Patents

Literature

543results about "Furnace linings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

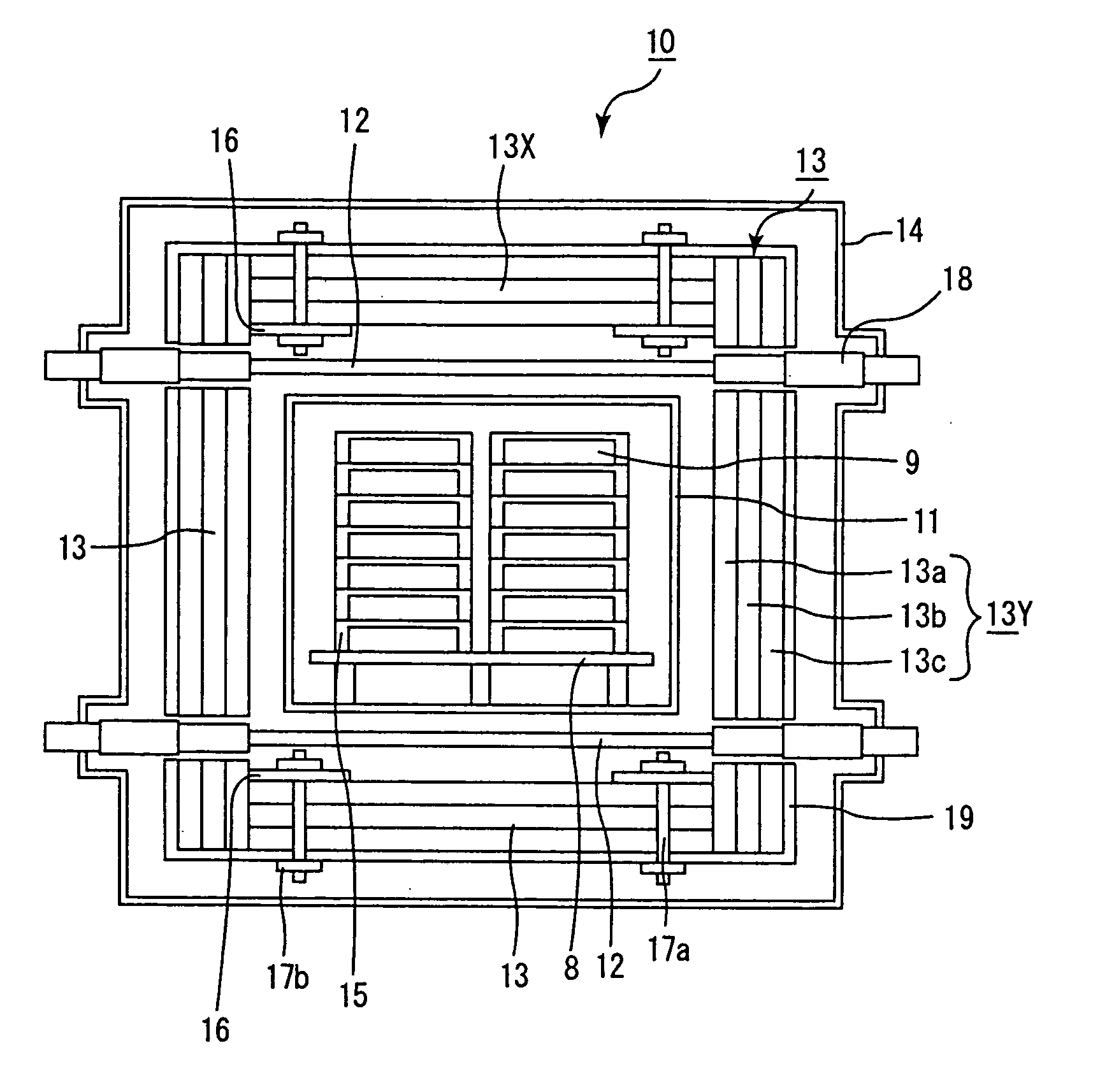

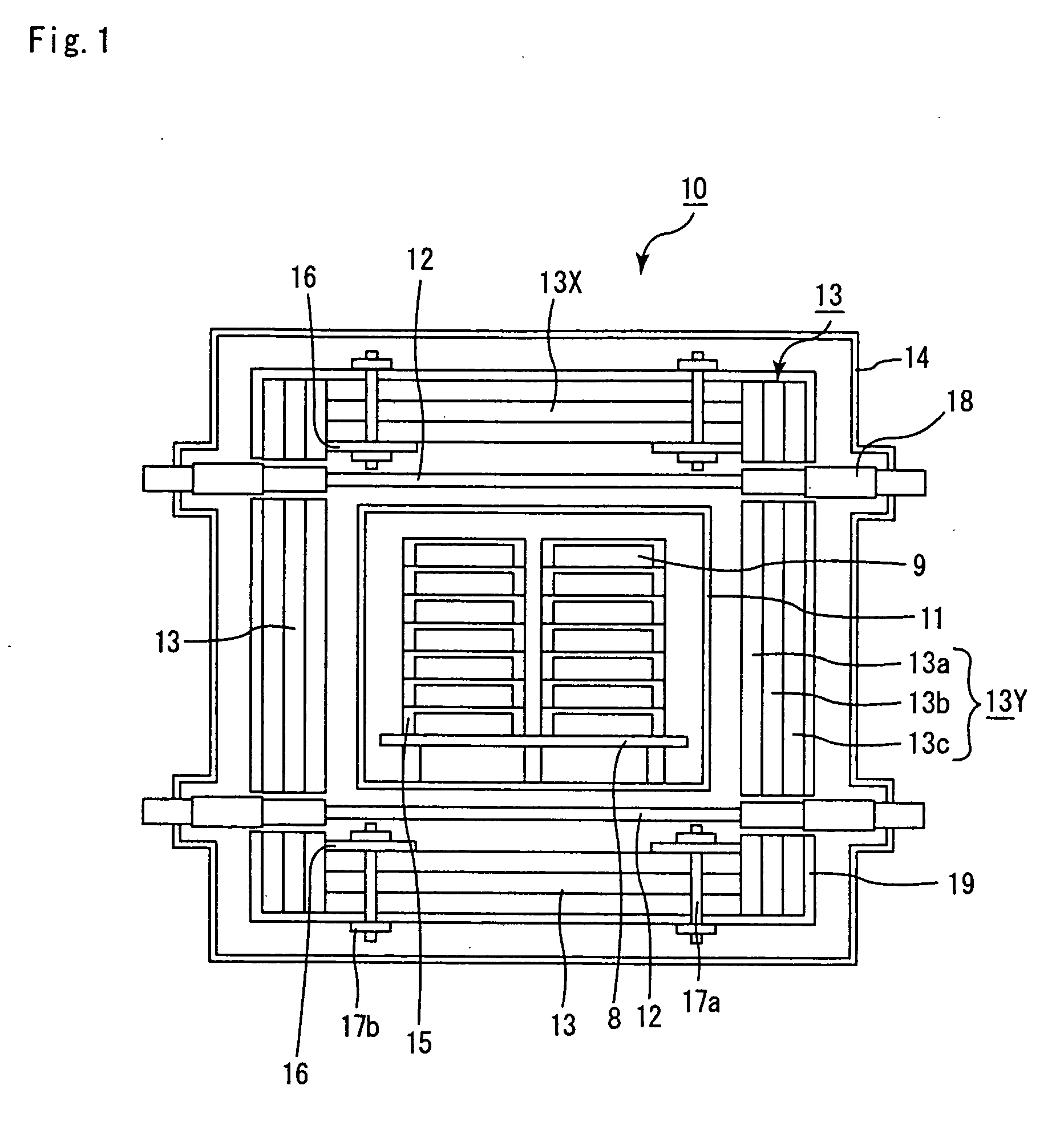

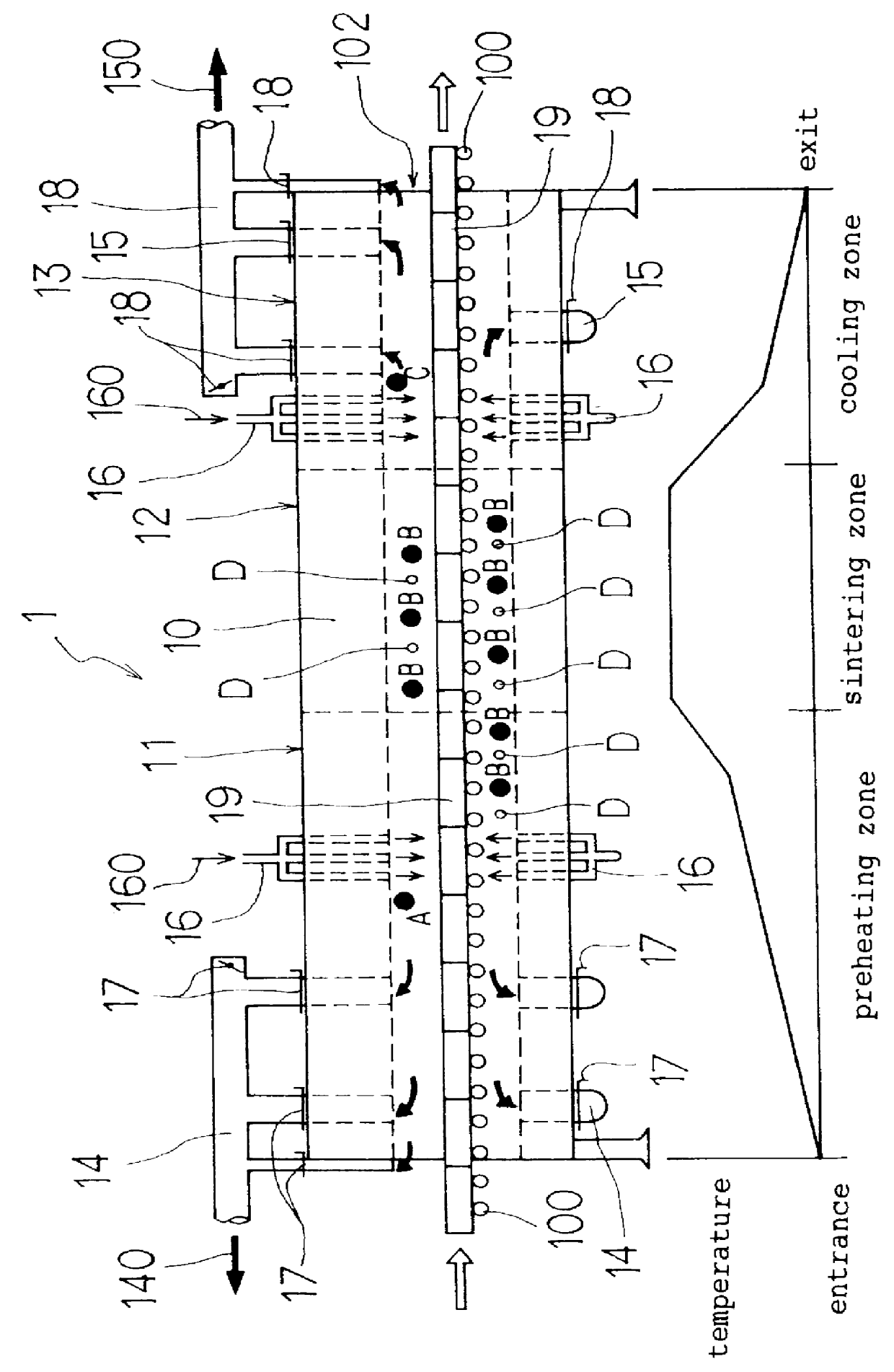

Firing furnace, porous ceramic member manufacturing method using the same, and porous ceramic member manufactured by the manufacturing method

ActiveUS20060029898A1Avoid warpingEnsuring spaceMuffle furnacesIncreasing energy efficiencyPorous ceramicsMaterials science

Owner:IBIDEN CO LTD

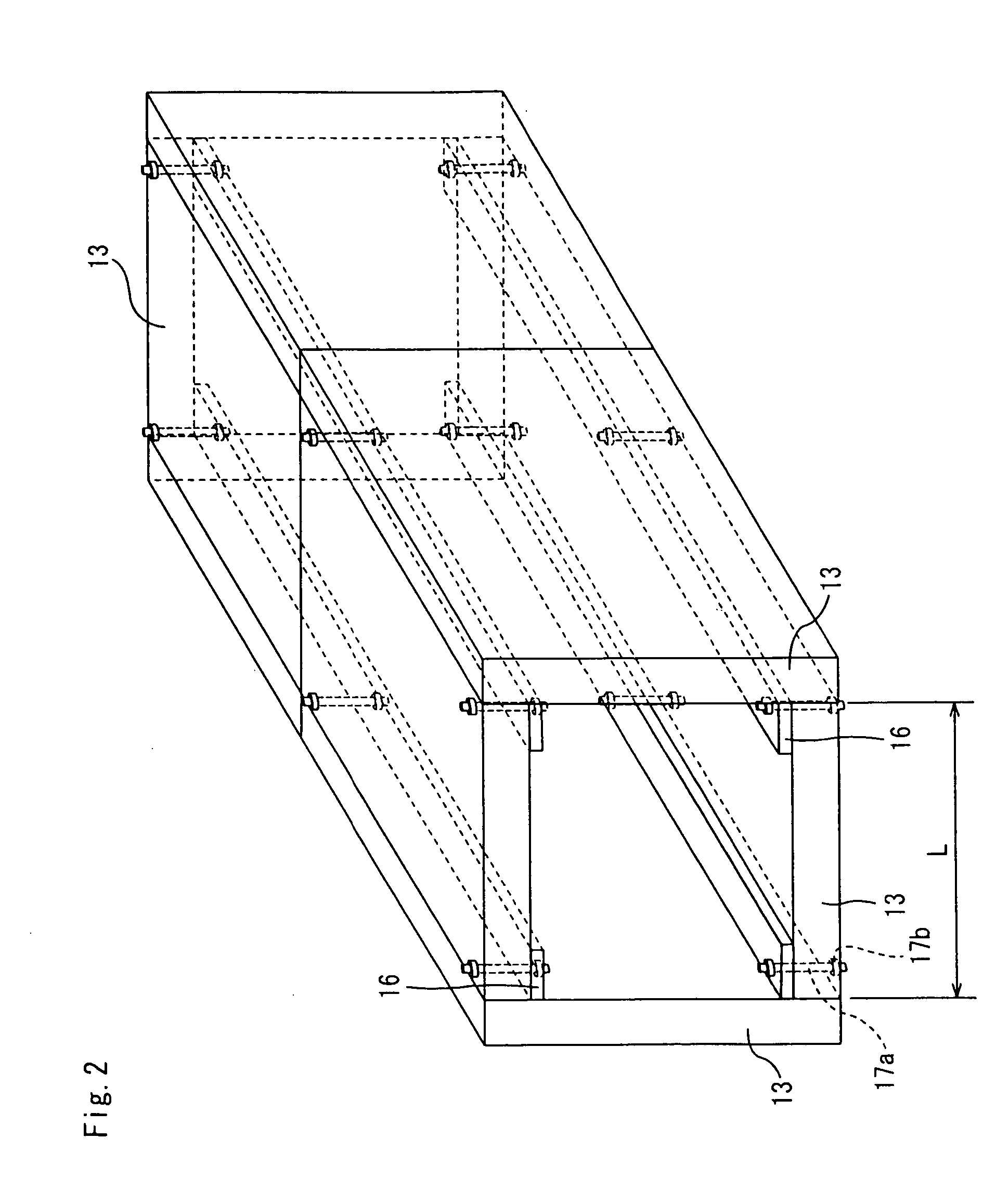

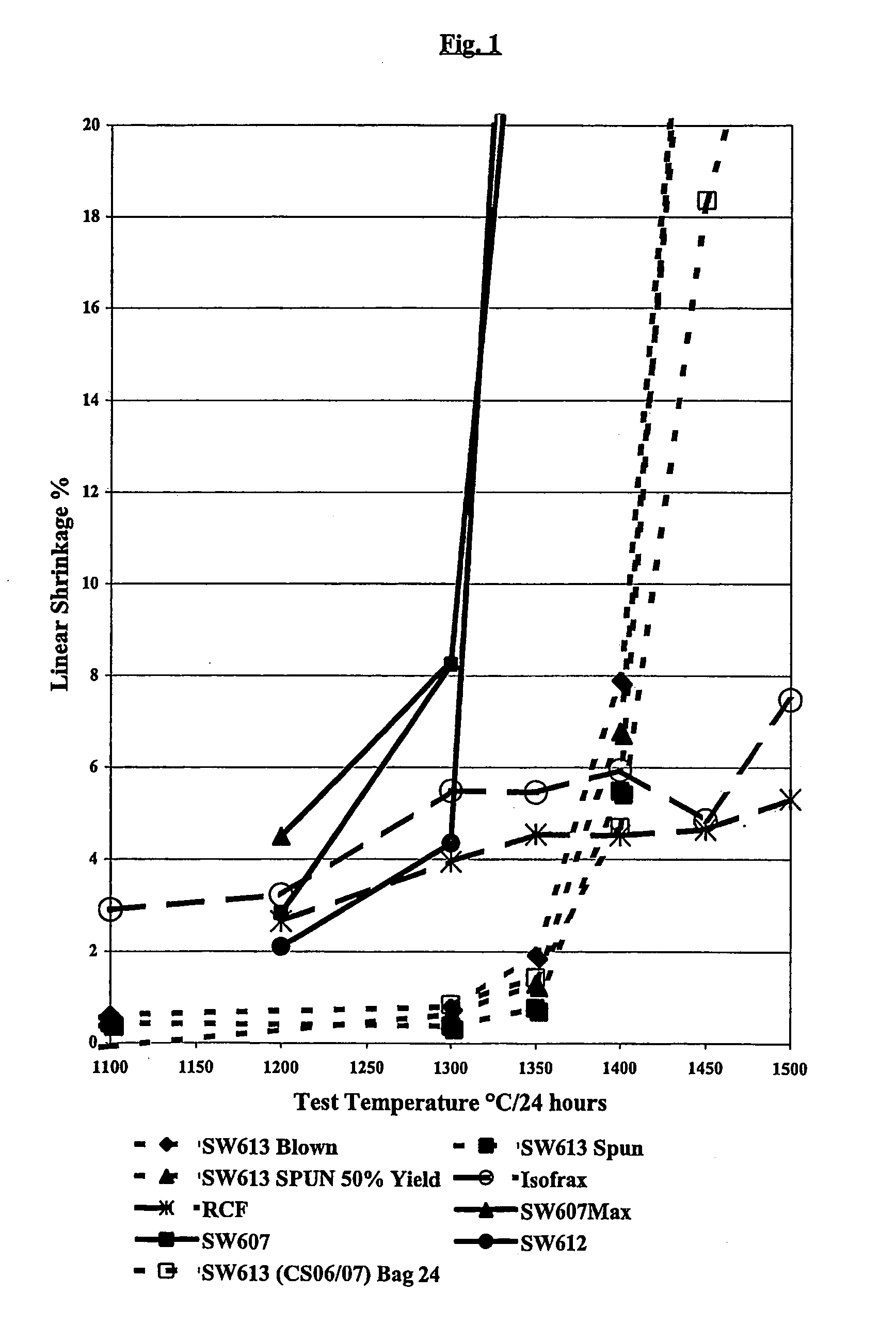

Saline soluble inorganic fibres

InactiveUS7153796B2Improve fiber qualityMinimise reduction is solubilityInorganic material artificial filamentsHeat proofingFiberThermal insulation

Thermal insulation is provided for use in applications requiring continuous resistance to temperatures of 1260° C. without reaction with alumino-silicate firebricks, the insulation comprises fibers having a composition in wt %65%<SiO2<86%MgO<10%14%<CaO<28%Al2O3<2%ZrO2<3%B2O3<5%P2O5<5%72%<SiO2+ZrO2+B2O3+5*P2O5 95%<SiO2+CaO+MgO+Al2O3+ZrO2+B2O3+P2O5 Addition of elements selected from the group Sc, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y or mixtures thereof improves fiber quality and the strength of blankets made from the fibers.

Owner:THE MORGAN CRUCIBLE CO PLC

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

Method and apparatus for fabrication and sintering composite inserts

InactiveUS6011248AInhibit migrationNot adversely propertyMechanical apparatusLinings repairWear resistantWear resistance

The present disclosure is directed to the fabrication of a highly wear layer either directly upon an article or tool support structure or body, or as a wear resistant insert or element which is subsequently attached to the tool body. The wear material is formed by sintering particulate material using the absorption of microwave energy as a means of heating. The disclosure also encompasses post manufacture annealing, using heating by microwave radiation, of both highly wear resistant inserts and composite articles which consist of a wear resistant layer and a body. The wear resistant material, whether fabricated directly upon an article or fabricated separately and subsequently affixed to an article, provides an abrasive wear surface and greatly increases the life of the article. Microwave sintered wear resistant surfaces for mills, drills, grinders, brakes, bearings, saw blades and other articles and assemblies are disclosed.

