Patents

Literature

107 results about "Hercynite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

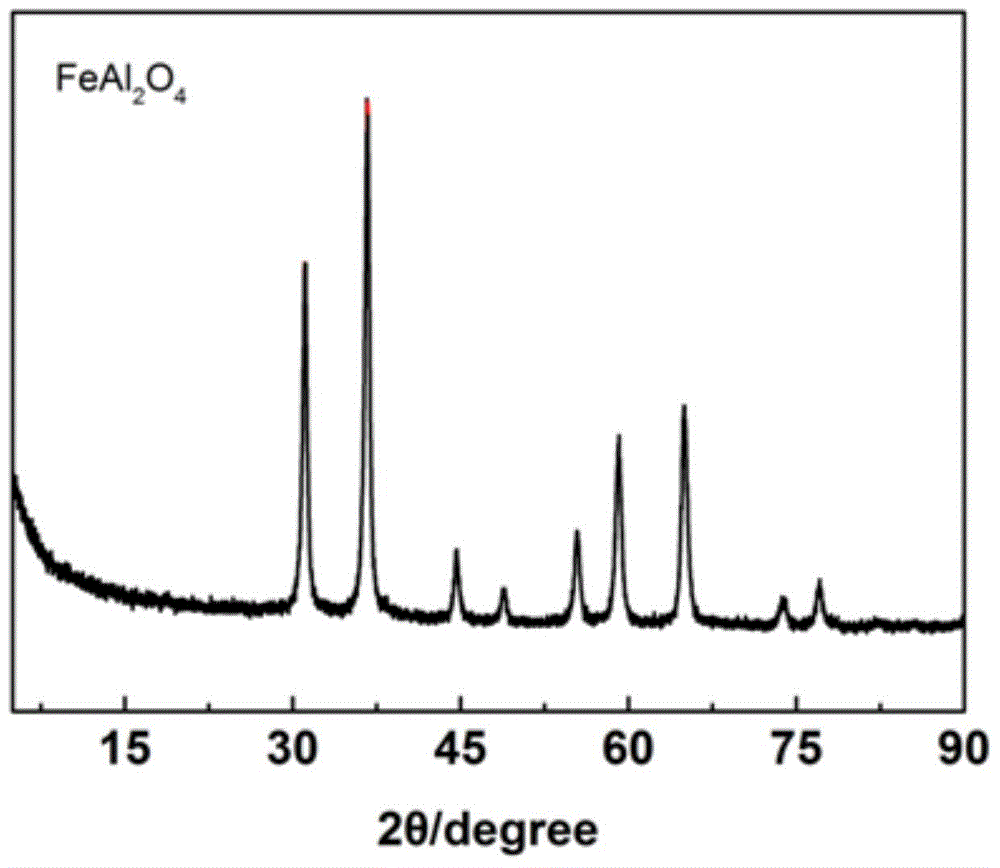

Hercynite is a spinel mineral with the formula FeAl₂O₄. It occurs in high-grade metamorphosed iron rich argillaceous sediments as well as in mafic and ultramafic igneous rocks. Due to its hardness it also is found in placers.

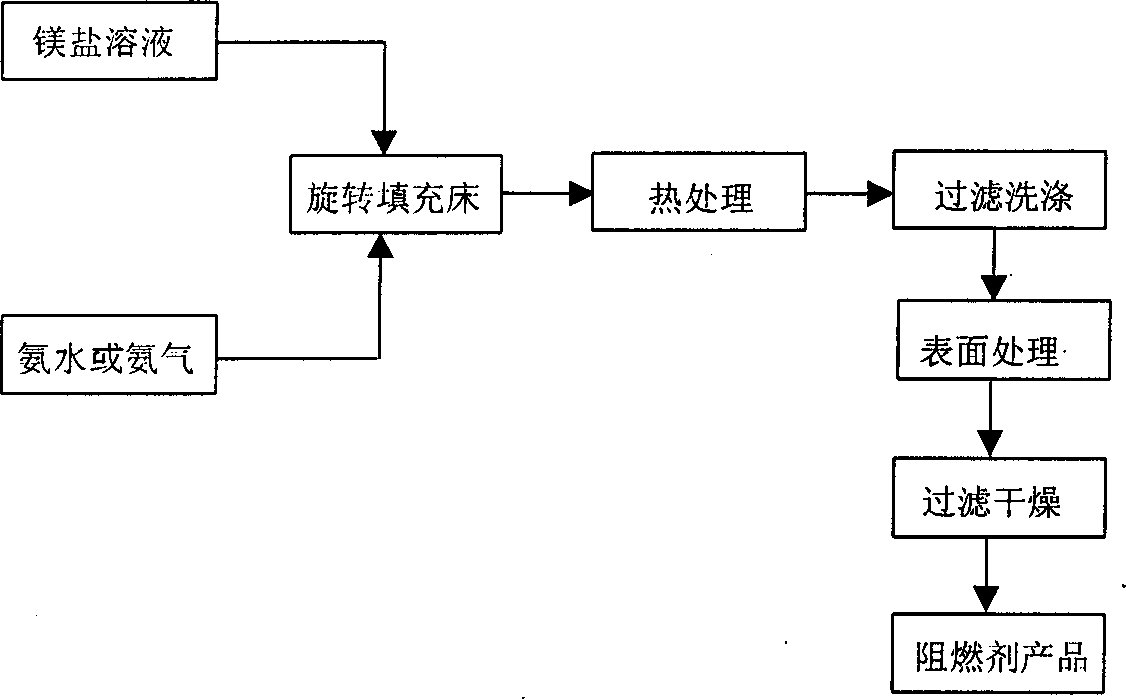

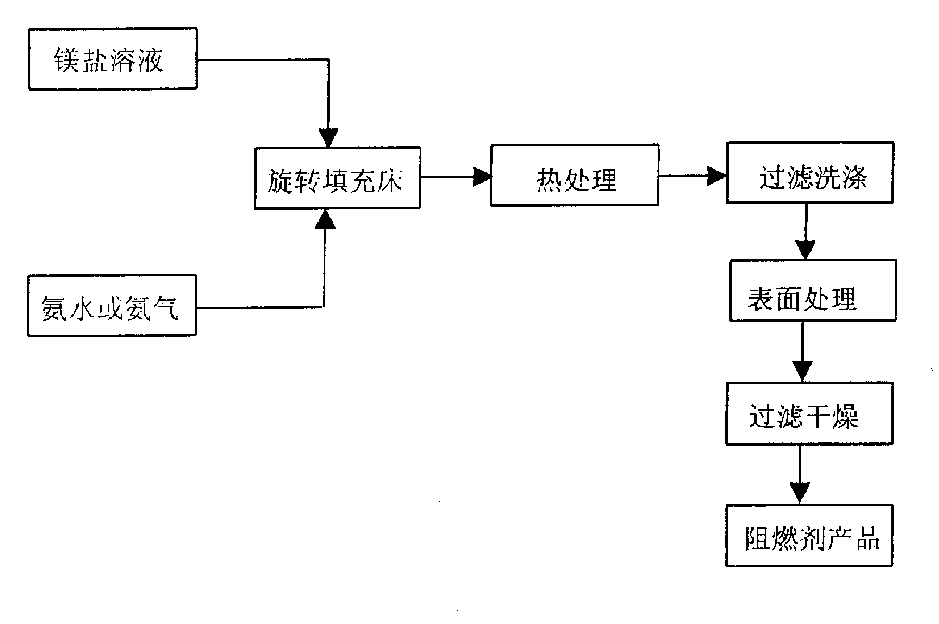

Preparation process of magnesium hydroxide fire-retarding nanomaterial

The present invention mainly is characterized by that it uses the magnesium chloride solution obtained by utilizing old bitter or magnesite through a refining process and industrial ammonia water or ammonia gas as raw material, or utilizes magnesium sulfate solution and industrial ammonia water or ammonia gas as raw material. Ultragravity (rotaryl filled bed) technology is adopted and utilizes liquid-liquid phase reaction or gas-liquid phase reaction mode is utilized to prepare nanometer magnesium hydroxide fire-retardant material. Said invention solves the defects of traditional process, such as complex process, high cost, non-uniform grain size and difficult control, etc.

