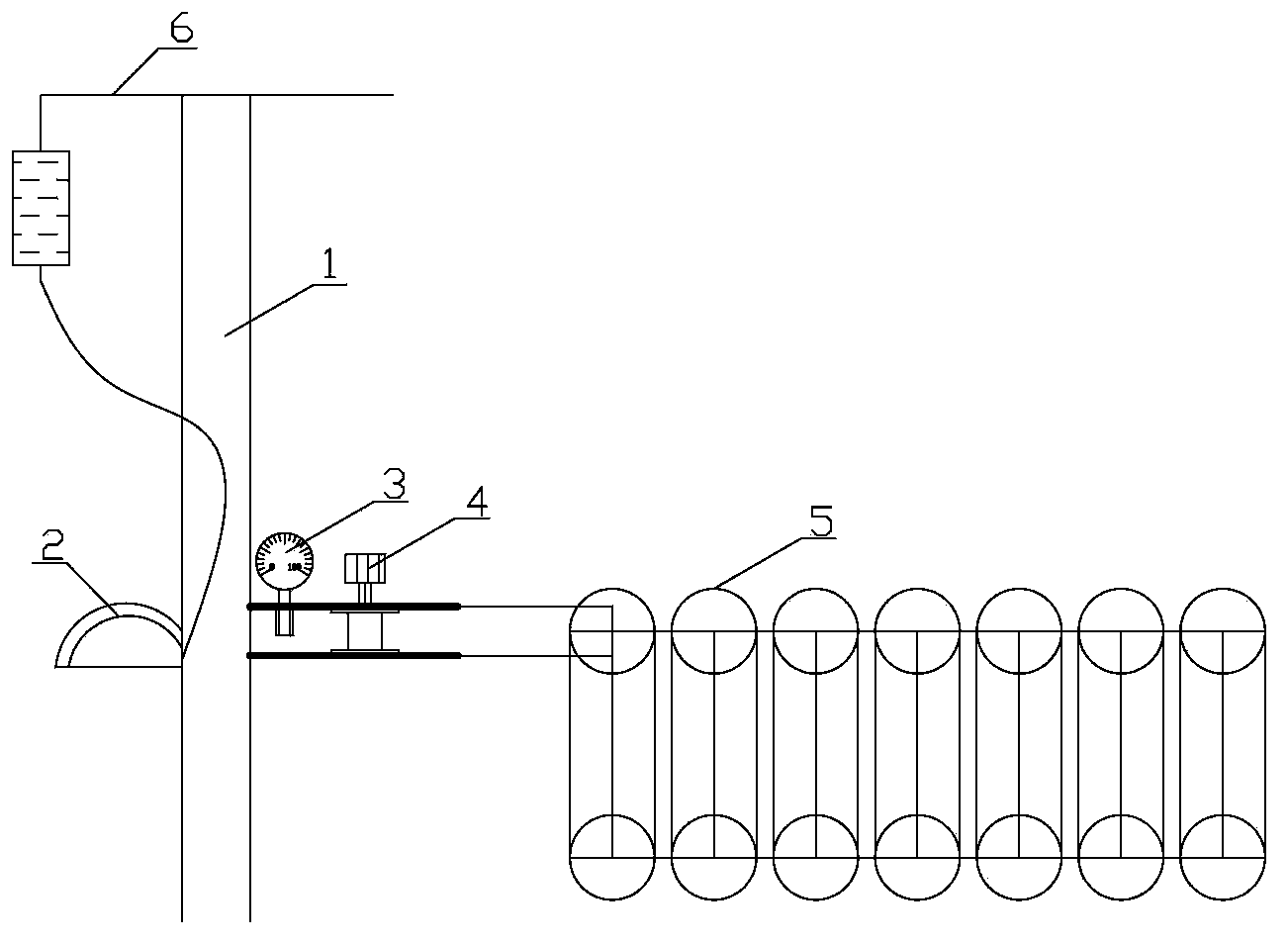

Temperature detection device of polishing interface and utilization of temperature signals in chemically mechanical polishing process

InactiveCN104897296AHigh precisionSimple device structureThermometers using electric/magnetic elementsUsing electrical meansTemperature senseMachining process

The invention provides a device for detecting temperature of a polishing interface in real time with high precision on the premise of not influencing a polishing technology process, ad also provides a method for using detected temperature signals to perform polishing endpoint judgment and polishing process monitoring. The temperature detection device consists of a temperature sensor, a signal processing module, a conductive slip ring, a signal receiving device, a power supply and leads connecting all the components. A temperature sensing area of the temperature sensor is in direct contact with the reverse side of a polished workpiece, a weak signal output by the sensor is processed by the signal processing module and then transmitted to the signal receiving device through the conductive slip ring, and then the signal receiving device carries out operation such as collection, processing and display of the signal. When another material layer is removed from a material layer of the polished workpiece, a polishing endpoint can be judged according to a situation of a change of the temperature of the polishing interface. The temperature of the polishing interface is compared with a normal temperature range of a polishing interface under the same technological parameters, and thus whether a machining process is normal or not can be judged.

Owner:GUANGDONG UNIV OF TECH

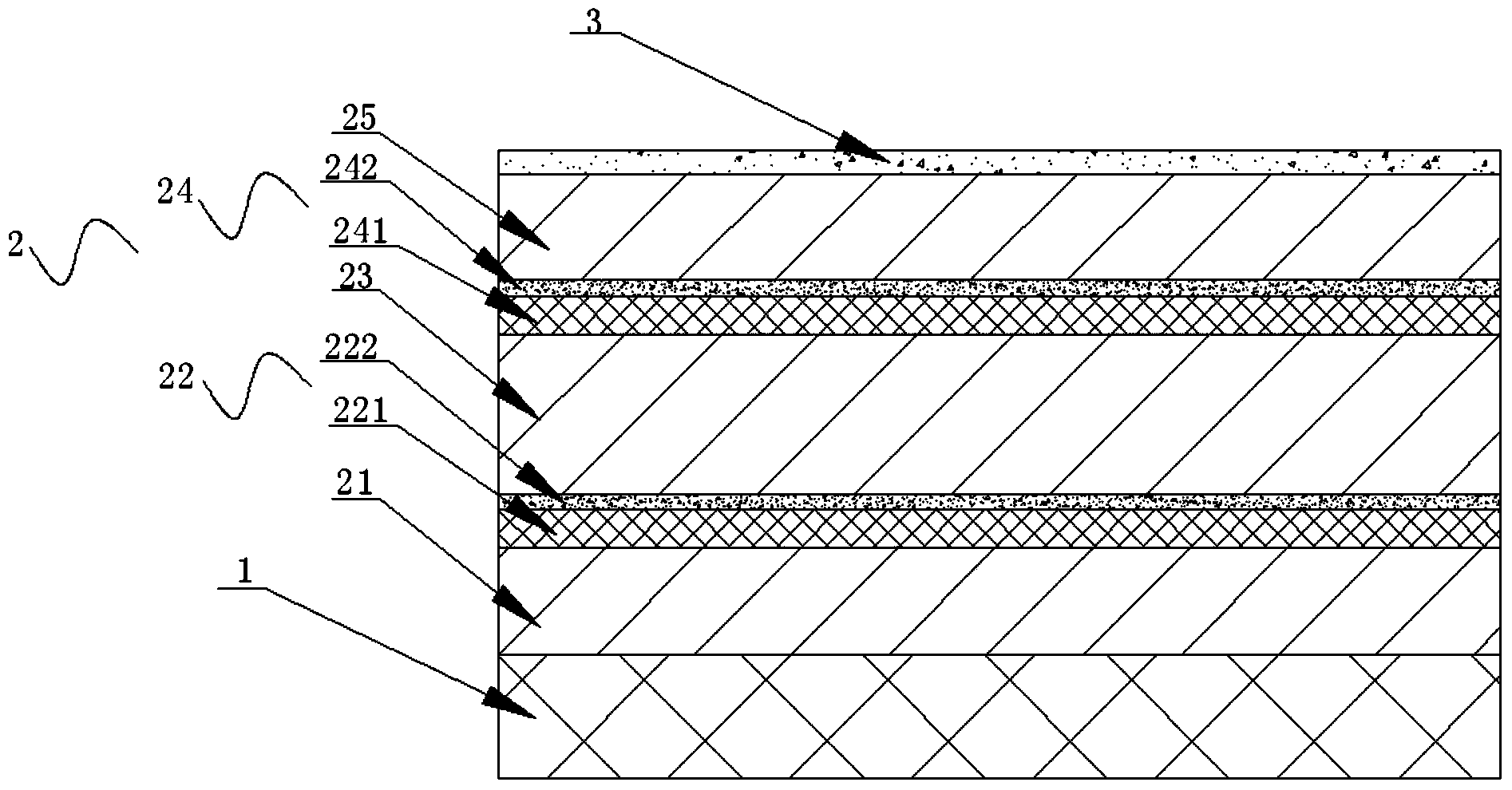

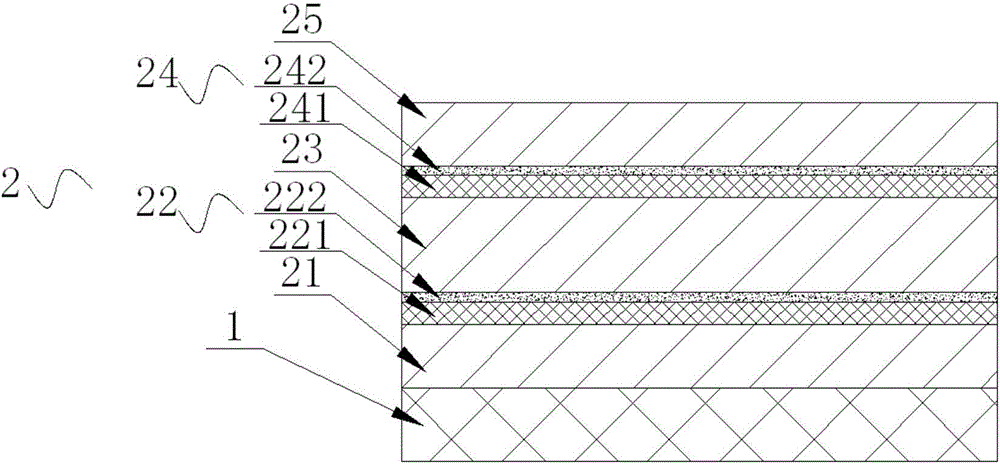

Window film core functional layer and preparation method thereof

InactiveCN104325760AImprove reflectivityReduce reflectivitySynthetic resin layered productsVacuum evaporation coatingCore functionPet substrate

The invention discloses a window film core functional layer and a preparation method thereof. The window film core functional layer comprises a PET substrate thin film, and a first transparent oxide layer, a first composite metal layer, a second transparent oxide layer, a second composite metal layer, a third transparent oxide layer and an outer side seal layer which are sequentially deposited from bottom to top by magnetron sputtering. The preparation method of the window film core functional layer comprises the step of sequentially performing coating in six chambers of a six-chamber coiling type magnetron sputtering coating machine or a double-roller and three-chamber coiling type magnetron sputtering coating machine to form the magnetron sputtering layers. The window film core functional layer has the beneficial effects that an Au layer with the thickness of 3-10nm is deposited at the outer side of the third transparent oxide by magnetron sputtering, so that the infrared reflectivity is increased to 90% from 80%; the reflectivity of visible light is reduced while the infrared reflectivity is increased, so that the temperature in a chamber using the window film core functional layer is maintained to be constant while lighting is not influenced.

Owner:邹申秀

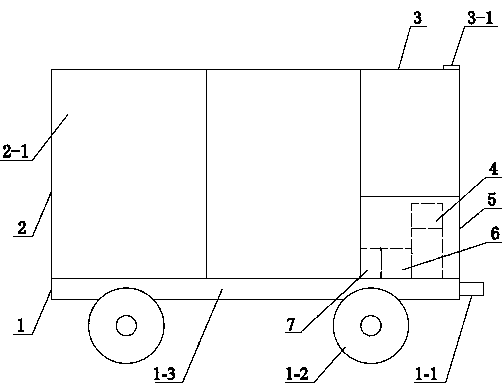

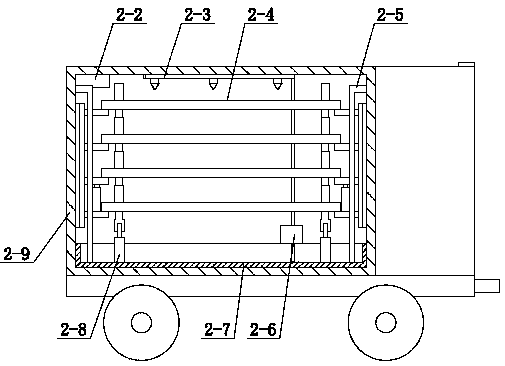

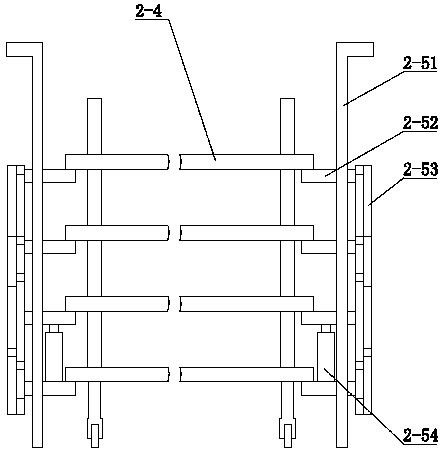

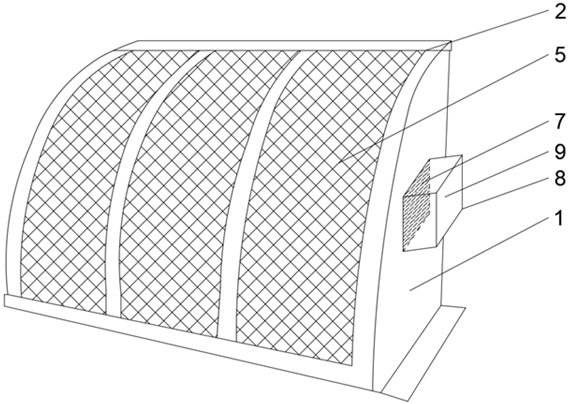

Road engineering material maintenance vehicle

PendingCN109702876ATemperature does not affectDoes not affect temperaturePreparing sample for investigationCeramic shaping apparatusAuto regulationWater channel

The invention discloses a road engineering material maintenance vehicle. The road engineering material maintenance vehicle comprises a trailer chassis, a maintenance tank and a water tank; the maintenance tank and the water tank are arranged on the trailer chassis parallelly, the maintenance tank is a sealed heat preservation tank body, and the water tank is closed; a water injection opening witha water injection plug is formed in the top of the water tank, and an air conditioner, a humidifier, a test-piece support, a water channel, a temperature sensor and a humidity sensor are arranged in the maintenance tank; a PLC and a power supply are arranged outside the maintenance tank, and the water channel and the water tank are connected through a water injection pump; the water channel supplies water to the humidifier, and the water injection pump, the air conditioner, the humidifier, the temperature sensor and the humidity sensor are all connected with the PLC through signal lines; and power lines of the water injection pump, the air conditioner, the humidifier and the PLC are connected with the power supply. The road engineering material maintenance vehicle is provided with the trailer chassis, and thus is convenient to drag by other power devices and easy to move, the temperature and humidity in the maintenance tank can be automatically adjusted according to the setting, the water channel is formed in the maintenance tank, the appropriate amount of water is injected into the water channel before maintenance each time, and the temperature in the maintenance tank is not influenced during humidity adjustment of the humidifier; and the road engineering material maintenance vehicle is provided with the power supply and thus is suitable for fields.