Owner:PENN STATE RES FOUND +1

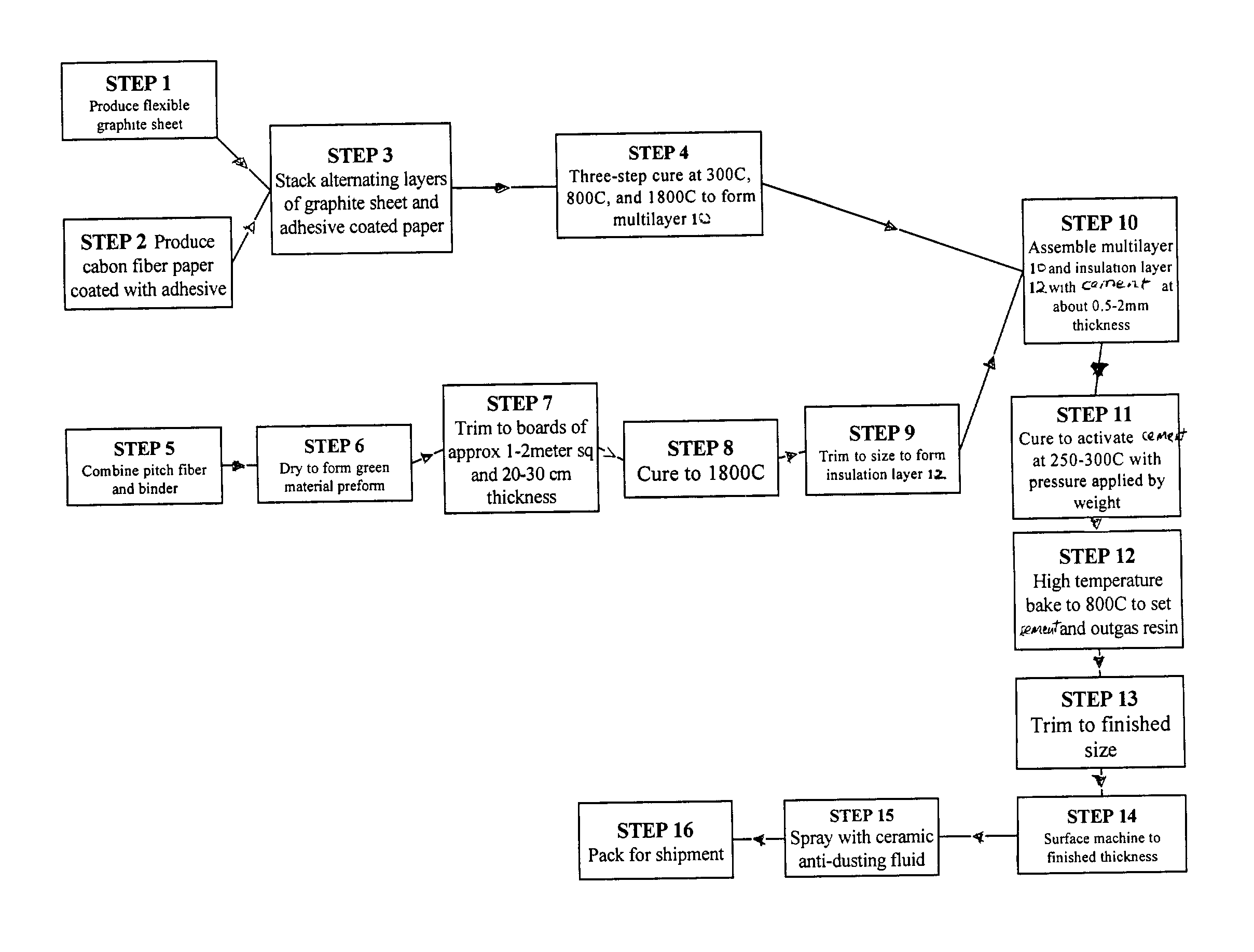

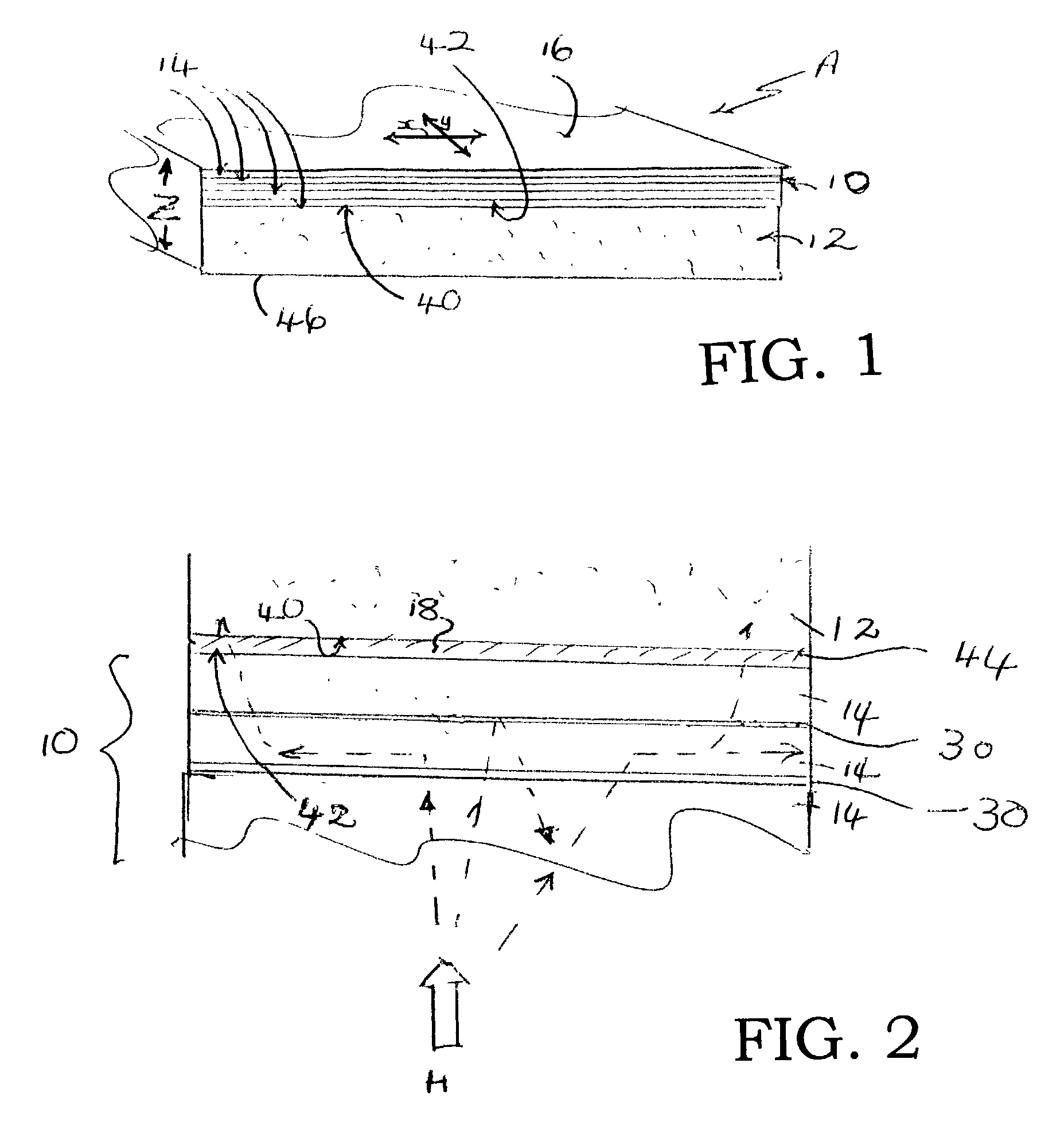

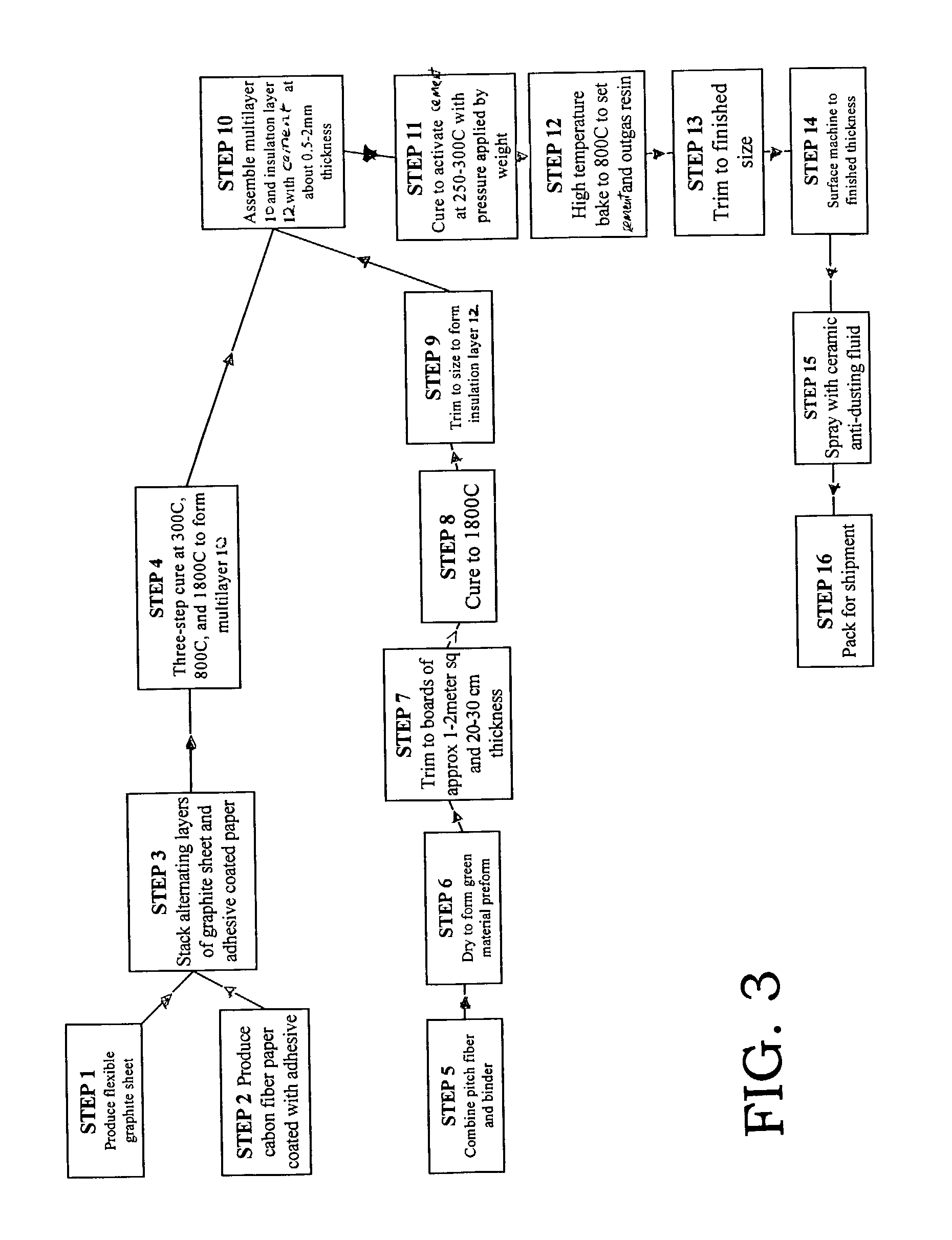

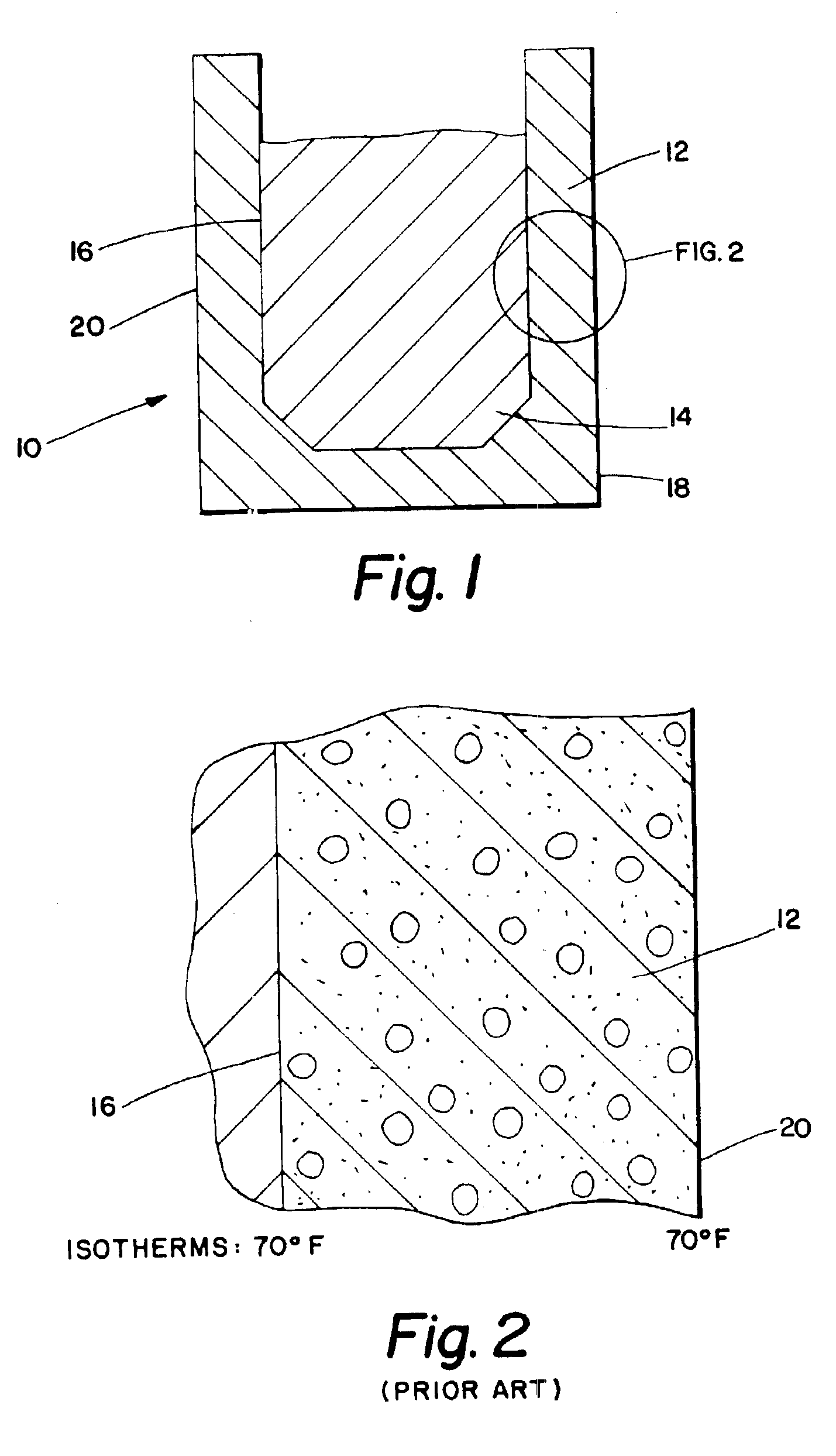

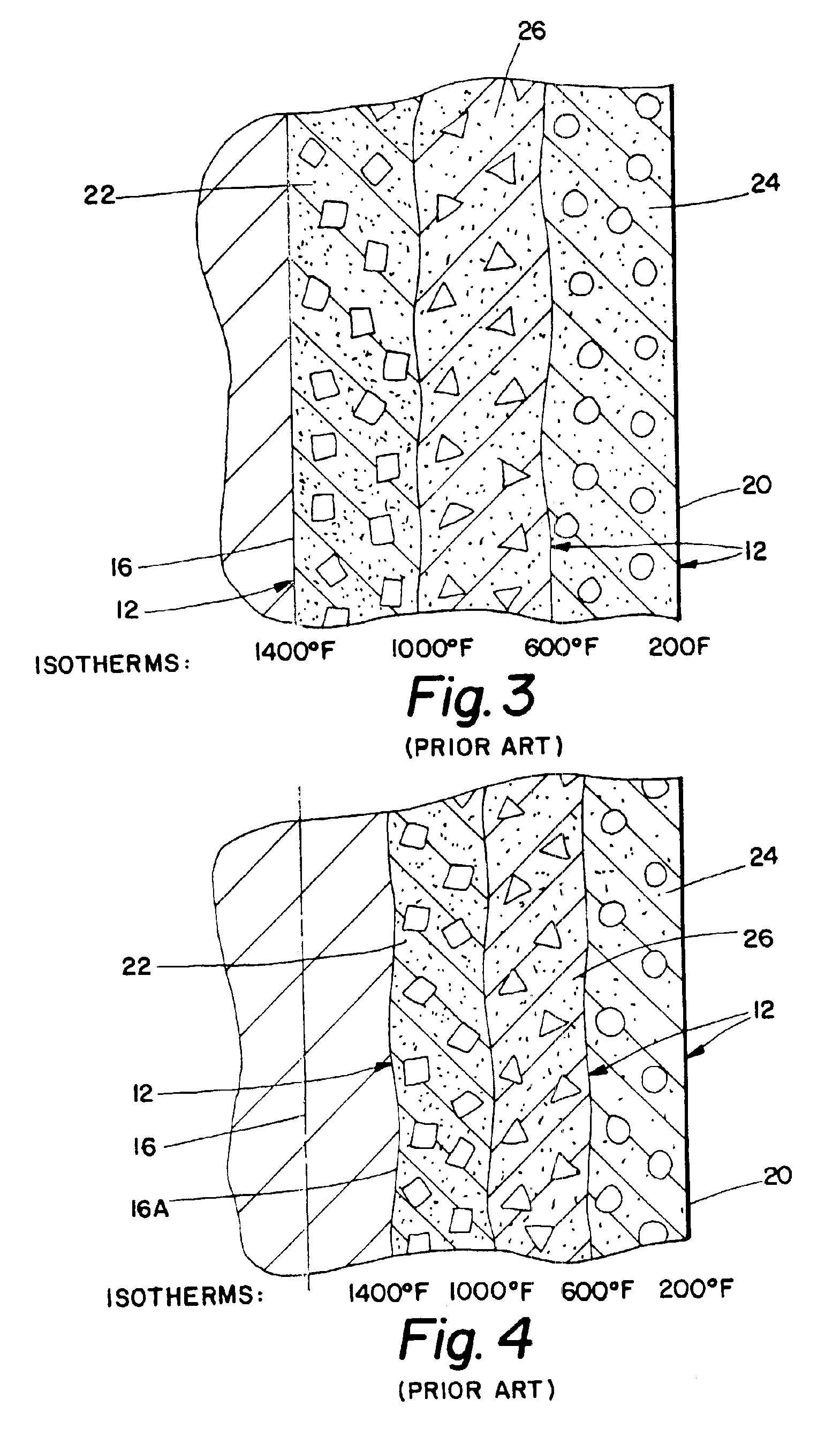

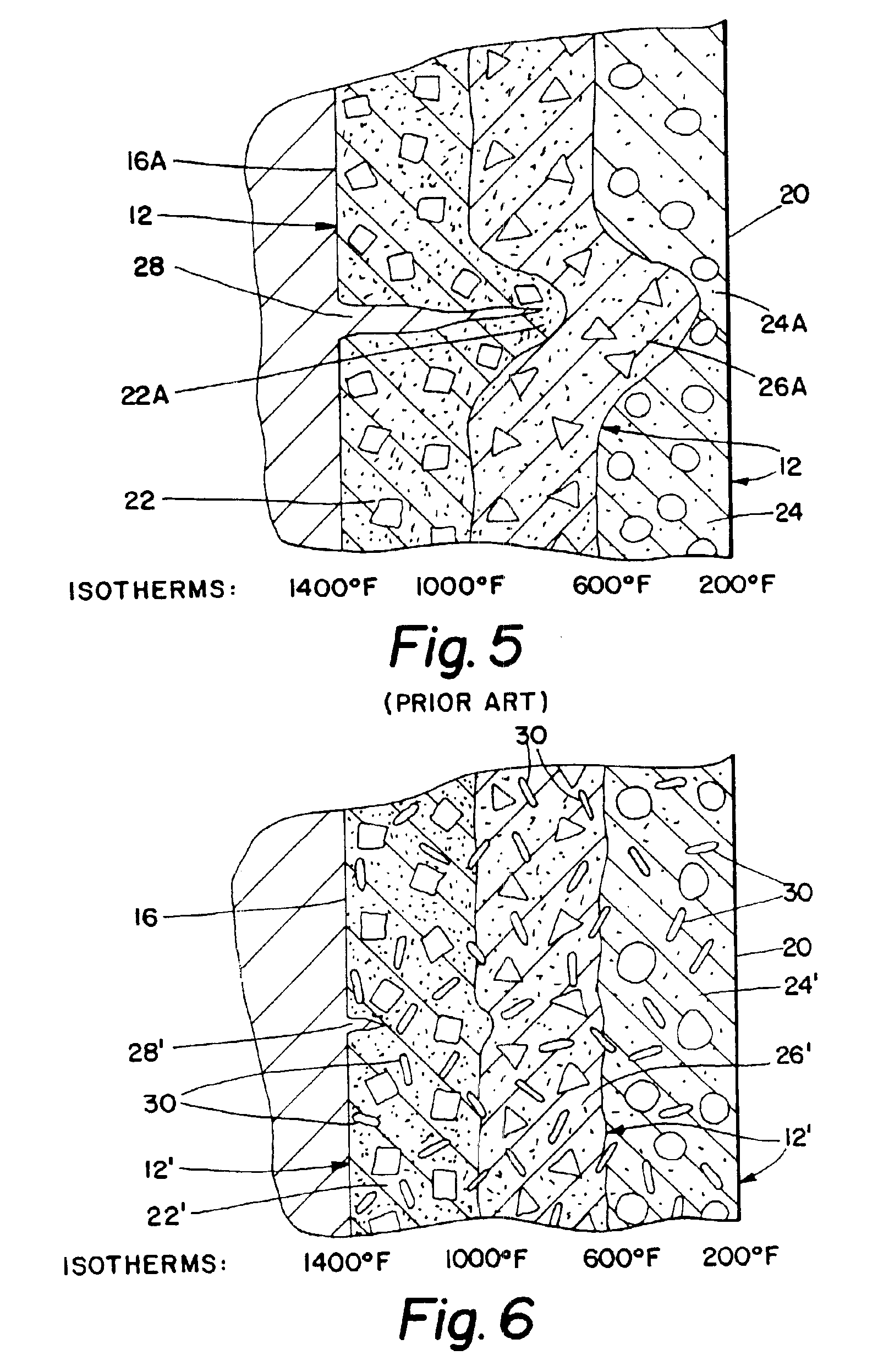

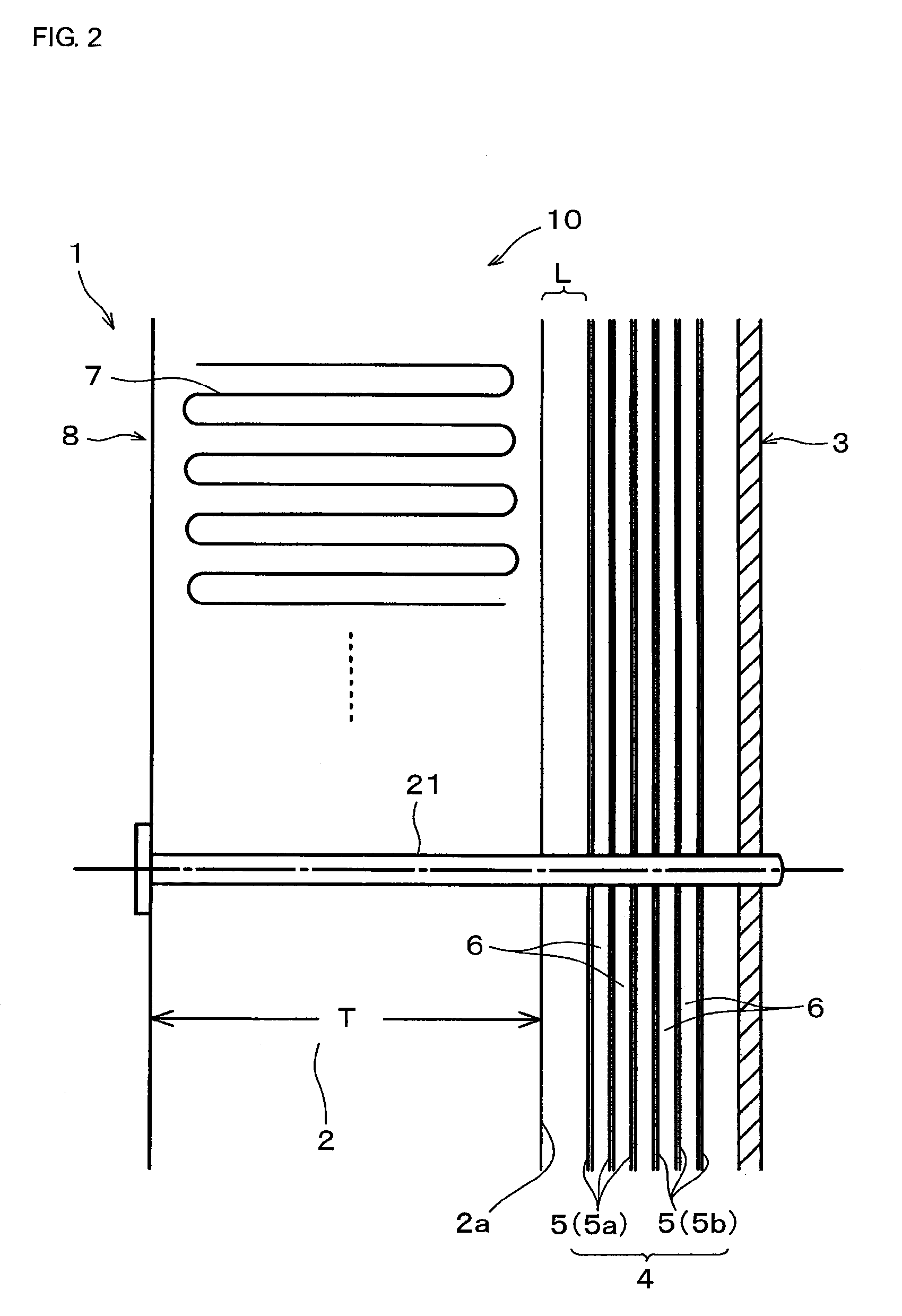

Composite high temperature insulator

InactiveUS20040076810A1Inhibit the formation of hot spotsHeat dissipationSolid waste managementCeramic layered productsFiberCarbon fibers

A composite high temperature insulator (A) includes a planar layer (10) having anisotropic thermal conductivity properties. A second planar layer (12) is formed from a rigid insulation material, such as a carbonized mixture of carbon fibers and a binder. The second layer is coextensive with the first layer and is preferably bonded thereto by a carbonaceous cement (44). When used to insulate a heat source, such as a furnace (50), convective heat is directed back to the source by the reflective surface (16) of the inner, anisotropic layer (10). Heat which enters the anisotropic layer is dissipated evenly through the plane of the layer along a plurality of heat paths defined by a plurality of layers (14) of flexible graphite. Accordingly, heat which reaches the outer, second layer (12) results in fewer hot spots than occur with a conventional rigid insulation material, thereby reducing the total amount of insulation material required to achieve a desired level of thermal insulation.

Owner:UCAR CARBON TECH

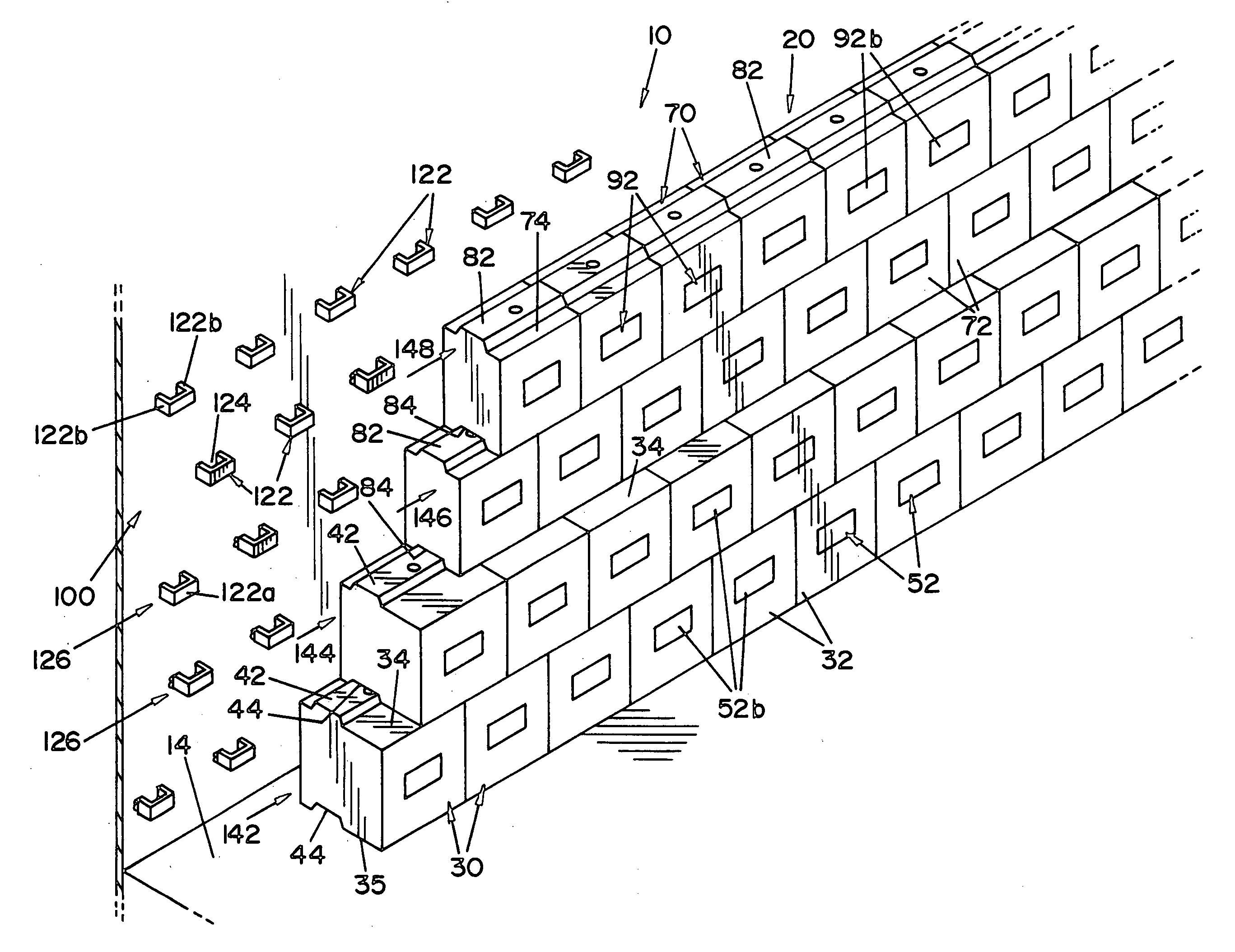

Refractory block and refractory wall assembly

InactiveUS20060242914A1Simple structureEasy to assembleWallsFurnace liningsRefractoryMaterials science

A refractory block for forming a wall structure comprising a body of cast refractory material. The body has a front face, a back face, a top face, a bottom face, and two opposing side faces. The body further has a projection formed on the top face and a recess formed in the bottom face, the projection being dimensioned to be received within the recess such that a projection on a block can be received in a recess on a block thereabove. A refractory anchor is embedded within the body. The anchor has a portion extending from the body through the back face.