Owner:BEIJING UNIV OF CHEM TECH

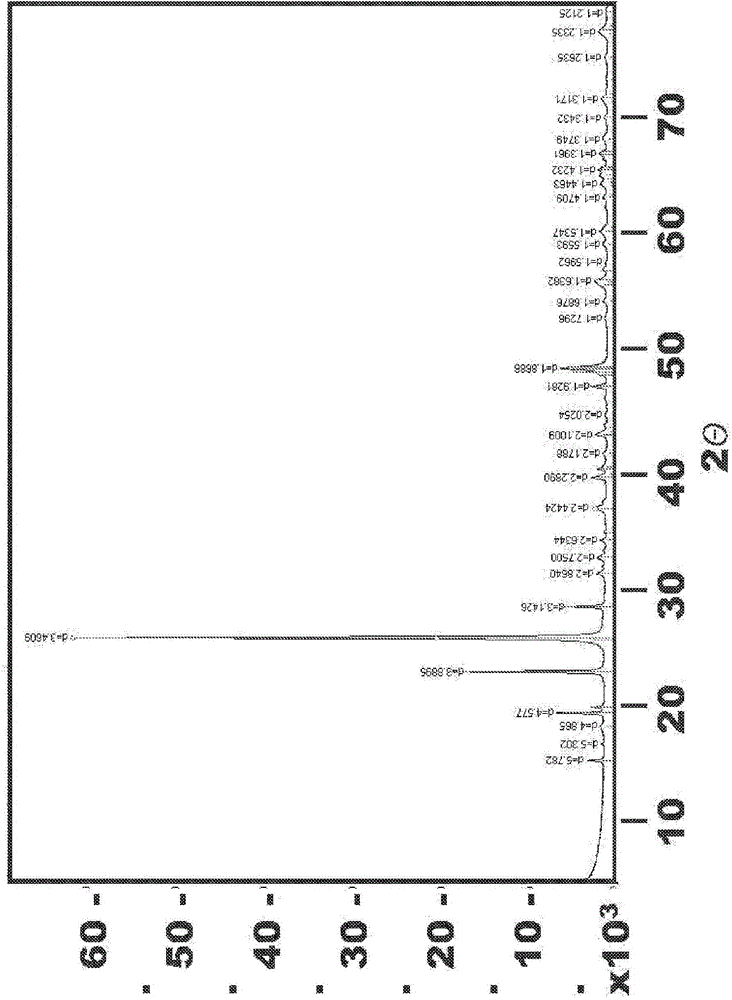

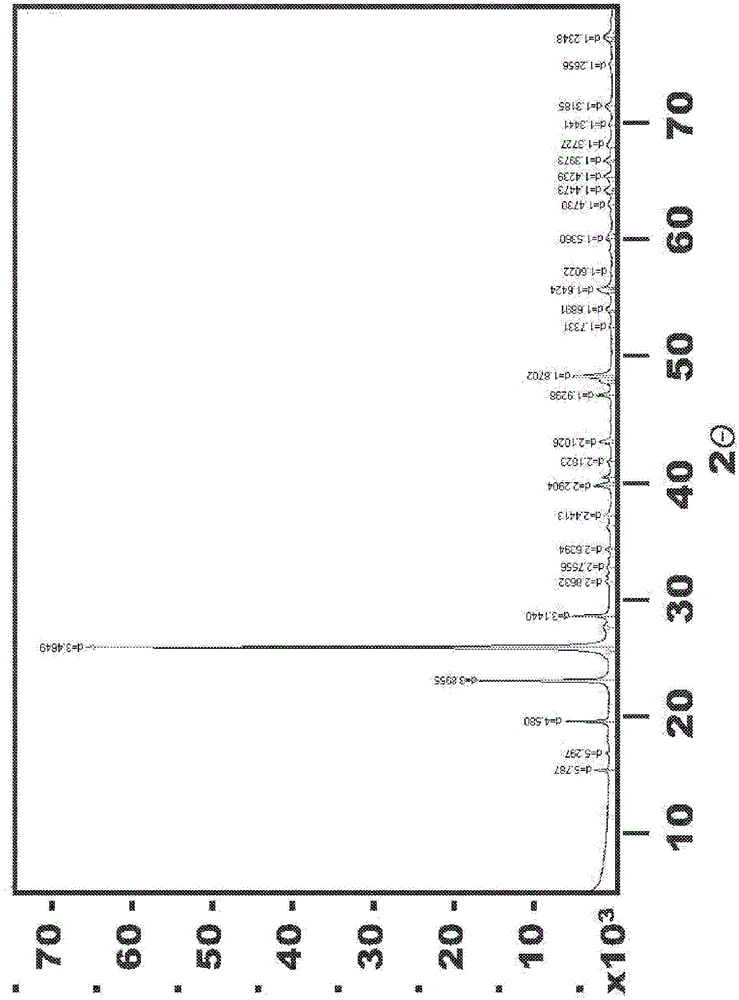

Method for synthesizing ferrum-aluminium spinelle

The invention relates to a synthesis method of hercynite and has the technical proposal that aluminium compound and iron compound are mixed according to the mol ratio of Al ion to Fe ion of two to one, added with TiO2 fine powder of 1-20wt percent of the mixture obtained from the mixing of the aluminium compound and the iron compound and 1-6wt percent of binding agent to be mixed for 5 to 180 minutes for formation and then dried for 20 to 30 hours under the temperature of 90 to 120 DEG C and warmed up to 1100 to 1700DEG C with a temperature rising speed of 0.5 to 10 DEG C / min in the atmosphere of nitrogen to be kept warm for 5 to 600 minutes and next naturally cooled so as to obtain the hercynite. The invention is characterized by simple technology, low reaction temperature, low cost of raw materials and no environmental pollution; due to the low oxygen content in the atmosphere of the nitrogen, Fe elements exist in the form of Fe<2+> and all aluminium and iron are transformed to FeAl2O4 under the firing temperature; in addition, as the TiO2 is introduced, Ti<4+> can easily enter into crystal lattice of the FeAl2O4 to produce oxygen-iron vacancy concentration and ferric-ion vacancy concentration so as to promote the sintering with apparent porosity less than or equal to 2 percent after sintering.

Owner:WUHAN UNIV OF SCI & TECH

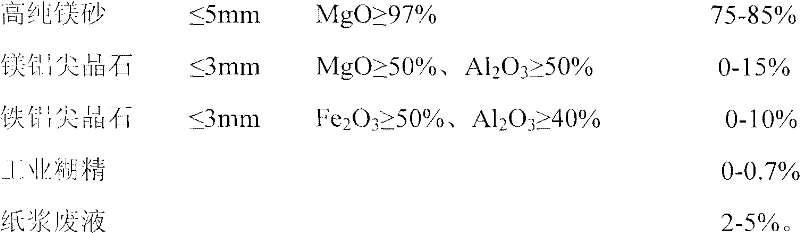

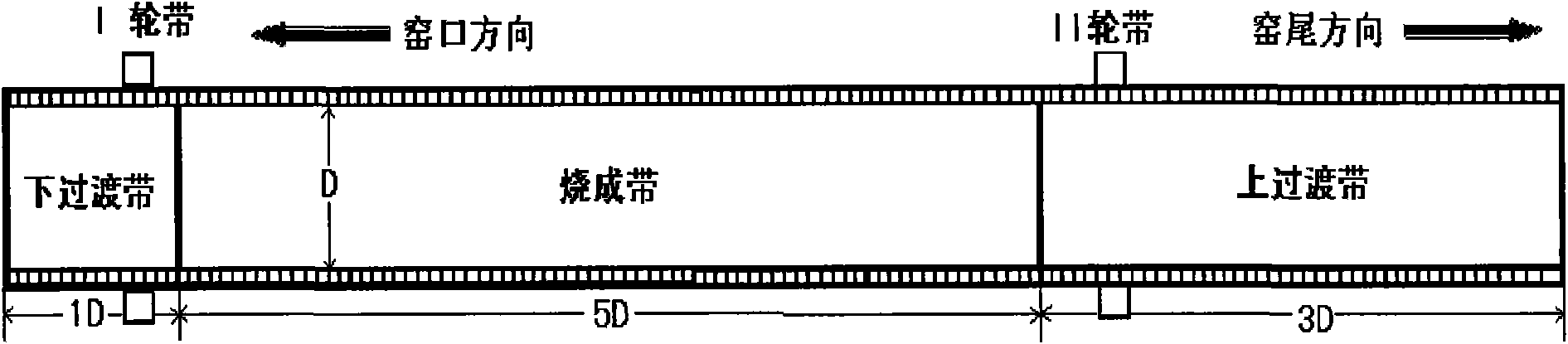

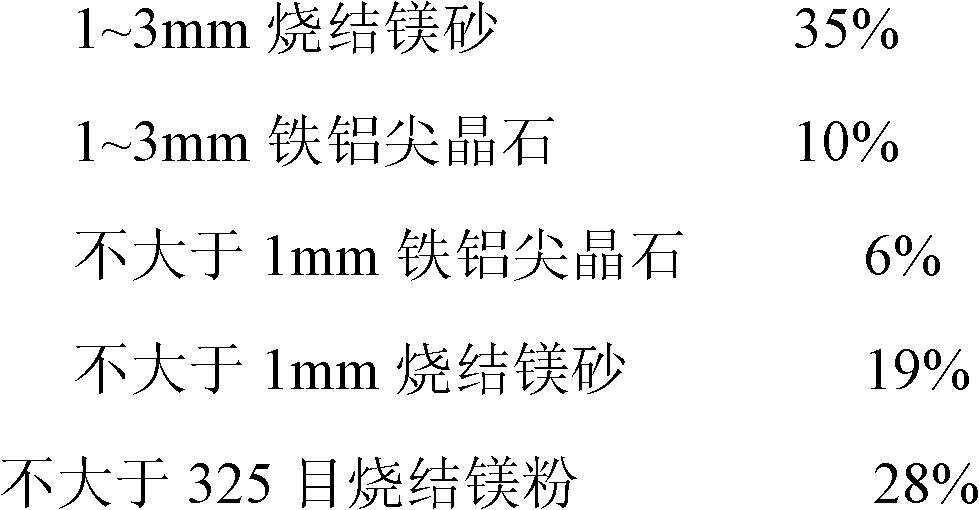

Magnesium-ferrum-aluminum composite spinel brick for large-scale cement kiln and preparation method thereof

The invention relates to a magnesium-ferrum-aluminum composite spinel brick for a large-scale cement kiln and a preparation method thereof, belonging to the field of refractory materials. The preparation method is characterized by comprising the following steps: by using high-purity magnesia, magnesia alumina spinel and hercynite as main raw materials and using pulp waste liquid and industrial dextrin as binders, mixing, pressing, drying, and firing at 1500-1700 DEG C to obtain the magnesium-ferrum-aluminum composite spinel brick. The product is applicable to firing zones and transition zones of cement kilns in all sizes, and can completely substitute magnesia-chromite bricks in the aspects of performance and cost, thereby implementing no chromium in the cement kiln refractory material. The product has obvious kiln skin adhesion effect, has the advantages of high heat and vibration stability, high temperature toughness and long running time (longer than 12 months), and performs very active functions on enhancing the running rate of the large-scale cement rotary kiln; and the fired magnesium-ferrum-aluminum composite spinel brick has the advantages of simple technique and low cost.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Magnesia-hercynite brick used by high temperature zone of cement kiln and use method thereof

InactiveCN101613214AExtended service lifeOptimizationRotary drum furnacesAdditive ingredientPulp mill

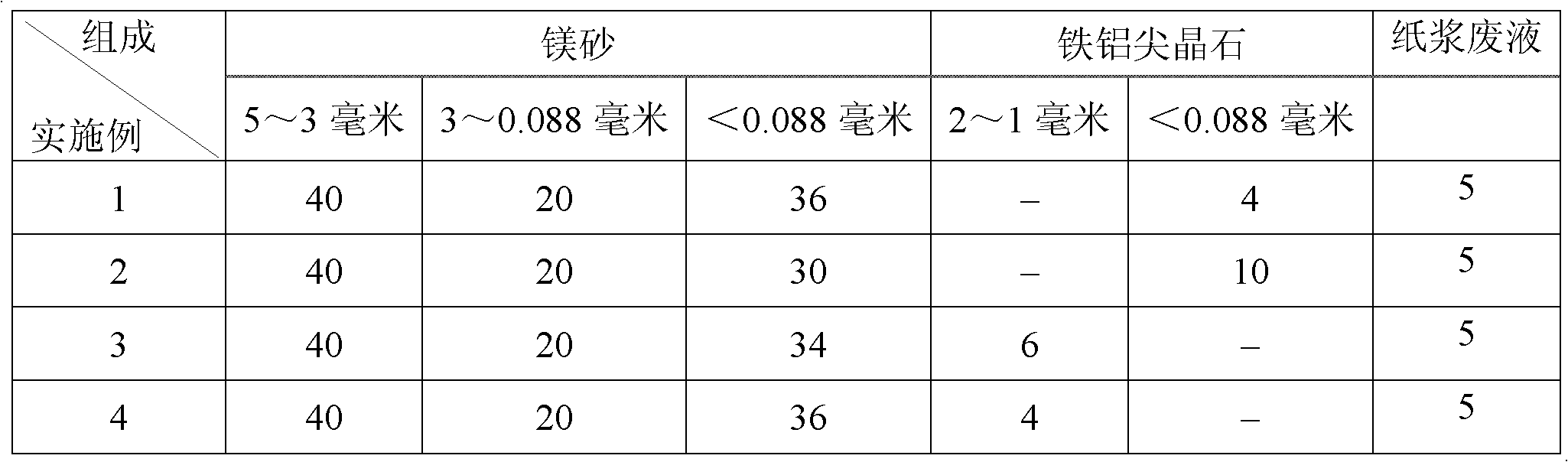

The invention belongs to the field of refractory materials and relates to a magnesia-hercynite brick used by the high temperature zone of a cement kiln and a use method thereof. The brick is characterized in that high-quality magnesia and electric melting synthesis hercynite are taken as main raw materials which comprises the following components in percentage by weight: 40-50 percent of 3-1mm coarse magnesia, 10-15 percent of 1-0.088mm medium magnesia, 30-35 percent of fine magnesia less than 0.088mm, and 6.5-11.5 percent of 3-0mm electric melting synthesis hercynite. The raw materials after mixing are added with pulp mill waste for mixing, pressing, drying and sintering at the temperature more than 1,600 DEG C, thus obtaining the magnesia-hercynite brick. The mass percentage of the ingredients of the produced magnesia-hercynite brick is as follows: 2.5-5.5 percent of Fe2O3, 4.0-6.0 percent of Al2O3 and 93.0-89.0 percent of MgO plus other microcomponents. According to different operating situations of different cement kilns and by combining the characteristic of chrome-free brick, the invention replaces magnesite-chrome brick region by region, makes full use of the advantages and bypasses the disadvantages, improves the cost performance of the refractory brick used by the high temperature zone to the greatest extent and realizes chrome-free refractory brick used by the cement kiln.