Owner:SHANDONG JIAOTONG UNIV

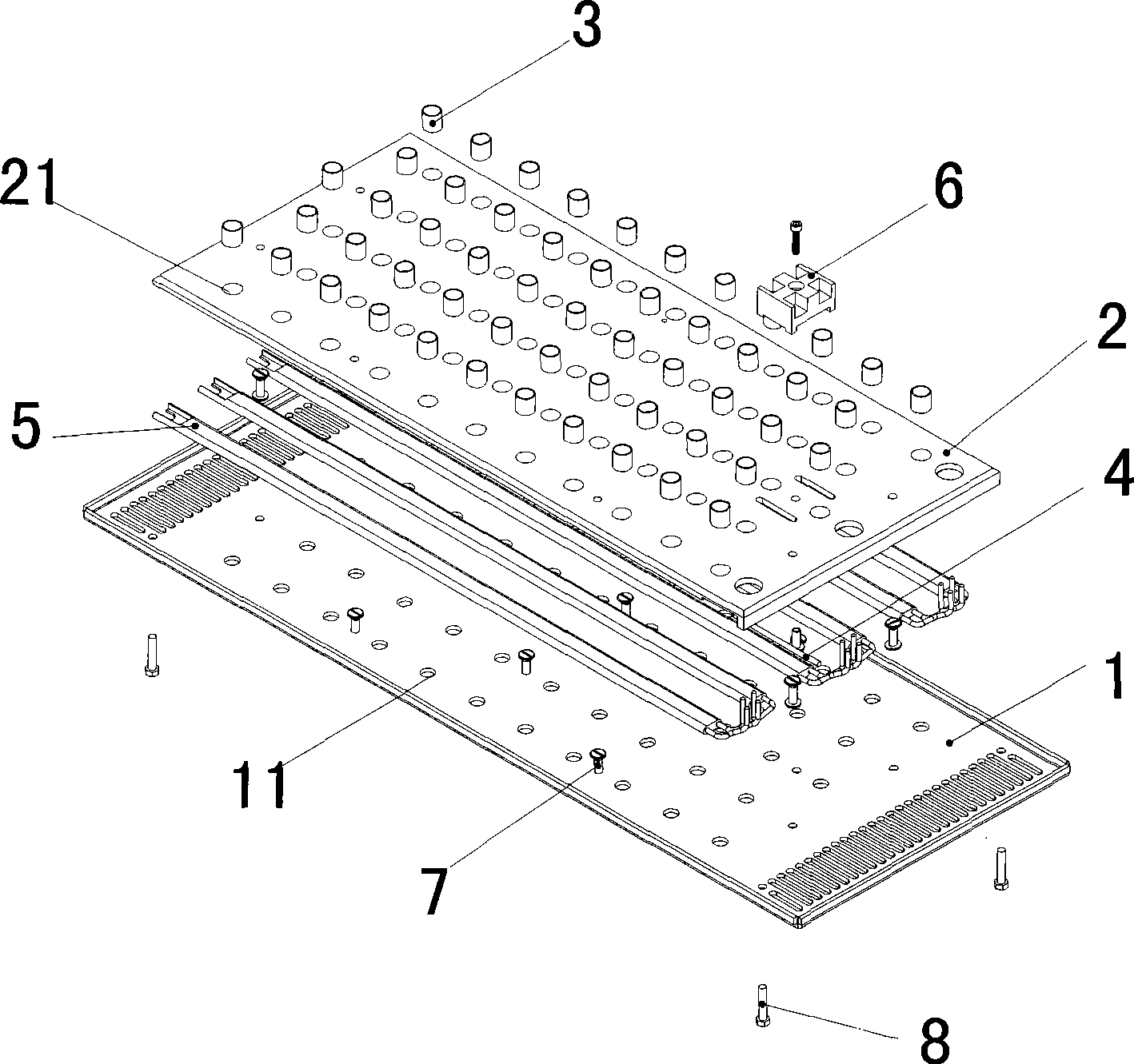

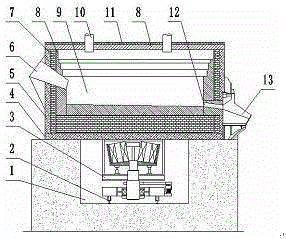

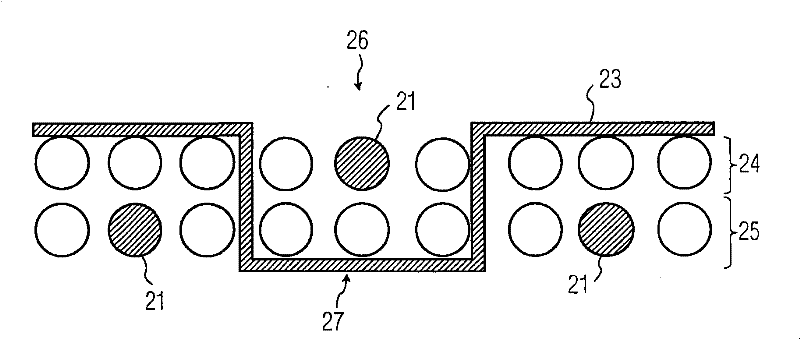

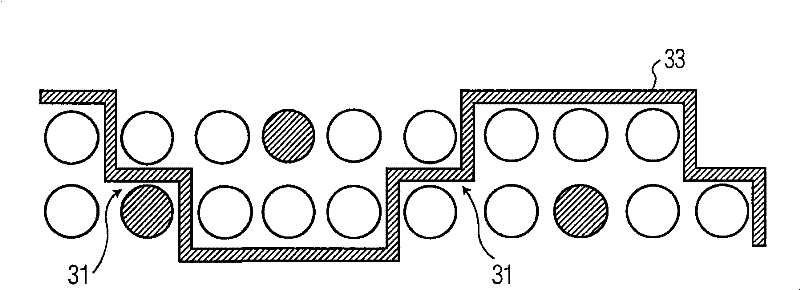

Receding aperture plate in cooling module of reflow welding stove

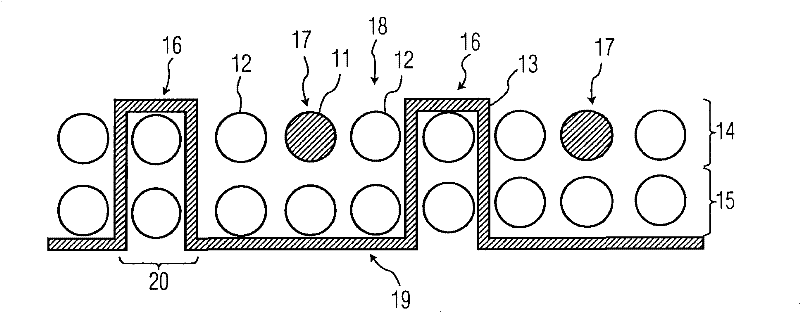

ActiveCN101468417AReduced cleaning and maintenanceImprove uptime and productivitySoldering auxillary devicesOrifice plateElectric heating

The invention relates to a reflux orifice plate in a reflow furnace cooling module, which comprises a reflux orifice plate body, a heat-preserving board, a plurality of air conducting pipes, a temperature sensor, an electric heating wire and a ceramic terminal. The reflux orifice plate body and the heat-preserving board are correspondingly provided with a plurality of through holes used for mounting the air conducting pipes; the air conducting pipes are connected to the refux orifice plate body and the heat-preserving board; the temperature sensor and the electric heating wire are arranged on the reflux orifice plate body respectively and arranged between the reflux orifice plate body and the heat-preserving board; and the ceramic terminal is arranged on the upper surface of the heat-preserving board and electrically connected with the temperature sensor. The reflux orifice plate can ensure that the surface temperature (about 150 DEG C) is slightly higher than the gasifying temperature of a soldering flux all the time, achieve the aim that the soldering flux is not adhered to or piled on the surface of the reflux orifice plate, and keep the cleanliness and free maintenance of the surface of the reflux orifice plate all the time. The reflux orifice plate can not influence the temperature of reflux cooling air completely under the condition that the heating wire works, and can meet the requirements of the cooling efficiency of a printed circuit board and a process temperature curve.

Owner:上海朗仕电子设备有限公司

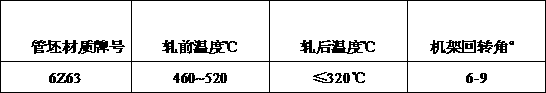

Preparation method of aluminum alloy tube busbar

The invention discloses a preparation method of an aluminum alloy tube busbar and belongs to the technical field of electric power. The aluminum alloy tube busbar is prepared from the following chemical components in percentage by weight: 0.20-0.60% of Si, 0.30-0.40% of Fe, 0.10-0.20% of Cu, 0.08-0.12% of Mn, 0.45-0.70% of Mg, 0.08-0.12% of Cr, 0.08-0.12% of Zn, 0.07-0.18% of Re, 0.08-0.12% of Ti,0.08-0.20% of Zr and the balance of Al. An aluminum alloy tube prepared by the preparation method of the aluminum alloy tube busbar is a seamless tube, has relatively high conductivity, and meanwhile, has very good mechanical properties at relatively high temperatures.

Owner:湖北兴和电力新材料股份有限公司

Device and method for controlling radial temperature gradient of silicon carbide monocrystalline growth

InactiveCN106048715AAdjustable temperatureTemperature does not affectPolycrystalline material growthFrom condensed vaporsFiberCarbon fibers

The invention relates to a device and method for controlling a radial temperature gradient of silicon carbide monocrystalline growth. The device comprises a carbon-fiber cone-shaped air blowing device arranged on a crucible cover, an upper port of the carbon-fiber cone-shaped air blowing device is connected with a carbon-fiber tee joint, one port of the carbon-fiber tee joint is connected with a frequency-conversion circulating air device, another port of the carbon-fiber tee joint is connected with a thermodetector, and the frequency-conversion circulating air device and the thermodetector are both connected with a PLC control system. The method comprises the steps that a technological set temperature is compared with a temperature measured by the thermodetector, and the PLC control system sends a signal to the frequency-conversion circulating air device to adjust the temperature. According to the device and method for controlling the radial temperature gradient of silicon carbide monocrystalline growth, the radial temperature can be changed without changing the radial position, the radial temperature can be adjusted automatically, the temperature is set according to the needs of a grown crystal, the stable radial temperature is maintained, it can be guaranteed that the crystal grows at the optimum temperature all the time, the crystal grows stably, and the crystal quality is improved.

Owner:JIANGSU BAIR PHOTOELECTRIC EQUIP CO LTD

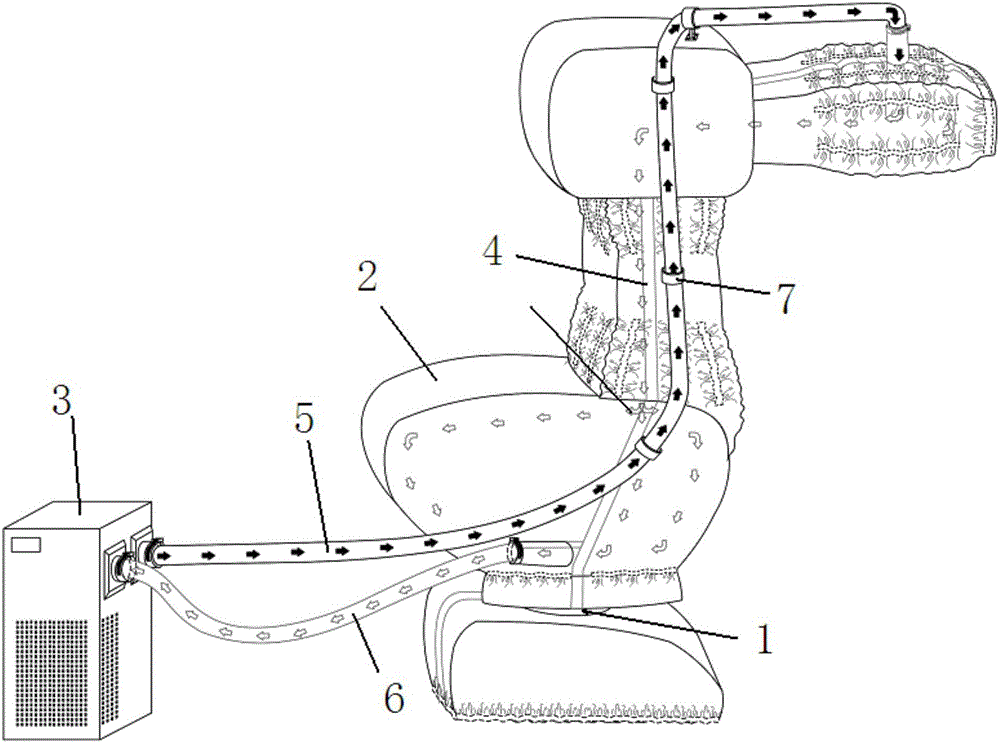

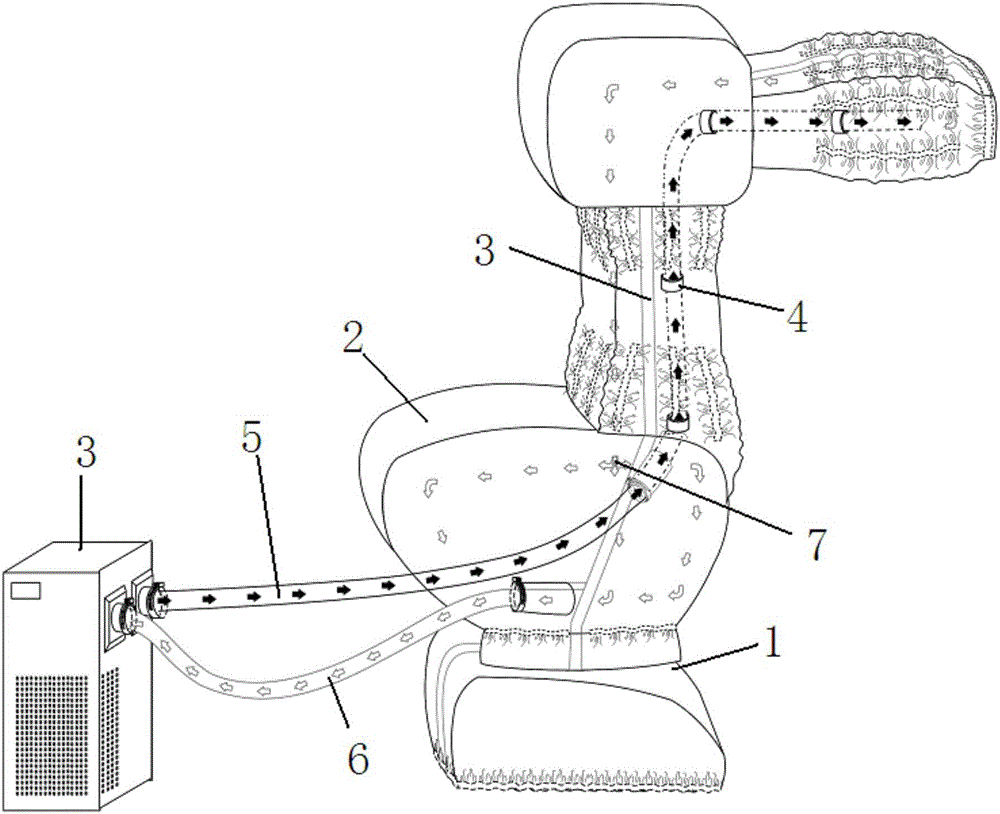

Temperature controlling device for robot protective clothing

InactiveCN106426285ADoes not affect normal workDoes not take up spaceManipulatorTemperature controlAssistive device/technology

The invention relates to the technical field of auxiliary equipment for robot control and discloses a temperature controlling device for robot protective clothing. The device comprises a robot, the robot protective clothing and an air conditioner; the robot protective clothing covers the robot; a sealed space is formed inside the robot protective clothing; an output end of the air conditioner is connected with an air inlet pipe; a return end of the air conditioner is connected with an air outlet pipe; one end of the air inlet pipe is located inside the top of the robot protective clothing; one end of the air outlet pipe is located inside the bottom of the robot protective clothing; the robot protective clothing is made of a heat insulating material; and the air inlet pipe, the air outlet pipe and the robot protective clothing are connected in a sealed manner. With the air conditioner, the temperature and the humidity inside the robot protective clothing reach the optimal values, so that the robot works under the most suitable working condition.

