Method for synthesizing hercynite

A ferroaluminum spinel and synthesis method technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of high synthesis cost by electrofusion method and difficult to control the atmosphere conditions of sintering method, and achieve low cost, reduced energy consumption, The effect of easy synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

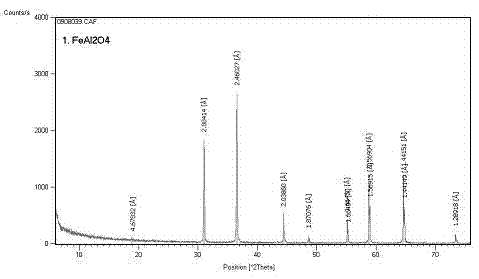

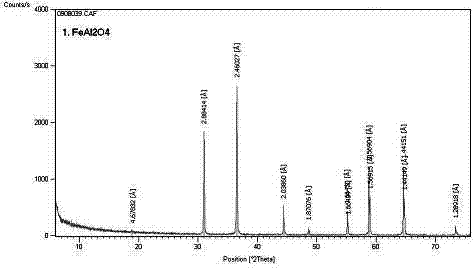

[0022] Using industrial grade iron oxide powder (particle size 100 mesh), industrial grade metal aluminum powder (particle size 150 mesh), industrial grade activated alumina micropowder (particle size 1100 mesh) as raw materials, the mass percentages are 42%, 5.2%, 52.8% respectively proportional weight. The raw materials were kneaded at a speed of 50r / min for 10h in a ball mill, and the uniformly mixed powder was pressed into a block sample with a 4MPa molding press, and then dried in an oven at 80°C for 24h. The dried samples were placed in a vacuum furnace, the pressure in the furnace was 20Pa, and they were sintered at 1500°C for 3h. The phase composition of the sample detected by XRD is pure iron-aluminum spinel ( figure 1 ).

Embodiment 2

[0024] Using industrial grade iron oxide powder (particle size 200 mesh), industrial grade metal aluminum powder (particle size 540 mesh), industrial grade activated alumina micropowder (particle size 1500 mesh) as raw materials, the mass percentages are 40%, 4.4%, 55.6% respectively proportional weight. The raw materials were kneaded at a speed of 160r / min for 2 hours in a ball mill, and the uniformly mixed powder was pressed into a block sample with a 1MPa molding press, and then dried in an oven at 110°C for 8 hours. The dried samples were placed in a vacuum furnace with an air pressure of 15 Pa and sintered at 1300°C for 3 hours. The phase composition of the sample detected by XRD is pure Fe-Al spinel.

Embodiment 3

[0026] Using industrial grade iron oxide powder (particle size 325 mesh), industrial grade metal aluminum powder (particle size 650 mesh), industrial grade activated alumina micropowder (particle size 900 mesh) as raw materials, the mass percentages are 44%, 5.8%, 50.2% respectively proportional weight. The raw materials were kneaded for 1 h at a speed of 200 r / min in a ball mill, and the uniformly mixed powder was pressed into a block sample with a 10 MPa molding press, and then dried in an oven at 90 °C for 10 h. The dried samples were placed in a vacuum furnace with an air pressure of 50 Pa, and were sintered at 1400° C. for 0.5 h. The phase composition of the sample detected by XRD is pure Fe-Al spinel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com