Owner:BEIJING TONGDA REFRACTORY TECH CO LTD +1

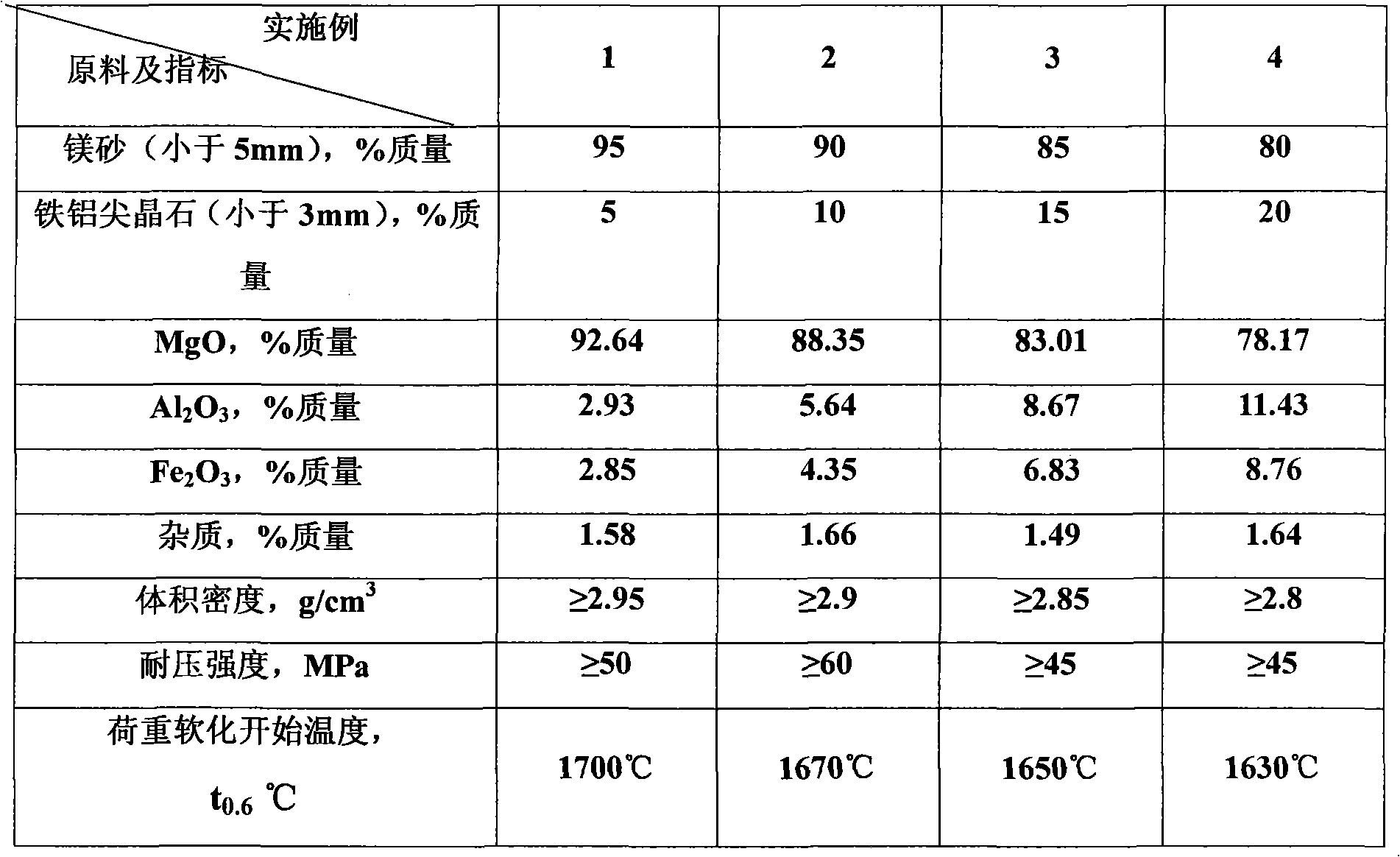

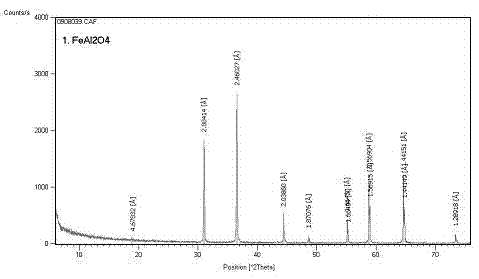

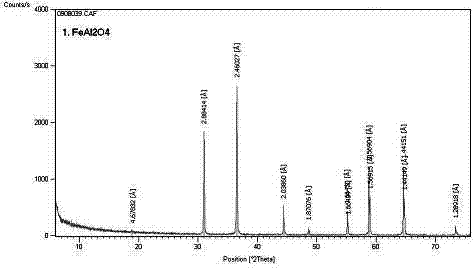

Magnesia-hercynite brick and preparation method thereof

InactiveCN101851105ASolve Cr

<sup>6+</sup>

pollution problemSolve pollutionRotary drum furnacesFurnace liningsBrickRefractory

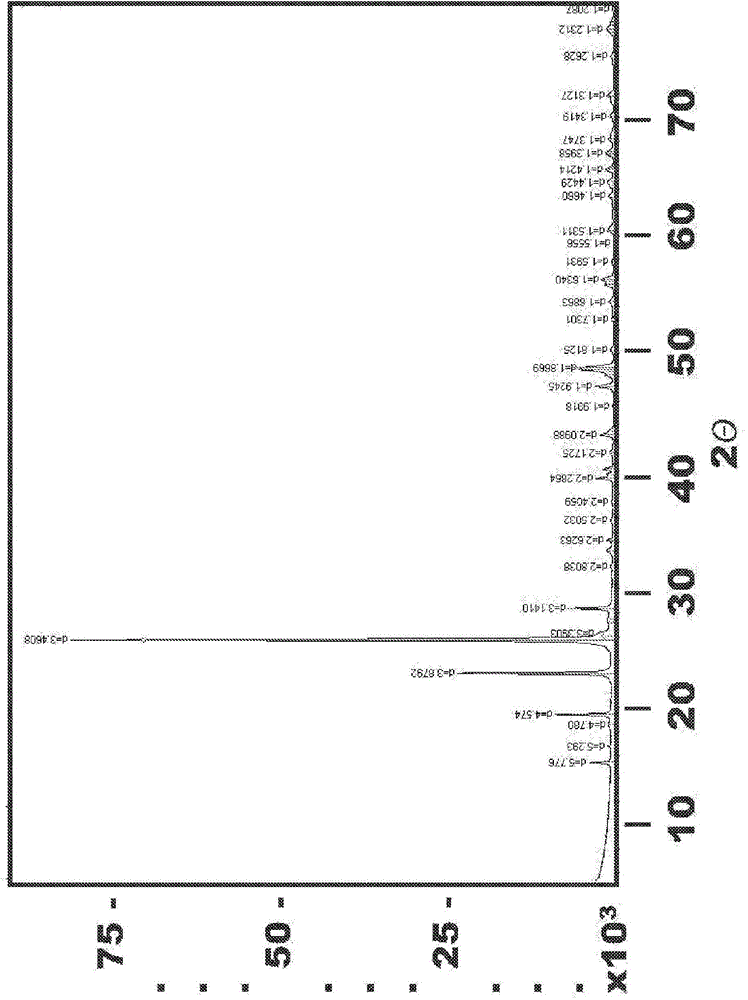

The invention relates to a magnesia-hercynite brick and a preparation method thereof, belonging to the technical field of refractory materials. The magnesia-hercynite brick comprises the following chemical components in weight percent: 2.5 to 9.6% of Fe2O3, 2.9 to 12% of Al2O3 and 76-93% of MgO, the main crystalline phase displayed by XRD spectrum line is FeO.Al2O3. The preparation method comprises the steps of additionally adding a binding agent, carrying out compression moulding, drying, and baking at high temperature to obtain the magnesia-hercynite brick, which is simple and practicable. The magnesia-hercynite brick can be applied to the fields suitable to high temperature, in particular to clinkering zones of a novel rotary kiln utilizing a dry line method, thus solving the problem of Cr6 + pollution caused by the use of magnesite-chrome bricks in clinkering zones.

Owner:SHANDONG SHENGCHUAN CERAMICS +3

Method for synthesizing hercynite

ActiveCN102583462AEasy to implementEasy to controlAluminium oxides/hydroxidesRaw materialVacuum furnace

The invention belongs to the technical field of preparation of materials and particularly relates to a method for synthesizing hercynite. Ferric oxide powder, aluminium metal powder and activated aluminium oxide powder are taken as raw materials and are synthesized into hercynite in a vacuum furnace through a solid-state sintering method, reduction is carried out on ferric oxide by metallic aluminium to generate aluminum oxide and metallic iron, excessive ferric oxide and metallic iron react to generate ferrous oxide, and finally ferrous oxide, generated aluminum oxide and added activated aluminium oxide react to generate hercynite. The method has the characteristics that the generation condition of the ferrous oxide is met through the reduction action of metallic aluminium on ferric oxide, a weak reducing atmosphere does not need to be controlled, and purified hercynite can be sintered in a vacuum condition, so that the rigorous requirement that the weak reducing atmosphere needs to be controlled when ferric oxide and aluminum oxide, serving as the raw materials, are sintered is avoided, and the technology is easy to control; and at the same time, large amount of heat radiated from the reduction reaction of ferric oxide by metallic aluminium can provide partial energy required by reaction, thereby reducing energy consumption.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Periclase-hercynite refractory material and preparation method thereof

The invention relates to a periclase-hercynite refractory material and a preparation method thereof. The adopted technical scheme comprises the following steps: mixing 80 to 98wt% of magnesia and 2 to 20wt% of hercynite-corundum composite material, adding a binding agent accounting for 3 to 8wt% of the mixture, uniformly stirring raw materials, and molding through mechanical pressing; then dryingthe molded billet for 8 to 36 hours under the condition of 110 DEG C, then sintering under the condition of 1450 to 1650 DEG C, and preserving heat for 4 to 15 hours to obtain the periclase-hercyniterefractory material. The prepared product has the main phases of periclase and hercynite, contains a small amount of magnesia-alumina spinel and is the periclase-hercynite refractory material which not only has higher kiln crust adhesiveness, higher refractoriness and good anticorrosion capability of alkali, sulfur, chlorine, clinkers and the like, but also has higher loading softening temperature, higher high-temperature strength and better thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method for rebonded electrically fused chrome corundum brick

The invention discloses a preparation method for a rebonded electrically fused chrome corundum brick. Corundum granules, chrome ore powder and chromic oxide powder are first prepared, electrically fused chrome corundum granules are synthesized according to a certain proportion, the materials are weighed according to 40 to 70 parts of corundum material, 8 to 20 parts of chrome ore material, 15 to 30 parts of synthesized electrically fused chrome corundum material and 1 to 3 parts of chromic oxide material, put into a mixing mill, added with aluminium dihydrogen phosphate solution, mixed, milled and pressed to form a semifinished green brick, and after drying and sintering, the finished product is prepared. The rebonded electrically fused chrome corundum brick has the characteristics of high refractoriness, high strength, high thermal shock resistance and strong corrosion resistance; because high-melting point chromohercynite and hercynite can be produced on the surface of a furnace liner and stuck on the furnace liner to form a protective layer, thus not only can the scouring resistance of the furnace liner be enhance, but also melt can be stopped from infiltrating the brick, and thereby the service life of the brick can be greatly prolonged.