Owner:SHANGHAI CHUNYU AUTOMATION EQUIP PROTECTION TECH CO LTD

Seasoner sponging drying machine group

InactiveCN100523685CReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCyclonePulp and paper industry

The invention includes a feeding device, a drying tower, a No. 1 fan, a No. 1 heater, a first-stage cyclone separator and a water film dust collector; a hot blast distributor is installed at the central hot blast inlet of the drying tower top and installed in the center of the hot blast distributor. And the atomizer connected with the feeding device, the top of the drying tower is provided with an air channel plate with a volute-shaped air channel, the inlet of the air channel plate is connected to the output pipeline of No. 1 heater, and the outlet of the air channel plate is connected to the The inlet connection of the hot air distributor; there is a jacket near the top of the drying tower body, the space between the jacket and the inner wall of the tower body is the air inlet channel for sweeping the wall, and the ring between the bottom of the jacket and the inner wall of the tower body The gap is the air outlet, and the wind passes through the annular gap to form a wall-sweeping wind. The invention adopts the air duct spiral cutting and wall-sweeping air inlet technology, which not only improves the drying efficiency, but also forms a wind film on the drying tower wall by providing the wall-sweeping wind. , The air film isolates the powder from contacting the tower wall to prevent the phenomenon of sticking to the wall.

