Preparation method of nanoscale hercynite

A kind of iron-aluminum spinel and nano-scale technology, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high thermal conductivity of iron-aluminum spinel, uneven particle size, and high energy consumption of electric melting method problem, achieve the effect of reducing the synthesis temperature and operation difficulty, reducing the calcination temperature and simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

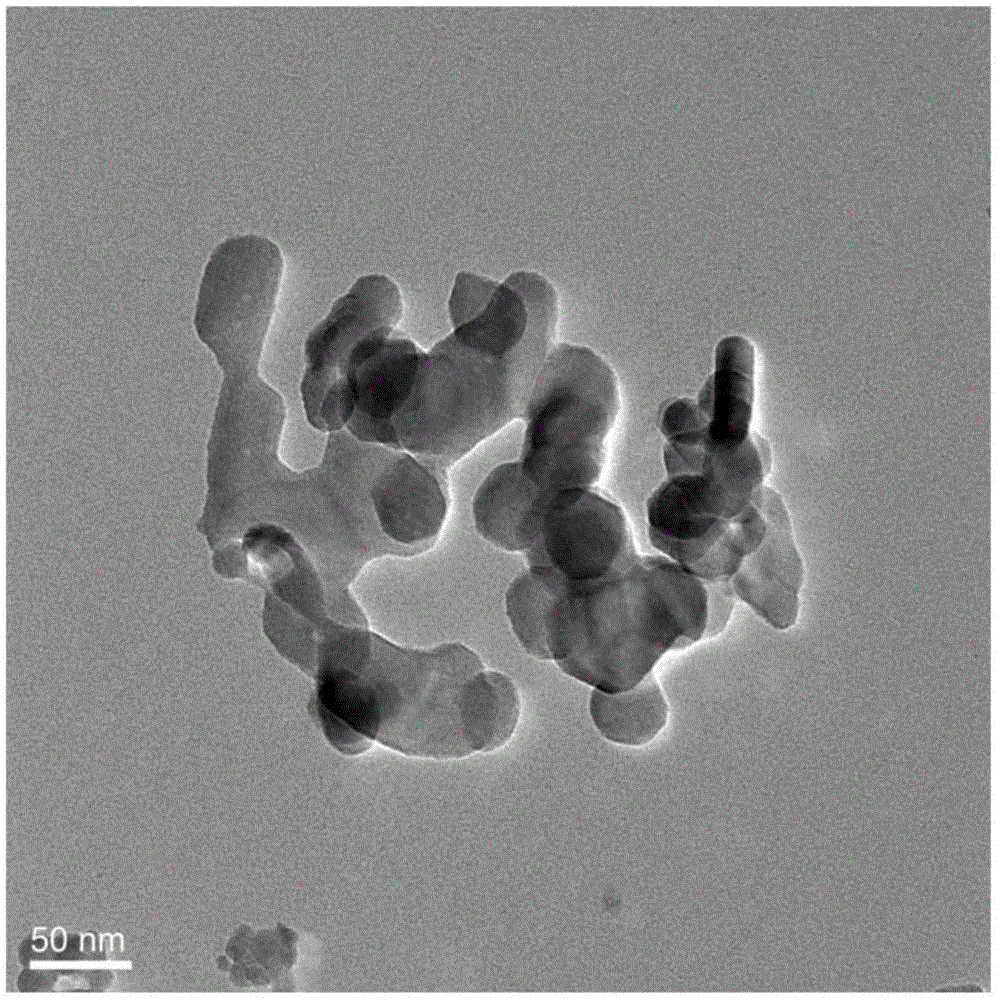

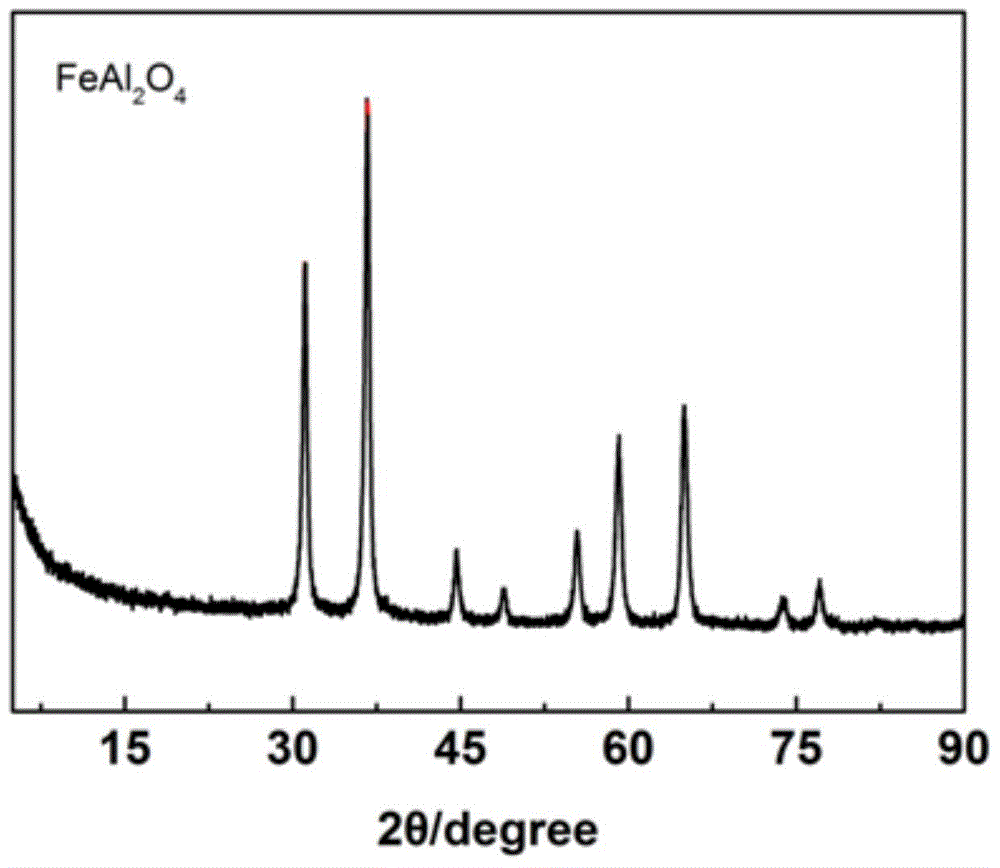

Image

Examples

Embodiment 1

[0021] A preparation method of nano-scale iron-aluminum spinel, the method comprises the steps of:

[0022] (1) Preparation of Fe-Al spinel precursor

[0023] Measure N,N-dimethylformamide and water to make a mixed solution with a volume ratio of 20:55 for subsequent use; weigh 4.22g aluminum nitrate nonahydrate, 1.245g terephthalic acid and 0.795g iron acetylacetonate and dissolve in 75mL of the mixed solution, heated and stirred until completely dissolved to obtain a reactant solution; put the prepared reactant solution in a closed container for aging at a temperature of 130°C for 48 hours, then lower it to room temperature, centrifuge to obtain a precipitate, add The precursor product was obtained after washing the precipitate three times with an appropriate amount of N,N-dimethylformamide.

[0024] (2) Preparation of nano-scale iron-aluminum spinel

[0025] Put the precursor product obtained in step (1) into a high-temperature furnace protected by nitrogen flow, raise th...

Embodiment 2

[0028] A preparation method of nano-scale iron-aluminum spinel, the method comprises the steps of:

[0029] (1) Preparation of Fe-Al spinel precursor

