Agitated reaction kettle for preparing novel aluminum product

A stirring type, reaction kettle technology, applied in the direction of stirring device, furnace type, lighting and heating equipment, etc., can solve the problem of low strength, and achieve the effect of increasing strength, ensuring normal operation, and speeding up the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

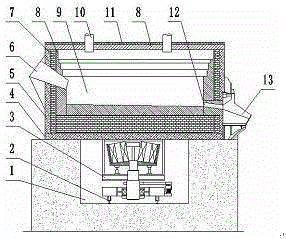

[0016] like figure 1 As shown, the present invention comprises a hollow cylindrical furnace body and a channel 1 arranged below the furnace body. The bottom of the channel 1 is provided with two parallel guide rails 2, and an electromagnetic mixer truck 3 is movably installed on the guide rail 2. Electromagnetic stirring device is installed on the car 3; Cylindrical body of furnace comprises furnace bottom, furnace wall, furnace 9, furnace top, charging port 6 and discharging port 12, and charging port 6 and discharging port 12 are arranged on the opposite side of furnace hearth 9 On both sides; the upper surface of the furnace bottom is inclined relative to the horizontal plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com