Owner:HARBISON WALKER REFRACTORIES

High temperature furnace-grade curing carbon fiber thermal insulating material and production technology thereof

ActiveCN101550017AImprove insulation effectSimple process, energy saving and environmental protectionCarbon fibresFurnace liningsFiberCarbon fibers

The invention discloses a high temperature furnace-grade curing carbon fiber thermal insulating material having simple technology and small coefficient of heat conductivity, and a production technology thereof, characterized in that the material is made of the carbon fiber by the steps of the preparation of a preform, densification, hot-vibration purification and machine processing; the invention is free from the processes of bonding, immersion, curing and charring in the preparation of the preform and has simple technology, great energy-saving property and environmental protection ability, the carbon fibers inside the preform are distributed in a crisscross pattern, strong in cohesive force, stable in structure and free from delamination, the coefficient of heat conductivity is not larger than 0.8 W / mK and the thermal insulating property is excellent; the product consists of the high-strength carbon fiber and carbon matrix and has outstanding performances such as high specific strength, good high temperature resistance, corrosion resistance and thermal insulating property, in addition, the product integrates the fire resistance and the thermal insulating property, can bear certain loads, and is an ideal upgraded product in taking the place of related high temperature furnace-grade graphite products and soft carbon felt.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

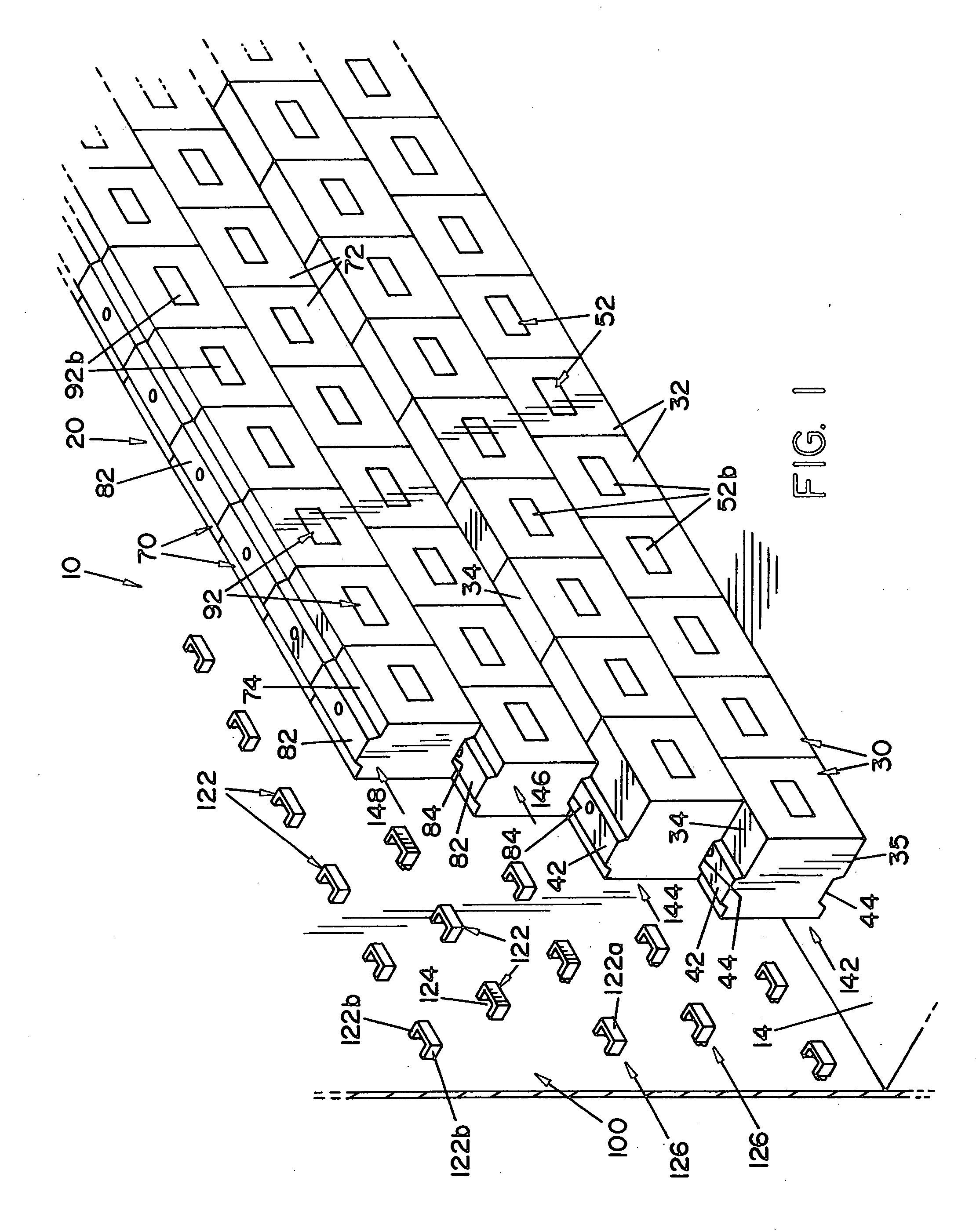

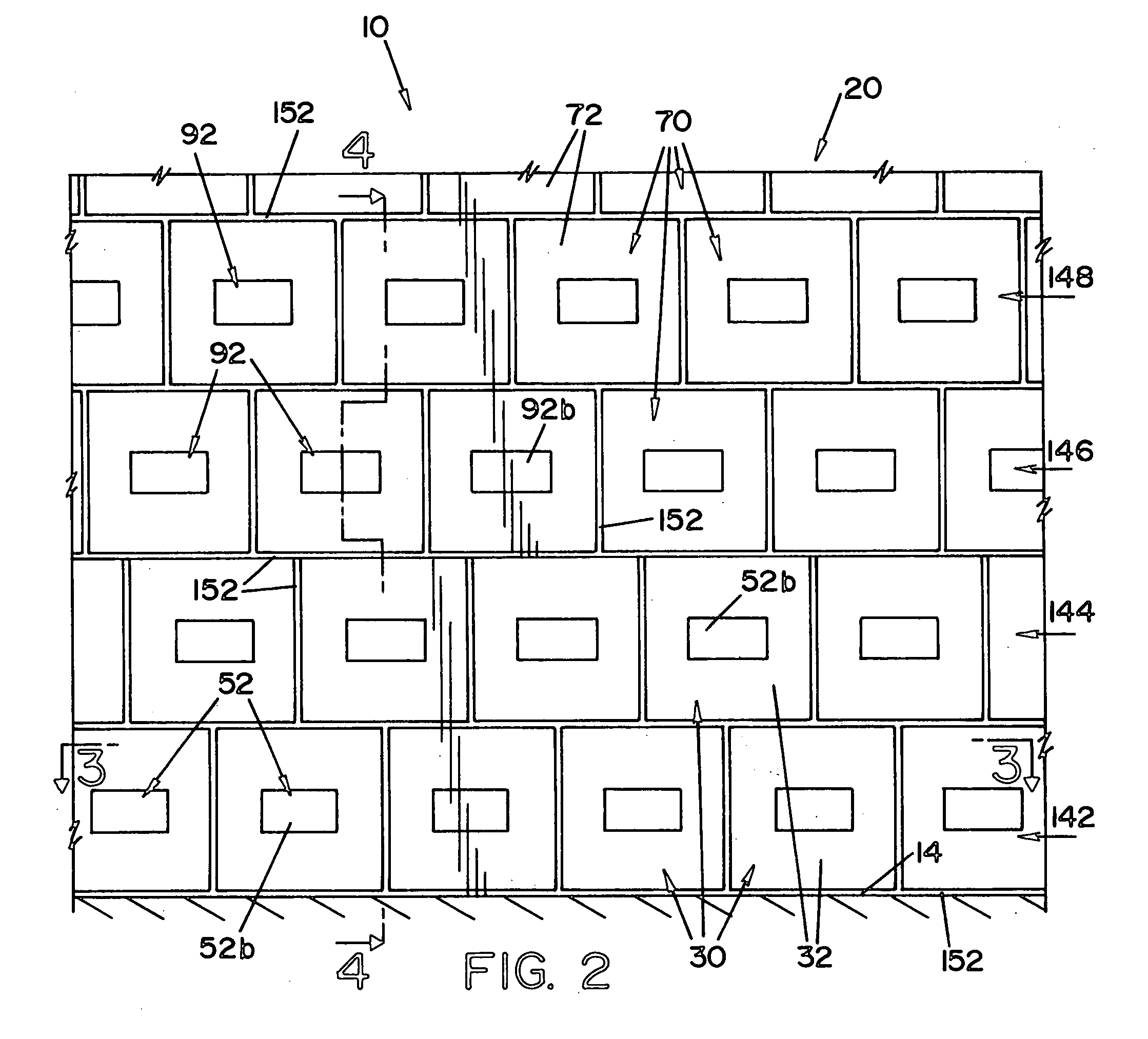

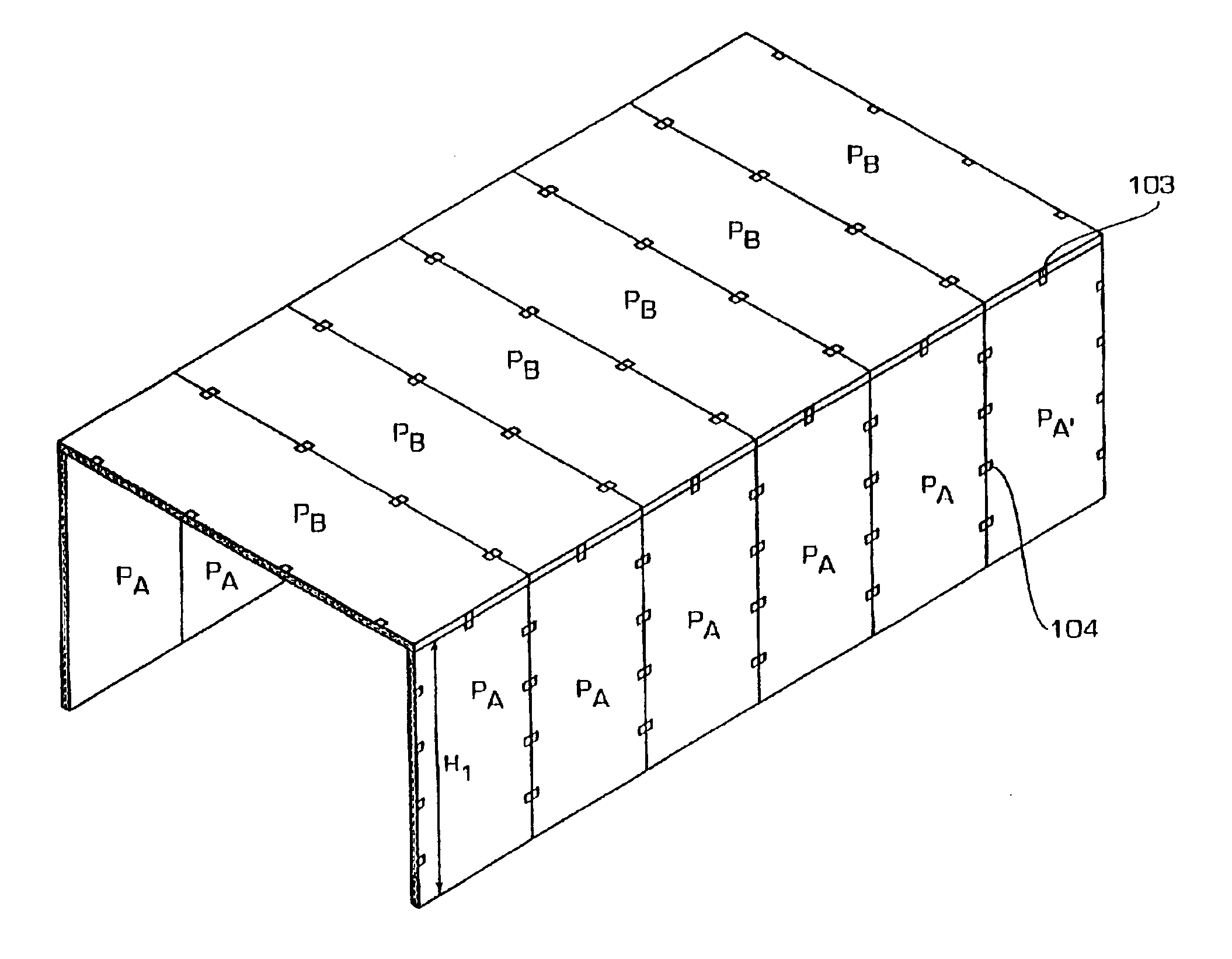

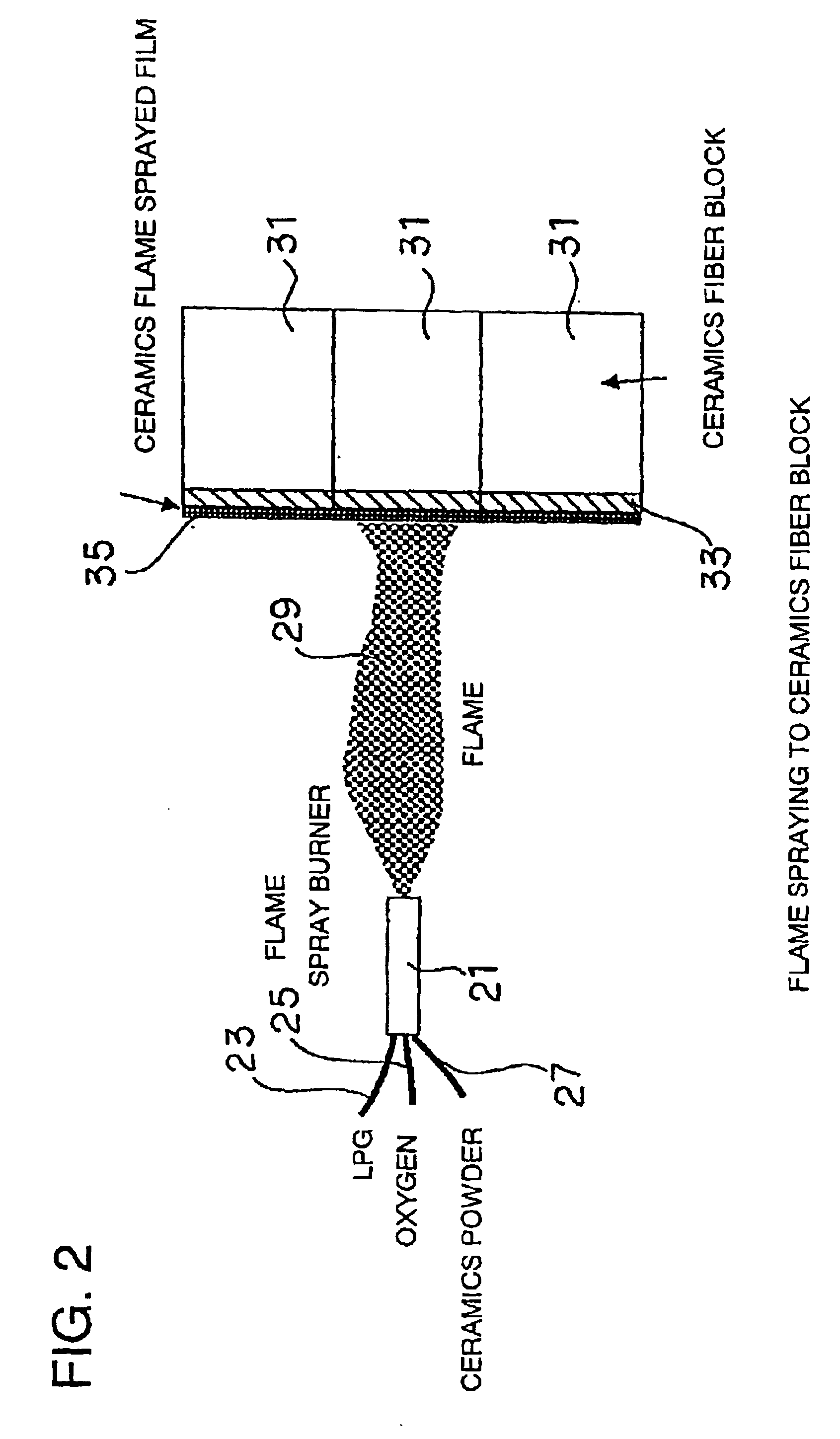

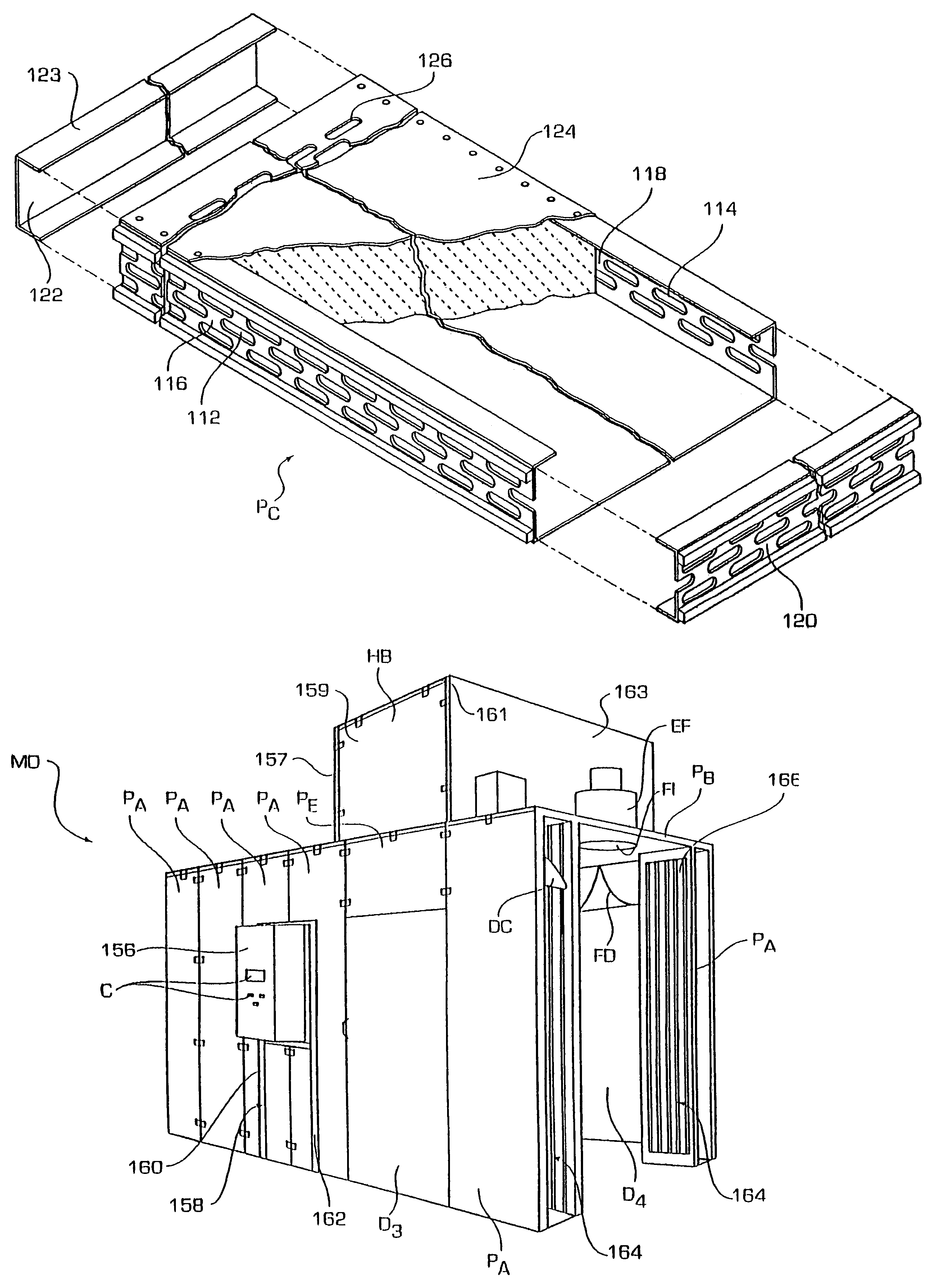

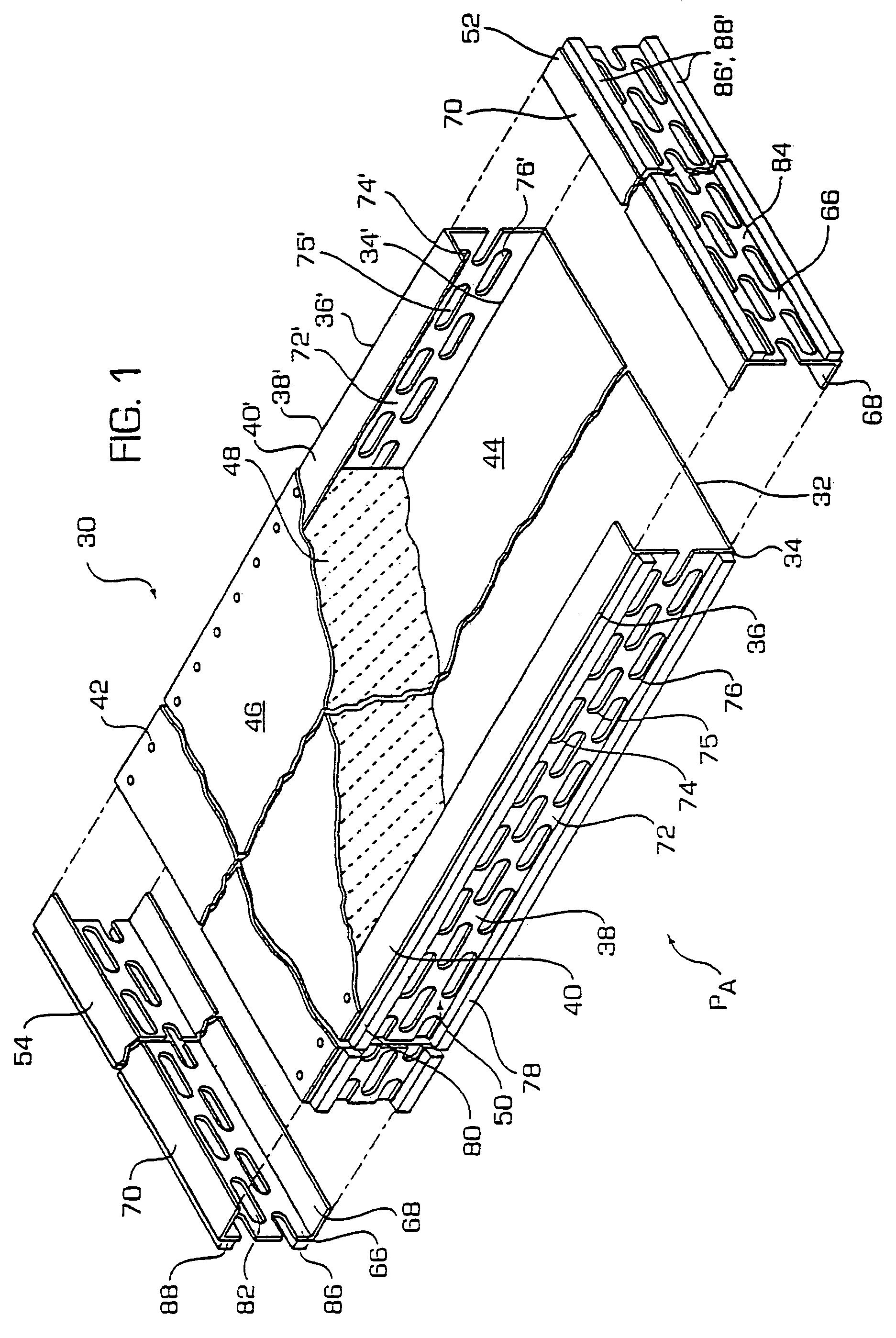

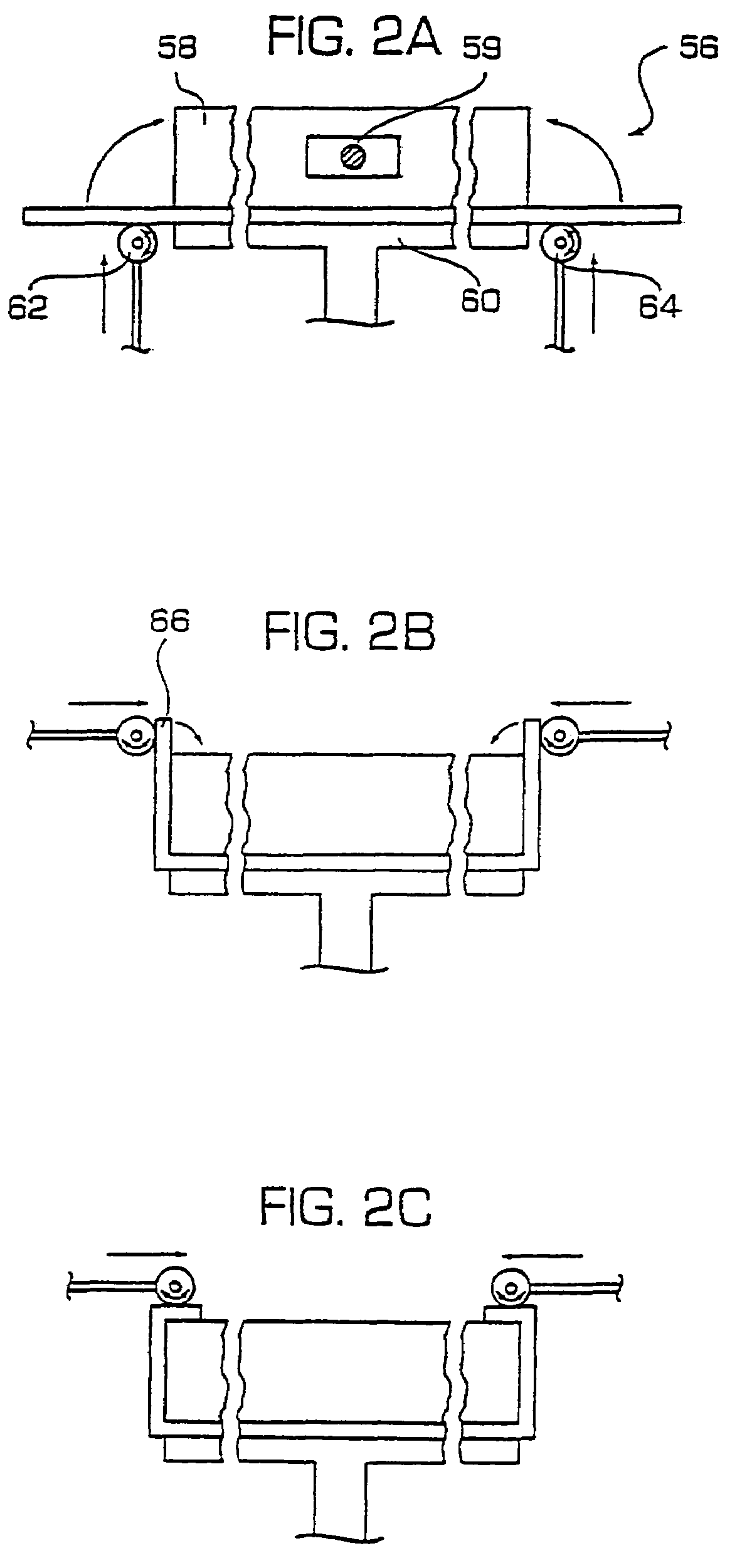

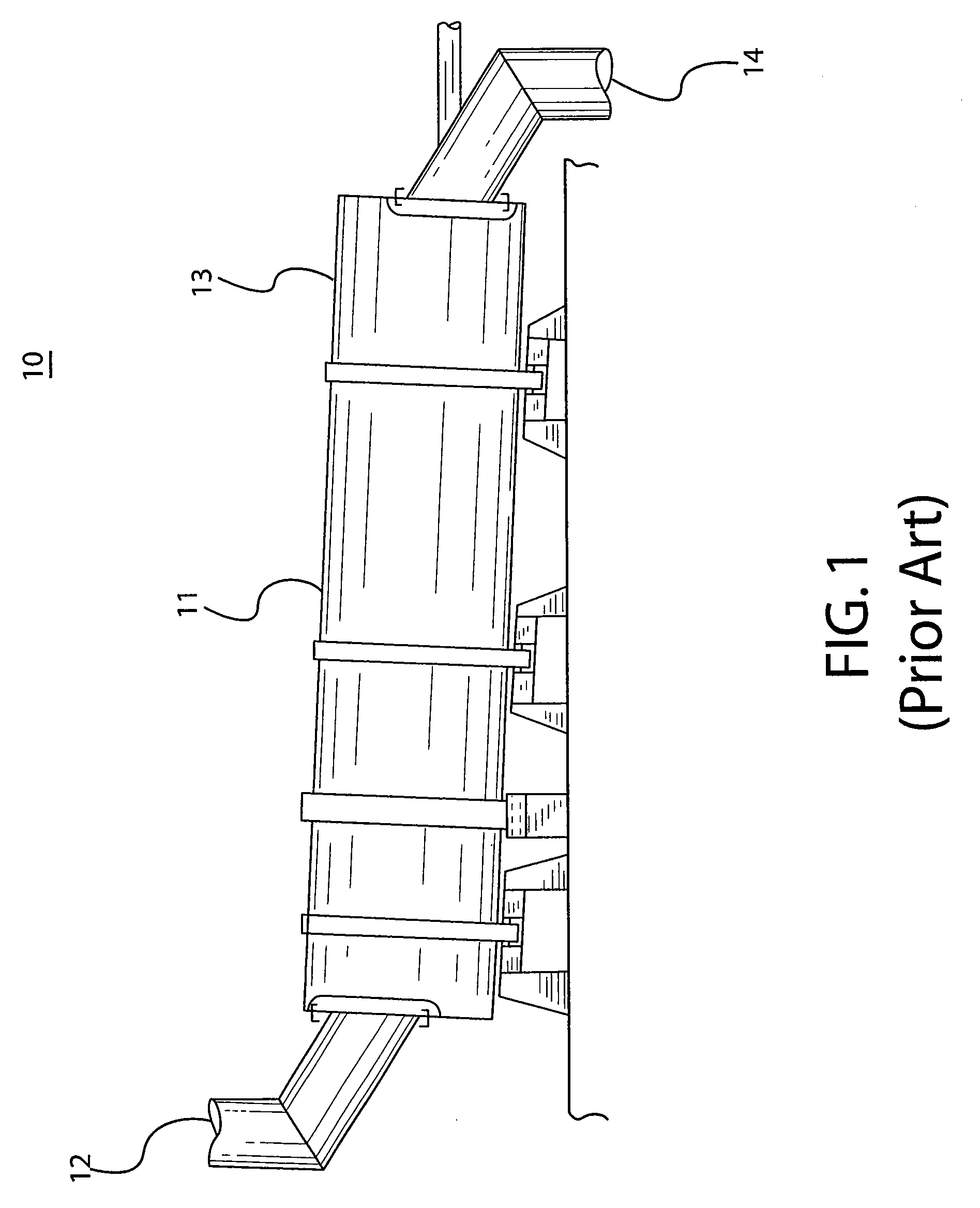

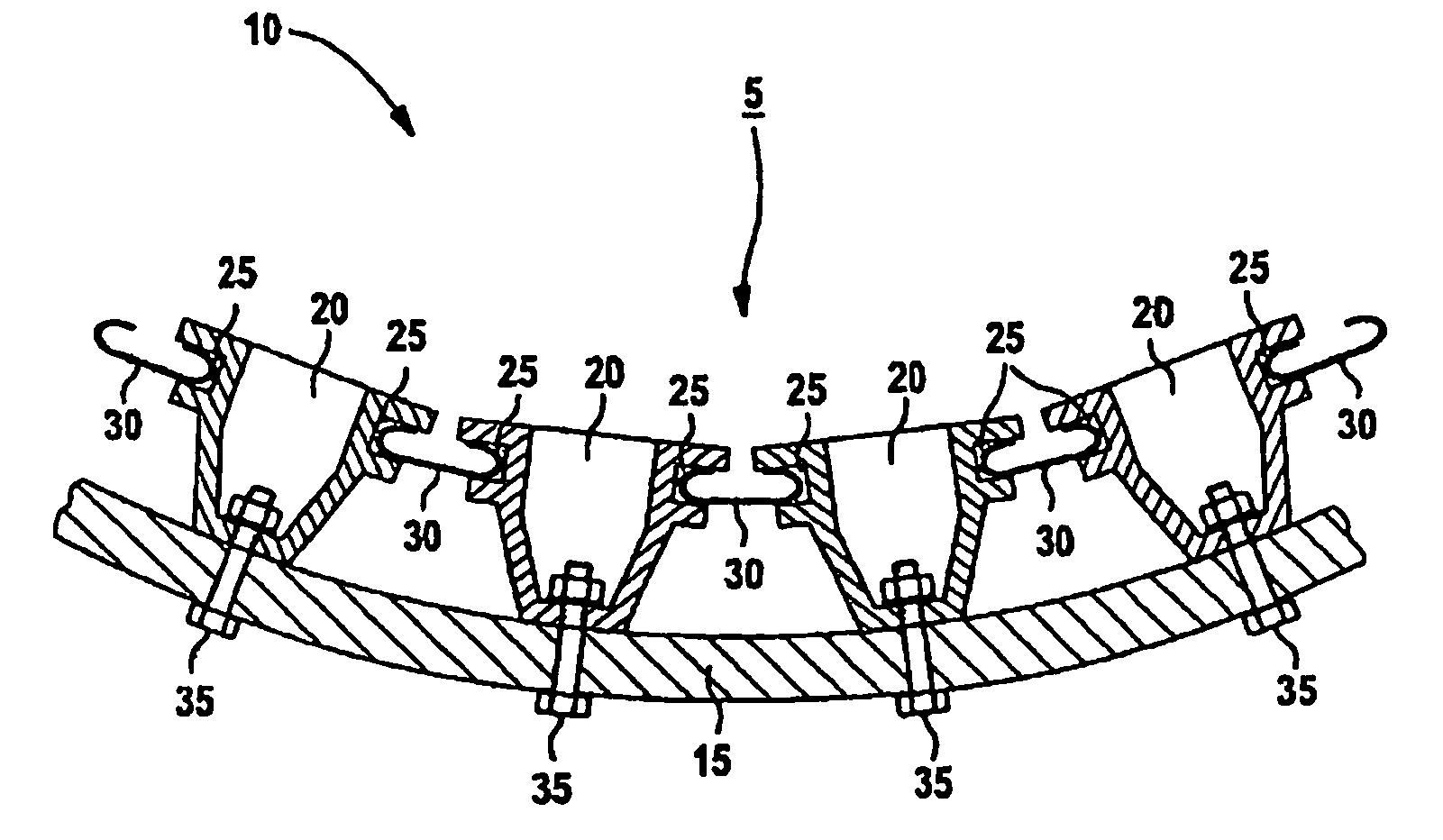