[0030] Measure N,N-dimethylformamide and water to make a mixed solvent with a volume ratio of 20:55, and set aside; weigh 2.11g aluminum nitrate nonahydrate and 0.29g aluminum oxide, 1.245g terephthalic acid and 0.795g Dissolve iron acetylacetonate in 75mL of the mixed solution, heat and stir until completely dissolved to obtain a reactant solution; put the prepared reactant solution in a closed container for aging at a temperature of 130°C for 48h, then cool down to room temperature, and centrifuge The precipitate was obtained, and an appropriate amount of N,N-dimethylformamide was added to wash the precipitate three times to obtain a precursor product.

[0031] (2) Preparation of nano-scale iron-aluminum spinel

[0032] Put the precursor product obtained in step (1) into a high-temperature furnace protected by nitrogen flow...

Embodiment 3

[0034] A preparation method of nano-scale iron-aluminum spinel, the method comprises the steps of:

[0035] (1) Preparation of Fe-Al spinel precursor

[0036] Measure N,N-dimethylformamide and water to make a mixed solution with a volume ratio of 20:55 for subsequent use; weigh 2.11g aluminum nitrate nonahydrate and 0.44g aluminum hydroxide, 1.245g terephthalic acid and 0.795 Dissolve 1 g of iron acetylacetonate in 75 mL of mixed solution, heat and stir until completely dissolved to obtain a reactant solution; put the prepared reactant solution in a closed container for aging at a temperature of 130°C for 48 hours, and then lower it to room temperature, The precipitate was obtained by centrifugation, and an appropriate amount of N,N-dimethylformamide was added to wash the precipitate three times to obtain the precursor product.

[0037] (2) Preparation of nano-scale iron-aluminum spinel

[0038] Put the precursor product obtained in step (1) into a high-temperature furnace p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com