Molded inorganic-fiber object and process for producing same

一种无机纤维、成型体的技术,应用在制造工具、陶瓷成型机、非织造布等方向,能够解决载重弱、纤维飞散、堆积粒子状物质等问题,达到耐高速风蚀性优异、抗机械冲击性优异、物性平衡优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] [Preparation of spinning solution]

[0092] Basic Aluminum Chloride: Al(OH) 3-x Cl x For example, it can be prepared by dissolving metallic aluminum in aqueous hydrochloric acid or aluminum chloride. The value of x in the above chemical formula is usually 0.45 to 0.54, preferably 0.5 to 0.53. As the silicon compound, silica sol is preferably used, and a water-soluble silicon compound such as tetraethyl silicate or a water-soluble siloxane derivative may also be used. As the organic polymer, for example, water-soluble polymer compounds such as polyvinyl alcohol, polyethylene glycol, and polyacrylamide are preferably used. Their degree of polymerization is usually 1000-3000.

[0093] For the spinning solution, the ratio of aluminum derived from basic aluminum chloride to silicon derived from the silicon compound is preferably expressed in terms of Al 2 o 3 and SiO 2 The mass ratio of aluminum is usually 99:1-65:35, preferably 99:1-70:30, the concentration of alumin...

Embodiment 1 and 2

[0152] An aqueous basic aluminum chloride solution having an aluminum concentration of 170 g / L and an Al / Cl (atomic ratio) of 1.8 was prepared. The aluminum content was quantified by chelate titration using EDTA. Next, silica sol and polyvinyl alcohol were added to the above aqueous solution, and then concentrated to obtain the ratio of aluminum to silicon (Al 2 o 3 and SiO 2 weight ratio) is 72:28, the total mass concentration of alumina and silica converted into oxide mass is about 30% by mass, and the viscosity is 40 poise (measured value using a rotational viscometer at 25°C). silk liquid. The spinning solution was spun by the blowing method, and then bundled to obtain a mat-shaped fiber aggregate of an alumina / silica-based fiber precursor. After needle-punching the mat-like fiber aggregate, it was fired at 1200°C to obtain a polycrystalline alumina / silica-based fiber aggregate (hereinafter, sometimes referred to as " Original cloth"). In addition, the above-mentione...