Owner:ZHENGZHOU HUAWEI REFRACTORIES

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

Chromium-free alkaline brick for cement kiln and preparation thereof

The invention particularly relates to a chromium-free basic brick for a cement kiln and a preparation method thereof. The preparation method adopts the technical proposal that: firstly, mixing 45 to 96 weight percent of magnesia, 2 to 17 weight percent of Al2O3, 1 to 10 weight percent of iron, 0 to 40 weight percent of hercynite or magnesium aluminate spinel and 0 to 10 weight percent of Fe2O3, and adding a water glass solution or a sodium tripolyphosphate solution or a sodium hexametaphosphate solution which is 3 to 6 weight percent of mixed materials; and secondly, performing mixing, forming, roasting and hardening treatment. The preparation method utilizes a high-temperature environment at a temperature of 1,500 DEG C when products are used to generate the hercynite through in-site chemical reaction in the service process of unfired bricks, so that the chromium-free basic brick for the cement kiln has the superior characteristics of periclase-hercynite bricks. The preparation technology is simple, does not require high-temperature firing, and saves energy resources; and metallic combination is formed in green bricks through plastic phase transition of metallic phases under the action of forming pressure, and has the function of reinforcing and plasticizing the green bricks, so that the green bricks have large volume density, high strength and good thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH +1

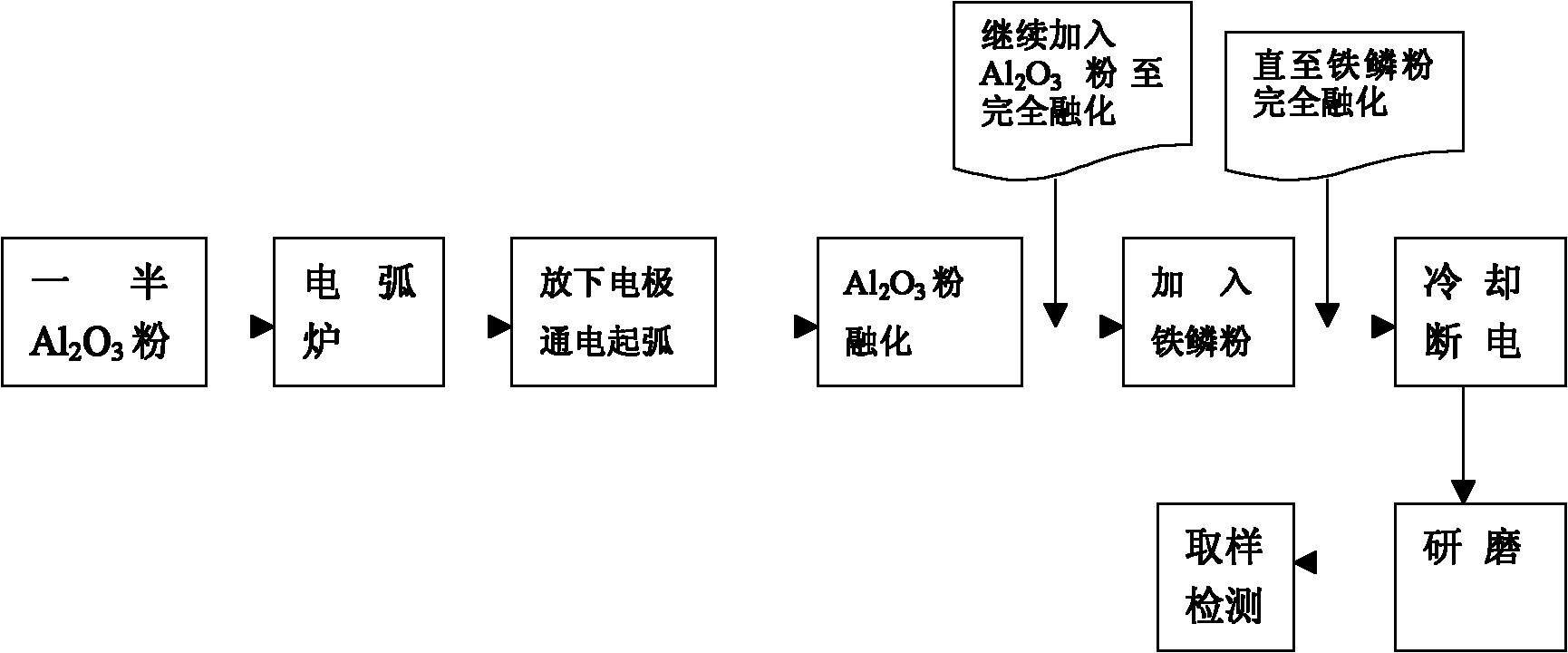

Fused hercynite-corundum composite material and preparation method thereof

The invention relates to a fused hercynite-corundum composite material and a preparation method thereof. The technical scheme is achieved by the following steps: firstly, using 34-44 wt% of Fe2O3 powder, 55-65 wt% of Al2O3 powder and 0.5-3 wt% of caustic-calcined magnesite powder as mixture, additionally adding 0.5-4 wt% of carbon powder of mixture; or, additionally adding 0.5-3 wt% of a bonding agent of mixture, uniformly stirring, drying a formed green body and then placing into a three-phase electric arc furnace, or directly uniformly stirring the raw materials and then placing into the three-phase electric arc furnace; secondly, fusing by adopting voltage of 90-220v, continuously smelting for 25-60min after all raw materials are smelted; or cooling smelted high-temperature synthesizedmaterials into the electric arc furnace for 24-48h, or guiding the smelted high-temperature synthesized materials into a water-cooling tank and cooling for 23-46h to obtain the hercynite-corundum composite material. The product prepared by the invention is the fused hercynite-corundum composite material comprising phase compositions of 80-98wt% of hercynite, 1-18wt% of corundum and 0.3-3wt% of magnesium aluminate spinel.

Owner:WUHAN UNIV OF SCI & TECH

Method for improving recovery rate of iron component in steel slag

ActiveCN106492981AIncrease sensible heatEfficient use ofRecycling and recovery technologiesMagnetic separationMolten stateAlkalinity

The invention discloses a method for improving the recovery rate of an iron component in steel slag. The method comprises the steps of: mixing modifiers in a predetermined proportion in the steel slag in a molten state, that is, in a process of discharging the molten steel slag, adding the modifiers into the steel slag, directly melting the modifiers by virtue of sensible heat of the steel slag, and changing the alkalinity of the steel slag by means of a molten state modifying method, wherein the adulterate amount of the modifiers is smaller than or equal to 25% by mass of the steel slag; and by adding the modifiers containing silicon oxide and / or iron oxide to recombine the component of the steel slag, increasing the contents of magnetite and hercynite so as to improve the recovery rate of the iron component. According to the method disclosed by the invention, sensible heat of the molten steel slag is effectively utilized, so that heat needs not to be compensated in the modifying process; the modifiers which are added into the steel slag are either cheap raw materials or solid wastes such as tailings and dust slime, so that optimization and synergic action of resources are realized. Meanwhile, by adding the modifiers containing silicon oxide and / or iron oxide and increasing the contents of magnetite and hercynite after component recombination, the recovery rate of the iron component in the steel slag is improved.