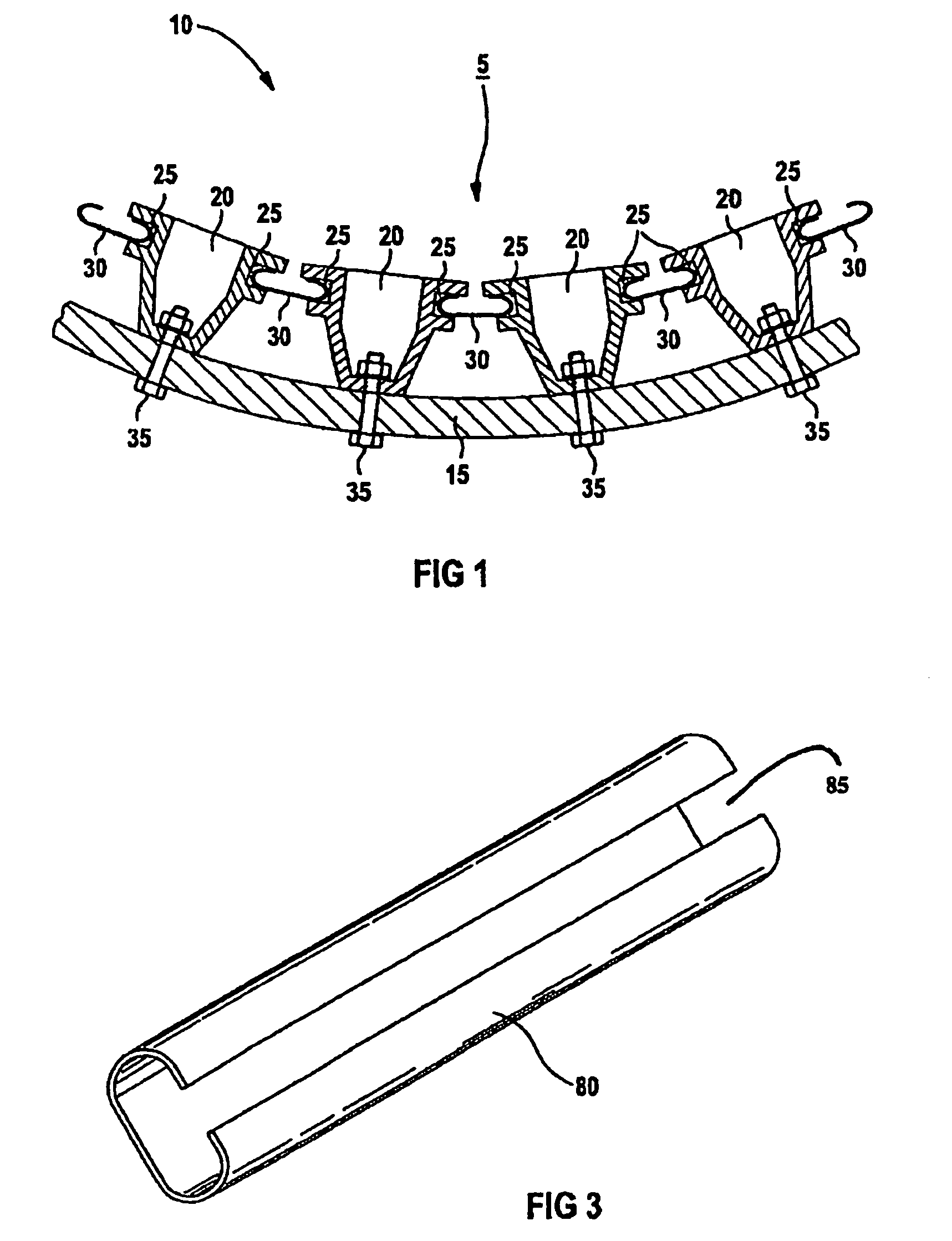

Modular oven, panel assembly and method of assembling the same

InactiveUS6905332B1Efficient productionQuick disassemblyMuffle furnacesLinings repairModularitySurface plate

A modular oven, such as a batch process oven, having a standardized set of self supporting, interconnectable panels which, when assembled, from a self-supporting heat containment shell, free of added structural support members. Also described are the self-supporting modular oven panels themselves having common roof, sidewall and end wall shell configuration and a method of assembling the panels such as in the expansion or conversion of a first modular oven assembly to a second assembly more conducive to current production requirements.

Owner:RAYPAUL INDS

Cement-free refractory

InactiveUS20120142518A1Shorten drying timeIncrease refractorinessBlast furnace componentsWood working apparatusRefractoryLiquid metal

A cement free refractory mixture contains aluminum oxide, silicon carbide, fumed silica, aluminum metal, an anti-oxidant, reactive alumina, and a carbon-bearing material. The mixture can be formed by conventional techniques to create refractory articles to contain or direct the flow of liquid metals. Refractory articles formed by the mixture do not require firing to achieve an initial cure.

Owner:VESUVIUS USA CORP

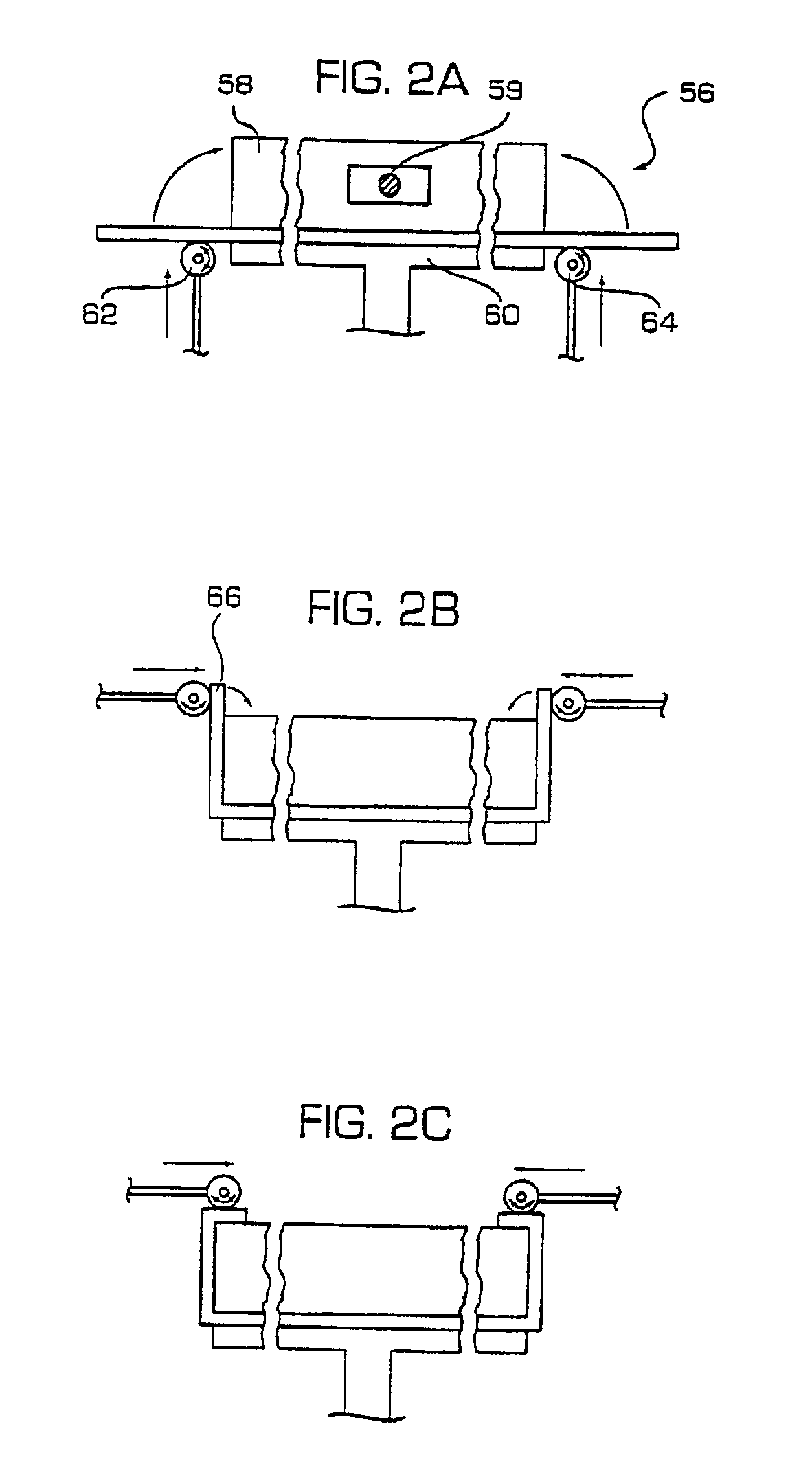

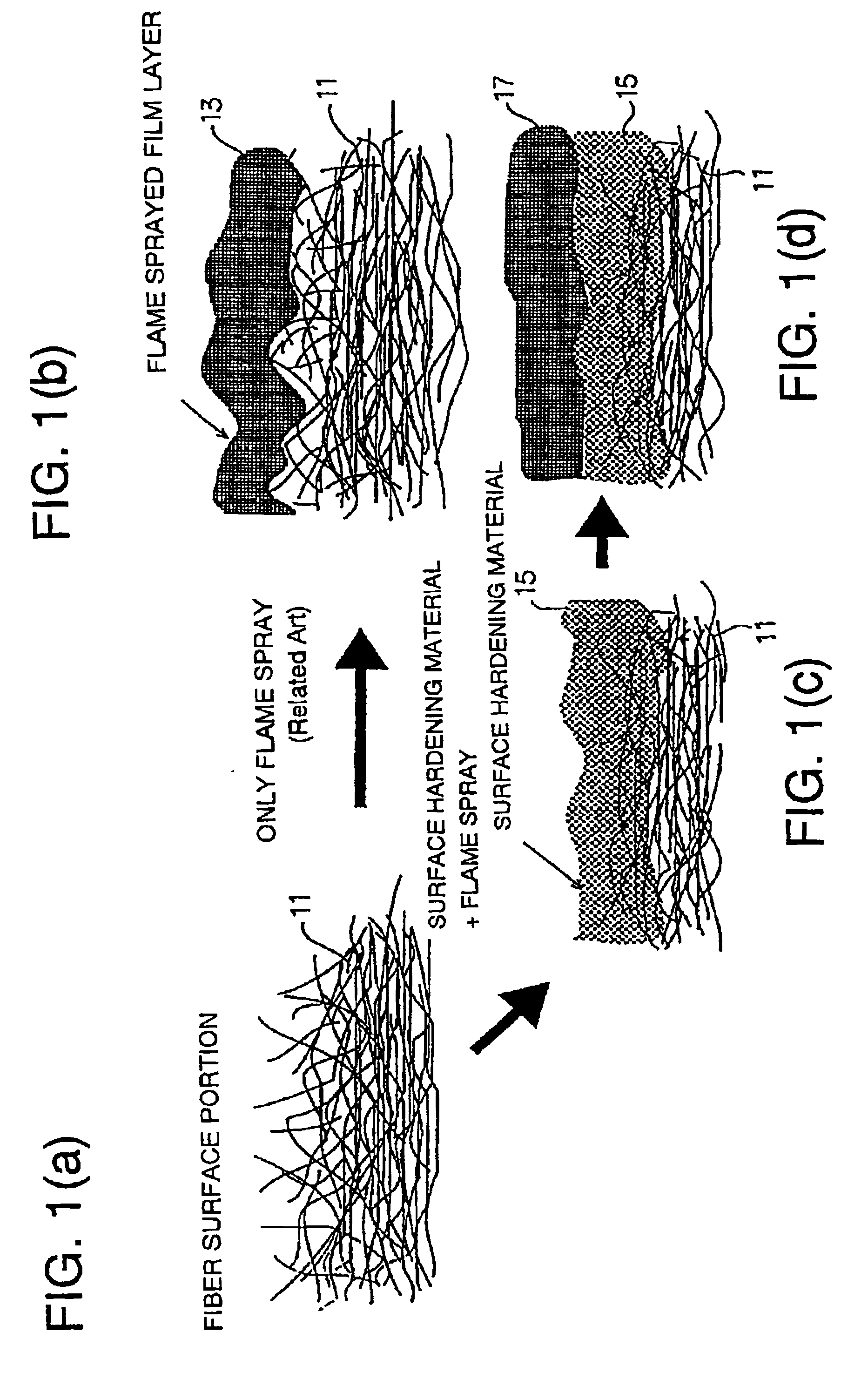

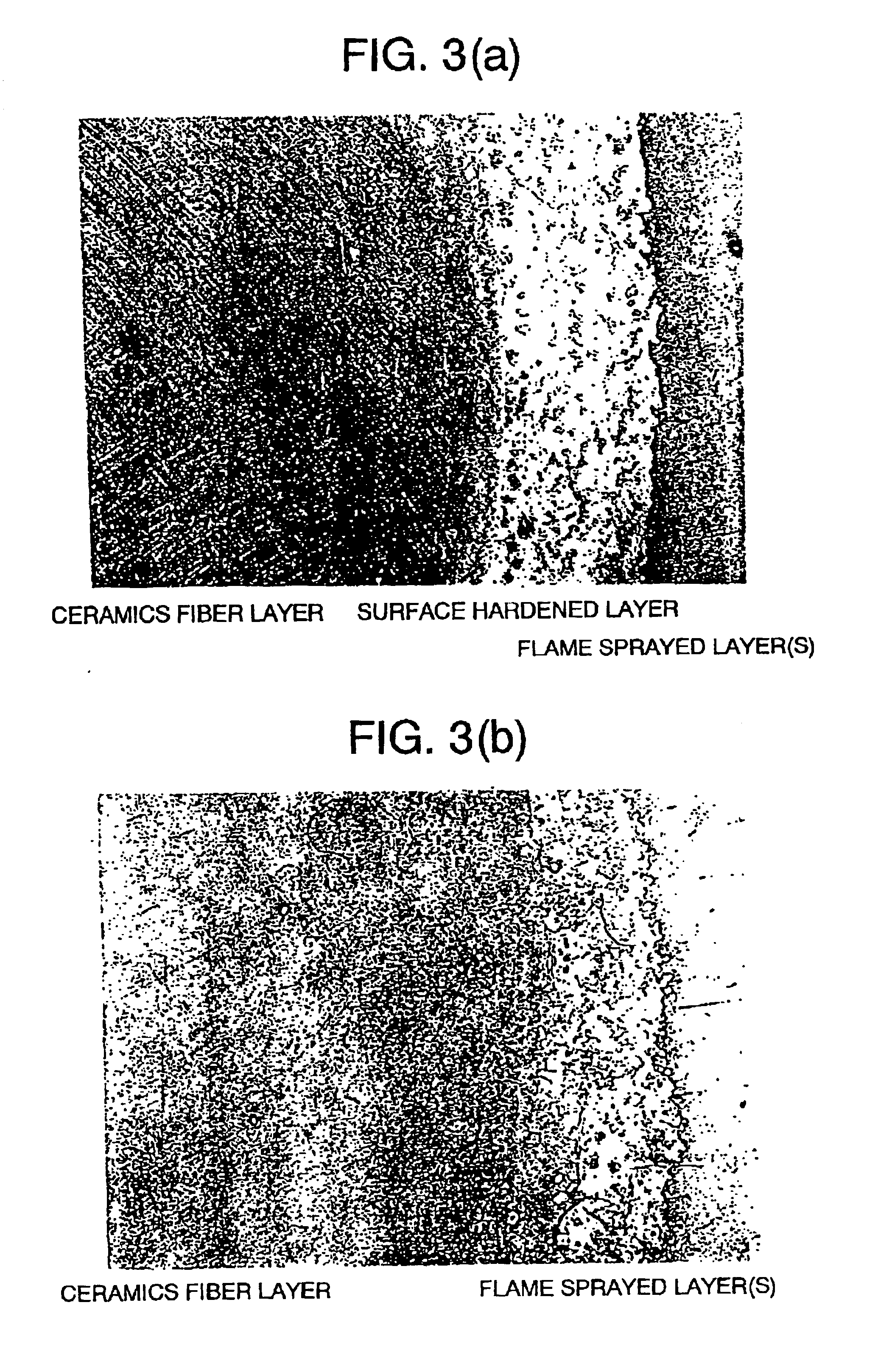

Highly endurable heat insulating material, method for production thereof, uses thereof, and working method therefor

A fire-resistant heat insulating material excellent in resistance to heat, resistance to slag, resistance to molten iron, resistance to wear, and resistance to mechanical impulse is provided. A highly endurable heat insulating material characterized by being provided on the surface of a layer of inorganic heat insulating fibers through the medium of a coating film of surface hardening material with a flame sprayed film of a fire-resistant ceramic substance.