Owner:JIANGSU XIANFENG DRYING ENG

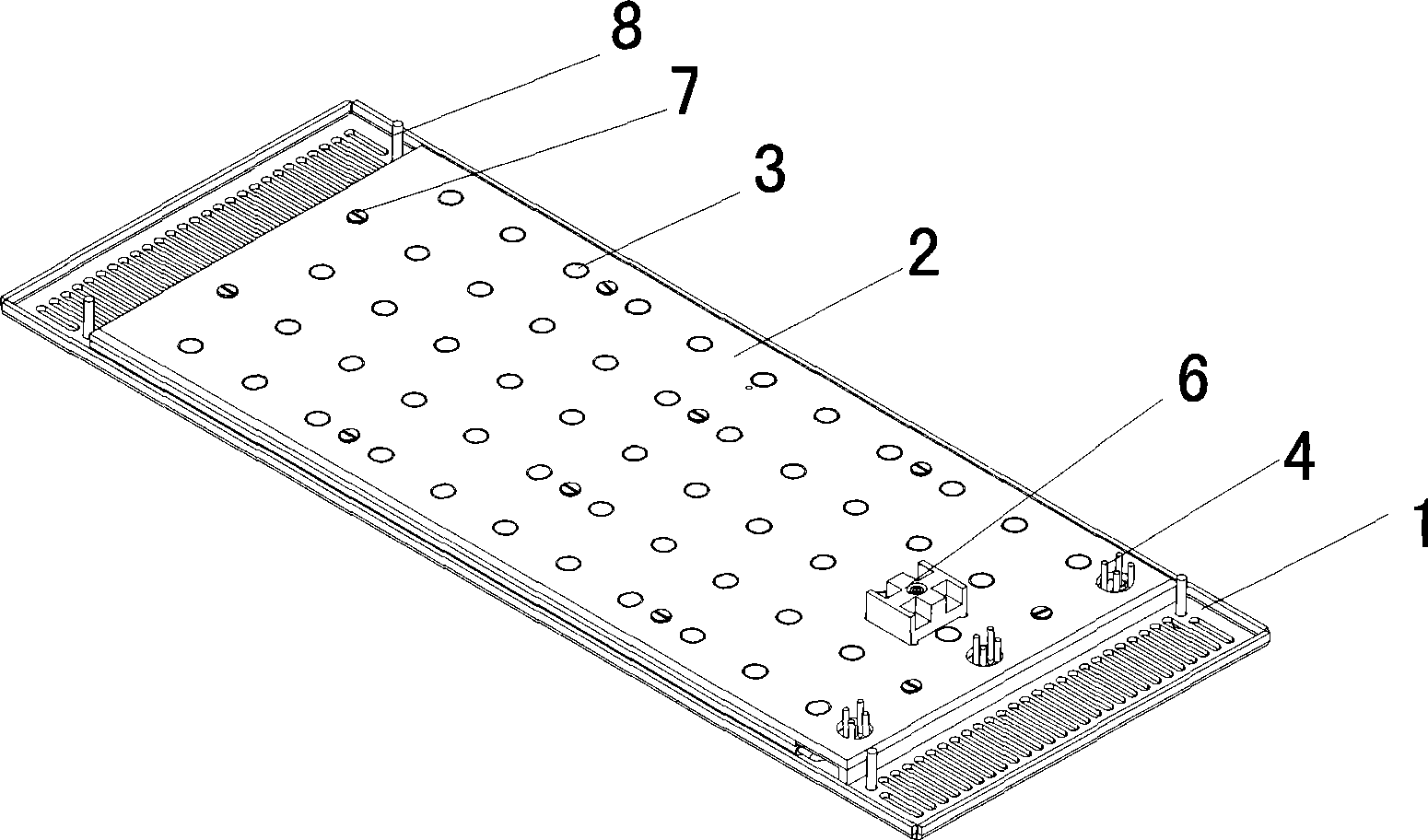

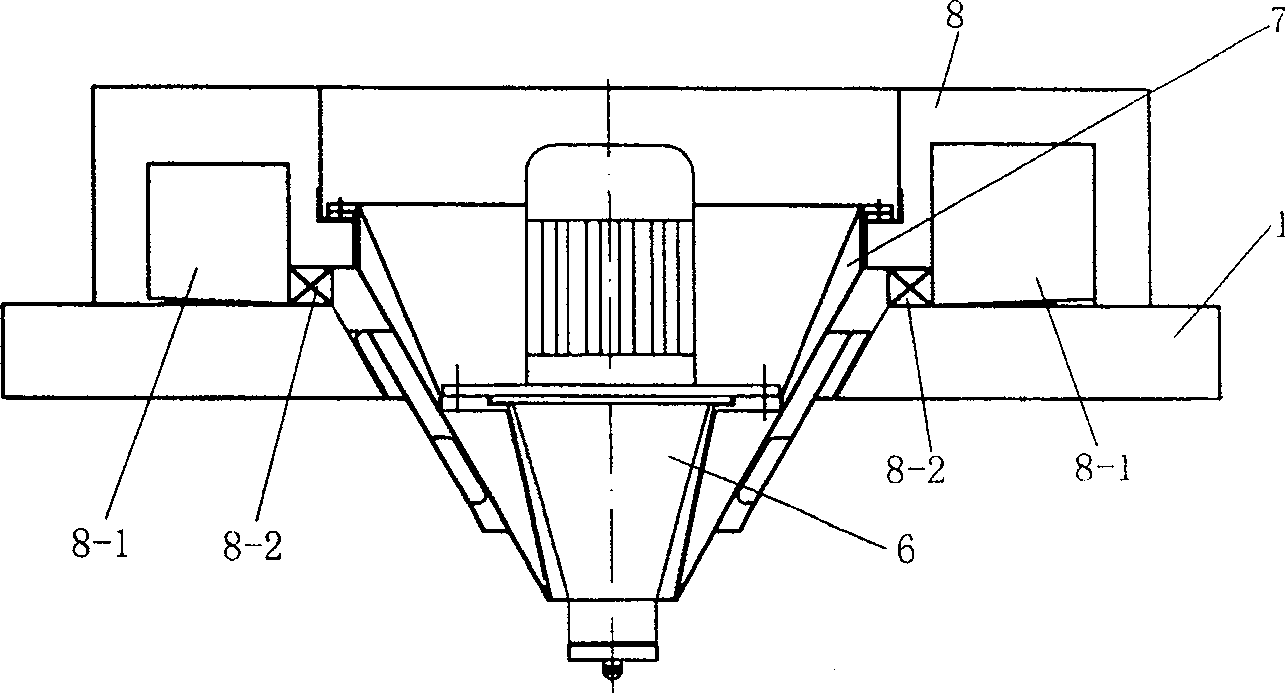

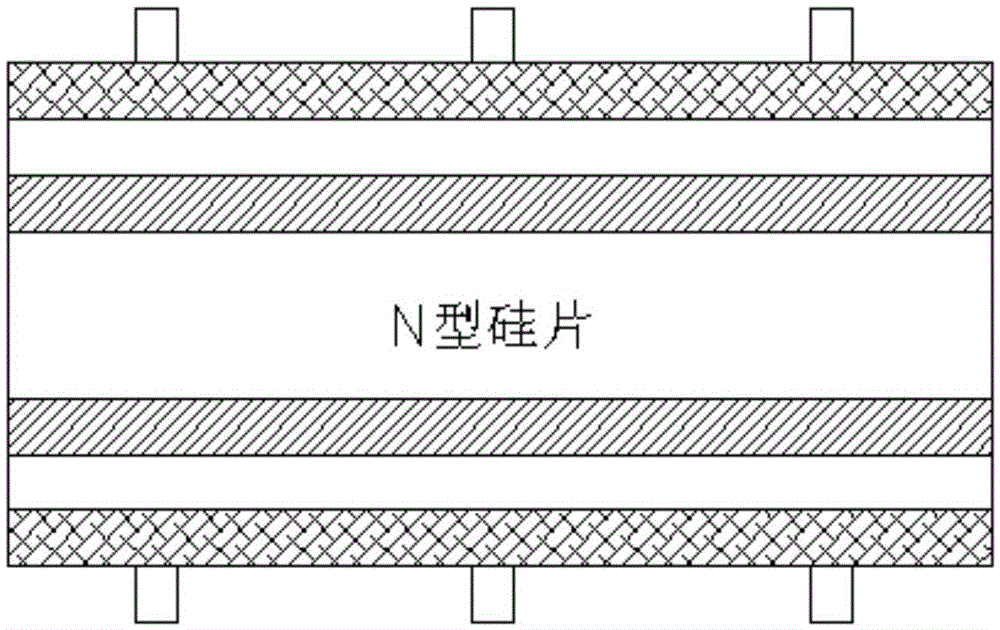

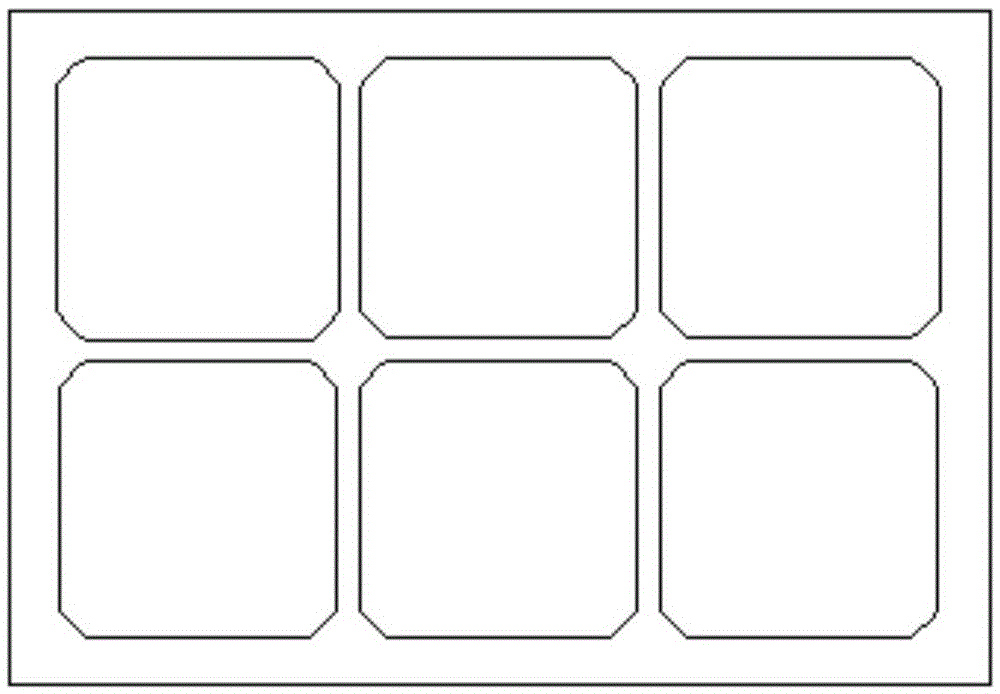

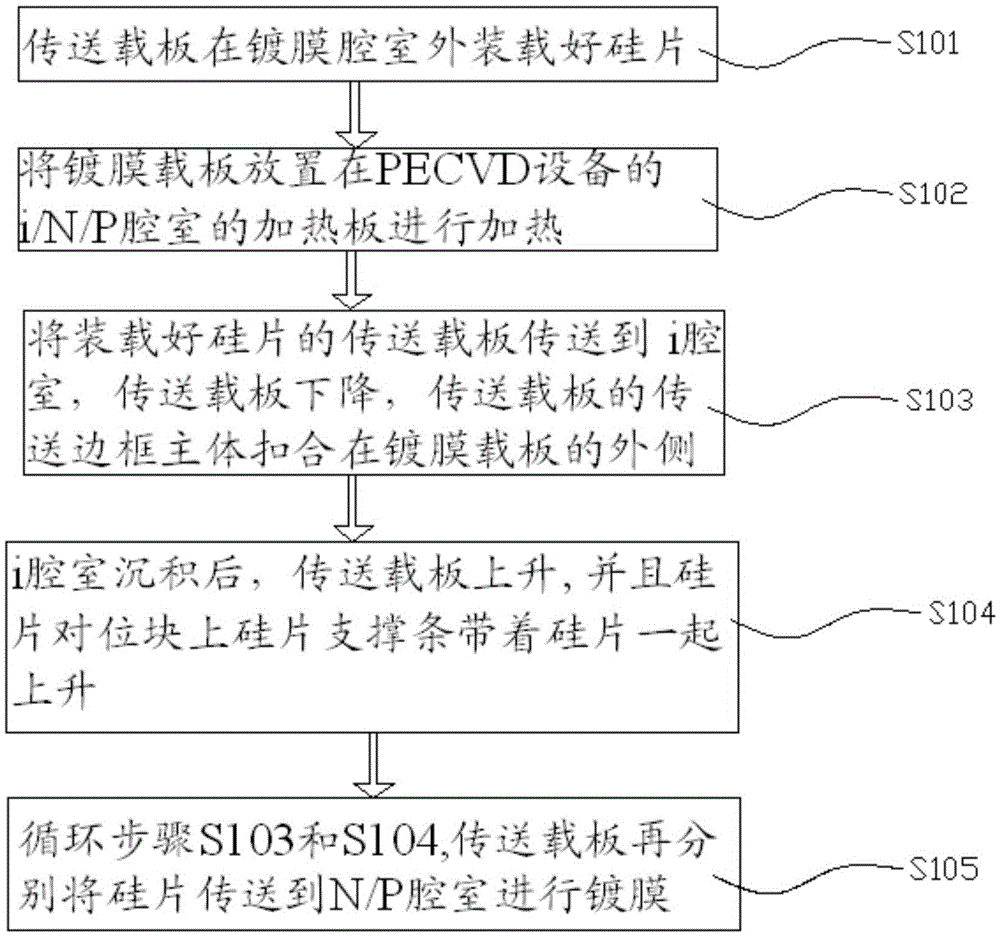

Film plating method for solar cell and support plates

InactiveCN106811738ATemperature does not affectReduce friction damageFinal product manufactureChemical vapor deposition coatingEngineeringSolar cell

The invention discloses a film plating method for a solar cell and support plates. The film plating method comprises the steps that the transmission support plate is loaded with a silicon slice outside a film plating chamber; the film plating support plate is placed on a heating plate of an i / N / P chamber of PECVD equipment to be heated, the film plating support plate comprises a base plate, and the base plate is provided with a silicon slice alignment groove corresponding to a bearing area of the transmission support plate and further provided with a metal wire alignment groove corresponding to a metal wire of the transmission support plate, and a silicon slice alignment block alignment groove corresponding to a silicon slice alignment block of the transmission support plate; the transmission support plate loaded with the silicon slice is transmitted to an i chamber, the transmission support plate declines, the silicon slice on the transmission support plate, the metal wire, the silicon slice alignment block and a silicon slice supporting strip sink into the corresponding alignment grooves in the film plating support plate separately, and a main transmission frame body of the transmission support plate is buckled on the outer side of the film plating support plate; after deposition in the i chamber is completed, the transmission support plate ascends, the silicon slice supporting strip on the silicon slice alignment block carries the silicon slice to rise together; and then, the silicon slice is transmitted to an N / P chamber for film plating through the transmission support plate.

Owner:GS SOLAR CHINA COMPANY

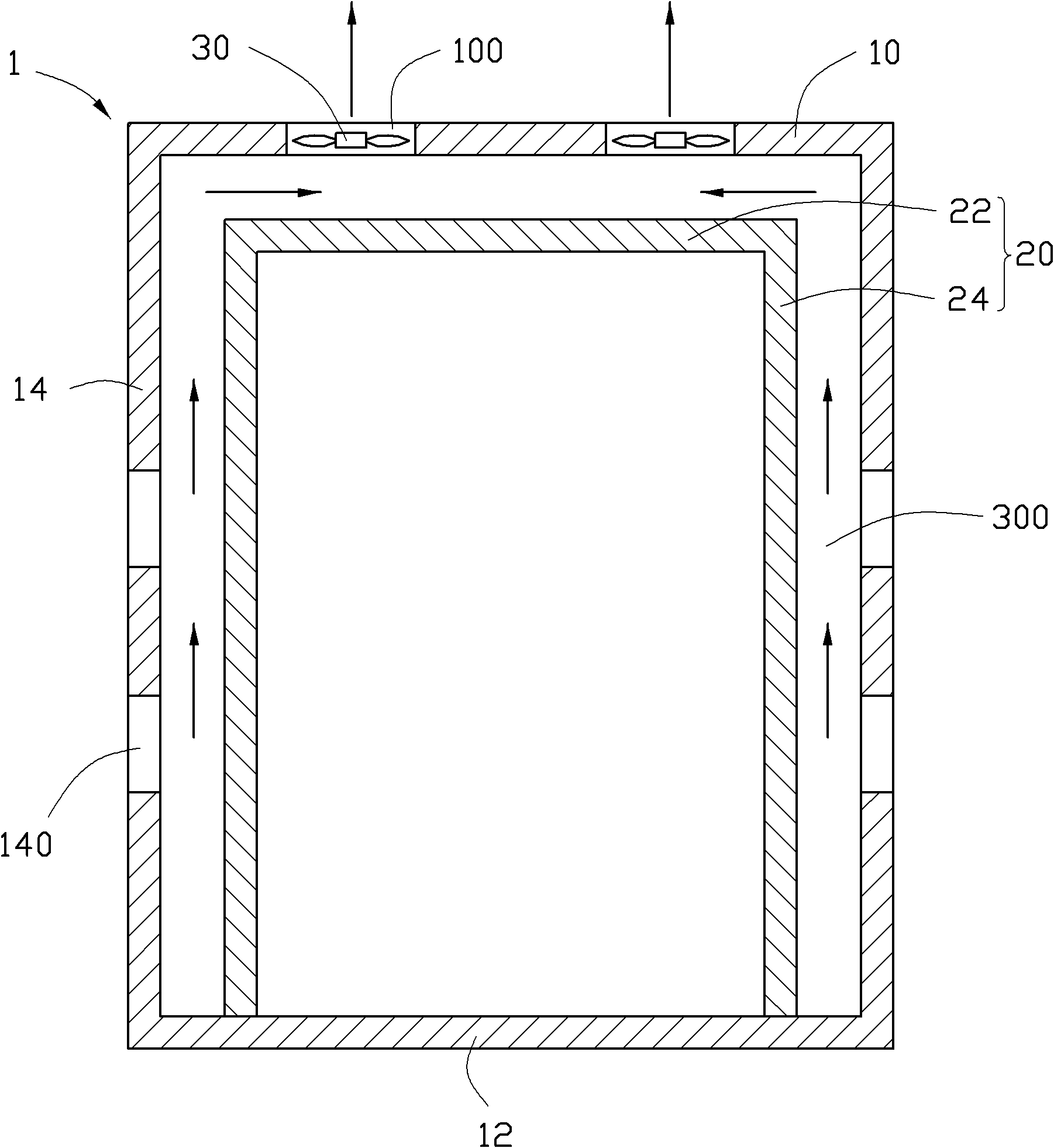

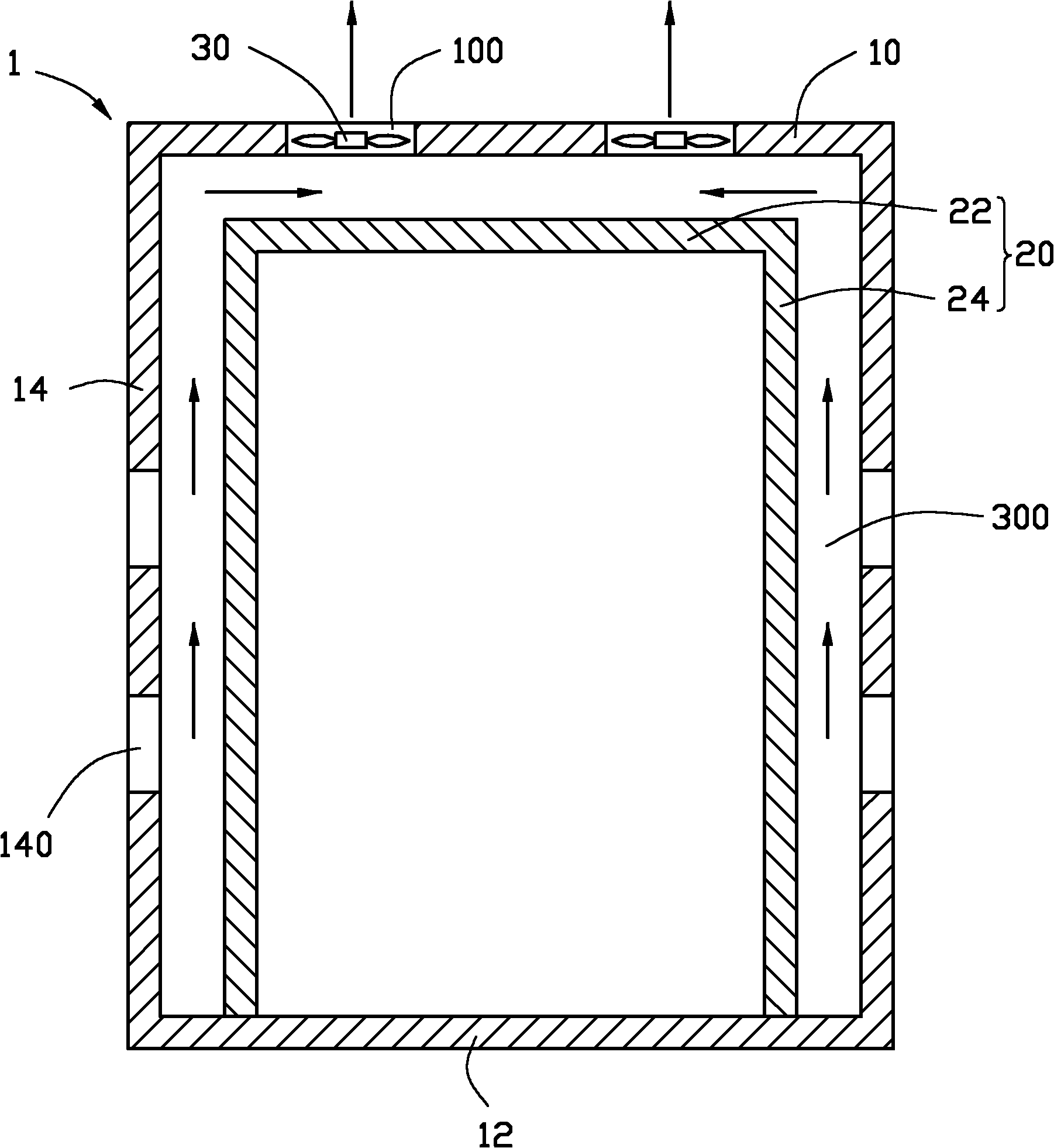

Container data center

InactiveCN102375511AReduce the temperatureTemperature does not affectDigital data processing detailsCold airNatural ventilation

The invention discloses a container data center, which comprises a machine room, wherein the machine room comprises an upper wall, a left side wall and a right side wall; a separator is arranged in the machine room; an airflow channel is formed between the separator and the upper wall and the left and right side walls; the upper wall is provided with a plurality of natural ventilators; and the left and right side walls are provided with a plurality of holes. The temperature in the machine room is raised due to radiation of sunlight, hot airflow is dissipated from the airflow channel through the natural ventilators, and cold air enters the machine room through the holes to reduce the temperature in the airflow channel, so that the temperature in the separator is not influenced.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

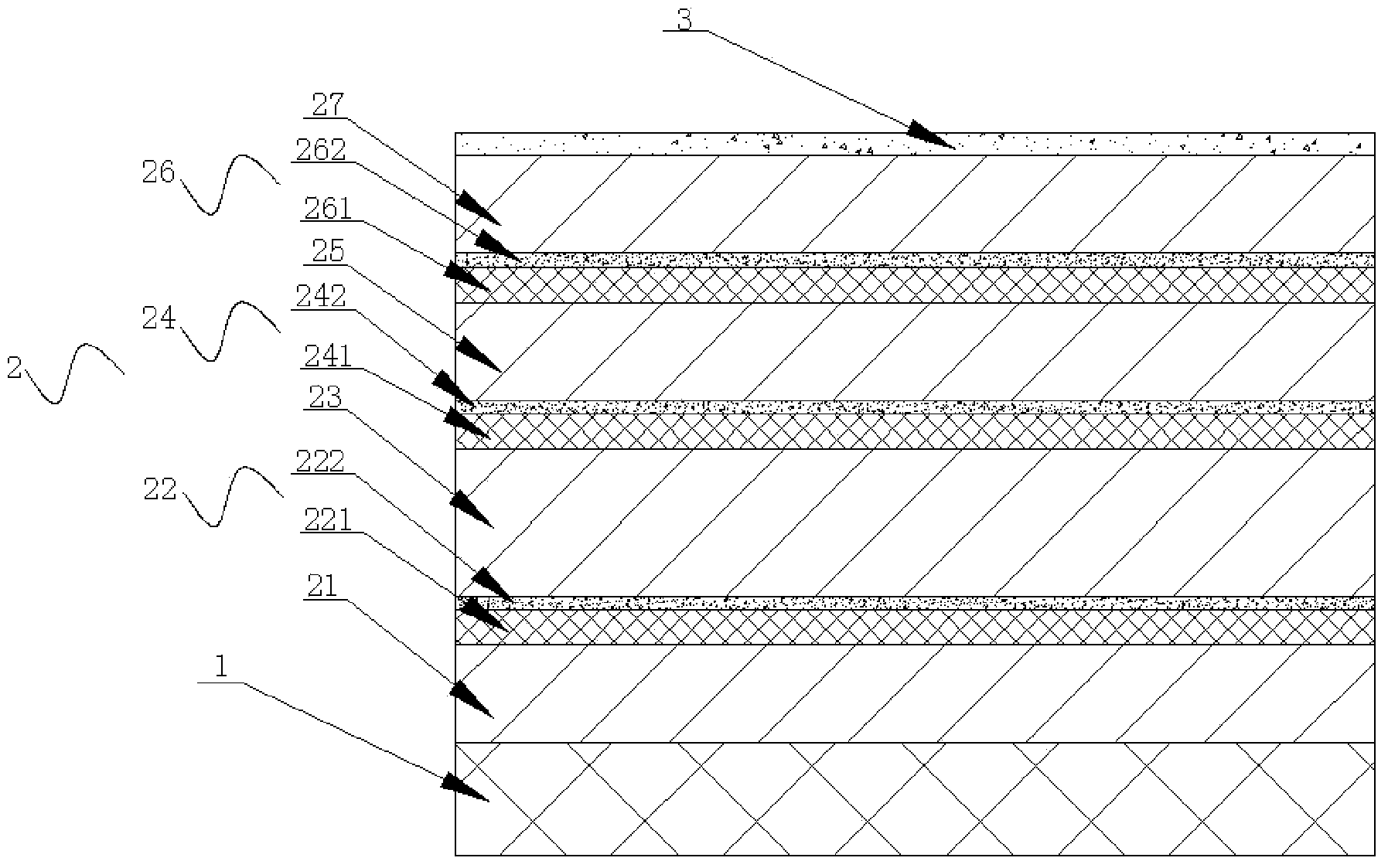

Window film core functional layer and method for manufacturing window film core functional layer

InactiveCN104309195AImprove reflectivityReduce reflectivitySynthetic resin layered productsVacuum evaporation coatingSputteringOptoelectronics

The invention discloses a window film core functional layer and a method for manufacturing the window film core functional layer. The window film core functional layer comprises a PET base thin film and a magnetron sputtering layer arranged on the PET base thin film, wherein the magnetron sputtering layer comprises a first transparent oxide layer, a first composite metal layer, a second transparent oxide layer, a second composite metal layer and a third transparent oxide layer which are sequentially arranged on the PET base thin film from bottom to top; and the method for manufacturing the window film core functional layer comprises the following step of sequentially carrying out magnetron sputtering film plating in five chambers of a five-chamber winding type magnetron sputtering film plating machine to form the magnetron sputtering layer. The window film core functional layer has the beneficial effects that the infrared light reflectivity is improved and the reflectivity of visible light is reduced, and the consumption of energy sources is saved; a metal layer is deposited and sealed at the upper part of an Ag layer so that the Ag layer is not contacted with oxygen and is not oxidized and the service life of the window film core functional layer is guaranteed; and the window film core functional layer can be manufactured in the five magnetron chambers in one step and the production efficiency is high.