Owner:UNIV OF SCI & TECH BEIJING

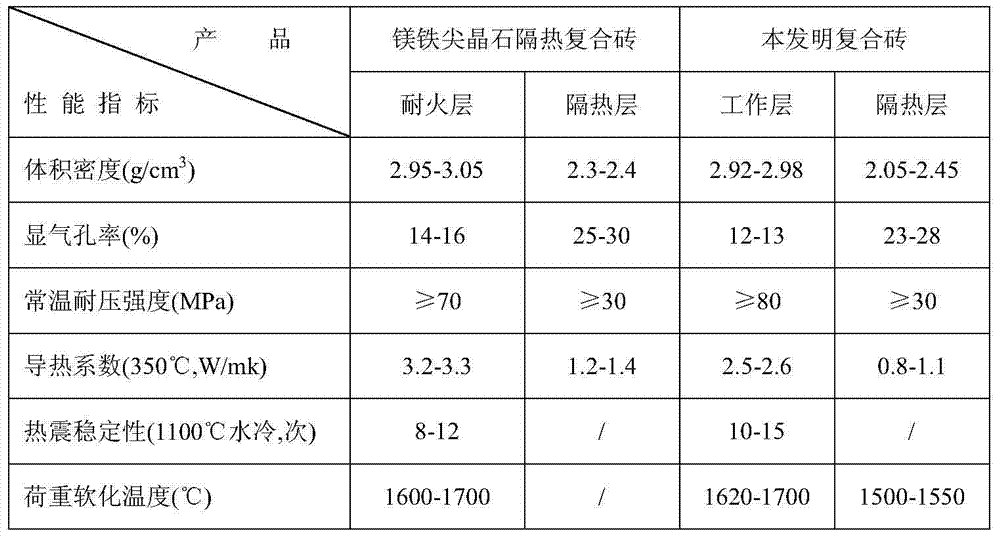

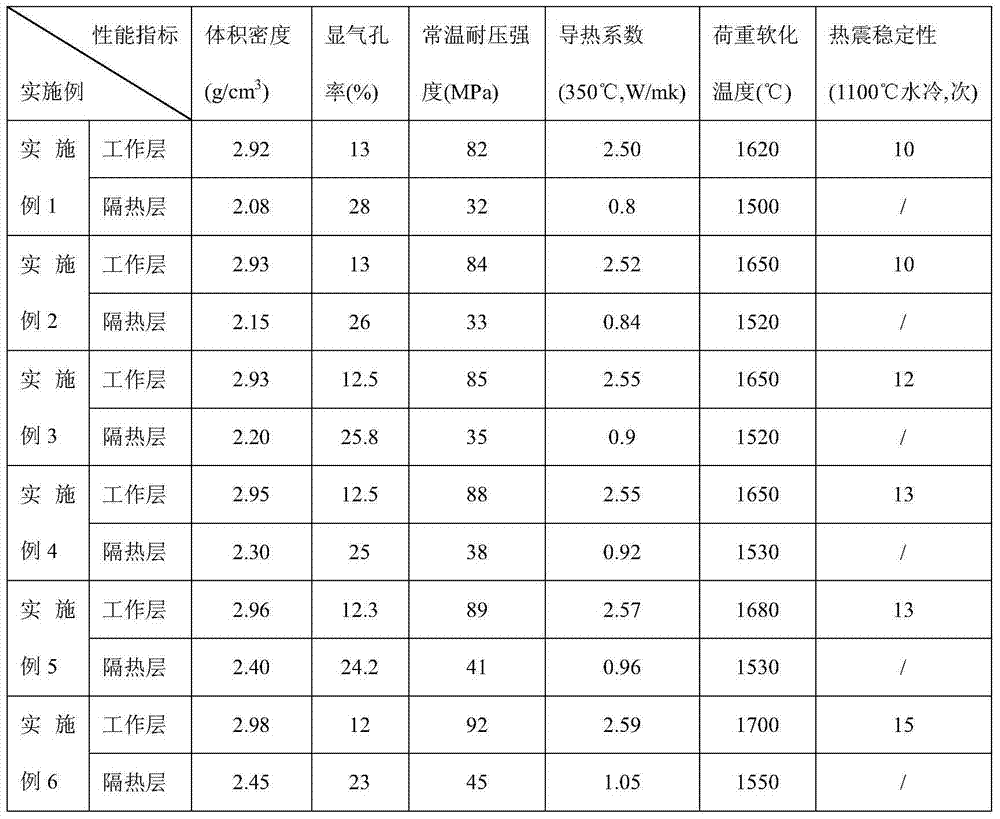

Periclase-pleonaste and hercynite/forsterite composite brick

The invention discloses a periclase-pleonaste and hercynite / forsterite composite brick prepared by compounding a working layer and a heat insulation layer, wherein the working layer is prepared from magnesium-iron sand, hercynite sand and fused magnesite which serve as main raw materials; the heat insulation layer is prepared from medium-heavy synthetic olivine sand, medium-light synthetic boltonite sand, magnesite particles, fine magnesia powder and rice hull ash which serve as main raw materials; and the periclase-pleonaste and hercynite / forsterite composite brick is prepared through the steps of proportioning; mixing; molding; drying; sintering and the like. The working layer of the composite brick disclosed by the invention is strong in erosion resistance, good in thermal shock resistance and low in heat conductivity coefficient and is easily adhered to a kiln coating; the heat insulation layer is favorable in high-temperature volume stability, relatively high in mechanical strength and relatively low in heat conductivity coefficient. Therefore, the composite brick can be used for a high-temperature zone of a rotary cement kiln and is long in service life and capable of remarkably reducing the heat loss of a kiln body and has favorable energy-saving and emission reduction effects.

Owner:河南瑞泰耐火材料科技有限公司

Hercynite and preparing method thereof

InactiveCN104072172AAvoid volume effectThe synthesis process is simpleChemical compositionFireproofing

The invention belongs to the technical field of fireproofing materials, and relates to hercynite and a preparing method thereof. The chemical components of the hercynite are Fe2O3 and Al2O3, wherein mass proportion of the Fe2O3 to Al2O3 is (35 to 44) to (65 to 56); the chemical components are calculated on the foundation that the FeO is converted into Fe2O3. According to the hercynite, volume effect due to that iron changes among different valence states is avoided; the synthetic process is simple to carry out easily. According to the advantage of the preparing method, compared with an N2 atmosphere realizing by an enclosed condition, utilizing a reducing atmosphere which adopts air to bury carbon is very easy to operate.

Owner:ZIBO CITY LUZHONG REFRACTORIES CO LTD +1

Wet process sintering production method for hercynite

The invention belongs to the technical field of fire resistant material production, and particularly relates to a wet process sintering production method for hercynite. The wet process sintering production method comprises the following steps: compounding 50-65% of aluminium oxide and 35-50% of metallic iron powder according to weight percentage, adding graphite, polyvinyl alcohol and water, grinding so as to obtain mud A, and performing dehydrating, vacuum pugging, drying and sintering on the mud A so as to obtain the hercynite, wherein the dosage of the graphite and the polyvinyl alcohol is respectively 1-5% and 0.1-0.3% of the total mass of the aluminium oxide and the metallic iron powder, and the amount of water is 1.0-1.2 times of the total mass of the aluminium oxide, the metallic iron powder, the graphite and the polyvinyl alcohol. The wet process sintering production method is simple in technology, low in labor intensity, environment-friendly and low in cost, the obtained hercynite is uniform in components and high in volume density, and the crystalline phase content reaches 97%.

Owner:SANMENXIA XINYANGSHAO SYNTHETIC MATERIALS

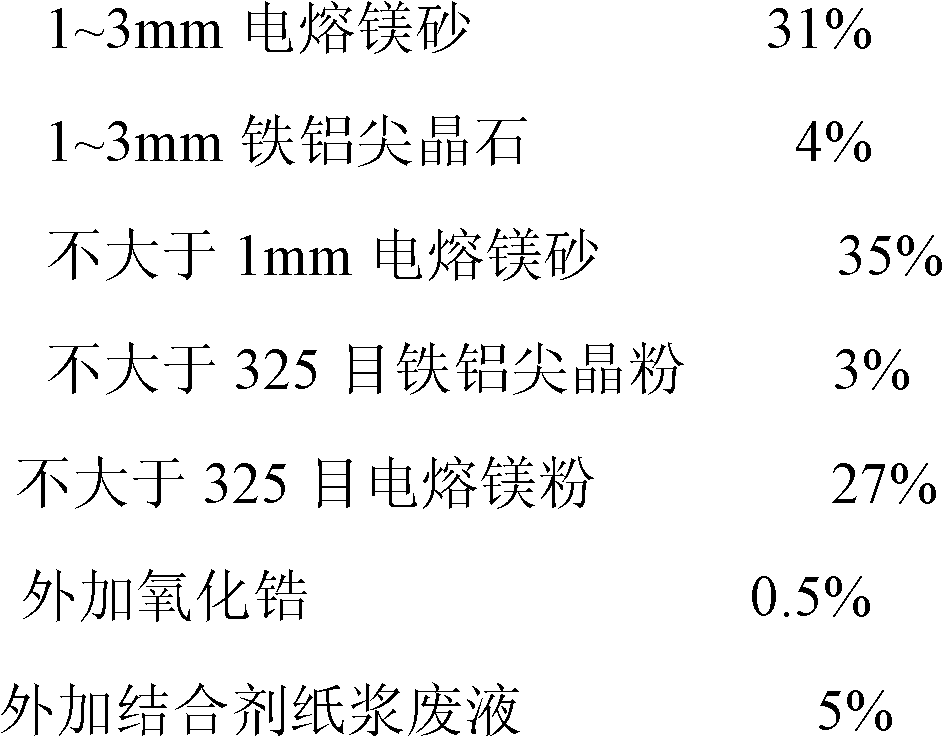

Magnesium-hercynite-structured heat-insulating integral composite brick and preparation method thereof

The invention relates to a magnesium-hercynite-structured heat-insulating integral composite brick. The composite brick comprises a magnesium-hercynite heavy working layer and a light heat-insulating layer prepared from a light aggregate and powder. The integral composite brick is prepared from composed materials of the heavy working layer and the light heat-insulating layer. The length dimensional ratio of the heavy working layer to the light heat-insulating layer is 1-5:3-1. The invention also relates to a preparation method of the magnesium-hercynite-structured heat-insulating integral composite brick. According to the invention, the heavy layer and the light layer are combined, such that the thermal capacity can be reduced, creep deformation can be overcome, and the service life can be prolonged.

Owner:ZHEJIANG UNIV

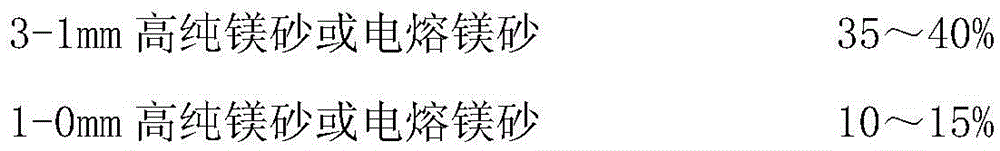

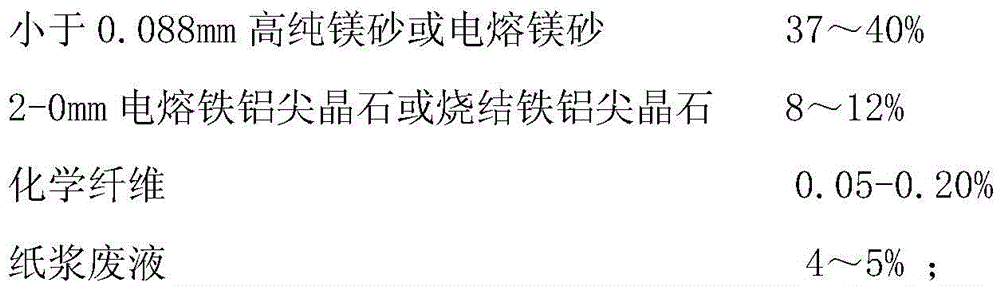

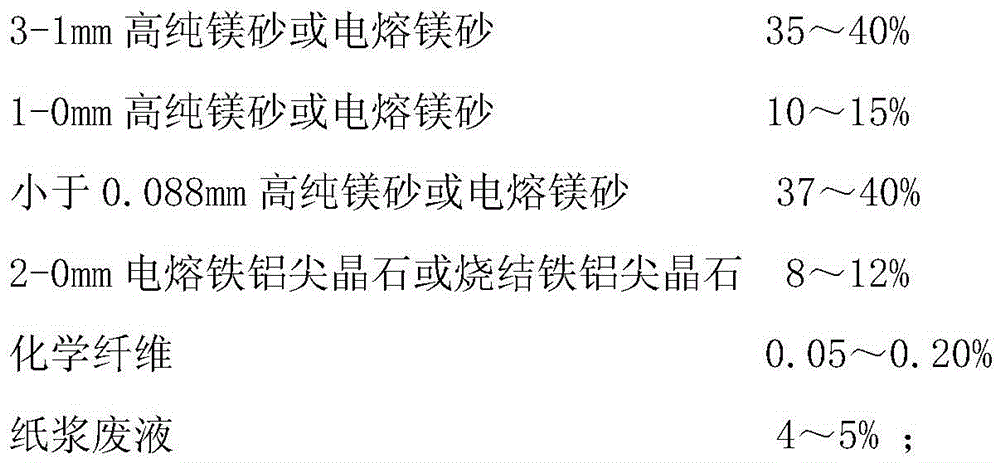

Low-heat-conductivity magnesia-hercynite brick used for cement rotary kiln and production method thereof

The invention discloses a low-heat-conductivity magnesia-hercynite brick used for a cement rotary kiln and a production method thereof. According to the invention, external temperature of a kiln body is reduced, and the effects of energy conservation and emission reduction are achieved. The magnesia-hercynite brick comprises the following components: high-purity magnesia or fused magnesia with a size of 3 to 1 mm, high-purity magnesia or fused magnesia with a size of 1 to 0 mm, high-purity magnesia or fused magnesia with a size of less than 0.088 mm, fused hercynite or sintered hercynite with a size of 2 to 0 mm, chemical fiber, and paper-pulp waste liquor with a concentration of 4 to 5%. The method comprises the following steps: material preparation, mixing and grinding, press molding into a green body, drying, and high-temperature sintering. According to the invention, uniform fiber micropores can be remained at a relative position in an internal structure of the magnesia-hercynite brick, so a gas-solid interface in the structure of a brick is increased; phonon dispersion of heat conduction of a solid phase is enlarged; heat conductivity of the brick is effectively reduced; and heat loss in a kiln is decreased.

Owner:UNIV OF SCI & TECH LIAONING

Refractory castable for molten iron desulphurization stirrer

The invention relates to a refractory castable for a molten iron desulphurization stirrer. The refractory castable comprises the following components in parts by weight: 30-35 parts of silica, 20-25 parts of silicon carbide, 30-40 parts of magnesia powder, 40-45 parts of alumina micro powder and 20-25 parts of hercynite, wherein the silica, the hercynite and the silicon carbide are aggregates and the magnesia powder and the alumina micro powder are powder.