Owner:NIPPON STEEL CORP

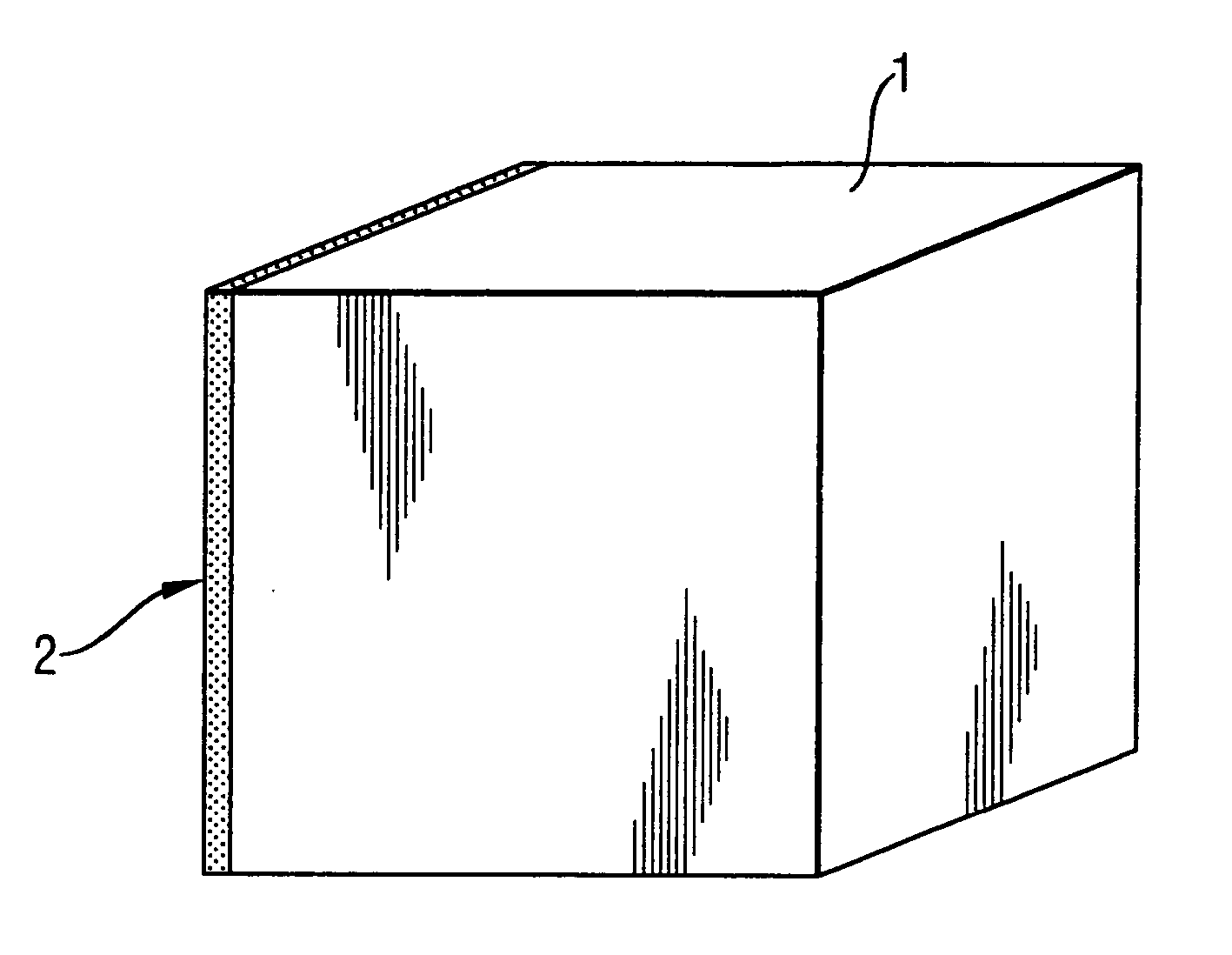

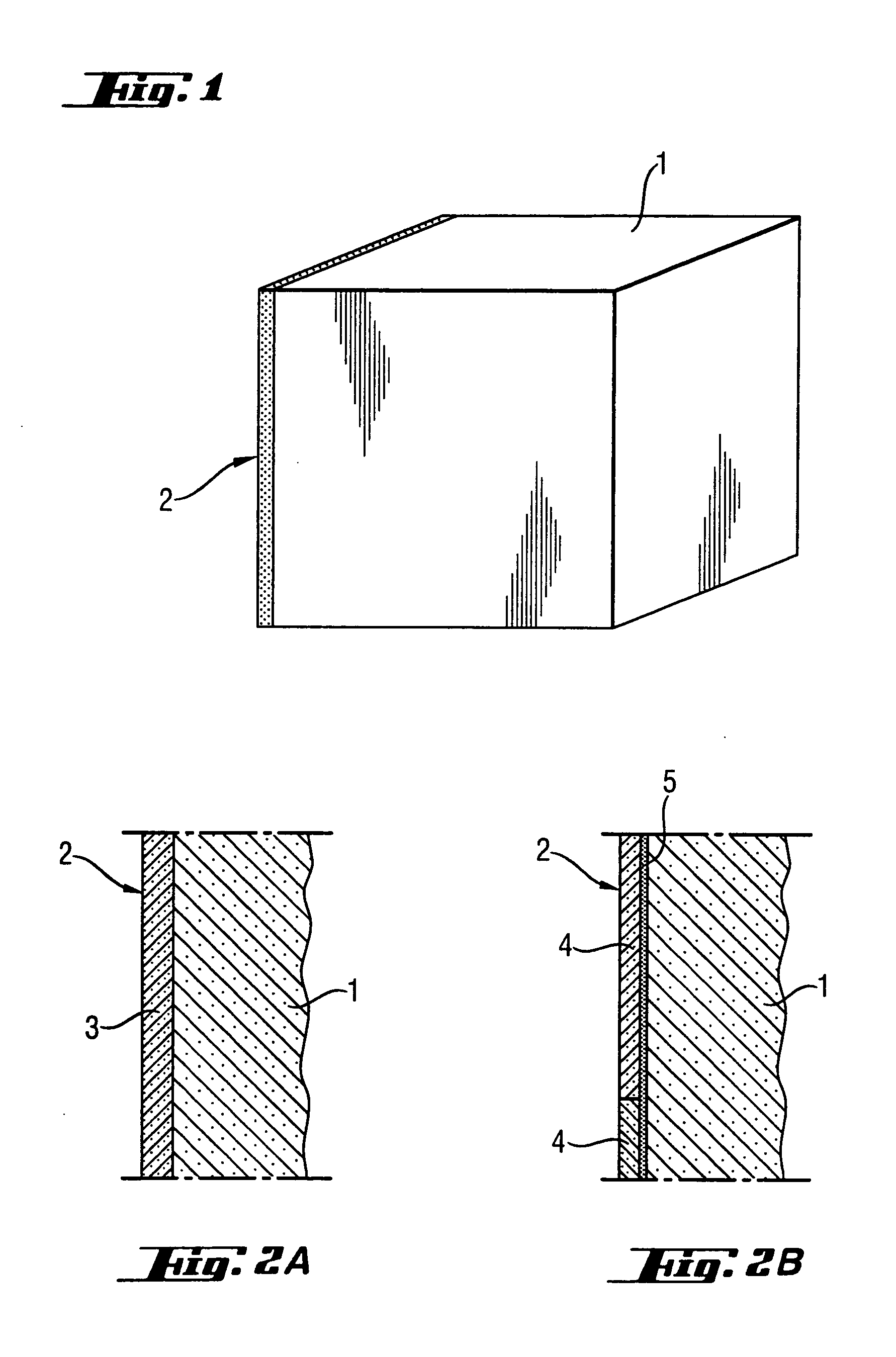

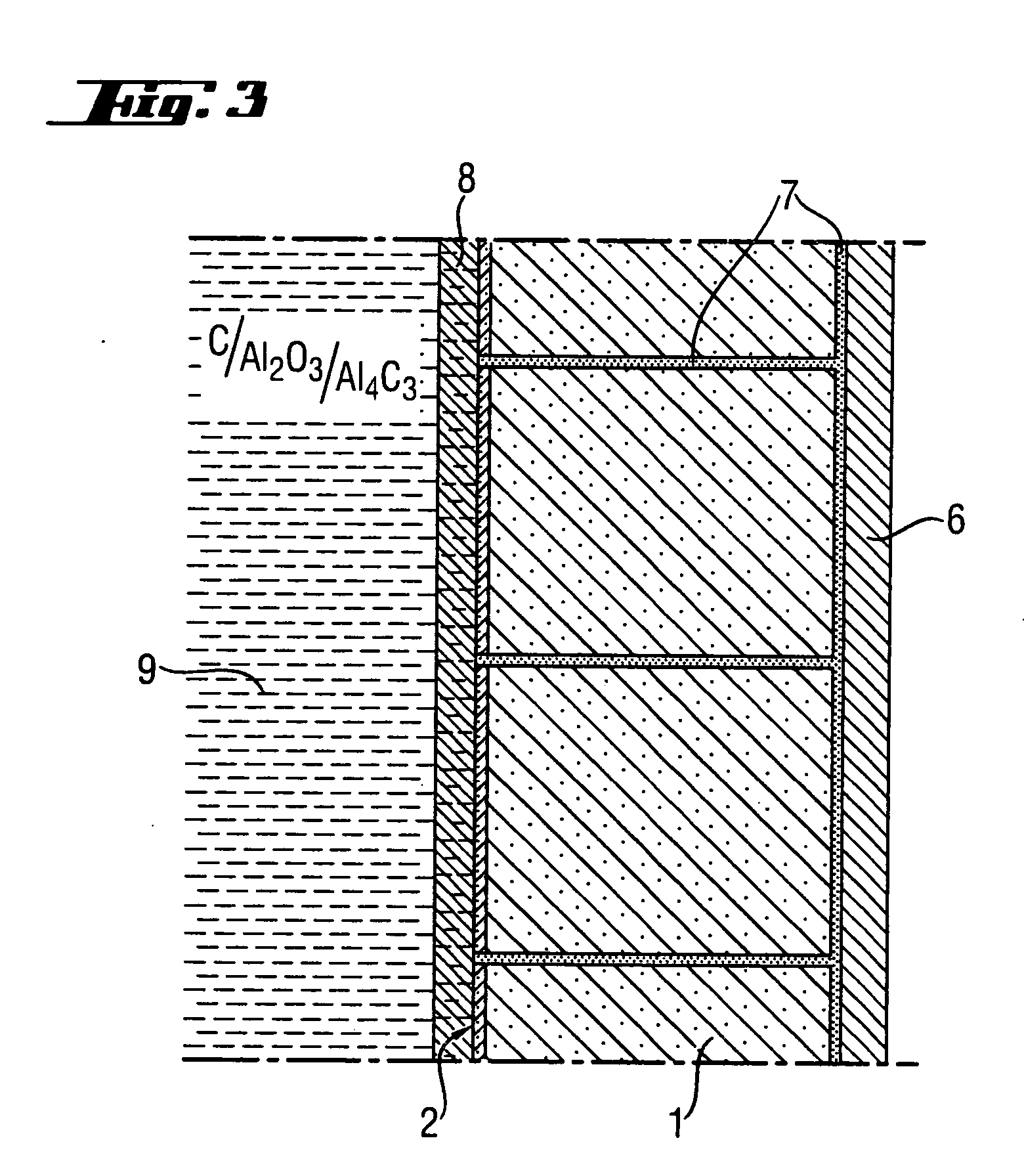

Lining for carbothermic reduction furnace

InactiveUS20050254543A1Effective heat dissipation systemOvercome disadvantagesElectric discharge heatingLinings repairRefractoryGraphite

An inner lining for the steel shell of a carbothermic reduction furnace for the production of alumina has a base layer of graphite and a coating layer of refractory material. The refractory material is corundum (Al2O3) bound by Sialon (Si.Al.O.N). The lining structure provides protection against the molten slag and it is not attacked by the CO-rich melt furnace atmosphere. Further, the lining does not contaminate the melt and it provides an effective heat dissipation system in case of a power shut-off.

Owner:SGL CARBON SE

Modular oven wall panel assembly

InactiveUS7216464B2Efficient productionRapidly assembled and disassembledStoves/ranges foundationsSelf-cleaning stoves/rangesModularityManufacturing engineering

A modular oven, such as a batch process oven, includes a standardized set of self supporting, interconnectable panels which, when assembled, from a self-supporting heat containment shell, free of added structural support members. The present invention is also directed at self-supporting modular oven panels and a method of assembling the panels such as in the expansion or conversion of a first modular oven assembly to a second assembly more conducive to current production requirements.

Owner:RAYPAUL INDS

Gasifier reactor internal coating

ActiveUS20060211566A1Reduce infiltrationReduce attackGasifier mechanical detailsFurnace liningsMetallurgyZirconium oxide

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

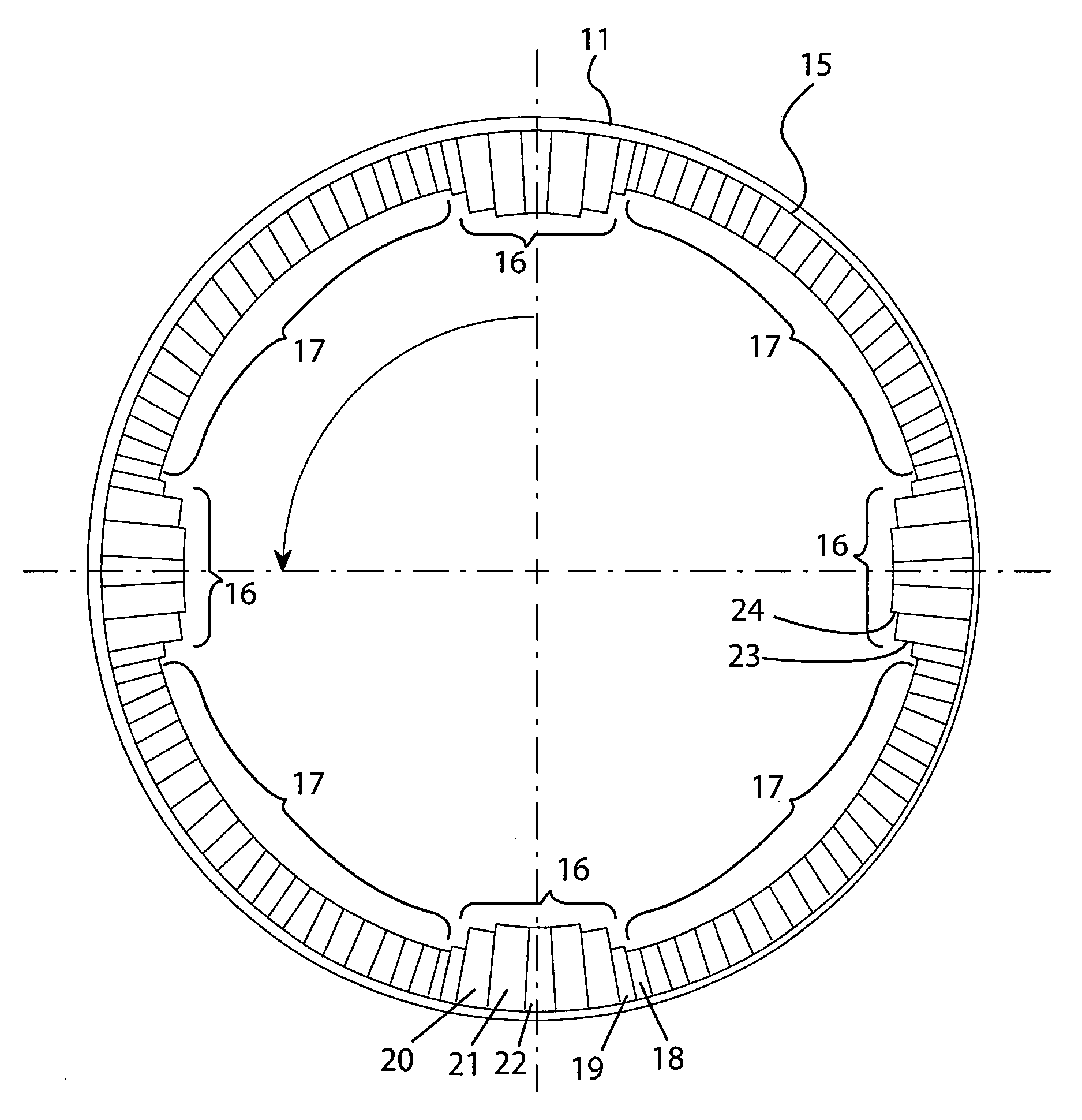

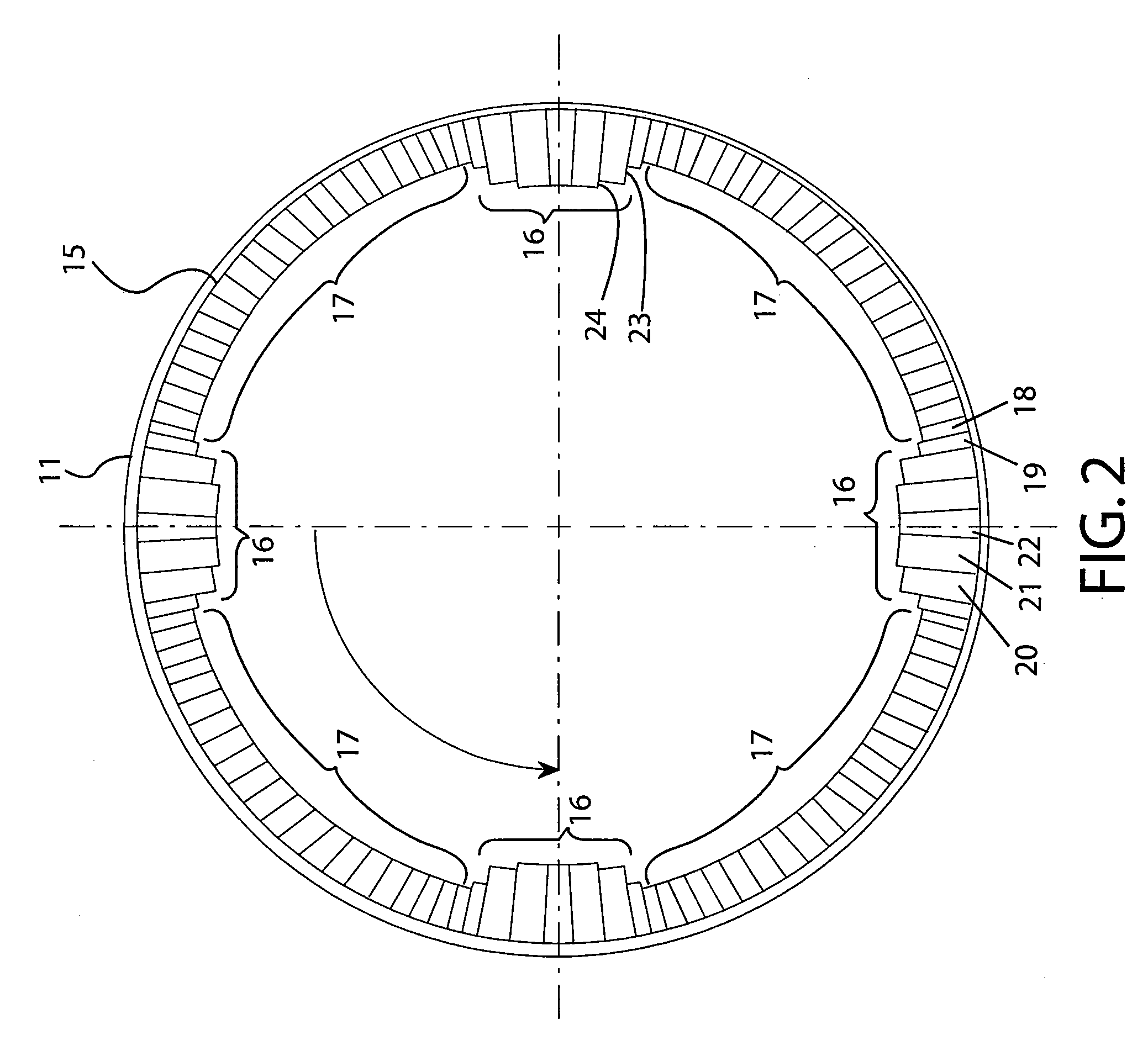

Rotary kiln lining and method

InactiveUS20120282563A1Difficult to repairCost efficientLinings repairRotary drum furnacesRefractoryEngineering

Provided is a rotary kiln having a cylindrical shell having an inner cylindrical surface and a longitudinal axis and a kiln lining disposed on the inner cylindrical surface of the shell. The kiln lining includes one or more radial portions of a first size of shaped refractory material disposed on the inner cylindrical surface of the shell along the longitudinal axis for at least a portion of the shell and one or more lifter sections comprising a second size of shaped refractory material that extend along the longitudinal axis for at least a portion of the shell and are between radial portions of the first size of shaped refractory material, wherein the second size of shaped refractory material is greater than the first size of shaped refractory material, such that the second size of shaped refractory material extends orthogonally from the inner cylindrical surface for a greater portion of the diameter of the shell than the first size of shaped refractory material, the second size of shaped refractory materials thereby forming a series of blunt faces. Also included are methods of processing materials using the inventive kiln lining, and methods of assembling the inventive kiln lining.

Owner:MAGNESITA REFRACTORIES

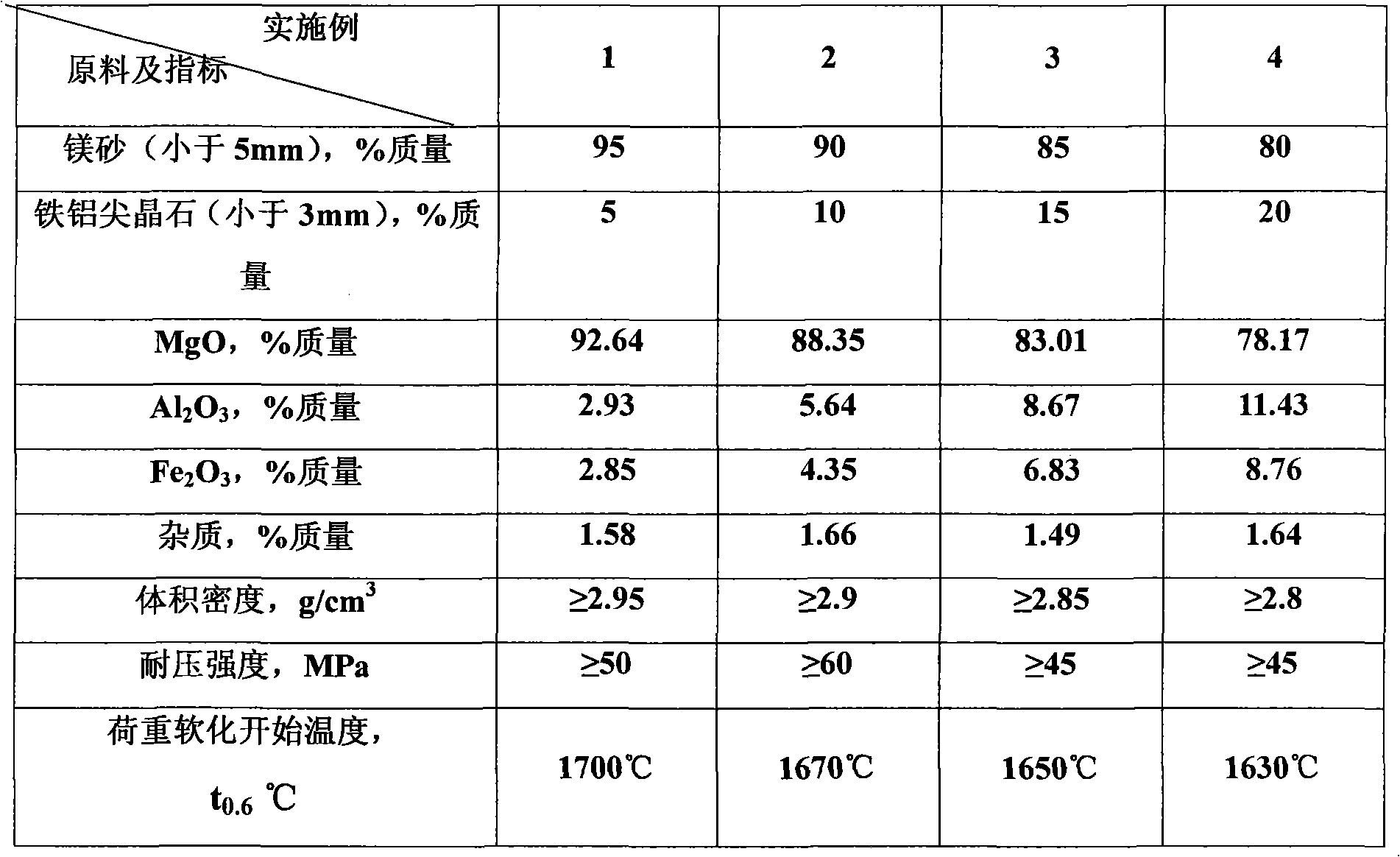

Magnesia-hercynite brick and preparation method thereof

InactiveCN101851105ASolve Cr

<sup>6+</sup>

pollution problemSolve pollutionRotary drum furnacesFurnace liningsBrickRefractory

The invention relates to a magnesia-hercynite brick and a preparation method thereof, belonging to the technical field of refractory materials. The magnesia-hercynite brick comprises the following chemical components in weight percent: 2.5 to 9.6% of Fe2O3, 2.9 to 12% of Al2O3 and 76-93% of MgO, the main crystalline phase displayed by XRD spectrum line is FeO.Al2O3. The preparation method comprises the steps of additionally adding a binding agent, carrying out compression moulding, drying, and baking at high temperature to obtain the magnesia-hercynite brick, which is simple and practicable. The magnesia-hercynite brick can be applied to the fields suitable to high temperature, in particular to clinkering zones of a novel rotary kiln utilizing a dry line method, thus solving the problem of Cr6 + pollution caused by the use of magnesite-chrome bricks in clinkering zones.

