Preparation process of magnesium hydroxide fire-retarding nanomaterial

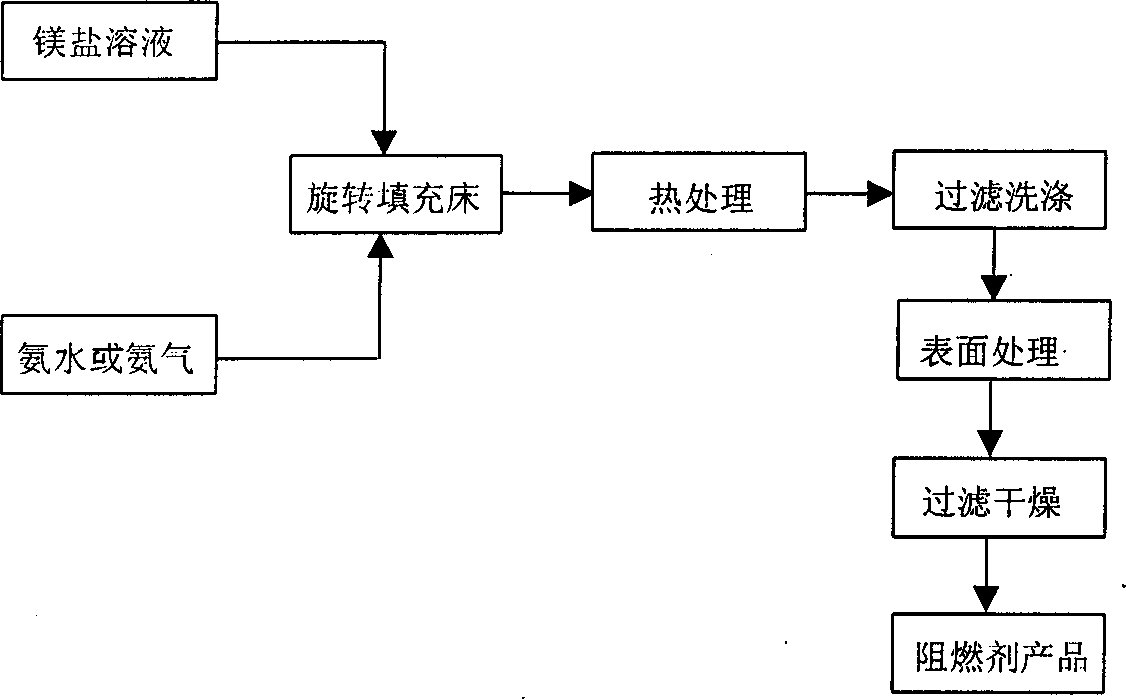

A nano-magnesium hydroxide and preparation process technology, which is applied in the field of new preparation process of nano-magnesium hydroxide materials, can solve the problems of large particle size, complicated process, uneven distribution, etc., and achieve uniform particle size and particle size distribution , The effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