Owner:中卫市胜金北拓建材有限公司

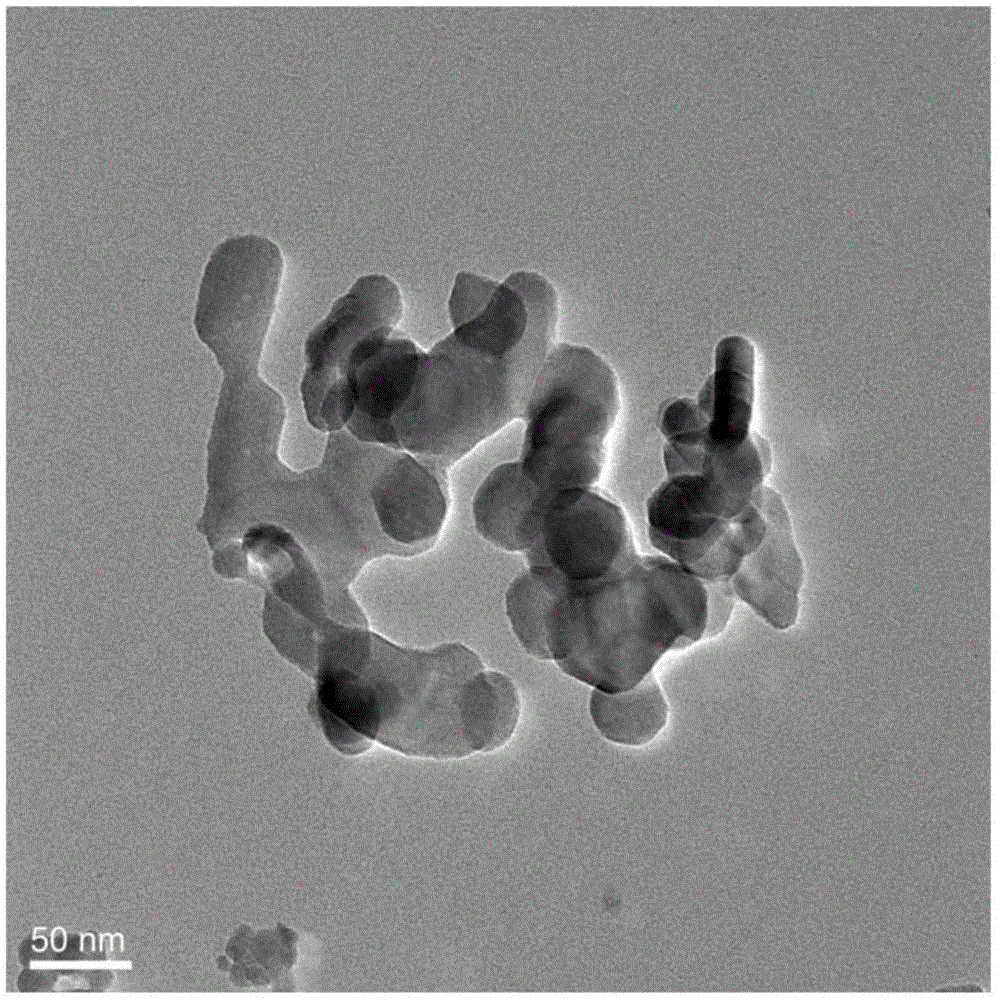

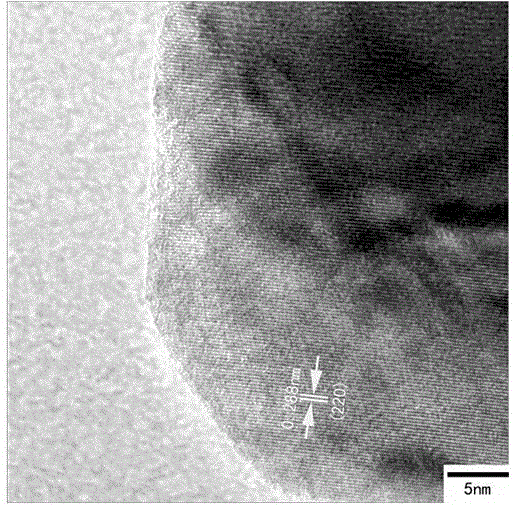

Preparation method of nanoscale hercynite

ActiveCN104803422AReduce usageAvoid introducingMaterial nanotechnologyIron compoundsCalcinationTerephthalic acid

The invention relates to a preparation method of nanoscale hercynite. The method comprises steps as follows: (1) a mixed solution of N,N-dimethyl formamide and water is prepared, wherein the volume fraction of the N,N-dimethyl formamide ranges from 65% to 85%; (2) an aluminum-containing compound, terephthalic acid and ferric acetylacetonate with the molar ratio being 15:10:3 are added to the solution prepared in Step (1) and evenly stirred, and a reactant solution is prepared; (3) the reactant solution prepared in Step (2) is aged in an airtight manner, then cooled to the room temperature and subjected to solid-liquid separation, and a hercynite precursor product is obtained; (4) the hercynite precursor product is placed in a high-temperature furnace for calcination and then cooled to the room temperature, and the nanoscale hercynite is obtained. Compared with the prior art, the preparation method has the advantages that the synthesis process is simple, the method is convenient to operate, the cost is low, the energy consumption is low and the like.

Owner:TONGJI UNIV

Casting material for prefabricated brick for feeding chamber and preparation method of casting material

The invention relates to the field of refractory materials, and in particular relates to a casting material for prefabricated bricks for a feeding chamber. The casting material comprises the following components in parts by weight: 20-50 parts of white corundum, 18-30 parts of mullite M45, 15-40 parts of electric smelted magnesium aluminate spinel, 10-30 parts of electric smelted hercynite, 3-5 parts of zirconium carbonate, 2-3 parts of silicon micro powder, 2-8 parts of alumina micro powder, 0.1-1 part of sodium tripolyphosphate, 4-8 parts of aluminum oxynitride, 5-9 parts of Lafarge cement, 3-5 parts of a preservative solution, 5-10 parts of a first external binding agent, 2-7 parts of a second external binding agent, 3-7 parts of a first solid additive and 1.5-6 parts of a second solid additive, wherein the preservative solution is prepared by preparing a first primary mixed liquid and adding other components in sequence; the electric smelted magnesium aluminate spinel comprises 15-25 parts of electric smelted magnesium aluminate spinel granules of 5-8mm, 5-20 parts of electric smelted magnesium aluminate spinel granules of 3-5mm, 5-15 parts of electric smelted magnesium aluminate spinel granules of 1-3mm and 5-15 parts of electric smelted magnesium aluminate spinel granules of 0-1mm. The casting material is good in prefabricated brick strength, a cement clinker is unlikely to adhere to prefabricated bricks, and the service life is longer than 3 years.

Owner:长兴兴鹰新型耐火建材有限公司

Abrasion-resistant anti-erosion pouring material for cement kiln tertiary air duct

The invention relates to the field of refractory materials, in particular to an abrasion-resistant anti-erosion pouring material for a cement kiln tertiary air duct. The abrasion-resistant anti-erosion pouring material is prepared from, by weight, 20-50 parts of white corundum, 18-30 parts of mullite M45, 15-40 parts of fused magnesium aluminate spinel, 10-30 parts of fused hercynite, 3-5 parts of zirconium carbonate, 3-5 parts of silicon carbide, 2-3 parts of silica micro powder, 2-8 parts of alumina micro powder, 0.1-1 part of sodium tripolyphosphate and 5-10 parts of additionally added binding agents. The fused magnesium aluminate spinel comprises 15-25 parts of fused magnesium aluminum pointed crystal particles ranging from 5 mm to 8 mm in particle size, 5-20 parts of fused magnesium aluminum pointed crystal particles ranging from 3 mm to 5 mm in particle size, 5-15 parts of fused magnesium aluminum pointed crystal particles ranging from 1 mm to 3 mm in particle size and 5-15 parts of fused magnesium aluminum pointed crystal particles ranging from 0 mm to 1 mm in particle size. The fused hercynite comprises 10-20 parts of fused hercynite particles ranging from 5 mm to 8 mm in particle size, 5-15 parts of fused hercynite particles ranging from 3 mm to 5 mm in particle size, 5-10 parts of fused hercynite particles ranging from 1 mm to 3 mm in particle size and 5-10 parts of fused hercynite particles ranging from 0 mm to 1 mm in particle size. The white corundum is formed by mixing white corundum with the particle size ranging from 1 mm to 5 mm with white corundum with the particle size ranging from 6 mm to 10 mm according to the mass ratio of 1:3-5. The pouring material is high in abrasion resistance, good in high temperature resistance and high in thermal shock resistance.

Owner:长兴兴鹰新型耐火建材有限公司

Colored and opaque glass-ceramic(s), associated colorable and ceramable glass(es), and associated process(es)

Disclosed herein are glass-ceramics having crystalline phases including β-spodumene ss and either (i) pseudobrookite or (ii) vanadium or vanadium containing compounds so as to be colored and opaque glass-ceramics having coordinates, determined from total reflectance—specular included—measurements, in the CIELAB color space of the following ranges: L*=from about 20 to about 45; a*=from about −2 to about +2; and b*=from about −12 to about +1. Such CIELAB color space coordinates can be substantially uniform throughout the glass-ceramics. In each of the proceeding, β-quartz ss can be substantially absent from the crystalline phases. If present, β-quartz ss can be less than about 20 wt % or, alternatively, less than about 15 wt % of the crystalline phases. Also Further crystalline phases might include spinel ss (e.g., hercynite and / or gahnite-hercynite ss), rutile, magnesium zinc phosphate, or spinel ss (e.g., hercynite and / or gahnite-hercynite ss) and rutile.

Owner:CORNING INC

Method for preparing magnesia-hercynite refractory material

InactiveCN101891491AEasy to hang kiln skinImprove thermal shock resistanceCompression moldingRefractory