Owner:SHANDONG SHENGCHUAN CERAMICS +3

Highly zirconia-based refractory and melting furnace

InactiveUS20120036895A1Improve corrosion resistanceAvoid crackingGlass furnace apparatusGlass pressing apparatusRefractoryOff phenomenon

A highly zirconia-based refractory suitable for an electric melting furnace, which has a high electrical resistivity and does not exhibit a chipping off phenomenon and which is scarcely susceptible to extraction of components even when in contact with molten low alkali glass and, hence, is less susceptible to cracking during operation. The highly zirconia-based refractory that includes, as chemical components by mass %, from 85 to 95% of ZrO2 in terms of inner percentage, from 3.0 to 10% of SiO2 in terms of inner percentage, from 0.85 to 3.0% of Al2O3 in terms of inner percentage, substantially no Na2O, from 0.01 to 0.5% of K2O in terms of outer percentage, from 1.5 to 3.0% of SrO in terms of inner percentage, and from 0.1 to 2.0% of Nb2O5 and / or Ta2O5 as a value obtained by [(Nb2O5 content)+(Ta2O5 content / 1.66)], in terms of inner percentage.

Owner:ASAHI GLASS CO LTD

Method for producing alumina-based porous supports

InactiveUS6165936ALess varianceImprove catalytic performanceCatalyst carriersCharge supportsKilnPhysical property

An alumina-based porous support with uniform physical properties is obtained in a rapid sintering process. An alumina raw material including a raw alumina powder and an inorganic binder is molded into an article, and the article is then sintered for 5 to 8 hours at 1520 to 1560 DEG C. using a roller hearth kiln.

Owner:NORITAKE CO LTD

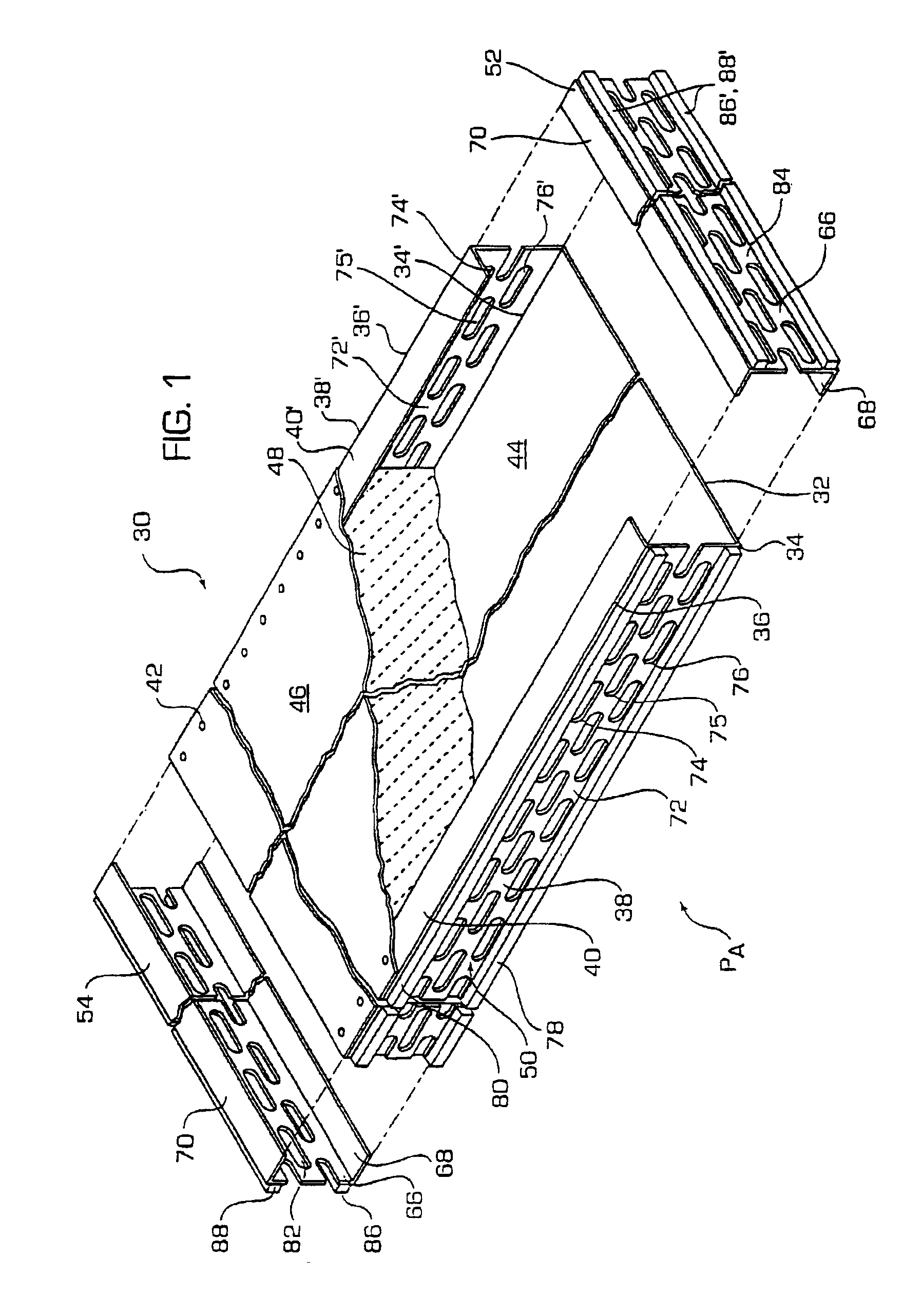

Heat shield arrangement for a hot-gas conducting component, in particular for structural pieces of gas turbines and method for production of said arrangement

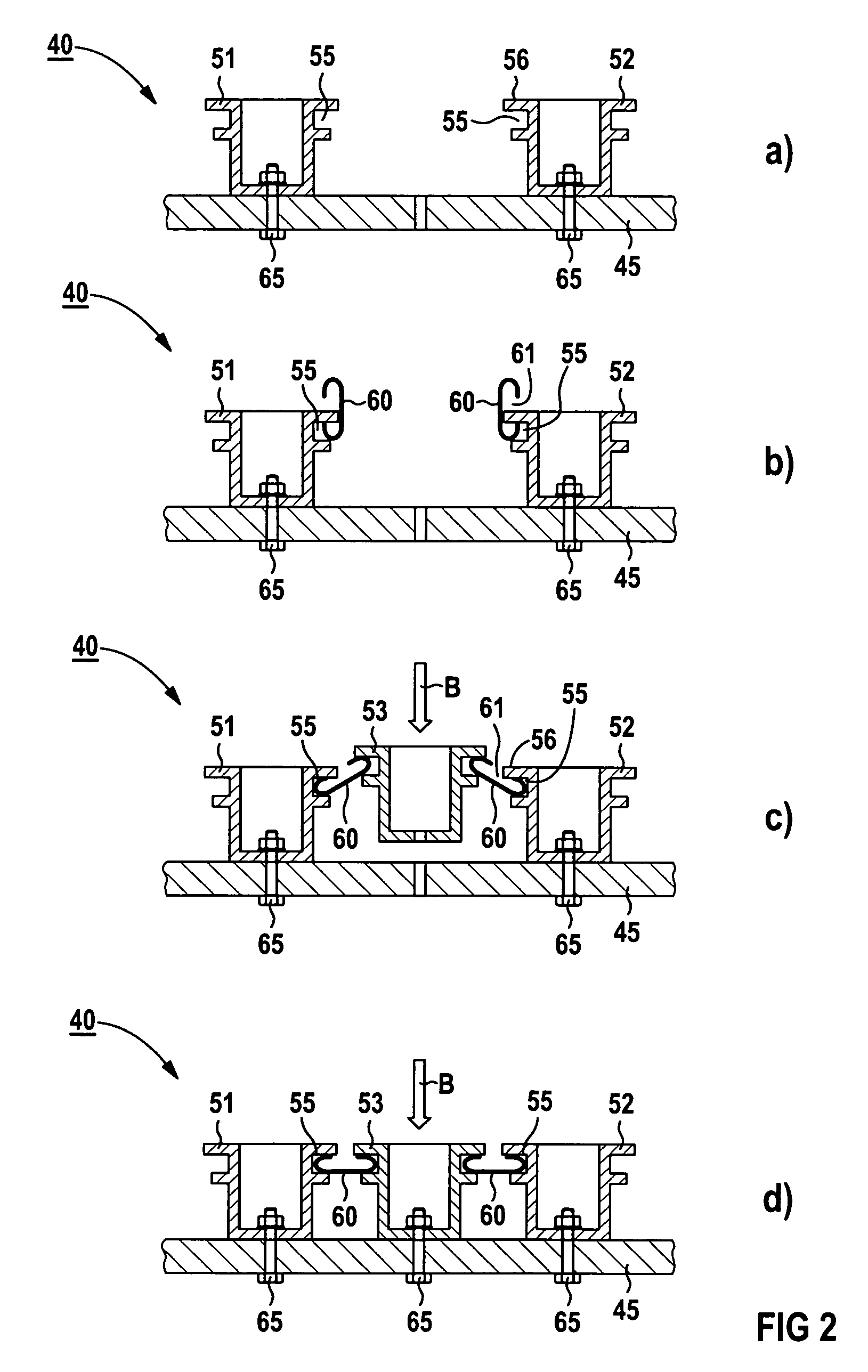

InactiveUS7021061B2Flexible applicationEasily and quickly producedContinuous combustion chamberEngine sealsCombustion chamberProduct gas

The invention relates to a heat shield arrangement for a hot gas conducting structure, in particular a metal component of a gas turbine unit or combustion chamber, with the heat shield elements anchored adjacently on a support structure to cover a surface. Said heat shield elements each comprise a lateral groove, arranged in the region of the edge of the surface thereof facing the hot gas, at least two adjacent shield elements are connected by at least one seal element mounted in the groove. The seal element is embodied as a sealing flap, which may be displaced from a first position to a second position and vice versa, whereby the first position is an open position without a sealing effect and the second position is a closed position with a sealing effect. According to said method the sealing flap is moved from the first to the second position by the movement of a heat shield element.

Owner:SIEMENS AG

Crack-resistant insulating dry refractory

Owner:ALLIED MINERAL PROD

Sintered product produced from a zircon-based charge

ActiveUS20110107796A1Improve the immunityGlass furnace apparatusFurnace liningsChemical compositionGlass furnace

The present invention relates to a sintered product elaborated from a starting charge containing 75-99% of zircon, in mass percentage based on the oxides and having the following average weight chemical composition, in mass percentages based on the oxides60%≦ZrO2≦72.8%,27%≦SiO2≦36%,0.1%≦B2O3+GeO2+P2O5+Sb2O3+Nb2O5+Ta2O5+V2O5,0.1%≦ZnO+PbO+CdO,B2O3+GeO2+P2O5+Sb2O3+Nb2O5+Ta2O5+V2O5+ZnO+PbO+CdO≦5%0% ≦Al2O3+TiO2+MgO+Fe2O3+NiO+MnO2+CoO+CuO≦5%,other oxides: ≦1.5%,for a total of 100%.Notably used in a glass furnace.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

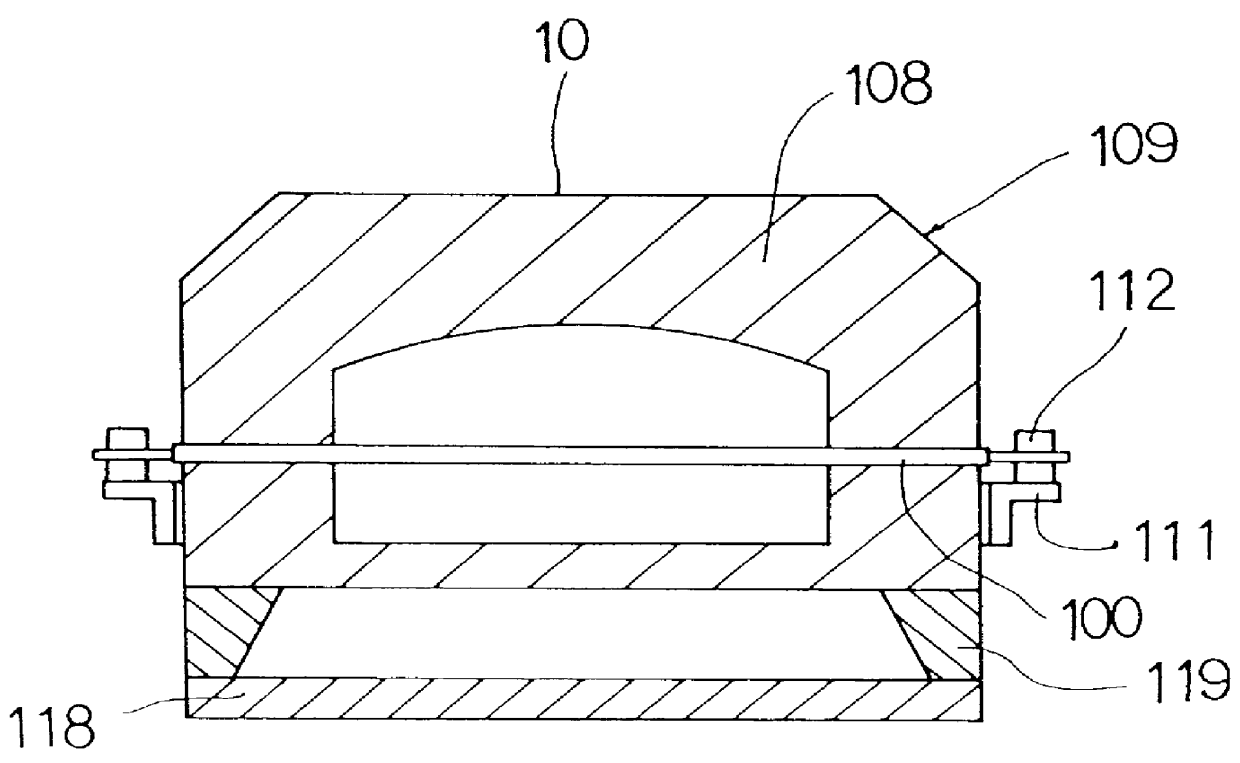

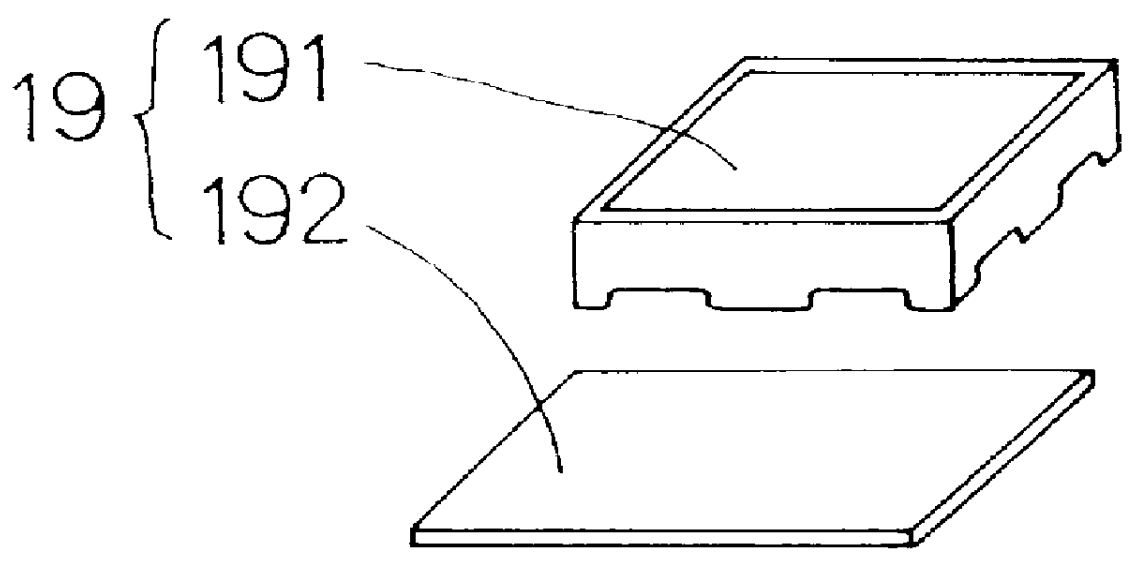

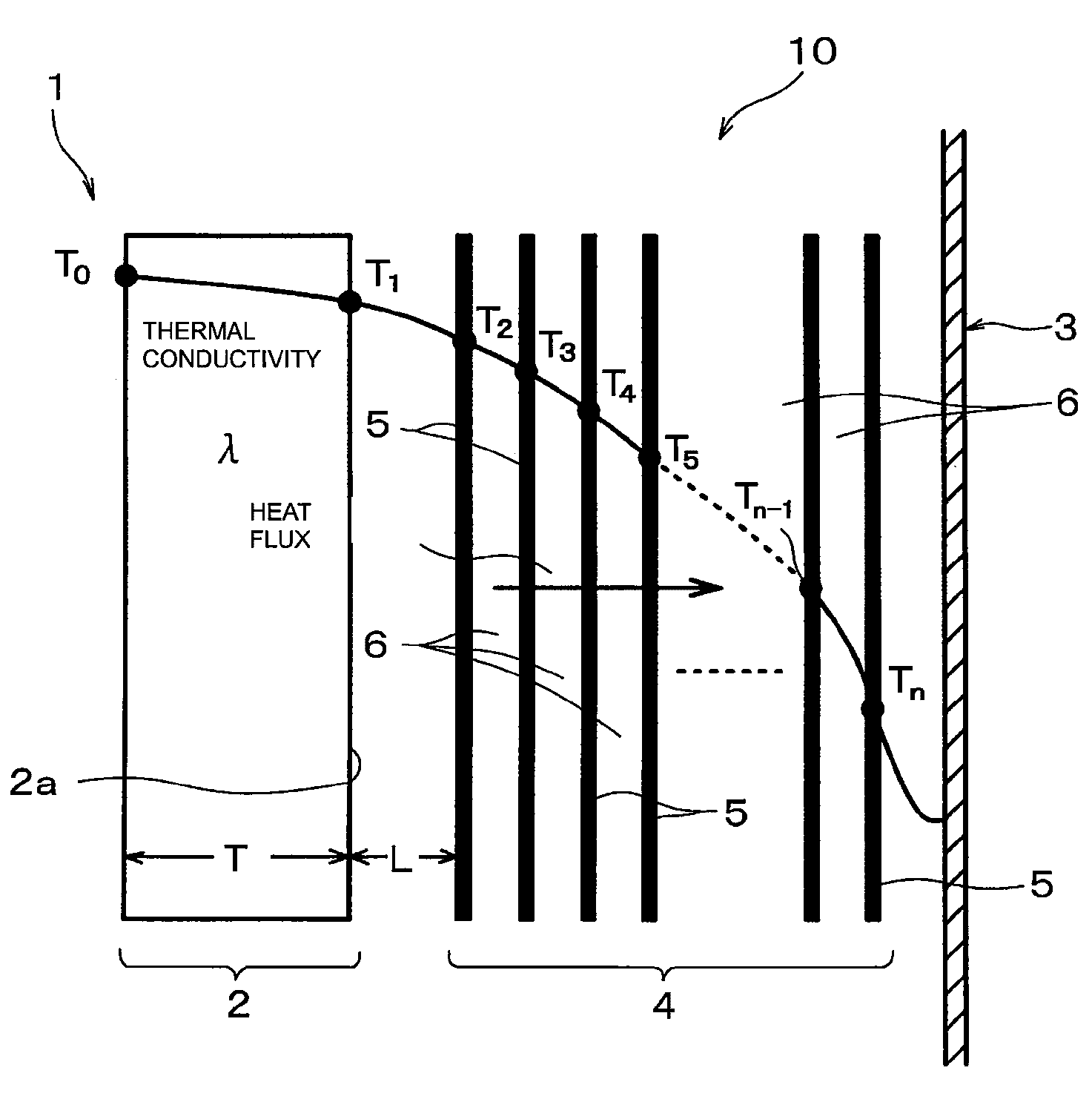

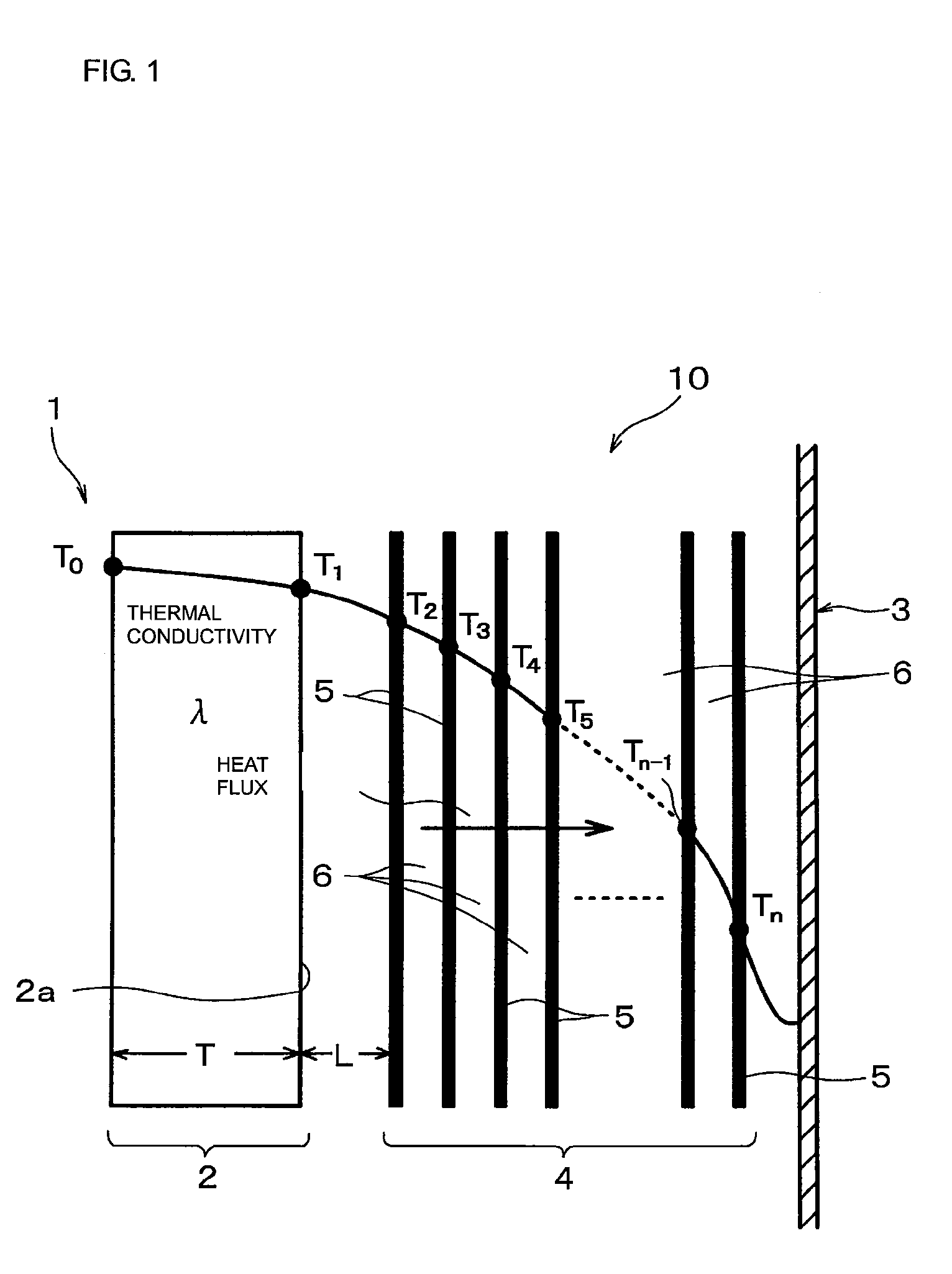

Heat-treating furnace

ActiveUS20090029307A1Avoid breakingEfficient preparationFurnace typesCeramic layered productsCeramic moldingComputer module

A heat treating furnace capable of continuously performing binder removal and subsequent firing without requiring a complicated configuration and increasing the equipment size and cost, for example, for degreasing a ceramic molding which is to be fired in a process for manufacturing a ceramic electronic component. A heat insulator is disposed to surround a heat treatment region in a case, and a reflector is disposed between the inner wall of the case and the insulator in order to reflect heat transferred from the heat treatment region through the heat insulator. A module heater including a heater embedded in the insulator is used. As the reflector, there is used a reflector having a structure in which a plurality of thin plates is arranged so that the main surfaces are arranged in parallel to each other with a predetermined space between the adjacent main surfaces.