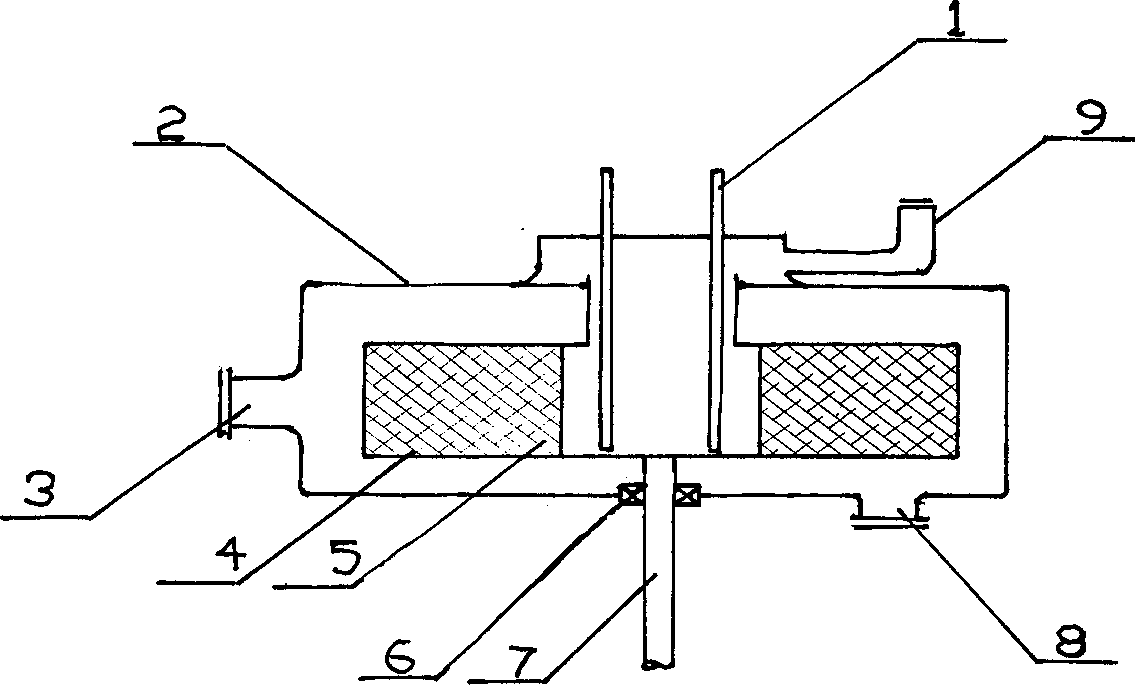

Method used

Image

Examples

Embodiment 1

[0047]In the liquid-liquid production mode, pour 30% magnesium salt solution and 20% industrial ammonia water into the liquid storage tank respectively, and heat up. The magnesium salt solution is controlled at 95°C, and the temperature of industrial ammonia is controlled at 35°C. Start the rotating packed bed and adjust the rotor speed to 700rpm. The magnesium salt solution and ammonia water are sent into the rotating packed bed according to the molar ratio of 1:2.5. Control the linear speed of the magnesium salt solution nozzle to 4m / s, and the industrial ammonia water nozzle speed to 7m / s to continuously feed into the rotating packed bed for reaction, with a pH value of 8.5, to obtain a suspension of magnesium hydroxide precipitate and ammonium salt. Then the magnesium hydroxide suspension was kept at 90°C by stirring the kettle, and the time was controlled at 120min. The resulting magnesium hydroxide suspension was filtered and washed 3 times with deionized water. Final...

Embodiment 2

[0049] In the liquid-liquid production mode, pour 30% magnesium salt solution and 20% industrial ammonia water into the liquid storage tank respectively, and heat up. The magnesium salt solution is controlled at 20°C, and the temperature of industrial ammonia is controlled at 20°C. Start the rotating packed bed and adjust the rotor speed to 1200rpm. The magnesium salt solution and ammonia water are sent into the rotating packed bed according to the molar ratio of 1:2.2. Control the linear speed of the magnesium salt solution nozzle to 4m / s, and the industrial ammonia water nozzle speed to 7m / s to continuously feed into the rotating packed bed for reaction, with a pH value of 8.5, to obtain a suspension of magnesium hydroxide precipitate and ammonium salt. Then the magnesium hydroxide suspension was kept at 90°C by stirring the kettle, and the time was controlled at 120min. The resulting magnesium hydroxide suspension was filtered and washed 3 times with deionized water. Fin...

Embodiment 3

[0051] In the liquid-liquid production mode, pour 30% magnesium salt solution and 20% industrial ammonia water into the liquid storage tank respectively, and heat up. The magnesium salt solution is controlled at 95°C, and the temperature of industrial ammonia is controlled at 30°C. Start the rotating packed bed and adjust the rotor speed to 1000rpm. The magnesium salt solution and ammonia water are sent into the rotating packed bed according to the molar ratio of 1:2.2. The linear speed of magnesium salt solution nozzle is controlled to be 6m / s, and the nozzle speed of industrial ammonia water is 10m / s to continuously feed into the rotating packed bed for reaction, the pH value is 8, and a suspension of magnesium hydroxide precipitate and ammonium salt is obtained. Then the magnesium hydroxide suspension was kept at 90°C by stirring the kettle, and the time was controlled at 120min. The resulting magnesium hydroxide suspension was filtered and washed 3 times with deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com