Magnesia-hercynite brick and preparation method thereof

A technology of magnesium-iron-aluminum spinel and iron-aluminum spinel, which is applied in the field of magnesium-iron-aluminum spinel bricks and its preparation, can solve the problems of large volume effect, unfavorable volume stability, etc., and achieve the effect of solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

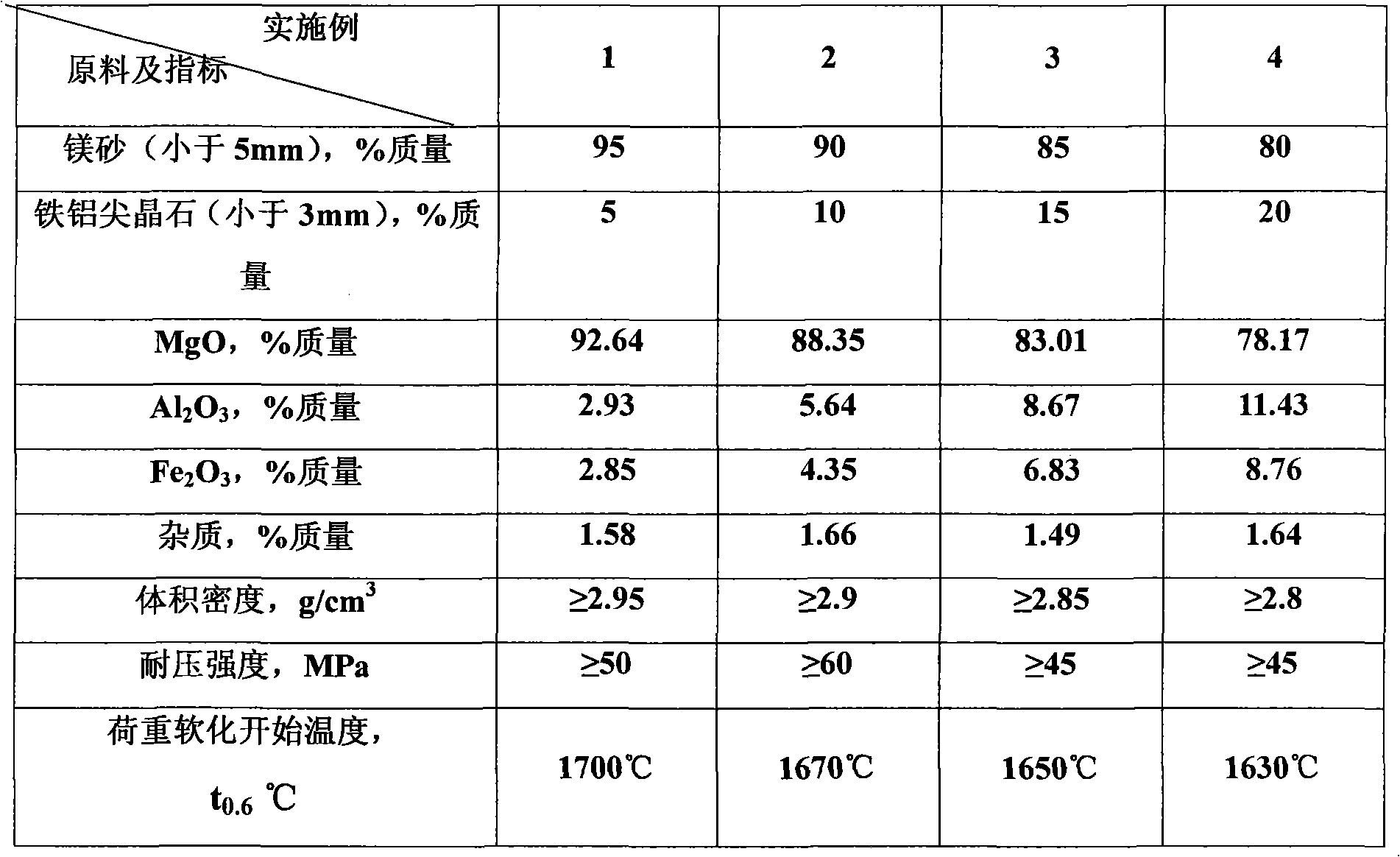

[0022] Add magnesia and pre-synthesized ferrous aluminum spinel into the mixer according to the proportion of chemical composition, and then add 2-4% of the above mixture as a binder, the binder is dextrin, pulp waste liquid, starch , methyl cellulose, resin or any combination of several, after mixing evenly, press on a 600-1200 ton press to form. After drying at 110°C, it is fired in a high-temperature kiln at 1400-1700°C to obtain chromium-free magnesium-iron-aluminum spinel bricks. The brick can be directly used in the firing zone of the cement rotary kiln.

[0023] Embodiment and product performance index situation are shown in Table 1. Among them, the maximum particle size of magnesia is 5mm; the maximum particle size of iron-aluminum spinel is 3mm. The chemical weight composition of the product is Fe 2 o 3 2.5-9.6%, Al 2 o 3 2.9-12%, MgO 76-93%.

[0024] Table 1, embodiment and product performance index situation table

[0025]

[0026] Among the four exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com