Owner:MURATA MFG CO LTD

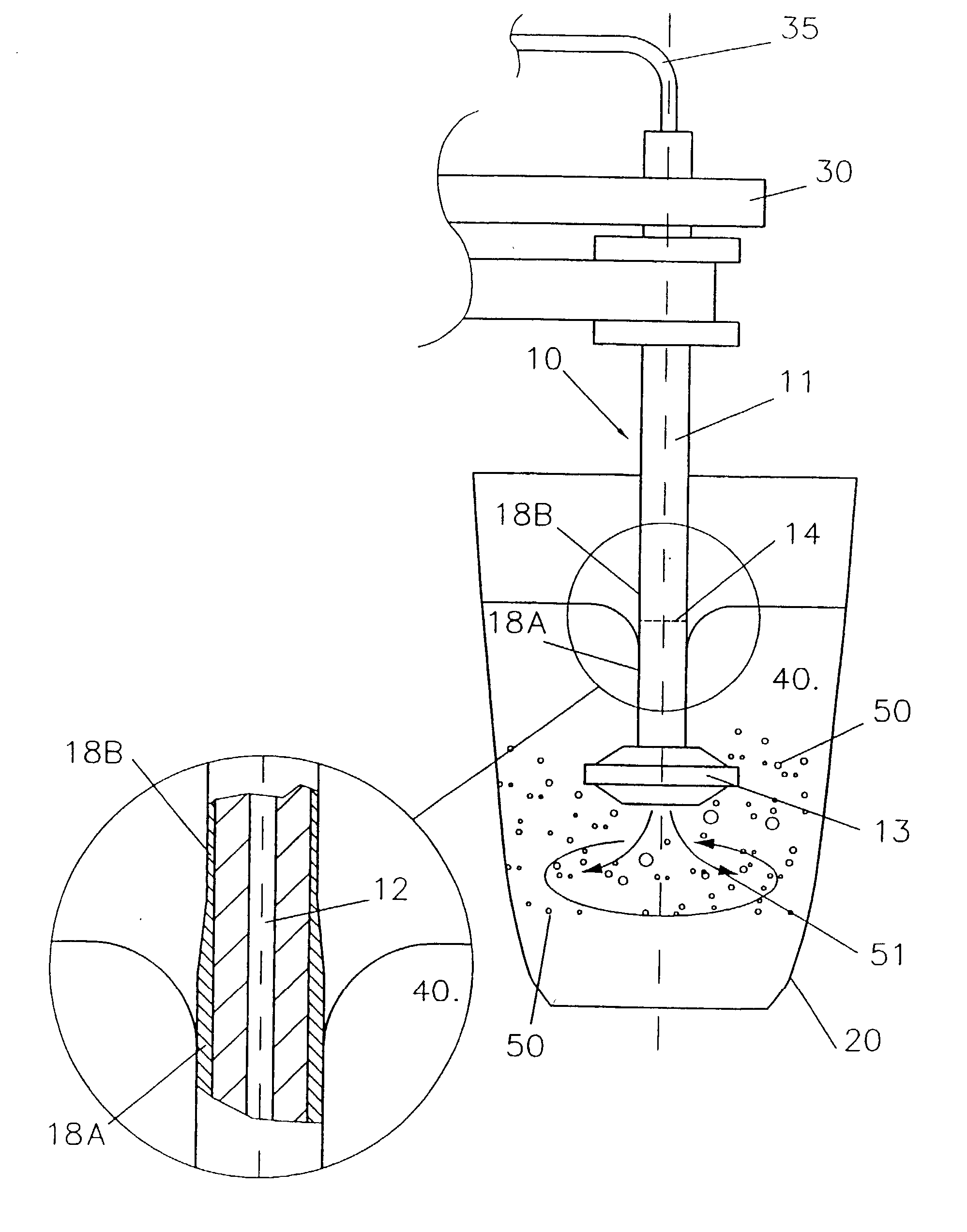

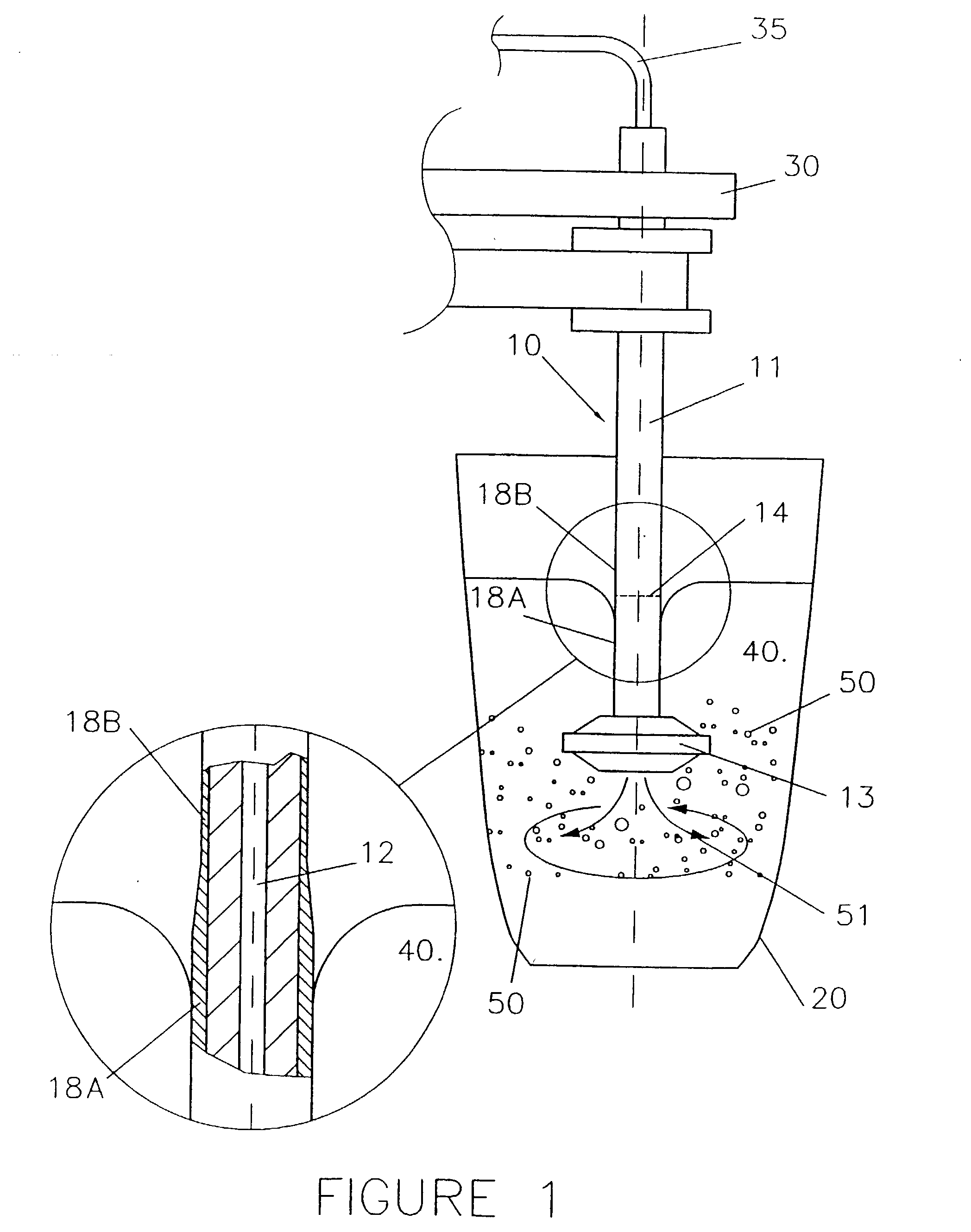

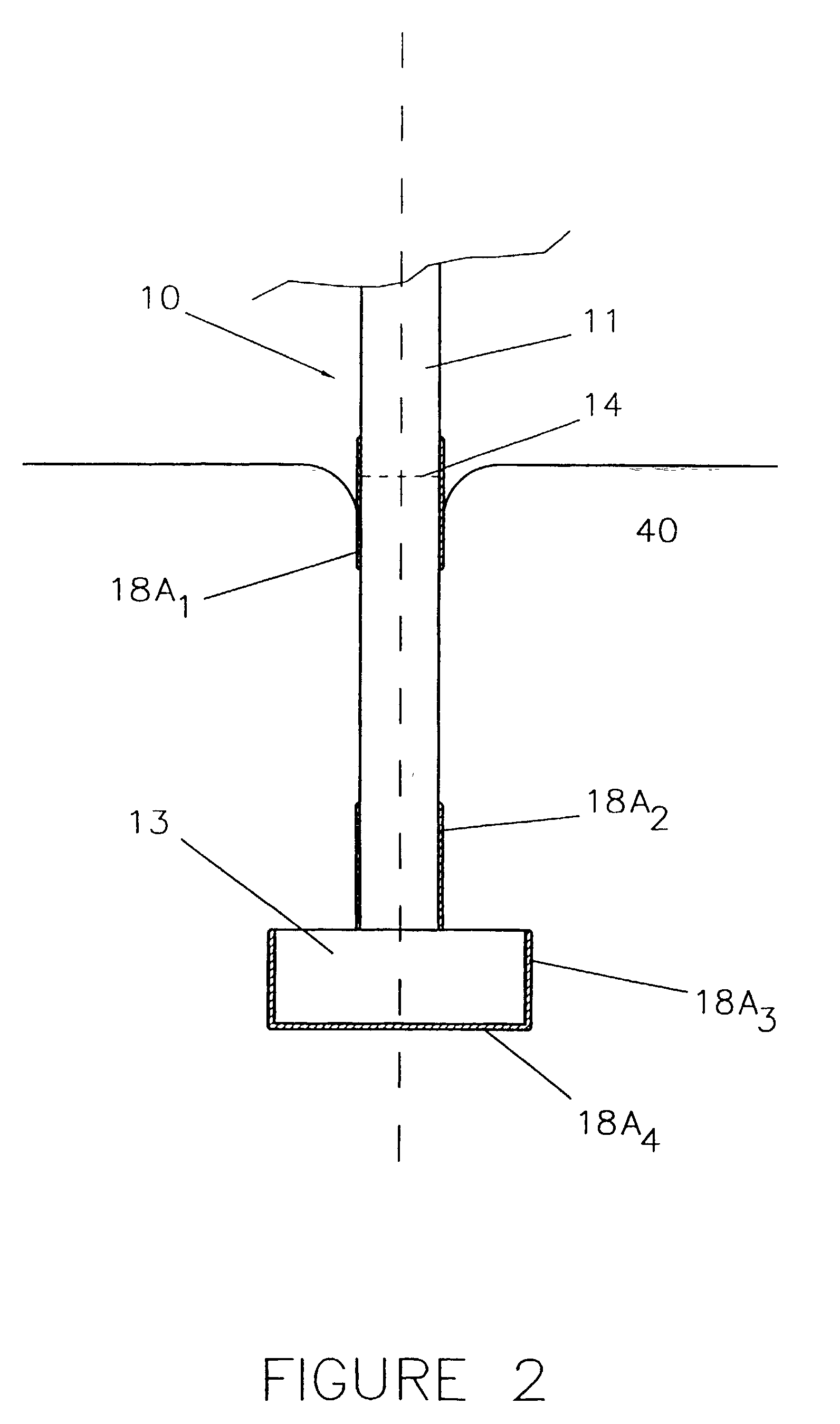

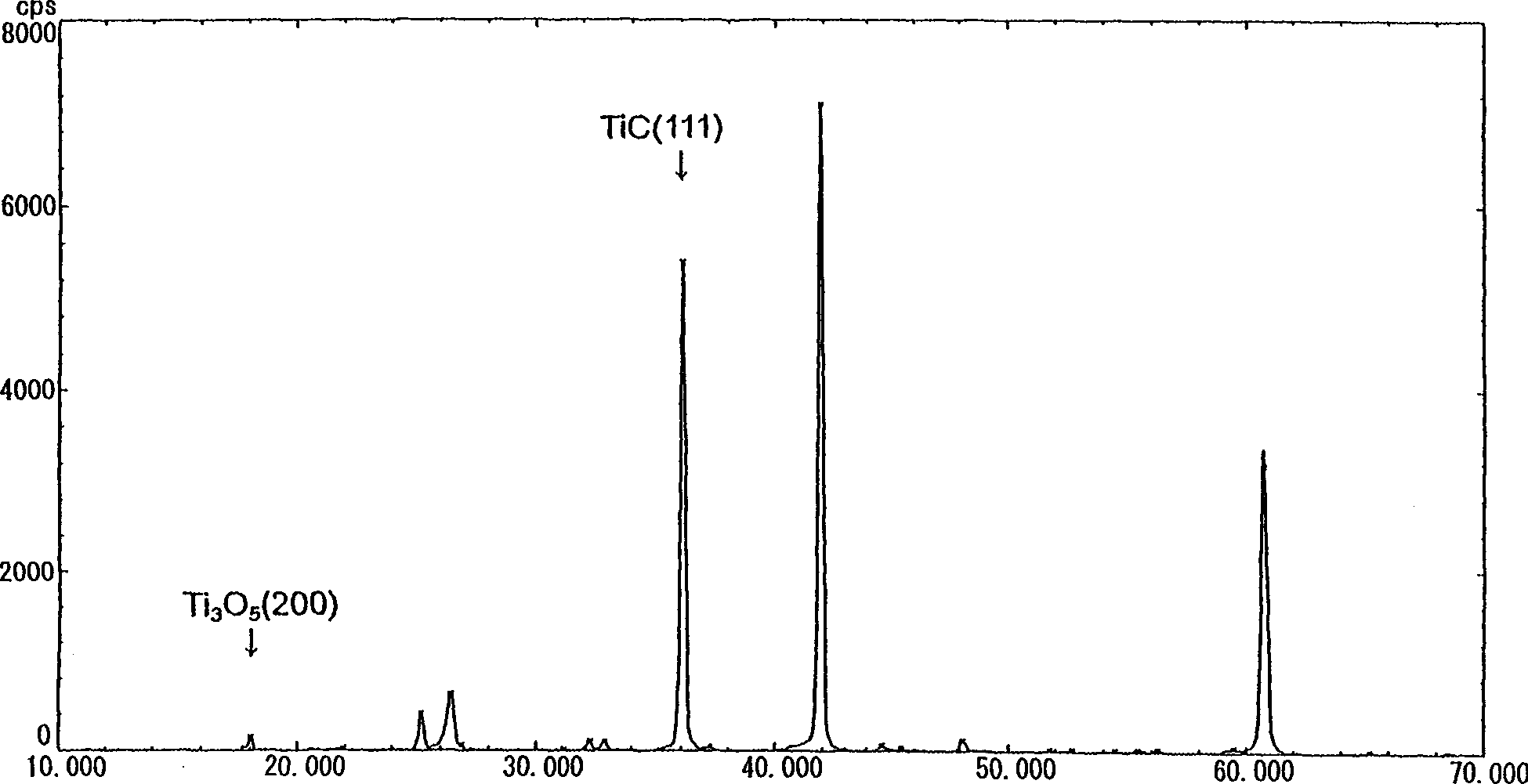

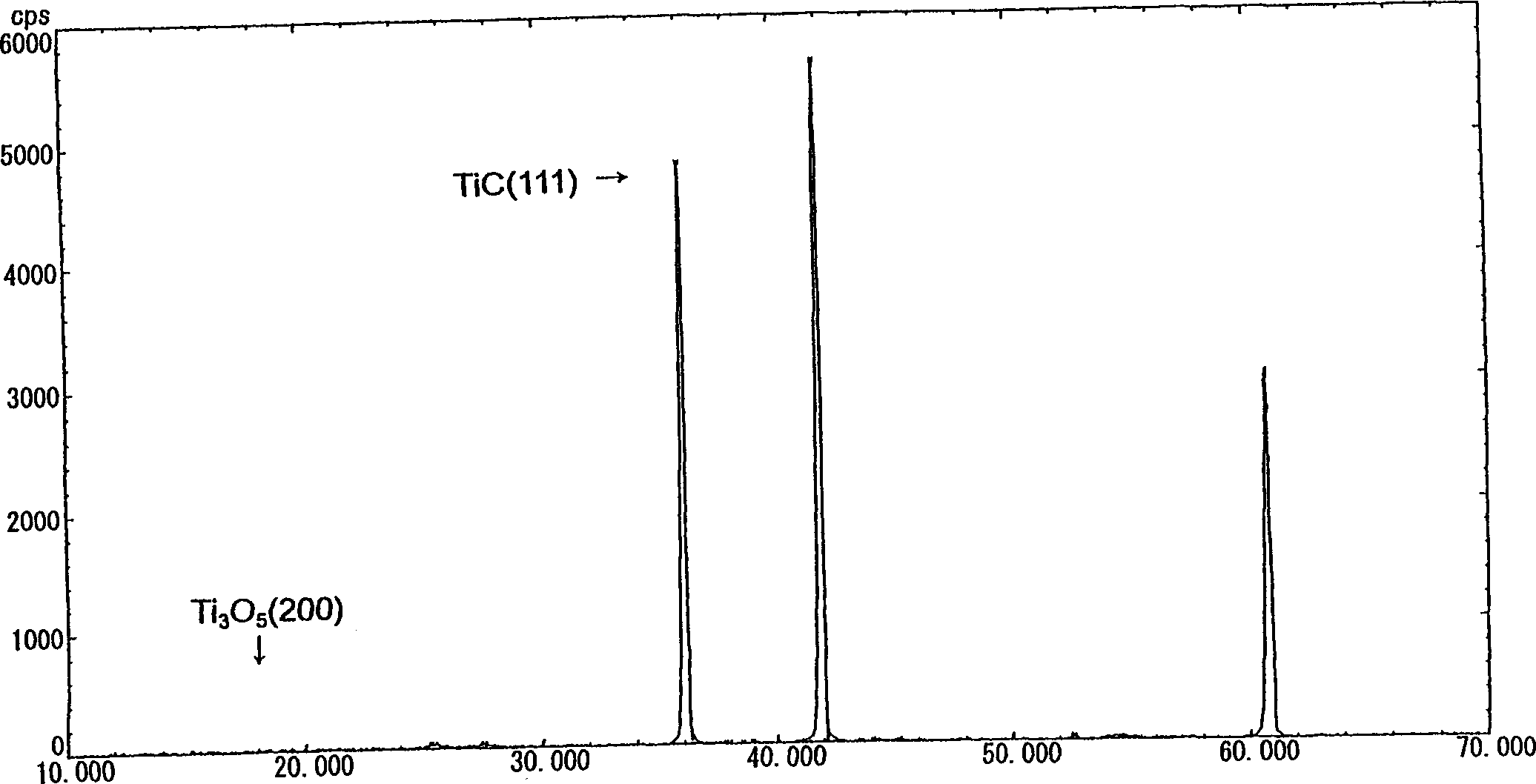

Protection coating of wear-exposed components used for refining molten metal

An apparatus for treating, in particular purifying or degassing, molten metal (40), comprising a component (10) exposable to molten metal to be treated and means (13) for imparting a rotary motion to the molten metal (40) about a substantially vertical axis. The apparatus is so arranged that during use at least part of a wear-exposed surface of the component (10) is temporarily or permanently in contact with molten metal (40), the contacting molten metal being in motion relative to the wear-exposed surface. The wear-exposed surface is coated with a slurry-applied protective coating (18A,18B) of refractory material in a heat stable binder, in particular an inorganic colloidal and / or polymeric binder, protecting the wear-exposed surface against erosion, oxidation and corrosion.

Owner:HOLZ K JAQUELINE +1

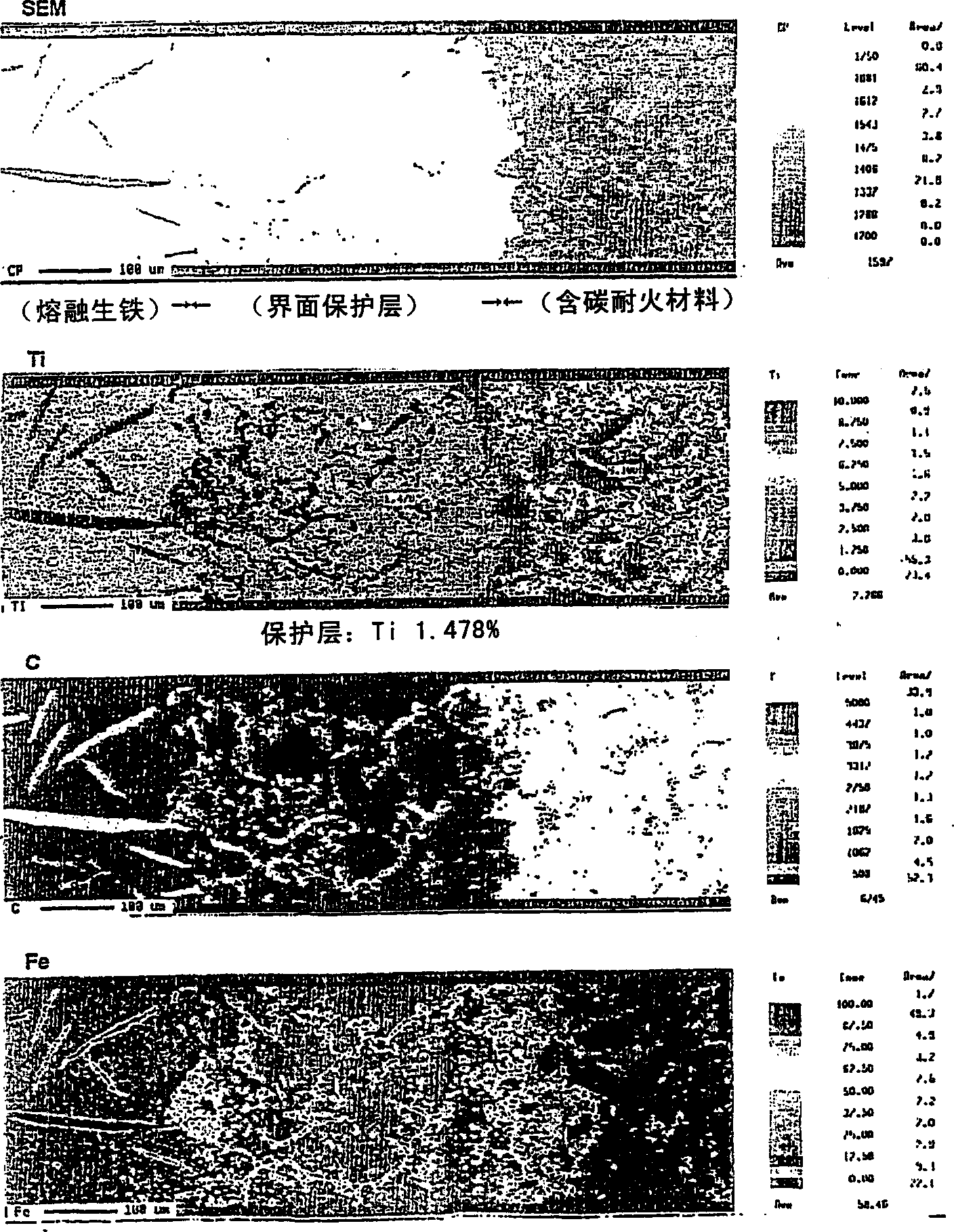

Carbonaceous refractory and method for preparing same

InactiveCN1366515AEasily wets molten ironImprove corrosion resistanceBlast furnace detailsCooling devicesTitanium nitrideCoke

Owner:NIPPON STEEL CORP +1

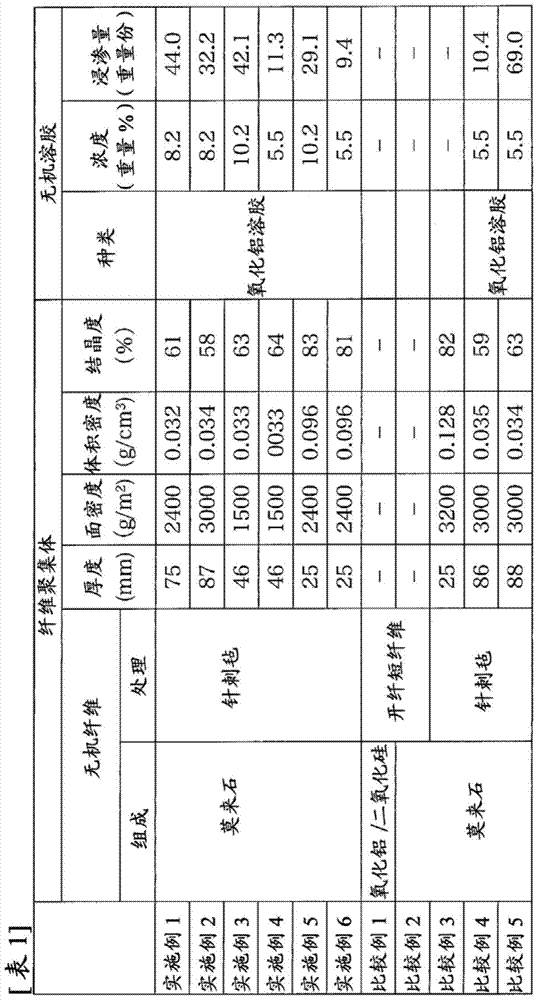

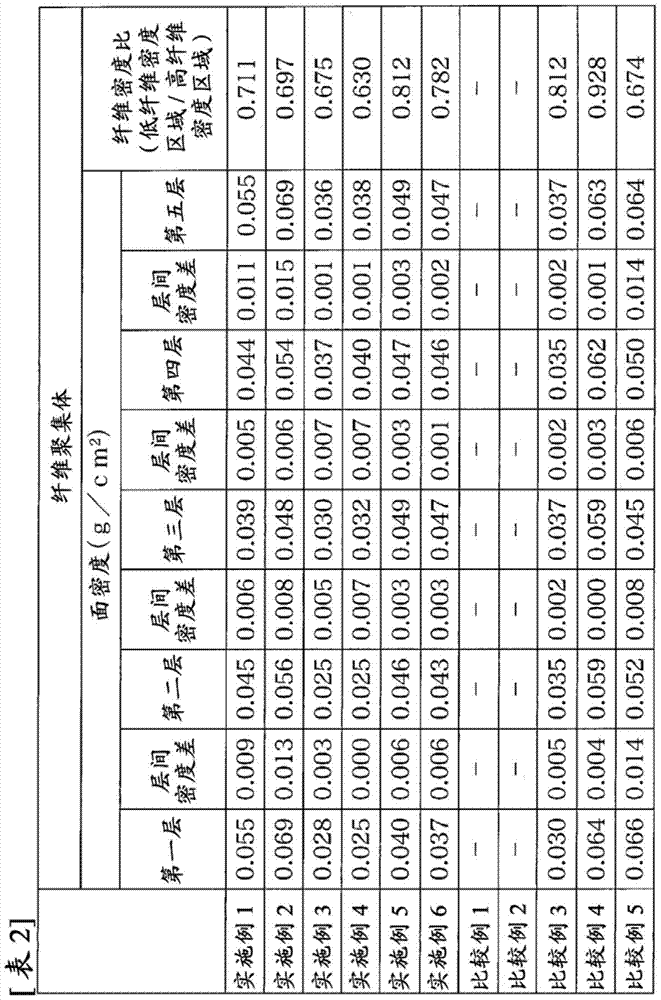

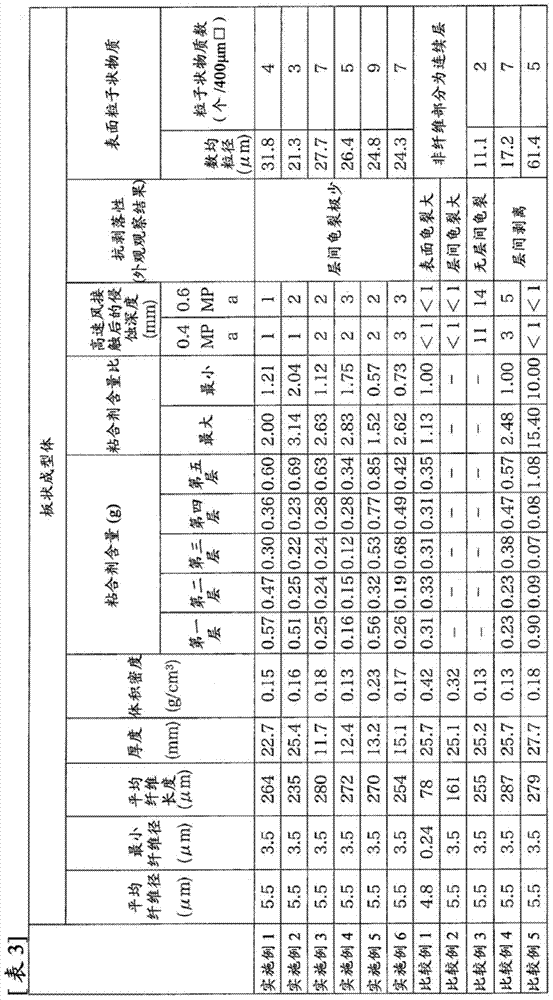

Molded inorganic-fiber object and process for producing same

ActiveCN103781954AImprove thermal shock resistanceExcellent balance of physical propertiesExhaust apparatusSilencing apparatusHazardous substanceShock resistance

Provided is a molded inorganic-fiber object which is characterized by being extremely lightweight, being reduced in flying of fibers or a particulate substance from the surface thereof, and being free from problems concerning environmental pollution, such as generation of a harmful substance. The molded object is excellent in terms of thermal shock resistance and mechanical shock resistance and of resistance to high-speed wind erosion, has an excellent balance among material properties, and can be used in various heat insulator applications. The molded inorganic-fiber object comprises inorganic fibers and inorganic binder particles and has at least a pair of regions, a high-fiber-density region and a low-fiber-density region, wherein the ratio of the content of the binder particles in the high-fiber-density region to the content thereof in the low-fiber-density region, as determined by a given method, is 0.5:1 to 5:1 and the inorganic binder particles in the outermost surface of the molded object have a number-average particle diameter, as determined by a given method, of 20-35 [mu]m, the number of the inorganic binder particles therein being less than 15.