Embodiment 3~6

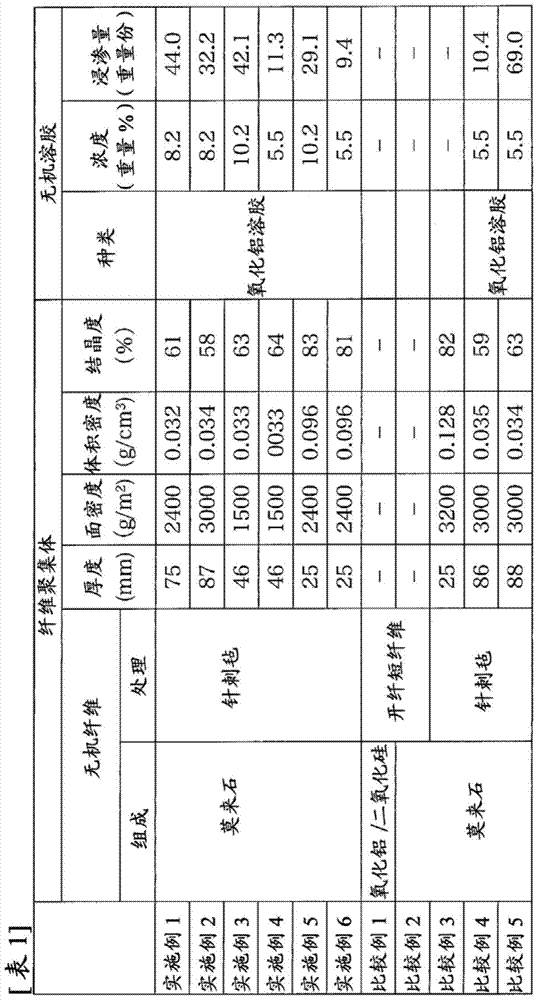

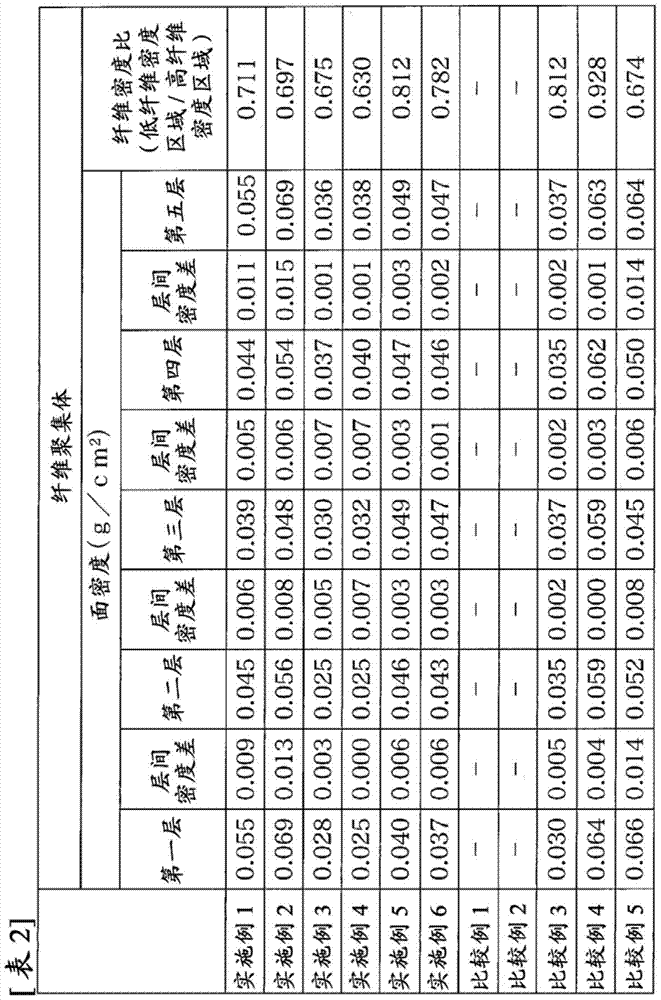

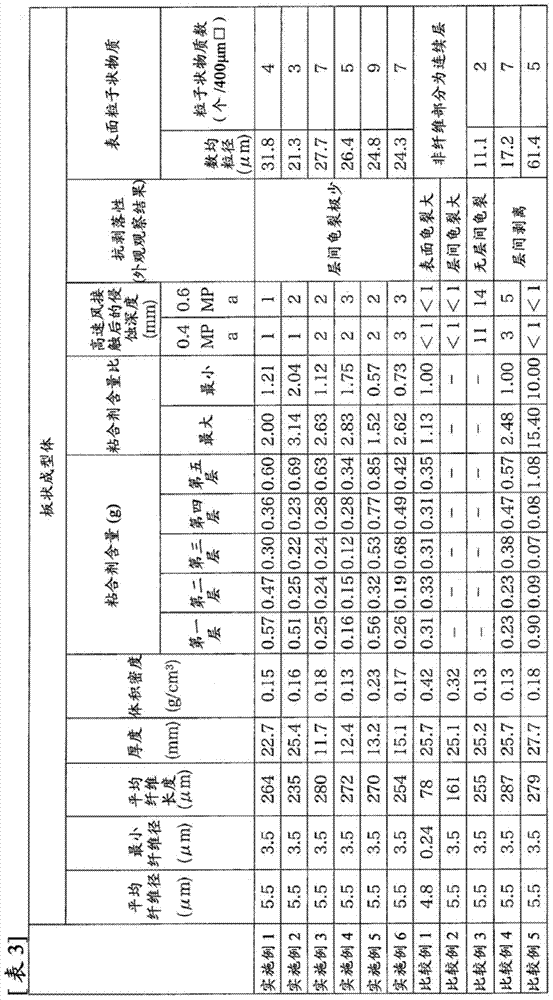

[0163] In Example 1, except that the original fabric was not laminated, and a single layer with the thickness, surface density, and bulk density shown in Table 1 was used, the same operation was performed as in Example 1, and the plate-shaped inorganic fiber molding shown in Table 3 was obtained. body. The compression height was divided into 5 equal parts for the first layer to the fifth layer. The surface density of each layer obtained, the density difference between the layers, and the fiber density ratio (low fiber density area / high fiber density area) are as follows: Table 2 shows. In Embodiment 3 and Embodiment 4, the first layer, the second layer and the third layer are low fiber density regions, and the fourth layer and fifth layer are high fiber density regions. Furthermore, in Example 5 and Example 6, the first layer is a low fiber density region, and the second to fifth layers are high density fiber regions. Table 3 shows the evaluation results of the obtained plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com