Owner:邹申秀

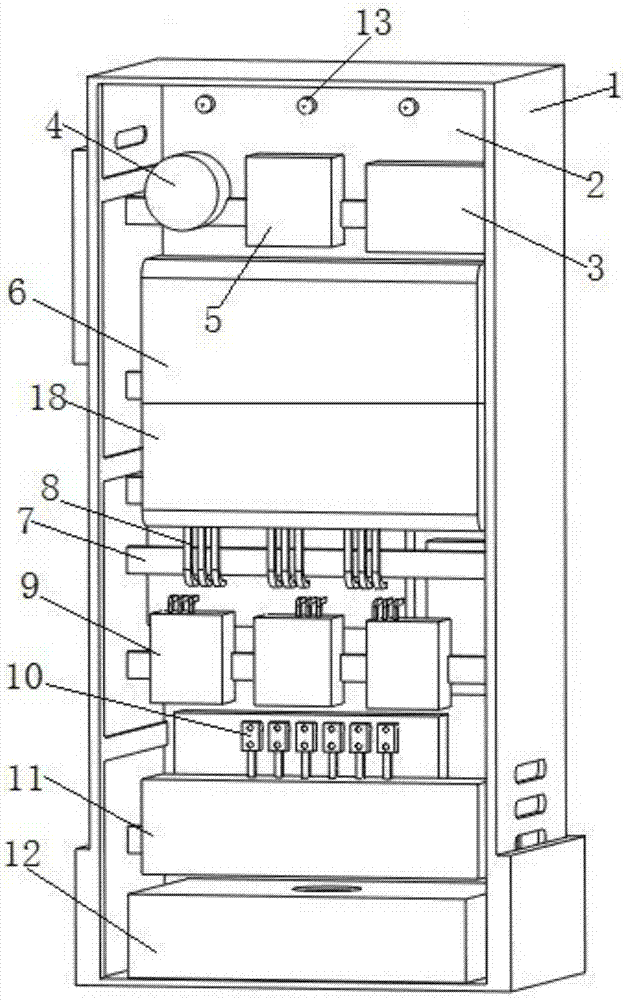

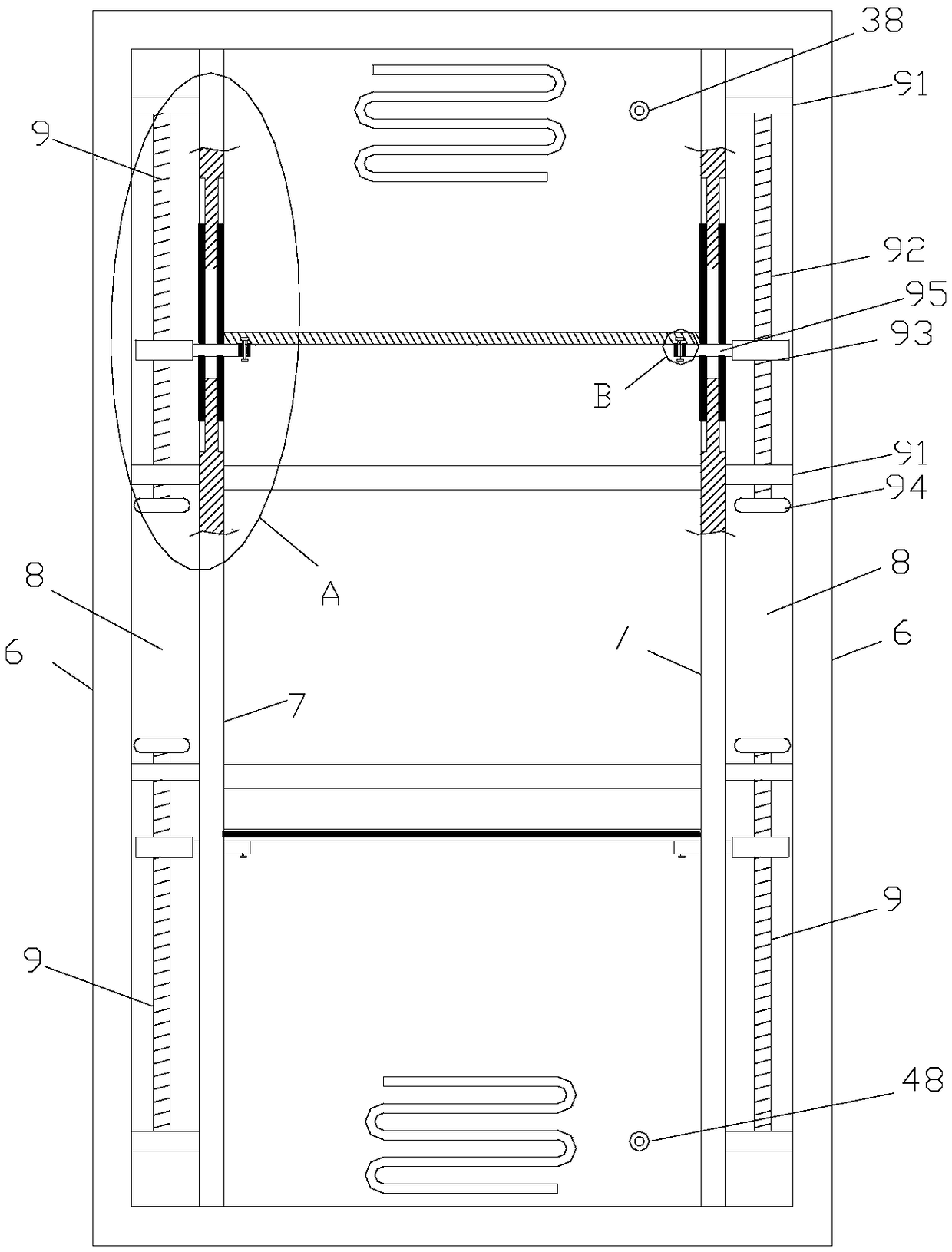

Power-saving device for large-size power equipment

InactiveCN106921168ASmall starting currentGuaranteed uptimeAC motor controlReactive power adjustment/elimination/compensationPower compensationHarmonic

The invention discloses a power-saving device and method for large-size power equipment. The power-saving device comprises a machine case, wherein a plurality of support frameworks are uniformly distributed in the machine case, an integrated control unit is arranged at one side of an upper part of each support framework, a control loop circuit box is arranged at one side of the integrated control unit, a proportional integral differentiation (PID) closed-loop detection extraction unit is arranged at the other side of the control loop circuit box, a speed regulation box is arranged at a lower side of the control loop circuit box, a power-saving main loop box is connected with a lower side of the speed regulation box, three groups of first connection lines are connected with a lower side of the power-saving main loop box, the other ends of the first connection lines are connected with a voltage stabilization unit, a line outlet of the voltage stabilization unit is connected with bypass control units through the three groups of first connection lines, a surge processing device is arranged at one side of the voltage stabilization unit, a reactive power compensation device is arranged at a lower side of the surge processing device, a line outlet of the reactive power compensation device is connected with a third connection line, and the other end of the third connection line is connected with a harmonic compensation device. By the power-saving device, harmonics can be eliminated, and power-saving operation is completed better.

Owner:ZHEJIANG YONGYUAN XINNENG TECH CO LTD

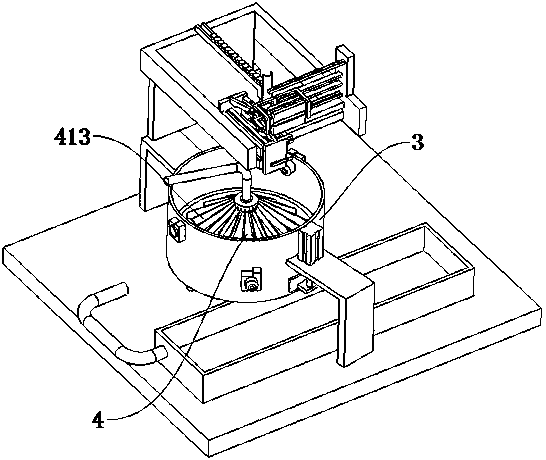

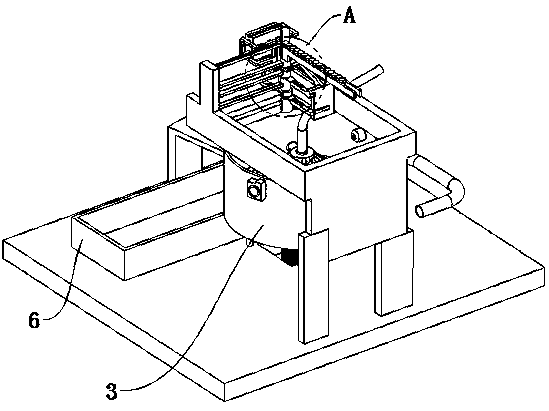

Automatic quenching equipment of bolt fasteners

The invention relates to the technical field of automobile fastener machining, in particular to automatic quenching equipment of bolt fasteners. The automatic quenching equipment comprises a heating part, a guiding barrel, a primary cooling oil pool, a secondary cooling oil pool and guiding parts. The heating part is arranged above the primary cooling oil pool, a flow diverting table capable of auto-rotating is arranged in the primary cooling oil pool, multiple flow diverting plates distributed around the circumference of the flow diverting table at equal intervals are arranged on the outer conical surface of the flow diverting table, a servo motor in transmission connection with the flow diverting table is arranged at the bottom of the primary cooling oil pool, the secondary cooling oil pool is laid beside the primary cooling oil pool, the guiding barrel is arranged over the heating part, the two guiding parts are arranged outside the guiding barrel and the heating part separately, anoil injection pipe communicating with the interior of the pool is arranged on the outer wall of the primary cooling oil pool, a discharge tank is arranged on the outer wall of the primary cooling oilpool, and the interior of the secondary cooling oil pool communicates with the oil injection pipe through an oil supply system. The machining quality of the bolts can be remarkably improved.

Owner:威德车业部件有限公司

Partition device, refrigerator and defrosting method

PendingCN112556287ATemperature does not affectLighting and heating apparatusCooling fluid circulationIceboxStructural engineering

The invention provides a partition device, a refrigerator and a defrosting method. The partition device is arranged between a fan cavity and an evaporator cavity of the refrigerator and comprises a static plate, a moving plate, a driving device, a plurality of pin keys and a plurality of opening and closing blades. When the opening and closing blades are in a first state, the triangular structureof each opening and closing blade forms a circle and seals one ventilation hole, so that the fan cavity is separated from the evaporator cavity; and when the opening and closing blades are in a secondstate, the ventilation holes are opened, and the fan cavity is communicated with the evaporator cavity. The defrosting method comprises the steps that whether the refrigerator needs to be defrosted or not is judged; if the judgment result is yes, a compressor is closed, a fan is closed, the partition device is controlled to partition the evaporator cavity and the fan cavity, and a defrosting heater works; whether a defrosting ending condition is met or not is judged; if yes, the compressor is started; whether a fan restarting condition is met or not is judged; and if the judgment result is yes, the partition device is controlled to communicate the evaporator cavity with the fan cavity, and the fan is started.