Owner:MAFTEC CO LTD

Alkali resistant silica refractory

InactiveUS6313057B1Prevent degradationWear is exacerbatedGlass furnace apparatusCrucible furnacesBrickGlass furnace

A fused silica refractory material made from quartz grains and a method of making the material which contains calcium oxide binder in an amount less than one weight percent. The reduction in calcium oxide binder prevents the degradation of fused silica refractory bricks in furnace environments containing alkali vapors, such as in oxygen-fuel fired glass furnaces. The invention also includes a method of preventing the degradation of silica refractory material by alkalis.

Owner:GMIC HLDG

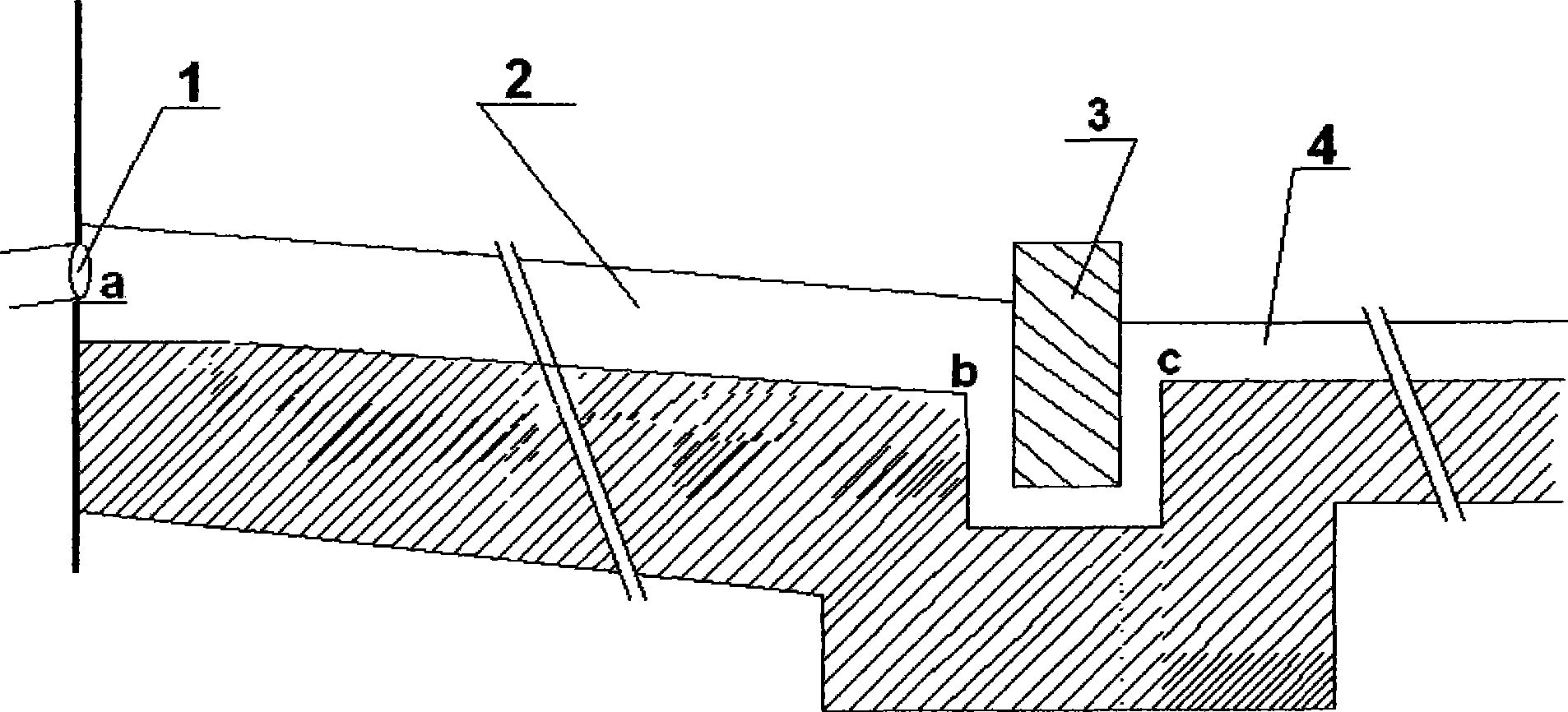

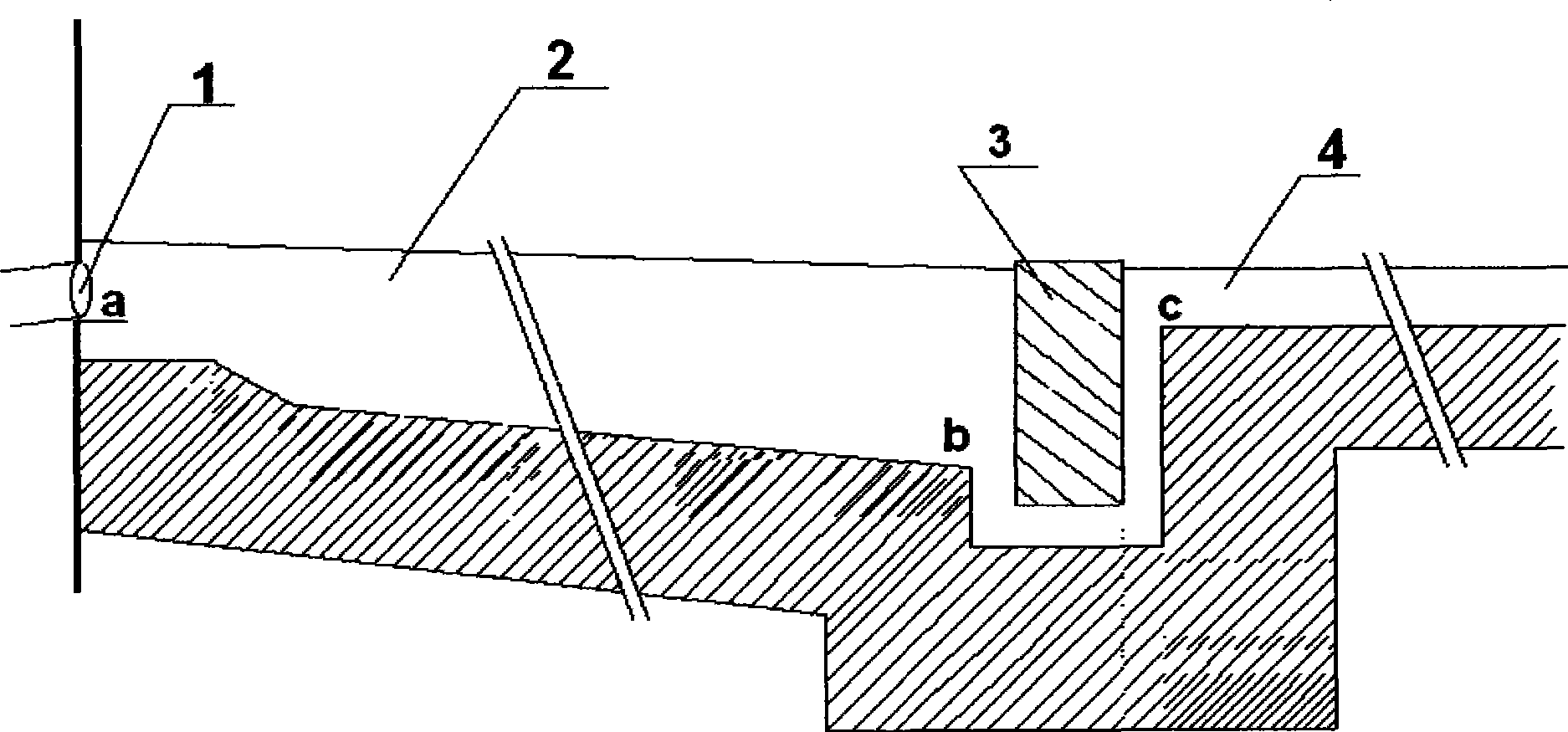

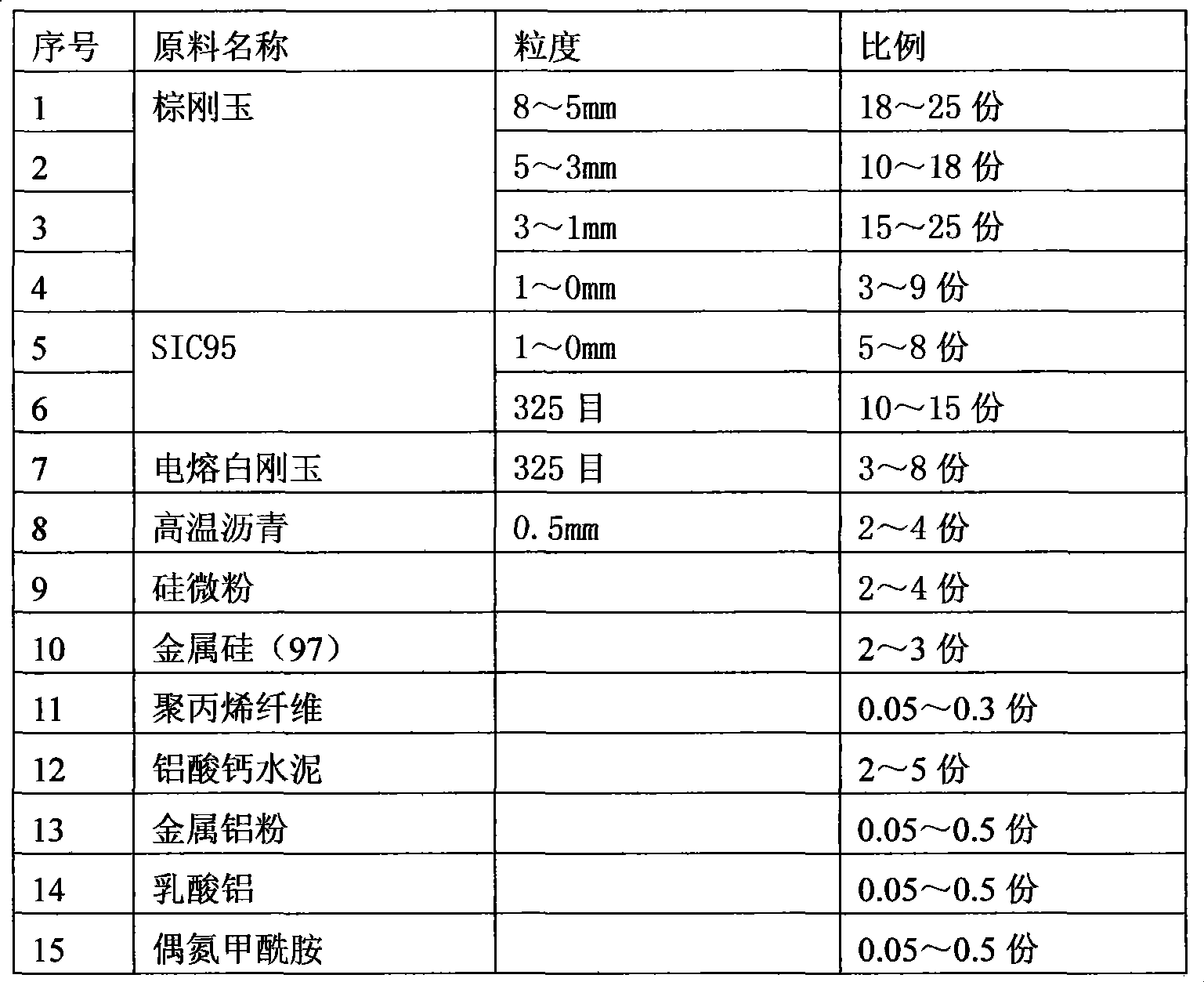

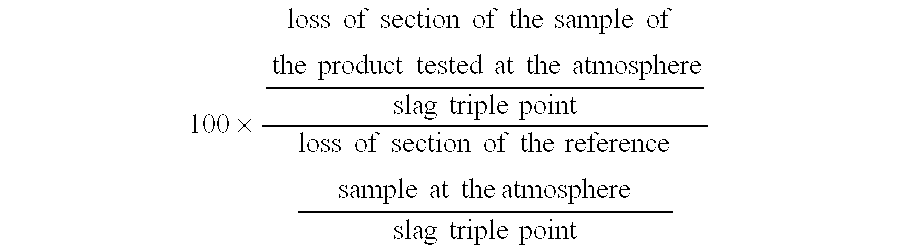

Single taphole blast furnace tapping channel iron storing type improving technology

InactiveCN101497930AImprove buffering effectExtend your lifeBlast furnace detailsDischarge devicesSlagRefractory

The invention relates to a technical proposal in which the tapping runner of a single taphole blast furnace is transformed into an iron-storage iron runner to enable the iron runner to have long service life. The invention uses the method of elevating the taphole elevation of a skimmer and lowering a main runner, so that more hot metal is always stored in the main tapping runner, thereby buffering the impact of hot metal on the runner bottom and improving the application environment of refractory of the main runner. The invention solves the problem of the explosion-proof performance of runner iron castable, thus achieving the purpose that the tapping runner of the single taphole blast furnace uses refractory castable to substitute the traditional ramming material. Both the surface and the inner side of the runner lining made of castable are compact, so the problem that the surface of the ramming material is compact and the inner side is loose does not occur, so that the service life of the iron runner can be substantially prolonged, and the consumption of iron runner material of iron yield per unit is also reduced, which not only improves the economic benefits, but also has the advantages of resource conservation and waste slag reduction, and substantially reduces the labor intensity of the maintenance work of furnacemen.

Owner:北京联合荣大工程材料股份有限公司

Powder for dry refractory material

InactiveUS20120309608A1Improve thermal shock resistanceImprove the immunityFurnace liningsOxideChemical composition

The invention relates to a powder comprising more than 70% of refractory particles, in weight percent relative to the weight of the powder, a particle of said powder being classed in the fraction called “matrix” or in the fraction called “aggregate”, according to whether it is smaller than, or equal to 100 μm, or larger than 100 μm, respectively, said powder comprising, in weight percent relative to the weight of the powder: between 0.1% and 18% of particles of a heat-activatable binder, called “heat-activatable binder particles”; and more than 40% of refractory particles, called “ATZ particles”, having the following chemical composition, in weight percentages on the basis of the oxides of said ATZ particles: 10%≦Al2O3≦55%; 35%≦TiO2≦80%; 1%≦MgO+Cr2O3≦10%; 8%≦ZrO2≦20%; SiO2≦8%.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Gasifier reactor internal coating

ActiveUS20090011920A1Improve the immunityEasy to optimizeGasifier mechanical detailsFurnace liningsMetallurgyMaterials science

A gasifier comprising an interior wall on which a layer is applied or an interior wall protected by an assembly of blocks, said layer or said blocks having at least one region of a sintered material containing:i) at least 25% by weight of chromium oxide Cr2O3; andii) at least 1% by weight of zirconium oxide, wherein at least 20% by weight of said zirconium oxide ZrO2 is stabilized in the cubic and / or quadratic form.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Highly zirconia-based refractory and melting furnace

InactiveUS8268742B2Improve corrosion resistanceAvoid crackingGlass furnace apparatusGlass pressing apparatusRefractoryOff phenomenon

Owner:AGC INC

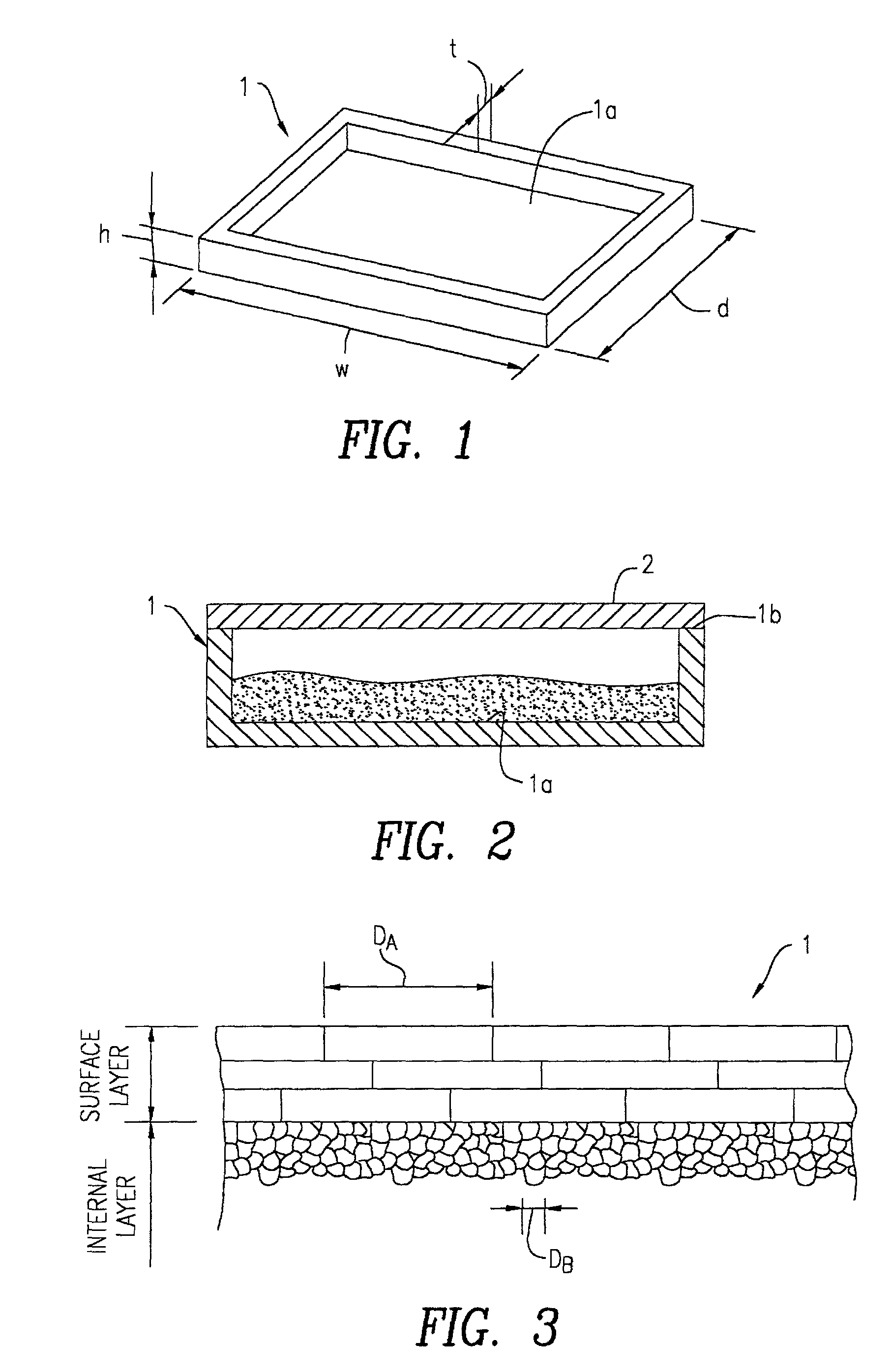

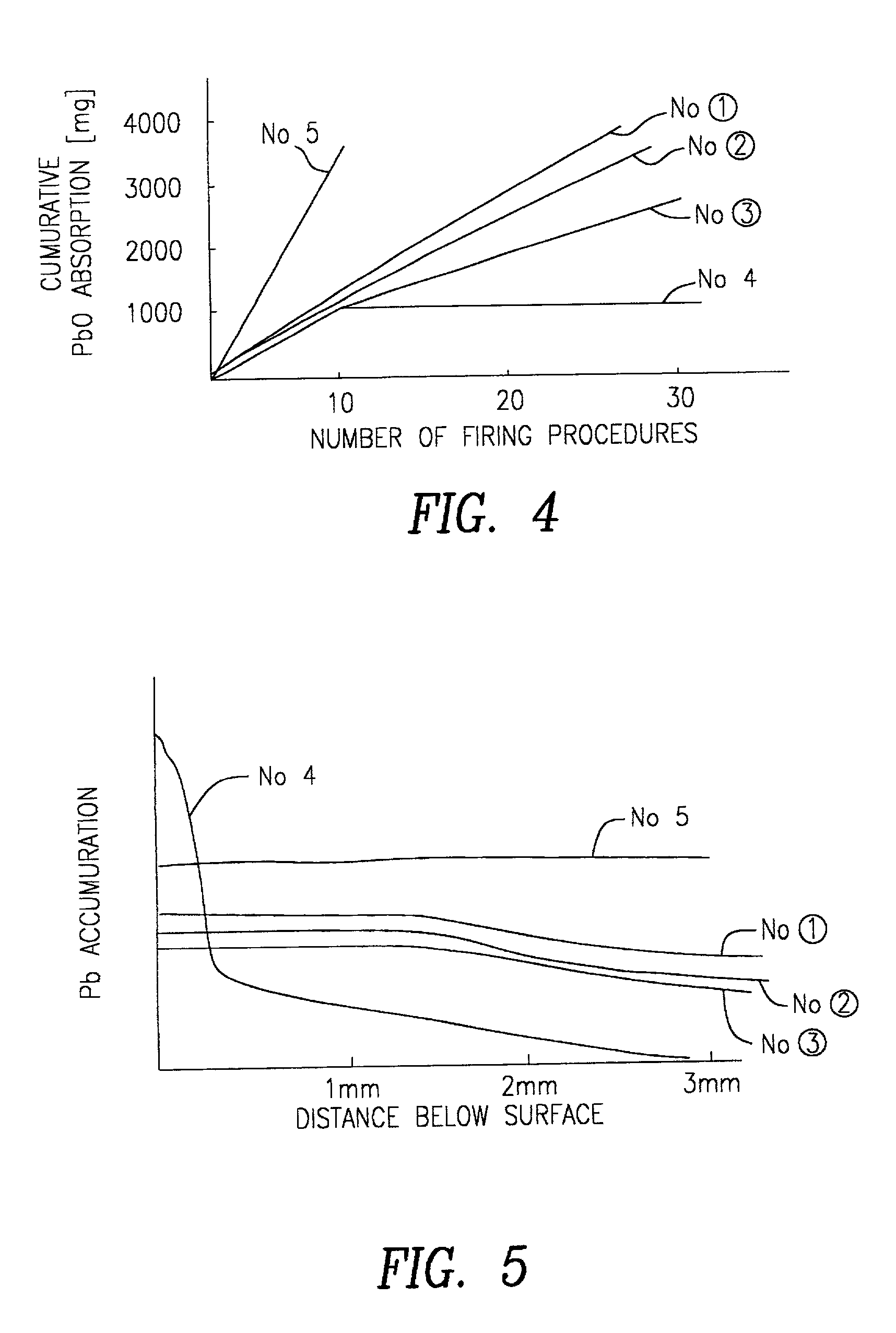

Alumina sintered compact and method of producing the same, and article for heat treatment using alumina sintered compact

InactiveUS20010044371A1Avoid accumulationControlled absorptionRecord information storageCeramic layered productsSurface layerTreatment use

An alumina sintered compact includes at least two layers including an internal layer and a surface layer formed on the surface of the internal layer, which internal layer is composed of alumina crystal grains formed by sintering of a fine alumina powder, and which surface layer is composed of alumina crystal grains formed by grain growth of a fine alumina powder and having a mean grain size larger than that of the alumina crystal grains of the internal layer. This alumina sintered compact can prevent the accumulation of PbO in a surface area while controlling the absorption of PbO.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com