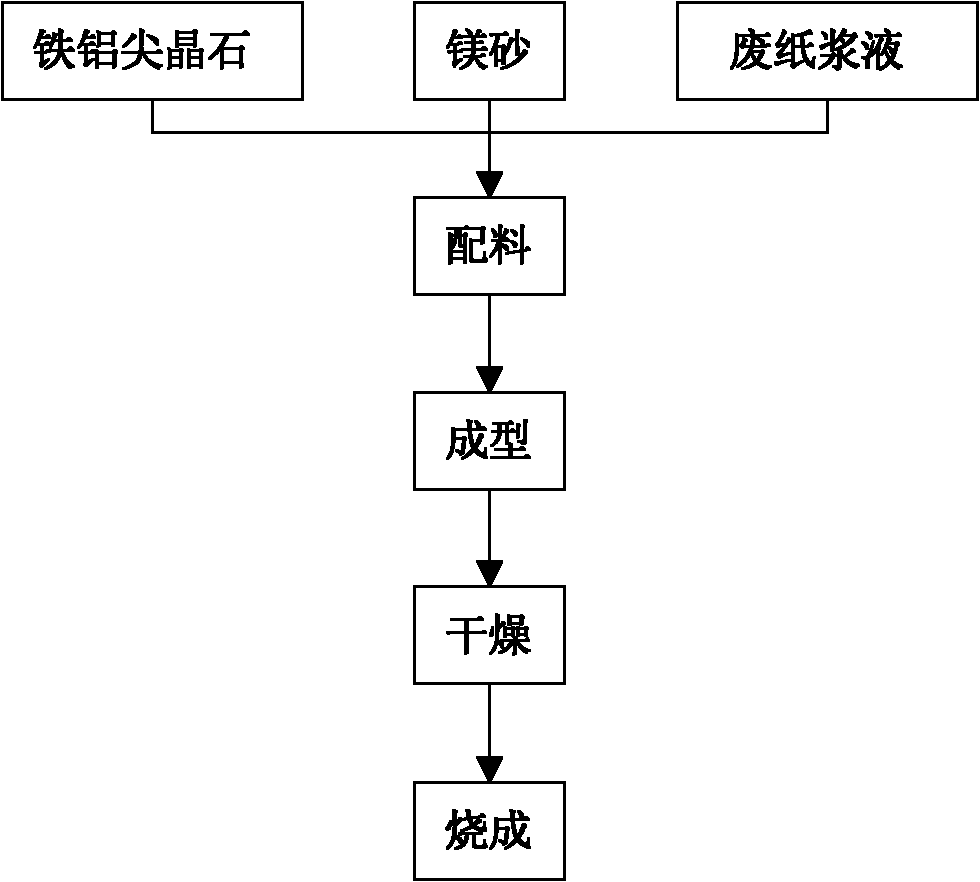

The invention discloses a method for preparing a magnesia-hercynite refractory material. The method comprises the following steps of: synthesizing the hercynite by using an electric smelting method; uniformly mixing the hercynite, magnesia and spent pulping liquor serving as raw materials according to a certain proportion, and sealing and baling the mixture; placing the prepared mixture into a mould for compression molding; drying the molded sample for 12 to 24 hours in a drying box; sintering the sample in a high temperature electric furnace; and cooling the sample to obtain the sintered magnesia-hercynite refractory material. The magnesia-hercynite refractory material prepared by the method has high kiln coating adherence, superior high temperature structural flexibility and superior cement clinker erosion resistance. The method has the advantages of simple process, high applicability and capability of being widely applied to various industries such as metallurgy, building materialsand the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

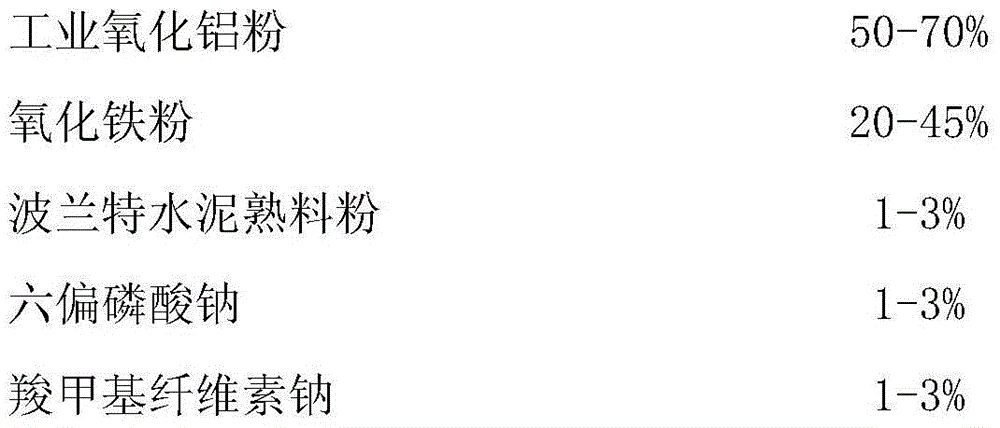

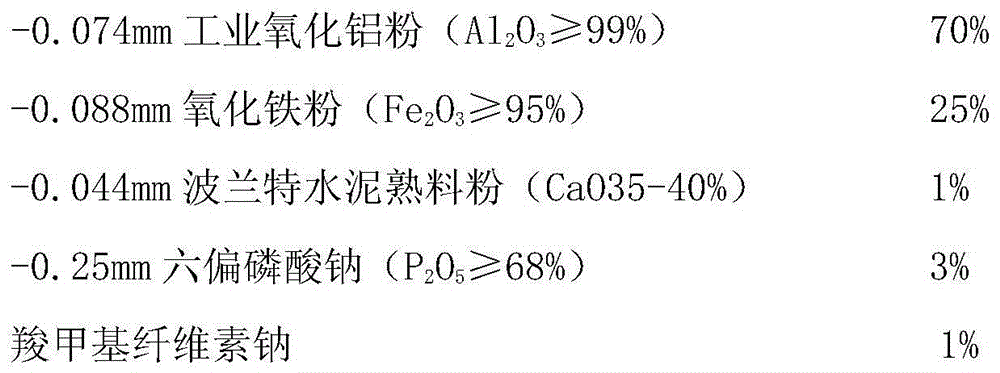

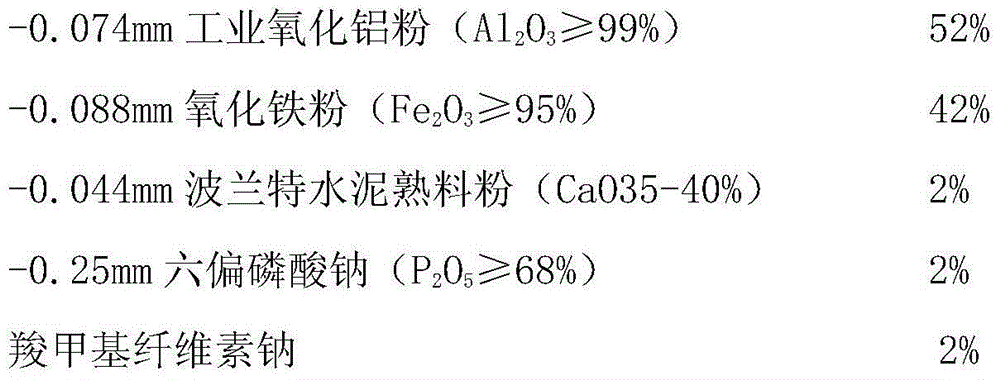

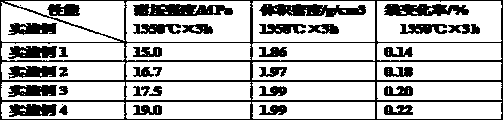

Coating capable of enhancing kiln coating adherence of firing zone of rotary cement kiln and application of coating

The invention discloses a coating capable of enhancing the kiln coating adherence of a firing zone of a rotary cement kiln and application of the coating. The kiln coating adherence of a magnesia-hercynite brick can be effectively improved. The coating comprises the following chemical components in percentage by weight: 50%-70% of commercial alumina powder, 20%-45% of iron oxide powder, 1-3% of portland cement chamotte powder, 1%-3% of sodium hexametaphosphate and 1%-3% of sodium carboxymethylcellulose. The coating comprises the following application steps: cleaning the surface of the magnesia-hercynite brick; uniformly spraying the coating on the surface of the magnesia-hercynite brick to form a paintcoat with the thickness of 1.5-2mm; and after spraying, standing for 5-8 hours, so that the paintcoat is naturally dried. With the magnesia-hercynite brick as a kiln coating material, the kiln coating adherence is enhanced by adopting the coating; the raw materials used by the coating are low in price; the kiln coating adherence is significantly improved; and the chrome-free development process of the rotary cement kiln is effectively promoted.

Owner:UNIV OF SCI & TECH LIAONING

Novel environment-friendly blast furnace stemming

The invention discloses novel environment-friendly blast furnace stemming which is characterized by comprising the following constituents by weight: 10 to 20 parts of disposable stemming, 5 to 15 parts of Yttrium mullite,10 to 20 parts of coal gangue rawore, 10 to 25 parts of modified magnesia-hercynite powder, 10 to 20 parts of modified clay, 10 to 33 parts of regenerative graphite electrode powder, 8 to 18 parts of a thickening agent, 3 to 8 parts of asphalt powder, 0.2 to 0.5 part of Glydol n 2002, 12 to 14.5 parts of an additive binding agent, and 0.1 part of nano-cellulose, wherein the thickening agent is a mixture of ferrovanadium ore and cupric oxide of which the weight ratio is 1 to 1. The stemming is low in cost, and high in air permeability, and can effectively maintain taphole reaming; during long-term storage, the service performance and operability of the stemming cannot decrease.

Owner:ANHUI SAFE ELECTRONICS

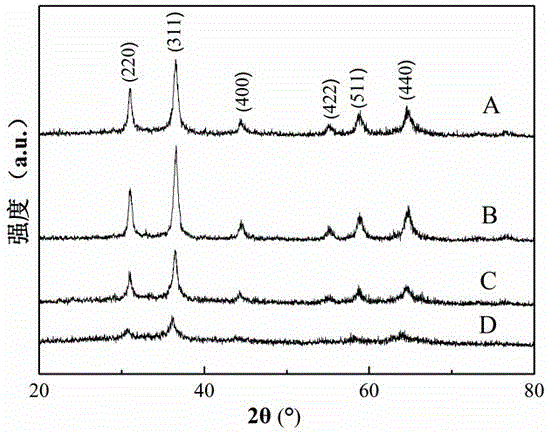

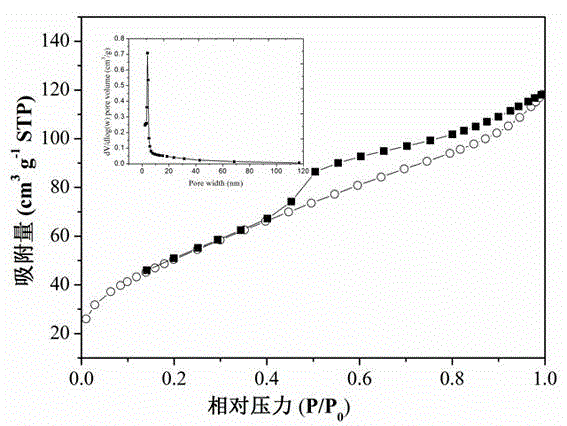

Hercynite synthesis method

The present invention discloses a method for synthesizing high specific surface area hercynite through rapid combustion. According to the method, ferric nitrate, aluminum nitrate, urea and one or a plurality of materials selected from trimethylamine hydrochloride, triethylamine hydrochloride, diethylamine hydrochloride and dimethylamine hydrochloride are adopted as raw materials, mixing is performed according to an amount ratio of 1:2:(2-8):(0.1-3), the mixture is heated to achieve a liquid state, heating is continuously performed until the liquid combusts, and the obtained solid is grinded to obtain the hercynite material. According to the invention, the urea and the ammonium salt are adopted as the mixed fuel, and are subjected to the oxidation reduction reaction with the nitrate, the heat released from the combustion reaction is utilized to ensure the formation of the spinel, the large amounts of the gases released by the reaction make the material have the porous structure and the high specific surface area, and the preparation method has characteristics of simpleness, no requirement of sophisticated equipment, short time and high product purity, and is suitable for industrial mass production.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

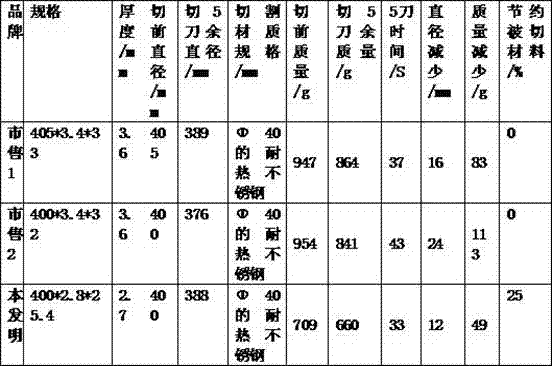

Stainless steel abrasive cutting wheel and preparation method thereof

ActiveCN106891271AImprove the finishImprove cutting efficiencyAbrasion apparatusGrinding devicesPorosityGrinding wheel