Owner:GREE ELECTRIC APPLIANCES INC

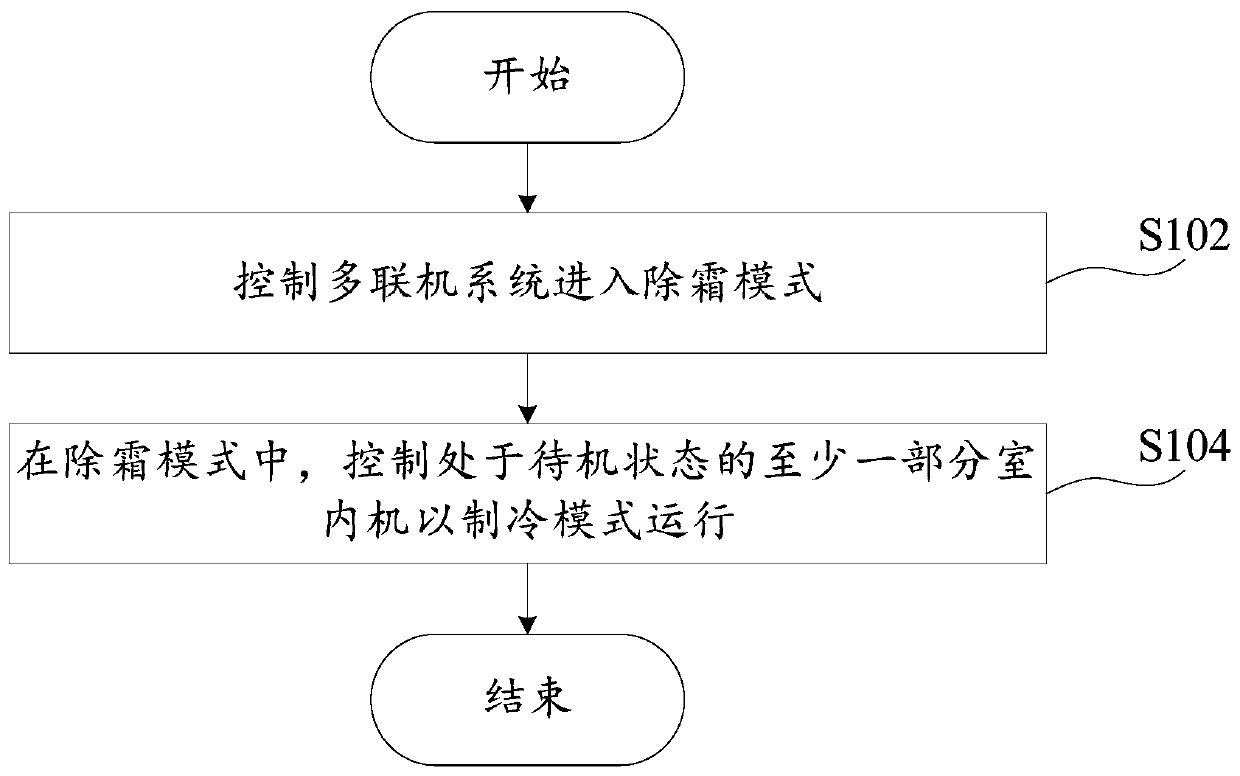

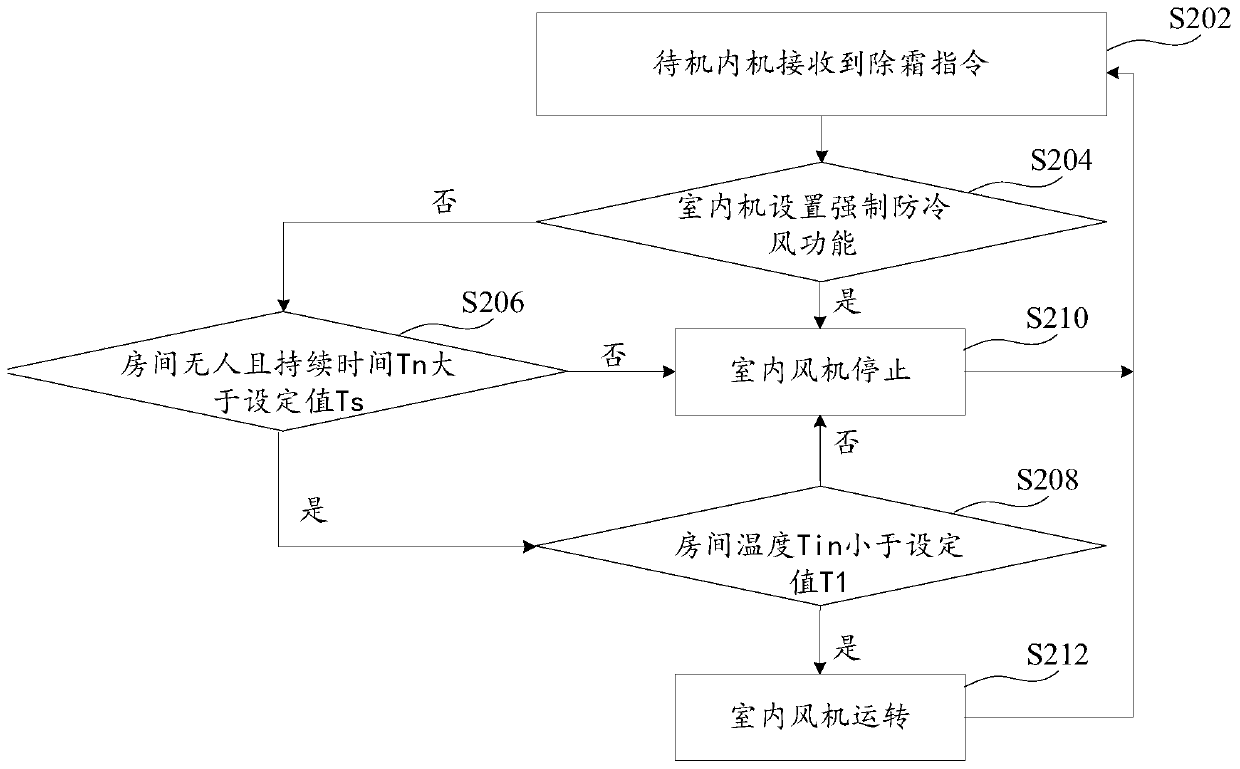

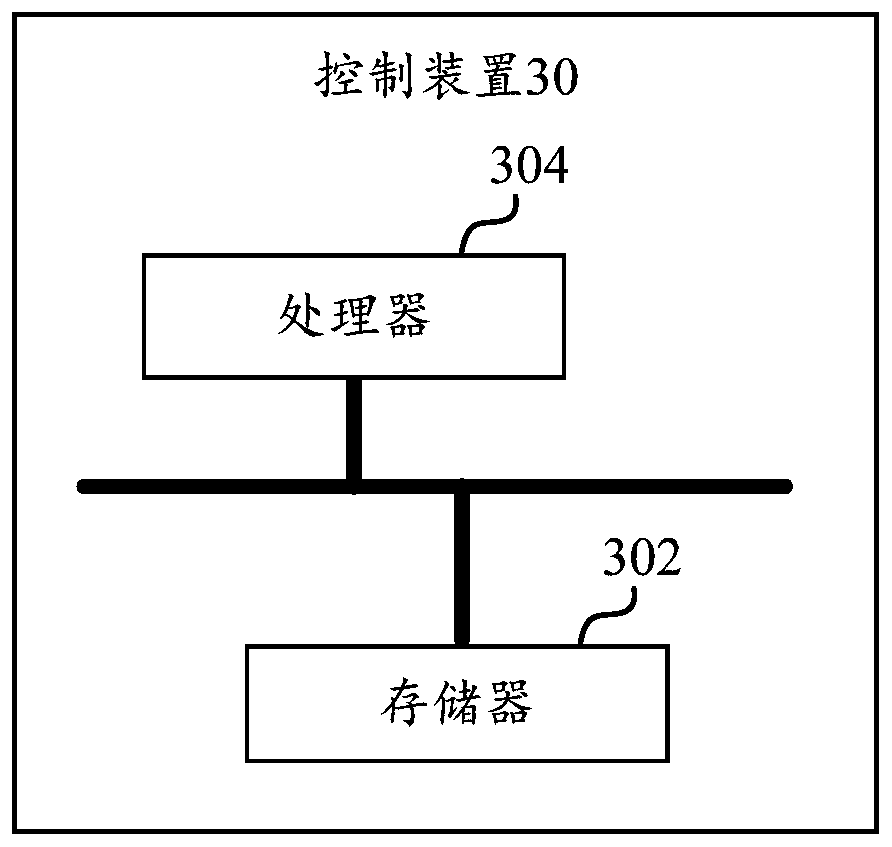

Control method, control device, a multi-split air conditioner system and readable storage medium

InactiveCN110553346ASpeed up the defrosting processReduce downtimeMechanical apparatusLighting and heating apparatusProcess engineeringEnergy consumption

The invention provides a control method, a control device, a multi-split air conditioner system and a readable storage medium. The control method is suitable for the multi-split air conditioner systemand includes the steps that the multi-split air conditioner system is controlled to enter a defrosting mode; and in the defrosting mode, at least part of indoor units in the standby state are controlled to run in a refrigerating mode. By means of the technical scheme, the defrosting process of outdoor units is accelerated, the defrosting time is shortened, the indoor unit shutdown waiting time during normal heating is shortened, in addition, an external heat source does not need to be increased for conducting heating and defrosting on the outdoor units, the heating effect cannot be affected,energy consumption is also reduced, the production cost of an enterprise is saved, and the use cost of a user is saved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

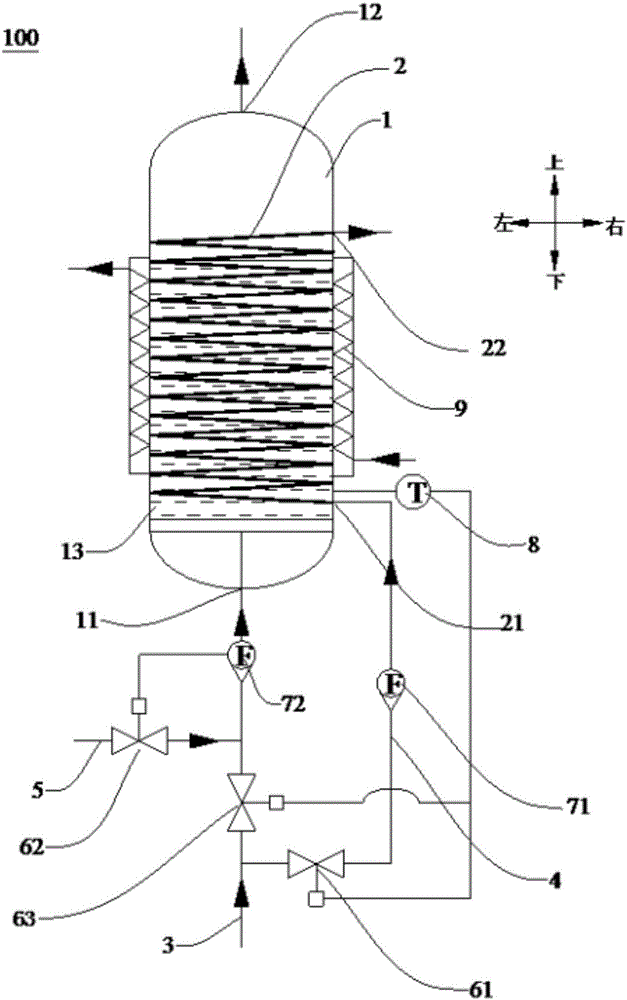

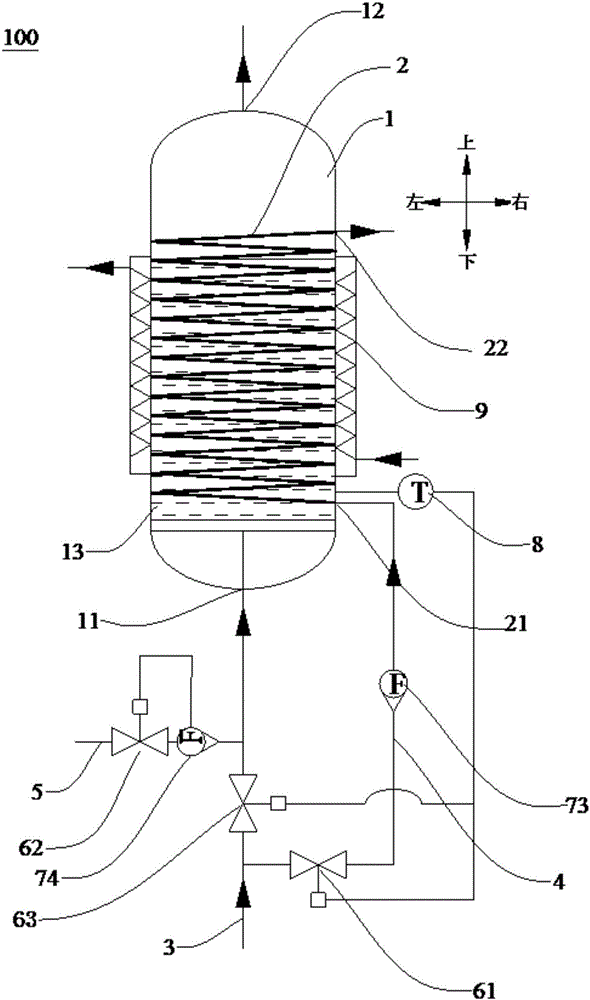

Slurry bed reaction system

PendingCN106824014ATemperature does not affectReduce the temperatureHydrocarbon by hydrogenationChemical/physical processesReaction temperatureProduct gas

The invention discloses a slurry bed reaction system, comprising: a reactor, a first heat exchanger, a raw material pipe, a bypass pipe and a gas supply pipe, a gas inlet and a gas outlet are formed on the reactor, and there is a slurry in the reactor ; The first heat exchanger is arranged on the reactor, and the first heat exchanger has a heat exchange medium inlet and a heat exchange medium outlet; the raw material pipe is used to transport raw material gas into the reactor, and the raw material pipe is connected with the gas inlet; the bypass pipe One end is connected with the raw material pipe, and the other end of the bypass pipe is connected with the heat exchange medium inlet; the gas supply pipe is connected with the gas inlet, and the flow rate of the gas in the gas supply pipe is not less than the flow rate of the gas in the bypass pipe. According to the slurry bed reaction system of the present invention, the reaction temperature can be effectively controlled to prevent overheating, and in the course of operation, the load of the system that provides raw material gas to the system and the pressure in the reactor do not change, thereby ensuring the supply The normal operation of the raw gas pipeline system improves the stability and reliability of the slurry bed reaction system.