The invention discloses a stainless steel abrasive cutting wheel. The stainless steel abrasive cutting wheel is characterized in that abrasive cutting wheel raw materials comprise mixed abrasive particles, filler, a pore-forming material, resin and a reinforcing material; the mixed abrasive particles comprise black silicon carbide, monocrystalline fused alumina, brown fused alumina, brown fused alumina-cerium oxide core / shell composite abrasive particles and hercynite; the filler comprises zeolite and silicon carbide micro powder; the resin refers to phenolic resin modified by cardanol; and the reinforcing material refers to a glass fiber mesh containing graphite. The stainless steel abrasive cutting wheel has the advantages that first, the abrasive tool porosity is large and chips can be contained conveniently; second, the temperature of a grinding area is low and workpiece burning can be avoided; third, by the adoption of the chemico-mechanical polishing principle of cerium oxide, the microcosmic condition of a cut-processing surface is improved, and the roughness is lowered; fourth, due to the fact that different kinds of abrasive particles at different hardness are matched in the mixed abrasive particles, cutting efficiency is high; fifth, the cutting tool edge is narrow, the cutting surface is flat, and expensive cut materials are saved; sixth, by designing a grinding layer and a non-grinding layer, cost is reduced; and seventh, no fluoride is contained, and environmental pollution is reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Road and bridge caulking asphalt and preparation method thereof

The invention discloses a road and bridge caulking asphalt. The road and bridge caulking asphalt comprises the following ingredients: a petroleum asphalt, a compatilizer, a stabilizer, an antioxidant,a flow modifier, a modified oxidized graphene, a modified bagasse molecular sieve, and SBS. The oxidized graphene and the bagasse molecular sieve are added, a net-shaped structure is formed in the inner part of the asphalt without crosslinking, the shock resistance effect is good; part of aluminum hydroxide and ferric oxide form a high-temperature-resistant high-stability hercynite structure at the high temperature, the high-temperature-resistant high-stability hercynite structure is adhered to the formed net-shaped structure, the structure is stabler, the high and low temperature resistanceproperty is better, the asphalt also has the functions of being waterproof, ultraviolet-proof and antiflaming at the same time; the bagasse molecular sieve is modified, so that the reaction effect isbetter in the subsequent process of reaction with the aluminum hydroxide. In conclusion, the road and bridge caulking asphalt can still be normally used for a long term even under the environment withthe limit difference of temperature.

Owner:许炜玮

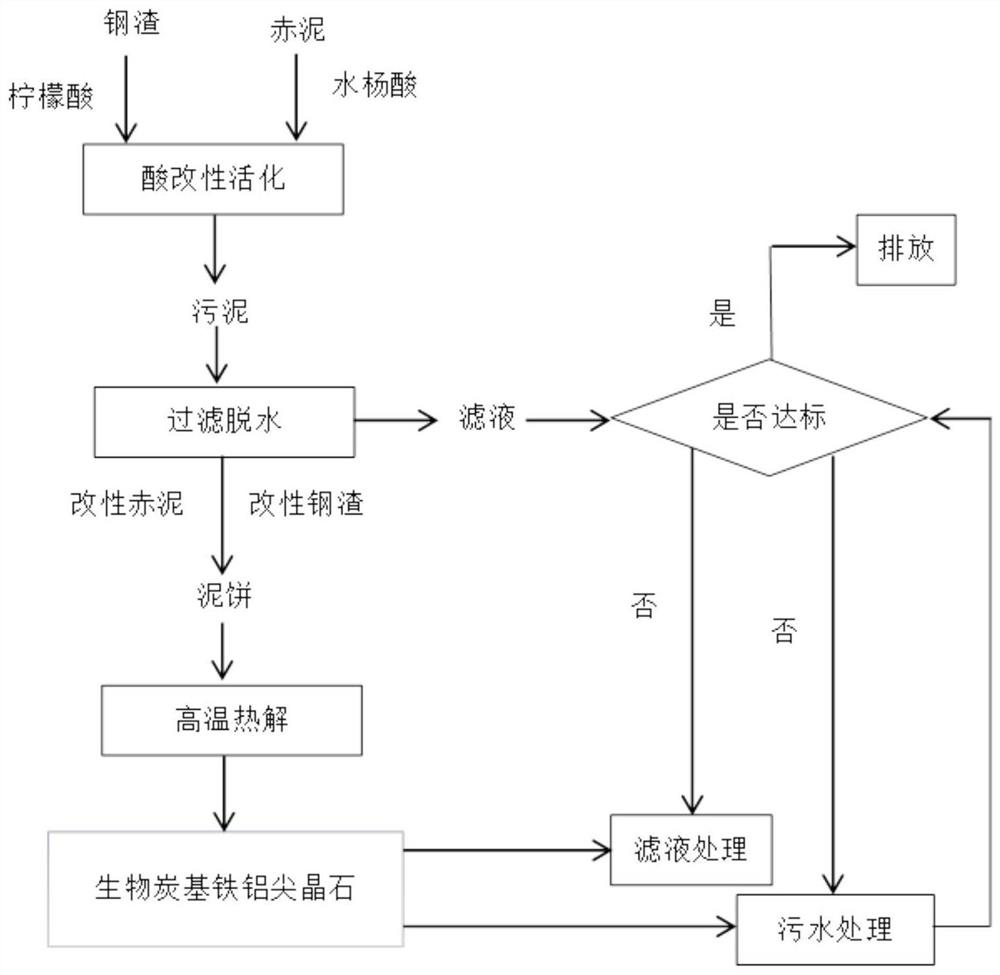

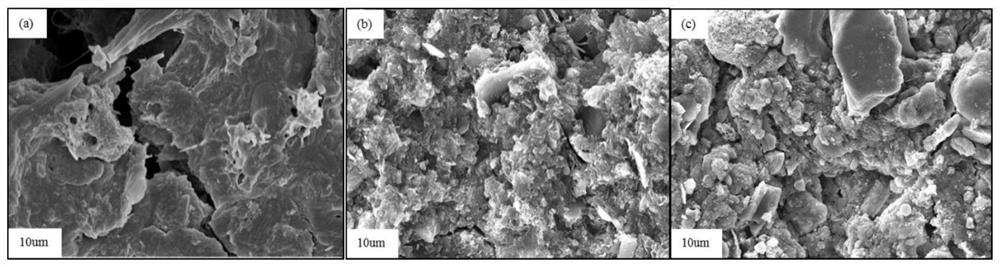

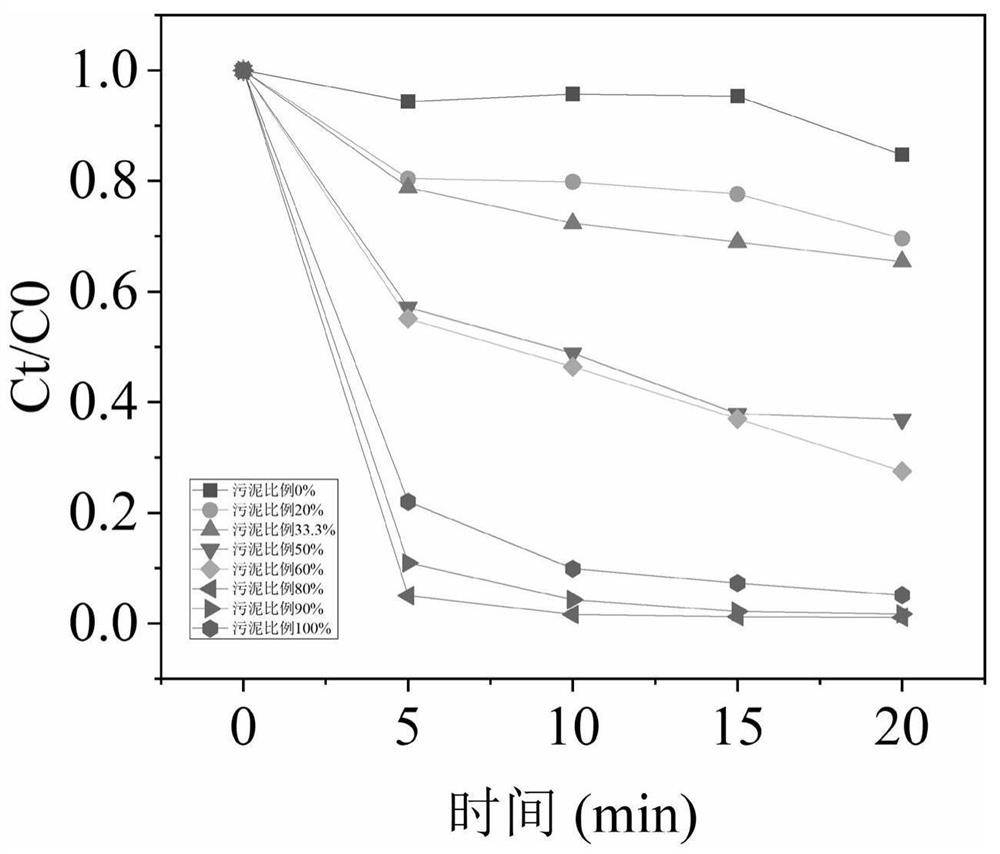

Method for treating sludge and sewage by using modified red mud and modified steel slag

ActiveCN113231012AFully stimulate the active ingredientsPromote generationOther chemical processesWater contaminantsSlagSludge

The invention discloses a method for treating sludge and sewage by using modified red mud and modified steel slag. The method comprises the steps of performing modification pretreatment on red mud and steel slag, adding the red mud and the steel slag into sludge, performing dehydration treatment, drying a dehydrated mud cake, performing high-temperature pyrolysis treatment on the dried mud cake, the modified red mud and the modified steel slag, preparing biochar-based hercynite, and using the biochar-based hercynite to treat sewage. According to the invention, co-treatment of the steel slag, the red mud and the sludge and recycling of the final product are realized. The method has important significance in expanding the application and application range of wastes such as the steel slag, the red mud and the sludge and improving the recycling rate of iron and aluminum resources; and the method can be widely applied to the field of sewage treatment, and the dual effects of degrading novel pollutants and adsorbing heavy metals are realized. The method disclosed by the invention has the characteristics of simple production process, easily available raw materials, wide product application range, good economic benefit and social benefit and the like.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Wide-temperature-range high-infrared-emissivity coating material and preparation method thereof

ActiveCN104909770APlay the role of energy-saving infrared high emissivityAct as a surface enhancerFiberAdhesive

The invention discloses a wide-temperature-range high-infrared-emissivity coating material and a preparation method thereof. The wide-temperature-range high-infrared-emissivity coating material is prepared by mixing wide-temperature-range high-infrared-emissivity powder and an adhesive in a weight ratio of 1:1-1:2.5. The wide-temperature-range high-infrared-emissivity powder is prepared from the following raw materials in percentage by weight: 5-30% of iron-ore-slag-base high-emissivity powder material, 25-50% of hercynite, 0-15% of magnetite, 0-20% of zirconium oxide, 20-40% of cerium oxide and 0-15% of molybdenum silicide. The adhesive is aluminum oxide sol. The wide-temperature-range high-infrared-emissivity coating material can be used on an aluminum oxide fiber refractory material surface, can be used at higher temperature, and has the high-infrared-emissivity energy-saving function and the surface reinforcement function.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com