Owner:SHENWU TECH GRP CO LTD

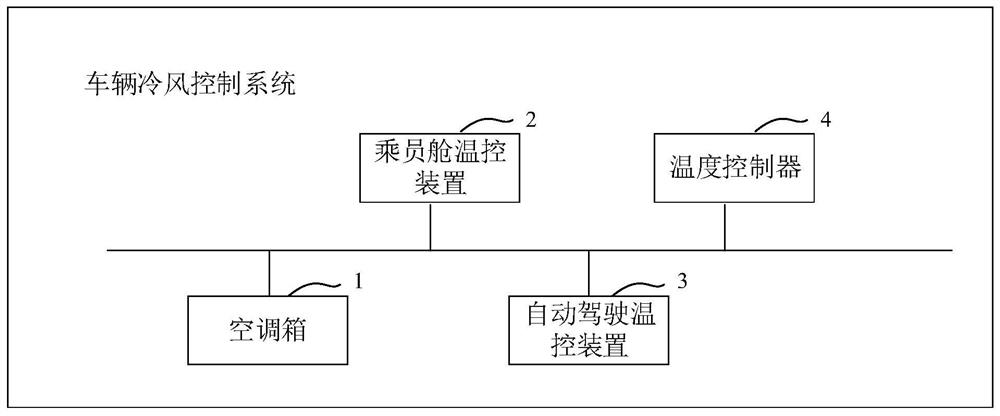

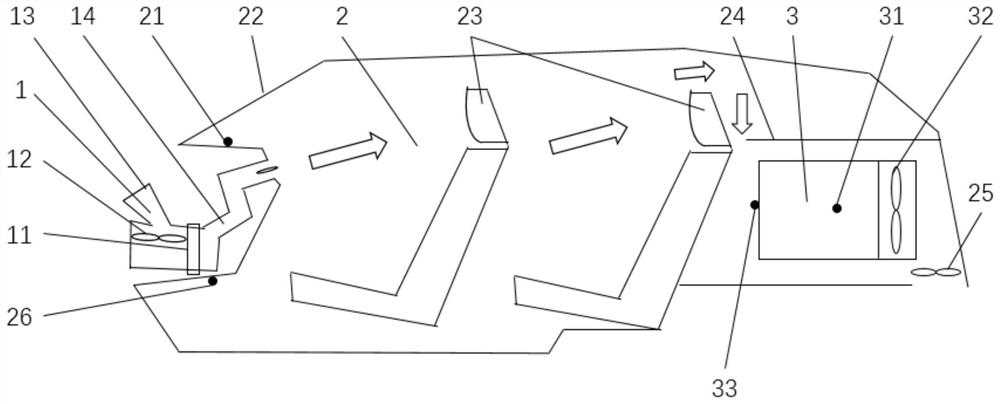

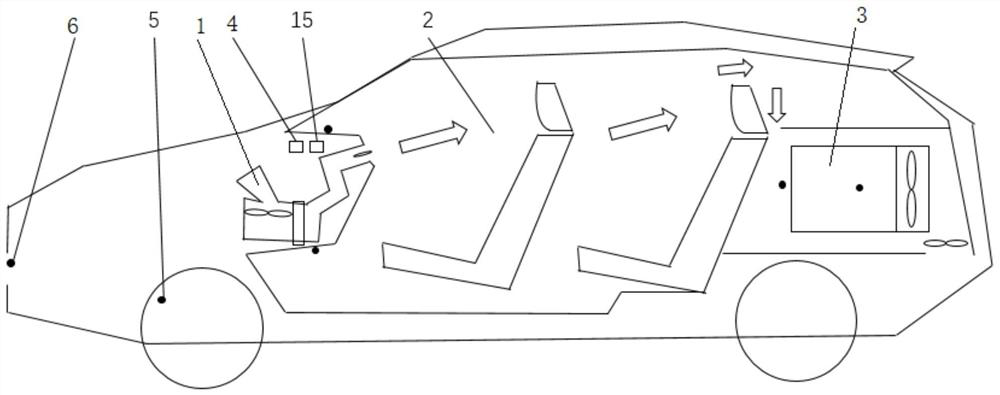

Vehicle cold air control system and method, vehicle and storage medium

ActiveCN112208298ASafe and reliable workComfortable temperatureAir-treating devicesVehicle heating/cooling devicesTemperature controlCold air

The invention discloses a vehicle cold air control system and method, a vehicle and a storage medium. The system comprises an air conditioning box arranged in front of a passenger compartment and usedfor generating refrigeration gas; a passenger compartment temperature control device which is arranged in the passenger compartment and used for monitoring the temperature of the passenger compartment; an automatic driving temperature control device which is arranged behind the passenger compartment and is used for acquiring and adjusting the temperature of an automatic driving host; and a temperature controller which is used for adjusting the temperature of the passenger compartment and / or the automatic driving host by controlling the connection of the air conditioning cabinet, the passengercompartment temperature control device and / or the automatic driving temperature control device. According to the vehicle cold air control system, the air conditioning box, the passenger compartment temperature control device, the automatic driving temperature control device and the temperature controller are arranged, the positions of all the devices are arranged, the temperature of the automaticdriving host can be reduced to a large extent through air flowing, and on the premise that the temperature of the passenger compartment is not affected, air in the passenger compartment is used for cooling the automatic driving host, and the effects of energy conservation and emission reduction are achieved.

Owner:CHINA FIRST AUTOMOBILE

Converter steel making device utilizing substance oxidization heat generating

InactiveCN110283960AControl the temperature independentlyEasy to removeManufacturing convertersSteelmakingEngineering

The invention relates to the technical field of steel making and discloses a converter steel making device utilizing substance oxidization heat generating. A furnace body is included, and the two sides of the furnace body are each fixedly connected with a feeding pipe; the top of the furnace body is fixedly connected with a gas inflow pipe, and the lower portion of the gas inflow pipe is movably connected with a push rod; the end, away from the gas inflow pipe, of the push rod is fixedly connected with a slide rail; the surface of the slide rail is in sliding connection with an oxidizing mechanism; a containing groove is fixedly connected to the portion, located on the lower portion of the oxidizing mechanism, in the furnace body; the two sides of the containing groove are fixedly connected with flowing openings, and solid substances can be formed and float on the upper portion molten iron; at the moment, the oxidizing mechanism is close to the surface of furnace slag, and a rotating mechanism is rotated, so that an adsorbing plate generates adsorbing face to adsorb the furnace slag; then the molten iron flows out of the flowing openings, and therefore the effect that after the furnace slag is used, the furnace slag can be cleared out without waiting that steelmaking ends is achieved; and due to the fact that the molten iron is in the containing groove, the temperature of the molten iron can be isolated and the oxidizing mechanism cannot be affected.

Owner:杭州铭铄机电科技有限公司

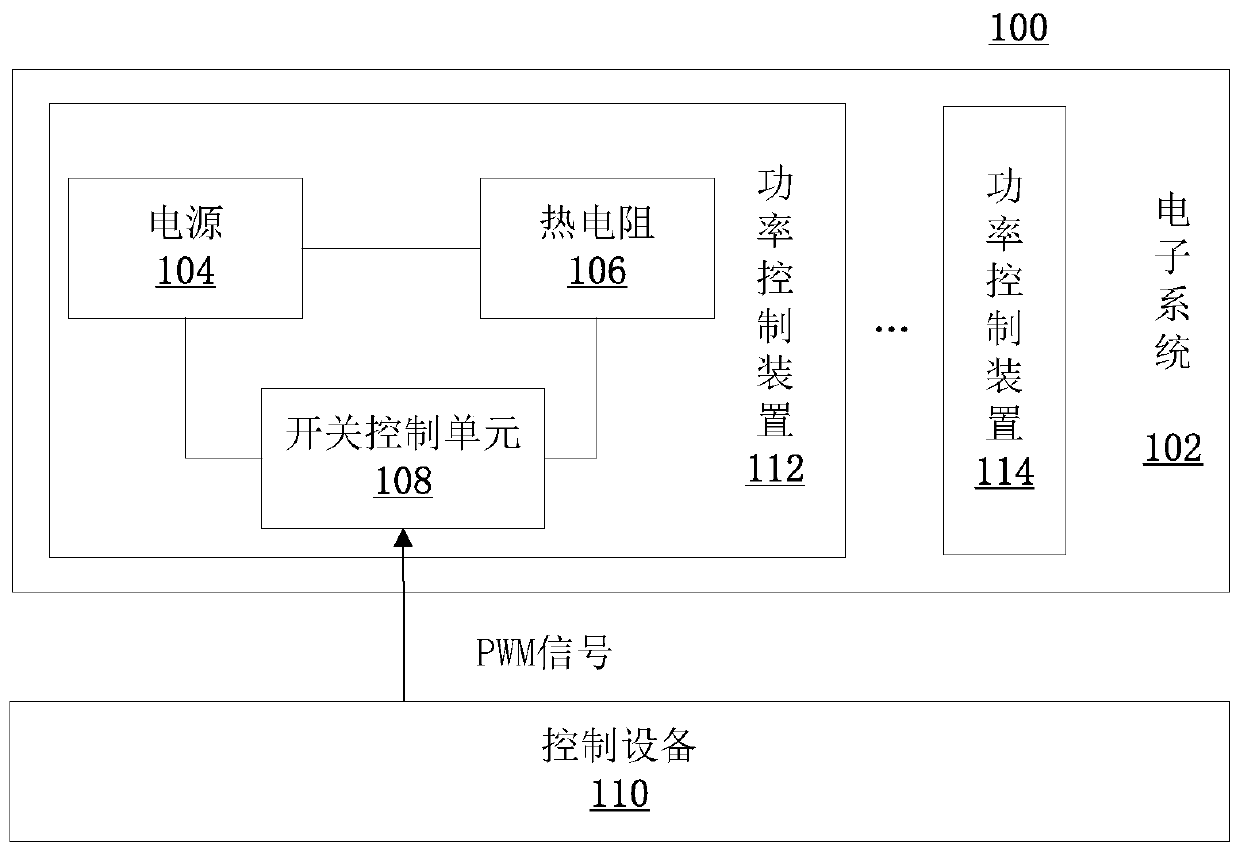

Thermal simulation device and method

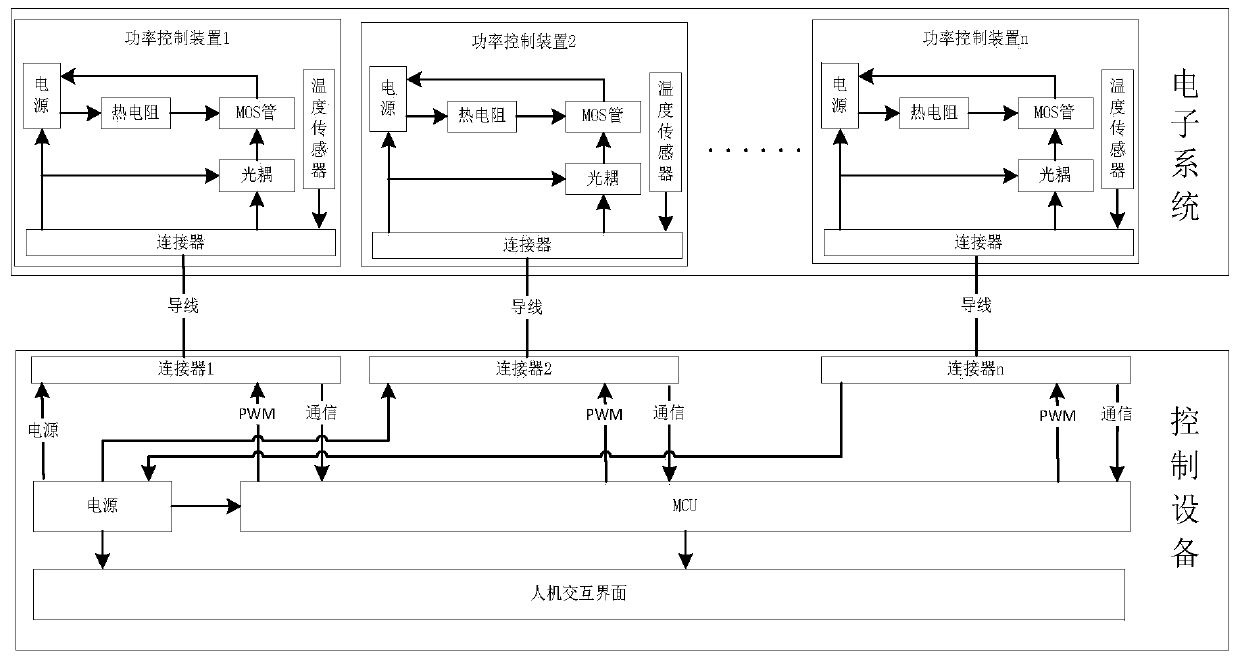

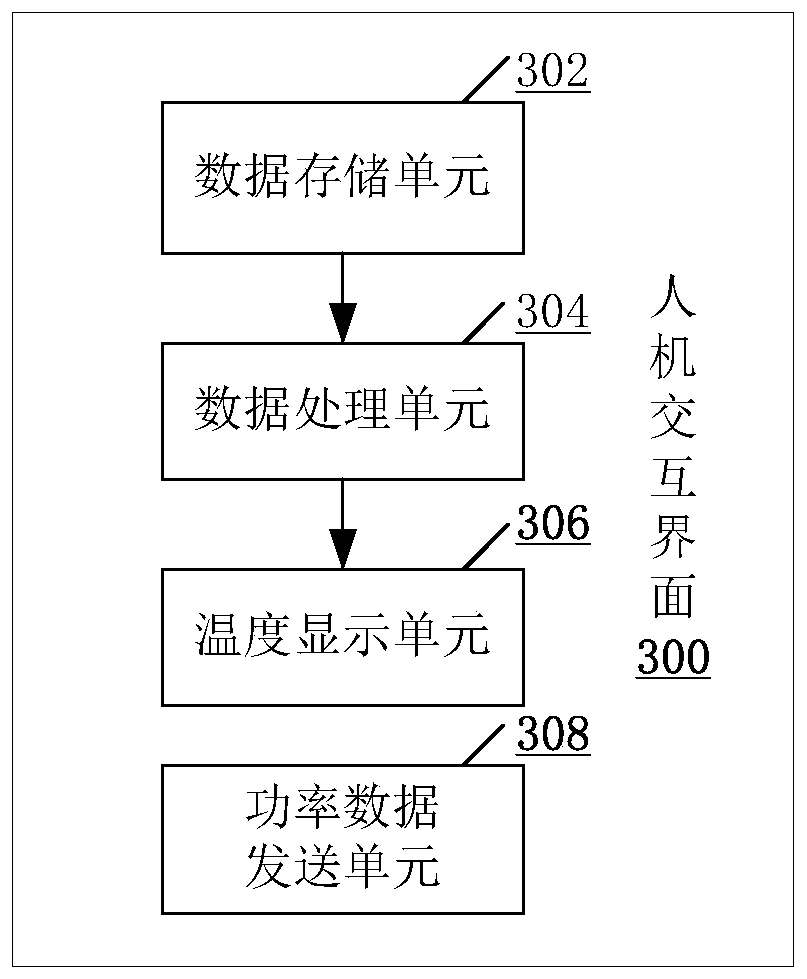

ActiveCN111220874AAccurately express temperature field changesRealize thermal simulation analysisElectrical testingElectronic systemsControl power

The invention relates to a thermal simulation device and method, and belongs to the technical field of simulation. The device comprises an electronic system and control equipment. The electronic system comprises a plurality of power control devices. Each power control device is used for simulating a corresponding heat generation device, each power control device comprises a power supply, a thermalresistor and a switch control unit, wherein the power supply, the thermal resistor and the switch control unit are electrically connected to form a loop; and the control equipment is used for generating a plurality of different PWM signals and transmitting the plurality of different PWM signals to the switch control unit, an effective voltage at the two ends of the thermal resistor being changedby changing a duty ratio of the PWM signals. The power consumption of different devices in the electronic system can be effectively simulated, so that the temperature field change in the electronic system is accurately expressed, the thermal design efficiency of the complex electronic system is improved, and the temperature field in the actual electronic system is prevented from exceeding the working temperature range of normal devices.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

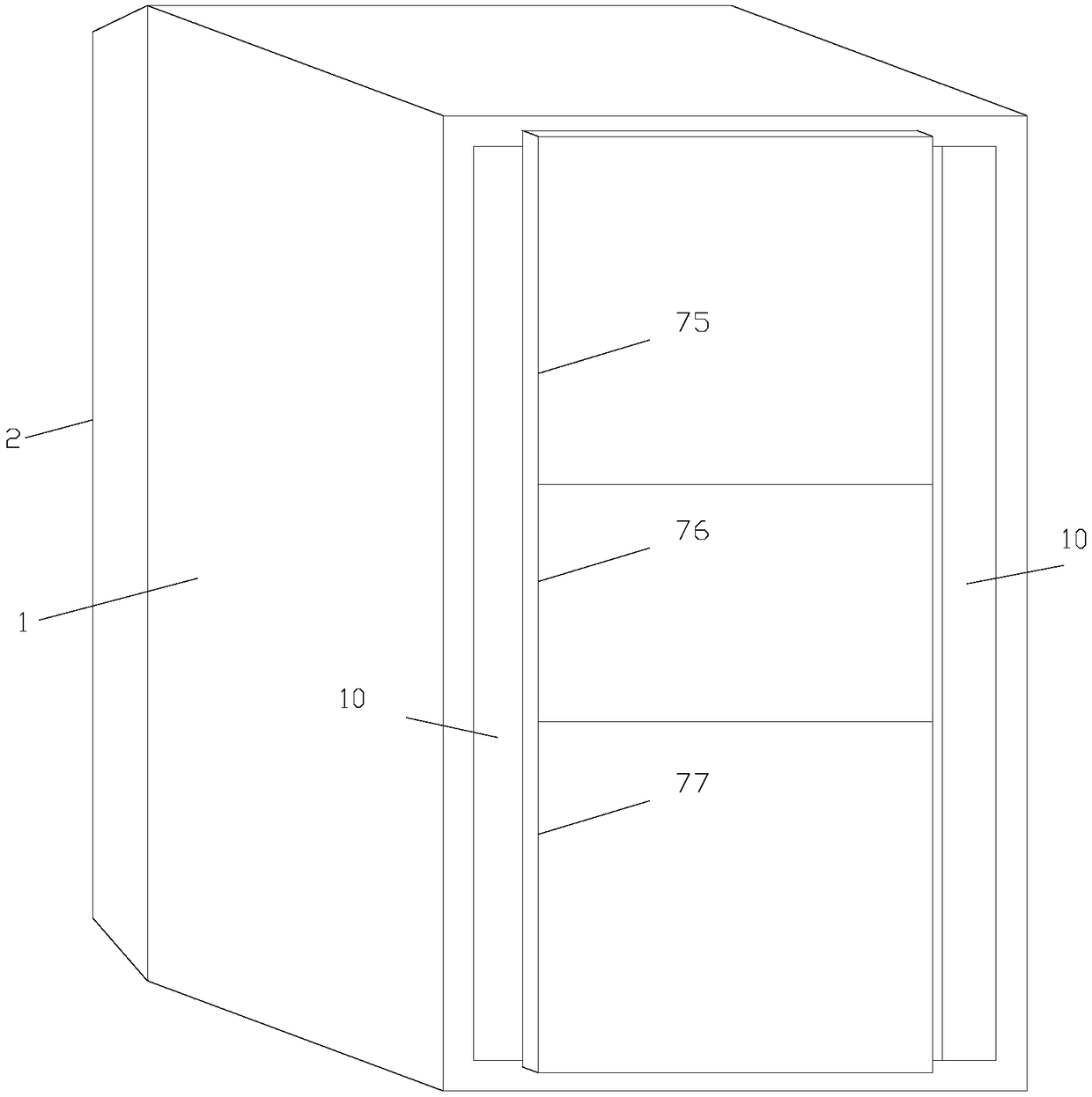

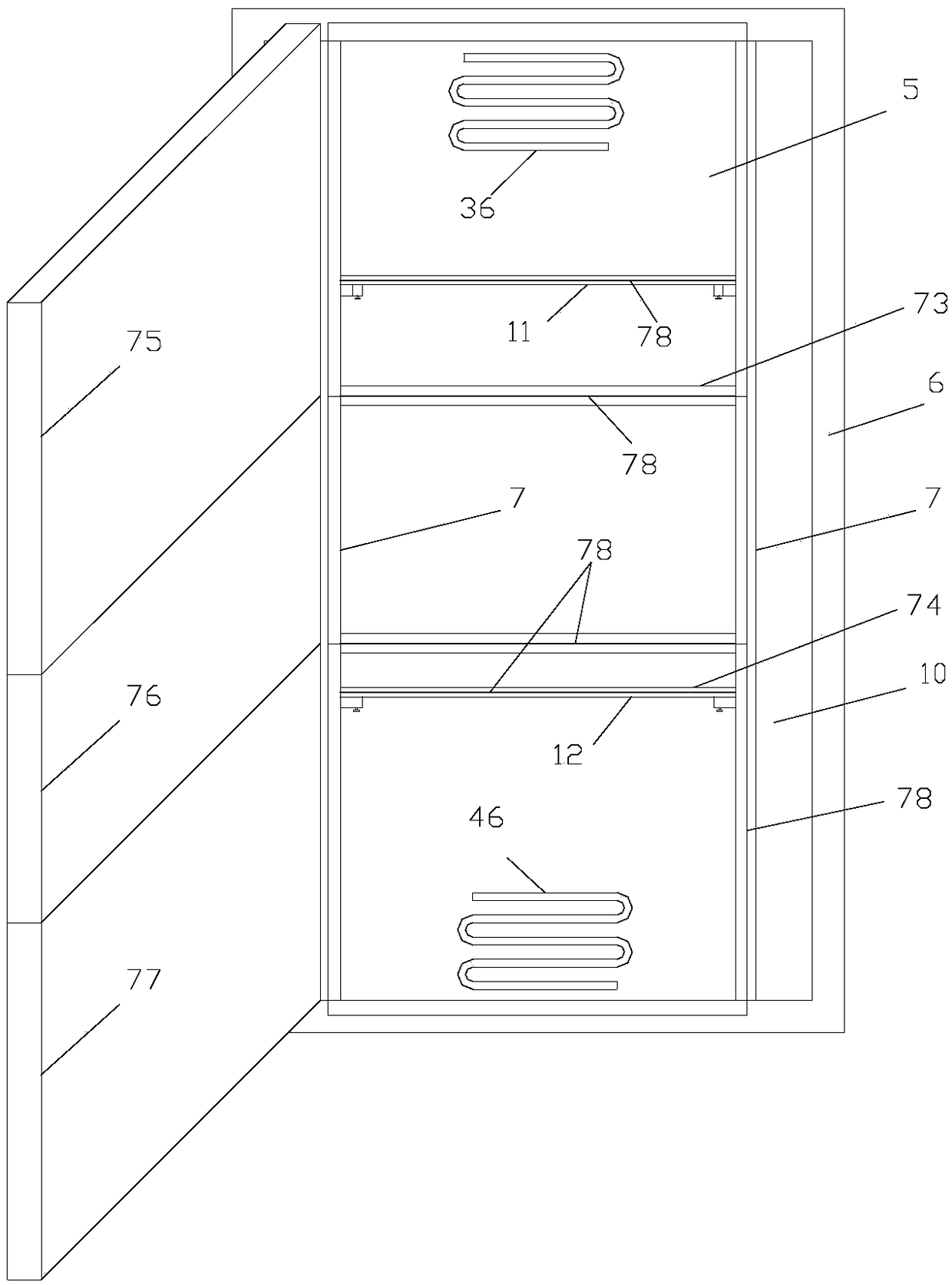

Wine cabinet, movable wine cabinet and coating thereof

ActiveCN108955083AImprove cooling effectMeet different wine needsDomestic cooling apparatusLighting and heating apparatusEngineeringCoating

The invention discloses a movable wine cabinet. The movable wine cabinet comprises a cabinet body, a back cavity, a first refrigerating system and a second refrigerating system; a left partition boardand a right partition board are arranged in the cabinet body, a device cavity is formed between each partition board and the corresponding side plate, an upper lifting device and a lower lifting device are arranged in each device cavity, an upper crosspiece and a lower crosspiece are arranged between the front end surface of the left partition board and the front end surface of the right partition board, and an upper shelving plate and a lower shelving plate are arranged between the two partition boards, wherein the upper shelving plate and the lower shelving plate can move up and down; an upper door, a middle door and a lower door are hinged to the end surface of one partition board; and the upper shelving plate and the lower shelving plate are correspondingly placed on shelving ribs ofthe lifting devices. The movable wine cabinet has the beneficial effects that firstly, three temperature zones are provided so as to store different kinds of wine; secondly, sizes of the temperature zones can be adjusted; thirdly, the whole wine cabinet is equipped with the three independent doors, so that the influence on the temperature of the other two zones can be reduced when one door is independently opened; and requirements of people can be better met. The invention further discloses a coating and a supporting wine rack.

Owner:HANGZHOU HANSEN SANITARY WARE CO LTD

Industrial and mining dust explosion venting system

PendingCN112901040ALower deflagration temperatureAvoid environmental pollutionFireproof doorsFire rescuePlunger pumpDust explosion

The embodiment of the invention discloses an industrial and mining dust explosion venting system. The system comprises an explosion venting window, a flame blocking and extinguishing assembly and a fire extinguishing assembly, wherein an explosion venting space is formed in the explosion venting window, the flame blocking and extinguishing assembly is composed of a plurality of layers of stainless steel metal net wires with different hole diameters, the fire extinguishing assembly comprises a water storage tank, a high-pressure plunger pump, a single water pipe, a plurality of water spraying pipes and nozzles, the water storage tank is installed at the lower end of the explosion venting window, one end of the high-pressure plunger pump is connected with the water storage tank through the single water pipe, the other end of the high-pressure plunger pump is connected with the nozzle through plurality of water spraying pipes, the nozzle is fixedly arranged on the inner wall of the explosion venting window, the water spraying direction of the nozzle faces the interior of the explosion venting space, a function of completely capturing detonation flames can be realized, internal explosion energy is absorbed, the detonation temperature is effectively reduced without influencing the ambient temperature, dust generated by detonation is retained, environmental pollution caused by dust leakage is avoided, potential harmful substances are prevented from entering the environment, and personnel around the equipment, the equipment and a building are protected from being threatened by explosion pressure.

Owner:湘潭方正电气成套设备有限公司

Agitated reaction kettle for preparing novel aluminum product

InactiveCN105716420AGuaranteed temperatureTemperature does not affectStirring devicesCharge composition/stateCombustion chamberEngineering

The invention discloses an agitated reaction kettle for preparing a novel aluminum product. The agitated reaction kettle comprises a hollow cylindrical furnace body and a channel arranged below the furnace body, wherein two parallel guide rails are arranged at the bottom of the channel; an electromagnetic agitating vehicle is movably mounted on the guide rails; an electromagnetic agitating device is mounted on the electromagnetic agitating vehicle; the cylindrical furnace body comprises a furnace bottom, a furnace wall, a combustion chamber, a furnace top, a feed opening and a discharge opening; the feed opening and the discharge opening are formed in two opposite sides of the combustion chamber; the upper surface of the furnace bottom is inclined relative to a horizontal plane, the highest point of the upper surface is located on the side with the feed opening, and the lowest point of the upper surface is located on the side with the discharge opening; and the outer side of the feed opening is connected with a discharge chute. The agitated reaction kettle can effectively increase the pouring speed, reduces heat loss in a pouring process and avoids the phenomenon that potential hazards are brought to normal production because the discharge opening cannot be opened.

Owner:焦伟丽

Glass substrate smelting furnace

InactiveCN105481230ALittle influence of temperatureTemperature does not affectTank furnacesLeft breastRight breast

The invention discloses a glass substrate smelting furnace which comprises a smelting furnace body (5). The smelting furnace body extends forwards to form a pre-smelting pond (1). Two feed inlets (2) are symmetrically formed in a front breast wall of the pre-smelting pond. A left breast wall and a right breast wall are each provided with a burning lance (3), and a smoke outlet (4) is further formed in the upper portion of the front breast wall. The pre-smelting pond is additionally arranged on the front side of the smelting furnace body, batch can be pre-smelted at high temperature firstly through the burning lances, and heated and pre-smelted liquid glass flows into a smelting pond of the smelting furnace body and only needs little energy to obviously improve smelting quality; meanwhile, the feed inlets are formed in the front breast wall of the pre-smelting pond, temperature influences of a material pile formed by the accumulated batch on the smelting furnace body can be reduced or even eliminated, and the material pile only fluctuates in the pre-smelting pond and does not affect the temperature of the smelting pond of the smelting furnace body. Process stability is guaranteed, and a good foundation is provided for product quality.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

Patient temperature control during surgery

An infrared radiant heating system for raising or maintaining a uniform core temperature of a patient's body during a surgical procedure without substantially affecting the temperature of surrounding regions of said patient's body, the infrared radiant heating system comprising: an infrared radiant heating mechanism, in use, located in an inconspicuous location adjacent to the patient to provide radiant heat to the entire body of the patient or to one or more portions of the patient's body; and a control mechanism in communication with the heating mechanism for controlling the intensity level and intensity distribution of the radiant heat on the patient's body such that in use the skin temperature of the patient's body is raised or maintained within a predetermined range resulting in a uniform core body temperature without substantially Affecting the temperature of the area surrounding the patient's body.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Transfusion needle plastic tube heater

InactiveCN102961807BTemperature does not affectDoes not affect the efficacyIntravenous devicesEngineeringBottle

The invention relates to a transfusion needle plastic tube heater, which comprises a vertical supporting rack which is communicated with warming equipment. The vertical supporting rack is axially and equally divided into two parts which can be opened and closed. A longitudinal deep hole for containing a transfusion needle plastic tube is arranged between the two parts. A transverse rod for hanging a transfusion bottle is arranged at the upper part of the vertical supporting rack. The lower part of the vertical supporting rack is connected with an arc-shaped hand warmer. An outlet which is communicated with the deep hole is arranged on the hand warmer. The transfusion needle plastic tube heater has the advantages that liquid medicine is heated during transfusion, the temperature does not influence the efficacy of the medicine, the hand feels warm after the hand is put into the hand warmer, the patient is enabled to feel comfortable during transfusion, phlebitis is prevented from occurring, the heater can also be connected with a heating passage and the cost is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

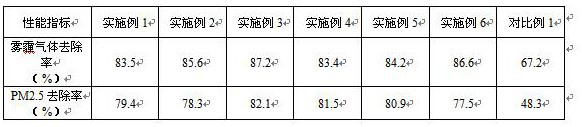

A kind of anti-smog gypsum wall material for prefabricated buildings and its preparation method

The invention relates to the field of anti-smog building materials, and discloses an anti-smog gypsum wall material for prefabricated buildings and a preparation method thereof. It includes the following preparation process: (1) adding photocatalyst, foaming agent, binder, and porous glass microspheres into deionized water to make porous glass microsphere glue; (2) using β-hemihydrate phosphogypsum, cement, Fly ash, foaming agent, polycarboxylate water reducing agent, salt water repellent, waste plastic fiber, water, crystal transformation agent, polyvinyl alcohol and hydrogen-containing silicone oil are used as raw materials to make microporous wall matrix materials; ( 3) Spray the glue on the surface of the base material to obtain a gypsum wall material with the function of removing haze. The gypsum wall material prepared by the invention has high porosity, strong adsorption capacity, high catalytic efficiency for nitrogen oxides, relatively simple preparation process, direct assembly, low construction difficulty, easy to obtain raw materials, low cost, and can be directly Large-scale promotion and application.

Owner:TAIZHOU BAOCHENG TECH SERVICES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com